Page 1

TAC 1500 / TAC 3000

EN

ORIGINAL INSTRUCTIONS

AIR CLEANER

TRT-BA-TAC1500/TAC3000-TC2018-55-006-EN

Page 2

Table of contents

Notes regarding the instructions ..........................................2

Safety .....................................................................................2

You can download the current version of the instructions and

the EUdeclaration of conformity via the following link:

Information about the device................................................4

Transport and storage...........................................................5

Assembly and start-up..........................................................5

Operation .............................................................................11

Available accessories..........................................................11

Errors and faults..................................................................11

Maintenance ........................................................................12

Technical annex...................................................................13

Disposal ...............................................................................15

Declaration of conformity ...................................................15

Notes regarding the instructions

Symbols

Warning of electrical voltage

This symbol indicates dangers to the life and health of

persons due to electrical voltage.

Warning

This signal word indicates a hazard with an average

risk level which, if not avoided, can result in serious

injury or death.

Caution

This signal word indicates a hazard with a low risk

level which, if not avoided, can result in minor or

moderate injury.

Note

This signal word indicates important information

(e.g. material damage), but does not indicate hazards.

Info

Information marked with this symbol helps you to carry

out your tasks quickly and safely.

Follow the manual

Information marked with this symbol indicates that the

instructions must be observed.

TAC 1500

https://hub.trotec.com/?id=42768

TAC 3000

https://hub.trotec.com/?id=42769

Safety

Read this manual carefully before starting or using the

device. Always store the manual in the immediate vicinity

of the device or its site of use!

Warning

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future

reference.

This appliance can be used by children aged from

8years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

• Do not use the device in potentially explosive rooms.

• Do not use the device in aggressive atmosphere.

• Set the device up in an upright and stable position.

• Let the device dry out after a wet clean. Do not operate it

when wet.

• Do not use the device with wet or damp hands.

• Do not expose the device to directly squirting water.

• Never insert any objects or limbs into the device.

• Do not cover or transport the device during operation.

• Do not sit on the device.

2 EN

air cleaner TAC 1500 / TAC 3000

Page 3

• This appliance is not a toy! Keep away from children and

animals. Do not leave the device unattended during

operation.

• Check accessories and connection parts for possible

damage prior to every use of the device. Do not use any

defective devices or device parts.

• Ensure that all electric cables outside of the device are

protected from damage (e.g. caused by animals). Never

use the device if electric cables or the power connection

are damaged!

• The electrical connection must correspond to the

specifications in chapter Technical data.

• Insert the mains plug into a properly secured mains

socket.

• Observe the technical data when selecting extensions to

the power cable. Completely unroll the extension cable.

Avoid electrical overload.

• Before carrying out maintenance, care or repair work on

the device, remove the mains plug from the mains socket.

Hold onto the mains plug while doing so.

• Switch the device off and disconnect the power cable from

the mains socket when the device is not in use.

• Do not under any circumstances use the device if you

detect damages on the mains plug or power cable.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Defective power cables pose a serious health risk!

• When positioning the device, observe the minimum

distances from walls and other objects as well as the

storage and operating conditions specified in the Technical

data chapter.

• Make sure that the air inlet and outlet are not obstructed.

• Make sure that there are no loose items or dirt located in

the immediate surroundings of air inlet and air outlet.

• Do not remove any safety signs, stickers or labels from the

device. Keep all safety signs, stickers and labels in legible

condition.

• Make sure that the suction side is kept free of dirt and

loose objects.

• Dispose of replaced filters properly, especially after

filtering substances hazardous to health (e.g. asbestos or

spray paint mists)

• Never use the device as storage place or footstep.

Intended use

Only use the device to clean atmospheric air from

non-conducting and non-combustible dusts, fogs or suspended

matter whilst using the appropriate filter classes and adhering

to the technical data.

Improper use

• Do not place the device on wet or flooded ground.

• Do not place any objects, e.g. clothing, on the device.

• Do not use the device outdoors.

• Do not use the device to siphon off vapours or fluids.

• Any operation other than as described in this manual is

prohibited. Non-observance renders all claims for liability

and guarantee null and void.

• Any unauthorised modifications, alterations or structural

changes to the device are forbidden.

Personnel qualifications

People who use this device must:

• be aware of the dangers that occur when working with

electrically driven air cleaners.

• have read and understood the instructions, especially the

Safety chapter.

Electrically skilled person

Electrically skilled personnel must be able to read and

understand electric circuit diagrams, to put electrical systems

into service and to maintain them, to wire control cabinets, to

ensure the functionality of electrical components and to identify

possible hazards from electrical and electronic systems.

Instructed person

Instructed persons have been informed of the tasks they were

entrusted with as well as of potential hazards resulting from

inappropriate behaviour. They are allowed to operate and

transport the device and perform simple maintenance activities

(cleaning the housing, cleaning the fan).

The device is to be maintained and looked after by instructed

personnel.

Residual risks

Warning of electrical voltage

Work on the electrical components must only be

carried out by an authorised specialist company!

Warning of electrical voltage

Before any work on the device, remove the mains plug

from the mains socket!

Hold onto the mains plug while pulling the power cable

out of the mains socket.

Warning

Dangers can occur at the device when it is used by

untrained people in an unprofessional or improper way!

Observe the personnel qualifications!

Warning

The device is not a toy and does not belong in the

hands of children.

EN 3

air cleaner TAC 1500 / TAC 3000

Page 4

Warning

Risk of suffocation!

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

Caution

Risk of injury from parts being whirled up!

Before switching the device on, make sure that there

are no loose parts (clothing, hair ...) located near the

air inlet or outlet!

Note

Observe the overvoltage protection.

The device comes equipped with an overvoltage

protection. When checking for electrical safety, please

bear in mind that the test voltage has to be reduced to

250V.

Note

Do not operate the device without an inserted air filter!

Without the air filter, the inside of the device will be

heavily contaminated. This could reduce the

performance and result in damage to the device.

Note

Do not use abrasive cleaners or solvents to clean the

device.

Behaviour in the event of an emergency

1. Switch off the device.

2. In an emergency, disconnect the device from the mains

feed-in: Hold onto the mains plug while pulling the power

cable out of the mains socket.

3. Do not reconnect a defective device to the mains.

Information about the device

Device description

Air cleaners are used to filter the room air. On building sites and

renovation areas high concentrations of dust can arise, for

instance when using angle grinders or during blasting, chiselling

or demolition operations as well as when mixing dry mortar or

tile cement.

Depending on the inserted filter, the air cleaners of the

TACseries serve to eliminate various dusts, e.g. from asbestos,

building rubble, quartz, flour, wood, etc., but also mould spores,

paint particles and mineral fibres in the air, possibly arising

during the above-mentioned operations.

This dust is to be vacuumed off as close as possible to the point

of origin in order to reduce the pollution of the breathing air to a

minimum. Depending on the used filter quality it is permissible

to employ the device for the separation of quartziferous mineral

dusts, wood dust, lead-containing dusts, artificial mineral fibres

or high-temperature fibres.

Application as vacuum generator for mould remediation and

asbestos abatement is also a possibility. In case of other

hazardous substances there are additional requirements; hence

observe the corresponding Technical Rules for Hazardous

Substances (TRGS) or the country-specific regulations.

The device is suited for:

• producing a vacuum in a room, e.g. in heavily

contaminated spaces;

• air purification in workspaces via air circulation, e.g. indoor

building sites, workshops etc.;

• producing overpressure in a room, e.g. cleanroom;

• supplying filtered fresh air.

The device is structured as follows:

• housing with stacking aid

• adjustable fan for air transport

• filter monitoring for air volume flow

The device may be equipped with various filters. It provides the

user with the possibility of configuring both the filter quality and

the filter chain arrangement for the respective field of

application. The filters must be selected according to the area of

application.

The device is approvable for asbestos abatement as per

TRGS519, dust classH.

Info

The filters are not included in the scope of delivery!

Choose the filters according to the area of application

from our filter range. Insert the selected filters prior to

initial start-up.

4 EN

air cleaner TAC 1500 / TAC 3000

Page 5

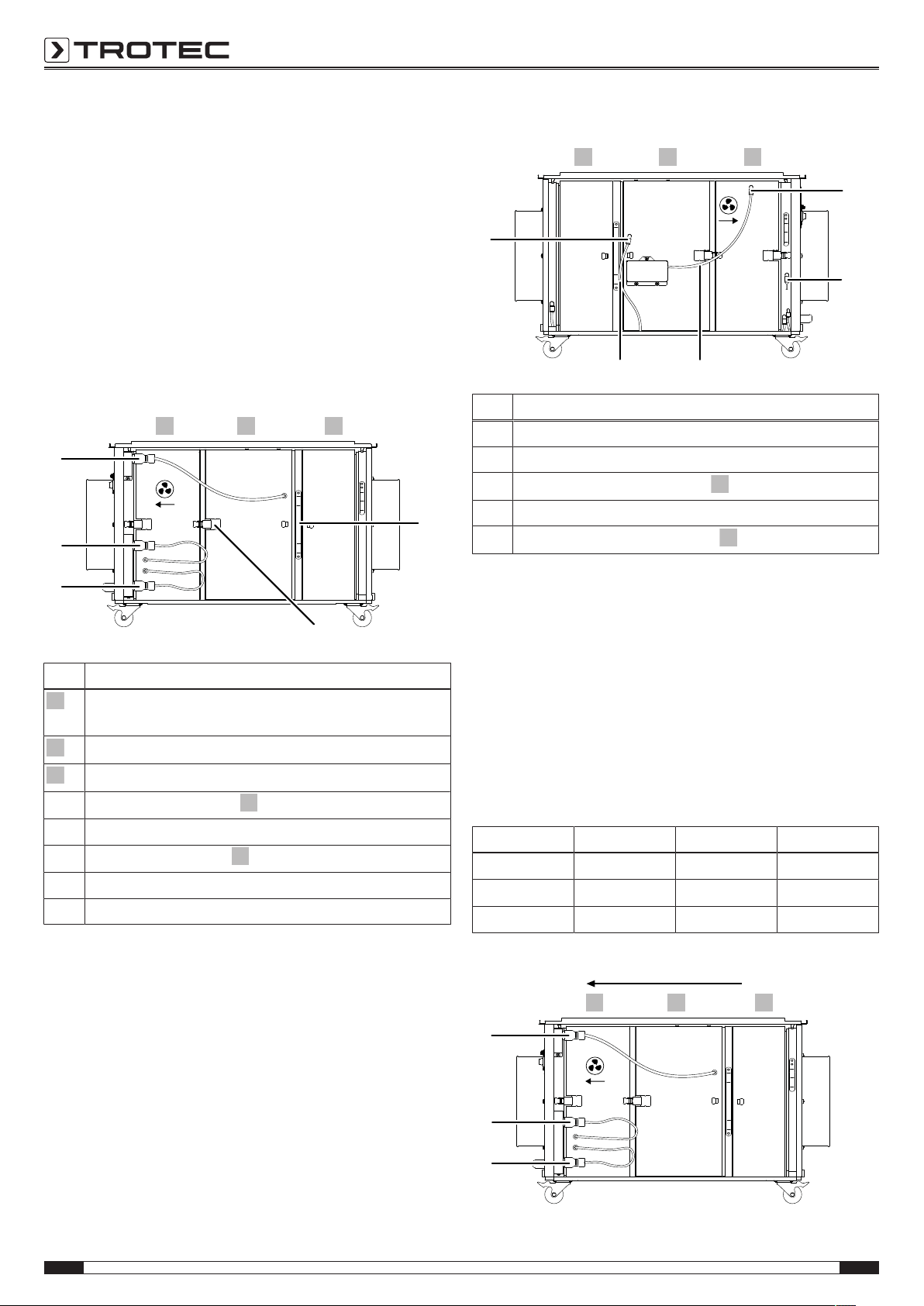

Device depiction

1

2

3

4

5

6

4

7

Transport and storage

Note

If you store or transport the device improperly, the

device may be damaged.

Note the information regarding transport and storage of

the device.

Transport

Before transporting the device, observe the following:

• Switch off the device.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

After transporting the device, observe the following:

• Set up the device in an upright position after transport.

Storage

When the device is not being used, observe the following

storage conditions:

• dry and protected from frost and heat

• in an upright position where it is protected from dust and

direct sunlight

• with a cover to protect it from invasive dust, if necessary

No. Designation

1 transport handles

2 control panel

3 air outlet opening

4 side panel (service flap)

5 wheel

6 operating hours counter

7 air inlet opening

Assembly and start-up

Scope of delivery

• 1x Device

• 1x Manual

Unpacking the device

1. Open the cardboard box and take the device out.

2. Completely remove the packaging.

3. Fully unwind the power cable. Make sure that the power

cable is not damaged and that you do not damage it during

unwinding.

EN 5

air cleaner TAC 1500 / TAC 3000

Page 6

Assembly

4

9

10

14

16

4. Remove further boxes from the device as required.

Inserting the filters

Info

The filters are not included in the scope of delivery!

Choose the filters according to the area of application

from our filter range. Insert the selected filters prior to

initial start-up.

Prior to start-up the filter chain of the device must be configured

according to the desired field of application. For this two filter

boxes are available.

The filter boxes are located behind the lateral service flaps(4).

1. For filter mounting remove the two side panels(4) towards

the top.

Note

For all filter installations always observe the correct

flow direction according to the direction of the air

current (air flow direction: from back to front)!

BOX 1: PRE-FILTER BOX

The pre-filter box can be equipped with a coarse filterG and/or

a fine filterF.

We recommend using at least one coarse filter for pre-cleaning,

so as to maximize the service life of the subsequent filter.

• coarse filter G: Z-line filter G4(14)

• fine filter F: pleated M5 to F9(16)

The coarse filter is to be assembled in a way that it is the first in

the air stream.

2. Open the tension locks(10) on both sides of the device.

3. First pull out the tensioning frame(9).

BOX 2: FILTER BOX

One of the following main filter types is inserted in the FILTER

BOX.

Version I:

High-efficiency particulate air filter: E10 to H14 or dust classM

toH(15)

The high-efficiency particulate air filter is inserted in the filter

box with its clip-on frame as follows:

1. Pull the clip-on frame out of the guiding grooves.

2. Attach the clip-on frame to the air outlet side of the HEPA

filter.

6 EN

air cleaner TAC 1500 / TAC 3000

Page 7

3. Push HEPAfilter and clip-on frame into filter box2. Make

15

17

14

15

16

sure that the clip-on frame again fits into the guiding

grooves. If applicable, place the HEPA filter with the clip-on

frame on a table and fit filter box2 to the clip-on frame

from above.

Filter types (not included in the scope of delivery)

The designated air filters are especially geared to these devices

and come with the largest possible filter surface based on the

geometric dimensions. This ensures maximum air flow rate and

service life for safe operation.

VersionII– alternative:

Bag filter: M5 to F9

When a bag filter is used, the fine filter in pre-filter box1 may

be omitted.

The bag filter is simply inserted in the filter box without further

assembly. The clip-on frame does not need to be removed for

this.

Note

When the device warns of a spent pre-filter (box1) or

main filter (box2), still a flow rate of 500m³/h

(TAC1500) or 1000m³/h (TAC3000) is ensured. For

an effective filtration of pollutants the scheduled

directives of the (German) employer's liability

insurance association recommend to exchange the

filter.

No. Designation

14 Z-line filter G4

15 HEPAfilter E10 to H14/ dust classM+H

16 pleated filterM5 toF9

17 bag filterM5 toF9

The Vario-shift function provides the user with the possibility of

selecting the filter quality and the filter ladder according to the

case of application and the applicable rules and regulations.

Filter ladder and configuration depend on the pollutant particle

size, filtration efficiency and the field of application. The filter

technology is monitored by sensors. For proper monitoring of

the filter function sensor hose lines are connected to both filter

boxes.

Configuration A

General configuration for the air filtration of coarse dusts and

fine particulates or the separation of suspended matter

according to EN60335-2-69 up to dust classH. Here the

filtration of dust particles and other suspended material harmful

and hazardous to health has priority. The filter ladder must be

operated in a vacuum, i.e. with terminal fan: the fan is to be

arranged downstream of the main filter FILTER BOX2.

EN 7

air cleaner TAC 1500 / TAC 3000

Page 8

Configuration B

3

2

1

I

II

III

9

10

1

2

3

2

3

3

2

1

11

12

13

S1 S2

3

2

3

2

1

I

II

III

Here air is usually lead from a contaminated area into a clean

area, e.g. as filtered fresh air supply. Suspended matter as per

EN1822-1:1998 up to filter classH14 can be filtered, a higher

filtration efficiency is possible with a reduced air volume. The

filter ladder is operated at excess pressure, i.e. with terminal

fine filter: the fan is to be arranged upstream of the main filter

FILTER BOX2.

The TACseries is equipped with Vario-shift function. This

means that the filter elements can be variably arranged for all

application scenarios and in line with the regulations.

Side view electrics:

Side view sensor hose side:

No. Designation

S1 sensor hoseS1

S2 sensor hoseS2

11

measuring position for fan box

12 measuring position for frame (here with dummy plug)

13

measuring position for filter box

No. Designation

PRE-FILTER BOX: COARSE FILTERG and/or FINE

FILTERF

FILTER BOX: HEPA filter or bag filter

FAN BOX

I

connection for filter box

II connection for fan control

III

connection for fan box

9 tensioning frame

10 tension lock

Arranging and connecting filter boxes

For maximum efficiency bag and Z-line filters are to be

assembled vertically.

1. Place PRE-FILTER BOX1 with inserted filter to the first

position behind the air inlet opening.

2. Insert FILTER BOX2 and FAN BOX3 according to the

desired configuration.

3. Insert the tensioning frame behind PRE-FILTER BOX1.

4. Close all tension locks, both on the side of the electrics

and on the sensor hose side.

5. Connect the cable connections on the side of the electrics

to the corresponding plugs:

Plug Cable Connection

CABLE 1

CABLE 2

CABLE 3

black grey III

white black II

black black I

ConfigurationA:

8 EN

air cleaner TAC 1500 / TAC 3000

Page 9

ConfigurationB:

3

2

1

I

II

III

3

2

1

11

12

13

S1 S2

3

2

1

11

12

13

S1

S2

A

B

C

C

D

Then connect the two sensor hoses on the sensor hose side in

accordance with the selected configuration:

Configuration A

(11): sensor hoseS2=> fan box3

(12): dummy plugB=> frame

(13): sensor hoseS1=> filter box2

Note

Push the sensor hoses firmly into the corresponding

sensor socket until the hose securely clicks into place.

The dummy plug has to be relocated depending on the

configuration – for proper functioning the sensor

sockets must not remain open.

In order to remove hose or dummy plug, press the outer ring of

the measuring point and pull hose or dummy plug at the same

time.

Configuration B

(11): sensor hose S1=> fan box3

(12): sensor hoseS2=> frame

(13): dummy plugB=> filter box2

Start-up

When positioning the device, observe the minimum distance

from walls or other objects as described in the Technical data

chapter.

EN 9

air cleaner TAC 1500 / TAC 3000

Page 10

• Before restarting the device, check the condition of the

power cable. If there are doubts as to the sound condition,

contact the customer service.

• Set the device up in an upright and stable position.

• Do not create tripping hazards when laying the power

cable or other electric cables, especially when positioning

the device in the middle of the room. Use cable bridges.

• Make sure that extension cables are completely unrolled.

• Position the device near the source of air contamination.

• When positioning the device, keep a sufficient distance to

heat sources.

• Make sure that no curtains or other objects interfere with

the air flow.

• Make sure that the air inlet and outlet are not obstructed.

Installation of the device in the room, the air of which is to

be purified

• When positioning the device, make sure it is located in the

centre of the room the air of which is to be cleaned.

Alternatively, you can also position the device near the

source of air contamination.

• Prior to operation you have to ensure that the filters have

been installed in the device as desired.

• Also check, whether the pressure sensors are connected

correctly. If the device, during operation, emits a warning

of a filter being spent, the respective filter has to be

replaced.

If the device issues a warning, although a new filter has

only just been inserted, check whether all sensor hoses

are firmly attached.

• The device works in recirculation mode, this means that

the contaminated air enters the air cleaner via the air inlet

opening and is blown out through the air outlet opening in

purified state.

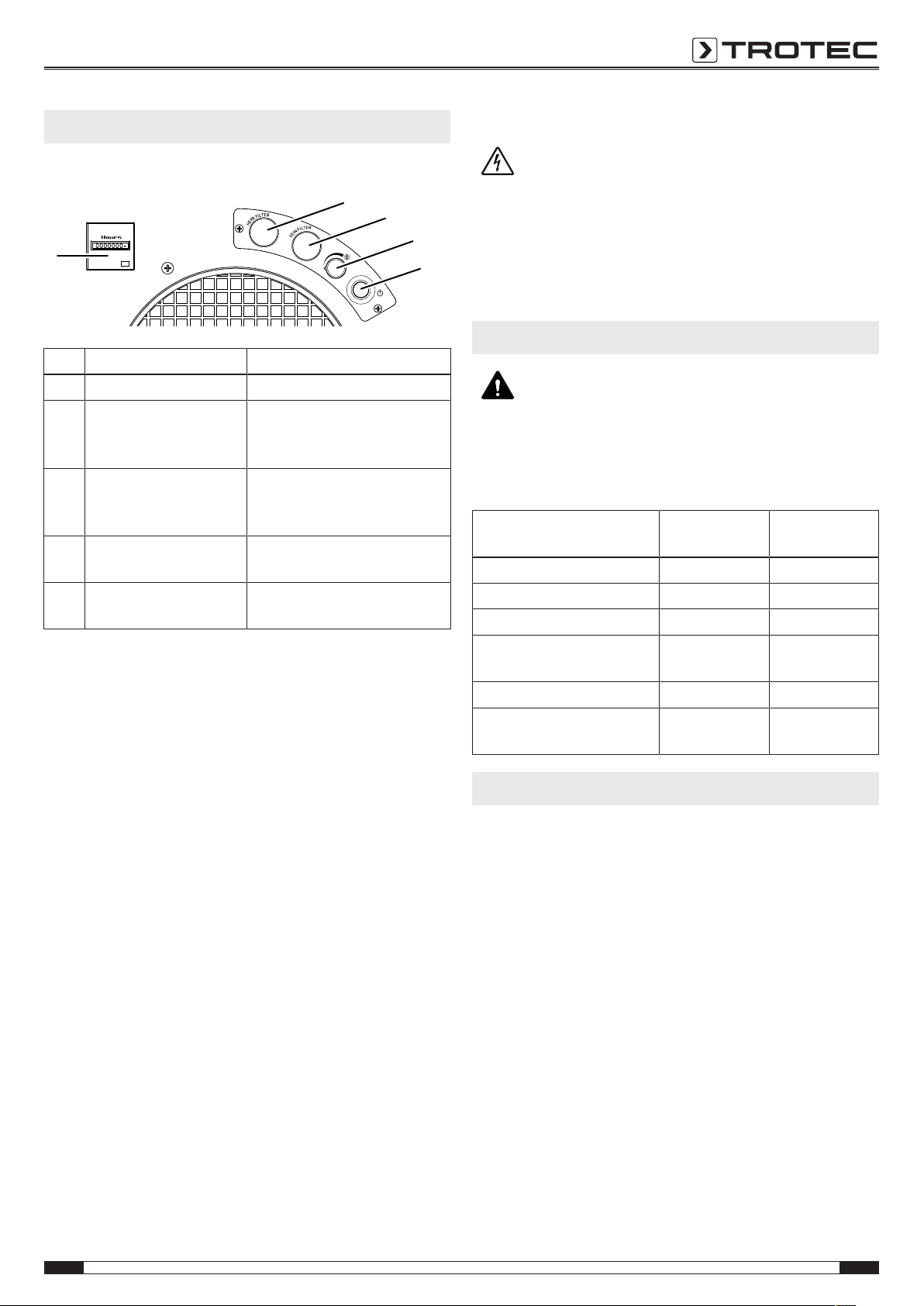

Air purification in sealed off area via air circulation:

Installation of the device outside of the room, the air of

which is to be purified

The device can be connected in either recirculation or

ventilation mode.

• In recirculation mode, the air to be cleaned is led via a

hose from the room into the air inlet opening of the device.

The purified air is fed through another hose from the air

outlet opening and back into the room.

• In ventilation mode, the air to be cleaned is led via a hose

from the room into the air inlet opening of the device. This

creates a slight negative pressure in the room. Clean, fresh

air flows in from outside.

Installation variants for maintaining the pressure:

When connecting hoses, the following must be observed:

• The used pipes and hoses must be designed for the

available static compression of the fans. They should

preferably be laid in a straight line and at full length. 7.6m

of air hose each can be connected to the air inlet and air

outlet openings of the device.

• There ought to be a minimum distance of 1m between air

inlet and air outlet opening.

Connecting the power cable

• Insert the mains plug into a properly secured mains

socket.

10 EN

air cleaner TAC 1500 / TAC 3000

Page 11

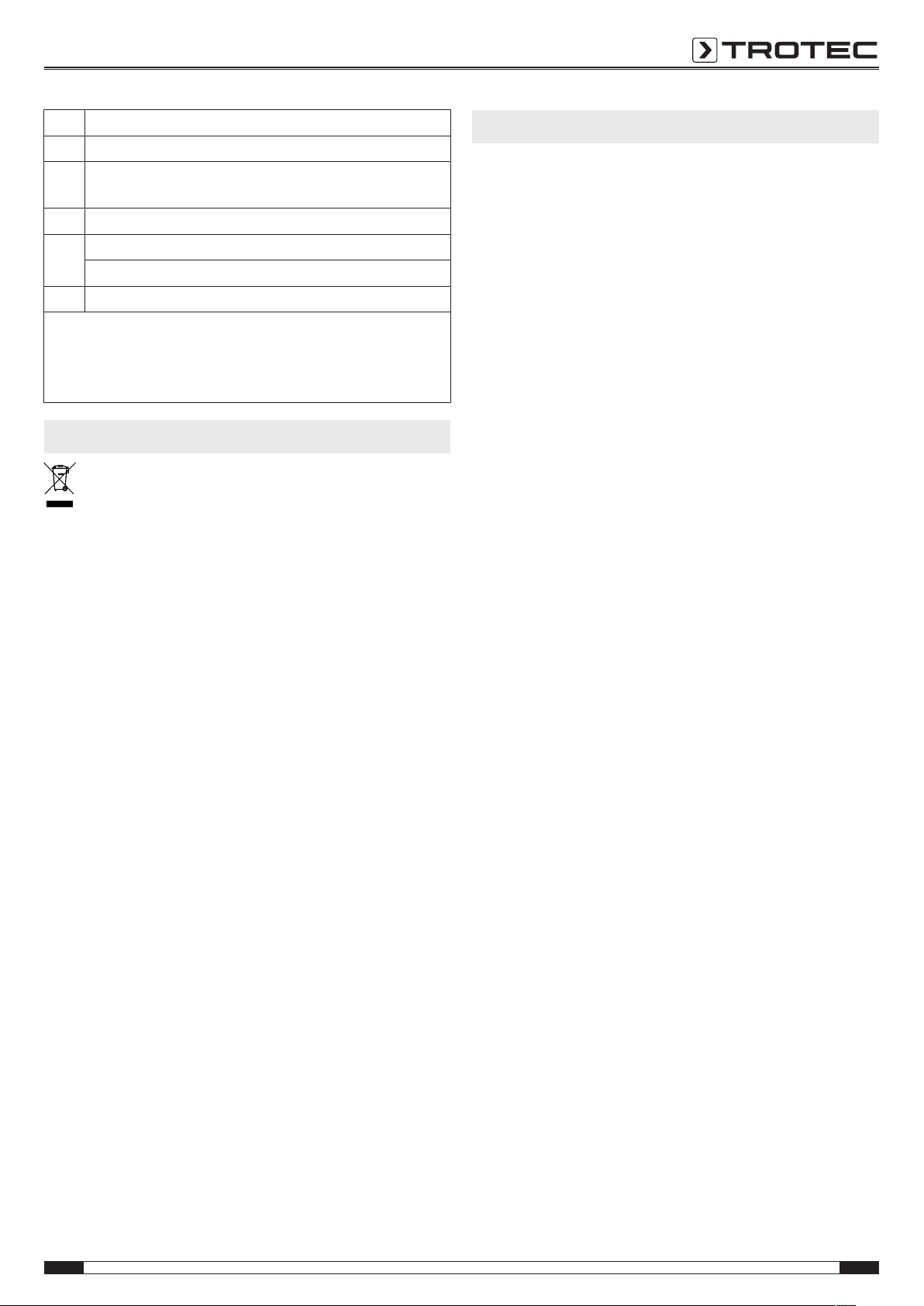

Operation

6

18

19

20

21

Operating elements

No. Designation Meaning

6 Operating hours counter Indication of operating hours

18 Visual and acoustic filter

change indicator

FILTER BOX2

19 Visual and acoustic filter

change indicator

PRE-FILTER BOX1

20 Air volume control dial For setting the desired air

21 Power button For switching the device on or

Switching the device on

Once you have positioned the device as described in the

Start-up chapter, you can switch it on.

1. Ensure that air inlet and outlet are not covered.

2. Turn the air volume control dial(20) counter-clockwise to

the lowest air volume.

3. Press the powerbutton(21).

ð The power button(21) lights up.

Indication of required HEPA or

bag filter change

Indication of required coarse or

fine filter change

volume

off

Shutdown

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

• Switch off the device.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

• Clean the device according to the Maintenance chapter.

• Store the device according to the Storage chapter.

Available accessories

Warning

Only use accessories and additional equipment

specified in the instructions.

Using insertion tools or accessories other than those

specified in the instructions may cause a risk of injury.

Designation Article number

TAC1500

Article number

TAC3000

G4 Z-line filter 7.160.000.404 7.160.000.428

F7 pleated filter cartridge 7.160.000.409 7.160.000.429

F7 bag filter 7.160.000.414 7.160.000.430

H13 HEPA filter approved

7.160.000.424 7.160.000.431

for dust classH

Spray paint filter 7.160.000.416 7.160.000.432

Air transport hose Tronect

6.100.001.200 6.100.001.205

SP-T, length7.6 m

Errors and faults

Adjusting the air volume

By use of the infinitely variable air flow regulation you can adjust

the fan speed and thus regulate the air flow rate of the device.

With the filter arrangement G4, F7 andH13 to meet the

requirements of dust classH, the device with connected

exhaust air hose (7.6m, laid in 290°arcs) reaches an air flow

rate of:

• TAC 1500: 600m³/h

• TAC 3000: 1150m³/h

If the filter change indicator(18) or(19) warns that a filter

change will soon be required, the following min. air flow rate

will still be ensured:

• TAC 1500: 500m³/h

• TAC 3000: 1000m³/h

Exchange the corresponding filters in a timely manner.

1. To increase the air volume, turn the air volume control

dial(20) clockwise.

2. To decrease the air volume, turn the air volume control

dial(20) counter-clockwise.

EN 11

The device has been checked for proper functioning several

times during production. If malfunctions occur nonetheless,

check the device according to the following list.

The device does not start:

• Check the power connection.

• Check the power cable and mains plug for damages.

• Check the on-site fusing.

• Wait for 10minutes before restarting the device. If the

device is not starting, have the electrics checked by a

specialist company or by Trotec.

The device is loud or vibrates:

• Check whether the device is set up in a stable and upright

position.

The device gets very warm, is loud or loses power:

• Check the air inlets and air filters for dirt. Remove external

dirt.

air cleaner TAC 1500 / TAC 3000

Page 12

The device gives off an unpleasant odour:

• Smoke, e.g. dense tobacco smoke, may produce odours

and contaminations in the air. Ventilate the room.

Note

Wait for at least 3 minutes after maintenance and

repair work. Only then switch the device back on.

Your device still does not operate correctly after these

checks?

Please contact the customer service. If necessary, bring the

device to an authorized specialist electrical company or to

Trotec for repair.

Maintenance

Activities required before starting maintenance

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

• Switch the device off.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

Visual inspection of the inside of the device for dirt

1. Remove the air filters.

2. Use a torch to illuminate the openings of the device.

3. Check the inside of the device for dirt.

4. If you see a thick layer of dust, clean the inside of the

device with a vacuum cleaner.

5. Reinsert the air filters.

Warning of electrical voltage

Tasks which require the housing to be opened

must only be carried out by authorised specialist

companies or by Trotec.

Note

Observe the overvoltage protection.

The device comes equipped with an overvoltage

protection. When checking for electrical safety, please

bear in mind that the test voltage has to be reduced to

250V.

Cleaning the housing

Clean the housing with a soft, damp and lint-free cloth. Make

sure that no moisture enters the housing. Protect electrical

components from moisture. Do not use any aggressive cleaning

agents such as cleaning sprays, solvents, alcohol-based or

abrasive cleaners to dampen the cloth.

Cleaning the inside of the device

1. First remove the filters and the filter frame as described in

the Assembly and start-up chapter.

2. Clean the inside of the device and the filter frame with a

soft, damp and lint-free cloth. Make sure that no moisture

enters the housing. Protect electrical components from

moisture. Do not use any aggressive cleaning agents such

as cleaning sprays, solvents, alcohol-based or abrasive

cleaners to dampen the cloth.

3. Reinsert the filters and the filter frameinto the device.

Changing the filter(s)

The filters must be changed if the filter change indicator for

FILTER BOX2(18) or PRE-FILTER BOX1(19) lights up during

operation and an acoustic signal is emitted.

If a filter needs to be replaced, please proceed as described in

the Inserting the filters section in the Assembly and start-up

chapter.

12 EN

air cleaner TAC 1500 / TAC 3000

Page 13

Technical annex

Technical data

Parameter Value

Model TAC1500 TAC3000

Article number 1.580.000.105 1.580.000.115

Recommended amount of air

500 m3/h 1000 m3/h

for dust classH

Dust class

(as per DIN60335-2-69)

dust classH (transmittance ≤0.005%) for substances with a max. allowable concentration of

≤0.1 mg/m³, carcinogenic hazardous substances as per GefStoffV §11 (Ordinance on

Hazardous Substances), TRGS 905 or 906 (Technical Rules for Hazardous Substances),

approvable for asbestos abatement as per TRGS519

Motor power 175 W 450 W

Mains connection 1/N/PE ~230V/ 50–60Hz 1/N/PE ~230V/ 50–60Hz

Nominal current 1.4 A 2.8 A

Connection cable CEE7/7, cable length 3m

rubber conduit (H05RR-F3G1) length= 3.5m

Air transport hose connector

200 mm 250 mm

inlet/outlet side

Sound level

61 dB(A) 65 dB(A)

(at a distance of 1m)

Dimensions

705x 362x 377mm 833x 460x 532mm

(lengthx widthx height)

Weight 22kg 36kg

Recommendation for filter combinations specific to the

TAC1500 TAC3000

application and corresponding room size suitability

suitable for rooms sized up to

Fields of application Filter combination m

3

2

m

1)

3

m

2

m

Coarse dust 2) (≤3ACH6)) G4 220 75 500 170

Fine particulates 3) (≤3ACH6)) G4 + F7 to F9 110 37 270 90

Suspended matter 4) (≤3ACH6)) G4 + H13 50 17 100 34

Hygienic areas 5) (≤3ACH6)) G4 + H13 35 12 70 23

1)

With an assumed room height of 3m; 2) Typical coarse dust tasks: sawing, filing; 3) Typical fine dust tasks: restoration works with

materials containing minerals or glass wool; 4) Typical suspended matter tasks: grinding, asbestos abatement or mould

remediation, mineral dusts etc.; 5) H13 downstream; 6) Air exchange per hour

Optional equipment TAC1500 TAC3000

Guiding wheels with pneumatic tyres, traceless on request on request

Trestle rollers (instead of guiding wheels) on request on request

Fork pockets for fork lifts on request on request

EN 13

air cleaner TAC 1500 / TAC 3000

Page 14

Performance charts

A

E

C

F

D

B

14 EN

air cleaner TAC 1500 / TAC 3000

Page 15

A Fan

B Recommended amount of air for dust classH

C With G4+H13filter combination (approval for dust

classH) and air transport hose*

D With G4+F7filter combination and air transport hose*

E With G4filter and air transport hose*

With spray paint filter and air transport hose*

F Without filter, with air transport hose*

* Connected to the pressure side, standard length 7.6m, laid

with one 90°arc. When the air hose is laid stretched and

arc-free, an increase of air volume by up to 25% is

possible!

Disposal

The icon with the crossed-out waste bin on waste

electrical or electronic equipment stipulates that this equipment

must not be disposed of with the household waste at the end of

its life. You will find collection points for free return of waste

electrical and electronic equipment in your vicinity. The

addresses can be obtained from your municipality or local

administration. For further return options provided by us please

refer to our website www.trotec24.com.

The separate collection of waste electrical and electronic

equipment aims to enable the re-use, recycling and other forms

of recovery of waste equipment as well as to prevent negative

effects for the environment and human health caused by the

disposal of hazardous substances potentially contained in the

equipment.

Declaration of conformity

The text below sets out the contents of the declaration of

conformity. The signed declaration of conformity can be found

at https://hub.trotec.com/?id=42768.

Declaration of conformity

in accordance with the ECMachinery Directive 2006/42/EC,

AnnexII, Part1, SectionA

Herewith, we– TrotecGmbH– declare that the machinery

designated below was developed, constructed and produced in

compliance with the requirements of the ECMachinery

Directive in the version 2006/42/EC.

Product model/ Product:

Product type:

Year of manufacture as of:

Relevant EUdirectives:

• 2011/65/EU: 1July 2011

• 2014/30/EU: 29March 2014

Applied harmonised standards:

• EN ISO 12100:2010

• ENISO 13849-1:2015

• ENISO 13857:2008

• EN 55011:2009

• EN60204-1:2006

• EN 60335-1:2012/AC:2014

• EN 60335-2-65:2003/A11:2012

• EN 61000-6-1:2007

• EN 61000-6-3:2007+A11:2011+AC:2012

Applied national standards and technical specifications:

• ENISO 14118:2018

• EN 60335-2-65:2003/A1:2008

Manufacturer and name of the authorised representative of

the technical documentation:

Trotec GmbH

Grebbener Straße 7, D-52525 Heinsberg

Phone: +49 2452 962-400

E-mail: info@trotec.de

TAC 1500

TAC 3000

air cleaner

2019

Place and date of issue:

Heinsberg, 30.09.2013

Detlef von der Lieck, Managing Director

EN 15

air cleaner TAC 1500 / TAC 3000

Page 16

Trotec GmbH

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...