Configuration manual

Expansion module

EM-IP

Description of data points for the BACnet/IP- or

Modbus/IP interface for EASYLAB/TROX UNIVERSAL

Firmware from 2.0

GB/en

Read the instructions prior to performing any task!

TROX GmbH

Heinrich-T

47504 Neukirchen-Vluyn, Germany

Germany

Telephone: +49 2845 202-0

Fax: +49 2845 202-265

email: trox@trox.de

Internet: http://www.troxtechnik.com

A00000051268, 3, GB/en

06/2019

rox-Platz

© TROX GmbH 2017

2

Expansion module EM-IP

Supplemental instructions

About this manual

Expansion module EM-IP is used to integrate the following devices into an IP-based network and connect

them to the central BMS using the BACnet/IP or

Modbus/IP protocol:

EASYLAB controller TCU3

EASYLAB adapter modules T

TROX UNIVERSAL CONTROLLER

This configuration manual is an addition to the installation manual and contains information on how to configure EM-IP as an interface to the central BMS.

Illustrations in this manual are mainly for information

and may dif

Other applicable documentation

In addition to these instructions, the following documents apply:

Installation manual for expansion module EM-IP

Documentation on

– EASYLAB controller TCU3

– Adapter module TAM

– TROX UNIVERSAL CONTROLLER

Project-specific wiring documents, if any

TROX Technical Service

To ensure that your request is processed as quickly as

possible, please keep the following information ready:

Product name

TROX order number

Delivery date

Brief description of the fault

Online www.troxtechnik.com

Phone +49 2845 202-400

fer from the actual design of EM-IP.

AM

Limitation of liability

The information in this manual has been compiled with

reference to the applicable standards and guidelines,

the state of the art, and our expertise and experience of

many years.

The manufacturer does not accept any liability for damages resulting from:

Non-compliance with this manual

Incorrect use

Operation or handling by untrained individuals

Unauthorised modifications

echnical changes

T

Use of non-approved replacement parts

The actual scope of delivery may differ from the information in this manual for bespoke constructions, additional order options or as a result of recent technical

changes.

The obligations agreed in the order

and conditions, the manufacturer's terms of delivery,

and the legal regulations in effect at the time the contract is signed shall apply.

We reserve the right to make technical changes.

Defects liability

For details regarding defects liability please refer to

Section VI, Warranty Claims, of the Delivery and Payment Terms of TROX GmbH.

The Delivery and Payment Terms of TROX GmbH are

available at www.troxtechnik.com.

Copyright

This document, including all illustrations, is protected by

copyright and pertains only to the corresponding

product.

Any use without our consent may be an infringement of

copyright, and the violator will be held liable for any

damage.

This applies in particular to:

, the general terms

Publishing content

Copying content

ranslating content

T

Microcopying content

Saving content to electronic systems and editing it

Expansion module EM-IP 3

Table of contents

1 Security.............................................................. 5

1.1 Correct use.................................................. 5

1.1.1 Incorrect use............................................. 5

1.2 Safety signs................................................. 5

1.3 Residual risks.............................................. 5

1.4 Risk of damage to property......................... 6

1.5 System owner's responsibility..................... 6

1.6 Qualified staff............................................... 6

1.7 Environmental protection............................. 6

2 Configuration..................................................... 8

2.1 IP configuration........................................... 8

2.2 Required software version........................... 8

2.3 Functions of the Reset push button............. 8

2.3.1 Rebooting EM-IP...................................... 8

2.3.2 Resetting the default IP address.............. 8

2.3.3 Activating the DHCP server...................... 8

2.3.4 Restoring the factory settings .................. 9

3 Web server settings........................................ 10

3.1 Supported browsers.................................. 10

3.2 Standard IP addresses.............................. 10

3.3 Supported users........................................ 10

3.4 Displaying the configuration manual as

PDF document..........................................

3.5 Web server navigation............................... 11

3.5.1 Accessing the web interface................... 11

3.5.2 Login....................................................... 11

3.5.3 Menu navigation..................................... 11

3.5.4 Functions of the ‘Plants’ menu.............. 12

3.5.5 Functions of the ‘Events’ menu............. 14

3.5.6 Functions of the ‘Analysis’ menu........... 14

3.5.7 Functions of the ‘Setup’ menu............... 15

3.5.8 Functions of the ‘Help’ menu................. 25

4 Interface information....................................... 26

4.1 BACnet interface....................................... 26

4.2 Modbus interface....................................... 37

4.3 Data points – detailed description............. 47

4.3.1 Input variables........................................ 47

4.3.2 Output variables..................................... 51

5 Maintenance..................................................... 71

5.1 Maintenance plan...................................... 71

5.2 Maintenance.............................................. 71

5.2.1 Replacing the battery of the RTC

module.................................................... 71

5.2.2 Replacing the EM-IP expansion

module.................................................... 72

5.2.3 Before re-commissioning........................ 74

6 Fault displays................................................... 75

6.1 LED status display..................................... 75

6.2 Webserver................................................. 75

10

7 Index................................................................. 76

Expansion module EM-IP4

Security

Residual risks

1 Security

Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

DANGER!

Imminently hazardous situation which is due to live

components and which, if not avoided, will result in

death or serious injury due to electrical voltage.

DANGER!

Imminently hazardous situation which, if not avoided,

will result in death or serious injury

NOTICE!

.

Residual risks

Failure of the network interface does not affect the control function of the volume flow controller but does af

data exchange with the central BMS. Safety-related

applications require further precautions.

fect

1.2 Safety signs

The following symbols and signs are usually found in

the work area. They apply to the very location where

they are found.

Electrical voltage

Location where a hazard due to electrical voltage exists.

Earthing

Potentially hazardous situation which, if not avoided,

may result in property damage.

ENVIRONMENT!

Environmental pollution hazard.

1.1 Correct use

Expansion module EM-IP provides a BACnet/IP or

Modbus/IP interface and a web server interface for

EASYLAB base components as well as for the TROX

UNIVERSAL CONTROLLER.

Use the expansion module for the following devices:

EASYLAB controller TCU3

EASYLAB adapter module T

TROX UNIVERSAL CONTROLLER

1.1.1 Incorrect use

Do not use the expansion module for areas of application that are not described in this manual.

Do not use the expansion module:

outdoors

in wet areas

in areas with potentially explosive atmospheres

AM

This symbol marks all equipotential bonding connection

points on EM-IP

.

1.3 Residual risks

EM-IP is a state-of-the-art product and meets current

safety requirements. Residual risks cannot be excluded,

however, and you should proceed with caution.

Always observe the safety notes in this manual to

reduce health hazards and prevent any hazardous situations.

Electric current

DANGER!

Danger of death due to electric current!

Danger of death if live components are touched.

– Switch off the supply voltage and secure it

against being switched on again before working

on the unit.

–

Only skilled qualified electricians are allowed to

work on live components.

– Equipotential bonding is required.

Expansion module EM-IP 5

Security

Environmental protection

1.4 Risk of damage to property

Temperature differences

NOTICE!

Risk of damage to property due to large temperature differences

If EM-IP has been kept in an unheated area, condensation may form and damage the electronic components beyond repair

– Let EM-IP warm up to room temperature before

you install it.

Electrostatic charge

NOTICE!

Risk of damage to property due to electrostatic

charge

Electrostatic charge can damage the electronics of

the expansion module.

– Before you remove the expansion module from

its protective wrapping, touch an equipotentially

bonded metal surface, e.g. a water pipe, for electrical earthing.

–

Avoid skin contact with any components or

printed circuits on the expansion module or the

main PCB.

– Wear conductive footwear and antistatic clothing.

.

Skilled qualified electrician

Skilled qualified electricians are individuals who have

suf

ficient professional or technical training, knowledge

and actual experience to enable them to work on electrical systems, understand any potential hazards related

to the work under consideration, and recognise and

avoid any risks involved.

Any work has to be carried out by individuals who can

be expected to carry out their assigned duties reliably.

Individuals whose reaction time is delayed due to

alcohol, drugs or other medication must not carry out

any work.

Passwords

Web server setup is password protected to prevent

unauthorised individuals from entering or changing data.

Ä

Chapter 3.3 ‘Supported users’ on page 10

1.7 Environmental protection

The following substances and materials which are

hazardous to the environment are used:

Electrical and electronic parts

Electrical and electronic parts may contain toxic materials and substances. These parts have to be disposed

of separately from other waste, i.e. taken to your local

reuse and recycling centre or disposed of by a specialist

disposal company.

1.5 System owner's responsibility

System owner's obligations

EM-IP is intended for commercial use. The system

owner is therefore subject to the legal obligations of

occupational health and safety regulations.

In addition to the safety notes in this manual, the applicable regulations for safety

environmental protection must also be complied with.

, accident prevention and

1.6 Qualified staff

Qualification

The work described in this manual has to be carried out

by individuals with the qualification, training, knowledge

and experience described below:

Network administrator

Network administrators design, install, configure and

maintain the IT infrastructure in companies or organisations.

Batteries

Batteries contain toxic heavy metals. They are hazardous waste and must be taken to a hazardous waste

collection point or disposed of by a specialist company.

Expansion module EM-IP6

Security

Environmental protection

Expansion module EM-IP 7

Configuration

Functions of the Reset push button > Activating the DHCP server

2 Configuration

IP configuration

2.1

Most configuration settings for EM-IP can be entered

Ä

using the integral web server

settings’ on page 10.

Network conflicts

The factory set default IP address and IP configuration of EM-IP may not be entirely compatible with the

target network. It may hence be better to first connect EM-IP during commissioning with a network

patch cable to the PC and to make the required configuration settings explained in section Ä Chapter

3 ‘Web server settings’ on page 10.

The Reset button (Fig. 1/1) allows you to choose

between two IP configurations and the original state at

the time of delivery.

If the connected PC is a DHCP client and if there is no

DHCP server, the client should generate its own

address within 60 seconds.

As a consequence, EM-IP can access the web server

even if the network characteristics of the PC are not

changed.

2.2 Required software version

The expansion module EM-IP with firmware 2.0 requires

the following software versions:

Chapter 3 ‘Web server

2.3 Functions of the Reset push button

Fig. 1: Reset push button

EM-IP has a Reset push button (Fig. 1/1).

Use the Reset push button for the following actions:

2.3.1 Rebooting EM-IP

Press the Reset push button (Fig. 1/1) briefly

(4 seconds max.).

The status LED (Fig. 1/2) becomes red for

ð

2 seconds, then the module is rebooted.

EASYLAB or adapter module TAM

– Software version 8.1 or higher

TROX UNIVERSAL CONTROLLER

– Software version 2.1 or higher

The software version is displayed in the EasyConnect

software, ‘Diagnosis’ , ‘Basic Device’

A product sticker on the main PCB also carries the software version number (only for version 3 or higher).

With earlier software versions there is no data exchange

between the expansion module EM-IP and controller.

This means that the network is not able to read out current values from the controller or to send any values.

You need not adapt the controller configuration with

the EasyConnect configuration software for the

expansion module to work.

line.

During the start phase, the status LED

(Fig. 1/2) is orange.

2.3.2 Resetting the default IP address

Press the Reset push button (Fig. 1/1) for

5 to 9 seconds (9 seconds max.).

The status LED (Fig. 1/2) blinks green, and

ð

EM-IP is set to the default IP address

(169.254.0.1) until the next reboot.

2.3.3 Activating the DHCP server

Press the Reset push button (Fig. 1/1) for

10 to 14 seconds (14 seconds max.).

The status-LED (Fig. 1/2) blinks green/red

ð

(alternating) as soon as the DHCP server is

activated.

While the DHCP server is active, it waits for

requests from a DHCP client in the network

and allocates an IP address to each client that

sends a request. This function simplifies the

connection from a PC to EM-IP.

Expansion module EM-IP8

2.3.4 Restoring the factory settings

Keep the Reset push button (Fig. 1/1) pressed for

more than 15 seconds.

The status LED (Fig. 1/2) blinks orange.

ð

Once the factory configuration has been set

again, the system is rebooted.

Configuration

Functions of the Reset push button > Restoring the factory settings

Expansion module EM-IP 9

Web server settings

Displaying the configuration manual as PDF document

3 Web server settings

Supported browsers

3.1

Browsers for Mac OS X

The following web browsers may be used with Mac OSX:

Safari version 6.0.5 or higher

Google Chrome version 70.0.xxx or higher

Mozilla Firefox

Browser with Microsoft Windows

The following web browsers may be used with Microsoft

Windows:

Microsoft Internet Explorer version 8 or higher

Google Chrome version 70.0.xxx or higher

Mozilla Firefox

3.2 Standard IP addresses

version 60 or higher

version 60 or higher

User

(group)

Guest Read-only access to

User Can change operating

Admin Can change user and

Change your password!

The password for each user group defaults. The

default passwords have to be changed by the network administrator at the time of commissioning

Ä

‘Displaying user administration’ on page 18.

Rights Default pass-

word

–

‘General settings’

User

mode default settings

and selected parameters for EM-IP

Admin

admin passwords as

well as all other settings

including BACnet/IP

and Modbus/IP

NOTICE!

EM-IP has the following standard IP address:

169.254.0.1/16 (i.e. subnet mask 255.255.0.0).

The integral DHCP server is not active upon delivery.

Use the Reset push button to activate it.

If the connected PC is a DHCP client and if there is no

DHCP server, the client should generate its own

address within 60 seconds. As a consequence, EM-IP

can access the web server even if the network characteristics of the PC are not changed.

3.3 Supported users

Personnel:

Network administrator

NOTICE!

Danger of injury or risk of damage to property

due to insufficiently qualified individuals!

Only network administrators may enter or change

Ä

data for the web server

staff’ on page 6.

If unauthorised individuals make changes in the

setup menu, the warranty becomes void.

Chapter 1.6 ‘Qualified

User and Admin cannot access the software at the

same time.

When Admin logs on to the web server

connection that may be active at that time is terminated.

User will be informed accordingly by a system message.

, any User

3.4 Displaying the configuration manual as PDF document

The ‘Setup’ menu of the web server is password protected to prevent unauthorised individuals from entering

or changing data. The Setup menu has been configured

ferent user groups.

for dif

Expansion module EM-IP10

Fig. 2: 'Help' menu

To display the configuration manual for EM-IP, go to the

‘Help’ menu, then select ‘Help/Manual’ on the left side

Ä

Chapter 3.5.8 ‘Functions of the ‘Help’ menu’

on page 25.

3.5 Web server navigation

3.5.1 Accessing the web interface

To access the web interface, just enter the IP address of

EM-IP (this should work unless you have changed the

browser settings).

1.

Connect EM-IP with a network cable to your PC Ä

EM-IP installation manual.

Fig. 3: Browser address field

2. Enter the IP address of EM-IP into the browser

Ä

address field

addresses’ on page 10.

The authentication window of the web inter-

ð

face is displayed.

Chapter 3.2 ‘Standard IP

Web server settings

Web server navigation > Menu navigation

Fig. 6: Login failed

If you enter an invalid user name or password,

‘Login failed’

3.5.3 Menu navigation

Fig. 7: Menu bar

Use the items in the menu bar (Fig. 7) at the top to navigate to any particular page.

(Fig. 6) is displayed.

Fig. 4: Accessing the web interface

3.

Log in

Ä

Chapter 3.5.2 ‘Login’ on page 11.

3.5.2 Login

You can access the functions of EM-IP only after you

have been authenticated.

Fig. 5: Login

Enter ‘User name’

3.3 ‘Supported users’ on page 10), then select

‘Login’ .

The starting screen of the web interface is dis-

ð

played.

and ‘Password’ (Ä Chapter

If you are logged in, your user name is displayed in

the top right corner

The menu items offer the following options:

Language selection

Fig. 8: Language selection for EM-IP

To choose between German and English, select the

appropriate flag (

Login

Fig. 9: Login menu

If you are logged in, your user name is displayed in the

top right corner (Fig. 9).

When you select this item and reply to the safety question; any other user who may be logged in is then

logged out, and the Login page is displayed for you to

log in.

.

Fig. 8).

Expansion module EM-IP 11

Web server settings

Web server navigation > Functions of the Plants menu

Ä

Chapter 3.5.2 ‘Login’ on page 11

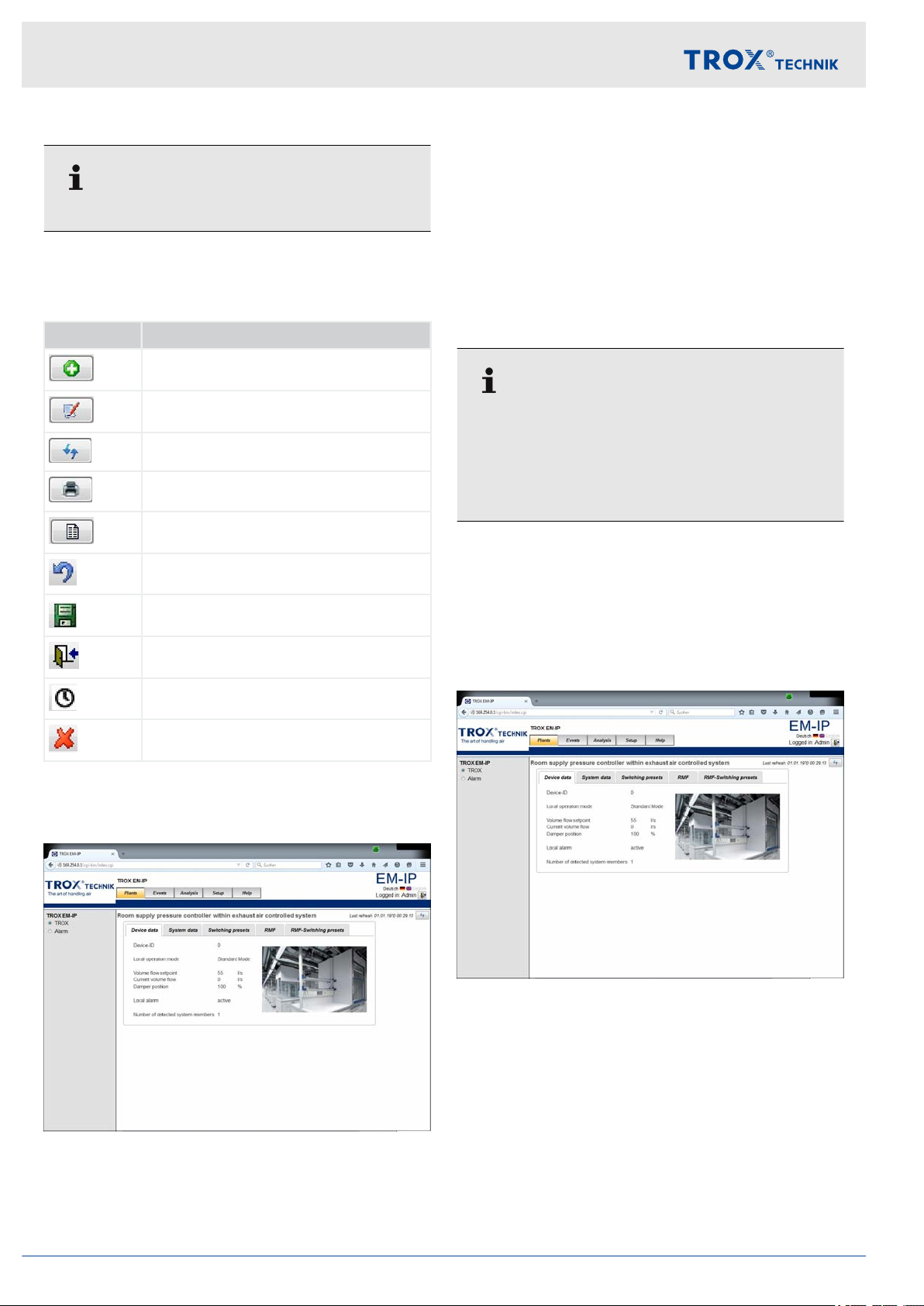

Symbols

The following symbols are used in the menus:

Field Function

Add a data source

A call to the ‘Plants’ menu item displays the web pages

that can be used to access the data points of the

respective controller

The following tabs are available:

Device data

System data

Switching presets

RMF

RMF switching presets

.

Edit a data source (add, delete, change)

Refresh screen

Print screen

Select date

Close menu

Save changes

Close menu/log out/change user

Set or change system and menu times

Delete

3.5.4 Functions of the ‘Plants’ menu

Plant

All users can view this menu item.

Users who log in as

data.

Users who log in as ‘Guest’ can only read data, but

not change anything.

This menu allows you to see data points and change

setpoint values if you are logged in as User or Admin.

The files (HTML pages) and data points you actually

see depend on the equipment function.

Device data

‘User’ or ‘Admin’ can change

Fig. 10: Plants menu

This is the page which you see after you log in.

Fig. 11: 'Device data' tab (example)

The ‘Device data’

Expansion module EM-IP12

tab shows the general device data.

System data

Fig. 12: System data point

The ‘System data’ tab shows all system members and

their parameters and functions.

Web server settings

Web server navigation > Functions of the Plants menu

Fig. 14: RMF tab

The ‘RMF’ tab shows data for the selected room.

RMF switching presets

Switching presets

Fig. 13: 'Switching presets' tab (example)

Use the ‘Switching presets’ tab to define how the

unused digital outputs (relays) should respond.

RMF

This tab is available only for room supply and room

extract air control.

This tab is available only for room supply and room

extract air control.

Fig. 15: 'RMF switching presets' tab

Use the ‘RMF switching presets’ tab to define operating

mode default settings, switching between room pressure setpoints and the opening or closing of optional

sun blinds.

Swiching between room pressure setpoints and controlling the sun blinds is only possible if the respective functions have been configured.

Expansion module EM-IP 13

Web server settings

Web server navigation > Functions of the Analysis menu

3.5.5 Functions of the ‘Events’ menu

Events

Fig. 16: Events menu

When you select the ‘Events’ menu, the defined events

are displayed.

Y

ou need to define/create events for data points

(BACnet objects) before they can be displayed

Ä

Chapter 3.5.7.11.2 ‘BACnet objects’ on page 23.

This menu item can only be accessed by ‘Admin’ .

Other users cannot access this menu item.

3.5.6 Functions of the ‘Analysis’ menu

Fig. 17: Analysis menu

When you select the ‘Analysis’ menu, the defined trend

logs are displayed.

Y

ou can start an analysis/trend log only after you have

created or configured this trend log (BACnet object).

Select ‘View’ to define whether you want to display the

evaluated measured values as diagrams or lists.

Use the selection bar on the left to select data sources

(trend log objects). To show and configure more events

or analyses, use the Setup menu.

Use ‘Period’ and ‘Start time’ to define an evaluation

period.

This menu item can only be accessed by ‘Admin’ .

Other users cannot access this menu item.

Fields of the ‘Analysis’ menu

Field Function

View Choose how you want to view data (dia-

gram or list).

Period Use this item to define a period.

Choice of: Day / 15 minutes, week,

month, quarter

Start time Start time for the evaluation.

Creating a new analysis:

of the ‘Setup’ menu’ on page 15

, year

Ä

Chapter 3.5.7 ‘Functions

Expansion module EM-IP14

Web server settings

Web server navigation > Functions of the Setup menu

3.5.7 Functions of the ‘Setup’ menu

Setup

Fig. 18: Setup menu

Select the ‘Setup’ menu to display the system settings.

Use ‘General settings’ in the ‘Setup’ menu to define

general plant/device settings.

Selecting the display name

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘Configuration’ , on the left, select

‘General’ .

The ‘General settings’ (Fig. 19) page is dis-

ð

played.

3. Select ‘BACnet description’ or ‘BACNET object

name’ , as required.

– When you select

entries from the Description field (Objects

menu) are used for data points.

– When you select ‘BACNET object name’ ,

the entries from the Object Name field

(Objects menu) are used for data points.

4. Use [Save] to confirm and save your entries.

‘BACnet description’ , the

.

You can access functions of the Setup menu only if

you are logged in as

Apart from the ‘Change password’ item, the functions of this menu can only be changed by ‘Admin’ .

If you are logged in as ‘Guest’ , you can only read

entries, but not change them.

3.5.7.1 General settings

‘Admin’ .

Selecting the ‘Gateway type’

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘Configuration’ , on the left, select

‘General’ .

The ‘General settings’ (Fig. 19) page is dis-

ð

played.

3. Select a gateway type: ‘W

‘BACnet/IP and webserver’ or ‘Modbus/TCP and

webserver’ .

Gateway types

– ‘W

ebserver only’

If you select ‘Webserver only’ , only the

web interface is available for communication.

This mode is suitable for local operation,

i.e. when no values need to be sent via the

BACnet or Modbus communication protocol.

– ‘BACnet/IP and webserver’

If you select ‘BACnet/IP and webserver’ ,

the web interface and the BACnet/IP protocol are available.

– ‘Modbus/TCP and webserver’

If you select ‘Modbus/TCP and

webserver’ , the web interface and the

Modbus/IP protocol are available.

ebserver only’ ,

.

Fig. 19: General settings

Expansion module EM-IP 15

Web server settings

Web server navigation > Functions of the Setup menu

4. Use [Save] to confirm and save your entries.

3.5.7.2

Fig. 20: Setting up plant views

Use the ‘Setup plant views’ item of the ‘Setup’

create and save your own pictures of plants.

3.5.7.3 Analysis

Editing an analysis

1. Select the ‘Setup’ menu from the menu bar

Setting up plant views

menu to

.

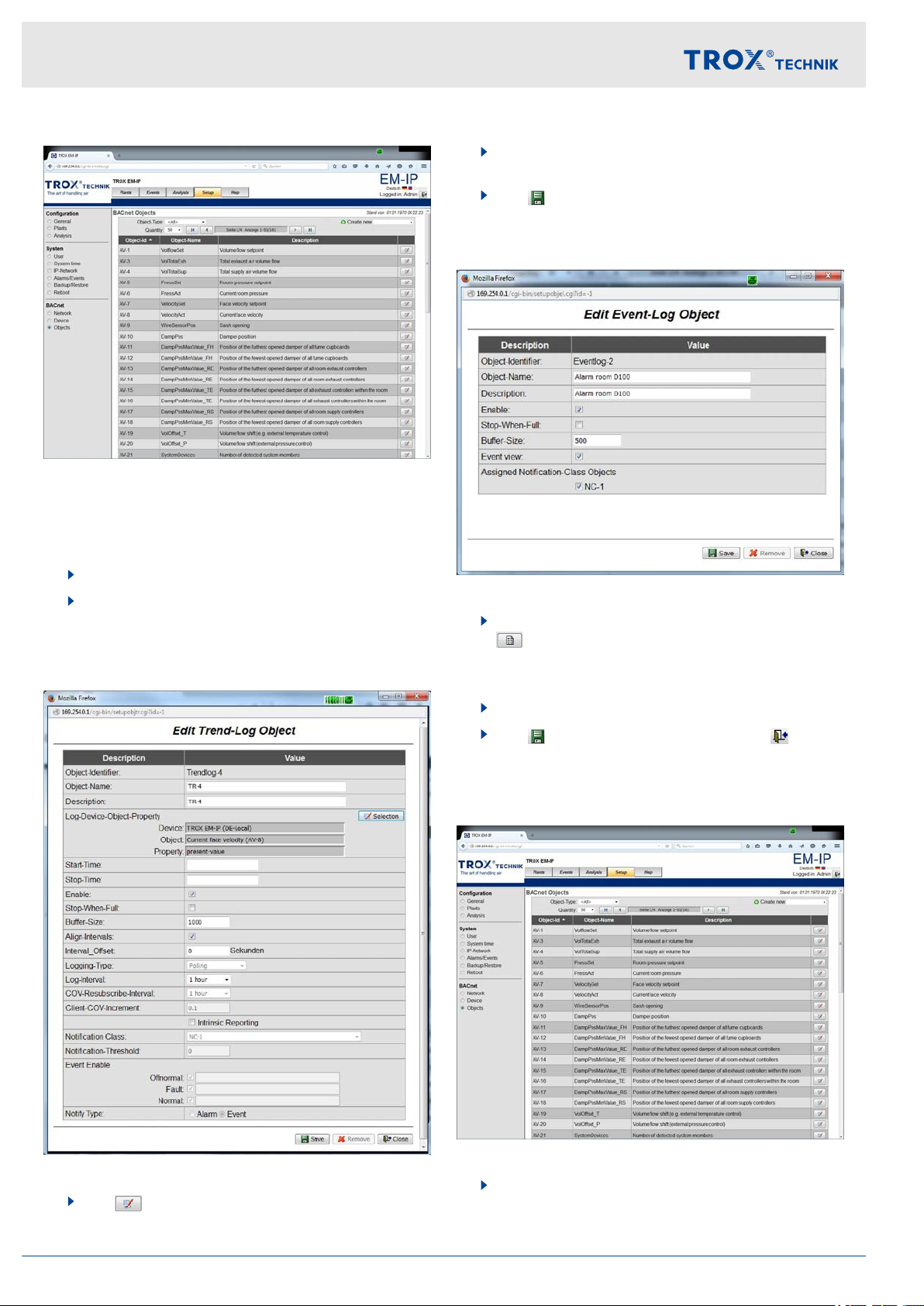

Fig. 22: Editing a trend log object (example)

4.

Press for the desired object.

The ‘Edit trend log object’

ð

displayed for the selected object type.

5. Enter the analysis values into the entry fields.

6.

Use [Save] to confirm and save your entries.

(Fig. 21) menu is

Fig. 21: BACnet objects

2. Under ‘BACnet’ , on the left, select ‘Objects’ .

The 'BACnet Objects' menu (Fig. 21) is dis-

ð

played.

3. Select an object type from the ‘Object type’ list.

Creating a new analysis/trend log

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘BACnet’ , on the left, select ‘Objects’ .

The ‘BACnet objects’ (Fig. 21) for the

ð

selected object type are displayed.

.

Expansion module EM-IP16

Fig. 23: Editing a trend log object

3.

Select [Add].

The ‘Edit trend log object’

ð

page is displayed.

Web server settings

Web server navigation > Functions of the Setup menu

Setting up an analysis

Fig. 25: Setting up an analysis

Select ‘Analysis’

‘Setup analysis’ and create a new analysis or change

an existing analysis.

Displaying 'Setup'

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘Configuration’ , on the left, select

‘Analysis’ .

The ‘Setup analysis’

ð

played.

3.

Select [Add].

A window opens where you can select a trend

ð

log object.

4. Select a trend log object.

from the ‘Setup’ menu to display

.

(Fig. 25) page is dis-

Fig. 24: Editing BACnet Device-Object-Property

4.

Select [Selection] in the ‘Log-Device-ObjectProperty’ line.

The ‘Edit BACnet Device-Object-Property’

ð

(Fig. 24) is displayed.

5. Enter the new values.

6.

Use ‘Save’ to save your entries.

7.

Select ‘Back’ to close the

[Edit BACnet Device-Objekt-Property] screen.

Viewing an analysis

Fig. 26: Viewing an analysis

The ‘Selection’

to view the new analysis.

item of the ‘Analysis’ menu allows you

Expansion module EM-IP 17

Web server settings

Web server navigation > Functions of the Setup menu

Viewing an analysis

1. Select the ‘Analysis’ menu from the menu bar

2. Go to ‘Selection’ , on the left, and select an anal-

ysis.

The analysis is displayed.

ð

3.5.7.4

The ‘User administration’ item of the ‘Setup’ menu

allows you to change access rights and passwords.

Displaying user administration

1. Select the ‘Setup’ menu from the menu bar

User administration

.

.

If you are logged in as Admin, you may change

both your own Admin password and passwords

for User

Changing passwords

5. Change the user profile.

6. Use [Save] to confirm and save your entries.

3.5.7.5

.

Setting the system time

Fig. 27: User administration

2. Under ‘System’ , on the left, select ‘User

The ‘User administration’ (Fig. 27) page is

ð

displayed.

3.

Select [Edit] for the user you want to change.

The Login screen is displayed.

ð

When you select this menu item, a webpage is displayed on which you can enter a

new user or change data for an existing

, including the password.

user

4.

NOTICE!

Risk of damage to property due to unauthorised access to passwords or user profiles.

Enter password.

Fig. 28: Setting the system time

’ .

If you want to use the Alarming, Trending, Scheduling or

Eventlog function, you need to set a system time for

.

EM-IP

If you select ‘Manual time synchronisation’ and the

power fails, the time will be maintained only if the

optional R

Setting the time manually

Setting the system time/date manually

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘System’ , on the left, select ‘System time’ .

ð

3. Go to ‘T

4. Go to ‘Date format’ and select a date format.

5. Enter the current date (use the number pad) into

the ‘Date’ field, then press [Enter] to confirm your

entry

TC module has been installed.

.

The ‘Setup system time’ (Fig. 28) page

opens.

ime zone’ and select a time zone.

.

Expansion module EM-IP18

6. Enter the current time (use the number pad) into

the ‘T

ime: h, m, s’ fields, then press [Enter] to

confirm your entries.

NTP time synchronisation

‘NTP time synchronisation’ allows you to receive time

messages from external NTP servers in the IT network.

Enter the IP address of the NTP server.

Time synchronisation messages set the local clock to

the correct time.

The optional Real Time Clock (RTC) is not required

in this case.

Web server settings

Web server navigation > Functions of the Setup menu

BACnet time synchronisation

Time synchronisation via BACnet requires a BACnet

time server in the network.

Scheduling

Fig. 30: Weekly schedule: [day of the week]

2.

Go to ‘Name’ / ‘W

select a day of the week.

The ‘W

ð

(Fig. 30) page is displayed.

3. Enter ‘T

4.

Use

‘Close’

5. Make entries for other days of the week as

described above.

6. After you have completed your entries on the ‘Edit

schedule object’ page, use ‘Save’

entries, then use

ime’ and ‘Value’.

to confirm and save your entries; use

to close the page.

eekly schedule’ and use

eekly schedule: [day of the week]’

to save your

‘Close’

to close the page.

to

Fig. 29: Editing a schedule object

1. Go to the ‘Setup system time’ (Fig. 28) page and

select ‘Set’ .

The ‘Edit schedule object’ (Fig. 29) page

ð

opens.

Expansion module EM-IP 19

Web server settings

Web server navigation > Functions of the Setup menu

3.5.7.6 IP network

This dialogue allows you to set or change network properties. If you change network properties, you may have

to change the PC settings also.

The Switch function allows you to deactivate the integral

network switch.

A daisy chain is no longer possible.

To activate web communication using the safe HTTPS

protocol, select ‘HTTPS’ .

IP network settings

1. Select the ‘Setup’ menu from the menu bar

.

Fig. 32: Alarm management

2. Under ‘System’ , on the left, select ‘Alarms/

Events’ .

The ‘Alarm management’ (Fig. 32) page is

ð

displayed.

3. Enter the relevant data.

4.

Use ‘Save’ to save your entries.

Fig. 31: IP network settings

2. Under ‘System’ , on the left, select ‘IP network’ .

The ‘IP network settings’ (Fig. 31) page is dis-

ð

played.

3. Enter the relevant data.

4.

Use ‘Save’ to save your entries.

3.5.7.7 Alarm management

This dialogue allows you to enter an SMTP server and

access data such that e-mails for events that you have

previously created in the ‘Objects’ area can be sent.

Opening the 'Alarm management' page

1. Select the ‘Setup’ menu from the menu bar.

3.5.7.8

The 'Backup' function allows you to save all the settings

you have made for EM-IP to a file; the 'Restore' function

allows you to restore data.

This page also allows you to update the operating

system software.

Follow the instructions on the screen.

Backup

Expansion module EM-IP20

Web server settings

Web server navigation > Functions of the Setup menu

Backup

1. Select the ‘Setup’ menu from the menu bar

Fig. 33: Backup

2. Under ‘System’ , on the left, select ‘Backup’ .

The ‘Backup’ (Fig. 33) page opens.

ð

3. Select ‘Backup’

4. Activate the desired option.

5. Select ‘Compress’ , if necessary

6.

Use ‘Start backup’ to start the backup process.

on the ‘Backup’ page.

.

Select ‘Search’ , then select the file to be restored

.

from the respective directory

5.

Use

process.

Loading an update

1. Select the ‘Setup’ menu from the menu bar

Fig. 35: Backup/Update

2. Under ‘System’ , on the left, select ‘Backup’ .

ð

‘Start transmission’

The ‘Backup’ (Fig. 33) page opens.

.

to start the restoring

.

Restoring data

1. Select the ‘Setup’ menu from the menu bar

Fig. 34: Backup/Restore

2. Under ‘System’ , on the left, select ‘Backup’ .

The ‘Backup’ (Fig. 33) page opens.

ð

3. Select ‘Restore’

4.

on the ‘Backup’ page.

3. Select ‘Update’ on the ‘Backup’ page.

4.

.

Follow the instructions on the screen.

Use ‘Search’ , then select software update from

the respective directory.

5.

Use ‘Start update’ to start the update process.

3.5.7.9

A new configuration is only installed if you have

selected ‘Activate configuration’ . Otherwise the current

configuration remains unchanged. When you carry out a

complete system reboot, the unit is completely

rebooted. The effect is the same as with switching it off

and on again.

After about 80 s the system is active again. You have to

log in again.

When you select ‘Reboot’ , EM-IP is immediately

rebooted. After a reboot no data will be transferred for

about 80 s.

Reboot

Follow the instructions on the screen.

Expansion module EM-IP 21

Web server settings

Web server navigation > Functions of the Setup menu

Reboot

1. Select the ‘Setup’ menu from the menu bar

Fig. 36: Reboot

2. Under ‘System’ , on the left, select ‘Reboot’ .

The ‘Reboot’ (Fig. 33) menu is displayed.

ð

3. Select ‘Activate configuration’ .

4.

TCP port

.

Enter the TCP port to be used for Modbus into the

[TCP-Port]

The default value is 502.

Slave address

Enter the Modbus slave address for EM-IP into the

[Slave address]

The default value is 1.

Enter settings

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘Modbus’ , on the left, select ‘Modbus/IP’ .

field.

field.

The ‘Modbus/IP’ (Fig. 37) menu is displayed.

ð

.

Follow the instructions on the screen.

Use the ‘Reboot’ button to start the reboot

process.

3.5.7.10

Modbus/IP

3. Enter the new values.

4.

Use

3.5.7.1

[Save] to save your entries.

1 Editing a BACnet/IP configuration

Fig. 37: Modbus/IP

The ‘Modbus/IP’ dialogue allows you to set slave

addresses and the TCP port.

Expansion module EM-IP22

Fig. 38: Editing a BACnet/IP configuration

The ‘Edit BACnet/IP configuration’

properties for a BACnet device object.

allows you to set the

Web server settings

Web server navigation > Functions of the Setup menu

Network number

Enter the network number into the [Network number]

field.

UDP port

Enter the UDP port to be used for BACnet into the

[UDP port] field.

The default value is 47808 (or 0xBAC0 as a hexadecimal value).

Operating mode

Use this field to enter the operating mode.

Normal

BBMD

Foreign Device (FD)

The default is 'Normal'.

3.5.7.11.1 Editing a device object

Fig. 39: Editing a device object

This menu allows you to enter device-specific BACnet

settings.

Editing device object properties

1. Select the ‘Setup’ menu from the menu bar.

2. Under ‘BACnet’ , on the left, select ‘Device’ .

The ‘Device’ (Fig. 39) page opens.

ð

NOTICE!

Using BBMD and Foreign Device (FD) incorrectly

may result in serious network problems (broadcast).

Only use these settings for networks where IT routers

block broadcast messages.

Editing a configuration

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘BACnet’ , on the left, select ‘Network’ .

The ‘Network’ (Fig. 38) menu is displayed.

ð

3. Enter new values or change option fields as

required.

4.

Use [Save] to save your entries.

.

3. Enter new values or change option fields as

required.

4.

Use [Save] to save your entries.

3.5.7.1

1.2 BACnet objects

The 'BACnet objects' page allows you to edit existing

data points.

This includes

Intrinsic reporting

Creating trend logs

Events and alarm notification

Scheduler

Expansion module EM-IP 23

Web server settings

Web server navigation > Functions of the Setup menu

Fig. 40: BACnet objects

The ‘BACnet objects’ page allows you to edit the properties of a BACnet device object.

Editing device object properties

1. Select the ‘Setup’ menu from the menu bar

2. Under ‘BACnet’ , on the left, select ‘Objects’ .

The ‘BACnet objects’ (Fig. 40) menu is dis-

ð

played.

Editing a trend log object

.

4. Enter new values or change option fields as

required.

5.

Use

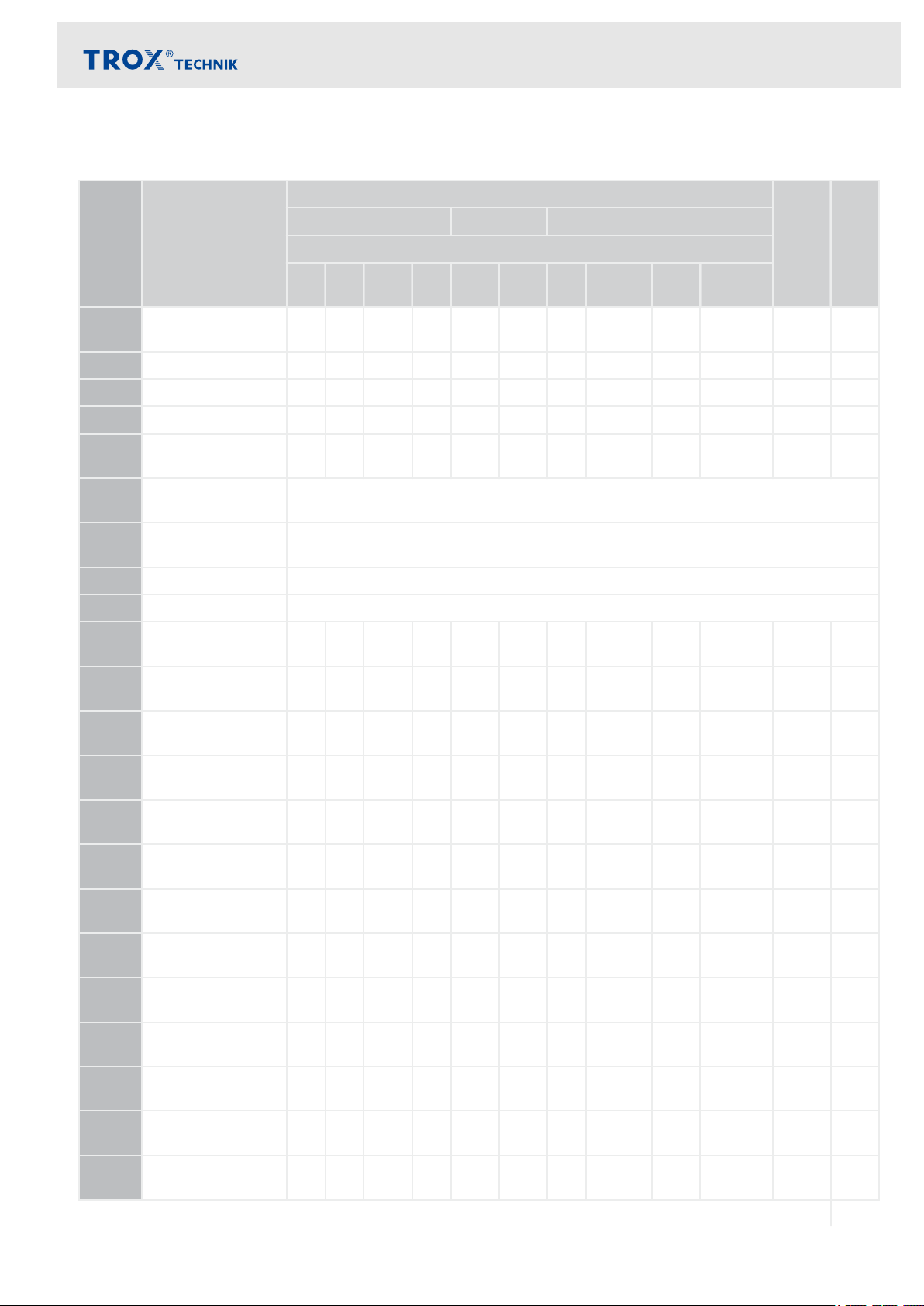

Editing an event log

Fig. 42: Editing an event log object

1. Go to ‘Setup system time’ (Fig. 28) and select

ð

2. Enter the relevant data.

3.

Use [Save] to save your entries, and [Close]

to close the menu.

‘Save’ to save your entries.

.

The ‘Edit event log object’

displayed.

(Fig. 42) menu is

Fig. 41: Editing a trend log object

3.

Use to select the object you want to edit.

The ‘Edit trend log object’

ð

page is displayed.

Creating/editing event and alarm notifications

Fig. 43: BACnet objects

1. Select the ‘Setup’ menu from the menu bar

.

Expansion module EM-IP24

Web server settings

Web server navigation > Functions of the Help menu

2. Under ‘BACnet’ , on the left, select ‘Objects’ .

The ‘BACnet objects’ (Fig. 43) menu is dis-

ð

played.

Creating

1.

Use

You may create the following new object types:

Notification class

Event log

T

ð

[Create new]

rend log

The respective page (

to select an object type.

Fig. 44) is displayed.

Displaying help

Fig. 45: Help (example)

Select the ‘Help’ menu from the menu bar.

The ‘Help’ menu (Fig. 45) is displayed.

ð

Fig. 44: Editing a notification class object (example)

2. Enter the relevant data.

3.

Use

to close the menu.

Editing

1.

Use to select the object you want to edit.

You may select the following object types:

Analog value

Binary value

Multistate value

ð

2. Enter the relevant data.

3.

Use [Save] to save your entries, and [Close]

to close the menu.

[Save] to save your entries, and [Close]

The respective page is displayed.

On the left of the screen you may select

information on diagnosis, the user's manual

and BACnet PICs as PDF.

3.5.8

When you select the ‘Help’ menu item, a page is displayed from which you can access help files.

If you are logged in as ‘User’ or ‘Admin’ , you may also

upload your own files.

Functions of the ‘Help’ menu

Expansion module EM-IP 25

Interface information

BACnet interface

4 Interface information

BACnet interface

4.1

Application

The expansion module EM-IP supports the following

BACnet interface functions in the BACnet-IP protocol

settings:

Native BACnet, i.e. the BACnet interface is imple-

mented on the field module (EASYLAB volume flow

controller)

External hardware components such as physical

gateways are not required

BACnet interface documentation includes the fol-

lowing documents: Protocol Implementation Conformance Statement (PICS), BACnet Interoperability

Building Blocks Supported (BIBBS), as well as a

description of the device object and the supported

objects

Abbreviations

EASYLAB:

FH - Fume cupboard controller

RR - Room controller for supply air or extract air

(RS, RE, PC)

RR RMF - Room controller with active room manage-

ment function

EC, SC - Single controller for supply air or extract air

(EC, SC)

TAM - Adapter module

TAM

RMF

WR - Defaults for the volume flow controller or

RD - Data provided by the volume flow con-

TROX UNIVERSAL CONTROLLER:

RS/RE - Volume flow controllers for supply or

RS/RE

RMF

PR*/PD* - Room pressure controller or duct for

PR*/PD*

RMF

See also the PICS list for EM-IP under ‘Help’ in the

web server

menu’ on page 25.

- Adapter module with active room management function

room, from the central BMS

troller or room

extract air

- Volume flow controller with active room

management function

supply or extract air

- Room pressure controller or duct with

active room management function

Ä

Chapter 3.5.8 ‘Functions of the ‘Help’

Expansion module EM-IP26

Interface information

BACnet PICS (extract)

Category Data

Date 2011-07-20

Vendor name/Vendor identifier TROX GmbH/329

Product name/Model no. EM-IP/EM-IP

Application/Firmware Revison 2.0

BACnet Protocol Revision 12

Standardized Device Profile BACnet Application Specific Controller (B-ASC)

BACnet interface

Interoperability Building Blocks Supported

Segmentation Capability No

Data Link Layer Options TCP-IP 10/100 Mbit

Device Address Binding No

Network Security Options No

Character Sets Supported ISO 10646 (UTF-8)

DS-RP-B, DS-WP-B, DS-RPM-B, DS-WPM-B, DS-COVU-B, AE-NI- B, AEACK-B, AE-ASUM-B, AE-ESUM-B, AE-INFO-B, AE-EL-I-B, SCHEDWS-I-B,

T

-VMT-I-B, T-ATR-B, DM-DDB-A, DM-DDB-B, DM-DOB_B, DM-DCC-B,

DM-TS-B, DMUTC- B, DM-RD-B, DM-LM-B, DM-R-B

Expansion module EM-IP 27

Interface information

BACnet interface

DeviceObject

Property Value Access

Object identifier Device instance; default = 17493 WR, RD; E

Device name Default = "Device17493"; project-specific description can be

entered, 62 characters max.

Object type Device (8) RD

System_Status OPERATIONAL (0) RD

Vendor_Name TROX GmbH RD

Vendor_Identifier 329 RD

Model_Name EM-IP RD

Description Default = “TROX EM-IP”; description can be entered,

126 characters max.

Location Default = ""; description can be entered, 62 characters max. WR, RD; E

Firmware_Revision V2.0 RD

Application_Software_Version

Protocol_Version 1 RD

Protocol_Revision 12 RD

Protocol Services Supported

Protocol_Object_T

ported

ypes_Sup-

TR2_02E RD

Who-is, Who-has, Read-Property, Write-Property, Devicecommunication-control, Reinitialize-device

DEVICE, ANALOG_VALUE, BINARY_VALUE, MULTISTATE_VALUE

WR, RD; E

WR, RD; E

RD

RD

Object_List EASYLAB: device, analog-value 1…31, binary-value 1…30,

multistate-value 1…8

Max_ADPU_Length_Accepted1024 RD

Segmentation_Supported NO_SEGMENTATION (3) RD

APDU_Timeout 5000 RD

Number_Of_APDU_Retries 3 RD

Device_Address_Binding – RD

Database_Revision 0 RD

Access rights:

RD: Read

WR: W

E: Save in EEPROM

rite

RD

Expansion module EM-IP28

Multistate Value Objects

In-

Description Unit Acc-

stance

Interface information

TCU3 TAM TROX UNIVERSAL

Available with equipment function

BACnet interface

Sup-

ess

port

COV

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

MV-2 Mode x¹ x x x x WR,

RD

MV-3 ModeAct x x x x x x RD Y

MV-4 RoomModeAct x x x x x x x RD Y

MV-5 SwitchPos x RD Y

MV-6 Sunblind x x x x x WR,

RD

MV-7 SC_SetLockHigh-

Not used

Prio

MV-8 SC_GetLockHigh-

Not used

Prio

MV-9 SC_SetPos Not used

MV-10 SC_GetPos Not used

MV-11 DampPosMax-

x x x x x x RD Y

State_FH

MV-12 DampPosMin-

x x x x x x RD Y

State_FH

MV-13 DampPosMax-

x x x x x x RD Y

State_RE

N

N

MV-14 DampPosMin-

State_RE

MV-15 DampPosMax-

State_TE

MV-16 DampPosMin-

State_TE

MV-17 DampPosMax-

State_RS

MV-18 DampPosMin-

State_RS

MV-26 DampPosMax-

State_EC

MV-27 DampPosMin-

State_EC

MV-28 DampPosMax-

State_SC

MV-29 DampPosMin-

State_SC

MV-30 DampPosMax-

State_TS

Abbreviations

Ä

‘Abbreviations’ on page 26

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

Expansion module EM-IP 29

Interface information

BACnet interface

In-

Description Unit Acc-

stance

TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

Sup-

port

COV

MV-31 DampPosMin-

State_TS

MV-32 DampPosMax-

State_VE

MV-33 DampPosMin-

State_VE

MV-34 DampPosMax-

State_VS

MV-35 DampPosMin-

State_VS

MV-36 DampPosMax-

State_PKE

MV-37 DampPosMin-

State_PKE

MV-38 DampPosMax-

State_PKS

MV-39 DampPosMin-

State_PKS

Abbreviations

Ä

‘Abbreviations’ on page 26

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

x x x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

Expansion module EM-IP30

Analogue Value Objects

In-

Description Unit Unit Acc-

stance

Interface information

TCU3 TAM TROX UNIVERSAL

Available with equipment function

BACnet interface

Sup-

ess

port

COV

AV-1 VolflowSet l/s

(87)

AV-2 VolflowAct l/s

(87)

AV-3 VolTotalExh l/s

(87)

AV-4 VolTotalSup l/s

(87)

AV-5 PressSet pa

(53)

AV-6 PressAct pa

(53)

AV-7 VelocitySet m/s

(74)

AV-8 VelocityAct m/s

(74)

AV-9 WireSensorPos %

(98)

AV-10 DampPos %

(98)

FH RR RR

EC,SCTAM TAM

RMF

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

x x x x x x RD Y

x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x RD Y

x x x x RD Y

x RD Y

x RD Y

x RD Y

x x x x x x x x RD Y

AV-11 Damp-

PosMax_FH

(98)

AV-12 Damp-

PosMin_FH

(98)

AV-13 Damp-

PosMax_RE

(98)

AV-14 Damp-

PosMin_RE

(98)

AV-15 Damp-

PosMax_TE

(98)

AV-16 Damp-

PosMin_TE

(98)

AV-17 Damp-

PosMax_RS

(98)

AV-18 Damp-

PosMin_RS

(98)

AV-19 VolOffset_T %

(98)

AV-20 VolOffset_P %

(98)

Abbreviations

Ä

‘Abbreviations’ on page 26

%

%

%

%

%

%

%

%

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x WR,RDN

x x WR,RDN

Expansion module EM-IP 31

Interface information

BACnet interface

In-

Description Unit Unit Acc-

stance

TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

Sup-

port

COV

FH RR RR

EC,SCTAM TAM

RMF

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

AV-21 SystemDevices – (95) x x x x x x x x x x RD Y

AV-22 VolflowExh l/s

x x x x x x x x x WR,RDN

(87)

AV-23 VolflowSup l/s

x x x x x x x x x WR,RDN

(87)

AV-24 SC_SetPos %

Not used

(98)

AV-25 SC_GetPos %

Not used

(98)

AV-26 Damp-

PosMax_EC

AV-27 Damp-

PosMin_EC

AV-28 Damp-

PosMax_SC

AV-29 Damp-

PosMin_SC

AV-30 Damp-

PosMax_TS

%

(98)

%

(98)

%

(98)

%

(98)

%

(98)

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

x x x x x x RD Y

AV-31 Damp-

PosMin_TS

%

(98)

x x x x x x RD Y

AV-32 Device_ID_0 – (95) x x x x x x x x x x RD Y

AV-33 Device_ID_1 – (95) x x x x x x x x x x RD Y

AV-34 Device_ID_2 – (95) x x x x x x x x x x RD Y

AV-35 Device_ID_3 – (95) x x x x x x x x x x RD Y

AV-36 Device_ID_4 – (95) x x x x x x x x x x RD Y

AV-37 Device_ID_5 – (95) x x x x x x x x x x RD Y

AV-38 Device_ID_6 – (95) x x x x x x x x x x RD Y

AV-39 Device_ID_7 – (95) x x x x x x x x x x RD Y

AV-40 Device_ID_8 – (95) x x x x x x x x x x RD Y

AV-41 Device_ID_9 – (95) x x x x x x x x x x RD Y

AV-42 Device_ID_10 – (95) x x x x x x x x x x RD Y

AV-43 Device_ID_11 – (95) x x x x x x x x x x RD Y

AV-44 Device_ID_12 – (95) x x x x x x x x x x RD Y

AV-45 Device_ID_13 – (95) x x x x x x x x x x RD Y

AV-46 Device_ID_14 – (95) x x x x x x x x x x RD Y

AV-47 Device_ID_15 – (95) x x x x x x x x x x RD Y

AV-48 Device_ID_16 – (95) x x x x x x x x x x RD Y

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP32

In-

stance

Interface information

BACnet interface

Description Unit Unit Acc-

TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

Sup-

port

COV

FH RR RR

EC,SCTAM TAM

RMF

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

AV-49 Device_ID_17 – (95) x x x x x x x x x x RD Y

AV-50 Device_ID_18 – (95) x x x x x x x x x x RD Y

AV-51 Device_ID_19 – (95) x x x x x x x x x x RD Y

AV-52 Device_ID_20 – (95) x x x x x x x x x x RD Y

AV-53 Device_ID_21 – (95) x x x x x x x x x x RD Y

AV-54 Device_ID_22 – (95) x x x x x x x x x x RD Y

AV-55 Device_ID_23 – (95) x x x x x x x x x x RD Y

AV-56 VolflowAct_0 l/s

x x x x x x x x x x RD Y

(87)

AV-57 VolflowAct_1 l/s

x x x x x x x x x x RD Y

(87)

AV-58 VolflowAct_2 l/s

x x x x x x x x x x RD Y

(87)

AV-59 VolflowAct_3 l/s

x x x x x x x x x x RD Y

(87)

AV-60 VolflowAct_4 l/s

x x x x x x x x x x RD Y

(87)

AV-61 VolflowAct_5 l/s

(87)

AV-62 VolflowAct_6 l/s

(87)

AV-63 VolflowAct_7 l/s

(87)

AV-64 VolflowAct_8 l/s

(87)

AV-65 VolflowAct_9 l/s

(87)

AV-66 VolflowAct_10 l/s

(87)

AV-67 VolflowAct_11 l/s

(87)

AV-68 VolflowAct_12 l/s

(87)

AV-69 VolflowAct_13 l/s

(87)

AV-70 VolflowAct_14 l/s

(87)

AV-71 VolflowAct_15 l/s

(87)

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP 33

Interface information

BACnet interface

In-

Description Unit Unit Acc-

stance

TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

Sup-

port

COV

AV-72 VolflowAct_16 l/s

(87)

AV-73 VolflowAct_17 l/s

(87)

AV-74 VolflowAct_18 l/s

(87)

AV-75 VolflowAct_19 l/s

(87)

AV-76 VolflowAct_20 l/s

(87)

AV-77 VolflowAct_21 l/s

(87)

AV-78 VolflowAct_22 l/s

(87)

AV-79 VolflowAct_23 l/s

(87)

AV-80 VolflowSet_R l/s

(87)

AV-81 PressSet_R pa

(53)

FH RR RR

EC,SCTAM TAM

RMF

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x x x x x x x x x RD Y

x x WR,RDN

x x WR,RDN

AV-82 Volt_AI2 volt

(5)

AV-83 Volt_AI3 volt

(5)

AV-84 Volt_AO2 volt

(5)

AV-85 DampPosMax-

V

alue_VE

AV-86 DampPosMin-

V

alue_VE

AV-87 DampPosMax-

V

alue_VS

AV-88 DampPosMin-

V

alue_VS

AV-89 DampPosMax-

V

alue_PKE

AV-90 DampPosMin-

V

alue_PKE

AV-91 DampPosMax-

V

alue_PKS

AV-92 DampPosMin-

V

alue_PKS

%

(98)

%

(98)

%

(98)

%

(98)

%

(98)

%

(98)

%

(98)

%

(98)

x x x x x x RD Y

x x x x x x RD Y

x x x x x x WR,RDN

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

x x x x RD Y

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP34

Binary Value Objects

Interface information

BACnet interface

In-

stance

Description Unit Acc-

TCU3 TAM TROX UNIVERSAL

ess

Available with equipment function

BV-1 LocalAlarm

FH RR RR

RMF

x x x x x x x x x x RD Y

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

(COVU)

BV-2 SummaryAlarm

x x x x x x RD Y

(COVU)

BV-3 PressAlarm

x x x x RD Y

(COVU)

BV-4 ManOP_Disable x¹ x x x x WR,RDN

BV-5 PressSetSel x x WR,RDN

BV-6 DI1 x x x x x x x x x x RD Y

BV-7 DI2 x x x x x x x x x x RD Y

BV-8 DI3 x x x x x x x x x x RD Y

BV-9 DI4 x x x x x x x x x x RD Y

Sup-

port

COV

BV-10 DI5 x x x x x x x x x x RD Y

BV-11 DI6 x x x x x x x x x x RD Y

BV-12 DO1 x x x x x x x x x x RD Y

BV-13 DO2 x x x x x x x x x x RD Y

BV-14 DO3 x x x x x x x x x x RD Y

BV-15 DO4 x x x x x x x x x x RD Y

BV-16 DO5 x x x x x x x x x x RD Y

BV-17 DO6 x x x x x x x x x x RD Y

BV-18 SC_Alarm Not used

BV-19 DO1_Set x x x x x x x x x x WR,RDN

BV-20 DO2_Set x x x x x x x x x x WR,RDN

BV-21 DO3_Set x x x x x x x x x x WR,RDN

BV-22 DO4_Set x x x x x x x x x x WR,RDN

BV-23 DO5_Set x x x x x x x x x x WR,RDN

BV-24 DO6_Set x x x x x x x x x x WR,RDN

BV-25 DO1_SetByLocal x x x x x x x x x x RD Y

1

only for individually selected operating mode (stand-alone operation)

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP 35

Interface information

BACnet interface

In-

Description Unit Acc-

stance

TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

Sup-

port

COV

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

BV-26 DO2_SetByLocal x x x x x x x x x x RD Y

BV-27 DO3_SetByLocal x x x x x x x x x x RD Y

BV-28 DO4_SetByLocal x x x x x x x x x x RD Y

BV-29 DO5_SetByLocal x x x x x x x x x x RD Y

BV-30 DO6_SetByLocal x x x x x x x x x x RD Y

BV-31 LocalAlarm_0 x x x x x x x x x x RD Y

BV-32 LocalAlarm_1 x x x x x x x x x x RD Y

BV-33 LocalAlarm_2 x x x x x x x x x x RD Y

BV-34 LocalAlarm_3 x x x x x x x x x x RD Y

BV-35 LocalAlarm_4 x x x x x x x x x x RD Y

BV-36 LocalAlarm_5 x x x x x x x x x x RD Y

BV-37 LocalAlarm_6 x x x x x x x x x x RD Y

BV-38 LocalAlarm_7 x x x x x x x x x x RD Y

BV-39 LocalAlarm_8 x x x x x x x x x x RD Y

BV-40 LocalAlarm_9 x x x x x x x x x x RD Y

BV-41 LocalAlarm_10 x x x x x x x x x x RD Y

BV-42 LocalAlarm_11 x x x x x x x x x x RD Y

BV-43 LocalAlarm_12 x x x x x x x x x x RD Y

BV-44 LocalAlarm_13 x x x x x x x x x x RD Y

BV-45 LocalAlarm_14 x x x x x x x x x x RD Y

BV-46 LocalAlarm_15 x x x x x x x x x x RD Y

BV-47 LocalAlarm_16 x x x x x x x x x x RD Y

BV-48 LocalAlarm_17 x x x x x x x x x x RD Y

BV-49 LocalAlarm_18 x x x x x x x x x x RD Y

BV-50 LocalAlarm_19 x x x x x x x x x x RD Y

BV-51 LocalAlarm_20 x x x x x x x x x x RD Y

BV-52 LocalAlarm_21 x x x x x x x x x x RD Y

BV-53 LocalAlarm_22 x x x x x x x x x x RD Y

BV-54 LocalAlarm_23 x x x x x x x x x x RD Y

1

only for individually selected operating mode (stand-alone operation)

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP36

Interface information

Modbus interface

4.2 Modbus interface

Application

The expansion module EM-IP supports the following

Modbus interface functions in the Modbus protocol settings:

Modbus is an open serial master-slave communica-

tion protocol which has become a de facto standard

for the industry

The master (e.g. central BMS) can address a

number of slaves (EASYLAB volume flow controllers) and use Modbus functions to request information from individual data points

Data access is based on numbered data registers

which the master has to define in order to request

data using Modbus functions

The slave responds by either returning the

requested information or an exception code (error)

Example: The Read Input Registers function (reg-

ister no. 3) returns the volume flow rate actual value

of the addressed controller

General information for a Modbus device can be

read out using the Read Device Identification function

RR RMF - Room controller with active room manage-

ment function

EC, SC - Single controller for supply air or extract air

(EC, SC)

TAM - Adapter module

TAM

RMF

WR - Defaults for the volume flow controller or

RD - Data provided by the volume flow con-

TROX UNIVERSAL CONTROLLER:

RS/RE - Volume flow controllers for supply or

RS/RE

RMF

PR*/PD* - Room pressure controller or duct for

PR*/PD*

RMF

- Adapter module with active room management function

room, from the central BMS

troller or room

extract air

- Volume flow controller with active room

management function

supply or extract air

- Room pressure controller or duct with

active room management function

Abbreviations

EASYLAB:

FH - Fume cupboard controller

RR - Room controller for supply air or extract air

(RS, RE, PC)

Expansion module EM-IP 37

Interface information

Modbus interface

Modbus functions

Function no. Description Meaning

1 (0x01) Read Coils Read states of 1 to 8 bits according to bit list

3 (0x03) Read Holding Registers Read several consecutive registers

4 (0x04) Read Input Registers Read several consecutive registers

5 (0x05) Write Single Coil Write state of a single bit

6 (0x06) Write Single Register Write single register

Exception codes

Codes Description Meaning

1 Illegal Function Code Unknown function or subfunction code

2 Illegal Data Address Invalid register address

3 Illegal Data Value Inconsistent coding for number of registers/bytes, data value

Exception codes (error codes) are returned in case of invalid function or register access.

Expansion module EM-IP38

Bit list for ReadCoil/WriteSingleCoil functions

Bit Unit Access

TCU3 TAM TROX UNIVERSAL

Interface information

Modbus interface

Available with equipment function

No. Description

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

0 ManOP_Disable x¹ x x x x WR,

RD

1 PressSetSel x x WR,

RD

2 Local Alarm x x x x x x RD

3 SummaryAlarm x x RD

4 PressAlarm x x RD

5 SC_SetlockHigh-

Not used

Prio

6 SC_GetLockHigh-

Not used

Prio

7 SC_Alarm Not used

8 LocalAlarm_0 x x x x x x RD

9 LocalAlarm_1 x x x x x x RD

10 LocalAlarm_2 x x x x x x RD

11 LocalAlarm_3 x x x x x x RD

12 LocalAlarm_4 x x x x x x RD

13 LocalAlarm_5 x x x x x x RD

14 LocalAlarm_6 x x x x x x RD

15 LocalAlarm_7 x x x x x x RD

16 LocalAlarm_8 x x x x x x RD

17 LocalAlarm_9 x x x x x x RD

18 LocalAlarm_10 x x x x x x RD

19 LocalAlarm_11 x x x x x x RD

20 LocalAlarm_12 x x x x x x RD

21 LocalAlarm_13 x x x x x x RD

22 LocalAlarm_14 x x x x x x RD

23 LocalAlarm_15 x x x x x x RD

24 LocalAlarm_16 x x x x x x RD

25 LocalAlarm_17 x x x x x x RD

26 LocalAlarm_18 x x x x x x RD

27 LocalAlarm_19 x x x x x x RD

1

only for individually selected operating mode (stand-alone operation)

Bits are read with function 1 (RD) or written with function 5 (WR).

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP 39

Interface information

Modbus interface

Bit Unit Access

TCU3 TAM TROX UNIVERSAL

Available with equipment function

No. Description

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

28 LocalAlarm_20 x x x x x x RD

29 LocalAlarm_21 x x x x x x RD

30 LocalAlarm_22 x x x x x x RD

31 LocalAlarm_23 x x x x x x RD

1

only for individually selected operating mode (stand-alone operation)

Bits are read with function 1 (RD) or written with function 5 (WR).

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP40

Interface information

Register list for Read***Registers and Write***Registers functions

Register Unit Acc-

No. Description TCU3 TAM TROX UNIVERSAL

Available with equipment function

Modbus interface

ess

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

0 Mode x¹ x x x x WR,

RD

1 ManOP_Disable x¹ x x x x WR,

RD

2 ModeAct x x x x x x RD

3 VolflowAct x x x x x x x x RD

4 VolflowSet x x x x x x RD

5 VelocityAct x RD

6 VelocitySet x RD

7 VolTotalExh x x x x x x x x x x RD

8 VolTotalSup x x x x x x x x x x RD

9 VolOffset_T x x WR,

RD

10 VolOffset_P x x WR,

RD

11 PressAct x x x x RD

12 PressSet x x x x RD

13 PressSetSel x x WR,

14 DampPos x x x x x x x x RD

15 DampPosMax_FH -

V

alue

16 DampPosMax_FH -

x x x x x x RD

x x x x x x RD

Status

17 DampPosMin_FH -

V

alue

18 DampPosMin_FH -

x x x x x x RD

x x x x x x RD

Status

19 DampPosMax_RE -

V

alue

20 DampPosMax_RE -

x x x x x x RD

x x x x x x RD

Status

21 DampPosMin_RE -

V

alue

22 DampPosMin_RE -

x x x x x x RD

x x x x x x RD

Status

1

only for individually selected operating mode (stand-alone operation)

RD

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP 41

Interface information

Modbus interface

Register Unit Acc-

No. Description TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

23 DampPosMax_TE -

V

alue

24 DampPosMax_TE -

FH RR RR

RMF

x x x x x x RD

x x x x x x RD

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

Status

25 DampPosMin_TE -

V

alue

26 DampPosMin_TE -

x x x x x x RD

x x x x x x RD

Status

27 DampPosMax_RS -

V

alue

28 DampPosMax_RS -

x x x x x x RD

x x x x x x RD

Status

29 DampPosMin_RS -

V

alue

30 DampPosMin_RS -

x x x x x x RD

x x x x x x RD

Status

31 LocalAlarm x x x x x x x x x x RD

32 SummaryAlarm x x x x x x RD

33 PressAlarm x x x x RD

34 WireSensorPos x RD

35 SwitchPos x RD

36 RoomModeAct x x x x x x RD

37 SystemDevices x x x x x x x x x x RD

38 SunBlind x x x x WR,

RD

39 StateDI x x x x x x x x x x RD

40 StateDO x x x x x x x x x x RD

41 VolflowExh x x x x x x x x x WR,

RD

42 VolflowSup x x x x x x x x x WR,

RD

43 SC_SetLockHighPrio Not used

44 SC_GetLockHighPrio Not used

45 SC_SetPos - Value Not used

46 SC_SetPos - Status Not used

47 SC_GetPos Not used

48 SC_Alarm Not used

1

only for individually selected operating mode (stand-alone operation)

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP42

Interface information

Modbus interface

Register Unit Acc-

No. Description TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

49 DampPosMax_EC -

V

alue

50 DampPosMax_EC --

Status

51 DampPosMin_EC -

V

alue

52 DampPosMin_EC --

Status

53 DampPosMax_SC -

V

alue

54 DampPosMax_SC --

Status

55 DampPosMin_SC -

V

alue

56 DampPosMin_SC --

Status

57 DampPosMax_TS -

V

alue

58 DampPosMax_TS --

Status

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

x x x x x x RD

x x x x x x RD

x x x x x x RD

x x x x x x RD

x x x x x x RD

x x x x x x RD

x x x x x x RD

x x x x x x RD

x x x x x x RD

x x x x x x RD

59 DampPosMin_TS -

V

alue

60 DampPosMin_TS --

x x x x x x RD

x x x x x x RD

Status

61 DO_Set x x x x x x x x x x WR,

62 DO_SetByLocal x x x x x x x x x x RD

63 LocalAlarm_* (0 – 7) x x x x x x x x x x RD

64 LocalAlarm_* (8 –

x x x x x x x x x x RD

15)

65 LocalAlarm_* (16 –

x x x x x x x x x x RD

23)

66 Device_ID_0 x x x x x x x x x x RD

67 Device_ID_1 x x x x x x x x x x RD

68 Device_ID_2 x x x x x x x x x x RD

69 Device_ID_3 x x x x x x x x x x RD

70 Device_ID_4 x x x x x x x x x x RD

71 Device_ID_5 x x x x x x x x x x RD

72 Device_ID_6 x x x x x x x x x x RD

1

only for individually selected operating mode (stand-alone operation)

RD

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP 43

Interface information

Modbus interface

Register Unit Acc-

No. Description TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

73 Device_ID_7 x x x x x x x x x x RD

74 Device_ID_8 x x x x x x x x x x RD

75 Device_ID_9 x x x x x x x x x x RD

76 Device_ID_10 x x x x x x x x x x RD

77 Device_ID_11 x x x x x x x x x x RD

78 Device_ID_12 x x x x x x x x x x RD

79 Device_ID_13 x x x x x x x x x x RD

80 Device_ID_14 x x x x x x x x x x RD

81 Device_ID_15 x x x x x x x x x x RD

82 Device_ID_16 x x x x x x x x x x RD

83 Device_ID_17 x x x x x x x x x x RD

84 Device_ID_18 x x x x x x x x x x RD

85 Device_ID_19 x x x x x x x x x x RD

86 Device_ID_20 x x x x x x x x x x RD

87 Device_ID_21 x x x x x x x x x x RD

88 Device_ID_22 x x x x x x x x x x RD

89 Device_ID_23 x x x x x x x x x x RD

90 VolflowAct_0 x x x x x x x x x x RD

91 VolflowAct_1 x x x x x x x x x x RD

92 VolflowAct_2 x x x x x x x x x x RD

93 VolflowAct_3 x x x x x x x x x x RD

94 VolflowAct_4 x x x x x x x x x x RD

95 VolflowAct_5 x x x x x x x x x x RD

96 VolflowAct_6 x x x x x x x x x x RD

97 VolflowAct_7 x x x x x x x x x x RD

98 VolflowAct_8 x x x x x x x x x x RD

99 VolflowAct_9 x x x x x x x x x x RD

100 VolflowAct_10 x x x x x x x x x x RD

101 VolflowAct_11 x x x x x x x x x x RD

102 VolflowAct_12 x x x x x x x x x x RD

103 VolflowAct_13 x x x x x x x x x x RD

104 VolflowAct_14 x x x x x x x x x x RD

105 VolflowAct_15 x x x x x x x x x x RD

1

only for individually selected operating mode (stand-alone operation)

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP44

Interface information

Modbus interface

Register Unit Acc-

No. Description TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

FH RR RR

RMF

EC,SCTAM TAM

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

106 VolflowAct_16 x x x x x x x x x x RD

107 VolflowAct_17 x x x x x x x x x x RD

108 VolflowAct_18 x x x x x x x x x x RD

109 VolflowAct_19 x x x x x x x x x x RD

110 VolflowAct_20 x x x x x x x x x x RD

111 VolflowAct_21 x x x x x x x x x x RD

112 VolflowAct_22 x x x x x x x x x x RD

113 VolflowAct_23 x x x x x x x x x x RD

114 VolflowSet_R x x WR,

RD

115 PressSet_R x x WR,

RD

116 Volt_AI2 x x x x x x RD

117 Volt_AI3 x x x x x x RD

118 Volt_AO2 x x x x x x WR,

RD

119 DampPosMax_VE -

V

alue

120 DampPosMax_VE --

x x x x RD

x x x x RD

Status

121 DampPosMin_VE -

V

alue

122 DampPosMin_VE --

x x x x RD

x x x x RD

Status

123 DampPosMax_VS -

V

alue

124 DampPosMax_VS -

x x x x RD

x x x x RD

Status

125 DampPosMin_VS -

V

alue

126 DampPosMin_VS -

x x x x RD

x x x x RD

Status

127 DampPosMax_PKE -

V

alue

128 DampPosMax_PKE -

x x x x RD

x x x x RD

Status

129 DampPosMin_PKE -

V

alue

1

only for individually selected operating mode (stand-alone operation)

x x x x RD

Abbreviations

Ä

‘Abbreviations’ on page 26

Expansion module EM-IP 45

Interface information

Modbus interface

Register Unit Acc-

No. Description TCU3 TAM TROX UNIVERSAL

Available with equipment function

ess

FH RR RR

EC,SCTAM TAM

RMF

130 DampPosMin_PKE -

x x x x RD

Status

131 DampPosMax_PKS -

V

alue

132 DampPosMax_PKS -

x x x x RD

x x x x RD

Status

133 DampPosMin_PKS -

V

alue

134 +DampPosMin_PKS

x x x x RD

x x x x RD

- Status

1

only for individually selected operating mode (stand-alone operation)

Ä

Abbreviations

‘Abbreviations’ on page 26

RMF

RS/RERS/RE

RMF

PR*/

PD*

PR*/PD*

RMF

Expansion module EM-IP46

Interface information

Data points – detailed description > Input variables

4.3 Data points – detailed description

The following is a detailed description of the information

that each data point provides; input variables and output

variables are described separately:

Name of data point

Access as viewed from the central BMS

WR – Defaults for the volume flow controller or

–

room, from the central BMS

– RD – Data provided by the volume flow con-

troller or room

List of volume flow controller equipment functions

for which the variable is available

– FH – Fume cupboard controller

– RR – Room controller for supply air or extract air

(RS, RE, PC)