trotec laser 1500 Operation Manual

SP1500 Operation Manual

SP1500 Operation Manual

Copyright© by Trotec Produktions und Vertriebs Ges.m.b.H.

All rights reserved.

Anyone who reproduces, copies or distributes this document, or parts of it, without the approval

of Trotec Produktions und Vertriebs Ges.m.b.H. is subject to prosecution.

We do not assume liability for any errors contained in this documentation.

We reserve the right to make technical changes.

Trotec Produktions und Vertriebs Ges.m.b.H.

Linzer Strasse 156,

A-4600 Wels, OÖ.

AUSTRIA

Tel.: +43-(0)7242-239-0

Fax: +43-(0)7242-239-7380

trotec@troteclaser.com

www.troteclaser.com

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 2 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Table of Contents

Table of Contents

1 Manufacturing label........................................................................................................5

2 Product Components .....................................................................................................6

3 Preface.............................................................................................................................7

3.1 General.................................................................................................................................... 7

3.2 Product Tracking ..................................................................................................................... 8

4 Technical Data ................................................................................................................9

4.1 General Description................................................................................................................. 9

4.2 Intended Use ........................................................................................................................... 9

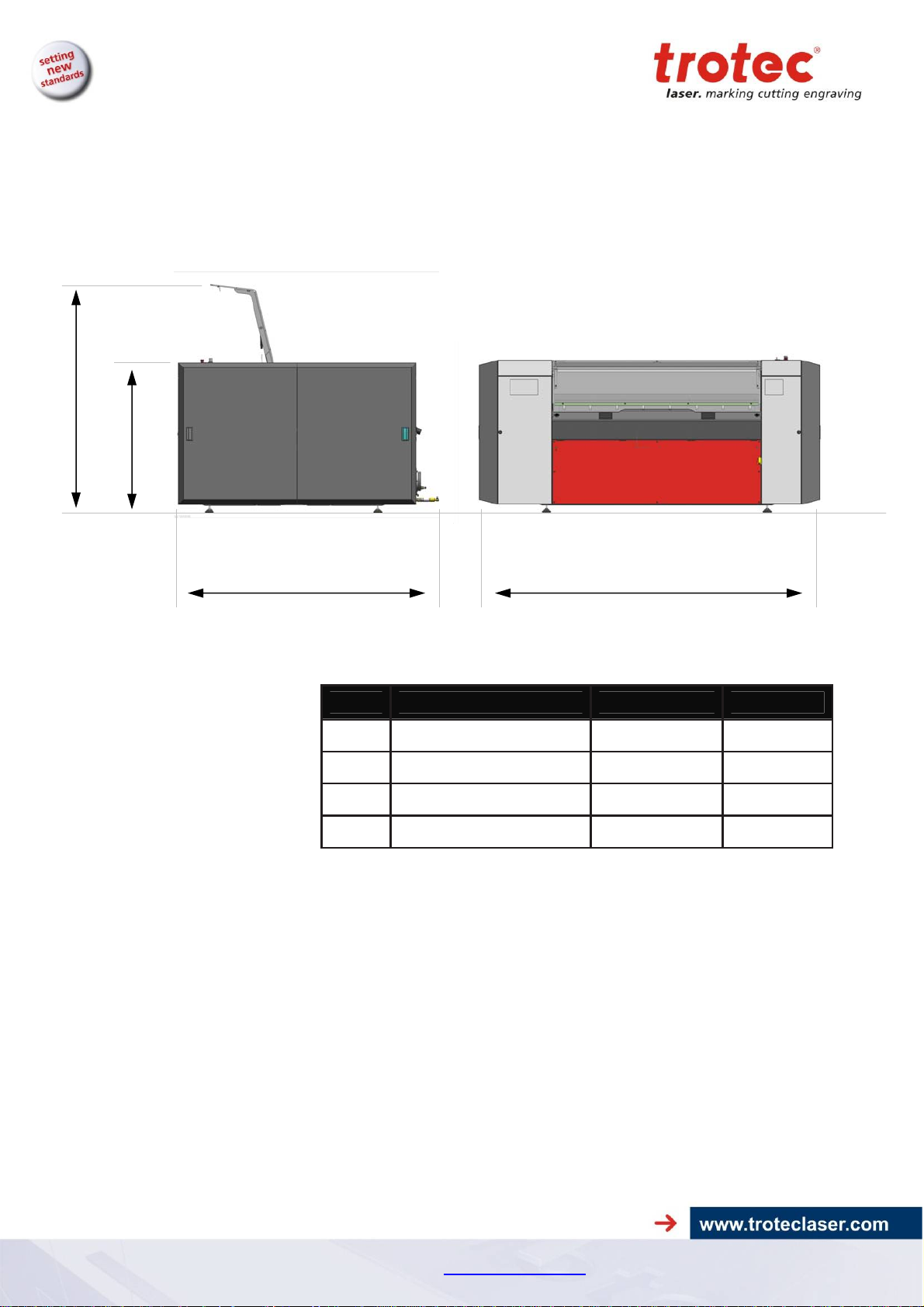

4.3 Dimensions............................................................................................................................ 10

4.4 Mechanical Design ................................................................................................................ 11

4.5 Control System...................................................................................................................... 11

4.6 Laser Tubes .......................................................................................................................... 11

4.7 Laser Safety .......................................................................................................................... 12

4.8 Ambient Conditions ............................................................................................................... 12

4.9 Options .................................................................................................................................. 12

4.10 Electrical Connection........................................................................................................... 13

4.10.1 Electrical connection for laser system .......................................................................... 13

4.10.2 Electrical connection for water cooling (option) ............................................................ 13

4.11 Materials.............................................................................................................................. 14

5 Safety.............................................................................................................................15

5.1 Safety Instructions................................................................................................................. 15

1.1 Intended user group........................................................................................................... 15

1.2 Operating instructions / Safety equipment......................................................................... 15

5.2 General Safety Instructions ................................................................................................... 16

2.1 General .............................................................................................................................. 16

2.2 Laser.................................................................................................................................. 19

2.3 Transport ........................................................................................................................... 20

5.3 Secondary Risks ................................................................................................................... 21

3.1 General .............................................................................................................................. 21

3.2 Crushing hazard ................................................................................................................ 21

5.4 Signage ................................................................................................................................. 22

6 Transport - Storage - Setup .........................................................................................24

6.1 Forklift transport .................................................................................................................... 24

6.2 Shipping conditions ............................................................................................................... 26

6.3 Unloading, inspection and damage reporting........................................................................ 26

6.4 Storage conditions................................................................................................................. 26

6.5 Storage Location ................................................................................................................... 26

6.6 Installation Site...................................................................................................................... 27

6.7 Space Requirements............................................................................................................. 27

6.8 Necessary Feed Lines........................................................................................................... 27

6.9 Setup ..................................................................................................................................... 28

6.10 Connections ........................................................................................................................ 29

6.10.1 Cooling System............................................................................................................. 30

7 Machine view................................................................................................................. 31

8 Operation.......................................................................................................................32

8.1 Key pad – Overview .............................................................................................................. 32

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 3 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Table of Contents

8.2 Key pad – Description ........................................................................................................... 33

8.3 Workpiece Removal Door ..................................................................................................... 36

8.4 Tables.................................................................................................................................... 37

8.4.1 Cutting Table (Standard Table) ...................................................................................... 37

8.4.2 Vacuum Table................................................................................................................. 37

8.5 Operation............................................................................................................................... 38

9 Maintenance..................................................................................................................39

9.1 Cleaning optics on the Laser Head ....................................................................................... 39

9.2 Cleaning the Mirrors .............................................................................................................. 40

9.3 Maintenance plan .................................................................................................................. 41

10 Appendix .....................................................................................................................42

10.1 EU – Declaration of conformity............................................................................................ 42

10.2 Acceptance report ............................................................................................................... 43

10.3 Acceptance report ............................................................................................................... 44

10.4 Response Form................................................................................................................... 45

10.5 How to create a Service File ...............................................................................................46

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 4 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

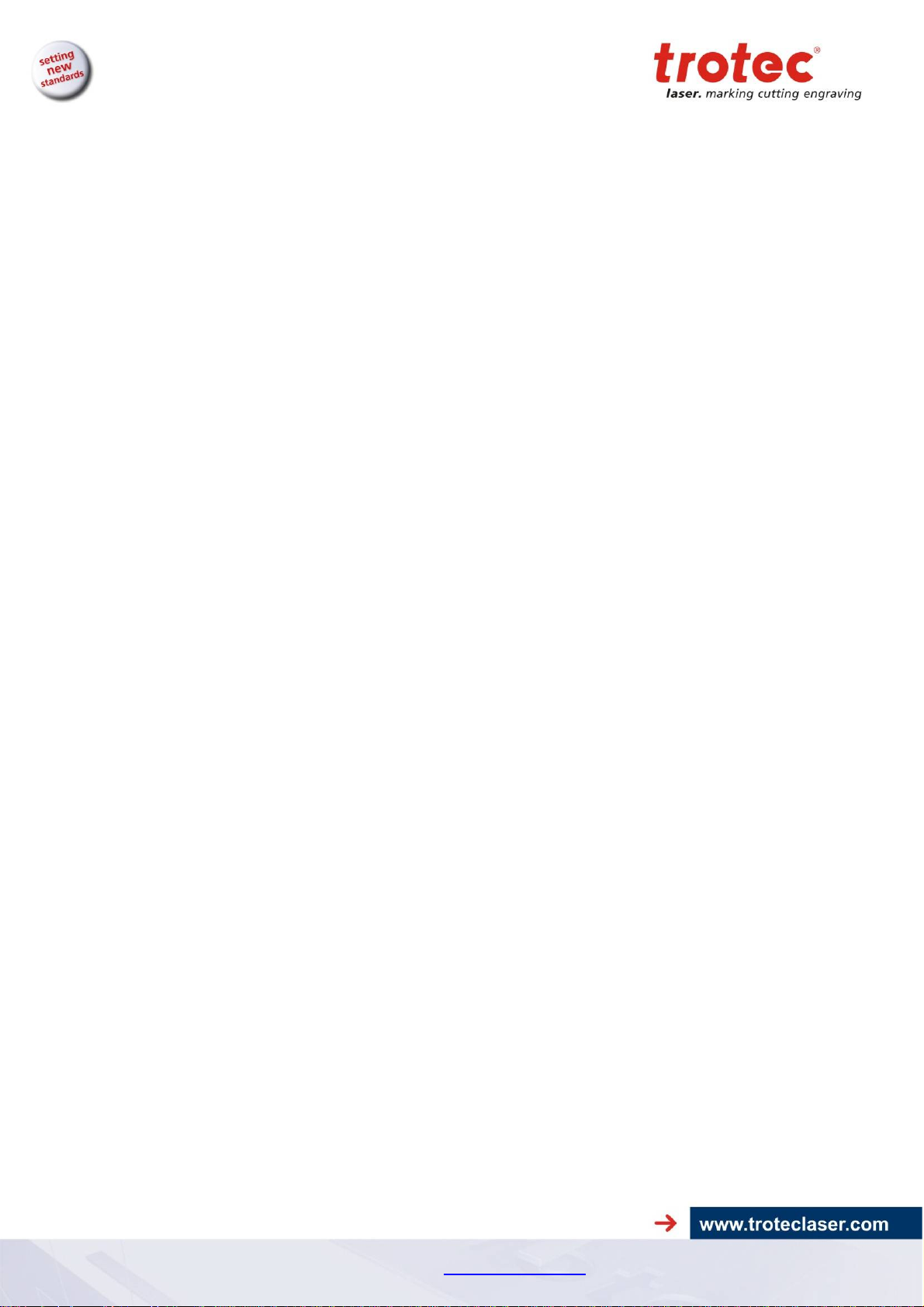

Manufacturing label

1 Manufacturing label

You find the manufacturing label with the CE-sign on the back side of the machine.

Enter the serial number, model and year of manufacture from the manufacturing label here.

This information is important for troubleshooting problems with the product and for ordering

replacement parts.

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 5 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

)

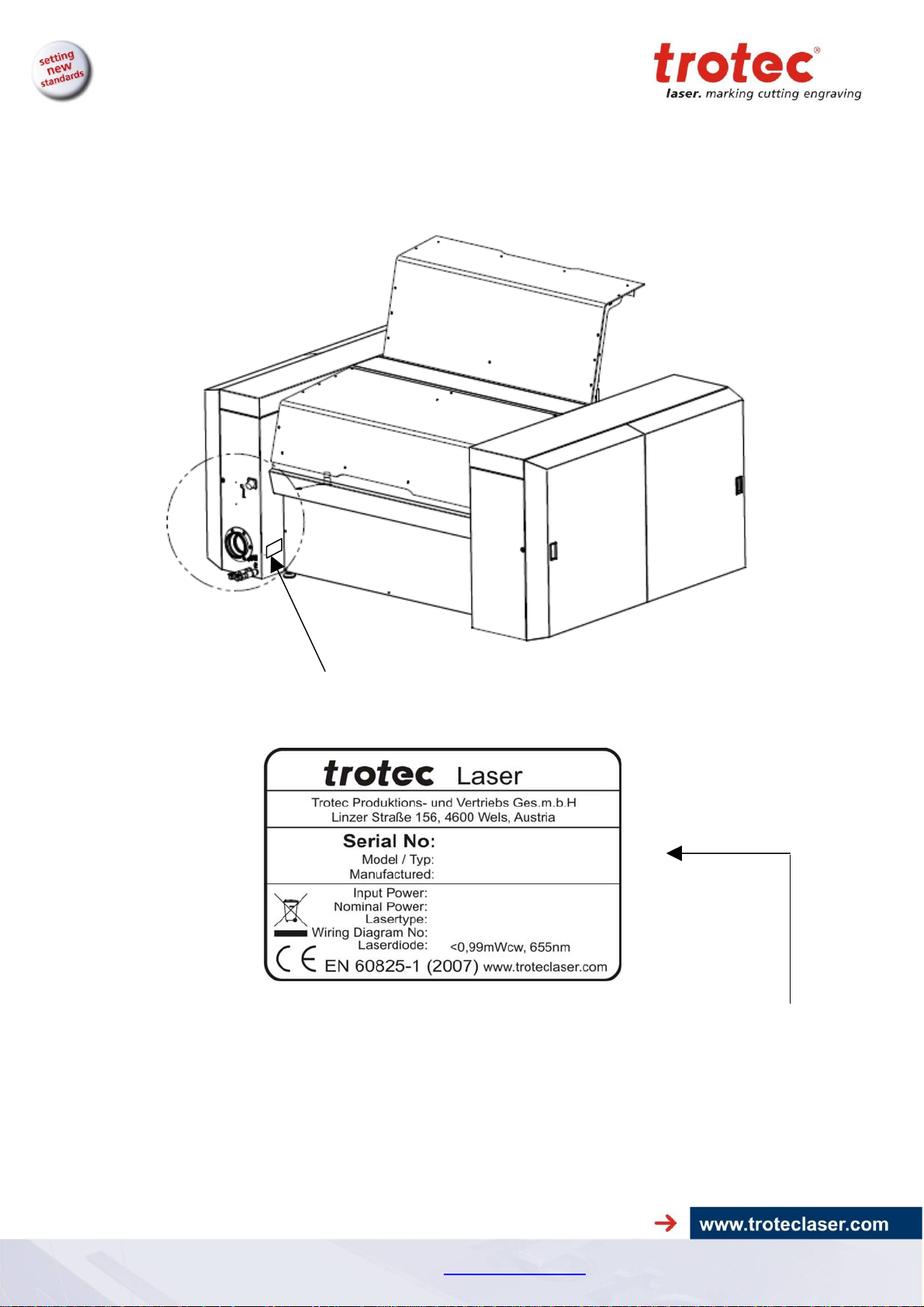

Product Components

2 Product Components

RS232-cable (TroCAM / iCUT

Lenses 2.5“ / 5“

(7.5“ optional)

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 6 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Preface

3 Preface

3.1 General

This operating manual is intended to simplify the following for you:

• Learning about the machine, and

• Utilizing the machine’s capabilities according to its

intended use.

The operating manual contains important notes on how to operate

the machine:

Safely,

•

Properly, and

•

Economically

•

Following the operating instructions helps you to:

Avoid hazards and risks,

•

Minimize repair costs and downtimes, and

•

Increase the reliability and service life of your machine.

•

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 7 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Preface

3.2 Product Tracking

We have a legal duty to track our products after delivery to our

customers.

In particular, this relates to:

This information serves as a basis for potential corrections and/or

changes to the product, and it is therefore of great interest to us.

We request that you inform us of any such events and offer us

your recommendations. This is the only way that we can improve

our products as necessary, and to make them as safe and reliable

as possible.

• Recurring faults in functions

• Anything that is unclear, e.g. in operation, maintenance

or instructions

• Any accidents that occur

• Other unusual observations

• Recommendations for improvement, requests

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 8 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Technical Data

4 Technical Data

4.1 General Description

All electronic components are integrated in the machine.

All necessary connections are made on the back side of the SP1500.

Controls for the SP1500 are located on the keypad.

The SP1500 is equipped with an interlock safety system. When

the interlock is activated, only setup tasks can be performed on the

SP1500.

The machine has a manual table changing system that enables use of the

optimal table for specific jobs.

4.2 Intended Use

The Trotec SP1500 is designed for engraving and cutting of the

materials listed in this document.

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 9 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Technical Data

4.3 Dimensions

D

C

B A

Item Description Dimension Units

A Length 2829 (112)

B Width 2197 (87) mm (inch)

C Height, closed

D Height, open

Weight – depends on product model ............... 1200 - 1300kg

1293 (51) mm (inch)

1950 (77) mm (inch)

(2646 - 2867 lbs)

mm (inch)

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 10 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

µ

Technical Data

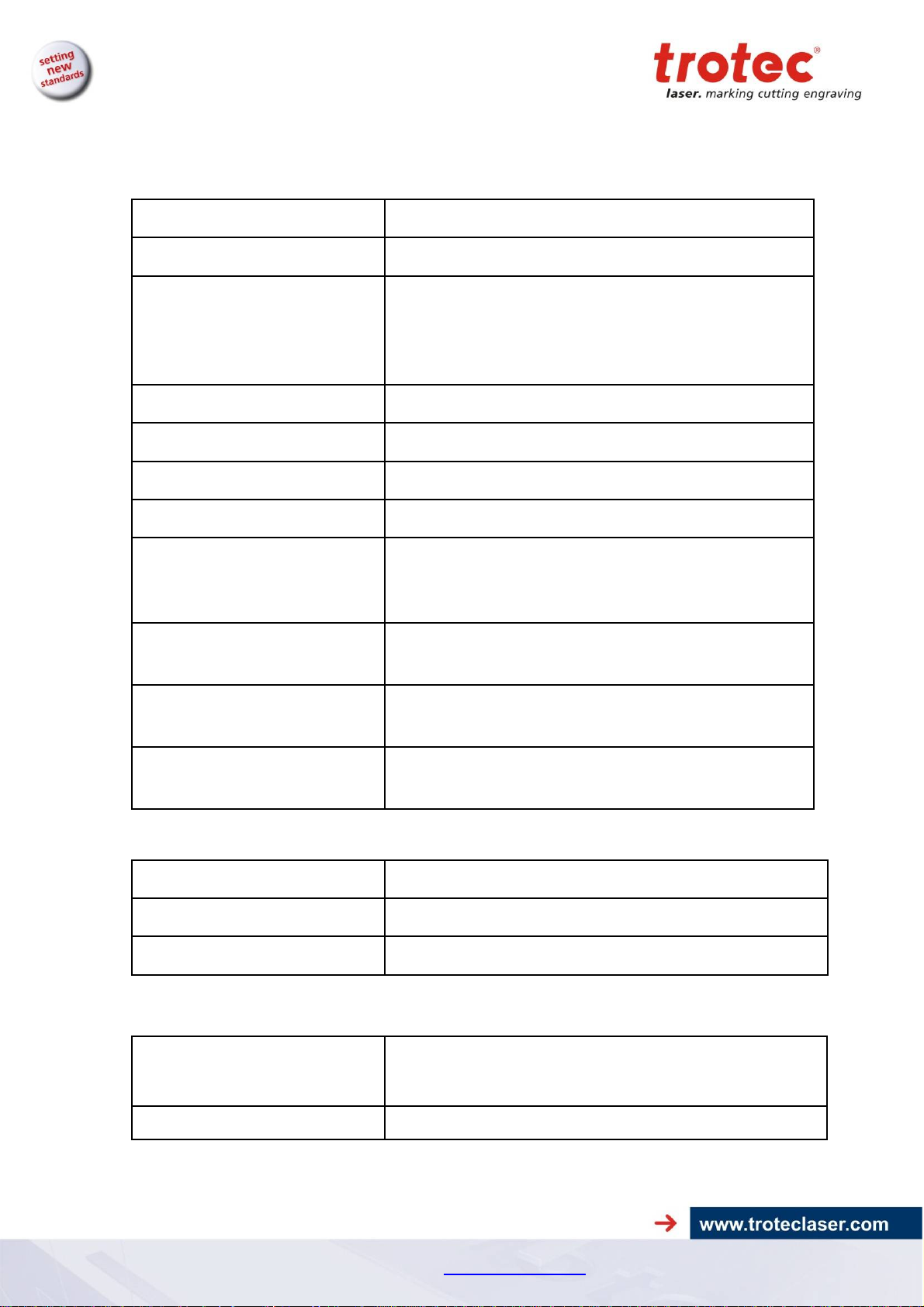

4.4 Mechanical Design

Working area 1500 x 1250 mm (59 x 49 in)

Feed area 1700 x 1600 mm (66 x 62 in)

Max. height of work piece 30 / 53 / 75 mm (1.18 / 2.08 / 2.95 in)

Speed of motion system 165 cm/s (65 in/sec)

Acceleration 9,55 m/s² (375 in/sec²)

Motor Brushless DC servomotor

(3 work table levels)

185 mm (7.28 in) without work table

(flatness cannot be guaranteed without work table)

Encoder Increment measuring system

Lenses

Max. area load of workpiece

table

Precision

Repeatability

4.5 Control System

Laser power Adjustable 0 – 100% (Typically 10-100%)

Hardware Interface USB, RS-232 (RS-232 mandatory for TroCAM and iCut)

Software Interface ASCII, HPGL, Trotec Protocol

2,5“ and 5.0” (Standard), 7.5” (optional)

Lenses and all reflective mirrors are air-flushed and

therefore protected from soiling (preinstalled air pump)

25 kg (55 lbs) over entire working area

±0,1 mm (±0.004 inch) over entire working

(depends on material)

< ±15 µm

(< ±0.00059 inch)

area

4.6 Laser Tubes

Laser tubes

Wavelength 10,6

Sealed off CO2 laser, maintenance free,

Laser power of 60-400W

m

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 11 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Technical Data

4.7 Laser Safety

Laser class

Interlock Dual interlock safety system

4.8 Ambient Conditions

Prescribed ambient temperature of +15° to +25°C (+59° to +77°F)

Humidity of 40% to max. 70%, no condensation,

dust-free environment (2nd degree per IEC60947-1)

4.9 Options

CCD-camera Registration marks and compensation system „i-Cut“;

Gas-Kit (for compressed air

respectively process gas)

CDRH Laser Safety; CE tested

Laser class 2

max. working area: 1100 x 700 mm (43 x 27.5 in)

Considered for control of compressed air and process

gas (free of mechanical dust, water and oil) max. flow

rate 150 l/min (40 gpm) with max. 10 bar (145 psi) max.

limit 4 bar on working head push fitting connection with

out diameter) connection on the machine with hose out

diameter of 6mm (0.23 in) resp. standard fitting for

compressed air.

Vacuum table Strong vacuum effect for thin or corrugated materials

(3500 m³/h at 500 Pa)

TroCAM

(refer to TroCAM brochure)

Extraction System lead /followup time

CAD / CAM software for perfect cutting results;

inclusively nesting-function, lead-in/lead-out, tool paths

Lead- and follow-up time fully adjustable

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 12 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Technical Data

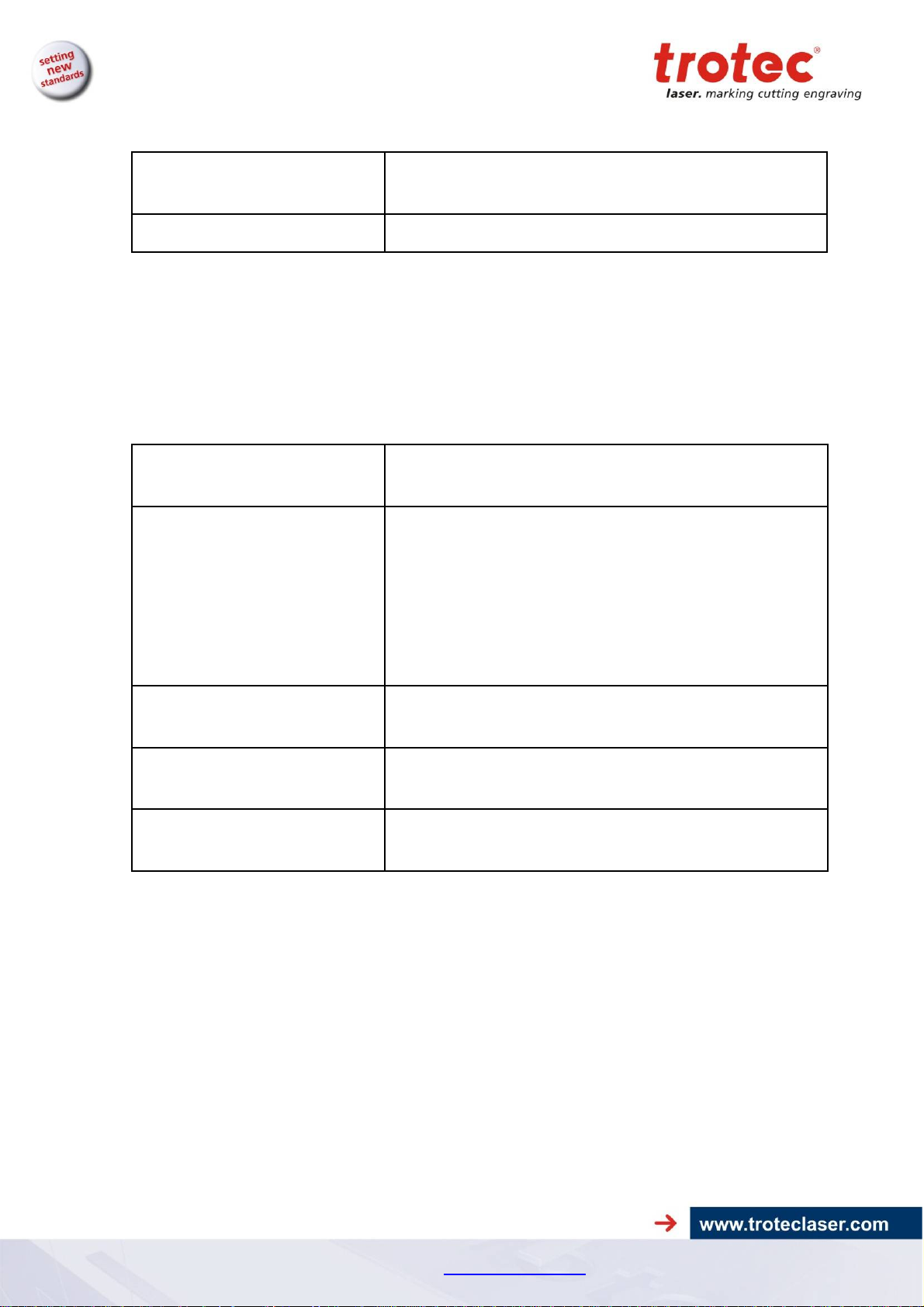

4.10 Electrical Connection

4.10.1 Electrical connection for laser system

Laserpower 60 W 100 W 200 W 400 W

Voltage

Fuse 16 A, slow 20 A, slow 3 x 20 A, slow 3 x 25 A, slow

Frequency 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Phases L, N, PE L , N, PE L1, L2, L3, N, PE L1,L2,L3,N, PE

Power 2,6 kW 3,5 kW 5,5 kW 9,5 kW

4.10.2 Electrical connection for water cooling (option)

EU

Laserpower

Required refrigerating capacity [W]

Chiller type Chilly 08-S Chilly 25-S Chilly 45-S CWK 90-S

Refrigerating capacity [W]

Rate of flow l/min 7,2 10 16 30

Pressure in bar 2,9 2,7 3,5 3,4

208/230 V,

1 phase

208/230 V,

1 phase

380/400 V,

3 phases

380/400 V,

3 phases

60 W 100 W 200 W 400 W

500 2300 4000 8000

890 2400 5300 9500

Supply voltage

1x230V

50/60Hz

1x230V

50/60Hz

1x230V

50Hz

3x400V

50/60Hz

Power Requirement 900 1800 3000 5900

L1, L2, L3,

Supply voltage L, N, PE L, N, PE L, N, PE

N, PE

US

Laserpower

Required refrigerating capacity [W]

60 W 100 W 200 W 400 W

500 2300 4000 8000

Chiller type Chilly 08-S Chilly 25-S Chilly 35-S CWK 90-S

Refrigerating capacity [W]

890 2400 4500 11000

Rate of flow l/min 8 10 15,2 36

Pressure in bar 3,7 3,5 3,7 4,8

Supply voltage

1x115V

60Hz

1x115V

60Hz

1x230V

50/60Hz

3x400V

50/60Hz

Power Requirement 900 1800 3000 5900

L1, L2, L3,N,

Supply voltage L, N, PE L, N, PE L, N, PE

PE

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 13 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Technical Data

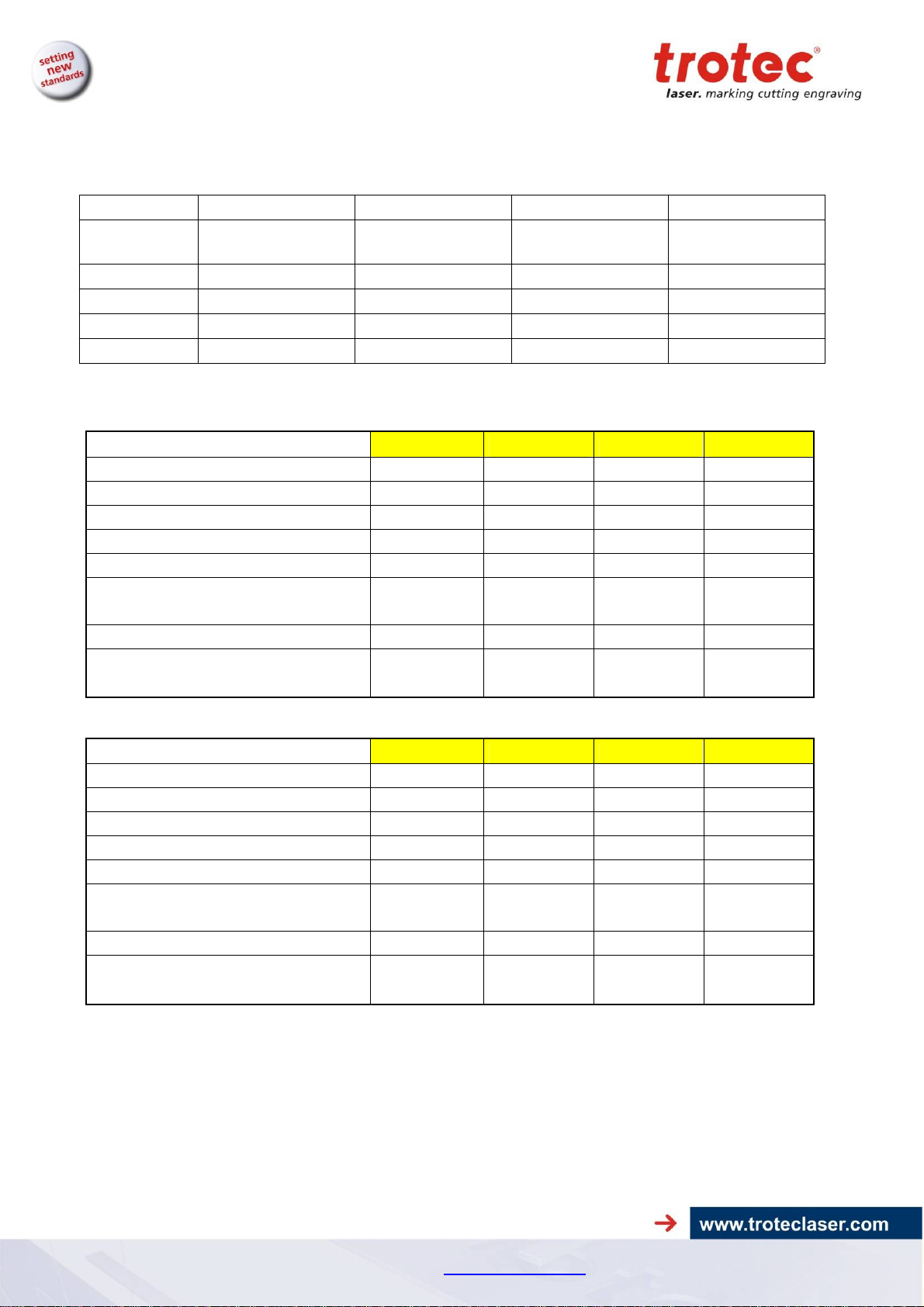

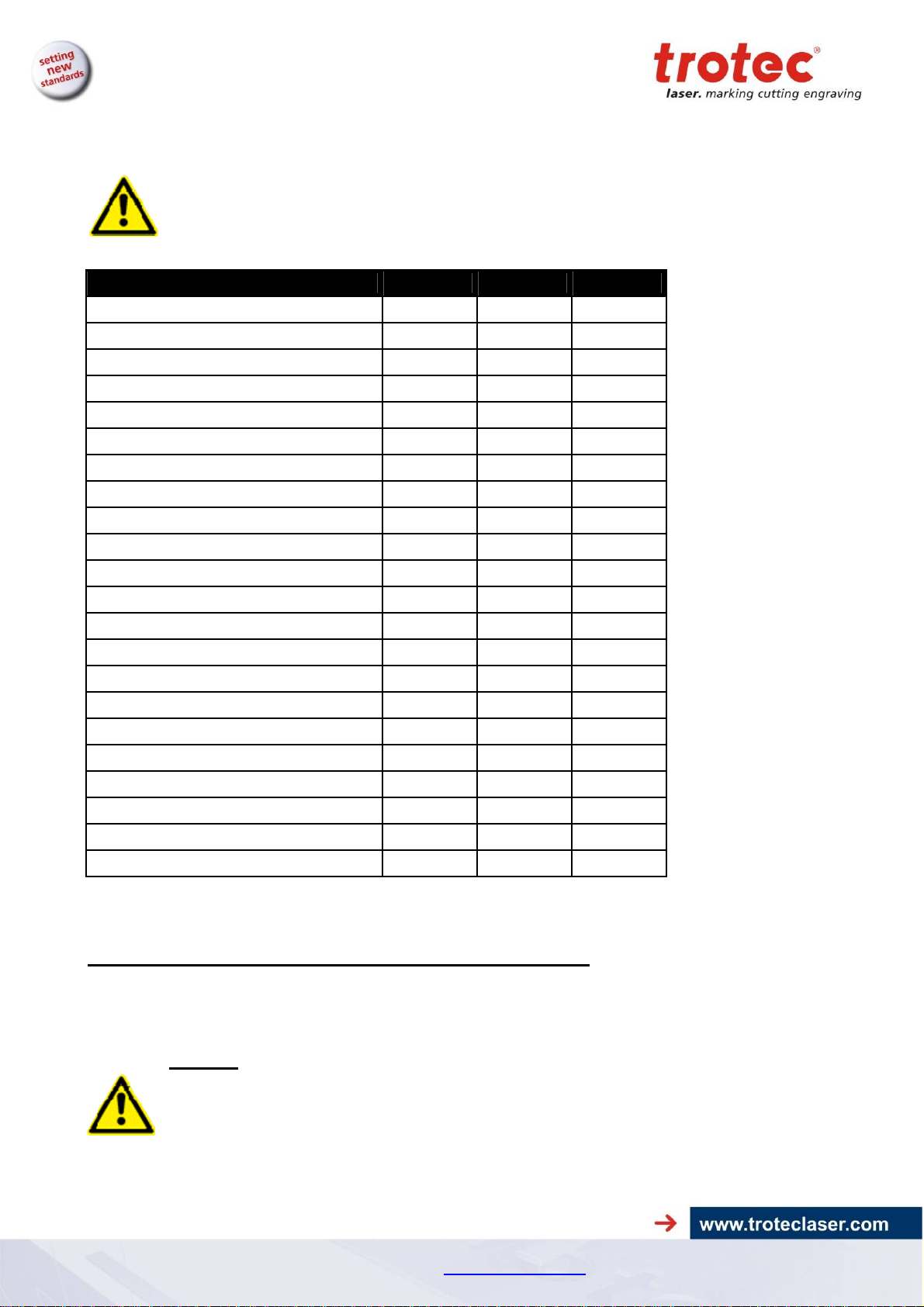

4.11 Materials

Caution when processing conductive materials (carbon fibers,…)! Conductive

dust or particles in the ambient air might damage electrical components and lead

to short circuits.

Bear in mind that those defects are NOT warranted.

Material Engraving Cutting Marking

Acrylic

Painted metal

Delrin

Stainless steel (with Thermark)

Anodized aluminum

Veneer

Handicrafts

Glass

Wood

Gum rubber

Ceramic

Cork

Plastics

Laser rubber

Leather

MDF

Melamine

Micro porous rubber

Paper

Polyester

Stone

PC (Polycarbonate)

Other materials only with written approval by Trotec

The following materials are not recommended for processing:

● ●

● ●

● ●

● ●

●

● ●

● ●

● ●

● ●

● ●

●

● ●

●

● ●

● ●

● ●

● ●

●

● ●

●

●

●

Polyurethane PUR, Polymethylenoxide POM, Polyvinyl chloride PVC, Polyvinyl butyral PVB,

Polytetrafluorethylene PTFE and materials containing epoxy or phenolic resins

Caution:

Trotec assumes no responsibility for any consequences of laser processing in any

application such as medical or pharmaceutical applications.

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 14 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

SP1500 Operation Manual

Safety

5 Safety

5.1 Safety Instructions

Operating personnel must read and understand the operating instructions, and especially the

“Safety” chapter, before operating the equipment. We recommend that the operator create internal

instructional documentation for equipment safety and operation and to acknowledge receipt of

these instructions/operating manual and participation in training/education in writing (see

documents in the Appendices)

1.1 Intended user group

The machine may only be operated by authorized persons.

Authorities must be clearly defined and observed, so that no unclear competencies result under the

aspect of safety. This applies in particular to work performed on the electrical equipment that may

only be performed by specially trained professionals.

Activity

Intended group of users

Control/operation Trained personnel

Other activities

(e.g. error correction, maintenance)

Specially trained personnel or

hired tradesmen

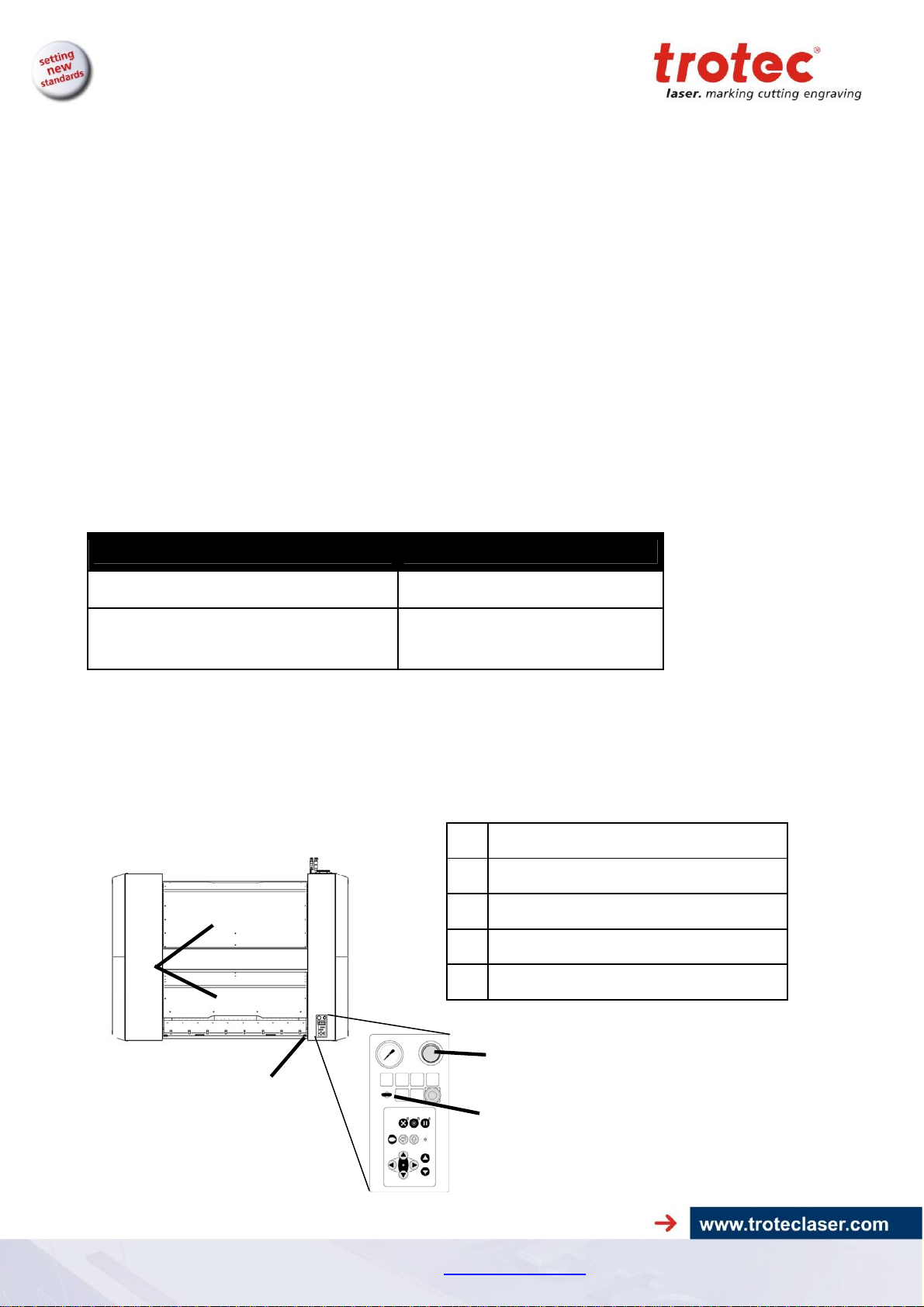

1.2 Operating instructions / Safety equipment

The safety zone is defined by the operator. Instructions and guidelines must be observed and

followed!

Top view

No. Description

EMERGENCY-OFF pushbutton

4

1

Key switch

2

ON-OFF switch

3

Safety covers

4

3

1

2

23/08/2010 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 15 / 47

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

Loading...

Loading...