Page 1

Speedy 360 flexx

Speedy 360 flexx

Operating manual

Operating manual

8032

8032

OM 8032_4.3_EN (07/2019)

OM 8032_4.3_EN (07/2019)

ENGLISH (Translation)

ENGLISH (Translation)

Page 2

Trotec Laser GmbH

+43 7242 239-7070

service-at@troteclaser.com

Trotec Laser Canada

+1 800 663 1149-902

techsupport@troteclaser.ca

Trotec Laser Deutschland

GmbH

+49 89 322 99 65-13

service-de@troteclaser.com

Trotec Laser UK

+44 0191 4188 110

service-uk@troteclaser.com

Trotec Laser Pty Ltd

+61 26413-5904

service@troteclaser.com.au

Trotec Laser AG

+41 32387-1611

service-ch@troteclaser.com

suisse@troteclaser.com

Trotec Laser España

+34 93 102 50 50

soporte@troteclaser.com

Trotec Laser Srl

+39 02 9475 5447

supporto.tecnico@troteclaser.com

Trotec Laser België

Trotec Laser Belgique

+31 850 70 51 55

support@troteclaser.nl

Trotec Laser GmbH

+86 189 500 735 62

china@troteclaser.com

Trotec Laser France SAS

+33 1 72 62 20 94

support.technique@trotec.fr

Trotec Laser Japan

Corporation

Tokyo: +81 42 313 0740

Osaka: +81 6 6180 2200

service-jp@troteclaser.com

High Speed Laser Systems S.

de R.L. de C.V.

+52 55 5351-7252

mexico@troteclaser.com

Trotec Laser Inc.

+1 866 226 8505, Option 2

support@troteclaser.com

2

Trotec Laser B.V.

+31 850 70 51 55

support@troteclaser.nl

Rubber Stamp & Engraving

+27 875 509-335

support@trodat.co.za

Trodat Polska Sp. z o.o.

+48 22 339 35 39

serwis_pl@trodat.net

Page 3

Trotec Laser GmbH

Freilingerstraße 99

4614 Marchtrenk, Austria

Invoice Address:

Linzerstraße 156

4600 Wels, Austria

Tel.: +43 7242 239-0

General contact to Technical Support:

Tel.: +43 7242 239-7000

E-mail: techsupport@troteclaser.com

www.troteclaser.com

3

Page 4

Technical Changes Technical specifications are subject to change without notice.

Trotec Laser GmbH reserves the right to improve or modify any of the products without

prior notice.

© Copyright This documentation with all illustrations is intellectual property of Trotec Laser GmbH.

The entire documentation is given to the user for personal use only. Reproduction,

translation or any distribution to third parties is not permitted without the prior consent of

Trotec Laser GmbH. Any breach of law will be prosecuted.

4

Page 5

Content

Content

1 General Information................................................................................................... 8

1.1 Information about this manual.............................................................................................. 8

1.1.1 Storage of the manual............................................................................................................8

1.1.2 Complementary documentation..............................................................................................8

1.2 Explanation of symbols..........................................................................................................9

1.3 Liability and warranty........................................................................................................... 10

1.4 Scope of delivery (standard configuration)........................................................................11

1.5 Type plate............................................................................................................................... 12

2 Safety......................................................................................................................... 13

2.1 General safety notes.............................................................................................................13

2.1.1 Intended use......................................................................................................................... 13

2.1.2 Improper use.........................................................................................................................14

2.1.3 Residual risk......................................................................................................................... 14

2.1.4 Machine modification............................................................................................................ 14

2.1.5 Operating modes.................................................................................................................. 14

2.1.6 Applicable safety regulations................................................................................................15

2.2 Laser safety........................................................................................................................... 17

2.2.1 Laser classification............................................................................................................... 17

2.3 Areas of responsibility......................................................................................................... 18

2.3.1 Responsibilities of the operating company...........................................................................18

2.3.2 Responsibilities of the operating personnel......................................................................... 19

2.4 Requirements for operating an service personnel............................................................19

2.5 Machine identification (warning and safety stickers)....................................................... 20

2.6 Safety devices....................................................................................................................... 21

2.7 Technical protective measures............................................................................................22

2.7.1 Main switch........................................................................................................................... 22

2.7.2 Key switch.............................................................................................................................22

2.7.3 Temperature sensor.............................................................................................................. 23

2.7.4 Emergency stop button........................................................................................................ 24

2.7.5 Interlock safety switches...................................................................................................... 24

2.7.6 Acrylic top lid........................................................................................................................ 24

2.7.7 Side cover.............................................................................................................................24

2.7.8 In case of safety device malfunction....................................................................................25

2.8 Secondary (indirect) hazards...............................................................................................25

2.8.1 Fire hazard............................................................................................................................25

5

Page 6

Content

2.8.2 Gases, fumes and dust........................................................................................................ 26

2.8.3 Reflection through materials................................................................................................. 27

2.8.4 Information about damaged optics....................................................................................... 28

2.8.5 Protective measures for damaged optics.............................................................................29

2.9 In case of emergency........................................................................................................... 30

3 Technical Data.......................................................................................................... 31

3.1 Dimensions and weight........................................................................................................ 31

3.2 Electrical requirements of the machine..............................................................................32

3.3 Exhaust system requirements............................................................................................. 33

3.4 Computer requirements........................................................................................................35

3.5 Materials................................................................................................................................. 36

4 Machine overview.....................................................................................................40

4.1 General overview...................................................................................................................40

4.2 Front door.............................................................................................................................. 41

4.3 Tables (multifunctional table concept)................................................................................41

4.3.1 Additional tabletops.............................................................................................................. 43

4.3.2 Table placement....................................................................................................................44

4.4 Lens(es).................................................................................................................................. 45

4.5 Nozzles................................................................................................................................... 46

5 Transport................................................................................................................... 47

5.1 Safety notes........................................................................................................................... 47

5.2 Delivery state......................................................................................................................... 47

5.3 Temperature and humidity................................................................................................... 49

5.4 Required tools for unloading and transport...................................................................... 49

5.5 Place of storage.................................................................................................................... 49

5.6 Transport inspection and reporting of defects.................................................................. 50

5.7 Unpacking the machine........................................................................................................51

5.8 Relocation of the machine................................................................................................... 52

6 Setup and installation.............................................................................................. 53

6.1 For your safety...................................................................................................................... 53

6.2 Temperature and humidity................................................................................................... 53

6.3 Space requirements.............................................................................................................. 54

6.4 Setup.......................................................................................................................................54

6.5 Connections........................................................................................................................... 55

6.5.1 Mains connection..................................................................................................................56

6.5.2 Connection the PC............................................................................................................... 56

6.6 Connection of additional components............................................................................... 57

6.6.1 Connecting an exhaust system from Trotec........................................................................ 57

6

Page 7

Content

7 Operation...................................................................................................................58

7.1 Before commissioning..........................................................................................................58

7.2 Software..................................................................................................................................58

7.3 Power On/Off......................................................................................................................... 58

7.4 Control panel......................................................................................................................... 61

7.4.1 Keypad..................................................................................................................................61

7.5 Lense placement................................................................................................................... 67

7.6 Switch laser source manually..............................................................................................68

7.7 Focusing methods................................................................................................................ 69

7.7.1 Focus tool............................................................................................................................. 70

7.7.2 Sonar TechnologyTM............................................................................................................. 72

7.7.3 Software focus...................................................................................................................... 73

7.7.4 Light barrier focus.................................................................................................................74

7.8 Rotary attachment (option).................................................................................................. 75

7.8.1 Installation and commissioning of the rotary attachment..................................................... 75

7.8.2 Mounting the work piece in the rotary attachment...............................................................76

7.8.3 Engraving process................................................................................................................ 77

8 Maintenance.............................................................................................................. 78

8.1 Safety notes........................................................................................................................... 78

8.2 Maintenance schedule.......................................................................................................... 79

8.3 Cleaning..................................................................................................................................80

8.3.1 Machine.................................................................................................................................80

8.3.2 Exhaust box.......................................................................................................................... 81

8.3.3 Optics in general.................................................................................................................. 82

8.3.4 Lens...................................................................................................................................... 82

8.3.5 Mirror.....................................................................................................................................84

8.3.6 Ultrasonic sensor (Option Sonar TechnologyTM).................................................................. 85

9 Troubleshooting........................................................................................................86

9.1 Error, cause and remedy...................................................................................................... 86

9.1.1 How to create a service file................................................................................................. 88

10 Contact details..........................................................................................................89

11 Disassembly..............................................................................................................90

12 Disposal.....................................................................................................................91

13 Appendix....................................................................................................................92

7

Page 8

General Information

1 General Information

For reasons of better legibility, gender-neutral form of address (e. g. "he/she") are not used in the operating

manual. It is expressly stated that in all text passages where natural persons or groups of persons are

mentioned, people of both sexes are always meant.

1.1 Information about this manual

Before beginning any work on the machine, read this manual completely and carefully.

Keep the manual for further consultation close to the machine.

This manual describes how to operate the machine properly and safely. Be sure to follow the safety

instructions given here, as well as any local accident prevention regulations and general safety regulations

applicable to the field of usage. Before beginning any work on the machine, ensure that the manual, in

particular the chapter entitled "Safety Information" and the respective safety guidelines, has been read in its

entirety and fully understood.

1.1.1 Storage of the manual

This manual is an integral part of the machine and must therefore be kept in the direct vicinity of the machine

and be accessible at all times.

1.1.2 Complementary documentation

Complementary documentation can be found on the supplied DVD.

Software manual

Trotec Laser GmbH JobControl®

8

Page 9

General Information

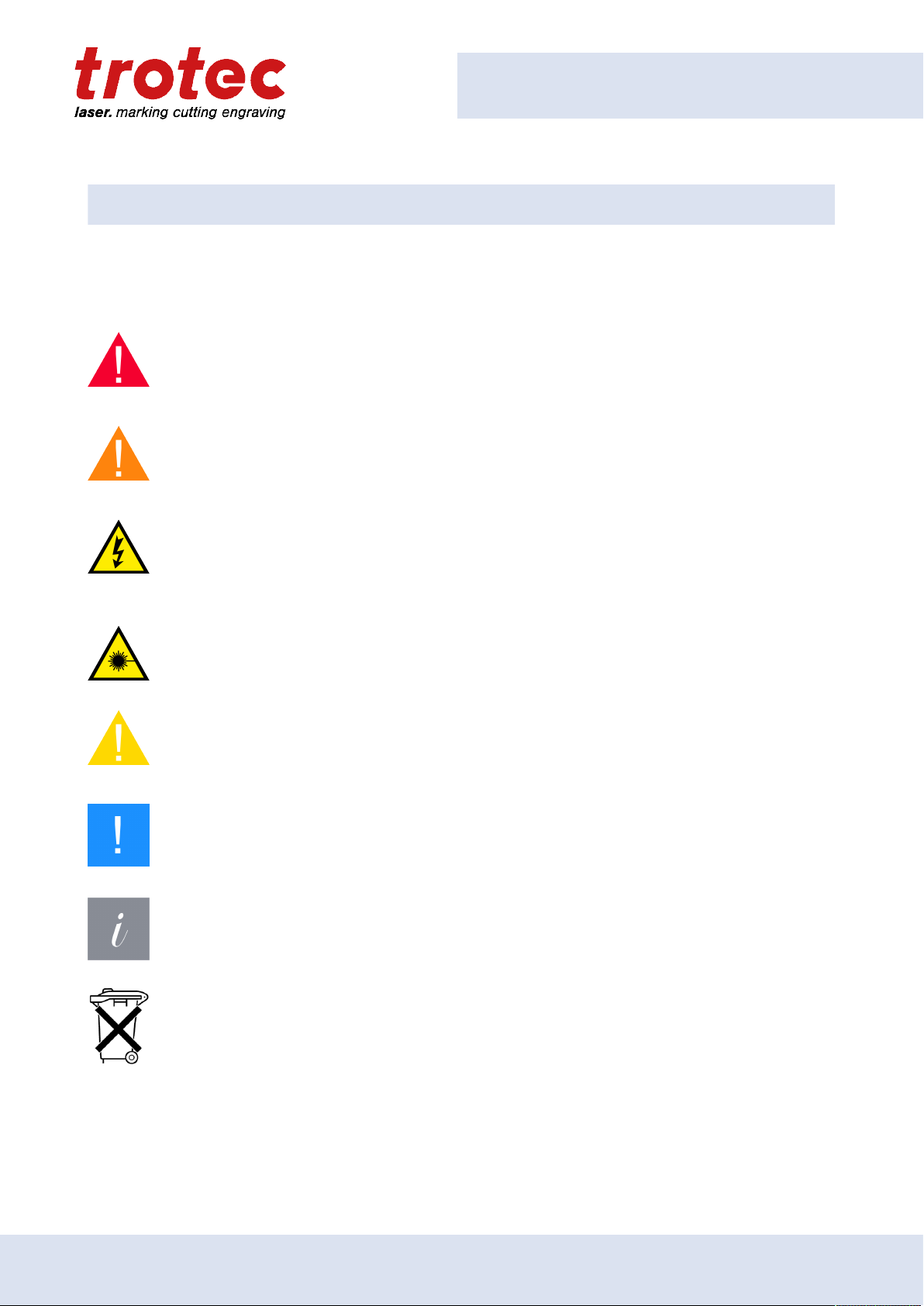

1.2 Explanation of symbols

Important technical safety notes and instructions in this manual are indicated by symbols. It is important to

observe and follow these notes and instructions on workplace safety. Avoid accidents, personal injury and

material damage to property by acting with extreme caution.

Danger

This symbol indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

Warning

This symbol indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Warning Current

This symbol warns of potentially dangerous situations related to the electric voltage. Failure to

observe the safety instructions leads to risk of serious injury or death. Particular care should be

taken during maintenance and repair work.

Warning Laser

This symbol warns of potentially dangerous situations related to the laser beam. Failure to

observe the safety instructions leads to risk of serious injury.

Caution

This symbol indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury.

Notice

This symbol indicates potential risks of damage to the supported product (or to property).

In addition, non-observance may result in damage, malfunction or failure of the machine.

Information

This symbol indicates tips and information which must be observed for efficient and trouble-free

handling of the product.

Disposal

This symbol indicates notes regarding the professional disposal of the product or accessories.

9

Page 10

General Information

1.3 Liability and warranty

Warranty periods specified in the manufacturers "warranty terms and conditions" shall be binding for the

buyer. If no warranty periods are specified, the general terms and conditions of sale, delivery and payment

apply.

All information, illustrations, tables, specifications and diagrams contained in this operating manual have

been carefully compiled according to the current state of technology. No liability is accepted with regard to

errors, missing information and any resulting damage or consequential loss.

Strict compliance with the safety procedures described in this operating manual and extreme caution

when using the equipment are essential for avoiding and reducing the possibility of personal injury or

damage to the equipment. The manufacturer shall not be liable for any damage and or faults resulting from

nonobservance of instructions in this manual.

Nonobservance of the operation, maintenance and service instructions described within this manual

absolves Trotec Laser GmbH from any liability in case of a defect.

Furthermore, Trotec Laser GmbH shall accept no liability whatsoever for damage caused by the use of nonoriginal parts and accessories.

Additionally, Trotec Laser GmbH shall not be held responsible for any personal injury or property damage, of

an indirect or specific nature, consequential loss, loss of commercial profits, interruption to business, or loss

of commercial information resulting from use of the equipment described in this manual.

It is strictly prohibited to make any alterations, to prepare translations, decompile, disassemble, reverse

engineer or copy the software.

Trotec Laser GmbH reserves the right to update any of the information, illustrations, tables, specifications

and diagrams contained in this operating manual with regard to technical developments at any time without

notice.

10

Page 11

General Information

1.4 Scope of delivery (standard configuration)

1. Laser machine

2. DVD (with laser software, printer driver and operating manual)

3. Focusing tool(s) (according to lens order)

4. Cleaning kit for optics

5. Nozzles (2 pcs.: ø3 and ø7)

6. Lens: 2.0'' (CO2), 3.2'' (fiber), 2.85" (flexx)

7. Ferromagnetic engraving table of multifunctional table concept (according to order)

8. Allen key kit (8-part)

9. Open-end wrench

10. Power cord 5 meters (according to order)

11. USB computer connection cable

12. RS232 cable (according to order)

13. Exhaust connection cable (according to order)

The actual scope of delivery may be different, depending on the special model, additional order options or

newest technical changes.

11

Page 12

General Information

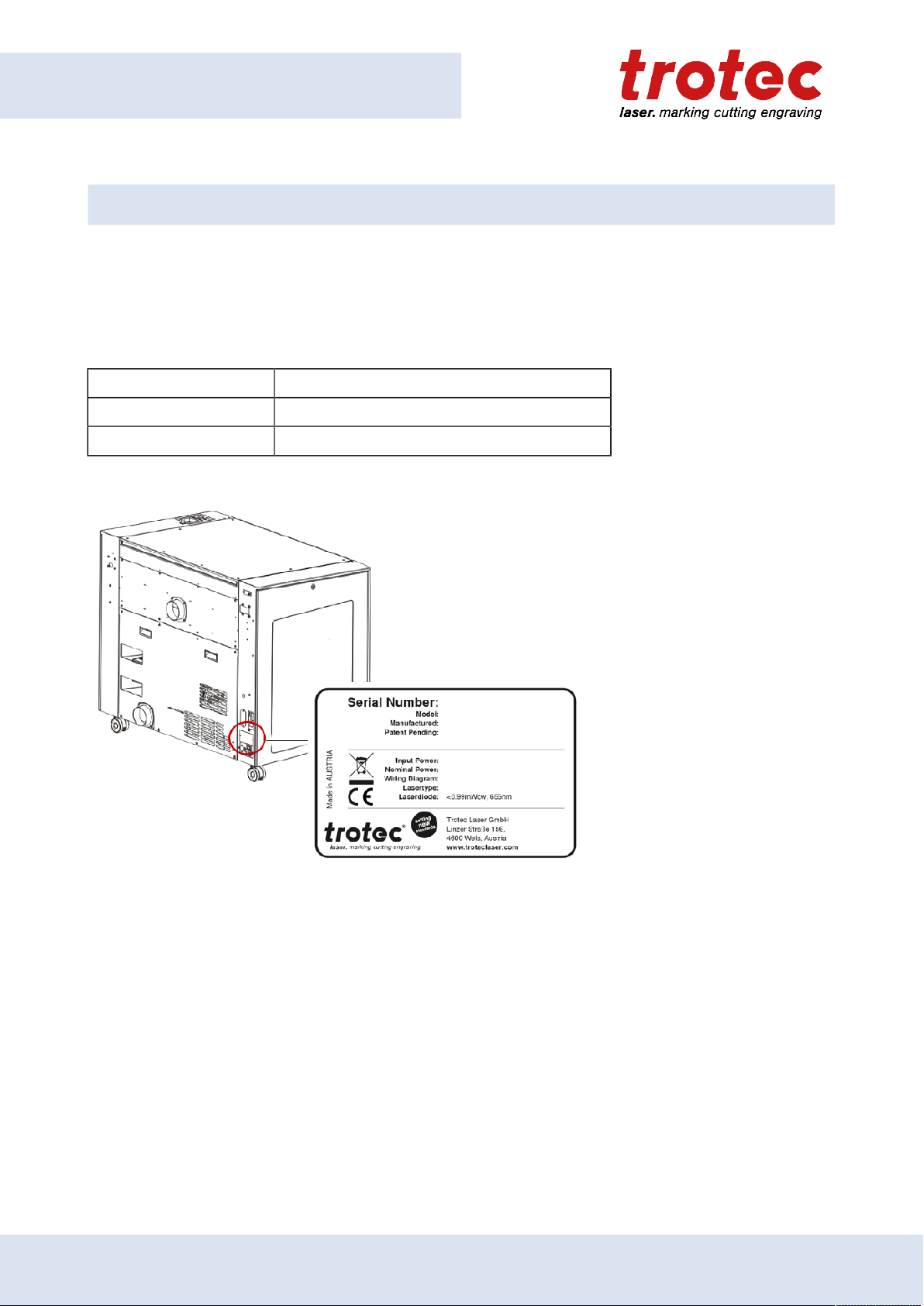

1.5 Type plate

The type plate with the CE mark is located on the rear of the machine.

Enter the serial number, model and year of manufacture into your manual and always refer to them when

contacting us for enquiries, troubleshooting or ordering of replacement parts.

Serial number:

Model:

Year of manufacture:

12

Page 13

Safety

2 Safety

TO AVOID POSSIBLE HARM READ AND FOLLOW THESE INSTRUCTIONS.

The machine is built at the time of it's development and production according to applicable, established

technical rules and is considered to be safe to operate.

Dangers can be caused by the machine if the machine:

■

is operated by unqualified personnel,

■

the personnel have not been trained,

■

the machine is used improperly or not as intended,

■

or if the machine is used for other intended purposes.

This chapter provides an overview of all important safety aspects that are necessary for optimum protection

of persons and safe and trouble-free operation of the machine. Other chapters of this manual contain specific

safety notes for the avoidance and prevention of hazards.

2.1 General safety notes

2.1.1 Intended use

The machine described in this manual is intended exclusively for laser cutting, engraving and

marking of non-metal and material according to the intended use of the machine using the supplied

software.

The system must be operated, maintained and repaired only by trained personnel familiar with the

designated field of use and the dangers of the machine!

Operate the machine only in technically flawless condition and when it fully complies with the EC Machinery

Directive.

For material details see chapter "Materials" or contact your local Trotec representative, or our Technical

Support.

The intended use of this machine also includes that all personnel involved in installation, set-up, operation

maintenance and repair of the machine must have read and understood the operating manual and in

particular the “Safety” section, and comply with the instructions.

13

Page 14

Safety

2.1.2 Improper use

Use of the machine for any purposes other than those intended or described in the present manual is

regarded as improper and therefore prohibited. Trotec Laser GmbH will not accept any liability for damage

caused by improper use. The risks in case of improper use are exclusively borne by the user.

Non-observance of the operation, maintenance and service instructions described within this manual

absolves Trotec from any liability in case of a defect.

2.1.3 Residual risk

Even if all safety regulations are observed, a residual risk remains during operation.

2.1.4 Machine modification

It is strictly prohibited to alter, refit or modify the machine in any way without the express consent of the

manufacturer.

Likewise, it is strictly prohibited to remove, bridge or bypass any safety devices. Operating conditions and

connection and setup values stated in the data sheet must be complied with at all times.

Operation of the system is permitted only with original parts and accessories by the manufacturer. Use of

third-party parts affects machine safety.

2.1.5 Operating modes

Normal operation

For normal operation the following conditions must be met:

•

Intended use of the machine (see chapter "Intended use").

•

Operation of the machine only by trained personnel.

•

Full functional and mounted safety devices.

•

Machine must be in technically flawless condition.

•

Only non-metal and material according to the intended use of the machine must be used.

14

Notice

During normal operation it is not necessary to wear safety glasses.

Page 15

Safety

Service operation

Service activities may be carried out only by authorized, trained service technicians. If side panels as well as

covers get removed and safety devices get bypassed, it can lead to direct and indirect scattered radiation.

The service operation is therefore declared as laser class 4 (US: class IV) and proper precautions need to be

taken (see "Laser classification").

2.1.6 Applicable safety regulations

The following directives and guidelines must be observed to avoid hazards when operating Trotec laser

systems:

Guidelines/Regulations

2006/42/EC EC Machinery Directive

2014/30/EU EMC Guideline

Applied harmonized standards

EN ISO 12100:2011-03 Safety of machinery - General principles for design - Risk assessment and

risk reduction.

IEC 60825-1:2014,

EN 60825-4:2011

IEC 60204-1:2005 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO/DIS 11553-1:2009-03 Safety of machinery - Laser processing machines - Part 1: General safety

IEC 61000-6-4:2007-02 Electromagnetic compatibility (EMC) - Part 6-4: Generic standards -

ISO 13857:2008 Safety of machinery - Safety distances to prevent hazard zones being

EN 55011+A1:2016-05 Industrial, scientific and medical equipment - Radio-frequency disturbance

Safety of laser products - Part 1: Equipment classification and requirements.

requirements.

requirements.

Emission standard for industrial environments.

reached by upper and lower limps.

characteristics - Limits and methods of measurement.

15

Page 16

Safety

Notice

Safety norms and regulations.

The general guidelines and directives listed within this manual may differ according to locality,

region or country.

Therefore, always observe the directives as well as the regulations of the institutions for

statutory accident insurance association applicable to you. The operator is responsible for

fulfilling all safety requirements, as Trotec Laser GmbH has no influence on the proper use of

the machine.

Observe the official regulations for your business location in accordance with the applicable

local legal regulations (on accident prevention regulations or employee protection), e.g. DGUV

regulation 11 for Germany.

16

Page 17

Safety

2.2 Laser safety

2.2.1 Laser classification

The laser safety class indicates the risk potential from accessible laser radiation.

The laser system is a Class 2 (US: Class II) laser marking system as per IEC 60825-1 "Safety of Laser

Products".

Warning Laser

Laser radiation of Class 2 (US: class II)

For Class 2 (US: class II) laser is short term exposure (up to 0.25 seconds) harmless to

the eyes and can therefore be operated without additional protective measures. However it

can cause irritation of the eyes if the natural avoidance reaction (staring into the laser beam

deliberately) or eyelid closure reflex is suppressed.

– Do not suppress the eyelid closure reflex.

– Do not stare directly into the laser beam.

– Close eyes, turn away.

– Never look at the laser beam directly with an optical instrument, e.g. a lens.

Class 2 (US: class II)

The accessible laser radiation of Class 2 (US: Class II) laser systems does not pose any hazard for the skin.

Diffuse reflections as well as any short-term irradiation of the eyes (exposure time max. 0.25 seconds) also

pose no risk due to the low output power.

However, it is possible to suppress the natural eyelid closure reflex and stare into the class-2 laser beam for

a time long enough for the eyes to get injured.

17

Page 18

Safety

2.3 Areas of responsibility

2.3.1 Responsibilities of the operating company

The operator has the following responsibilities:

•

It is the responsibility of the operator to comply with the national official and statutory regulations for the

operation of a class 4 (US: class IV) laser system or laser system with a build in laser source of class 4

(US: class IV).

•

In addition to the safety notes and instructions stated in this manual, consider and observe the local

accident prevention regulations and general safety regulations that apply at the operation site of the

machine.

•

A CO2 fire extinguisher must always be at hand, as the laser beam can ignite flammable materials.

•

If the machine is used industrially, the operator is subject to the legal obligations concerning industrial

safety.

•

All personnel involved in installation, set-up, operation, maintenance and repair of the machine must

have read and understood this manual and in particular the “Safety” section. The personnel must be

trained and informed about all the functions, potential dangers and safety issues of the machine on a

yearly basis.

•

The user is recommended to prepare company internal instructions considering the occupational

qualifications of the personnel employed in each case, and the receipt of the instruction/this manual or

the participation in the introduction/training should in each case be acknowledged in writing.

•

Keep the manual in the immediate vicinity of the machine so that it is accessible at all times to all

persons working on or with the machine.

•

Authority for the individual activities relating to the application of the machine (e.g. installation, operation,

maintenance and cleaning) must be clearly defined and observed, so that no unclear competencies

result under the aspect of safety. This applies in particular to work to be performed on the electrical

equipment that may only be performed by qualified specialists.

•

Maintenance and repair work as specified in the manual must be carried out regularly.

•

For all activities concerning installation, set-up, start-up, operation, modifications of conditions and

methods of operation, maintenance, inspection and repair, the switch-off procedures that may be

provided in the manual must be observed.

•

Provide appropriate personal protection equipment (e.g. protective goggles according to wavelength and

laser power).

•

The operator is responsible for the safety-related state of the machine.

•

Do not store any flammable materials in the working area or in the immediate vicinity of the device.

Particularly, residues of processed materials have to be removed to prevent any fire hazard.

•

The operator must ensure cleanliness and accessibility at and around the machine by corresponding

instructions and controls.

18

Page 19

2.3.2 Responsibilities of the operating personnel

The operating personnel has the following responsibilities:

•

Always wear personal protective equipment.

•

It is the duty of the operating personnel to check the machine before start of work for externally visible

damage and defects, and to immediately report any changes that appear (including behavior during

operation) that may affect the safety of the machine. It must be made sure that the machine is operated

only in perfect condition.

•

The machine must not be left unattended while it is operating (supervised operation).

•

Switch off the machine described herein at the main switch for periods of non-use.

•

Operate the machine described here only with a lens in place. A missing lens may cause the unfocused

laser beam to be reflected out of the housing.

•

Stop this machine immediately in case of failure.

•

No working methods are permitted that affect the safety of persons or of the machine.

•

Always keep clean the machine and its components such as lens and mirrors.

Safety

Caution

The adjustment of the beam path may only be carried out by service personnel of Trotec Laser

GmbH.

2.4 Requirements for operating an service personnel

The requirements for the operating and service personnel are:

•

The personnel must have read and understood this manual and in particular the "Safety" section.

•

The personnel must not be under the influence of drugs, alcohol or reactivity affecting medication when

working on or with the machine.

•

The personnel must be familiar with using the CO2 fire extinguisher.

•

The personnel must be trained in order to be qualified to operate the machine. If the personnel lack the

necessary knowledge for working on or with the machine, they must first be trained and note down the

training in the training verification form.

Activity Intended user group Definition

Control/operation/other

activities (e.g. troubleshooting,

maintenance)

Qualified personnel

or Trotec service

technicians

Qualified personnel are those who can

judge the work entrusted to them and detect

potential risks based on their occupational

training, knowledge and experience as

well as their understanding of the relevant

regulations.

19

Page 20

Safety

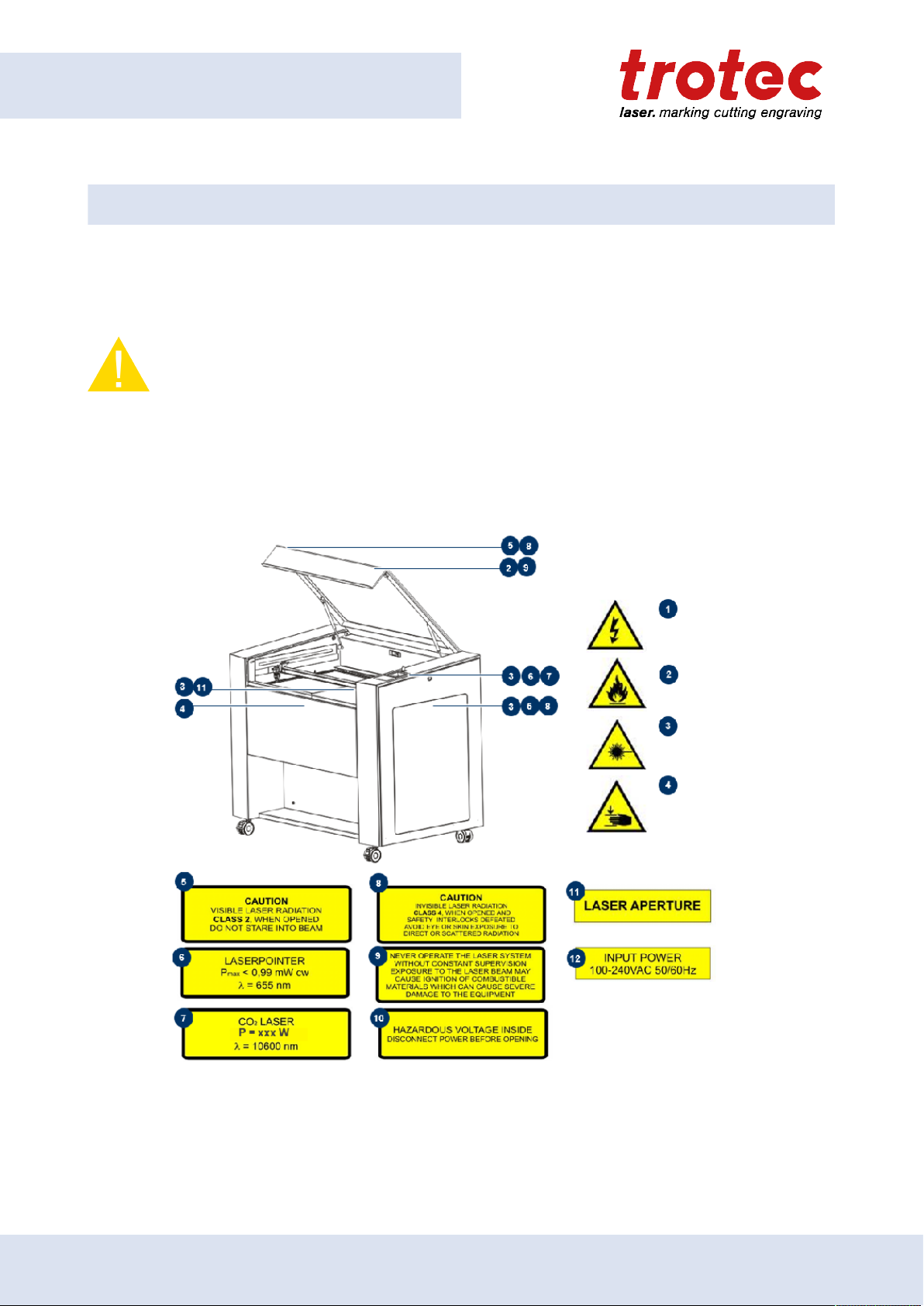

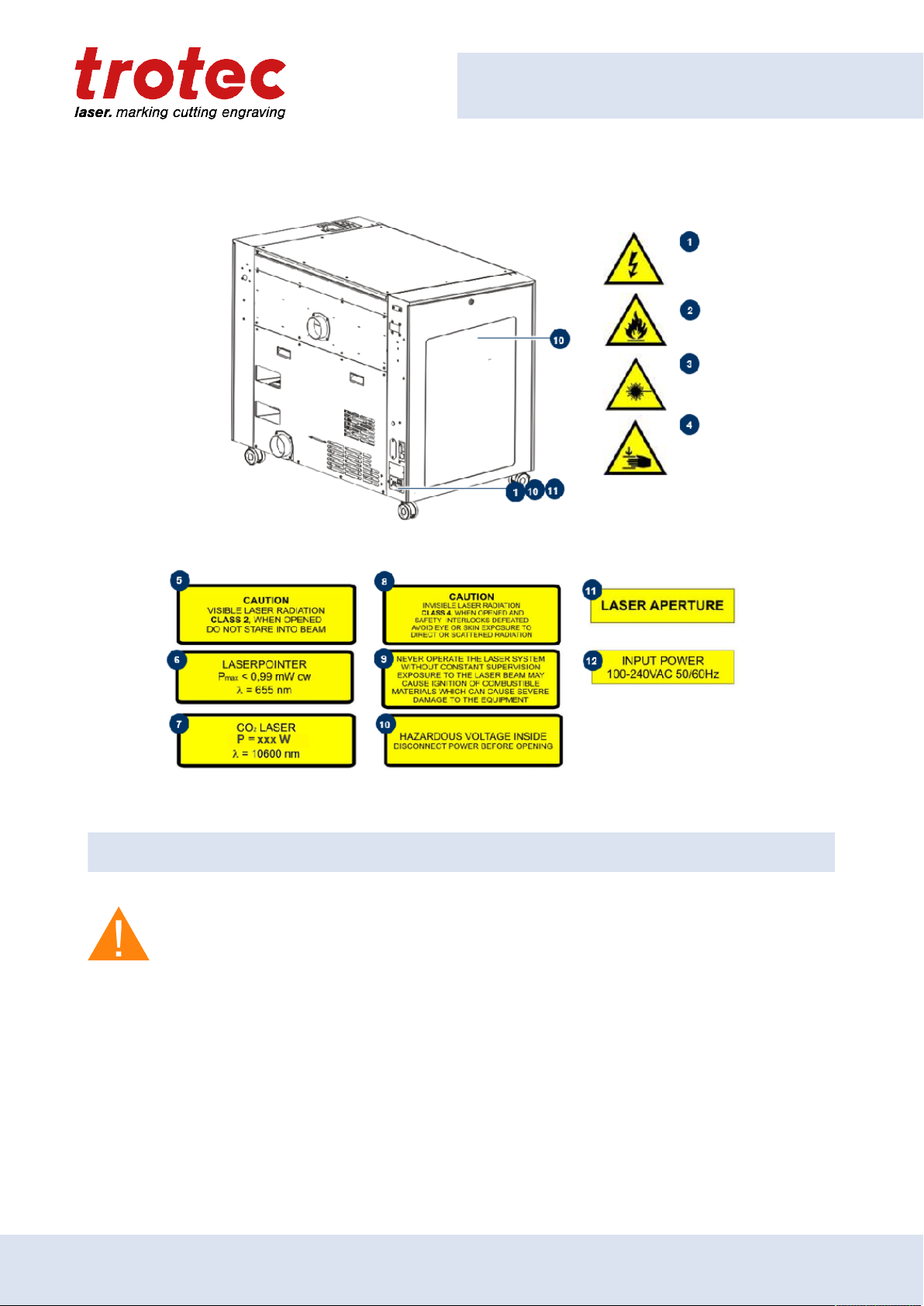

2.5 Machine identification (warning and safety stickers)

The warning and information labels are attached in the positions of the machine that could represent a

source of danger during set-up and operation. Therefore, pay attention to the information on the labels.

Caution

Lost or damaged warning and safety stickers.

If any warning and safety stickers are lost or damaged, the user is not able identify risks

anymore, and there is danger of injury.

– Replace lost or damaged labels immediately.

– Contact your Trotec Laser GmbH dealer for details.

20

Page 21

Safety

2.6 Safety devices

Warning

Danger from laser beam.

Safety and protection devices that are not installed or are not fully functional can lead to bodily

injury and material damage.

– Do not remove, modify or deactivate the interlock safety switches or protective covers on

the machine. Safety and protection devices must be fully functional at all times.

– In case of assumed or presumed damage of safety devices, disconnect the machine from

the mains.

– Damaged safety and protection devices need to be replaced by a Trotec technician

immediately.

21

Page 22

Safety

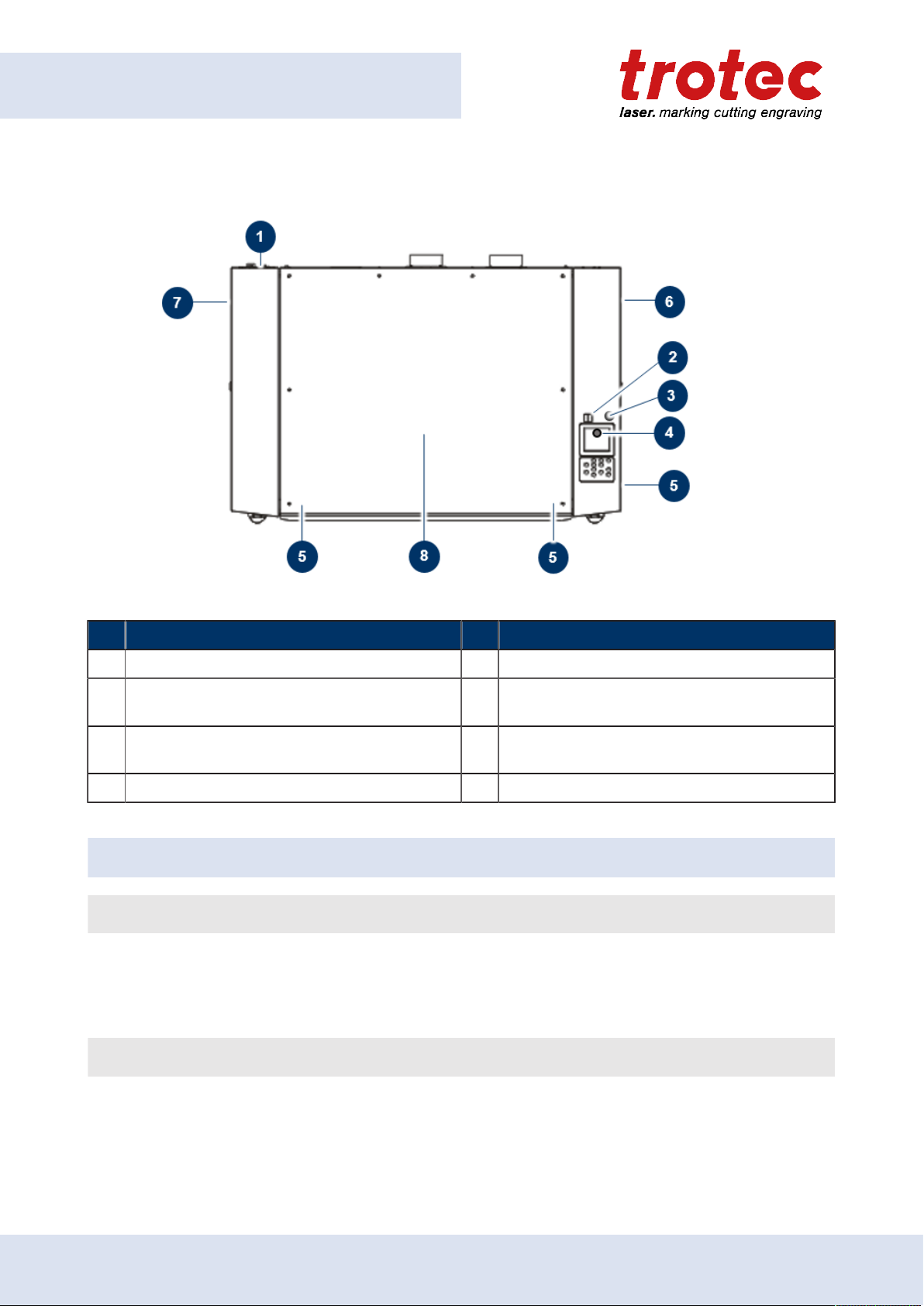

The machine is equipped with following safety devices:

No. Description No. Description

1 Main switch 5 Interlock safety switch

2 Emergency stop button (only with temperature

sensor option)

3 Temperature sensor reset button (only with

temperature sensor option)

4 Key switch 8 Acrylic top lid

6 Side panel right (with interlock safety switch)

7 Side panel left (with interlock safety switch)

2.7 Technical protective measures

2.7.1 Main switch

Pressing the main switch on the backside of the machine to disconnect the machine from the mains power

supply.

2.7.2 Key switch

Turning the key switch counterclockwise powers off the motor, laser source and electric system. Through the

key switch, operation by non-authorized personnel can be prevented.

22

Page 23

Safety

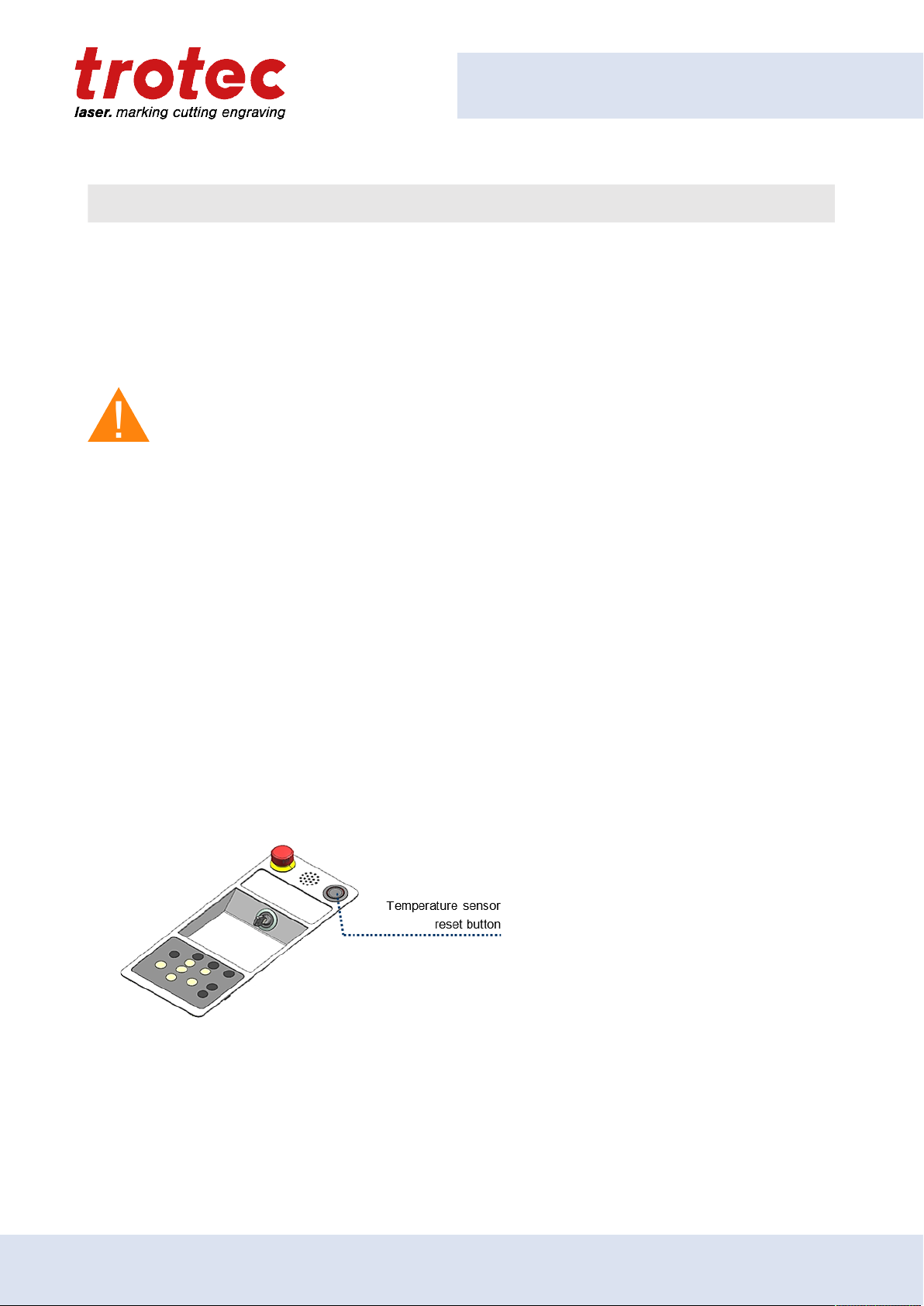

2.7.3 Temperature sensor

The temperature sensors ensure reliable temperature monitoring of the interior of the machine and are

available as additional option.

If a preset temperature value is exceeded, an acoustic alarm continuously sounds to warn the operator of

abnormal temperature trends during processing.

Warning

Fire hazard

The acoustic alarm upon startup of the machine indicates that the sensors are operating

properly. However, the sensors do not guarantee fire prevention.

– The unit must not operate unattended despite the integrated temperature sensors.

– If the acoustic alarm does not sound when the machine is switched on, check the

functionality of the sensors.

– In case of questions, contact our experienced Technical Support in your local area.

Functional test of the temperature sensors

When the machine with the temperature sensor option is activated, all sensors are checked for proper

function, and you will hear an acoustic signal.

If you do not hear an acoustic signal, please check the cables, connections, etc., or contact your local

Technical Support.

Temperature sensor alarm acknowledgement

Press the temperature sensor reset button

to acknowledge the alarm.

23

Page 24

Safety

2.7.4 Emergency stop button

The Emergency stop button, which is located above the operation panel, is present only if the machine is

equipped with an optional temperature sensor.

When pressing an Emergency stop button, the electric circuit immediately shuts off.

The laser beam is interrupted, and all movements are stopped.

The function of the Emergency stop button is:

Firstly: To prevent any risks to the operating personnel.

Secondly: To avoid any damage to/destruction of the machine/material.

Emergency stop button acknowledge

1. Turn the Emergency stop button counterclockwise

to unlock it (green marker is visible).

2. Reboot the laser system to acknowledge the laser

fault.

2.7.5 Interlock safety switches

Interlock safety switch query the closed status of the acrylic top lid, side panels and front door. If the safety

devices are open or not present, the laser cannot be operated. However, the pilot laser stays active.

2.7.6 Acrylic top lid

The type of acrylic top lid depends on the laser type. It protects the operator from uncontrolled emission of

laser radiation.

2.7.7 Side cover

The side panels protect from laser light and must always be closed and properly attached.

24

Page 25

Safety

2.7.8 In case of safety device malfunction

Actual or presumed damage to the safety devices can cause injury or damage. Following measures must be

carried out.

1. Press the emergency stop button.

2. Disconnect the machine from the mains.

3. Contact our Technical Support in your local area.

2.8 Secondary (indirect) hazards

2.8.1 Fire hazard

Warning

Fire hazard

Fire hazard from gas and processing of inflammable materials.

– Do not operate the device without supervision.

– Keep CO2 fire extinguisher ready at hand in the immediate vicinity of the device.

If a main laser beam comes into contact with inflammable material, e.g. paper, the latter may ignite, quickly

leading to fire. Therefore, before switching on the laser and after deactivating the Standby-mode you must

make sure that there is no inflammable material in the path of the laser beam.

Furthermore, gases formed beneath the material being processed may ignite, especially if the extraction

requirements are not met.

The risk of flaming is increased in case of insufficient care and cleaning as well.

Additionally, regularly control the air cooling system on your laser. In particular, the filters and ventilators

should be checked regularly for proper function to avoid defects caused by overheating.

25

Page 26

Safety

2.8.2 Gases, fumes and dust

Depending on the materials being processed and the parameters selected, laser processing may generate

gases, fumes, aerosols or dust. Depending on the material, such by-products may be toxic. In individual

cases, the reaction products may be electrically conductive dusts. If these enter electric systems, shortcircuiting with personal injury and property damage may occur.

The operator is responsible for ensuring presence of a suitable extraction system and compliance with the

relevant guidelines in order to protect persons and the environment. The guideline VDI 2262 1-3 "Workplace

air" provides, among other things, additional remarks.

The operator must also ensure that gases, fumes or dust do not settle on the processing lens. Any dirt

accumulating on the processing lens can lead to loss of performance, poor processing results and damage

to the device.

26

Page 27

Safety

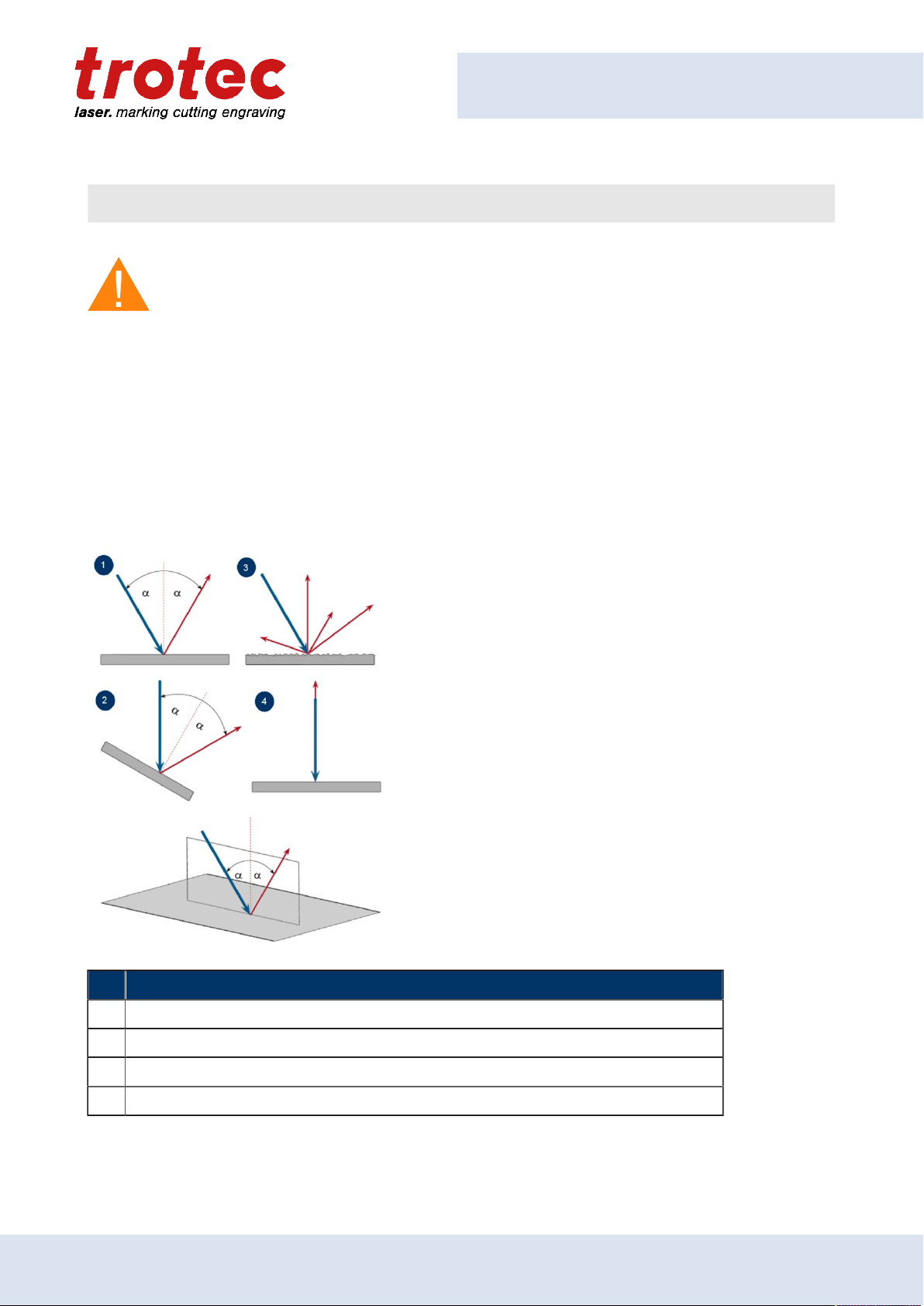

2.8.3 Reflection through materials

Warning

Danger from laser beam.

Invisible laser radiation of reflecting materials can cause serious injury or material damage.

– Only material according to the intended use of the machine may be used.

– Do not use material with high reflecting surfaces such as aluminum, chromium, precious

metals, metal foils, stainless steel, brass, copper and titanium.

– Take special care with surfaces formed convex and concave.

– Do not leave or put objects on the work surface/working area.

Laser beam reflection

The reflecting law is valid for the reflection of the laser radiation: Angle of incidence = failure corner

No. Description

1 Directed reflection: Reflected ray on smooth surface.

2 Directed reflection: Reflected ray on sloping surface.

3 Diffuse reflection: Reflected ray on rough surface.

4 Directed reflection: Horizontally reflected ray on smooth surface.

27

Page 28

Safety

2.8.4 Information about damaged optics

Warning

Damage to optics.

Soiled optics absorb laser radiation and can thus be destroyed. Broken or damaged lenses as

well as thermal decomposition of lenses release particles which cause serious damage to the

health.

– The passive reflectors and optics in the area of the laser beam guidance should be cleaned

regularly.

– Special care is required when handling, attaching and cleaning these elements.

– Do not exert non-uniform pressure.

– Do not use tools or hard objects to clean the surface.

– Never touch the optics with your bare fingers.

– Never use cleaning tissues twice.

– When lenses get broken, damaged or thermal decomposed follow the protective measures.

– Disposal according to regulations and laws valid in the user's country.

– Lenses with scratches or lenses with penetrations must not be used anymore!

Scratched or destroyed lens surface

Be aware that scratches in the coating may release small quantities of thorium, which may be harmful upon

inhalation or swallowing.

Thermal decomposition

Upon thermal decompositions, vapors of selenium oxide and zinc oxide are formed. Upon inhalation or

swallowing there is danger of poisoning. Indicators for thermal decomposition of ZnSe include deposits in the

form of red or white powder and an unpleasant odor.

Broken lenses

When optical components of zinc selenide (ZnSe) are destroyed, toxic dusts and vapors are formed which

must not be inhaled. The dust can additionally cause irritations of the eyes, skin and respiratory tract. If a

lens has been destroyed during operations, care is to be taken during removal and cleaning.

28

Page 29

2.8.5 Protective measures for damaged optics

Protective measures in case of thermal decomposition and scratched or broken lenses

•

For disposal use a protective mask or respiratory filter to prevent inhalation or ingestion of thorium.

•

Wash hands thoroughly after contact with a scratched coating.

Protective measures in case of a broken lens

•

Upon perception of an unpleasant odor, switch off the machine.

•

Hold your breath.

•

Leave the area of the machine.

•

Before approaching the system again, wait for at least 30 min until the reaction has abated.

•

Wear proper protective clothing (respiratory protection, protective goggles, protective suit, rubber or

plastic gloves).

•

Provide ventilation.

•

When approaching the system again, pay attention to odors.

•

Remove all lens fragments.

•

Avoid raising or dispersing dust.

Safety

Disposal

The ZnSe dust and the lens are to be collected drily and disposed of with fragments, broom,

shovel and protective clothing into hermetically sealable containers or plastics bags as

hazardous waste.

Do not dispose of optical components as domestic waste, and do not let them enter the

sewer or water bodies.

Dispose of according to regulations and laws valid in the users' country.

29

Page 30

Safety

2.9 In case of emergency

In case of malfunction

•

In case of unusual operating states, open the acrylic top lid to stop working process or respectively press

the Emergency stop button, if available and switch off the laser device.

•

When appropriate disconnect the machine from the mains.

•

Inform laser safety officer and supervisor.

•

Follow the Operating manual.

•

Have repair work performed by Trotec Laser GmbH service technicians only.

•

In case of fire: Use only CO2 fire extinguisher to quench the fire, insofar as this is possible without

endangering yourself.

Notice

After a deletion, Trotec Technical Support must be involved before the system is put back into

operation.

In case of accident, First Aid

•

If due to laser irradiation eye injury has occurred (upon exceedance of the maximum allowable irradiation

rate), the accident victim must immediately be presented to an ophthalmologist.

•

Assumption of eye injury is justified whenever laser irradiation has occurred and the maximum allowable

irradiation rate may have been exceeded.

•

First aider must pay attention to self-protection.

•

Power off the device.

•

Remove injured person from the danger zone and provide First Aid.

•

Call emergency doctor!

30

Page 31

3 Technical Data

The technical data sheet can be found in the appendix of this manual.

3.1 Dimensions and weight

Technical Data

Description Dimension

A Length 1221 mm (48 inch)

B Width 830 mm (32.67 inch) / 790* mm (32.8 inch)*

C Height, closed with base frame 1055 mm (41.55 inch)

D Height, open 1750 mm (68.89 inch)

* Without exhaust hose connectors on the back and with the top lid open.

Weight (depends on the machine type): 235 bis 250 kg (518 to 551 lbs)

31

Page 32

Technical Data

3.2 Electrical requirements of the machine

Laser power 35–50 W (CO2)

10-50 W (fiber)

AC

Voltage 230VAC 115VAC 230VAC 115VAC 230VAC 230VAC

Fuse 8AT 16AT 10AT 16AT 12AT 12AT

Power consumption 1200 W 1200 W 1400 W 1400 W 1900 W 1900 W

AC = air condition

55–80 W (CO2)

10-50 W (fiber)

AC

85–100 W

(CO2)

10-50 W

(fiber)

AC

105–120 W

(CO2)

10-50 W

(fiber)

AC

Caution

Inadequate or inappropriate power sources can lead to machine damage and are not covered

by any liability.

Verify that the electrical outlet is capable of providing the proper voltage, frequency and

amperage required by the laser machine described in this manual.

Caution

Electrical noise, unstable power supply as well as voltage spikes in power supply can cause

interference and possible damage to the electronics of the laser machine.

32

Notice

Use an individual circuit for the laser machine and the PC and an individual circuit for the

exhaust system. Install your computer to the same circuit as the laser machine to prevent

electromagnetic interactions.

Furthermore it is highly recommended that you use a overvoltage protection switch to protect

your computer equipment.

If electrical power fluctuations, brownouts or power outages are a problem in your area, an

electrical line stabilizer, UPS (Uninterruptible Power Supply) or backup generator are required.

When installing any of these devices, ensure that they meet the electrical requirements of the

laser machine.

Page 33

3.3 Exhaust system requirements

Danger

Danger of emission of toxic gases, vapors or dust.

During laser operation, toxic aerosols may be produced.

– The laser system may be operated only with properly installed and operating exhaust

system.

– Check with the material manufacturer for its toxic effect.

Caution

The laser may only be operated with properly installed and operating exhaust system. Damage

to the system, caused by the use of not any exhaust system or improper extraction equipment,

will not be covered by any liability.

Technical Data

The requirements for the exhaust system and recommended Trotec exhaust systems for standard

applications depend on the working table installed in the machine.

Recommended exhaust systems for Speedy serie:

Exhaust system Speedy 100 Speedy 300 Speedy 360 Speedy 400

Atmos Nano ✓

(only Speedy

100 fiber)

Atmos Cube

(Atmos Compact)

Atmos Mono

Atmos Mono Plus

Atmos Duo Plus ✓ ✓ ✓

Vent Set 300

(without Speedy

✓

100 flexx)

✓

✓

✓

✓

(only Speedy

300 fiber)

✓

(without

vacuum table)

✓

(without

vacuum table)

✓

(without

vacuum table)

✓

(without table

exhaust)

✓

(without table

exhaust)

Vent Set 400

✓ ✓

Vent Set 500 ✓ ✓ ✓

✓

(without

vacuum table)

(without

vacuum table)

✓

33

Page 34

Technical Data

Notice

– Connection has to be carried out by our Technical Support.

– Observe instructions for operation and maintenance according to the operating manual of

the exhaust system.

Technical data of the corresponding exhaust systems:

Exhaust system Hose connection ø [mm]

(inside diameter)

Atmos Nano 45 200 8500 (230V)

Atmos Cube

(Atmos Compact)

Atmos Mono 70 320 8500 (230V)

Atmos Mono Plus 70 320 8500 (230V)

Atmos Duo Plus 70 (2x) 320 8500 (230V)

Vent Set 300 80 max. 1000 max. 2550

Vent Set 400 100 max. 1000 max. 3800

Vent Set 500 100 max. 1200 max. 7000

80 250 8500 (230V)

Volume flow [m³/h] Pressure[Pa]

5800 (115V)

5800 (115V)

5800 (115V)

Requirements for the exhaust system:

Machine Volume flow [m³/h] Pressure [Pa]

Speedy 100 200 1000

200 (without table exhaust) 1000 (without table exhaust)Speedy 300

350 (with table exhaust) 1600 (with table exhaust)

300 (without table exhaust) 2500 (without table exhaust)Speedy 360

400 (with table exhaust) 4200 (with table exhaust)

Speedy 400 400 4200

The monitoring point for flow rate and pressure is at the exhaust port at the laser machine. Pressure loss

by hoses / pipes or filter parts of the exhaust system has to be determined and additionally calculated when

selecting a proper exhaust system.

A powerful exhaust system keeps the lifetime of optics and mechanical components, the cutting quality and

the laser power interacting with the workpiece from being impaired by fumes and dust accumulating in the

machine.

34

Page 35

Notice

The exhaust power available for the application will be reduced by e. g. bends, small hose

diameters and long hoses.

You should therefore note the following:

– Avoid bends.

– Keep hose as short as possible.

– Use hose diameters as large as possible.

Applications generating large amounts of dust or fumes may require a stronger exhaust system.

Use of separate exhaust systems for head and table exhaust may also be necessary.

In this case it is absolute necessary to consult your distributor.

3.4 Computer requirements

Technical Data

When using a more powerful computer, the graphics are generated and displayed faster, and the computing

times and the times for data transfer to the laser are reduced.

The following recommendation represents the minimum requirements:

•

Operating systems

Windows Vista® 32/64-bit (with Service Pack 1 or later)

Windows 7® 32/64-bit

Windows 8® 32/64-bit

Windows 8.1® 32/64-bit

Windows 10® 32/64-bit

•

Microsoft® .NET framework 3.5 or later

•

Adobe® Reader 9.0 or later

•

Local administrator privileges (for required software installations)

•

2 GHz processor or faster

•

2 GB RAM or greater (Windows Vista®, Windows 7 / 8 / 8.1 / 10)

•

80 GB hard driver or larger

•

1024 x 768 monitor resolution or greater

•

True Color graphics card (24-bit color depth)

•

2 free USB interfaces

•

DVD-ROM drive

35

Page 36

Technical Data

3.5 Materials

List of material

Cutting Engraving MarkingMaterial EN Material DE

CO2Fiber Flexx CO2Fiber Flexx CO2Fiber Flexx

Metal

Aluminum Aluminium ✓ ✓ ✓ ✓

Aluminum,

anodized

Chromium Chromium

Precious metal Edelmetalle ✓ ✓ ✓ ✓

Metal foils

up to 0.5mm

(Aluminum,

Brass, Copper,

precious metal)

Stainless steel Edelstahl ✓ ✓ ✓ ✓

Metal, painted beschichtetes

Brass Messing ✓ ✓ ✓ ✓

Copper Kupfer ✓ ✓ ✓ ✓

Titanium Titan ✓ ✓ ✓ ✓

Aluminium,

eloxiert

Verchromte

Oberflächen

Metallfolien

bis zu 0,5mm

(Aluminium,

Messing, Kupfer,

Edelmetall)

Metall (lackiert)

✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓

36

Page 37

Plastic

Technical Data

Acrylonitrile

butadiene styrene

(ABS)

Acrylic/PMMA,

i.e. Plexiglas®

Rubber Gummi

Polyamide (PA) Polyamid (PA) ✓ ✓ ✓ ✓ ✓ ✓

Polybutylene

terephthalate

(PBT)

Polycarbonate

(PC)

Polyethylene (PE) Polyethylen (PE) ✓ ✓ ✓ ✓ ✓ ✓

Polyester (PES) Polyester (PES) ✓ ✓ ✓ ✓ ✓ ✓

Polyethylene

terephthalate

(PET)

Polyimide (PI) Polyimid (PI) ✓ ✓ ✓ ✓ ✓ ✓

AcrylnitrilButadienStyrolCopolymer (ABS)

Acryl(PMMA),

z.B. Plexiglas®

(Stempelgummi)

Polybutylenterephthalat

(PBT)

Polycarbonat

(PC)

Polyethylenterephthalat

(PET)

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

Polyoxymethylene

(POM) -i.e.

Delrin®

Polypropylene

(PP)

Polyphenylene

sulfide (PPS)

Polystyrene (PS) Polystyrol (PS) ✓ ✓ ✓ ✓ ✓ ✓

Polyurethane

(PUR)

Foam (PVC free) Schaumstoff

Polyoxymethylen

(POM) z.B

Delrin®

Polypropylen

(PP)

Polyphenylensulfid

(PPS)

Polyurethan

(PUR)

(PVC frei)

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓ ✓

37

Page 38

Technical Data

Miscellanious

Wood Holz ✓ ✓ ✓ ✓

Mirror Spiegel ✓ ✓ ✓ ✓

Stone Stein ✓ ✓

Paper (white) Papier (weiß) ✓ ✓ ✓ ✓ ✓ ✓

Paper (colored) Papier (farbig) ✓ ✓ ✓ ✓ ✓ ✓ ✓

Food Lebensmittel ✓ ✓ ✓ ✓ ✓ ✓ ✓

Leather Leder ✓ ✓ ✓ ✓ ✓ ✓

Fabric Textilien ✓ ✓ ✓ ✓

Glass Glas ✓ ✓

Ceramics Keramik ✓ ✓ ✓ ✓ ✓

Cardboard Karton ✓ ✓ ✓ ✓ ✓ ✓

Cork Kork ✓ ✓ ✓ ✓ ✓ ✓

Markierungsmittel

(auf Metall oder

Keramik/Glas)

z.B. markSolid

✓ ✓ ✓ ✓

Warning

Prohibited materials:

– Leather and artificial leather that contains chromium (VI)

– Carbon fibers (Carbon)

– Polyvinyl chloride (PVC)

– Polyvinyl butyral (PVB)

– Polytetrafluorethylene (PTFE, Teflon)

– Beryllium oxide

– Materials containing halogens (fluorine, chlorine, bromine, iodine and astatine), epoxy or

phenolic resins.

Take care when processing the following materials:

– Manganese

– Chromium

– Nickel

– Cobalt

– Copper

– Lead

– any material with the naming addition “flame-retarding” since it might contain bromine.

38

Page 39

Technical Data

Warning

Serious injury or material damage.

The use of prohibited or unreleased materials can cause serious injury or material damage and

will not be covered under warranty.

Only use approved and released materials.

Notice

Please contact our experienced application specialists or a sales partner near you, if:

– You are unsure about the processing of a material.

– You have additions for further materials for us or in your opinion a material was not listed.

We recommend performing a material processing test with the above mentioned material, using

the appropriate configuration.

Trotec Laser GmbH assumes no responsibility for any consequences of laser processing in any

application, especially with medical or pharmaceutical applications.

39

Page 40

Machine overview

4 Machine overview

4.1 General overview

No Description No Description

1 Acrylic top lid 13 Side panel left

2 Service plug connector 14 Cover for laser source and power supplies

3 Laser head 15 Connector for exhaust tube

4 Interlock safety switch 16 USB port for PC

5 Connector for rotary attachment 17 RS-232 port for PC

6 X-axis 18 Connectors for exhaust cable

7 Table 19 Type plate

8 Key switch 20 Main switch

9 Keypad 21 Mains connection

10 Interlock safety switch 22 Connector for JobControl®Vision

11 Front door 23 Fuse(s)

12 Side panel right 24 LED interior illumination

40

Page 41

4.2 Front door

Machine overview

Loading and unloading of heavy and bulky parts or replacement

of the table is very comfortable thanks to the front door that can

be opened to up to 180°.

Notice

The door is interlocked, therefore it must be closed

before any laser operation is possible.

4.3 Tables (multifunctional table concept)

Multifunctional base frame

The multifunctional base frame is bolted to the mounting

frame, which is attached to the Z-axis.

Notice

All table variants rest on the base frame. With exception of the ferromagnetic engraving table

which may also be placed directly on the mounting frame if there is no base frame present.

Ferromagnetic engraving table

The ferromagnetic construction allows mounting thin

materials such as paper, films or foils with magnets to

ensure an even and flat surface. An even working area is

essential for achieving optimal results for laser engraving

and marking applications.

41

Page 42

Machine overview

Vacuum table

Aluminum slat cutting table

The vacuum table fixates various materials to the working

table using vacuum. This ensures correct focusing over

the entire surface, leading to better engraving results. In

addition, it reduces the handling effort associated with

mechanical mounting.

The vacuum table is the ideal table for thin and lightweight

materials, such as paper, foils and films, that generally do

not rest flatly on the surface.

The cutting table with aluminum slats is ideal for cutting

thicker materials (8 mm thickness and above) and for parts

wider than 100 mm.

The slats can be arranged individually, consequently the

table can be adjusted to each individual application.

Acrylic slat cutting table

The cutting table with acrylic slats prevents reflection during

cutting. This table is used in particular for cutting thicker

materials (8 mm thickness and above) and for parts wider

than 100 mm.

The slats can be arranged individually, consequently the

table can be adjusted to each individual application.

42

Page 43

Aluminum cutting grid table

Acrylic cutting grid table

Machine overview

This robust cutting table offers excellent stability and is

particularly suitable for cutting tasks with parts smaller than

100 mm, as these remain in a flat position after the cutting

The special acrylic cutting grid table prevents reflection

during cutting. It is therefore ideal for cutting acrylics,

laminates or plastic films with parts smaller than 100 mm,

as these remain in a flat position after the cutting.

Notice

The equipment of the machine may vary depending on the model.

4.3.1 Additional tabletops

Honeycomb tabletop

The honeycomb tabletop is especially suitable for

applications that require minimal reflection and optimum

flatness of the material, e.g. cutting of membrane

keyboards.

The honeycomb tabletop is an additional option for the

vacuum and ferromagnetic engraving tables.

Available in following sizes:

0.5 inch nominal comb size

0.25 inch nominal comb size

43

Page 44

Machine overview

4.3.2 Table placement

1. Place a suitable table on the multifunctional base frame.

2. Fixate the table by pressing the push buttons.

Notice

All table variants rest on the base frame. However the ferromagnetic engraving table may also

be placed directly on the mounting frame without the base frame.

Maximum material load is:

– For static loads up to 220 lbs (100 kg).

– For dynamic loads up to 66 lbs (30 kg).

Caution

Damage of the multifunctional base frame or impairment of the exhaust function.

When workpieces are processed directly in the multifunctional base frame without a table, the

base frame be damaged, and impairment of the exhaust function is possible.

Process workpieces only on suitable tables.

44

Page 45

4.4 Lens(es)

Machine overview

CO

2

1.5'' red

Part number:

85973

2.0'' black

(standard)

Part number:

85974

2.0'' CL brown

Part number:

95909

Fiber Flexx

3.2'' green

Part number:

1380

5.0'' light blue

Part number:

37781

2.85'' gold

(standard)

Part number:

9567

2.5'' silver

Part number:

85975

4.0'' blue

Part number:

90026

Notice

The equipment of the machine may vary depending on the model.

45

Page 46

Machine overview

4.5 Nozzles

Ø 3

Short nozzle with small hole.

Ø 7

Short nozzle with big hole.

46

Page 47

Transport

5 Transport

5.1 Safety notes

Warning

Risk of injury

There is risk of injury from falling parts during transport, loading and unloading of the machine.

– Follow the safety notes.

Observe the safety notes to avoid damage to the machine from improper handling during transport:

•

Always move the machine with utmost care and attention.

•

Transport the machine/machine components only in its original packaging.

•

Take the machine’s center of gravity into account when transporting it (minimize the risk of tipping over).

•

Observe the packaging symbols (e.g. transport the machine only in upright position).

•

Take measures to prevent the machine from slipping sideways, tipping or falling over.

•

Transport the machine as carefully as possible in order to prevent damage.

•

Avoid vibrations.

•

When transporting the machine overseas, the device must be packaged airtight and protected against

corrosion.

•

When transporting outdoors, transport only in vehicles with roof or sufficient weather protection.

•

Protect the machine against transportation damage using straps and inserts, and leave sufficient gaps to

other transported items.

•

Do not place any other loads or items on the machine or machine components.

5.2 Delivery state

Unless otherwise agreed, the machine is delivered in a wooden crate that contains the laser machine and

additional accessories. Transport the machine only in its original packaging.

Caution

Risk of injury

There is risk of injury from falling parts during transport, loading and unloading of the machine.

•

Follow the safety notes.

47

Page 48

Transport

Observe the packaging symbols:

Note the shockwatch sign:

48

Page 49

5.3 Temperature and humidity

Transport conditions

Transport temperature (ambiente temperature): -10 °C to +40 °C

Relative humidity: Maximum 70%, non-condensing

•

Avoid high temperature fluctuations.

Storage conditions

Storage temperature (ambiente temperature): +0 °C bis +30 °C

Relative humidity: Maximum 60%, non-condensing

Transport

•

Avoid high temperature fluctuations.

5.4 Required tools for unloading and transport

Required tools:

•

Unloading - Forklift

•

Transport - Pallet truck

5.5 Place of storage

•

Keep the machine sealed in its packaging until it is assembled or installed.

•

The storage location must be dry, free of dust, caustic materials, vapors and combustible materials.

•

Store in a storage room or packaged with adequate weather protection.

•

Avoid exposure of the machine to shocks or vibrations.

•

Avoid extreme temperature fluctuations.

•

Take particular care when packing away electronic components.

•

When storing for a longer period, apply a coat of oil to all bare-metal machine parts.

•

Regularly check the overall condition of all parts and of the packaging.

49

Page 50

Transport

5.6 Transport inspection and reporting of defects

•

Immediately after receipt inspect the delivery to ensure that it is complete and has not suffered any

damage.

•

If any transport damage is visible, do not accept the delivery, or accept it only with reservation.

•

Record the scope of the damage on the transport documents or delivery note.

•

For all defects that are not discovered upon delivery, be sure to report them as soon as they are

detected, since damage claims must be filed within a certain period, as mandated by law.

50

Page 51

Transport

5.7 Unpacking the machine

Only trained and authorized personnel are permitted to transport and unpack the machine. To avoid falling off

of any wooden parts or tipping of the machine, be very careful when opening the transport case.

Notice

Keep the original packaging case, in case of machine needs to be transported or relocate.

Dispose all waste according to the applicable waste disposal law.

Caution

The lens unit should be unpacked only after installation of the machine. The lenses are highquality optical components which must be kept clean in order to ensure optimum marking

results. Never touch the lenses with bare fingers.

Steps:

1. Position the transport case vertically on level ground (using a pallet truck or forklift).

2. Remove any vertical tightening straps.

3. First remove the top and afterwards the side plates of the transport case.

4. Slide out the two wooden rails in the form of ramps that are stored beneath the machine.

5. To secure the machine against moving, the wheels are locked using wooden blocks.

In order to remove those blocks, put the two wooden rails together, push the upper part of the rails under

one side of the machine and press down the rail in order to reach a levering effect.

6. Pull out the blocks.

7. Repeat this procedure on the opposite side as well.

8. Now you can pull out the blocks.

51

Page 52

Transport

5.8 Relocation of the machine

Steps:

1. Switch off the machine.

2. Disconnect the power cable.

3. Remove the exhaust system.

4. Reposition the machine (e.g. with auxiliary equipment if necessary) and place it on a level, clean floor.

5. Adjust the machine.

6. Initial commissioning of the electrical system.

7. Carry out function test.

Caution

Transport the machine only in its original packaging. Ensure the wooden crates are properly

secured otherwise the crates can slip, tip or fall over during transport.

Observe the corresponding safety norms and regulations from the chapters "Safety notes" and

"Transport".

– When transporting over long distances, use transport boxes including transport securing.

Notice

If you would like to relocate the machine, contact our experienced Technical Support in your

local area.

52

Page 53

6 Setup and installation

6.1 For your safety

Notice

The setup has to be carried out by Technical Support.

6.2 Temperature and humidity

Ambiente conditions

Setup and installation

Operating temperature (ambiente temperature): +15 °C to +25 °C

Relative humidity: 45-65%, non-condensing

•

If the system has been exposed to large temperature fluctuations, it must first be brought back to room

temperature before commissioning.

Environmental conditions

•

Provide sufficient illumination at the workplace.

•

Ensure a dust-free environment (II° according to IEC60947-1).

•

Shielding from EMC.

•

Freedom of interfering electrical installations, hoses and pipe lines.

•

Power supply free of fluctuations.

53

Page 54

Setup and installation

6.3 Space requirements

Ensure there is shielding or sufficient clearance to or from the wall and neighboring objects.

6.4 Setup

Observe the following steps:

1. Transport the machine to the installation location according to the specifications stated in the chapter

“Transport”.

2. Make sure all the packaging material has been removed.

3. Remove any transport protections.

4. Install the two exhaust connectors at the rear of the machine.

They have been removed for safety reasons and for transport through doors.

5. The machine must stand upright.

6. Make sure the protective glass is intact.

7. Now connect the electrical components.

– Mains connection

– PC connection

– Exhaust connection

8. Install the software and register your system during the installation process.

54

Page 55

6.5 Connections

Caution

Install the connections exactly in the order described, otherwise electrostatic charging can

damage your computer and/or the electronics of the laser system.

Setup and installation

No Description No Description

1 USB port for PC 5 Mains connection

2 RS-232 port for PC 6 Fuse

3 Connector for exhaust connection

cable

4 Main switch 8 Exhaust connection

7 JobControl® Vision connector

55

Page 56

Setup and installation

6.5.1 Mains connection

•

Connect the end of the mains connection cable to the main connection socket.

Warning Current

Wrong voltage can cause damage to the machine.

Do not operate the machine, if the mains voltage does not match the voltage required by the

exhaust system, as this may cause damage to the machine.

Make sure that the mains voltage matches the voltage required by the exhaust system.

Notice

Depending on the laser type and region, the main fuses (6) are either covered or open next to

the connector.

6.5.2 Connection the PC

1. Connect the laser to a free interface or USB port on your computer.

2. Connect the computer to the mains.

3. Switch on the computer.

56

Page 57

Setup and installation

6.6 Connection of additional components

6.6.1 Connecting an exhaust system from Trotec

Warning Current

Wrong voltage can cause damage to the machine.

Do not operate the machine, if the mains voltage does not match the voltage required by the

exhaust system, as this may cause damage to the machine.

Make sure that the mains voltage matches the voltage required by the exhaust system.

Connecting:

1. When using an original Trotec exhaust system, also connect this, using the exhaust connection cable

included, to the exhaust cable connection on the laser.

2. Plug the ends of the exhaust hose into the exhaust nozzle that is intended for this purpose on the

exhaust system and on the laser. The position of the connector depends on the type of the exhaust

system.

3. Plug in the mains cable of your exhaust system into the mains socket.

Follow the operation and maintenance instructions in the Manual of the exhaust system.

57

Page 58

Operation

7 Operation

Warning

Personal injury or damage to property due to improper operation.

Improper operation can lead to serious personal injury or damage to property.

– Work on the laser machine may only be carried out by authorized and instructed personnel

familiar with the operation of the machine, observing all safety regulations.

7.1 Before commissioning

Check the following points before commissioning:

•

Completeness and technically flawless condition of the machine and safety devices.

•

Order and cleanliness at the workplace.

•

Cleanliness of optical components (free of dust and dirt).

•

Activated exhaust system.

•

Complete electrical installation.

•

Correct input voltage of the electrical installation.

•

Environmental conditions according to technical specification.

•

Compliance with all laser safety regulations and measures.

•

Fulfill and compliance with all laser safety requirements.

If errors or functional deviations should occur during the inspection of the listed points, the machine is not