Page 1

www.troteclaser.com

Operation Manual

SpeedMarker 1300

Page 2

SpeedMarker 1300

www.troteclaser.com

Trotec Produktions- u. Vertriebs GmbH cannot be held responsible for any direct or

indirect damages, which result from using or working with the products electric circuits or software described herein. The apparatus must be used only by trained and

skilled personnel. Before use the manual should be read and followed carefully.

Furthermore Trotec Produktions- u. Vertriebs GmbH reserves the right to change or

alter any product described herein without prior notice.

In case of failure, please check the device first. If unsuccessful, please note all data of

the device (year of manufacture, software version, etc.) and call us from a telephone

next to the switched on device.

For queries or technical problems please contact your dealer or Trotec Produktions- u.

Vertriebs GmbH directly at the above address.

TROTEC PRODUKTIONS UND VERTRIEBS GMBH

Linzer Straße 156

A – 4600 Wels

AUSTRIA

Tel.: ++43/7242/239-7000

Fax: ++43/7242/239-7380

E-Mail: techsupport@troteclaser.com

www.troteclaser.com

Copyright

This documentation with all illustrations is intellectual property of Trotec Produktions- u. Vertriebs GmbH.

The entire documentation is given to the user for personal use only. This documentation must not be reproduced or made available to others without our written permission. Any breach of law will be prosecuted.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 2 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 3

SpeedMarker 1300

www.troteclaser.com

Contents

1 Introduction ....................................................................................................................................... 5

Scope of SpeedMarker 1300 ...................................................................................................... 5

2 General Information ......................................................................................................................... 5

Operation Manual Use ................................................................................................................ 6

Intended Use .............................................................................................................................. 6

Disposal Remarks ....................................................................................................................... 7

3 Technical Data ................................................................................................................................ 16

SpeedMarker 1300 Dimensions ............................................................................................... 16

3.1.1 Interior (Standard version) .............................................................................................. 16

3.1.2 Interior (with software controlled Y-axis) ........................................................................ 17

3.1.3 Exterior dimensions ........................................................................................................ 18

Setup......................................................................................................................................... 19

Datasheet ................................................................................................................................. 20

4 EU – Declaration of Conformity ...................................................................................................... 8

5 Safety ................................................................................................................................................. 9

Laser Classification ..................................................................................................................... 9

Safety regulations ..................................................................................................................... 10

General Safety Information ....................................................................................................... 10

5.3.1 Safety-conscious Working .............................................................................................. 10

5.3.2 Safety Information for the User and/or Operating Personnel ......................................... 11

Laser Safety Information........................................................................................................... 11

Warning and Information Labels ............................................................................................... 12

Risks ......................................................................................................................................... 14

Gases, Fumes and Dust ........................................................................................................... 15

6 Transport and Installation ............................................................................................................. 23

Unoading, Inspection and Reporting Faults ............................................................................. 23

Scope of Supply (Standard Configurations) ............................................................................. 23

Transport in Packaging Case ................................................................................................... 24

Unpack the Machine ................................................................................................................. 24

Storage and Packaging ............................................................................................................ 25

Transport Protection ................................................................................................................. 25

Plant-internal tranport (Repositioning the System) ................................................................... 25

7 System Overview ............................................................................................................................ 26

General System Overview of SpeedMarker 1300 .................................................................... 26

Processing Area Layout............................................................................................................ 29

7.2.1 SpeedMarker 1300 Software controlled Z- and X-axis .................................................. 29

7.2.2 SpeedMarker 1300 Software controlled Z- X- and Y-axis .............................................. 30

7.2.3 General axis design ........................................................................................................ 30

Power Supply Connector .......................................................................................................... 31

Safet Devices ............................................................................................................................ 34

7.4.1 Main Switch .................................................................................................................... 34

7.4.2 Emergency Stop Device ................................................................................................. 35

7.4.3 Safety switches inside the safety door ........................................................................... 36

7.4.4 Laser protection glass .................................................................................................... 36

7.4.5 Laser protection shutter .................................................................................................. 36

7.4.6 Cover plate ..................................................................................................................... 36

8 Operation ......................................................................................................................................... 37

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 3 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 4

SpeedMarker 1300

www.troteclaser.com

Control Elements on the Front of SpeedMarker 1300 .............................................................. 37

8.1.1 LEDs on the Keypad ...................................................................................................... 37

8.1.2 SpeedMarker 1300 Keypad ............................................................................................ 38

8.1.3 Emergency Stop and Automatic Start Button ................................................................. 38

Control Elements ...................................................................................................................... 32

8.2.1 Control Rack ................................................................................................................... 32

8.2.2 Laser Rack ..................................................................................................................... 32

8.2.3 Industrial-PC ................................................................................................................... 33

9 Commissioning............................................................................................................................... 39

General Instructions .................................................................................................................. 39

Installation of SpeedMarker 1300 ............................................................................................. 39

Before Commissioning .............................................................................................................. 39

Power On Procedure ................................................................................................................ 40

Manual Mode ............................................................................................................................ 41

9.5.1 Safety door ..................................................................................................................... 41

9.5.2 Software controlled X and Z-axis (optional: Y-axis) ....................................................... 41

Automatic Mode ........................................................................................................................ 42

9.6.1 Automatic mode sequence ............................................................................................. 42

SpeedMarker 1300 Power Off Procedure ................................................................................ 42

10 Setting up ........................................................................................................................................ 43

Setting up the Focus ................................................................................................................. 43

Positioning the Workpiece ........................................................................................................ 43

11 Troubleshooting ............................................................................................................................. 44

Error Analysis ........................................................................................................................... 44

Common Errors ........................................................................................................................ 44

12 Maintenance .................................................................................................................................... 46

General Maintenance ............................................................................................................... 46

Maintenance schedule .............................................................................................................. 47

Cleaning the Lenses ................................................................................................................. 47

Replacing the Filter Mat ............................................................................................................ 48

Observation window ................................................................................................................. 49

13 Disassembly.................................................................................................................................... 49

Sequence .................................................................................................................................. 49

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 4 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 5

SpeedMarker 1300

www.troteclaser.com

1 Introduction

In choosing the SpeedMarker 1300, you have selected a second generation high-quality galvo laser marking

system. The Yb fiber laser source means the system has an extremely long life-cycle and minimal mainte-

nance costs.

The combination of a high quality galvo scanner and a fiber laser produce highly precise marking results in

short marking times.

This, together with the marking software and the available interfaces, provides a flexible and productive

marking solution of the highest quality standards.

Scope of SpeedMarker 1300

This operational manual is valid for all construction stages and different options of SpeedMarker 1300.

SpeedMarker 1300 with Software controlled Z- and X-Axis

SpeedMarker 1300 with Software controlled Z, X- und Y-Axis

For detailed information see chapter "Technical Data".

2 General Information

Strict compliance with the safety procedures described in this Operationmanual and exercising extreme caution when using the equipment are essential for avoiding and reducing the possibility of personal injury or

damage to the equipment.

All information, illustrations, tables, specifications and diagrams contained in this Operationmanual have been

carefully compiled according to the art current at the time of going to press. No liability is accepted with regard

to errors, missing information and any resulting damage or consequential loss.

Trotec Produktions und Vertriebs Ges.m.b.H. reserves the right to update any of the information, illustrations,

tables, specifications and diagrams contained in this Operationmanual with regard to technical developments

at any time without notice.

Any software incorporated in this equipment should only be used for the purpose for which it was supplied by

Trotec Produktions und Vertriebs Ges.m.b.H. It is strictly prohibited for the user to undertake any alterations,

conversions, translations into another computer language or copies (except for any essential back-up copies).

Trotec Produktions und Vertriebs Ges.m.b.H. is not responsible for any personal injury or material damage, of

either an indirect or specific nature, consequential loss, loss of commercial profits, interruption to business, or

loss of commercial information resulting from the use of the equipment described in this manual.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 5 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 6

SpeedMarker 1300

www.troteclaser.com

Please read and follow this Operation Manual carefully, before installation and oper-

ation.

Ensure the operation manual is accessible at all times.

Damage to persons and/or material can result from not following individual points of

the Operation Manual!!

If the Operation Manual is not observed, this area represents a particular danger for the

operating personnel or the personnel responsible for maintenance.

Caution: This component is under voltage. In these areas strictly observe the safety instructions regarding electricity. Care is to be taken in particular during maintenance and

repair work.

Caution: In this area pay attention to the possible dangers of the laser beam.

Note or information on individual components of the device, that simplify the use or make

it more understandable.

Only mark approved materials using suitable parameters

Non-observance of the instructions for operation, maintenance and repair described

in this Operation Manual excludes any liability of the manufacturer if a defect occurs..

The system must only be operated, maintained and repaired, by personnel that are

familiar with the designated field of use and the dangers of the machine!

Perform maintenance and service according to the specifications in this operation

manual

Use a suitable extraction system to remove fumes, dust or other reaction products

Operation of the system is only permitted with equipment and spare parts supplied or

listed in the spare parts and consumables lists.

Use of the system in other areas is against the designated use. The manufacturer

does not admit liability for damage to personal and/or equipment resulting from such

use.

Operation Manual Use

Operation of the system is only permitted with equipment and spare parts supplied or listed in the spare parts

and consumables lists.

The following symbols are used for easier understanding of the Operation Manual:

Intended Use

The SpeedMarker 1300 is intended exclusively for laser marking using the supplied marking software.

The following points should also be observed as part of the intended use:

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 6 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 7

SpeedMarker 1300

www.troteclaser.com

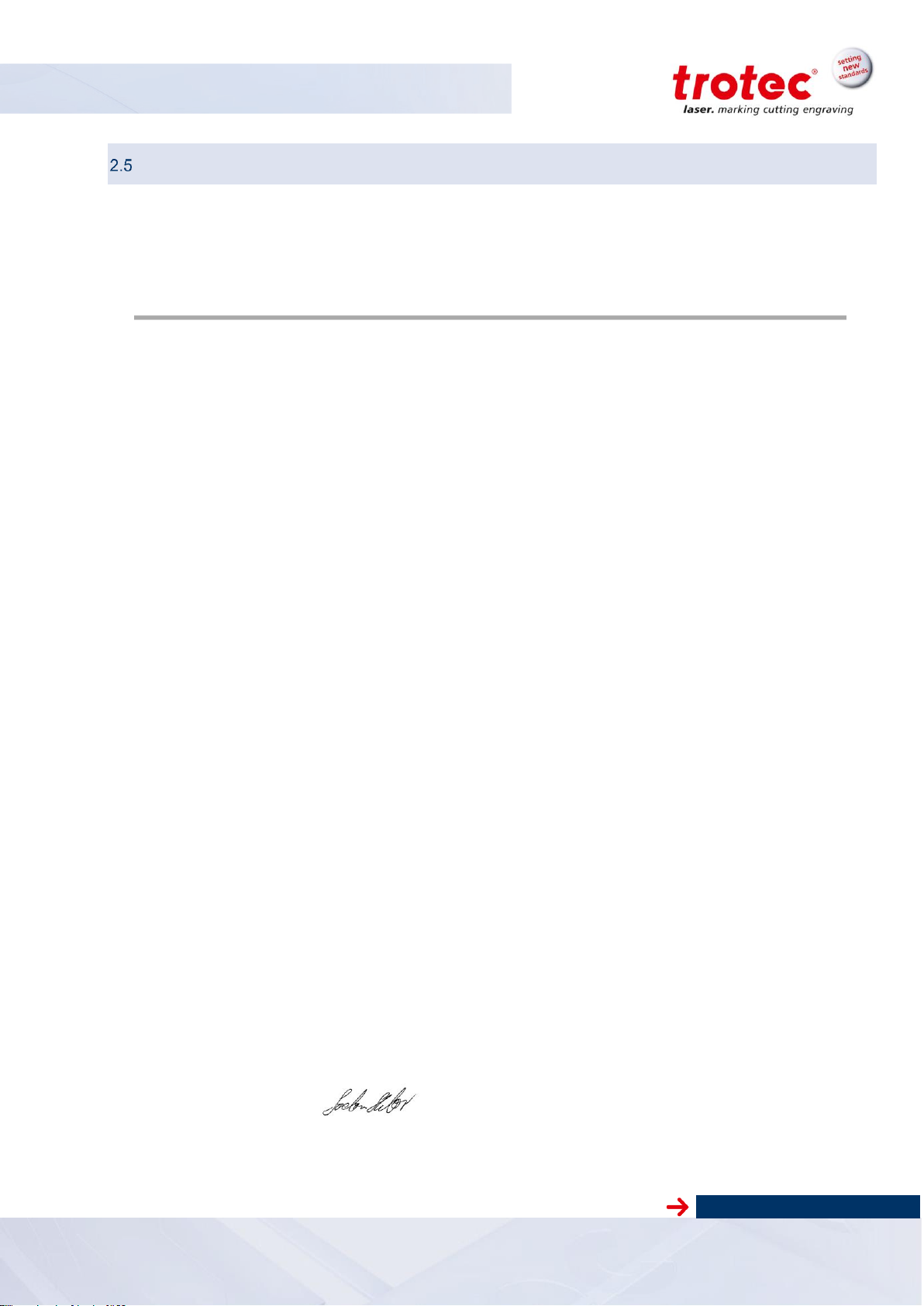

Enter the serial number, model and year of manufacture from the manufacturing label

here.This information is important for troubleshooting problems and ordering replacement

parts.

Disposal Remarks

Do not dispose the machine with domestic waste!

Electronic devices have to be disposed according to the regional directives on electronic

and electric waste disposal.In case of further questions, please ask your supplier.

Use suitable tools if you have to disassembly the machine. All separate parts need to be

sorted into the different material types and also be disposed according to the regional directives on electronic and electric waste disposal.

Manufacturer's Label

The Manufacturer's Label is located on the backside of the machine.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 7 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 8

SpeedMarker 1300

www.troteclaser.com

EU – Declaration of conformity

for the purposes of EC machinery directive 2006/42/EC, appendix II 1. A

Maker

Community resident authorised to assemble technical documents

Trotec Laser Automation GmbH

Jochen Huber

Planckstr. 12

Trotec Laser Automation GmbH

88677 Markdorf

Planckstr. 12

88677 Markdorf

Description and identification of the machinery

Product/commodity

LWS1300-xx

Model

LWS1300

Standard number

0202

Project numberr

0202_SpeedMarker 1300

Commercial nameg

SpeedMarker 1300

ORder

0202

Function

Laser Workstation

It is expressly declared that the machinery fulfils all the relevant provisions, where appropriate, of the

following EC directives.

2006/42/EG

Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery,

and amending Directive 95/16/EC (recast) (1)

2004/108/EG

Directive 2004/108/EC of the European Parliament and of the Council of 15 December 2004 on the

approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC

2006/95/EG

Directive 2006/95/EC of the European Parliament and of the Council of 12 December 2006 on the

harmonisation of the laws of Member States relating to electrical equipment designed for use within

certain voltage limits (codified version) (1)

References of the harmonised standards applied in compliance with article 7 paragraph 2

EN 60825-1:2007

Safety of laser products - Part 1: Equipment classification and requirements (IEC 60825-1:2007)

EN ISO 13849-1:2008

Safety of machinery - Safety-related parts of control systems - Part 1: General principles for design

(ISO 13849-1:2006)

EN ISO 12100:2010-11

Safety of machinery - General principles for design - Risk assessment and risk reduction. (ISO

12100:2010)

EN 61000-6-4:2007/A1:2011

Electromagnetic compatibility (EMC). Generic standards. Emission standard for industrial environments

Markdorf, 27.11.2014

Place,date

Signature

i.A. Jochen Huber, Electric construction

EU – Declaration of Conformity

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 8 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 9

SpeedMarker 1300

www.troteclaser.com

Class 2 (US: class II)

The accessible laser radiation of Class 2 (US: calss II) laser systems does not pose any

hazard for the skin. Any short-term radiation of the eyes also poses no risk due to the low

level output. In the event of longer, more intensive radiation, the eye is protected by the

natural lid reflex.

The SpeedMarker 1300 uses a Class 2 (US: calss II) pilot laser. In order to prevent irrita-

tion of the eyes during operation, the operator should not look directly at the laser source.

Diffuse reflections of the pilot laser are entirely harmless.

Class 4 (US: class IV)

High powered lasers (visible or invisible) considered to present potential acute hazard to

the eye and skin for both direct (intrabeam) and scatter (diffused) conditions. Also have

potential hazard considerations for fire (ignition) and byproduct emissions from target or

process materials.

It is the responsibility of the operator of the machine to take take appropriate messurements to eliminate any dangers such as fire or explosions through the laser beam.

When dealing with class 4 (US: class IV) laser follow the following precautions:

According to BGV B 2 „Laser Emission“ a trained laser safety officer hast o

be appointed to evaluate potentiial hazards and to ensure that appropriate

control measurers are implemented.

The laser controlled area shall be posted with appropriate warning signs or warning

lamps.

The laser controlled area shall be defined to contain the laser radiation.

Also it must be protected agains unauthorized acess.

The operator of class 4 laser systems always has to wear appropriate safety

glasses.

An indicator (typically a light) to provide a warning of laser emission in advance of

and during the emission time;

3 Safety Information

Laser Classification

The laser safety class indicates the risk potential based on the level of accessible laser radiation.

The SpeedMarker 1300 is a Class 2 laser marking system as per DIN EN 60825-1 “Safety of laser products”.

Integrated laser source of the SpeedMarker 1300 is a

Speedmarker FL , Class 4 (US: class IV) laser marking system identified according to DIN EN 60825-1.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 9 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 10

SpeedMarker 1300

www.troteclaser.com

The general ordinances and directives listed above may differ according to locality, region or

country. Therefore, always observe the directives applicable to you.

The customer is always responsible for carrying out all safety requirements as TROTEC Produktions und Vertriebs Ges.m.b.H. has no influence over the proper use of the machine.

The system integrator is responsible for observing the directives listed above when integrating our

laser systems

All personnel involved in installation, set-up, operation maintenance and repair of the machine, must have read and understood the Operation Manual and in particular the "Safety"

section. The user is recommended to generate company-internal instructions considering

the professional qualifications of the personnel employed in each case, and the receipt of

the instruction/Operation Manual or the participation at introduction/training should be

acknowledged in writing in each case.

The machine must only be operated by trained and authorized personnel.

The scopes of competence for the different activities in the scope of operating the

machine must be clearly defined and observed, so that under the aspect of safety

no unclear questions of competence occur. This applies in particular to activities

on the electric equipment, which must only be performed by special experts.

For all activities concerning installation, set-up, start-up, operation, modifications

of conditions and methods of operation, maintenance, inspection and repair, the

switch-off procedures that may be provided in the Operation Manual must be observed.

Safety regulations

The following directives and ordinances must be observed to avoid hazards when operating TROTEC laser

systems.

EN 60825-1 Safety of Laser Products - Part 1: Equipment Classification, Requirements and

User´s Guide

EN 60950 Safety of Information Technology Equipment

EN 61010-1 Safety Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use; General Requirements

BGV B2 (VBG93) Laser beam

UL 60950 Standard for Safety for Information Technology Equipment

UL 31011-1 Electrical Equipment for Laboratory Use - Part 1: General

21 CFR 1040.10 Performance Standard for Light Emitting Products - Specific Laser Products

21 CFR 1040.11 Performance Standard for Light Emitting Products - Specific Purpose Laser

Products

General Safety Information

3.3.1 Safety-Conscious Working

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 10 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 11

SpeedMarker 1300

www.troteclaser.com

No working methods are permitted that affect the safety of the machine.

The operator must also ensure that no unauthorized persons work with the machine

(e.g. by activating equipment without authorization).

It is the duty of the operator, to check the machine before start of work for externally

visible damage and defects, and to immediately report changes that appear (includ-

ing behavior during operation) that affect the safety.

The user must provide that the machine is only operated in perfect condition.

The user must guarantee the cleanness and accessibility at and around the machine

by corresponding instructions and controls.

Principally, no safety components may be removed or disabled (already here we em-

phasize the imminent dangers, for example severe burns, loss of eye-sight). If the re-

moval of safety components is required during repair and service, the replacement of

the safety components must be performed immediately after completion of the ser-

vice and repair activities.

Preparation, retooling, change of work piece, maintenance and repair activities must

only performed with equipment switched off, by trained personnel.

It is forbidden to perform unauthorized modifications and changes to the machine. It

is emphasized, that any unauthorized modifications to the machine are not permitted

for safety reasons.

Without safety precautions, the following risks exist with exposure to laser radiation:

Eyes: Burns to the retina for NIR (Near Infra Red) LASER

Skin: Burns

Clothing: Danger of fire

The laser beam must never be directed onto persons or animal!

Never try to modify or remove the safety devices or cover of the laser head!

Never try to modify or disassemble the laser and do not try to start up a system that

had been modified or disassembled

Dangerous radiation exposure can result from the use of operation or

adjustment equipment other than that described here, and if different

operational methods are performed.

3.3.2 Safety Information for the User and/or Operating Personnel

Laser Safety Information

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 11 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 12

SpeedMarker 1300

www.troteclaser.com

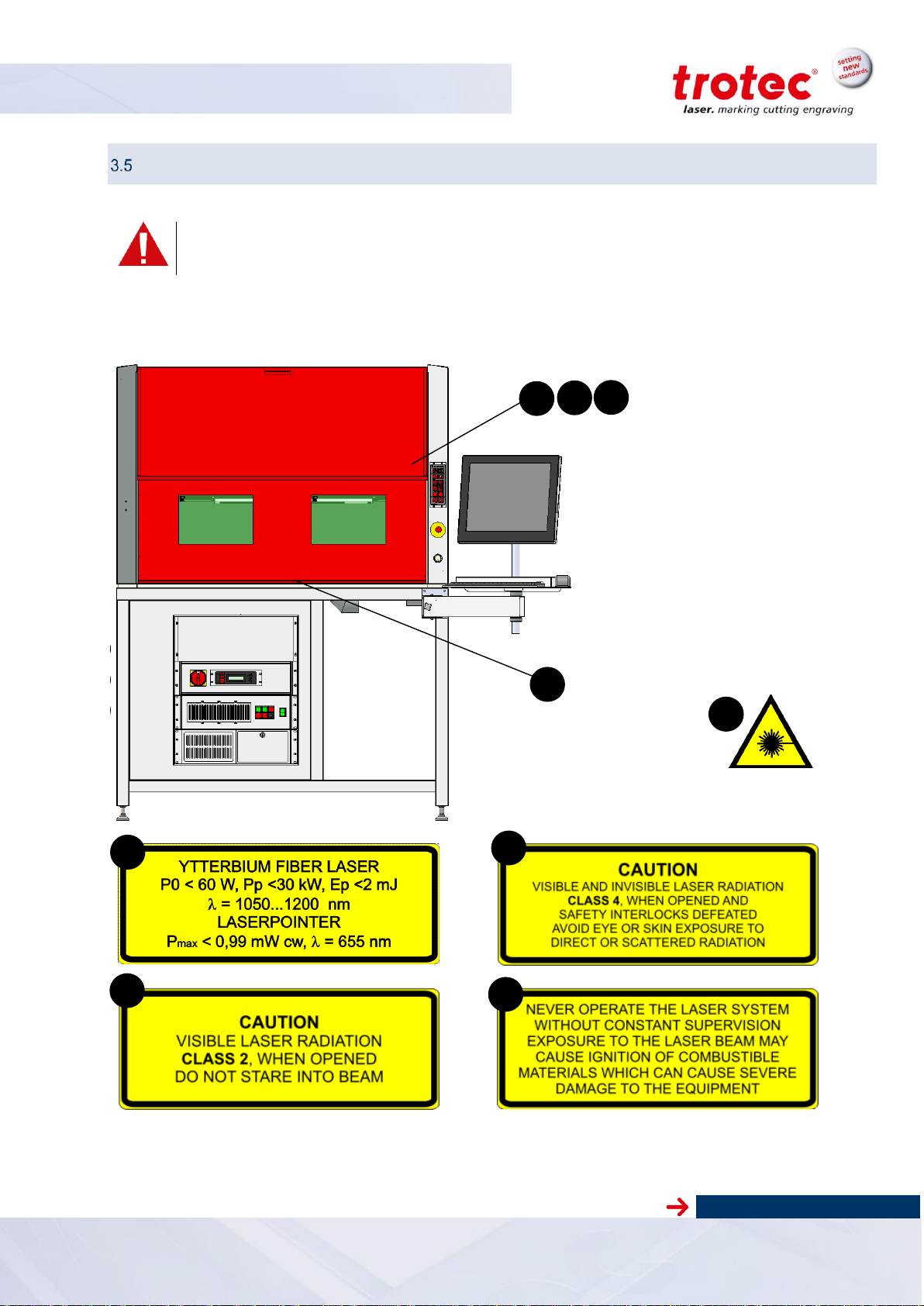

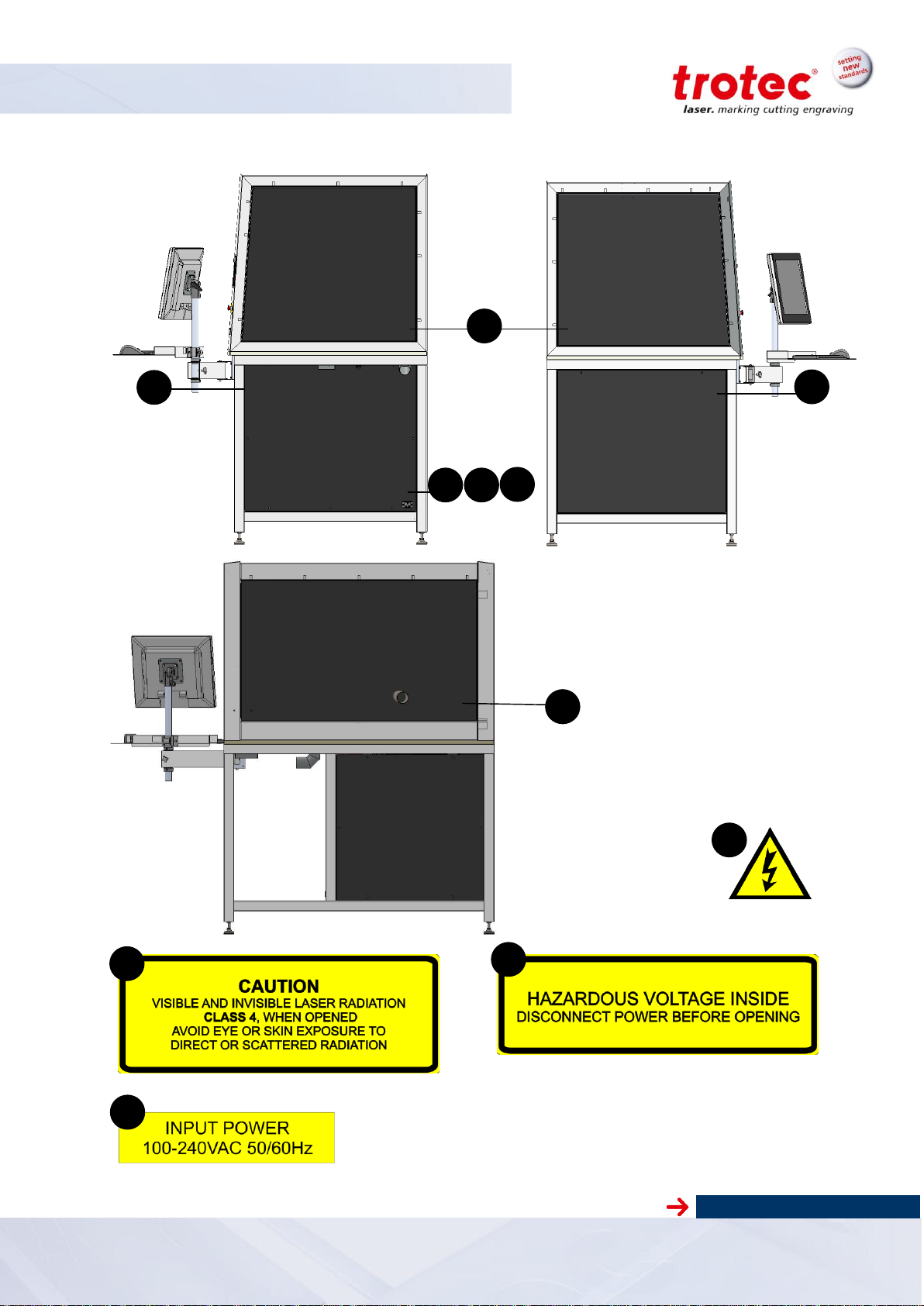

The warning and information labels are attached in such positions of the machine that

could represent a source of danger during set-up and operation. Therefore, follow the information on the labels. If labels are lost or damaged, they must be replaced immediately

13

6

4 3

7

6

3 8

8

10

1 1 2

3

2

3

4

5

3

Warning and Information Labels

Front View

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 12 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 13

SpeedMarker 1300

www.troteclaser.com

1 2

3

4

1

2

22334

4 1 3

3

Right Side View Left Side View

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 13 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 14

SpeedMarker 1300

www.troteclaser.com

Risk posed by the incorrect actions of untrained individuals!

The improper use of the machine can lead to injury and/or damage to the machine.

Inform personnel about the machine’s function and any other risks and record this in

the training records.

Observe official regulations regarding the operation of machines and accident prevention

regulations

Risk posed by missing, faulty or bridged safety installations and machine components!

Faulty or missing safety installations and machine components can lead to death, injury

and/or damage to the machine.

Check carefully that safety installations and machine components are functioning

properly and are fault free.

The specified actions should be undertaken immediately if parts are faulty or defec-

tive.

Risk posed by incorrect operation (in particular in setup-mode)!

Setting and operating the machine with limited knowledge of its function can lead to injury

and/or damage to the machine.

Read and observe the operating and safety instructions before commissioning the

machine!

Risk posed by incorrect operation by unauthorised individuals!

Setting and operating the machine with limited knowledge of its function can lead to injury

and/or damage to the machine.

Never leave the machine unattended while in operation.

Turn off the machine at the main switch when not in use.

Risk posed by missing machine signage!

Making the wrong assumptions can lead to the risk that the machine is operated incor-

rectly.

Replace missing machine signage.

Risk posed by non-repairable faults!

Any non-repairable fault may damage the machine.

Turn off the machine and call customer service!

Risks

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 14 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 15

SpeedMarker 1300

www.troteclaser.com

Risk posed by using inferior spare parts or parts of other manufacturers!

The use of inferior spare parts or parts produced by other manufacturers impairs the

safety of the machine and invalidates the Declaration of Conformity (CE) supplied with it.

Wear parts or damaged mechanical, safety or electrical components should be re-

placed by original spare parts.

Risk posed by missing protective equipment!

Wear the appropriate workwear.

Wear safety glasses (class 4/USA: Class IV)

Use a suitable extraction system.

Risk posed by laser marking reaction products!

A suitable extraction system must be used when laser marking due to the possible gener-

ation of gases, fumes and any other partially toxic by-product.

In individual cases, the reaction products may consist of static dust. If this enters any

electrical systems it can cause short circuits leading to personal injury and material damage.

Risk posed by flammable or explosive materials!

Class 4 laser radiation such as that emitted by the SpeedMarker 1300 may ignite materi-

als or cause explosions. Among others it should be ensured that:

Parameters are selected so that the material does not overheat

The system is monitored if necessary

Dust is extracted safely

There is no accumulation of any flammable residues or remnants in the workspace.

Gases, Fumes and Dust

Depending on the materials being marked and the parameters selected, laser marking may generate gases,

fumes, aerosols or dust.

The toxicity of such by-products depends on the material.

The operator is responsible for ensuring a suitable extraction system is in place and for compliance with the

relevant guidelines in order to protect individuals and the environment.

The guideline VDI 2262 1…3 "Workplace air " provides, among other things, additional remarks.

The operator must also ensure that gases, fumes or dust do not settle on the processing lens. Any dirt accu-

mulating on the processing lens can lead to a loss of performance, poor marking results and damage to the

device.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 15 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 16

SpeedMarker 1300

www.troteclaser.com

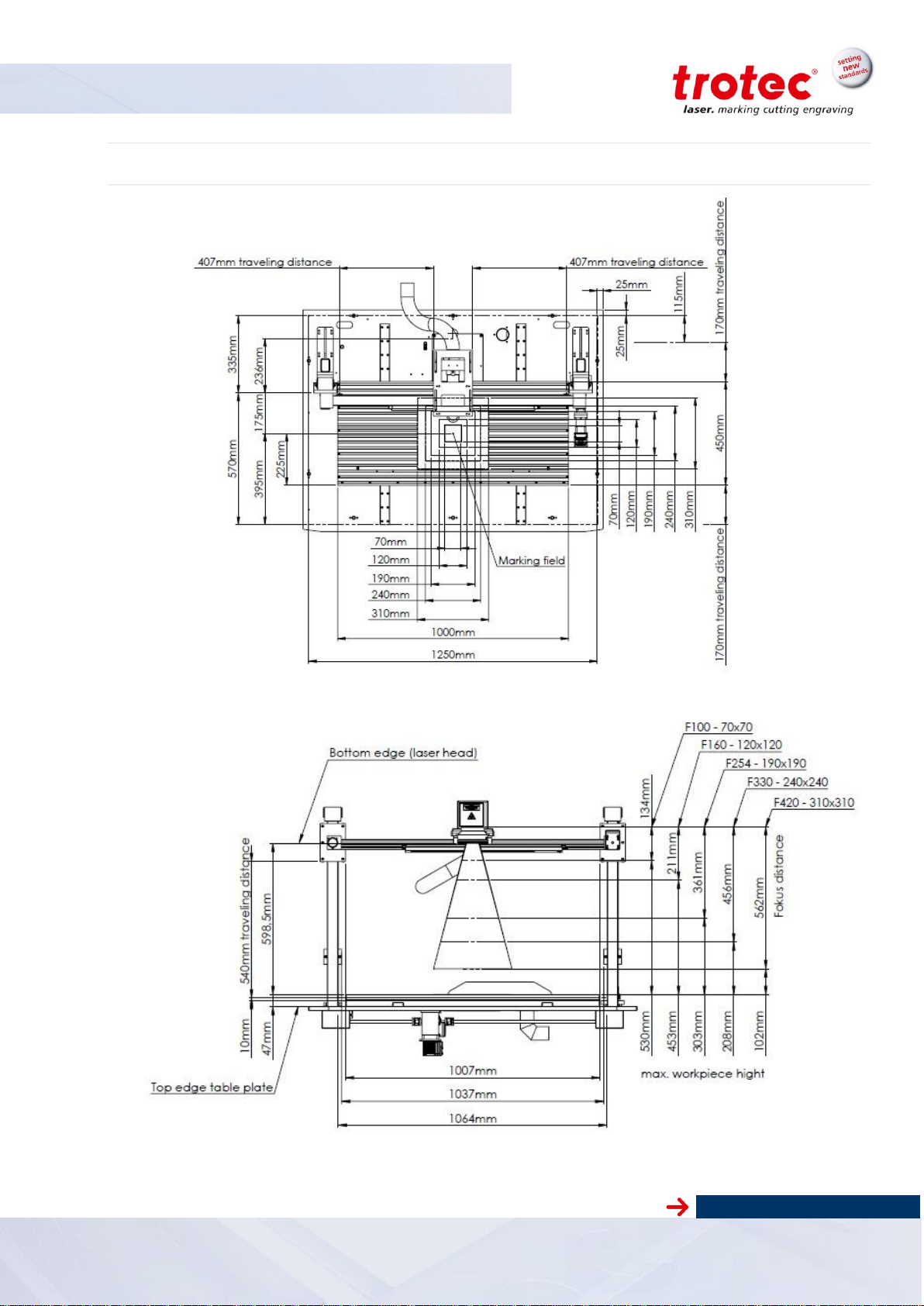

4 Technical Data

SpeedMarker 1300 Dimensions

4.1.1 Interior (Standard version)

Figure 1: Top view

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 16 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Figure2: Front view

Page 17

SpeedMarker 1300

www.troteclaser.com

4.1.2 Interior (with software controlled Y-axis)

Figure 3. Top view with Y-axis

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 17 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Figure 4: Front view with Y-axis

Page 18

SpeedMarker 1300

www.troteclaser.com

4.1.3 Exterior dimensions

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 18 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Figure 5: Front and side view

Page 19

SpeedMarker 1300

www.troteclaser.com

Setup

Figure 6: Setup

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 19 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 20

SpeedMarker 1300

www.troteclaser.com

Laser (Fiber Laser)

Laser

Q-Switched Yb-Fiber Laser, maintenance free

Wavelength

1064 nm ± 8

Pulse Duration

110 ns ± 20

Beam Quality

M² < 1,5

Power stability

better ± 5%

Cooling

Air cooled

Laser type

FL 10

FL 20

FL 30

FL 50

Max. average output power

10 W

20 W

30 W

50 W

Max. Pulse Energy

0,5 mJ

1 mJ

1 mJ

1 mJ

Pulse Repetition Rate

20-80 kHz

20-80 kHz

30-80 kHz

50-80 kHz

Integrated Pilot Laser

Galvo System

Standard:

F-160

Lens / Focal length

F-100

F-254

F-330

F-420

Marking area [mm x mm]

70 x 70

120 x 120

190 x 190

240 x 240

310 x 310

Focus Diameter

~ 27 µm

~ 45 µm

~ 68 µm

~ 88 µm

~ 112 µm

Writing Speed

(Option high speed scan head)

640 cps – 1 mm single line with F = 160 mm

(900 cps – 1 mm single line with F = 160 mm)

Positioning Speed

(Option high speed scan head)

10.000 mm/s with F = 160 mm

(15.000 mm/s with F = 160 mm)

Datasheet

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 20 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 21

SpeedMarker 1300

www.troteclaser.com

Workstation

Interior dimensions (W x D)

1250 x 898 mm²

Door opening (W x H)

1100 x 377 mm²

Door

Manual and/or automatic

Maximum part size (W x D)

S. drawings – depends on shape

Maximum part height*

Depends on lens

*27 mm less with optional Yaxis

557 mm

F-100

480 mm

F-160

330 mm

F-254

235 mm

F-330

129 mm

F-420

Maximum load

200 kg (50kg with y-axis)

Working table

Aluminum T-slot plate (Isel PT 25): 1100 x 375 mm²

1000 x 450 mm² with software controlled Y-axis

Axis

Software controlled Z- and X-axis: standard

Y-axis: optional

Traveling distance Z-axis

530 mm

Traveling distance X-axis

810 mm

Traveling distance Y-axis

325 mm

Maximum marking field with

X-axis [W x D in mm]

880 x 70

930 x 120

1010 x 190

1050 x 240

1120 x 310

Maximum marking field with

X- and Y-axis* [W x D in mm]

*Option

880 x 395

930 x 445

1010 x 515

1050 x 565

1120 x 635

Color

RAL 3002, RAL 7016, RAL 7035

Control

Computer

Industrial PC as 19" Rack Unit, 3RU high, 4 GB RAM, HDD 250 GB,

DVD ROM, Windows® 7

Interfaces

USB, Ethernet, RS232,

Interfaces Laser

Laser-Interlock, Marking-Start (24 VDC), Marking-Stop (24 VDC),

E-Stop, Error-Reset, Laser-Busy, optional digital I/O’s (24 VDC),

Software

SpeedMark

Tolerance on dimension: 1%

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 21 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 22

SpeedMarker 1300

www.troteclaser.com

Options / Accessories

Optional lenses and galvo scanners

F-100, F-160, F-254, F-330, F-420

High speed scan heads with lenses

(no F-420 lens in combination with high speed scanner)

Axis system

Software controlled Y-axis

Focus Finder

Second pilot laser for precise and user friendly adjustment of working distance

Software

DirectMark printer driver: Laser marking as easy as printing. Independent from software

Extended I/O interface

Additional in- and outputs, 24 VDC

Additional optional accessories

Rotary unit with different chucks

Counter bearing for rotary unit

Base plate for rotary unit

Foot switch for efficient and user friendly control of the system

Exhaust systems

Transport reels

Dimensions / Installation / Laser Safety

Dimensions (W x H x D)

1300 x 1790 x 960 mm³

Weight (with Laser)

380 kg (400 kg with Y-axis)

Ambient conditions

Operating temperature range +5 to +35° C.

Relative humidity max. 90 %; Non-Condensing

Electrical Requirements

115 - 230 VAC, 16 A, 50/60 Hz, 1/N/PE

Power Consumption

< 1100 W

System Protection

Marking Head: sealed against spray water (IP 54)

Laser Rack Unit: dust protected (IP20)

Laser class

CDRH Laser Safety

Laser Class 2

CE tested

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 22 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 23

SpeedMarker 1300

www.troteclaser.com

CAUTION

The lens unit should only be uncovered following installation. The lenses are high quality

optical components which must be kept clean in order to ensure optimum marking results.

Never touch the lenses with bare fingers!

5 Transport and Installation

Unoading, Inspection and Reporting Faults

After unloading:

Inspect the machine and machine components for transportation damage.

Check screws and screw joints

Check the delivery for completeness.

Remove all transport packaging.

In the event of transportation damage or incomplete delivery:

Record all details in writing immediately.

Note all claims on the transportation documents.

Photograph any damage.

Send report to TROTEC.

Scope of Supply (Standard Configurations)

1x SpeedMarker 1300

2x key for SpeedMarker 1300

2x key for Industrial PC

2x key for laser rack

1x CD with marking software

1x CD with Windows Backup

1x lens cleaning kits

1x Allen key set

1x IEC connector

1x extraction system connection cable (optional)

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 23 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 24

SpeedMarker 1300

www.troteclaser.com

CAUTION

During transport the transport case can slip, tip or fall over.

Alsways secure the transport case and take into account the center of gravity of the

box.

Center of gravity

Tilt

Shockwatch

crossbar

(in front)

Top

Vertical

tightening straps

Transport in Packaging Case

The System may only be transported in the original packaging and must be secured against slippage and tipping. The packaging case . Unload the transport case with a suitable forklift.

Unpack the Machine

Only trained and authorised personned are permitted to tranport and unpack the machine.

To avoid that any wooden parts are falling off or the machine is tipping, be very careful when opening the

transport case. Two persons are needed to unpack the machine.

Position the transport case on level ground.

Remove the vertical tightening straps.

Remove the top of the transport case.

Screws for

Side panel

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 24 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 25

SpeedMarker 1300

www.troteclaser.com

CAUTION

When transporting the System over great distances the orignial tranport box including interior protection needs to be used.

Storage and Packaging

The storage location must be free of caustic materials, vapors and combustible materials. In storage room or

packaged with adequate weather protection.

Storage conditions:

Storage temperature: +0 bis +40°C (+0 to104°F)

Relative humidity: max. 85%

Transport Protection

Once the SpeedMarker 1300 has been unpacked from the wooden packaging, remove the plastic foam from

the front of the machine and at the door mechanism. Foam might be placed above and below the door

weight.

Interior protection on the door mechanism

Plant-internal tranport (Repositioning the System)

The LWS needs to be transported in an upright position; avoid any strong vibrations.

1. Shut off the machine using the main switch.

2. Unplug the electrical supply.

3. Remove the exhaust system.

4. Use an appropriate fork lift to slightly lift the System,

5. Reposition and

6. Park the System on clean, solid level ground again.

7. Adjust the machine, setup the electrics and carry out a performance test.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 25 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 26

SpeedMarker 1300

www.troteclaser.com

1

Safety glass

6

Feet

2

Safety door

7

Keypad

3

Control Rack

8

Monitor, keyboard and mouse

4

Laser Rack

9

Emergency Stop button

5

Industrial-PC

10

Start button

1

2

3

4

5

6

1098

7

6 System Overview

General System Overview of SpeedMarker 1300

It consists of the the following components and functional units.

Front view:

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 26 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 27

SpeedMarker 1300

www.troteclaser.com

1

Swivel arm

2

Power supply connector

1

Protection cover

2

Cover

1

2

1

2

Right hand side:

Left hand side:

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 27 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 28

SpeedMarker 1300

www.troteclaser.com

1

Extraction system connector

1

Rear view:

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 28 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 29

SpeedMarker 1300

www.troteclaser.com

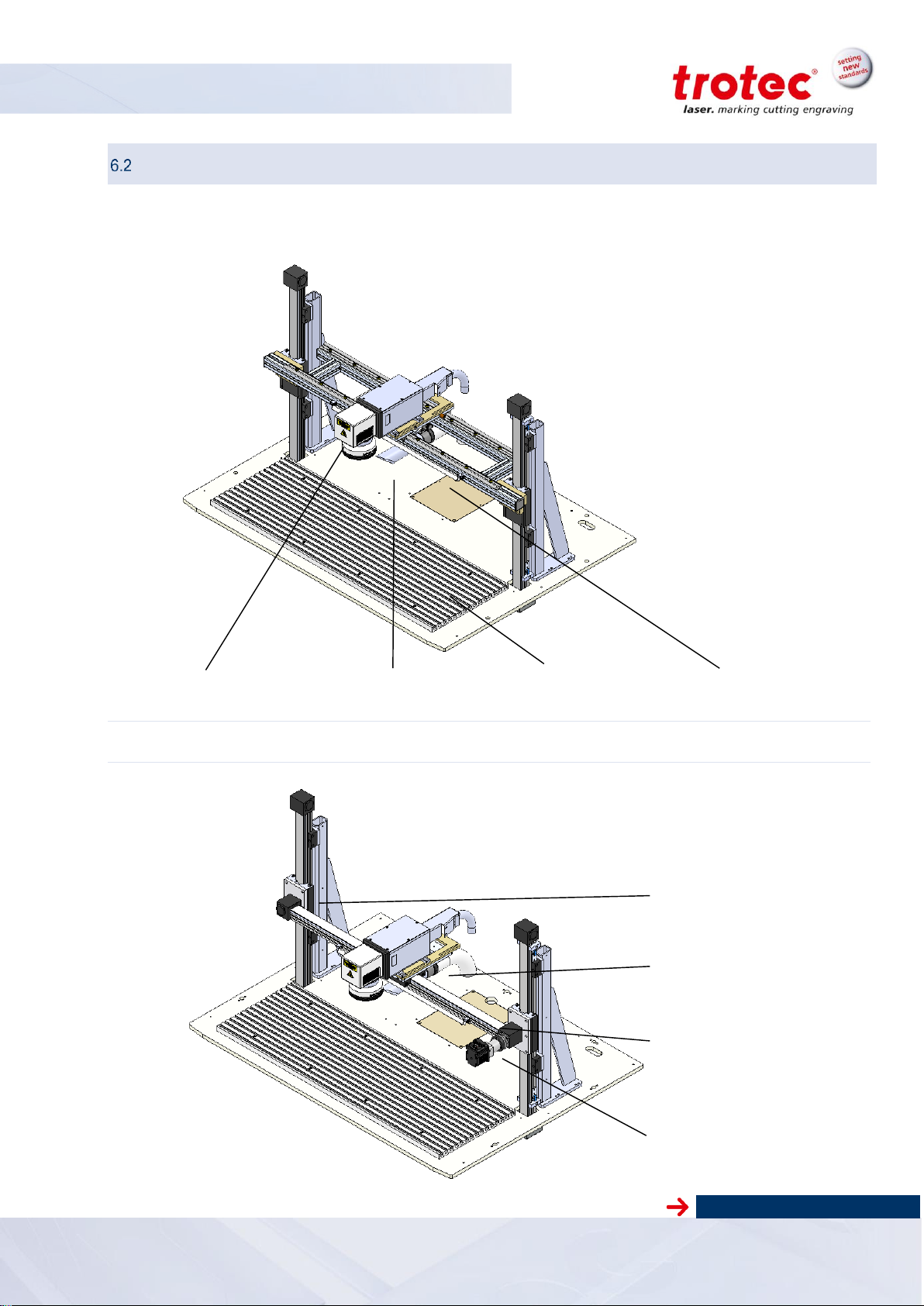

Processing Area Layout

The processing area contains the axis system. The processing area is closed during the marking process.

Laser head Extraction T-slot plate Lighting

6.2.1 SpeedMarker 1300 Software controlled Z- and X-axis

Limit switch (left side)

Axis drive

Limit switch (right side)

Axis drive assembly

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 29 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 30

SpeedMarker 1300

www.troteclaser.com

6.2.2 SpeedMarker 1300 Software controlled Z- X- and Y-axis

Limit switch (at the back)

Limit switch (in front)

Axis system

6.2.3 General axis design

Each axis system consists of a linear servo axis with precision.

Z- and Y-axis with tandem-axis and the X-axis have two limit switches and two mechanical stops.

The laser head is mounted above the adapter plate on the X-axis. The X-axis is mounted on the Z-axis.

The Y-axis is a movable table where objects can be placed.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 30 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 31

SpeedMarker 1300

www.troteclaser.com

1

Extraction system connector

2

Power supply connector

1

2

Power Supply Connector

The power supply connector is at the rear of the SpeedMarker 1300

The air assist hose (with 40mm) can be connected.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 31 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 32

SpeedMarker 1300

www.troteclaser.com

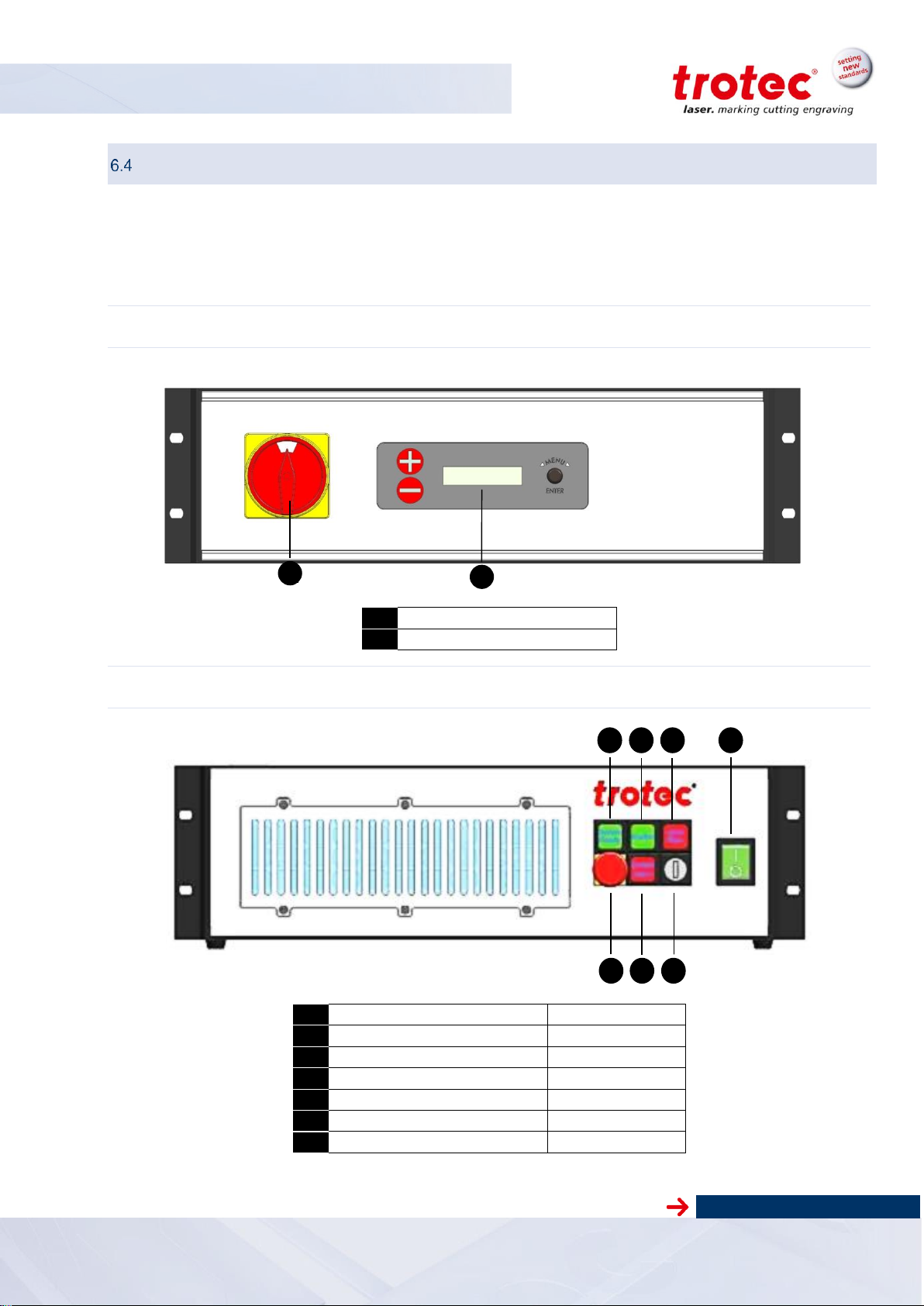

1

Main switch

2

LCD display

1

System ready

Control lamp

2

Shutter

Control lamp

3

Laser busy

Control lamp

4

Main laser switch

5 EMERGENCY STOP

Switch

6

System Alarm

Button

7

Key switch

1

2

24 1

3

5 6 7

Control Elements

The control elements consist of:

Control Rack

Laser Rack

Industrial-PC

6.4.1 Control Rack

The control module controlls the safety door, automatic mode,…

6.4.2 Laser Rack

The laser rack controlls the laser head and laser rack.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 32 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 33

SpeedMarker 1300

www.troteclaser.com

1

PC protective cover

1

6.4.3 Industrial-PC

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 33 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 34

SpeedMarker 1300

www.troteclaser.com

Do not alter or deactivate the safety switches or protective covers on the laser head or the

machine.

All safety and protection devices must be installed and fully functional every time the machine is put into operation.

Safety Devices

The SpeedMarker 1300 is fitted with the following safety devices:

Main switch

Emergency stop button

Safety switches on the safety doors

Observation window of laser protection glass

Laser protection shutter

Cover plates

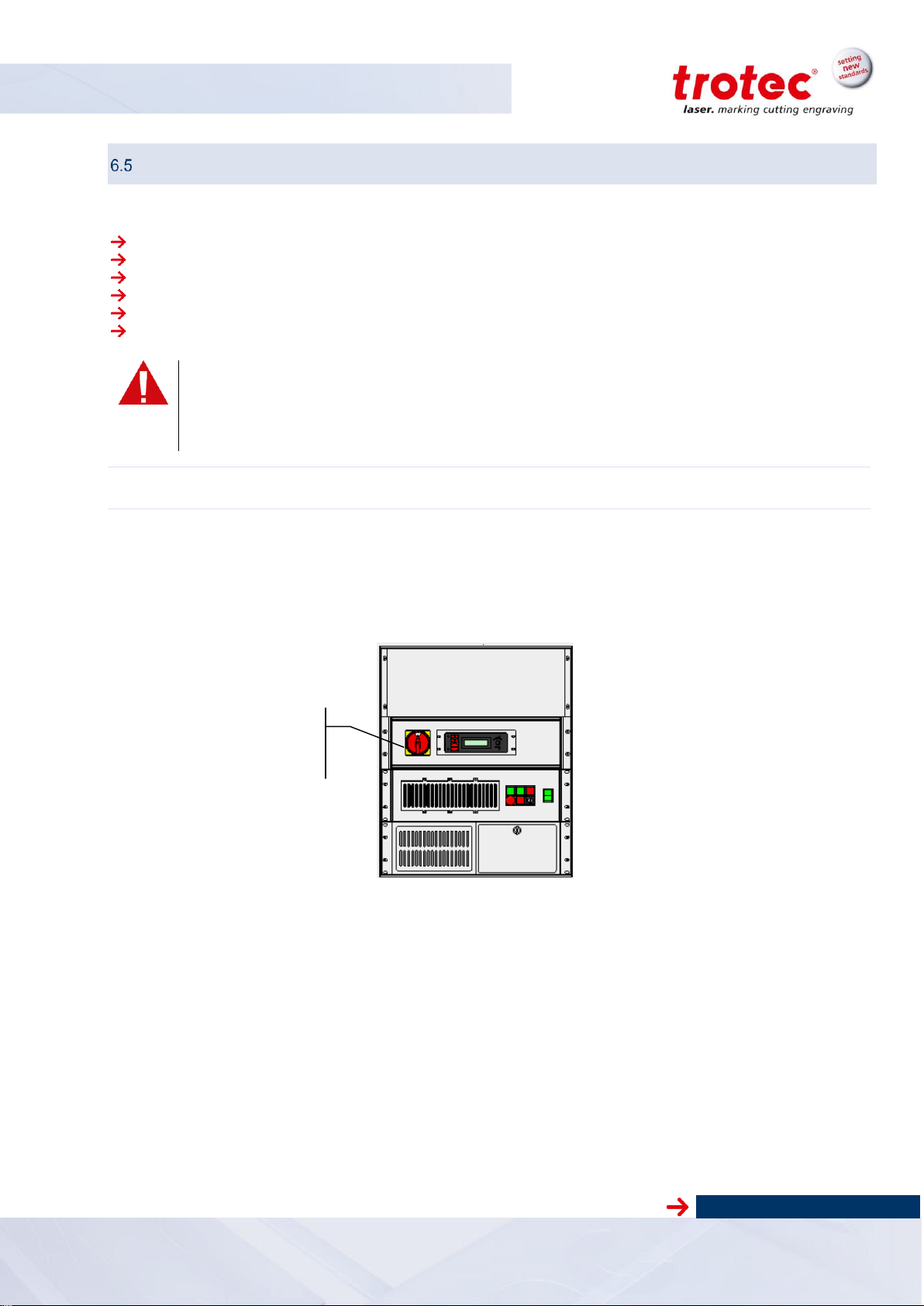

6.5.1 Main Switch

The main switch is situated at the system control unit at the lower part of the machine.

With the main switch the entire machine but also the laser get switched off

Main switch

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 34 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 35

SpeedMarker 1300

www.troteclaser.com

gency stop button

Press the "Emergency stop"

button

2. Acknowledge the

emergency stop

error message

Press the "ON" button on the

keypad

3. Acknowledge the

laser error message

Press the "ON" button on the

keypad

OR: Press the "System

alarm" button on the laser

rack module

"System Alarm" button

"Start" button

"Emergency stop"

button

Keypad: "ON"

button

6.5.2 Emergency Stop Device

There is one emergency stop button located on the front of the SpeedMarker 1300 and a second emergency

stop button on the laser module.

The function of the emergency stop device is

Firstly: to prevent any risks to the operating personnel.

Secondly: to avoid any damage to/destruction of the machine/material.

The emergency stop automatically shuts off the electric circuit. The laser beam is interrupted by the shutter. All

movements are stopped. When the emergency stop function is triggered, an error message is displayed.

6.5.2.1 Emergency stop acknowledgement - Steps

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 35 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 36

SpeedMarker 1300

www.troteclaser.com

ATTENTION

All protection plates must be mounted all times.

6.5.3 Safety switches inside the safety door

The monitoring todetermine whether a safety guard is open or closed is performed by two protective switches.

The marking process can not be started when the safety doors are open. However the pilot laser stays active.

6.5.4 Laser protection glass

The light green observation window in the front door is made of laser protection glass in accordance with DIN

EN 201. The glass consists of a special material depending on the type of laser used and which absorbs the

laser radiation. The glass should be replaced if it becomes damaged.

6.5.5 Laser protection shutter

If a safety circuit in the laser cell is open, the laser protection shutter shuts momentarily. For reasons of safety

this disconnection functions via safe components. The laser is interrupted mechanically. An error message is

issued.

6.5.6 Cover plate

Cover plates protect from laser light.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 36 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 37

SpeedMarker 1300

www.troteclaser.com

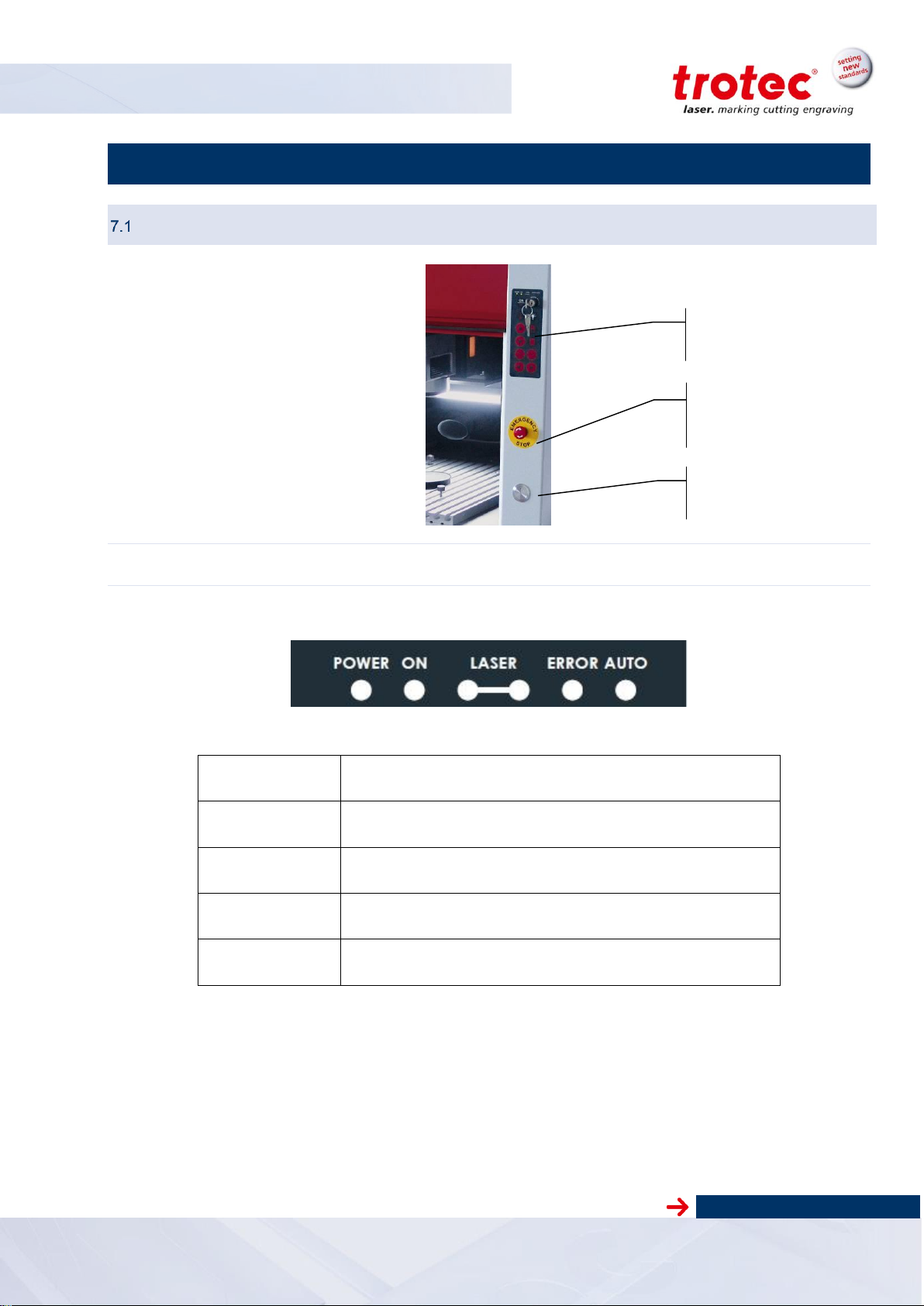

Power

The SpeedMarker 1300 power supply is switched on

ON

The SpeedMarker 1300 control mechanism is switched on

Laser – Laser

The laser marker is active

Error

There is an error which has not yet been acknowledged

Auto

Automatic mode is active

"Start" button

"Emergency Stop"

button

Keypad

7 Operation

Control Elements on the Front of SpeedMarker 1300

7.1.1 LEDs on the Keypad

The LEDS on the control panel have the following meanings:

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 37 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 38

SpeedMarker 1300

www.troteclaser.com

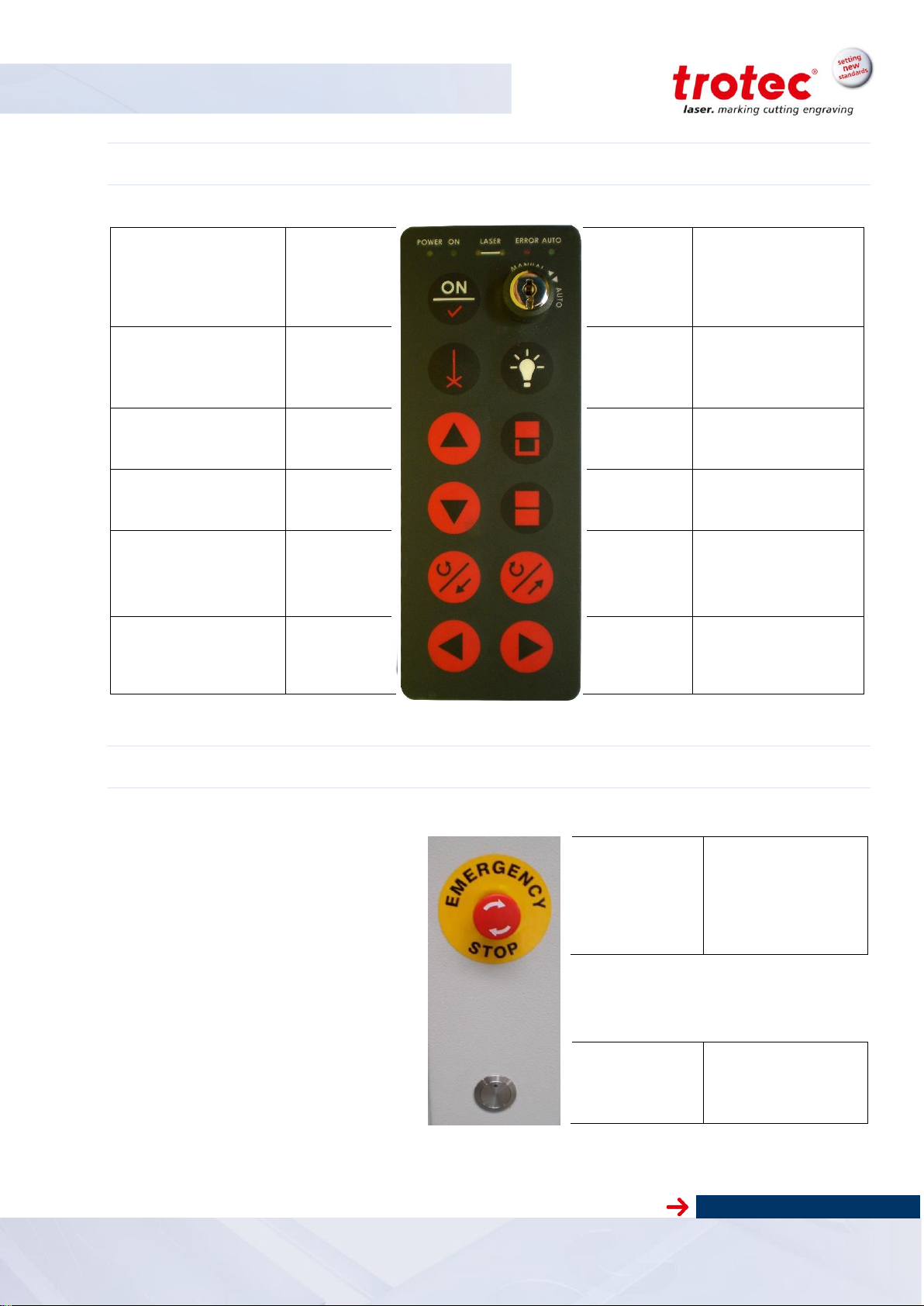

Used to acknowledge the

system once it has been

switched on, or after an

emergency stop or fault

ON button

Key switch

Used to select either automatic or manual mode

No function

Light

Used to switch the lighting in the processing

area on or off

Used to move the Z-axis

upwards

Z axis

move up

Open safety

door

Used to open the safety

doors

Used to move the Z-axis

downwards

Z axis

move down

Close safety

door

Used to close the safety

doors

Used to move the Y-axis

forwards

Y axis

move

forward

(optional)

Y axis

move

backward

(optional)

Used to move the Y-axis

backwards

Used to move the X-axis

left

X axis move

left

(optional)

X axis move

right

(optional)

Used to move the X-axis

right

EMERGENCY

STOP

Used to stop the

SpeedMarker 1300 in

an emergency (PC

power supply remains

uninterrupted)

Automatic

Start Button

Used to start processing in automatic

mode

7.1.2 SpeedMarker 1300 Keypad

7.1.3 Emergency Stop and Automatic Start Button

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 38 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 39

SpeedMarker 1300

www.troteclaser.com

The ambient air temperature must be between +15°C und +35°C and the relative air

humidity not exceed 90% (non-condensing).

If the system has been subject to significant temperature variations, it must be brought

back to room temperature before being commissioned.

A laser system consists of high quality electrical and optical components. Mechanical

stresses, vibrations and impacts must always be avoided.

There must be sufficient air supply to both 19” modules. The accumulation of heat due

to covered ventilation slots or filter pads can damage the system.

Remove the entire packaging material.

Remove all transport protection.

The machine must stand upright.

Check if the supply voltage and frequency are correct.

Check if the power cable is intact and replace it if necessary.

Check if the power plug is undamaged and intact.

Before connecting the power cable to the SpeedMarker 1300 or the socket, turn the

main switch on the SpeedMarker 1300 to the OFF position.

Check if the laser protection glass is intact.

Check the electrical installation is complete and the input voltage is correct.

Ensure that the optical components are free from dust and dirt.

Have the protective covers been removed from the focusing objective lens?

Check the environmental conditions against the technical specification.

Are you familiar with the laser safety regulations?

Have all laser safety measured been fulfilled?

The system may then only be switched on once all provisions for complying with laser

safety have been checked by an authorised individual and confirmed to have met the

standards.

8 Commissioning

General Instructions

Installation of SpeedMarker 1300

Before Commissioning

In order to ensure the unit is installed correctly, the following points should be checked:

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 39 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 40

SpeedMarker 1300

www.troteclaser.com

Power On Procedure

1. Switch on the SpeedMarker 1300 main switch.

2. The Industrial PC gets switched on automatically. Alternatively it can be switched on manually by pressing the button behind the protective cover.

3. Switch on the laser rack by pressing the "I/O“ switch.

4. Turn the key swith on the laser rack module 90° clockwise (so it is horizontal).

5. Wait for the system to be powered up and the SpeedMark software to start..

6. Unlock the emergency stop button if necessary. See chapter "Emergency Stop Device"

7. Turn the key switch for manual or automatic mode.

8. The SpeedMarker 1300 is now ready for operation.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 40 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 41

SpeedMarker 1300

www.troteclaser.com

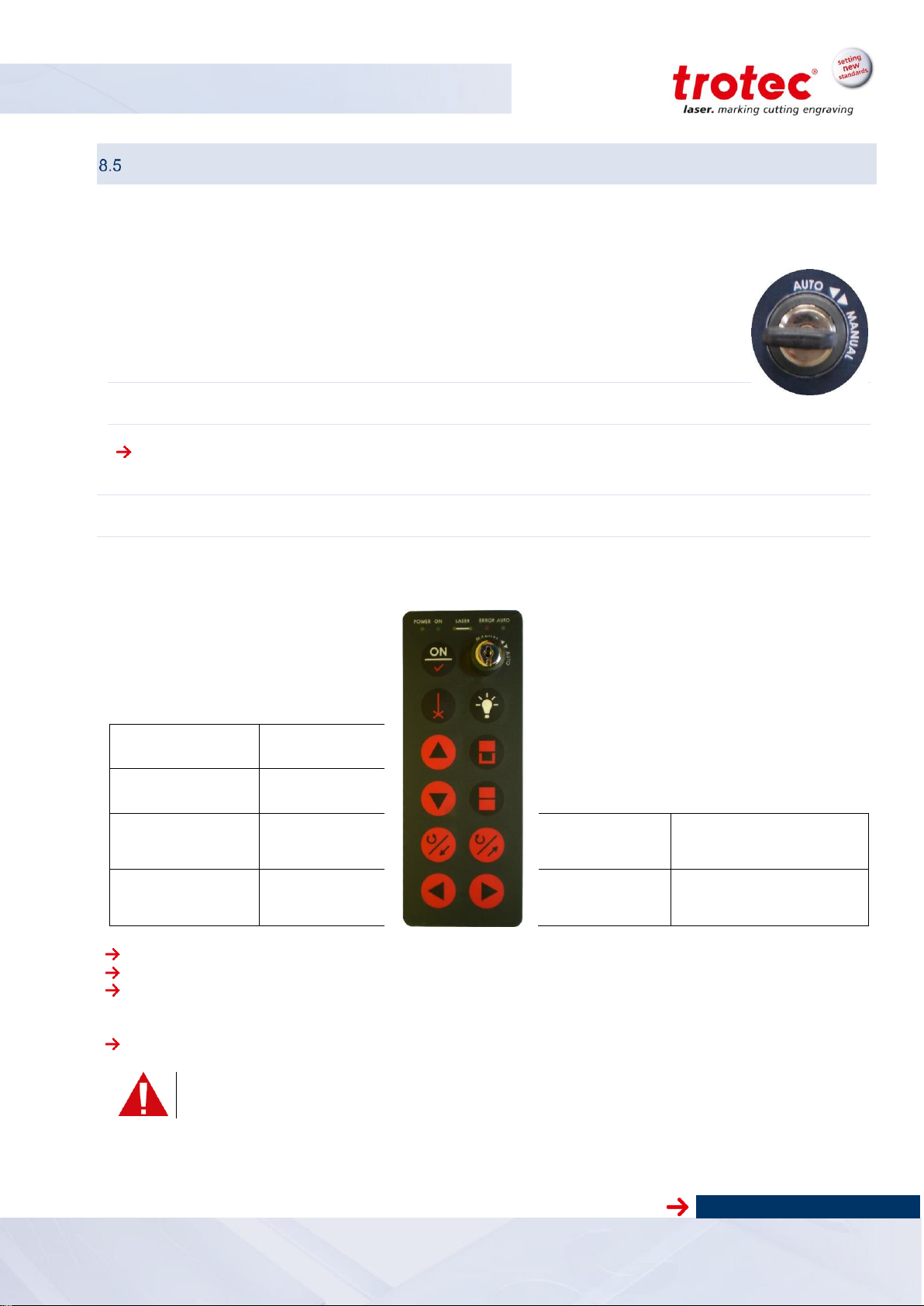

Used to move the Zaxis upwards

Z move up

Used to move the Zaxis downwards

Z move down

Used to move the Yaxis forwards

Y axis move

forward

(optional)

Y axis move

backward

(optional)

Used to move the Y-axis

backwards

Used to move the Xaxis left

X axis move

left

(optional)

X axis move

right

(optional)

Used to move the X-axis

right

CAUTION

Risk of crushing when moving the axis.

Manual Mode

When turning the key switch to manual mode all functions of the machine can be carried out manually. Manual

mode is used to check the machine and test the marking. Marking is only possible when the safety door is

closed. Please note the safety door can be opened and closed manually.

The functions are:

Open and close the safety doors.

Move the axis manually.

Start the marking process.

8.5.1 Safety door

Use the “Open safety doors” and “Close safety doors” buttons on the keypad to open and close the safety

doors.

8.5.2 Software controlled X and Z-axis (optional: Y-axis)

Use the following buttons to move the axis manually:

The axis are restricted by the upper and lower limit switches.

When travelling down- or upwards, take care that the objective does not collide with the workpiece.

After starting the SpeedMarker 1300 or carrying out an emergency stop acknowledgement a reference run

neds to be performed. Referencing can be started manually within the marking software or automatically

when starting the marking software.

In automatic mode the axis are controlled by the Industrial PC.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 41 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 42

SpeedMarker 1300

www.troteclaser.com

INFO

The key switch needs to be set to AUTO and the laser rack control

software has booted up. .

Automatic Mode

When the key switch is set to auto mode all functions of the machine will be carried out automatically. Auto

mode is used for an automatic production process. Marking is only possible when the safety door is closed.

Please note the safety door can be opened and closed manually.

8.6.1 Automatic mode sequence

1. Use the “Automatic Start button” to start the marking process.

2. The safety door closes.

3. The marking process is carried out automatically.

4. The safety doors open once the marking is completed.

5. Use the “Automatic Start button" to start a new marking process.

SpeedMarker 1300 Power Off Procedure

1. Stop the software on the industrial PC.

2. Shut down the laser PC operating system.

3. The SpeedMarker 1300 may be switched off using the main switch on the control rack as soon as the

industrial PC operating system has been shut down.

4. Now the SpeedMarker 1300 is switched off.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 42 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 43

SpeedMarker 1300

www.troteclaser.com

CAUTION

Risk of injury when working with mechanical components.

It is absolutely essential to maintain the correct focal distance for every laser

marking process. Only when in focus will the laser beam achieve the power density necessary for permanent and clearly legible marking.

Lens

Focal distance (A)

F-100

~134,6 mm

F-160

~211,6 mm

F-254

~361,6 mm

F-330

~456,59 mm

F-420

~562,59 mm

B

A

C

9 Setting up

Setting up the Focus

Prior to any marking it is therefore necessary to set the correct focal distance between the marking head and

the workpiece. An incorrect focal distance is the most common cause of poor or even indistinguishable

markings.

Position the laser by moving the Z-axis until the ideal marking result has been reached.

The focal distance (A) is measured between the lower edge of the galvo head (B) and the upper surface of

the workpiece (C). The correct focal distance depends on the lens used (focal length).

Positioning the Workpiece

Use the “Border Mark” function in the marking software to indicate the marking field with the pilot laser.

Move the workpiece under the laser until it is in the correct marking position.

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 43 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 44

SpeedMarker 1300

www.troteclaser.com

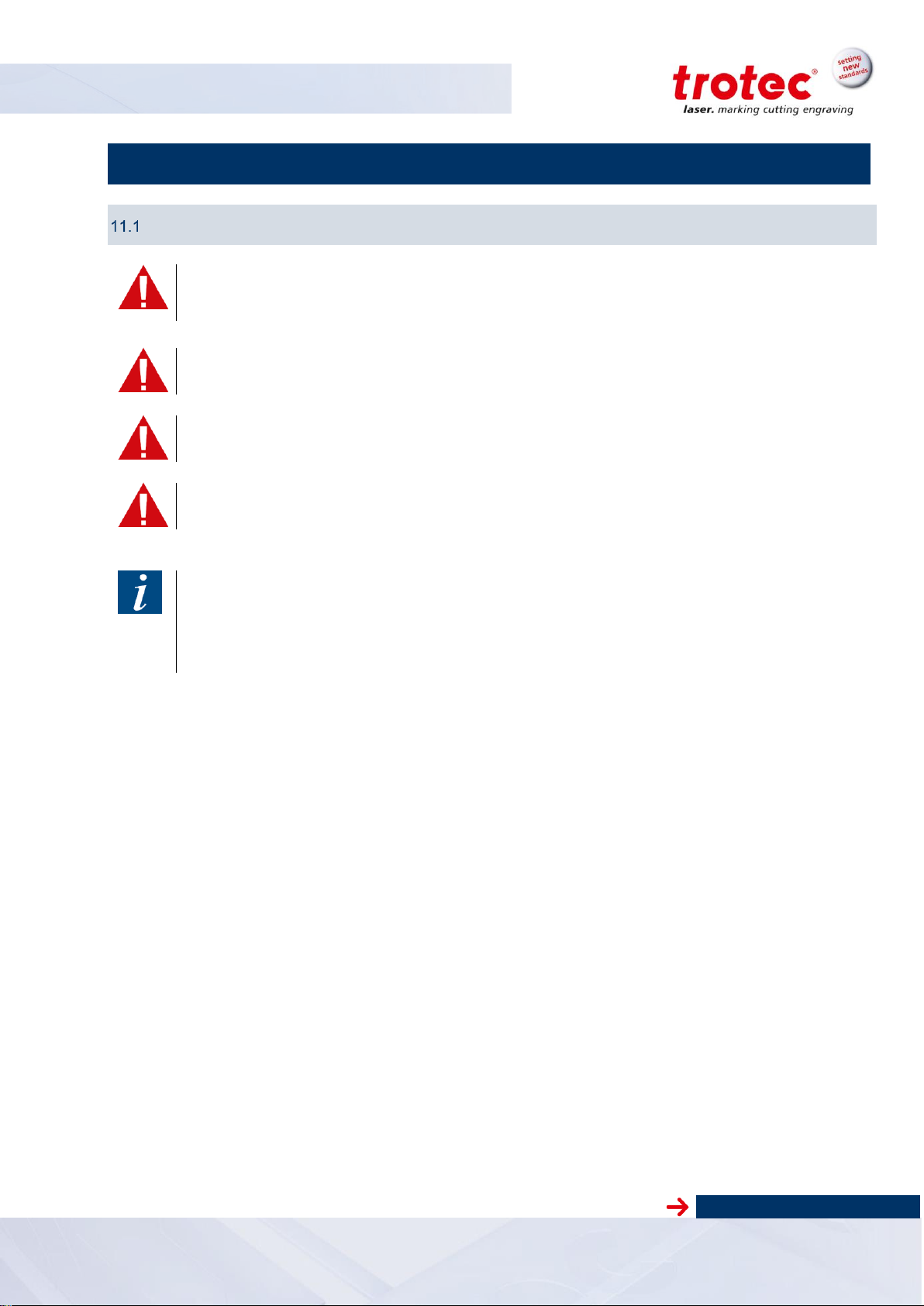

Maintenance and repair work should only be carried out by Trotec Produktions und Vertriebs Ges.m.b.H. or one of its authorised personnel under observation of the safety regulations.

Possible Error Messages at Control Rack

Troubleshooting

Emergency stop button

Unlock the emergency stop button and acknowledge the

error

Safety door error

Start the safety door again in manual mode; if necessary,

check the safety doors for heaviness/lack of movement

Output error

The electronic output of the cell control system has been

overloaded; switch the main switch off and on again.

Problem

Possible Cause

Resolution

Not possible to turn on laser

module

System switched off

Turn on main switch

The key is missing from the key

switch on the laser module or is in

the vertical position.

Place the key in the switch on the laser

module and turn to the horizontal position

Emergency stop button has been

activated

Release the emergency stop button

System power plug not installed

correctly

Check the System power plug has been installed correctly

Error notification

10 Troubleshooting

This chapter should assist maintenance personnel with the identification and resolution of operational faults

based on error messages and symptoms.

Movements and functions may only be performed when there are no errors and all devices are ready for operation. This state is prerequisite for starting the SpeedMarker 1300. If this state changes during operation, the

laser cell stops.

The error must be acknowledged using the “ON” button on the keypad.

Error Analysis

If an error occurs, the “Error LED” light flashes on the keypad. The error may be read on the display.

Common Errors

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 44 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 45

SpeedMarker 1300

www.troteclaser.com

Problem

Possible Cause

Resolution

Not possible to turn on laser

module

Incorrect or no voltage supply to

the System

Check the System 230/110V power

supply

Laser module power plug not installed correctly

Check the laser module power plug

has been installed correctly

Faulty fuse in laser power supply

Replace fuse

Not possible to turn on

SpeedMarker 1300

Emergency stop button has been

activated

Release the emergency stop button

System power plug not installed

correctly

Check the System power plug has

been installed correctly

Incorrect or no voltage supply to

the System

Check the SpeedMarker 1300

230/110V power supply

Error message on

loading the program

Plug or cable not installed correctly

Check the plug and cable are installed correctly

Check the installation

Laser power supply switched off

Turn on main switch

Software not installed correctly

Re-install software

Software terminated irregularly

Restart PC

No laser beam

Laser not in focus

Check working distance

Shutter is closed

Open shutter - if not possible

check interlock circuit

Incorrect laser parameters

Check the parameters in the program. Use suitable parameters for

the material and application

Focussing lens dirty

Check the lens for dirt and clean as

required.

Insufficient laser output

Laser not in focus

Check working distance

Incorrect laser parameters

Check the parameters in the program. Use suitable parameters for

the material and application

Focussing lens dirty

Check the lens for dirt and clean as

required.

Missing symbols

Focussing lens dirty

Check the lens for dirt and clean as

required.

Surface of the material dirty

Clean material surface

The marking plane is not parallel

to the focussing lens

Ensure that the entire marking surface is parallel to the focussing lens

Other faults

Contact TROTEC Support

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 45 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 46

SpeedMarker 1300

www.troteclaser.com

CAUTION

Before any maintenance work takes place, ensure that the power supply

has been switched off and the system is de-energised.

All maintenance work must be carried out according to the safety regulations.

Using explosive or flammable cleaning agents present a ristk of fire or explosion:

No flammable or explosive liquide is allowed to be stored near the machine.

INFO

In order to ensure the maximum availability and lifetime of the system, we recommend

you regularly check the filter system and ventilation and keep the surrounding area clean.

A visual inspection of the lenses is likewise recommended before switching on the system.

11 Maintenance

General Maintenance

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 46 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 47

SpeedMarker 1300

www.troteclaser.com

Daily

Weekly

Monthly

Annually

System Component

Lenses

Check

If necessary

clean

Guide bar for door weights

Clean

Entire working area – general

cleaning

Clean

Visual inspection of laser protection glass for integrity

Check

if necessary

replace

Function check of every individual emergency stop devices

Check

Visual inspection of the safety

door cables for integrity

Every 6 month

Check

If necessary replace

Exhaust System

Filter

According tot he operation manual oft he exhaust system

Filter mat

Activated carbon filter

INFO

Laser optics are highly sensitive and their surfaces are not as hard as traditional

glass. They can also be easily damaged by cleaning. It is therefore necessary to ensure that any dirt is removed using a suitable suction device and that the surrounding

area is cleaned regularly.

Never touch the optical components with your fingers! Oily or dirty hands may damage the

lens surfaces.

To remove larger pieces of dirt, only use a soft lens cleaning cloth in conjunction with high

proof (min. 98 %) alcohol or special lens cleaning liquid.

Do not dip the cleaning cloth in the cleaning solution. This contaminates the solution and

makes it unusable. Place drops of the solution on the cloth!

Do not use any tools or hard objects to clean the surfaces. Scratches cannot be repaired.

Small bellows should be used to remove dust.

Do not use compressed air as it contains small quantities of oil and water.

Maintenance schedule

Cleaning the Lenses

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 47 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 48

SpeedMarker 1300

www.troteclaser.com

Distribute the cleaning fluid carefully using small circular motions. Start at the centre of the

lens and move outwards to the edge. Keep moving the cloth until the entire surface is

clean.

Do not exert any pressure on the lens.

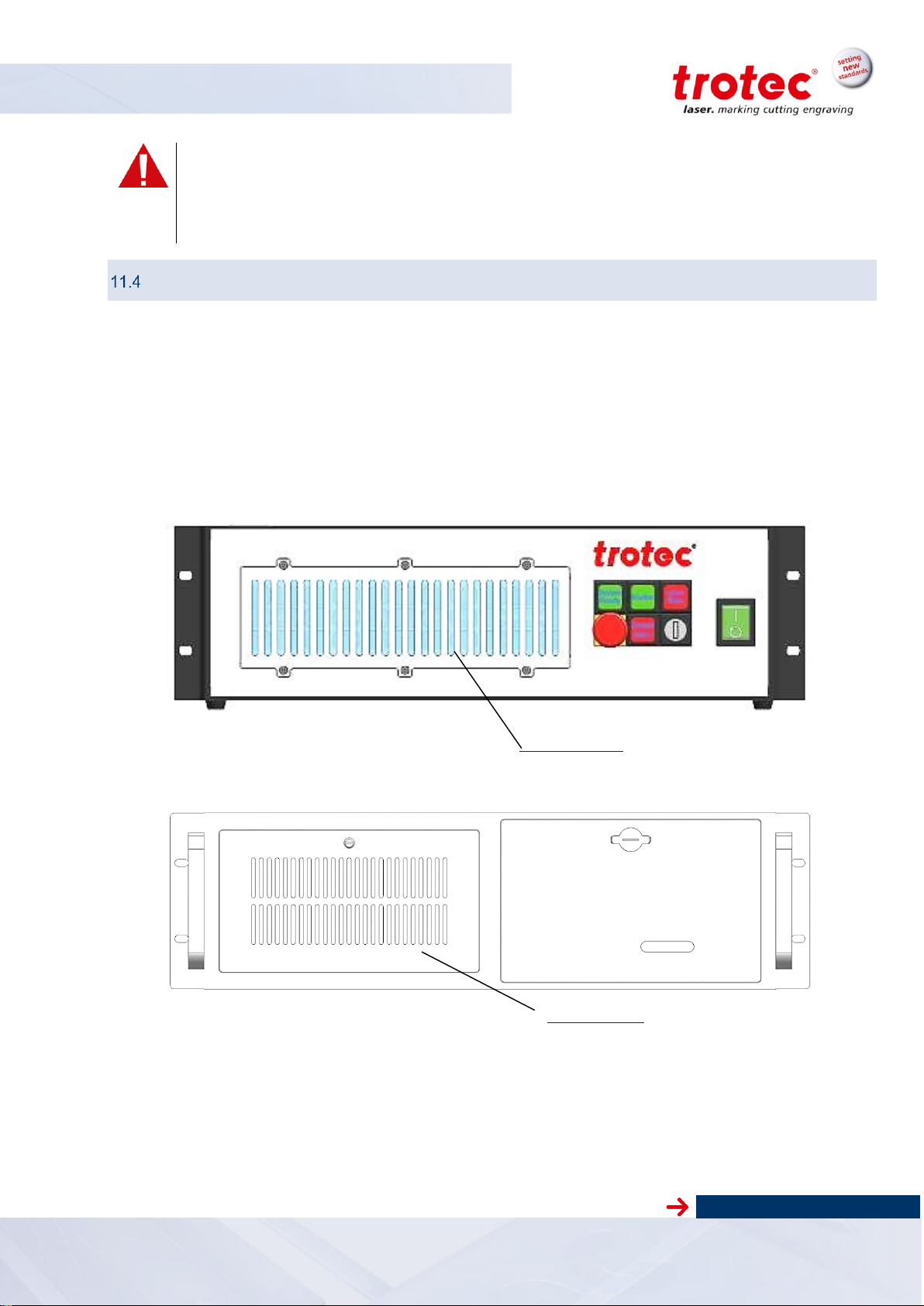

Filter mat cover

Replacing the Filter Mat

This laser system is fitted with a ventilation system. A filter mat is used to protect the electronic components

from dust and dirt in the ambient air.

This filter mat should be checked and replaced at regular intervals in order to ensure optimum cooling.

The filter mat is located behind the ventilation slots on the front of the laser rack or PC.

Filter Mat Laser Rack

Filter Mat Industrial PC

Filter mat cover

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 48 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Page 49

SpeedMarker 1300

www.troteclaser.com

CAUTION

Injury may occur when disassembling the machine. Therefore always wear

suitable protective clothing (Safety glasses, safety shoes, and so on).

CAUTION

The machine must be disconnected from the power supply.

INFO

Always use suitable tools to disassembly the machine. Mind the springs!

Observation window

The observation window is made of a special, coloured plastic. In order not to damage it, it should only be

cleaned with clean water and possibly a little detergent if necessary. Use a soft cloth in order not to scratch the

surface.

Benzene, alcohol, acetone, solvent or similar cleaning agents will damage the laser protection glass, which

must be replaced immediately.

Scratches must also be avoided. The laser protection glass must be replaced immediately if it becomes

scratched.

12 Disassembly

Sequence

1. Remove all work pieces from the processing area.

2. Press the "Emergency stop" button.

3. Shut of the laser souce module

4. Switch off the main switch.

5. Remove the exhaust system.

6. Disconnect the power supply.

Follow the special disposal instruction

Ausgabe 3.2, Stand 17/11/14 © TROTEC Produktions- u. Vertriebs GmbH 49 / 49

Technische Änderungen vorbehalten Freilingerstraße 99, A-4614 Marchtrenk

Loading...

Loading...