Page 1

TTR 800 / TTR 1400

EN

ORIG INAL INS TRUC TION S

DESI CCAN T DE HUMI DIFI ER

TRT-BA-TTR800-TTR1400-TC-001-EN ID TECHN. ANHANG

Page 2

Table of contents

Notes regarding the instructions .......................................... 1

Follow the manual

Information marked with this symbol indicates that the

instructions must be observed.

Safety .....................................................................................2

Information about the device................................................4

Transport and installation.....................................................9

Assembly and installation...................................................10

Start-up................................................................................13

Operation .............................................................................14

Errors and faults..................................................................15

Maintenance ........................................................................18

Harmful influences on rotors ..............................................21

Disposal ...............................................................................22

Options.................................................................................23

Technical annex...................................................................32

Notes regarding the instructions

Wear hearing protection

Information marked with this symbol indicates that you

should wear hearing protection.

Wear protective gloves

Information marked with this symbol indicates that you

should wear protective gloves.

Wear foot protection

Information marked with this symbol indicates that you

should wear safety boots.

You can download the current version of the instructions and

the EUdeclaration of conformity via the following link:

TTR 800

https://hub.trotec.com/?id=42450

Symbols

Warning of electrical voltage

This symbol indicates dangers to the life and health of

persons due to electrical voltage.

Warning

This signal word indicates a hazard with an average

risk level which, if not avoided, can result in serious

injury or death.

Caution

This signal word indicates a hazard with a low risk

level which, if not avoided, can result in minor or

moderate injury.

Note

This signal word indicates important information (e.g.

material damage), but does not indicate hazards.

Info

Information marked with this symbol helps you to carry

out your tasks quickly and safely.

TTR 1400

https://hub.trotec.com/?id=42451

1 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 3

Safety

Read this manual carefully before starting or using the

device. Always store the manual in the immediate vicinity

of the device or its site of use!

Warning

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future

reference.

• Do not use the device in potentially explosive rooms.

• Do not use the device in aggressive atmosphere.

• Set the device up in an upright and stable position.

• Let the device dry out after a wet clean. Do not operate it

when wet.

• Do not use the device with wet or damp hands.

• Do not expose the device to directly squirting water.

• Ensure sufficient lighting at the device.

• Never insert any objects or limbs into the running device.

• Do not cover or transport the device during operation.

• Do not sit on the device.

• Check accessories and connection parts for possible

damage prior to every use of the device. Do not use any

defective devices or device parts.

• Ensure that all electric cables outside of the device are

protected from damage (e.g. caused by animals). Never

use the device if electric cables or the power connection

are damaged!

• The electrical connection must correspond to the

specifications on the nameplate. Additionally, information

regarding the electrical connection is provided in the

technical annex.

• Insert the mains plug(if any) into a properly secured mains

power socket.

• Observe the device's power input, cable length and

intended use when selecting extensions to the power

cable. Completely unroll extension cables. Avoid electrical

overload.

• Before maintenance, care or repair work disconnect the

device from the mains and secure it against unauthorized

restart.

• Before carrying out maintenance, care or repair work on

the device, remove the mains plug from the mains socket.

Hold onto the mains plug while doing so.

• Do not under any circumstances use the device if you

detect damages on the mains plug or power cable.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Defective power cables pose a serious health risk!

• When positioning the device, observe the minimum

distances from walls and other objects as well as the

storage and operating conditions specified in the technical

annex.

• Make sure that the air inlet and outlet are not obstructed.

• Make sure that the suction side is kept free of dirt and

loose objects.

• Do not remove any safety signs, stickers or labels from the

device. Keep all safety signs, stickers and labels in legible

condition.

• Before starting any internal work on the device, discharge

the EMCfilters, e.g. using load resistors.

• Only transport the device in an upright position.

Intended use

The desiccant dehumidifiers of the TTRseries are only to be

used for dehumidifying atmospheric air. Any other use possibly

exceeding the intended purpose is considered to be improper

use.

Intended use comprises:

• observing all the information in the instructions

• compliance with the inspection and maintenance tasks

• observing the permissible operating and surrounding

conditions according to the technical data (see Technical

annex)

The following minimum requirements must be met:

• permissible ambient temperature: -20°C to +40°C

• relative humidity: max. 95%RH non-condensing

After consultation with Trotec other operating conditions are

possible with respectively modified versions.

EN 2

desiccant dehumidifier TTR 800 / TTR 1400

Page 4

Improper use

• Dehumidifiers are not suited for the installation on or the

intake of fluids, e.g. from filled tanks or tubs, flooded

installation areas or the like.

• If supplying the system with contaminated air, the

"harmful influences on rotors" must be observed!

• Do not expose the device to the weather without suitable

protection.

• Any unauthorised modifications, alterations or structural

changes to the device are forbidden.

• Any operation other than as described in this manual is

prohibited. Non-observance renders all claims for liability

and guarantee null and void.

Personnel qualifications

People who use this device must:

• be aware of the dangers that occur when working with

electric devices in damp areas.

• have read and understood the instructions, especially the

Safety chapter.

The following applies to the staff categories stated below:

Electrically skilled person

Electrically skilled personnel must be able to read and

understand electric circuit diagrams, to put electrical systems

into service and to maintain them, to wire control cabinets, to

ensure the functionality of electrical components and to identify

possible hazards from electrical and electronic systems.

Instructed person

Instructed persons have been informed of the tasks they were

entrusted with as well as of potential hazards resulting from

inappropriate behaviour. They are allowed to operate and

transport the device and perform simple maintenance activities

(cleaning the housing, cleaning the fan).

The device is to be maintained and looked after by instructed

personnel.

Personnel training

• Only trained and instructed personnel may work at or with

the dehumidifier – observe the personnel qualifications.

• The responsibilities of the personnel for the following tasks

must be clearly defined:

– set-up and assembly

– installation

– start-up and operation

– maintenance and repair

• The control unit may only be operated by instructed

personnel.

Personal protective equipment

Wear hearing protection

Wear hearing protection when standing near the

running device.

Wear protective gloves

For start-up, maintenance and troubleshooting always

wear suitable protective gloves.

Wear foot protection

For transportation, start-up, maintenance and

troubleshooting always wear suitable foot protection.

Residual risks

Warning of electrical voltage

Work on the electrical components must only be

carried out by a qualified electrician!

Warning of electrical voltage

Make sure to de-energize the device before starting

work on electrical components.

Set the main switch to the 0position or pull the mains

plug (if any) from the mains socket.

Warning

Dangers can occur at the device when it is used by

untrained people in an unprofessional or improper way!

Observe the personnel qualifications!

Warning

The device is not a toy and does not belong in the

hands of children.

Warning

Risk of suffocation!

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

3 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 5

Caution

Only use residual current devices sensitive to all types

of current (type B or B+). The integrated EMC filters

can lead to instantaneously tripped RCDs.

Use residual current devices with a minimum triggering

level of > 300 mA and delayed tripping (type K).

Note

Do not operate the device without an inserted air filter!

Without the air filter, the inside of the device will be

heavily contaminated. This could reduce the

performance and result in damage to the device.

Note

Dirt accumulating inside the rotor can substantially

reduce the dehumidification performance or damage

the rotor beyond repair.

Supplying the system with contaminated air might

damage the rotor. Observe the information regarding

"Harmful influences on rotors".

Note

After a power failure the device will restart

automatically provided that it was not switched off in

the meantime. This behaviour is desired and necessary

to ensure operation with little supervision.

Behaviour in the event of an emergency

1. Switch off the device.

2. In an emergency, disconnect the device from the mains

feed-in: Hold onto the mains plug while pulling the power

cable out of the mains socket.

3. Do not reconnect a defective device to the mains.

Information about the device

General description

Dehumidifiers operating on the desiccant principle are used to

tackle drying tasks in the field of process engineering, airconditioning, on construction sites and for the dehumidification

of production and storage facilities, where a particularly low

humidity level is required over a broad temperature range.

The desiccation technique enables the safe and economic

operation even at low operating temperatures.

Design

The basic device consists of the following components:

• fans for air transport

• air filters behind every air inlet

• separate sectors for process air (to be dehumidified) and

regeneration air (humid exhaust air)

• purging sector for heat recovery

• rotor desiccant wheel for the dehumidification with silica

gel

• drive unit with gear motor, toothed belt pulley and toothed

belt

• heater battery for heating regeneration air

• Depending on the selected options further components are

possible (see Technical annex).

During dehumidification the desiccant wheel turns continuously

at a low speed (depending on the configuration 2 to 40rotations

per hour).

Via the sectors the desiccant wheel is simultaneously charged

with the process and regeneration air so it can constantly

absorb and release moisture.

Process air

The air to be dehumidified is sucked in by means of a fan. The

process air(4) flows through the desiccant wheel's

dehumidification sector(1).

In doing so, the contained moisture is withdrawn by the sorbent

(silica gel) and retained (desiccation). Due to physical processes

the temperature of the dry air(6) increases. Later the dried air

flows towards the dry air outlet.

EN 4

desiccant dehumidifier TTR 800 / TTR 1400

Page 6

Regeneration air

The regeneration air(5) is also sucked in with its own fan and

guided through the purging sector(3). During dehumidification

the desiccant wheel warms up as a result of the released

desiccation heat and the regeneration heat. The purging

sector(3) serves the purpose of heat recovery and for cooling

the desiccant wheel, leading to a reduced energy input and

improvement of the dehumidification performance – especially

at lower dew points. Whilst flowing through the heater

battery(7) the air is heated to approx. 100°C to 140°C

(depending on the intake temperature) and at the same time the

relative humidity is extremely reduced.

In passing through the regeneration sector(2), the thusly

prepared air now again absorbs the moisture retained by the

silica gel (desorption). Then the extremely humid regeneration

air(8) is discharged to the outside via the humid air outlet.

Schematic diagram

Design configuration and components

rotor

The desiccant dehumidifier works with a desiccant wheel (rotor

A) which is composed of layers of smooth and corrugated nonwoven fabric with chemically bonded silica gel. Thus created is

a honeycomb structure with a large number of axial air ducts

with a large surface and direct connection to the inner pore

structure of the silica gel.

On account of the desiccant wheel's good mechanical and

physical properties no silica gel is discharged. It may be

supplied with saturated air with a relative humidity of up to

100% but not with water drops. The rotor is incombustible.

Rotor drive

The rotor is driven by an electric gear motor.

The power is transmitted by means of synchronized pulley and

timing belt.

Rotor rotation control

The device is equipped with a rotation control for an early

recognition of a possible rotor standstill.

Rotor bearing

The rotor is mounted on a stainless steel axle with

maintenance-free plain bearing bushes.

No. Designation

1 Dehumidification sector

2 Regeneration sector

3 Purging sector

4 Process air inlet

5 Regeneration air inlet

6 Dry air outlet

7 Heater battery

8 Humid air outlet (regeneration air)

Rotor sealing

An automatically clearance-compensating gasket system seals

the rotor and the individual air sectors against one another.

Filter

Air filters are located in each individual air inlet – depending on

the field of application designed either as coarse or fine filter for

removing the dust in the air currents.

Fans

Used are radial fans or mixed-flow fans with energy-saving EC

motors. For an easy adjustment of the volumetric flow rates a

potentiometer is located behind the front cover. Therefore, the

fan speed for process air and regeneration air can be adjusted

according to the specifications. Hence, additional throttle valves

in the air lines are rendered redundant.

5 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 7

Regeneration air heater

Heating the regeneration air is effected by means of electric

heater batteries consisting of individual resistance heating

elements. Depending on the dehumidifier model and size of the

heater these can be designed as single- or multi-stage versions.

The regeneration temperature is regulated by a thermostatic

two-step control.

Safety temperature monitors(STW) measure both the

regeneration exhaust air temperature(RAL) and the

regeneration air temperature heating(RHZ). Primarily the

regulation is geared to a preferably constant RHZ. With a

decreasing moisture load however RAL might positively rocket,

so that the heating is down-regulated before reaching the RHZ.

Achieved in this way is an optimum performance adjustment of

the regeneration energy to the operating point.

Safety components

In order to protect the basic device from inadmissible

temperatures, it comes equipped with the following safety

components:

• a differential pressure switch (ΔP switch) to monitor the air

flow direction and the flow rate of the regeneration air

• a safety temperature limiter (STB RHZ) to monitor the max.

permissible temperature after heating (thermostat

maximum)

• a safety temperature limiter (STB RAL) as rotation control

for the rotor; it is situated in the exhaust air flow and

tripped by an inadmissible temperature rise resulting from

rotor standstill

• Depending on the selected options further components are

possible (see Technical annex).

Electrical system

The entire switching and control technology is located in the

integrated electrical control box on the dryer housing. The

electrical control box is designed for a high safety standard with

protection type IP53 (see Technical annex).

Depending on the model, the terminals for remote monitoring

and control can either be accessed via the front cover or the

cover of the control box. This is also the place to access the

reset buttons of the safety temperature limiters and the

potentiometers for fan regulation. The cable gland for the mains

feed-in is located at the side of the device. The power supply is

connected directly to the terminals of the emergency stop main

switch.

Housing

Depending on the model the housing of the dehumidifier is

made of galvanized sheet steel or stainless steel sheet.

Options

There are additional options available for the desiccant

dehumidifiers of the "TTR..." series (see also chapter "Options"

in these instructions).

Note

If a safety component is tripped, the device will be

switched off (STOP), but the overrun will remain

active.

Wait until the entire rundown period has lapsed before

accessing internal parts of the device.

EN 6

desiccant dehumidifier TTR 800 / TTR 1400

Page 8

Types of application

regeneration air intake (19)

humid air discharge (18)

process air (11)

dry air (17)

TTR

Pressure-neutral

dual air circuits

inside the device

TTR

Pressure-neutral

dual air circuits

inside the device

ΔP=0

TTR

excess pressure

P+

P-

ΔP

Key for exemplary types of application:

Circulating air drying for indoor installation

The device is positioned in the room to be dehumidified.

• The device operates in recirculation mode.

• The air transport line for the regeneration air inlet(19) is

to be led outside.

• The air transport line for the humid air outlet

(regeneration air(18)) is to be led outside.

Example 1: Circulating air drying for indoor installation

Circulating air for drying outdoor installation

• The air transport line for the process air inlet(17) is led

into the room to be dried in order to take in the humid

air from the room.

• The air transport line for the dry air outlet(11) is led into

the room in order to feed dry air into it.

Ventilation mode for outdoor installation

• The air transport line for the dry air outlet(11) is led into

the room to be dehumidified in order to feed dry air into

it.

Example 2: Circulating air drying for outdoor installation

Example 3: Ventilation mode for outdoor installation

7 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 9

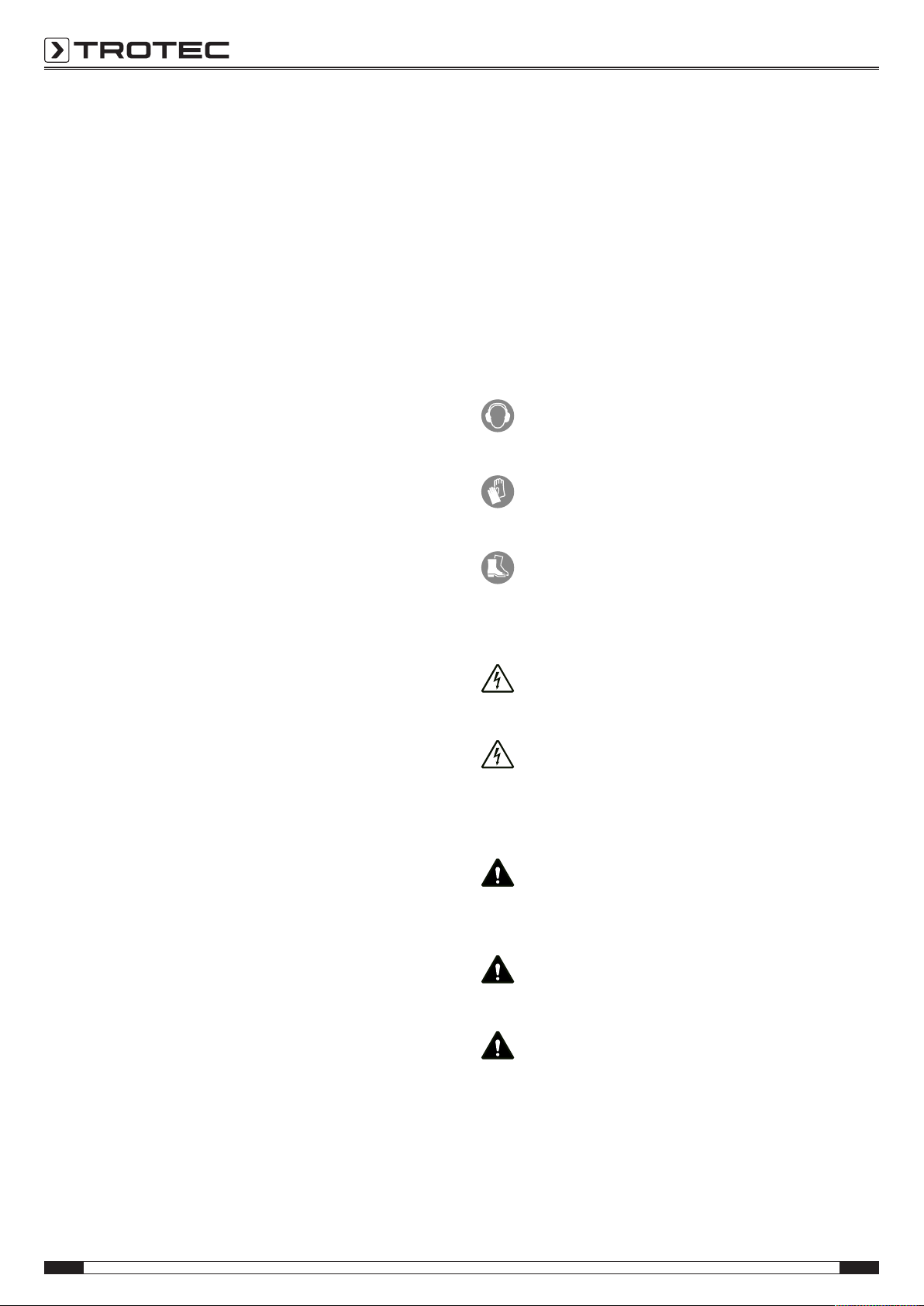

Device depiction

9

10

11

12

13

14

11

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

Product labelling

For an unmistakable identification, the desiccant dehumidifier is

provided with a nameplate.

The nameplate is located inside the control box and in the area

of the cable inlet.

The nameplate bears a CEmark.

No. Designation

9 Front cover (hinged)

10 Air filter access and maintenance doors

11 Dry air outlet with connection for an air transport line

12 Forklift pockets

13 Main switch with emergency stop function

14 Cable gland for mains cable (on site)

15 Control panel

16 Electrical control box cover

17 Process air inlet with connection for an air transport

line

18 Humid air outlet (regeneration air) with connection for

19 Regeneration air inlet with connection for an air

20 Control box ventilation system incl. air filter(s)

21 Cable inlet for control lines

an air transport line

transport line

Key

The illustration features the nameplate of a TTR5200 by way of

example. The device-specific information and technical data

differ depending on the model and the selected options (see

Technical annex).

No. Designation Unit

22 Type or device name

23 Trotec item no.

–

–

24 Dehumidification capacity [kg/h]

@ 20°C/ 60%RH

25 Power connection

–

26 Power consumption P= [kW]

I= [A]

@400V

27 Mains supply [A]

28 Operating range [°C]

29 Dry air volume [m3/h]/ [Pa]

30 Regeneration air volume [m3/h]/ [Pa]

31 Weight [kg]

32 Version

33 Serial number

–

–

EN 8

desiccant dehumidifier TTR 800 / TTR 1400

Page 10

Transport and installation

Warning

Risk of severe injuries due to falling device.

The device may only be lifted by use of the forklift

pockets or lifting straps. Pipe sockets or other

attachment parts must not be used as lifting points!

The carrying capacity of the lifting gear must be

suitable for the weight of the device (see Technical

annex).

Optionally the device is delivered with a transport frame incl.

crane lifting lugs with holes for crane eyes or similar (see

Technical annex).

The following should be observed before transporting the device

using lifting gear:

Warning

Risk of death due to suspended loads.

Make sure that nobody is situated in the immediate

proximity.

• Only instructed persons are allowed to perform the

transport by use of lifting gear.

• Consider the centre of gravity when transporting the load.

Installing the device

• Position the device on firm, dry and level ground.

Depending on the floor load capacity a panel for weight

distribution is to be provided. A proper foundation is not

necessary.

– Avoid slippery and oscillating ground.

– Position the device allowing a sufficient distance for air

inlet and outlet and for connecting the air transport

lines.

– Make sure there is enough space to operate and

maintain the device (see Technical annex).

• Only place the device under a roof. On request devices

with a higher type of protection are available for outdoor

installation. Make sure that no water can reach the device

interior via the air inlet and outlet openings. If required,

connect an air transport line to minimize the risk.

Optionally the device is delivered with weather protection

equipment. Do not expose the device to the weather

without this weather protection equipment.

• Ensure a sufficient distance between humid air outlet and

air inlet. In case of direct-intake devices the distance

between humid air outlet and the suction nozzles should

amount to at least 2m to prevent the humid exhaust air

from being sucked right back in.

• The air transport lines must be designed for the available

static compression of the fans (see Technical annex).

• The regeneration exhaust air line(C) must be laid with a

slight decline (min. 1.5%) so that possibly accumulating

condensate cannot flow back into the device or obstruct

the air flow. If an incline cannot be avoided, it is necessary

to deliberately create a nadir (lowest point) for draining

(e.g. using a syphon).

Inserting the air filter

Note

To avoid damages to the device, do not operate the

device without inserted air filters!

Prior to installation and switching the device on, check

whether all air filters are inserted.

Information regarding the air filter installation and filter change

can be found in the Maintenance chapter.

9 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 11

Schematic diagram

A

C

B

D

D

34

35

Optionally, a mirror-inverted assembly is also possible.

Assembly and installation

Power connection

Warning of electrical voltage

Work on the electrical components must only be

carried out by a qualified electrician!

The illustrations below feature the series from the TTR800

through to the TTR3700 and can be used exemplarily for all

device versions of the TTRseries. The mains supply terminals

are situated directly at the main switch behind the main switch

cover.

1. Loosen the two screws(34) of the front cover.

No. Designation

A Process air inlet

B Regeneration air inlet

C Humid air outlet (regeneration air)

D Dry air outlet

2. Slightly lift the front cover and open it.

3. Loosen the screws(35) of the electrical control box cover.

4. Remove the electrical control box cover either by pulling it

forwards or by lifting it.

EN 10

desiccant dehumidifier TTR 800 / TTR 1400

Page 12

5. Guide your mains cable through the cable gland at the

device and connect it to the power supply terminals. To

connect the device please observe the wiring diagram in

the technical annex. The phase sequence can be chosen

freely.

6. Fix the cable, screw down the cable gland and observe the

strain relief.

In the device version shown below, the mains supply terminals

are also situated directly at the main switch behind the main

switch cover. The illustrations below feature the series from the

TTR5200 through to the TTR13500:

3. Guide the mains cable through the cable gland at the

device and connect it to the power supply terminals. To

connect the device please observe the wiring diagram in

the technical annex. The phase sequence can be chosen

freely.

4. Fix the cable, screw down the cable gland and observe the

strain relief.

Connecting the control lines

Remote ON/OFF

If you want to operate the device optionally via remote mode,

e.g. from a remote control centre or factory master control

system, connect the external switching contact (N/Ocontact) to

the respective terminals. The control voltage amounts to 24V

DC (for detailed information please refer to the wiring diagrams

in the technical annex).

Control via external hygrostat (%RH)

You can control the device via an external hygrostat (option).

The control voltage amounts to 24VDC.

The external hygrostat is to be connected to the terminal strip in

accordance with the wiring diagram (see Technical annex).

If the relative humidity level falls below the set target value, the

contact closes and terminates the dehumidification process.

The illustrations below show the terminals for remote switch-on

and relays with potential-free contacts:

1. Set the main switch to 0.

2. Loosen the screws and open the cover.

ð The cover can only be opened if the main switch is set

precisely to the 0position!

11 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 13

Ventilation mode process air

Select the operating mode Ventilation mode process air if

constant air movement is also required at times without the

need for drying. If so, reposition the respective jumper (blue) of

the corresponding terminals (for detailed information please

refer to the wiring diagrams in the technical annex).

The process air fan keeps running even if the hygrostat

switches off and the external contact of the hygrostat is opened.

Hygrostat and fan operation are only switches off when

switching of the device (STOP), the fan will be switched off at

the end of the rundown period.

You can always change back to the normal dehumidification

operating mode by replugging the jumper.

Ventilation mode process air can be activated both when in onsite or remote mode.

Remote signalling contacts

Remote signalling is effected by means of potential-free

changeover contacts that can be tapped directly at the

corresponding relays.

1. BETRIEB/ OPERATION

2. STÖRUNG/ FAULT

3. FILTER/ WARNING

These remote signalling contacts correlate with the lamps on

the control panel (see description in the Operation chapter).

For the correct assignment observe the wiring diagrams in the

technical annex.

Inserting the air filter

Check whether all air filters are inserted before switching the

device on for the first time. The illustrations below are

schematic representations:

1. Open the left door of the control cabinet.

2. Check whether the correct filters have been inserted in

both the process air inlet and the regeneration air inlet (see

Technical annex).

3. Check whether the filter for the control box ventilation

system has been inserted:

EN 12

desiccant dehumidifier TTR 800 / TTR 1400

Page 14

Start-up

Requirements

• Check whether all air filters have been inserted properly.

• Check whether all doors, flaps and covers are closed or

screwed in place.

• Check whether all air transport lines have been connected

and screwed down properly and whether they are secured

by means of tension belts.

• Check whether all air transport routes are clear and free

from foreign objects or obstacles.

• Check the permissible operating conditions according to

the technical data.

• Make the basic settings while observing the information

contained in the Technical annex if applicable.

Warning of electrical voltage

Work on the electrical components must only be

carried out by a qualified electrician!

Make sure that the electric installation complies with

the technical documentation.

Ensure the continuity of the protective conductor

system.

Initial start-up

If the "Flowmatic S" option is installed, continue with step4.

For an ideal operation of the device the regeneration air flow

must be adjusted according to the technical data.

The potentiometers can be accessed via the front cover:

– target value fan speed process air(Proz.) and

– target value fan speed regeneration air(Reg.) for adjusting the

air volume via the fan speed.

For adjustment work, measurements or the like, which have to

be carried out during operation, one must on principle switch

over to manual operation (ON-SITE)!

1. Turn the selection switch to positionI.

2. Open the front cover(9).

ð The two potentiometers are located behind the front

cover on the right-hand side:

– target value fan speed process air(Proz.) and

– target value fan speed regeneration air(Reg.) for

adjusting the air volume according to the information

provided in the technical annex.

3. Adjust the regeneration air volume in ON-SITE mode.

This also allows an adjustment to the on-site air transport

lines for optimum operation.

4. The proceed as with the normal start-up.

13 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 15

36

41

37

39

40

38

13

Operation

No. Designation

13

Main switch with emergency stop function

0: The device is switched off.

I: The device is switched on.

36

BEREIT / STAND BY lamp

Indicates operational readiness for REMOTE operation:

- mains voltage present

- selection switch in positionII – REMOTE OPERATION

- REMOTE-ON not yet activated

37

FILTER lamp

Indicates the insufficient air flow rate of one or more air

filters. The differential pressure controllers monitor the air

flow rate of the filters and so report a dirty filter at an early

stage.

Replace a dirty filter in due time to prevent an impairment

of the device functions.

38

STÖRUNG / FAULT lamp and RESET button

Collective fault message with device switch-off (STOP)

tripped by

- a safety temperature limiter (STB RHZ) to monitor the

max. permissible temperature after heating (thermostat

maximum)

- a safety temperature limiter (STB RAL) as rotation control

for the rotor; it is situated in the exhaust air flow and

tripped by an inadmissible temperature rise resulting from

rotor standstill

- a differential pressure switch (ΔP switch) to monitor the

air flow direction and the flow rate of the regeneration air

- phase error, check the feed-in and fusing

- motor fault of the fans regeneration air or process air

- possibly collective fault messages of additional options

(see Technical annex)

No. Designation

39

BETRIEB / OPERATION lamp

Indicates the start-up of the device after switching it on via

- selection switch to positionI

or - selection switch to positionII and remote-ON contact

closed

40

Selection switch ON-SITE/REMOTE OPERATION

I – 0 – II

I: ON-SITE OPERATION

II: REMOTE OPERATION

0: Control OFF (STOP)

41

NACHLAUF / RUN ON lamp

Indicates the rundown operation of the device at operating

temperature after switching off the control voltage.

Note:

The main switch serves for switch-on and may only be used as

emergency stop switch for disconnection from the mains in

case of an emergency.

Warning

In order to prevent a defect of the heater battery

due to heat accumulation or an unnecessary

tripping of the safety temperature limiterSTB when

switching off the unit, the regeneration air blower

is provided with a temperature-controlled rundown

period of approx. 5minutes.

Wait until the entire rundown period has lapsed before

accessing internal parts of the device.

For normal switch-off (STOP) please use the selection switch

ON-SITE/REMOTE OPERATION I–0–II(40), which initiates the

rundown function (NACHLAUF/ RUNON lamp(41) illuminated).

Only disconnect the device from the mains for transport or

storage via the main switch at the end of the rundown period.

Switching the device on

ü The device is connected to the properly fused feed-in.

1. Turn the main switch(13) to positionI.

2. Select the desired operating mode via the selection

switchI–0–II(40):

ð A) on-site operationI

Turn the selection switch to positionI: the BETRIEB/

OPERATION lamp(39) is illuminated – the device starts

up.

ð B) remote operationII

Turn the selection switch to positionII: the BEREIT/

STANDBY lamp(36) is illuminated until the REMOTE-ON

contact is activated – as soon as the REMOTE-ON

contact has been activated, the BETRIEB/ OPERATION

lamp(39) will be illuminated – the device starts up.

EN 14

desiccant dehumidifier TTR 800 / TTR 1400

Page 16

Note

In order to attain the full dehumidification performance

and to prevent damages due to an insufficient

regeneration air flow, the air volumes specified in the

technical annex must be observed.

Dirty air filters reduce the volumetric flow rate and

must be replaced in due time.

Switching the device off (STOP)

1. Turn the selection switch(40) to position0 or open the

REMOTE-ON contact.

ð The BETRIEB/ OPERATION lamp(39) goes out.

ð The NACHLAUF/ RUN ON lamp(41) is illuminated.

ð The device switches over to rundown operation.

Rundown operation

In order to discharge the trapped heat from the heater, the

regeneration air blower will continue to operate for approx.

5min (temperature-controlled). The control unit remains active.

During rundown the device may be restarted at any time.

The fans start up smoothly, delayed by approx. 20s the device

switches into normal operation.

Upon expiry of the rundown period the regeneration air blower

stops, the indicator lights go out.

Errors and faults

The fault recognition switches the device off (STOP), only the

rundown operation remains active.

After having eliminated the cause of the fault, the fault message

of the STB or rather the STB is to be reset via the corresponding

reset button.

1. STB RHZ

2. STB RAL

3. - possibly reset button for additional options

(see Technical annex)

1. Open the front cover and remove the respective cover of

the reset buttons.

Shutdown

For a complete switch-off, e.g. for transport or maintenance

activities, switch the emergency stop main switch(13) to the

0position at the end of the rundown period.

Storage

• Store the cleaned device in a dry location and protect it

against dust.

• Before restarting the device, check the condition of the

power cable. If you are doubting its perfect condition, have

the cable repaired or call the customer service.

• Have the device checked once a year by an electrically

skilled person at any rate.

2. Press the corresponding reset button and reattach the

cover.

3. Then press the STÖRUNG / FAULT – RESET button(38) to

acknowledge the STB faults or the ΔP fault message.

15 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 17

Troubleshooting

Fault Cause of error Measure

"Fault" indicator light illuminated • rotation control (STB RAL) responds

• rotor at a standstill

• process air flow interrupted

• regeneration air temperature increased

inadmissibly

• Check thermostat setting.

• Check rotor drive and toothed belt for

proper functioning, repair if necessary.

• Check process air fan for proper

functioning.

• Check throttle valves, if any.

• Press reset button.

• maximum thermostat (STB RHZ) responds

• regeneration air flow interrupted

• regeneration air temperature increased

inadmissibly

• Check thermostat setting.

• Check regeneration air fan for proper

functioning.

• Check throttle valves, if any.

• Check filters.

• Press reset button.

• differential pressure switch for

regeneration air does not switch

• Check hose connection.

• Check setting, correct if necessary.

• Check pressure switch for proper

functioning.

• fan does not rotate/fans do not rotate • See below.

Insufficient dehumidification

performance

• air volumes incorrect • Calibrate air volumes.

• Check filters.

• Check housing (panels/doors) for air leaks.

• Check radial and circumferential seal at

the rotor.

• Check throttle valves, if any.

• Check rotational direction of fans.

• regeneration heating failed • Check heater for proper functioning,

measure temperatures, have it replaced if

necessary.

• Check fuses, replace them if necessary.

• Check relays, contactors, have them

replaced if necessary.

• Check control thermostat setting.

• filter dirty • Change filter.

• process air flow interrupted • Check process air fan for proper

functioning, have it replaced if necessary.

• Check air passages, flaps.

• rotor is not turning • Check belt/chain tension.

• Check drive motor for proper functioning,

have it replaced if necessary.

• Check toothed belt pulley for tight fit,

fasten it if necessary.

• incorrect rotor rotation direction • Correct rotational direction.

EN 16

desiccant dehumidifier TTR 800 / TTR 1400

Page 18

Fault Cause of error Measure

Insufficient dehumidification

performance

• seals are not seated properly or are

defective

• Correct seal position (particularly radial

seals) or replace them.

• air leaks at nozzles and fans • Eliminate air leaks.

• regeneration air flow interrupted • Check regeneration air fan for proper

functioning.

• Check air passages, flaps.

• rotor defective • Have rotor replaced.

Fans do not rotate • electrical supply interrupted • Check and restore connection.

• phase missing • Check phases.

• impeller not fastened • Fasten impeller.

• motor defective • Have motor replaced.

Metallic sounds, rattling • fan impeller not fastened • Check process air and regeneration air

fan, have them replaced if necessary.

• Fasten impeller.

• toothed belt or chain of rotor drive slips • Check toothed belt/chain tension.

• Check toothed washer/pinion and carrier

(along rotor circumference) for damage.

• Check rotor for smooth running, replace

bearing if necessary.

Warning

This device can be dangerous if it is repaired by

unqualified persons in an improper way. Any faults the

elimination of which requires mechanical or electrical

intervention may only by carried out by qualified

specialists or service staff.

If the fault cannot be rectified despite following the

checklist above, please contact one of our subsidiaries

or our headquarters.

17 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 19

Maintenance

Activities required before starting maintenance

Warning of electrical voltage

Before starting any internal work on the device, switch

the main switch to position0. For disassembly a cooldown period of at least 30minutes should be

observed. Before starting any internal work, check that

all motors and fans are at a standstill and that the

device has cooled down.

Activities required before starting maintenance

• For adjustment work, measurements or the like which

have to be carried out during operation, always switch over

to manual operation (ON-SITE).

• If the dehumidifier was previously operated, one is to wait

for the end of the rundown period before switching the

device off and for the end of the cool-down period of at

least 30minutes before disassembly.

• Secure all plant sections and operating media (such as

vapour) up- and downstream the dehumidifier against

inadvertent start-up.

• For all maintenance, inspection and repair work, deenergize the dehumidifier and secure the main switch

against inadvertent restart.

• Attach a warning sign and secure the device against

restart.

Air filters for air inlet, dry air and regeneration air

1. Open the door for accessing the air filter behind the air

inlets. In case of a standard version this means the left

door of the cabinet; if mirror-inverted, use the right door.

2. Pull the filters for the individual air inlet openings out

towards the front.

3. Change the filters as needed.

Notes on maintenance and repair activities

• Perform the stipulated adjustment, maintenance and

inspection work in due time.

• Inform the operating personnel before starting any

maintenance and repair work.

• Upon completion of the maintenance work check all

loosened screwed connections for tight fit.

• Upon completion of the maintenance work check all safety

devices for proper functioning.

Air filter change

The filter change intervals depend on the degree of air pollution

and the filter quality. Dirty filters impair the performance ability

of the dehumidifier.

A filter change is required at the latest when the filter change

indicator FILTER on the control panel lights up.

4. Then close the cabinet door again.

EN 18

desiccant dehumidifier TTR 800 / TTR 1400

Page 20

Air filter of the electrical control box

Check the air filter of the electrical control box once a month

and replace the filter mat as needed.

1. To do so, open the filter flap at the electrical control box.

2. If it is dirty, replace the filter. Then close the flap again

until it snaps into place.

19 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 21

General maintenance

Safe operation of the device requires the components listed

below to be checked and cleaned after 12 months at the

If the device is used in rough surroundings with an increased

dust exposure, we recommend performing a visual inspection

during every air filter change.

latest or after every 4000 operating hours as well as all

damaged components to be replaced. Furthermore, an electrical

safety test must be conducted.

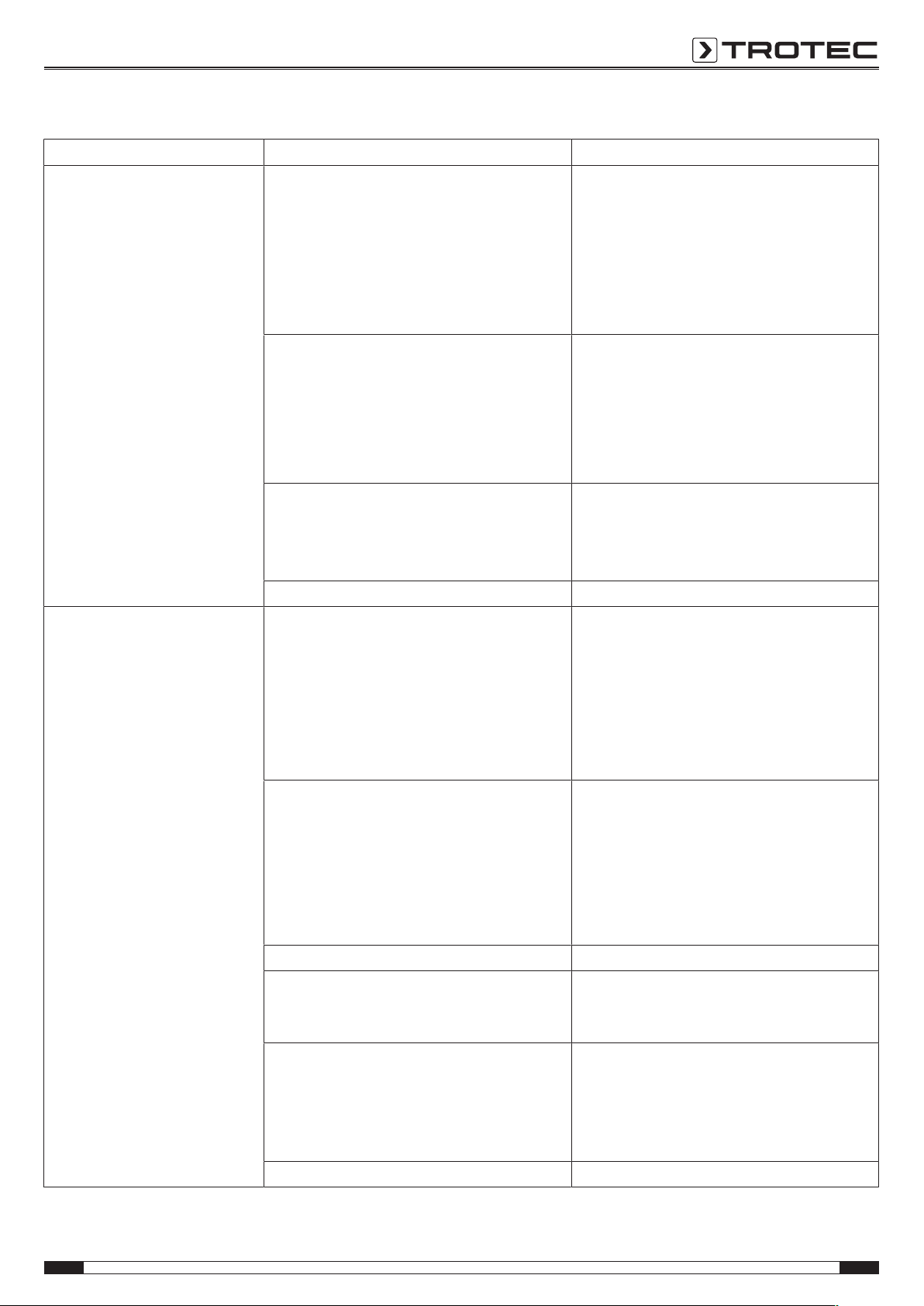

Component Activity Comments Replacement/

interval

Differential pressure switch Function test Switching point As required if

defective

Gear motor Function test 4,000 h

Solid-state relay SSR Function test Disconnection As required

Power relay Function test Disconnection As required

Emergency stop main switch Function test Disconnection of all phases As required

Regeneration heating Function test Measure currents, clean surface if necessary As required

Safety temperature limiter Function test Switching point, clean capillary tube As required

Temperature probe Function test Check signals, clean probe As required

Temperature monitor Function test Switching point, clean capillary tube As required

Thermal switch NO 60 °C Function test Switching point As required

Time relay Function test Time setting As required

Air filter Visual inspection Check condition, replace if necessary Filter indication

Filter fan Visual inspection Filter change, clean impeller As required

Radial seals, desiccant wheel Visual inspection Check condition, replace if necessary As required

Control cabinet Visual inspection Clean, blow out dust if necessary As required

Desiccant wheel Visual inspection Obstructions, check surfaces for damage, replace if

As required

necessary

Door seals Visual inspection Check condition, replace if necessary As required

Circumferential seals, desiccant wheel Visual inspection Check condition, replace if necessary As required

Regeneration air fan Visual inspection Clean impeller, check speed adjustment, measure

4,000 h

currents

Dry air fan Visual inspection Clean impeller, check speed adjustment, measure

4,000 h

currents

Toothed belt Visual inspection Check tension and condition, replace if necessary As required

Screw terminal connections Fit Retighten if necessary As required

Toothed belt pulley Fit Check connection to gear shaft As required

Care

Do not use a cleaning agents containing solvents to avoid

damage to the surfaces and operating elements of the devices.

Clean the surfaces and operating elements of the devices with a

damp cloth and solvent-free cleaning agents only.

EN 20

desiccant dehumidifier TTR 800 / TTR 1400

Page 22

Harmful influences on rotors

The listed substances remain in the rotor material or the rotor

elements and can bring about the following effects:

Some of the substances and compounds listed below are typical

examples for substances dissolving the honeycombed silica gel

rotors or else negatively affecting the dehumidification

performance.

• Reduced performance owing to the clogging of the silica

gel's pores

• Reduced performance owing to the chemical reaction with

the silica gel

The sorption rotor should not be charged with air which is

contaminated with the following or similar substances. Even

minor concentrations in the air can have lasting harmful effects

on the rotor material and the sorption capacity.

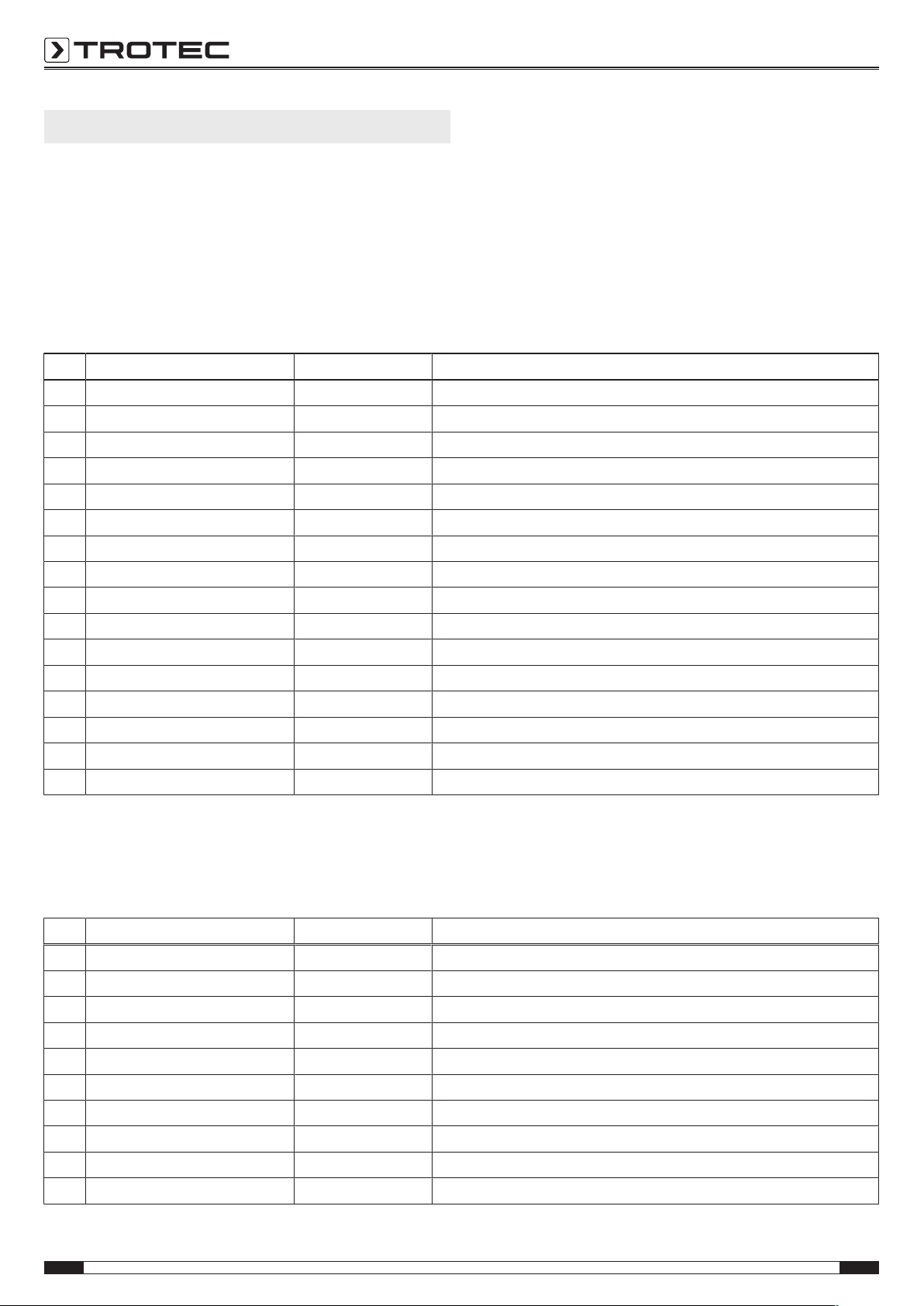

A) Inorganic substances (examples)

No. Substances Chemical formula Effects

1 lithium chloride LiCl reduced productivity of the silica gel

1

2 sodium hydroxide NaOH destruction of the silica gel structure

3 potassium hydroxide KOH destruction of the silica gel structure

4 sodium chloride NaCl reduced productivity of the silica gel

5 potassium chloride KCl reduced productivity of the silica gel

6 calcium chloride CaCl

7 magnesium chloride MgCl

8 ammonia NH

3

2

2

reduced productivity of the silica gel

reduced productivity of the silica gel

destruction of the silica gel structure

1

1

1

1

9 hydrofluoric acid HF destruction of the mechanical strength of the rotor material

10 aluminium chloride AlCl

3

reduced productivity of the silica gel

11 sea water reduced productivity of the silica gel

1

1

12 steam with a high temperature destruction of the silica gel structure

13 softener clogs the silica gel pores

14 strong acids pH ≤ 2...3 destruction of the mechanical strength of the rotor material

15 bases pH ≥ 7...8 destruction of the sorption capacity of the silica gel

16 amines R-NH

2

reduced productivity of the silica gel

1

B) Organic substances (examples)

The solvents or volatiles listed below have a high boiling point

and a low vapour pressure. Provided these substances are

adsorbed by silica gel, they remain in the material on a

permanent basis.

No. Substances Chemical formula Effects

1 oil mist clogs the silica gel pores

2 cyclohexanone C6H10O reduced productivity of the silica gel

3 isopropyl alcohol CH3H8O reduced productivity of the silica gel

4 o-xylene C8H

5 m-xylene C8H

6 p-xylene C8H

10

10

10

reduced productivity of the silica gel

reduced productivity of the silica gel

reduced productivity of the silica gel

7 phenol C6H5OH reduced productivity of the silica gel

8 o-dichlorobenzenes C6H4Cl

2

reduced productivity of the silica gel

9 methyl bromide CH3Br reduced productivity of the silica gel

10 glycerin C3H8O

1)

Reduces the internal pore surface of the silica gel leading to a loss of performance.

3

reduced productivity of the silica gel

1

1

1

1

1

1

1

1

1

21 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 23

Disposal

The icon with the crossed-out waste bin on waste

electrical or electronic equipment stipulates that this equipment

must not be disposed of with the household waste at the end of

its life. You will find collection points for free return of waste

electrical and electronic equipment in your vicinity. The

addresses can be obtained from your municipality or local

administration. For further return options provided by us please

refer to our website www.trotec24.com.

The separate collection of waste electrical and electronic

equipment aims to enable the re-use, recycling and other forms

of recovery of waste equipment as well as to prevent negative

effects for the environment and human health caused by the

disposal of hazardous substances potentially contained in the

equipment.

The information regarding proper disposal of the desiccant

dehumidifier is based on the current status of May2017.

The disposal regulations are likely to have changed by the time

of disposal. Therefore you have to inform yourself of the current

disposal regulations and take changes into account.

You are responsible for deleting any personal data stored on the

waste equipment to be disposed of.

Warning

Potential environmental hazard due to incorrect

disposal.

Failure to follow the rules on disposal or an improper

disposal of contaminated air filters can lead to

environmental hazards.

In order to carry out the disposal professionally, you

have to be a qualified specialist.

Recycle empty batteries.

Observe the currently applicable regional and, as the

case may be, national disposal regulations.

Supplies

1. Shut down the desiccant dehumidifier definitely.

2. Disconnect the desiccant dehumidifier definitely from any

supplies (current, water etc.).

3. Remove any supplies such as air filters, oils, coolant,

batteries etc.

4. Dispose of these supplies separately according to the

applicable regulations.

Components of the desiccant dehumidifier

The desiccant dehumidifier is composed of the following

disposable materials:

• Steel, sheet steel, hardened steel, e.g. screws, motor

shafts, component parts

• Different types of plastic, e.g. installation material,

insulation material, window

• Rubber parts, e.g. seals and feet

• Plastic hoses

• Power cables, electric lines, electrical devices such as

motors, controls, electronic components, electrical control

elements, installation material, sensors

Final disassembly

For disassembly of the desiccant dehumidifier please proceed

as follows:

1. Carefully disassemble the assemblies and parts that you

want to continue to use in order to avoid damage to these

parts.

2. Take notes so that you can re-assemble the used parts

correctly.

3. Provide appropriate temporary storage facilities to be able

to store the amounts of different materials separately.

4. Use the specified fastening elements for disassembly:

Remove the specified fastening elements to separate the

parts from one another.

5. If possible, do not use any angle grinders or welding

equipment as this would cause unnecessary additional

effort.

6. Always work in pairs when disassembling large parts.

7. After disassembly has been completed, have the parts

collected by a qualified disposal company.

8. Store parts to be used again.

Return to manufacturer

The desiccant dehumidifier does not comprise any components

that are intended to be returned to the manufacturer.

Notification of authorities and manufacturer

An official deregistration of the desiccant dehumidifier is not

required. This could, however, change if the disposal

regulations are amended. Make sure to dispose of the desiccant

dehumidifier correctly.

Should you be unable to dispose of the device properly, please

contact the manufacturer and instruct him to carry out the

disposal on your behalf.

EN 22

desiccant dehumidifier TTR 800 / TTR 1400

Page 24

Options

Control module Millenium option

With four-line plain text display for status, warning and fault

messages.

The device comes equipped with a freely programmable logic

module offering the following functions:

Basic functions

• Function monitoring of fans, heating system and rotor drive

• All warnings or faults are displayed in plain text (for full

particulars see chapter Errors and faults)

• Information regarding important basic settings and

operating conditions (target and actual values) is displayed

in plain text

• The energy management is optimized by a constant

monitoring and continuous control of the regeneration

temperatures RHZ and RAL

Further optional functions (factory configuration required)

• continuous control of the outlet humidity level in partialload operation (only in combination with a moisture

measuring device and humidity control kit)

• continuous control of the outlet temperature of the dry air

(only in combination with a temperature probe,

temperature control kit, additional electrical heating or air/

water heat exchanger with control valve)

• 2-stage air volume switching for reducing the outlet

humidity level through a lower volumetric flow (only in

combination with FlowmaticS)

• electric reheater for heating the dry air additionally

The Millenium control module is located behind the left section

of the front cover inside the electrical control box. To be able to

read the control module's display, first open the front cover of

the device (see instructions):

Operation

The PLC will be activated as soon as the main switch is

switched on. The start screen (return) can be opened at any

time by pressing the [ESC]button.

Returning to the start screen is also possible via the [B]button:

You can browse the screens using the buttonsA and B. The

following screens will be displayed:

• Welcome and version number.

• Indication of target and actual values for RHZ and

RALtemperatures (humid air outlet).

• Indication of target and actual values for differential

pressure, humidity level, dew point. The display may vary

depending on the option installed.

• Indication of basic settings (distributed over several screen

pages).

• Display of basic settings

• Target value inputs for optional additional heating and

additional cooling.

• Target value input for optional switch-over to a lower dry

air volume.

23 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 25

Operation screens of the control module Millenium

1. Start screen

In addition to the contact data this screen also shows the version number of

the installed programme of your Millenium.

Please quote this when contacting.

2. Temperature screen

Display of maximum and actual values for the regeneration and exhaust air

temperatures

MAXIMUM RHZ Target value regeneration air temperature

ACTUAL RHZ Actual value regeneration air temperature

MAXIMUM RAL Target value regeneration exhaust air temperature

ACTUAL RAL Actual value regeneration exhaust air temperature

3. Temperature and rotor screen

T-RHZ MIN. Minimum temperature of the regeneration air after

completion of waiting period

DELAY-TIME Waiting period in seconds

CHECKSUM Counter for automatic switch-off when hot

ROTORSPEED Current control value of the rotor speed [1/10h]

4. Relative humidity screen (optional)

1Ext/2Int/3P Selection target value external=1, internal=2,

control value external=3

ACT.Moist Actual value humidity in [%RH]

SetP.Int. Target value humidity in [%RH], can be modified

SetP.Ext. Target value external humidity in [%RH], display only

5. Dew point screen (optional)

1Ext/2Int/3P Selection target value external=1, internal=2,

control value external=3

ACT.Moist Actual value humidity in [°Cdp]

SetP.Int. Target value humidity in [°Cdp], can be modified

SetP.Ext. Target value external humidity in [°Cdp], display only

EN 24

desiccant dehumidifier TTR 800 / TTR 1400

Page 26

6. Process air regulation – additional heating screen (optional)

1Heat2Cool3P Heating=1, cooling=2, transmission external

signal=3

HEAT. ON Switch-on point for additional heating

HEAT. OFF Switch-off point for additional heating

ACT.TEMP. Actual value of the temperature sensor

7. Process air regulation screen (optional)

1Heat2Cool3P Heating=1, cooling =2, transmission external

signal=3

ACT.TEMP. Actual value of the temperature sensor

SetP.Int. Internal target value

>-20SetExt. External target value

Value above -20°C= PLC switches over from

internal to external target value.

Value below -20°C= The internal target value

applies.

8. Process air regulation screen (optional)

1Heat2Cool3P Heating=1, cooling=2, transmission external

signal=3

ACT.TEMP. Actual value of the temperature sensor

Stw In Ext. External control value

OutValveDry OutputO6 PWMsignal

Control value for control valve

9. Dry air fan screen (optional)

Speed regulation of the process air fan if activated in the service menu

SWITCHPOINT Switching point input

SPEEDSTEP Display of high/low speed level

HIGH=0/ LOW=1 HIGH=0: high speed

LOW=1: low speed

10. Control valve regeneration heating screen (optional)

1Ext2Int3Pas Selection target value external=1, internal=2,

control value external=3

Set.RegValve External signal

Out RegValve OutputO6 PWMsignal

Control value for control valve regeneration heating

25 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 27

Info

All optional displays only appear if the respective

function was activated at the factory.

Basic settings

The basic settings are made in the factory. Signal conversions

and the corresponding scales must be coordinated with Trotec

prior to delivery or can be adjusted (optionally) during start-up

by Trotec service personnel.

For applications with moisture control it is recommended to

request the Trotec service personnel for possibly required fine

adjustments of the control parameters.

Changing values

ü Values that can be modified are highlighted by flashing bars

(black bar in the example below).

Emergency operation

If the Millenium logic module fails, the following changes have

to be made:

• Setting the regeneration air heating to emergency

operation

Warning of electrical voltage

Work on the electrical components must only be

carried out by a qualified electrician!

Please proceed as follows to set the regeneration air heating to

emergency operation:

1. Within the screen you can move up and down using the

buttons+ and -.

2. In order to edit the value, press the OKbutton.

ð The flashing bar disappears and the value is displayed.

3. Press the buttons+ or - to increase or reduce the value.

4. Confirm your selection by pressing the OKbutton.

Abort unwanted changes using ESC.

5. Press the buttons+ or - to go to the next changeable

value.

6. Repeat the steps 2 to 4 until all values are set.

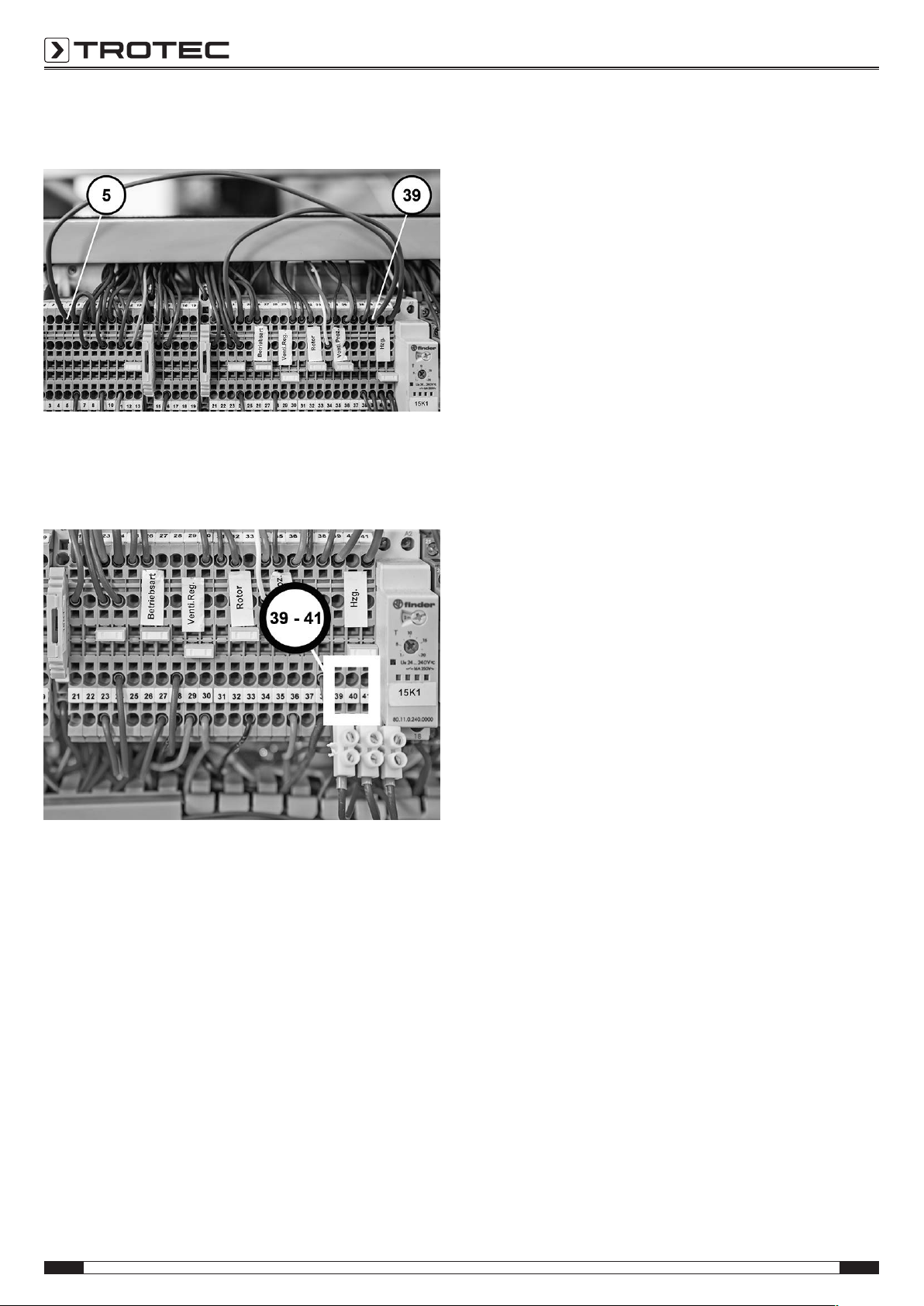

1. Find the terminals5, 23 and 39 to 41 on the terminal

stripX6.

2. Set the first jumper from X6.23 to X6.41 as shown below.

EN 26

desiccant dehumidifier TTR 800 / TTR 1400

Page 28

3. Set the second jumper from X6.5 to X6.39 as shown

below.

4. In the second line from the bottom, disconnect the three

wires of the contacts X6.39, X6.40, X6.41 as shown below.

5. Isolate each of the three disconnected wires using a luster

terminal or similar.

Warnings and faults

Note

Rectify any faults immediately to ensure economical

operation of the device.

• During operation the electrical components relevant for the

respective operating mode are monitored for proper

functioning.

• In case of failure or malfunctions plain text messages are

indicated on the display of the logic module so as to enable

quick troubleshooting.

• Depending on the level of impairment of the device's

operational safety the messages are divided into warnings

and faults.

• A warning does not entail the shutdown of the device and

is displayed by periodically recurring plain text messages

on the display. The "warning" indicator light lights up.

• In case of faults the device is shut down (STOP) and the

indicator light "fault" lights up.

• For reasons of safety the device can only be restarted after

the faults have been rectified and the RESET button has

been actuated (=>deletes the error memory).

• The source of a fault will be permanently indicated on the

display. Until the fault is rectified, it will be displayed again

before long whilst the action linked to the fault is triggered.

Error and fault messages can be reset by pressing the reset

button.

6. Set a jumper from X6.40 to X6.41. The modifications are

completed.

27 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 29

Warnings

Plain text message Cause of error Measure

FILTER WECHSELN (change filter)

• filter dirty • Replace all air filters.

The differential pressure switches switch

via the air filters when the max.

permissible pressure drop is exceeded.

HEIZUNG ZU KALT (heating too cold)

After 30min under full load the RHZ

temperature must reach a value of at

least 60°C, in controlled operation the

value is not prompted.

• regeneration air not reaching the

minimum temperature

• regeneration air volume too high

• intake temperature too low

• Check heater current, if required,

repair heater battery.

• Check regeneration air volume.

• Check switching devices and contacts.

• control signals interrupted

WENIG REGEN.-LUFT (little amount of

regeneration air)

Differential pressure switch monitors the

pressure loss via regeneration heating

and regeneration sector at the rotor and

releases the heating when a minimum

value is reached.

• regeneration air volume too low

• regeneration air filter dirty

• pressure loss at piping or on-site

components too high

• regeneration air fan defective or

phases faulty

• Adjust the regeneration air volume.

• Replace air filter.

• Check piping.

• Check rotary field.

• Replace fan.

• incorrect flow direction

• negative pressure at regeneration air

inlet to high

Faults

Plain text message Cause of error Measure

VENTI. PROZ.LUFT (fan process air)

Fault message from EC motor

VENTI. REGEN.LUFT (fan regeneration

air)

Fault message from EC motor

• fan reports a fault

• fan defective

• differential pressure transmitter

defective

• phase error/mains supply AC/DC

• fan reports a fault

• phase error/mains supply AC/DC

• fan defective

• Check fan, have it replaced if

necessary.

• Check wiring and contacts.

• Check mains supply.

• Adjust air volume.

• Check fan, have it replaced if

necessary.

• Check wiring and contacts.

• Check mains supply.

ROTOR-ANTRIEB (rotor drive)

Rotor rotation control/inductive proximity

switch is evaluated

• toothed belt slipping

• toothed washer loosened

• gear motor defective

• fuse tripped

• Check belt tension and carrier.

• Tighten toothed washer or have it

replaced.

• Check gear motor, have it replaced if

necessary.

• Check voltage supply and signal line of

gear motor.

THERMOSTATE (thermostats)

Safety temperature limiters (STB) are

prompted.

If an additional heating is used, the STB

is prompted, too.

• At least one STB tripped. • Check STBs for proper functioning,

clean sensors if necessary.

• Selected max. RHZ is too high.

• Check setting at STB, adjust.

• Check regeneration air volume.

If the fault cannot be rectified, please contact one of our

subsidiaries or our headquarters.

EN 28

desiccant dehumidifier TTR 800 / TTR 1400

Page 30

Flowmatic S option

The configuration of FlowmaticS depends on your order.

The regeneration air control is configured at the factory and

does not require any further adjustment.

Target value control: The process air is set via the

"Venti.Proz." potentiometer or an external target value.

Setting the target value:

The upper "Venti.Proz." potentiometer

serves to define the target value for the

process/dry air volume in m3/h.

The topmost point roughly marks the

regulated nominal air volume and the

point in the middle marks the nominal

air volume in emergency operation.

The points indicate the rough settings for

emergency operation (failure of

FlowmaticS).

Setting the actual value:

The default values are additionally indicated on a label attached

to the FlowmaticS.

The settings for the actual value can be made in the

FlowmaticS menu:

Actual value control: Enter the desired target value at the

FlowmaticS(▲/▼). For this purpose, keep changing the

value until the desired value is shown on the display. The

FlowmaticS will now adjust the value until the fan has reached

its maximum speed.

Note

If "Base Setup" is displayed, you have browsed too far

through the menu. Press the "ESC"button in this case.

1. Press both buttons▲/▼ simultaneously. The

"INFO"menu will be displayed.

2. Press the ▼button until the "SETTING"menu is displayed.

3. Press the "P"button.

4. Press the ▼button until the "SETPOINT1"menu is

displayed.

5. Press the "P"button. The indication flashes.

6. Use the buttons▲/▼ to reduce or increase the set value

as desired.

7. Finally press the "P"button to save the settings for the

new target value.

29 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 31

Electric reheater for dry air option

For additional reheating of the escaping dry air.

The electric reheater is integrated in the "dehumidifier" housing

part of the TTR.

The reheating temperature is preset at the factory and generally

does not require any modification.

The access for setting the temperature "7B2" of the electric

reheater is located in the electrical control box behind the right

housing cover.

Resetting the safety temperature limiters (STB)

If the temperature limiter has tripped, it must be reset:

1. Open the right control cabinet cover (see Operation chapter

in the manual).

2. Unscrew the protective cap of the STB reset device "7B1".

3. The STB can now be reset with a pen or screwdriver.

Operation without electric heating

Warning of electrical voltage

Work on the electrical components must only be

carried out by a qualified electrician!

Should it be necessary to operate the desiccant dehumidifier

without the electric reheater, simply reposition the jumper.

The jumper for manual changeover is located behind the front

cover on the right-hand side.

Operation with electric heating Operation without electric heating

4. Afterwards, screw the protective cap back on.

EN 30

desiccant dehumidifier TTR 800 / TTR 1400

Page 32

Weather protection equipment option

The weather protection equipment prevents the harmful

penetration of rain water or similar and comprises:

• weather protection grids at air inlets

• additional seals

• exhaust pipe arc for humid air

• control panel protection

Note

Suitable on-site roofing or similar shall be provided in

order to protect the device from a high solar irradiation

(overheating) and snow loads (penetration of

snowmelt).

31 EN

desiccant dehumidifier TTR 800 / TTR 1400

Page 33

Technical annex

EN 32

desiccant dehumidifier TTR 800 / TTR 1400

Page 34

Page 35

Trotec GmbH & Co. KG

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...