Page 1

TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

EN

ORIGINAL INSTRUCTIONS

DEHUMIDIFIER

TRT-BA-TTK165ECO-TTK170ECO-TTK380ECO-TC2017-16-004-EN

Page 2

Table of contents

Notes regarding the instructions ..........................................2

Safety .....................................................................................2

You can download the current version of the instructions and

the EUdeclaration of conformity via the following link:

Information about the device................................................4

Transport and storage...........................................................6

Assembly and installation.....................................................6

Operation .............................................................................10

Available accessories..........................................................14

Errors and faults..................................................................15

Maintenance ........................................................................16

Technical annex...................................................................19

Disposal ...............................................................................22

Declaration of conformity ...................................................22

Notes regarding the instructions

Symbols

TTK 165 ECO

https://hub.trotec.com/?id=40461

TTK 170 ECO

https://hub.trotec.com/?id=40716

TTK 380 ECO

https://hub.trotec.com/?id=42742

Warning of electrical voltage

This symbol indicates dangers to the life and health of

persons due to electrical voltage.

Warning

This signal word indicates a hazard with an average

risk level which, if not avoided, can result in serious

injury or death.

Caution

This signal word indicates a hazard with a low risk

level which, if not avoided, can result in minor or

moderate injury.

Note

This signal word indicates important information (e.g.

material damage), but does not indicate hazards.

Info

Information marked with this symbol helps you to carry

out your tasks quickly and safely.

Follow the manual

Information marked with this symbol indicates that the

instructions must be observed.

Safety

Read this manual carefully before starting or using the

device. Always store the manual in the immediate vicinity

of the device or its site of use!

Warning

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future

reference.

This appliance can be used by children aged from

8years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

• Do not use the device in potentially explosive rooms.

• Do not use the device in aggressive atmosphere.

• Set the device up in an upright and stable position.

• Let the device dry out after a wet clean. Do not operate it

when wet.

2 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 3

• Do not use the device with wet or damp hands.

• Do not expose the device to directly squirting water.

• Never insert any objects or limbs into the device.

• Do not cover or transport the device during operation.

• Do not sit on the device.

• This appliance is not a toy! Keep away from children and

animals. Do not leave the device unattended during

operation.

• Check accessories and connection parts for possible

damage prior to every use of the device. Do not use any

defective devices or device parts.

• Ensure that all electric cables outside of the device are

protected from damage (e.g. caused by animals). Never

use the device if electric cables or the power connection

are damaged!

• The electrical connection must correspond to the

specifications in chapter Technical data.

• Insert the mains plug into a properly secured mains

socket.

• Observe the device's power input, cable length and

intended use when selecting extensions to the power

cable. Completely unroll extension cables. Avoid electrical

overload.

• Before carrying out maintenance, care or repair work on

the device, remove the mains plug from the mains socket.

Hold onto the mains plug while doing so.

• Switch the device off and disconnect the power cable from

the mains socket when the device is not in use.

• Do not under any circumstances use the device if you

detect damages on the mains plug or power cable.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Defective power cables pose a serious health risk!

• When positioning the device, observe the minimum

distances from walls and other objects as well as the

storage and operating conditions specified in the Technical

data chapter.

• Make sure that the air inlet and outlet are not obstructed.

• Make sure that the suction side is kept free of dirt and

loose objects.

• Do not remove any safety signs, stickers or labels from the

device. Keep all safety signs, stickers and labels in legible

condition.

• Only transport the device in an upright position with an

emptied condensation tank or drain hose.

• Discharge the collected condensate before transport and

storage. Do not drink it. Health hazard!

Intended use

Only use the device for drying and dehumidifying room air, while

adhering to and following the technical data.

Intended use comprises:

• dehumidifying and drying:

– living rooms, bedrooms, bathrooms and basements

– laundries, holiday homes, camper vans, boats

• maintaining the dryness of:

– storage spaces, archives, laboratories, garages

– bathrooms, wash rooms, changing rooms etc.

Improper use

The device is not intended for industrial use.

• Do not place the device on wet or flooded ground.

• Do not place any objects, e.g. clothing, on the device.

• Do not use the device outdoors.

• Any unauthorised modifications, alterations or structural

changes to the device are forbidden.

• Any operation other than as described in this manual is

prohibited. Non-observance renders all claims for liability

and guarantee null and void.

Personnel qualifications

People who use this device must:

• be aware of the dangers that occur when working with

electric devices in damp areas.

• have read and understood the instructions, especially the

Safety chapter.

Maintenance tasks which require the housing to be opened

must only be carried out by specialist companies for cooling and

air-conditioning or by Trotec.

EN 3

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 4

Residual risks

Warning of electrical voltage

Work on the electrical components must only be

carried out by an authorised specialist company!

Warning of electrical voltage

Before any work on the device, remove the mains plug

from the mains socket!

Hold onto the mains plug while pulling the power cable

out of the mains socket.

Warning

Dangers can occur at the device when it is used by

untrained people in an unprofessional or improper way!

Observe the personnel qualifications!

Warning

The device is not a toy and does not belong in the

hands of children.

Warning

Risk of suffocation!

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

Note

Do not operate the device without an inserted air filter!

Without the air filter, the inside of the device will be

heavily contaminated. This could reduce the

performance and result in damage to the device.

Behaviour in the event of an emergency

1. Switch off the device.

2. In an emergency, disconnect the device from the mains

feed-in: Hold onto the mains plug while pulling the power

cable out of the mains socket.

3. Do not reconnect a defective device to the mains.

Information about the device

Description of the device

The device uses the principle of condensation to automatically

dehumidify rooms.

The fan sucks damp room air through the air inlet, the air filter,

the evaporator and to the condenser located behind it. The air is

cooled at the cold evaporator until it is below the dew point.

Water vapour contained in the room air precipitates on the

evaporator fins as condensation or rime. The dehumidified,

cooled air is slightly warmed at the condenser and blown out

again. The drier air thus conditioned mixes with the air in the

room. The humidity in the room where the device is positioned

is reduced as air constantly circulates through the device.

Depending on the air temperature and the relative humidity, the

condensed water either drops continuously or only during the

defrost phase through the integrated drain nozzle into the

condensation tank below. It is fitted with a float to measure the

filling level.

In case of the device TTK 165 ECO defrosting takes place

electronically in air circulation mode.

The devices TTK170ECO and TTK380ECO come with a hot

gas automatic defrost system. Here, the hot gas of the

refrigerant circuit is used actively for fast and effective

defrosting. This makes the devices TTK170ECO and

TTK380ECO considerably more effective at temperatures

below 15°C.

Once the maximum filling level of the condensation tank is

reached or in case the condensation tank is not installed

correctly, the condensation tank indicator light (see chapter

Device depiction) is illuminated. The compressor and fan will

switch off. The condensation tank indicator light only goes out

again once the emptied condensation tank is reinserted.

If required, an external hygrostat can be connected to the

devices TTK170ECO and TTK380ECO for controlling the

humidity level. Moreover, an operating hours counter helps you

to meet the maintenance deadlines.

Optionally, the condensed water can be drained by attaching a

hose at the condensation connection.

The device can reduce the relative humidity of a room to approx.

30%.

Because of the heat radiation generated during operation, the

room temperature may rise slightly.

Info

The illustrations in this operating manual feature the

device TTK 170 ECO by way of example. However, the

depicted operating steps and explanations also apply to

the devices TTK165ECO and TTK380ECO unless

otherwise mentioned.

4 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 5

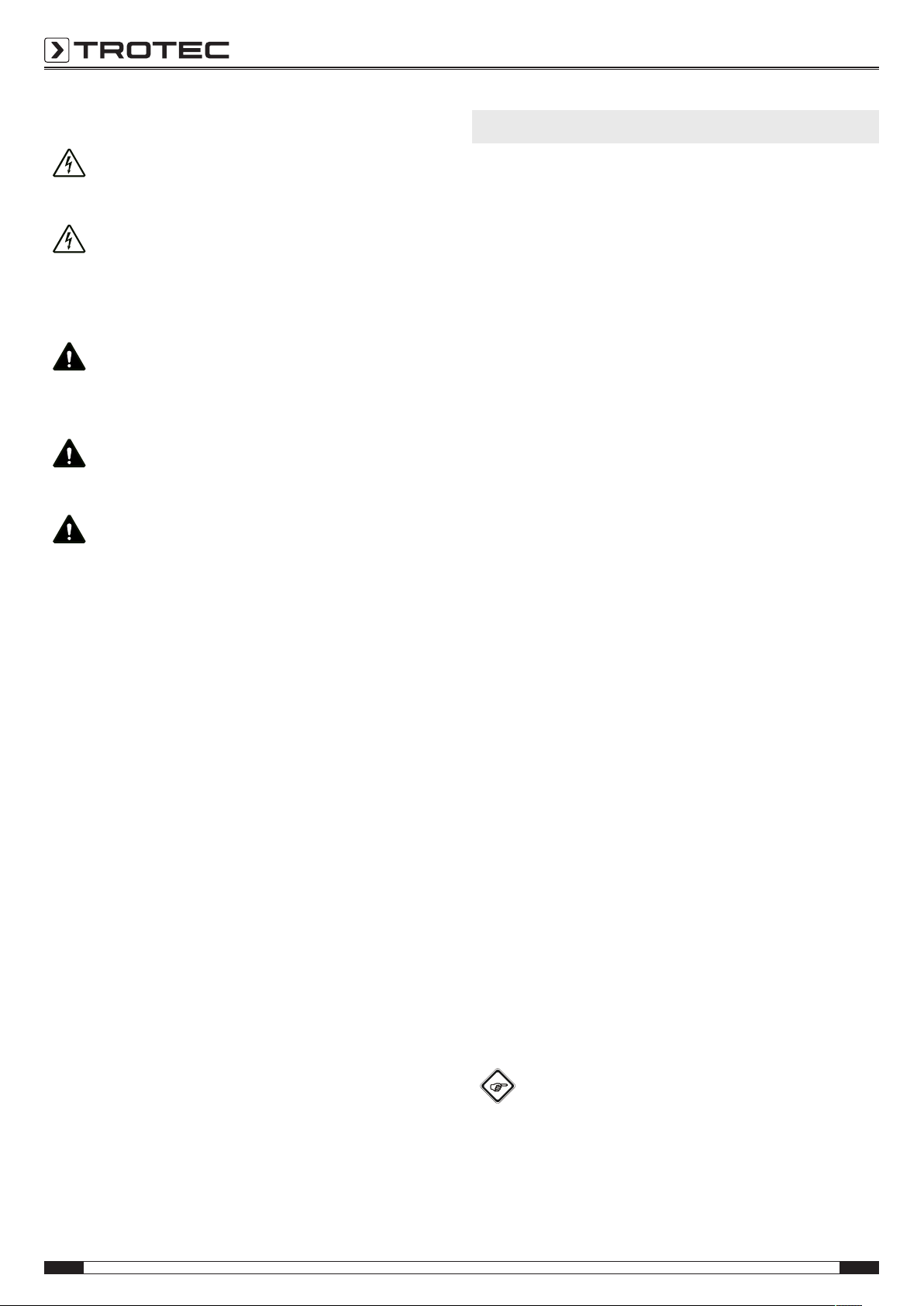

Device depiction

1

2

3

4

10

11

12

13

TTK 170 ECO

TTK 165 ECO

1

2

3

4

10

11

5

6

9

8

7

5

TTK 165 ECO / TTK 170 ECO

1

2

3

4

10

11

12

13

TTK 380 ECO

5

6

9

7

TTK 380 ECO

EN 5

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

No. Designation

1 Transport handle

2 Air inlet with air filter

3 Condensation tank (behind cover)

4 Feet

5 Air outlet

6 Power cable holder

7 Wheels

8 Air filter

9 Condensation drain hose connection

10 On/off switch

11 Condensation tank indicator light

12 Operating hours counter

13 Connection for optional external hygrostat

Page 6

Transport and storage

Note

If you store or transport the device improperly, the

device may be damaged.

Note the information regarding transport and storage of

the device.

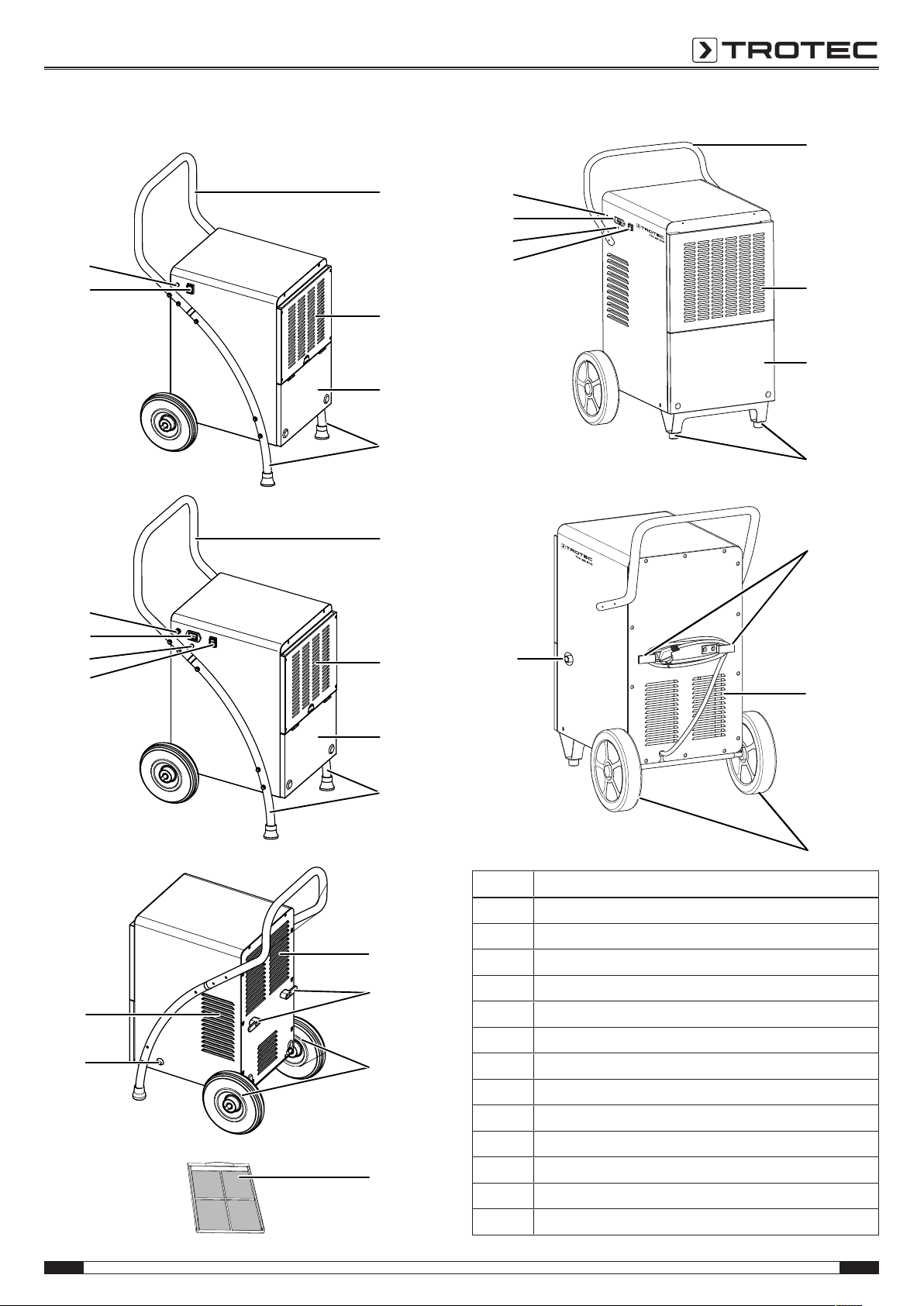

Transport

To make the device easier to transport, it is fitted with a

transport handle and two wheels.

Before transporting the device, observe the following:

• Switch off the device.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

• Do not use the power cable to drag the device.

• Drain the remaining condensate from the device and the

condensation drain hose (see chapter Maintenance).

• Do not incline the device by more than 45°, for otherwise

the device could be damaged.

Storage

Before storing the device, proceed as follows:

• Drain the remaining condensate from the device and the

condensation drain hose (see chapter Maintenance).

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

When the device is not being used, observe the following

storage conditions:

• dry and protected from frost and heat

• in an upright position where it is protected from dust and

direct sunlight

• with a cover to protect it from invasive dust, if necessary

• Place no further devices or objects on top of the device to

prevent it from being damaged.

Assembly and installation

Scope of delivery

TTK 165 ECO / TTK 170 ECO

• 1x Device

• 1x Air filter

• 2x Transport wheel

• 1x Axle

• 2x Standard split pin

• 2 x Linchpin

• 4x Washer

• 1 x Transport handle

• 2 x Foot

• 2 x Large screw

• 10 x Small screw

• 1x Manual

TTK380ECO

• Only wheel the device on a level and smooth surface.

After transporting the device, observe the following:

• Set up the device in an upright position after transport.

• After having transported the device in horizontal position,

leave the device to rest for 12to24hours, so the

refrigerant can accumulate within the compressor. Wait

12to24hours before switching the device back on! Acting

contrary might lead to compressor damage and a

malfunctioning device. Any warranty claims will be voided

in this case.

• 1x Device

• 1 x Transport handle

• 1x Air filter

• 4x Screw

• 1x Manual

Unpacking the device

1. Open the cardboard box and take the device out.

2. Completely remove the packaging.

3. Fully unwind the power cable. Make sure that the power

cable is not damaged and that you do not damage it during

unwinding.

6 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 7

Assembly

4

4

4

14

15

Use tools suitable for the intended task.

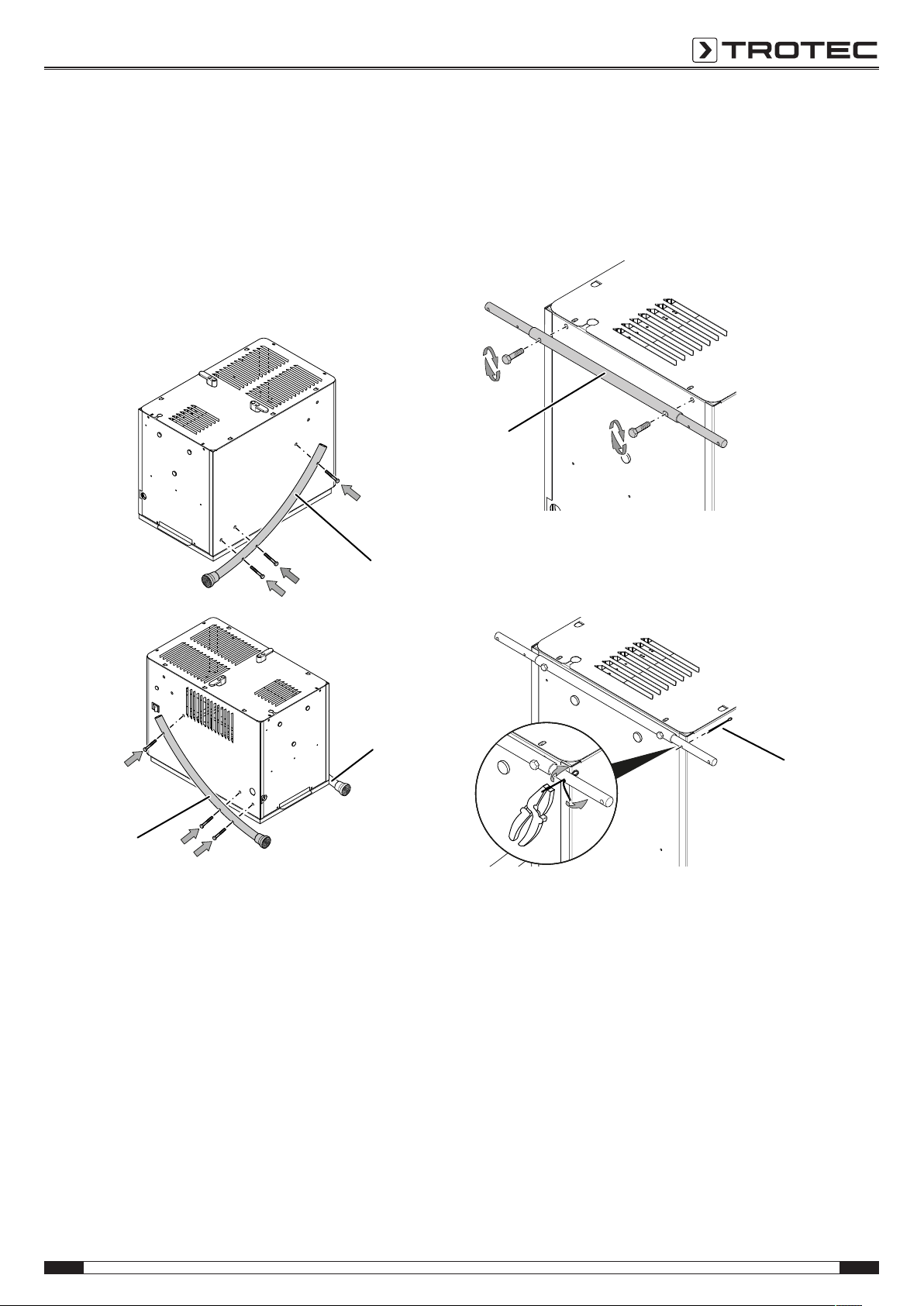

Mounting the feet TTK165ECO/ TTK170ECO

Prior to initial start-up, the feet must be attached to the device.

To do so, please proceed as follows:

1. Place the device on its front side.

2. Mount the two feet(4) to the device sides using six

screws. The feet must protrude from the bottom side of the

device.

Mounting the wheels TTK165ECO/ TTK170ECO

Prior to initial start-up, the wheels and the axle must be

attached to the device. To do so, please proceed as follows:

ü The device is placed on its front side.

1. Use two large screws to fasten the axle(14) to the rear

bottom side of the device. Ensure tight fit.

2. Insert a standard split pin(15) into the inner hole of the

axle up to the stop. Bend the end of the split pin outwards

to fix the split pin.

3. Then mount the wheels.

3. Place a washer(16) on the axle(14).

4. Place a wheel(7) in front of the washer(16).

EN 7

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 8

5. Place a second washer(16) in front of the wheel(7).

7

14

16

16

17

17

16

1

4

6. Insert a linchpin(17) into the hole in front of the

washer(16) up to the stop. Turn over the ring of the

linchpin(17).

Mounting the transport handle

Prior to initial start-up, the transport handle must be attached to

the device. To do so, please proceed as follows:

TTK 165 ECO / TTK 170 ECO

1. Mount the transport handle(1) to both feet(4) using four

screws.

TTK380ECO

1. Mount the handle(1) on both sides of the device using two

hexagon screws each.

7. Repeat this process on the other side of the axle.

8. After mounting the wheels and the feet, place the device in

an upright position.

Note

Leave the device to rest for 12to24hours, so the

refrigerant can accumulate within the compressor.

Wait 12to24hours before switching the device back

on! Acting contrary might lead to compressor damage

and a malfunctioning device. Any warranty claims will

be voided in this case.

8 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 9

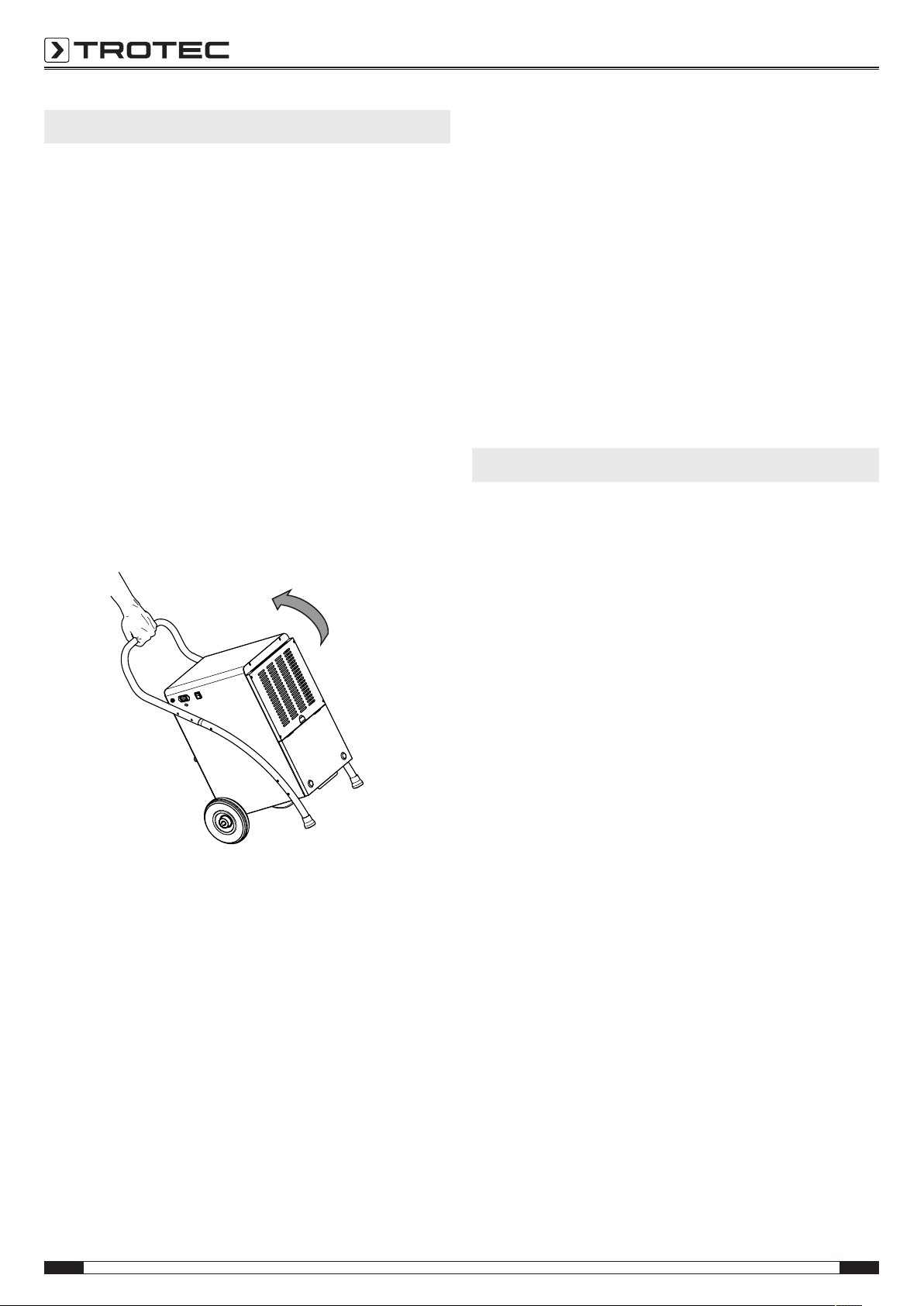

Start-up

A

B

C

C

D

When positioning the device, observe the minimum distance

from walls or other objects as described in the Technical data

chapter.

Inserting the air filter

Note

Do not operate the device without an inserted air filter!

Without the air filter, the inside of the device will be

heavily contaminated. This could reduce the

performance and result in damage to the device.

• Make sure that the air filter is installed before switching

the device on.

• Before restarting the device, check the condition of the

power cable. If there are doubts as to the sound condition,

contact the customer service.

• Set the device up in an upright and stable position.

• Do not create tripping hazards when laying the power

cable or other electric cables, especially when positioning

the device in the middle of the room. Use cable bridges.

• Make sure that extension cables are completely unrolled.

• When positioning the device, keep a sufficient distance to

heat sources.

• Make sure that no curtains or other objects interfere with

the air flow.

• When positioning the device, particularly in wet areas,

secure it locally with an RCD (residual current device)

which complies with the respective regulations.

• Do not incline the device by more than 45°, for otherwise

the device could be damaged.

EN 9

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 10

Inserting the condensation tank

TTK 165 ECO

10

11

12 10

13

TTK 380 ECO

11

• Ensure that the float inside the condensation tank is

inserted correctly.

• Ensure that the condensation tank is empty and inserted

correctly.

TTK 165 ECO / TTK 170 ECO

Operation

Notes:

• Avoid open doors and windows.

• After being switched on, the device operates fully

automatically.

• The compressor switches on approx.3minutes after the

device has been switched on.

• The fan continuously runs in dehumidification mode until

the device is switched off.

Operating elements

TTK165ECO

TTK380ECO

• Guide the condensation drain hose into the opening on top

of the condensation tank.

Connecting the power cable

• Insert the mains plug into a properly secured mains

socket.

TTK 170 ECO / TTK 380 ECO

No. Designation Meaning

10 On/off switch For switching the device on or off

11 Indicator light Indication of full condensation

tank

12 Operating hours

Indication of operating hours

counter

13 Hygrostat connection Connection for hygrostat

operation (optional)

10 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 11

Switching the device on

Once you have completely installed the device as described in

the Start-up chapter, you can switch it on.

Press the on/off switch(10). The device starts to dehumidify in

continuous operation.

Note

Only use the device in an upright position, otherwise

the compressor could be damaged.

Memory function

After a power failure during operation the device will switch

back on.

Auto stop function

If the condensation tank is full or not inserted correctly, the

device will stop automatically.

Operating hours counter

The devices TTK170ECO and TTK380ECO are equipped with

an operating hours counter(12). The hour display has five digits.

Operation with hose attached to the condensation

connection

TTK 165 ECO / TTK 170 ECO

For continuous operation or unattended dehumidification, please

connect a suitable condensation drain hose to the device.

ü A suitable hose (diameter: 12mm) is ready for use.

ü The device is switched off.

1. Open the front cover.

2. Remove the condensation tank.

3. Guide the condensation drain hose through the hole in the

device's bottom panel.

EN 11

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 12

4. Push one end of the hose onto the hose connection at the

condensation tank.

5. Refit the condensation tank into the device. Guide the other

hose end to a suitable drain or sufficiently dimensioned

collection container.

TTK380ECO

ü A suitable hose (diameter: 16mm) is ready for use.

ü The device is switched off.

1. Open the front cover.

2. Remove the condensation tank.

6. Please note that the hose must not be kinked.

3. Connect the condensation drain hose to the connection

inside the housing.

12 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 13

4. Refit the condensation tank into the device.

5. Close the front cover.

7. Guide the other hose end to a suitable drain or sufficiently

dimensioned collection container. Please note that the

hose must not be kinked.

8. Make sure that the condensation drain hose is installed

with a continuous decline.

Remove the hose if you want to collect the condensate in the

condensation tank again. Allow the hose to dry prior to storage.

6. Push one end of the hose onto the hose connection on the

outside of the housing.

EN 13

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 14

Automatic defrost

At low ambient temperatures, ice may form at the evaporator

during dehumidification. The device will then carry out an

automatic defrost. Dehumidification is briefly interrupted during

defrosting. The fan keeps running.

In case of the device TTK 165 ECO defrosting takes place

electronically in air circulation mode. In defrost mode, the

compressor switches off while the fan keeps running and

circulates the compressor's waste heat around the evaporator

for defrosting.

The devices TTK170ECO and TTK380ECO come with a hot

gas automatic defrost system based on the bypass procedure.

Here, the hot gas of the refrigerant circuit is used actively for

fast and effective defrosting. As soon as ice starts to form, a

special valves opens automatically, redirects the hot gas to the

evaporator, and closes again after defrosting is completed so

that drying operation can be continued via the regular

refrigerant circuit. Unlike air circulation defrosting, hot gas

automatic defrosting allows for considerably shorter defrost

phases, which is an essential requirement for effective

dehumidification in low-temperature surroundings (below 15°C)

such as unheated rooms. After all, the actual dehumidification

process only takes place when defrosting is not in progress.

The duration of the defrost process can vary. Do not switch off

the device during automatic defrost. Do not remove the mains

plug from the mains socket.

Available accessories

Warning

Only use accessories and additional equipment

specified in the instructions.

Using insertion tools or accessories other than those

specified in the instructions may cause a risk of injury.

TTK 170 ECO / TTK 380 ECO

Designation Article number

Air filter TTK 165 ECO 7.710.000.115

Air filter TTK 170 ECO 7.710.000.006

Air filter TTK 380 ECO 7.710.000.851

External condensate pump 6.100.003.020

Hygrostat HG110 with jack plug

(TTK170ECO and TTK380ECO)

6.100.002.044

External hygrostat (optional)

The devices TTK170ECO and TTK380ECO allow for

connection of the external hygrostat HG110. The desired

humidity can be regulated by use of a hygrostat. The external

hygrostat is connected to the connection for the external

hygrostat(13).

Shutdown

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

• Switch off the device.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

• If necessary, remove the condensation drain hose and any

residual fluid from it.

• Empty the condensation tank, if need be.

• Clean the device according to the Maintenance chapter.

• Store the device according to the Storage chapter.

14 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 15

Errors and faults

The device has been checked for proper functioning several

times during production. If malfunctions occur nonetheless,

check the device according to the following list.

The device does not start:

• Check the power connection.

• Check the power cable and mains plug for damage.

• Check the on-site fusing.

• Check the filling level of the condensation tank and empty

it if necessary. The condensation tank indicator light(11)

must not light up.

• Check the condensation tank for correct seating.

• Check the room temperature. Observe the device's

permissible operating range according to the technical

data.

• Check the float in the condensation tank for dirt. If

necessary, clean the condensation tank. The float must be

able to move freely.

The device is running, but there is no formation of

condensate:

• Check whether the condensation drain hose is positioned

correctly.

• When using the condensate pump: Check the

condensation tank and hoses for dirt.

• Check the room temperature. Observe the device's

permissible operating range according to the technical

data.

• Ensure that the relative room humidity complies with the

technical data.

• Check the air filter for dirt. If necessary, clean or replace

the air filter.

• From the outside, check the condenser for dirt (see

chapter Maintenance). If the condenser is dirty, have it

cleaned by a specialist company or by Trotec.

• The device might carry out an automatic defrost. During

automatic defrost, the device does not dehumidify.

The compressor does not start:

• Check the room temperature. Observe the device's

permissible operating range according to the technical

data.

• Ensure that the relative room humidity complies with the

technical data.

• Check whether the overheating protection of the

compressor has tripped. Disconnect the device from the

mains and let it cool down for approx. 10minutes before

reconnecting it.

• The device might carry out an automatic defrost. During

automatic defrost, the device does not dehumidify.

The device gets very warm, is loud or loses power:

• Check the air inlets and air filters for dirt. Remove external

dirt.

• From the outside, check the device for dirt (see chapter

Maintenance). If the inside of the device is dirty, have it

cleaned by a specialist company for cooling and airconditioning or by Trotec.

Note

Wait for at least 3 minutes after maintenance and

repair work. Only then switch the device back on.

Your device still does not operate correctly after these

checks?

Please contact the customer service. If necessary, bring the

device to a specialist company for cooling and air-conditioning

or to Trotec for repair.

The device is loud or vibrates:

• Check whether the device is set up in a stable and upright

position.

Condensate is leaking:

• Check the device for leaks.

EN 15

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 16

Maintenance

Maintenance intervals

Maintenance and care interval before every

start-up

Check the air inlets and outlets for

X X

dirt and foreign objects and clean if

necessary

Clean the exterior

Visually check the inside of the

device for dirt

Check the air filter for dirt and

X X

foreign objects and clean or replace

if necessary

Replace the air filter

Check for damage

X

Check the attachment screws

Test run

Empty the condensation tank and/or

drain hose

Maintenance and care log

Device type: .............................................

as needed at least every

2weeks

X X

X X

X X

X

at least every

4weeks

at least every

6months

X

Device number: ....................................

at least

annually

X

Maintenance and care interval

Check air inlets and outlets for dirt

and foreign objects and clean if

necessary

Clean the exterior

Visually check the inside of the

device for dirt

Check the air filter for dirt and

foreign objects and clean or replace

if necessary

Replace the air filter

Check for damage

Check the attachment screws

Test run

Empty the condensation tank and/or

drain hose

Comments

1. Date: ...................................

Signature: ................................

5. Date: ...................................

Signature: ................................

9. Date: ...................................

Signature: ................................

13. Date: .................................

Signature: ................................

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

2. Date: ....................................

Signature: .................................

6. Date: ....................................

Signature: .................................

10. Date: ..................................

Signature: .................................

14. Date: ..................................

Signature: .................................

3. Date: ....................................

Signature: .................................

7. Date: ....................................

Signature: .................................

11. Date: ..................................

Signature: .................................

15. Date: ..................................

Signature: .................................

4. Date: ....................................

Signature: .................................

8. Date: ....................................

Signature: .................................

12. Date: ..................................

Signature: .................................

16. Date: ..................................

Signature: .................................

16 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 17

Activities required before starting maintenance

Cleaning the air filter

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

• Switch the device off.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

Warning of electrical voltage

Tasks which require the housing to be opened

must only be carried out by authorised specialist

companies or by Trotec.

Refrigerant circuit

• The entire refrigerant circuit is a maintenance-free,

hermetically sealed system and may only be maintained or

repaired by specialist companies for cooling and airconditioning or by Trotec.

Cleaning the housing

Clean the housing with a soft, damp and lint-free cloth. Ensure

that no moisture enters the housing. Protect electrical

components from moisture. Do not use any aggressive cleaning

agents such as cleaning sprays, solvents, alcohol-based or

abrasive cleaners to dampen the cloth.

Note

Ensure that the air filter is not worn or damaged. The

corners and edges of the air filter must not be

deformed or rounded. Before reinserting the air filter,

make sure that it is undamaged and dry!

The air filter has to be cleaned as soon as it is dirty. This is

brought to light e.g. by a reduced capacity (see chapter Errors

and faults).

1. Remove the air filter from the device.

Visual inspection of the inside of the device for dirt

1. Remove the air filter.

2. Use a torch to illuminate the openings of the device.

3. Check the inside of the device for dirt.

4. If you see a thick layer of dust, have the inside of the

device cleaned by a specialist company for cooling and airconditioning or by Trotec.

5. Put the air filter back in.

2. Clean the filter using a slightly damp, soft, lint-free cloth. If

the filter is heavily contaminated, clean it with warm water

mixed with a neutral cleaning agent.

3. Allow the filter to dry completely. Do not insert a wet filter

into the device!

EN 17

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 18

4. Reinsert the air filter into the device.

Emptying the condensation tank

If the condensation tank is full or not installed correctly, the

condensation tank indicator light(11) will be illuminated. The

compressor and fan will switch off.

1. Take the condensation tank out of the device.

4. Refit the condensation tank into the device.

Make sure not to damage the float when inserting or

removing the condensation tank.

In doing so, make sure that the float is positioned

correctly.

Also make sure that the condensation tank is inserted

correctly, otherwise the device cannot be switched back

on.

2. Empty the condensation tank over a drain or sink.

Activities required after maintenance

If you want to continue using the device:

• Reconnect the device to the mains.

If you do not intend to use the device for a considerable time:

• Store the device according to the Storage chapter.

3. Rinse the tank with clear water. Clean the tank regularly

using a mild cleaning agent (no detergent!).

18 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 19

Technical annex

Technical data

Model TTK165ECO TTK170ECO TTK380ECO

Max. dehumidification

52 l / 24h 52 l / 24h 80 l/ 24h

performance

Dehumidification performance

50l / 24h 50l / 24h 79l / 24h

@ 30°C and 80%RH

Amount of air 350 m3/h 350 m3/h 950 m3/h

Operating range (temperature) 5°C to 32°C 5°C to 32°C 5°C to 32°C

Operating range (relative humidity) 30% to 90 %RH 30% to 90 %RH 30% to 90 %RH

Input voltage 220–240V/ 50Hz 220–240V/ 50Hz 220–240V/ 50Hz

Max. power input 0.9 kW 0.9 kW 1.15 kW

Nominal current 3.6 A 4.2 A 5.2 A

Recommended fusing 10A 10A 10A

Refrigerant R-410A R-410A R-410A

Amount of refrigerant 400 g 405 g 890 g

GWP factor 2088 2088 2088

CO2 equivalent 0.84t 0.85t 1.445t

Water tank 5 l 6.6 l 11.1 l

Sound pressure level

56 dB(A) 56 dB(A) 65 dB(A)

(1m distance)

Dimensions

495x 455x 900 mm 495x 455x 900 mm 530x 575x 1060 mm

(lengthx widthx height)

Minimum distance to walls and

other objects

top (A):

rear (B):

sides (C):

front (D):

50 cm

50 cm

50 cm

50 cm

50 cm

50 cm

50 cm

50 cm

50 cm

50 cm

50 cm

50 cm

Weight 30 kg 31 kg 53 kg

EN 19

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 20

Wiring diagram

TTK165ECO

TTK170ECO

20 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 21

TTK380ECO

EN 21

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 22

Disposal

The icon with the crossed-out waste bin on waste

electrical or electronic equipment stipulates that this equipment

must not be disposed of with the household waste at the end of

its life. You will find collection points for free return of waste

electrical and electronic equipment in your vicinity. The

addresses can be obtained from your municipality or local

administration. For further return options provided by us please

refer to our website www.trotec24.com.

The separate collection of waste electrical and electronic

equipment aims to enable the re-use, recycling and other forms

of recovery of waste equipment as well as to prevent negative

effects for the environment and human health caused by the

disposal of hazardous substances potentially contained in the

equipment.

The device is operated with fluorinated greenhouse gas which

can be dangerous for the environment and contribute to global

warming when emitted to the atmosphere.

Further information is provided on the nameplate.

Dispose of the refrigerant appropriately and according to the

national regulations.

Declaration of conformity

The text below sets out the contents of the declaration of

conformity. The signed declaration of conformity can be found

at https://hub.trotec.com/?id=40461.

Declaration of conformity

in accordance with the ECMachinery Directive 2006/42/EC, AnnexII, Part1,

SectionA

Herewith, we– TrotecGmbH– declare that the machinery

designated below was developed, constructed and produced in

compliance with the requirements of the ECMachinery

Directive in the version 2006/42/EC.

Product model/ product:

Product type:

Year of manufacture as of:

Relevant EU directives:

• 2014/30/EU: 29March 2014

Applied harmonised standards:

• EN ISO 12100:2010

• EN 55014-1:2006/A1:2009

• EN 55014-1:2006/A2:2011

• EN 60335-1:2012/A11:2014

• EN60335-2-40:2003

• EN 60335-2-40:2003/A11:2004

• EN 60335-2-40:2003/A12:2005

• EN 60335-2-40:2003/A1:2006

• EN 60335-2-40:2003/A2:2009

• EN 60335-2-40:2003/A13:2012

• EN61000-3-2:2014

• EN 61000-3-3:2013

• EN 62233:2008

Applied national standards and technical specifications:

• EN 55014-2:2015

Manufacturer and name of the authorised representative of

the technical documentation:

Trotec GmbH

Grebbener Straße 7, D-52525 Heinsberg

Phone: +49 2452 962-400

E-mail: info@trotec.de

TTK 165 ECO, TTK 170 ECO,

TTK 380 ECO

dehumidifier

2019

Place and date of issue:

Heinsberg, 18.06.2010

Detlef von der Lieck, Managing Director

22 EN

dehumidifier TTK 165 ECO / TTK 170 ECO / TTK 380 ECO

Page 23

Trotec GmbH

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...