Page 1

OPERATION MANUAL

8010 Trotec Speedy 100 / R

BA 8010_3.0_EN (10/2016) 1 / 68

Page 2

Trotec Laser GmbH

Linzer Strasse 156

A – 4600 Wels

AUSTRIA

Ph.: +43/7242/239-0

E-Mail: trotec@troteclaser.com

www.troteclaser.com

Trotec cannot be held responsible for any direct or indirect damages, which result from using or

working with the products electric circuits or software described herein. The apparatus must be used

only by trained and skilled personnel. Before use the manual should be read and followed carefully.

Furthermore Trotec reserves the right to change or alter any product described herein without prior

notice.

In case of failure, please check the device first according to section 6.1 Tips for Troubleshooting. If

unsuccessful, please note all data of the device (year of manufacture, software version, etc.) and

call us from a telephone next to the switched on device.

For queries or technical problems please contact your dealer or Trotec directly at the above address.

This documentation with all illustrations is intellectual property of Trotec Laser GmbH.

The entire documentation is given to the user for personal use only. This documentation must not

be reproduced or made available to others without our written permission. Any breach of law will be

prosecuted.

BA 8010_3.0_EN (10/2016) 2 / 68

Page 3

TABLE OF CONTENTS

1 GENERAL ........................................................................................................................ 5

1.1 Operation Manual Use – General Information ........................................................................................ 5

1.2 Designated Use .......................................................................................................................................... 6

1.3 Disposal remarks ....................................................................................................................................... 6

1.4 Technical Data / Device Specification ..................................................................................................... 7

1.4.1 Technical Data Speedy 100 .................................................................................................................. 7

1.4.2 Technical Data Speedy 100R ............................................................................................................... 9

1.5 Manufacturer's Label ............................................................................................................................... 11

1.6 EU – Declaration of conformity .............................................................................................................. 12

2 SAFETY .......................................................................................................................... 13

2.1 General Safety Information ..................................................................................................................... 13

2.2 Laser Safety Information ........................................................................................................................ 14

2.3 Safety Precautions when Operating the Device ................................................................................... 15

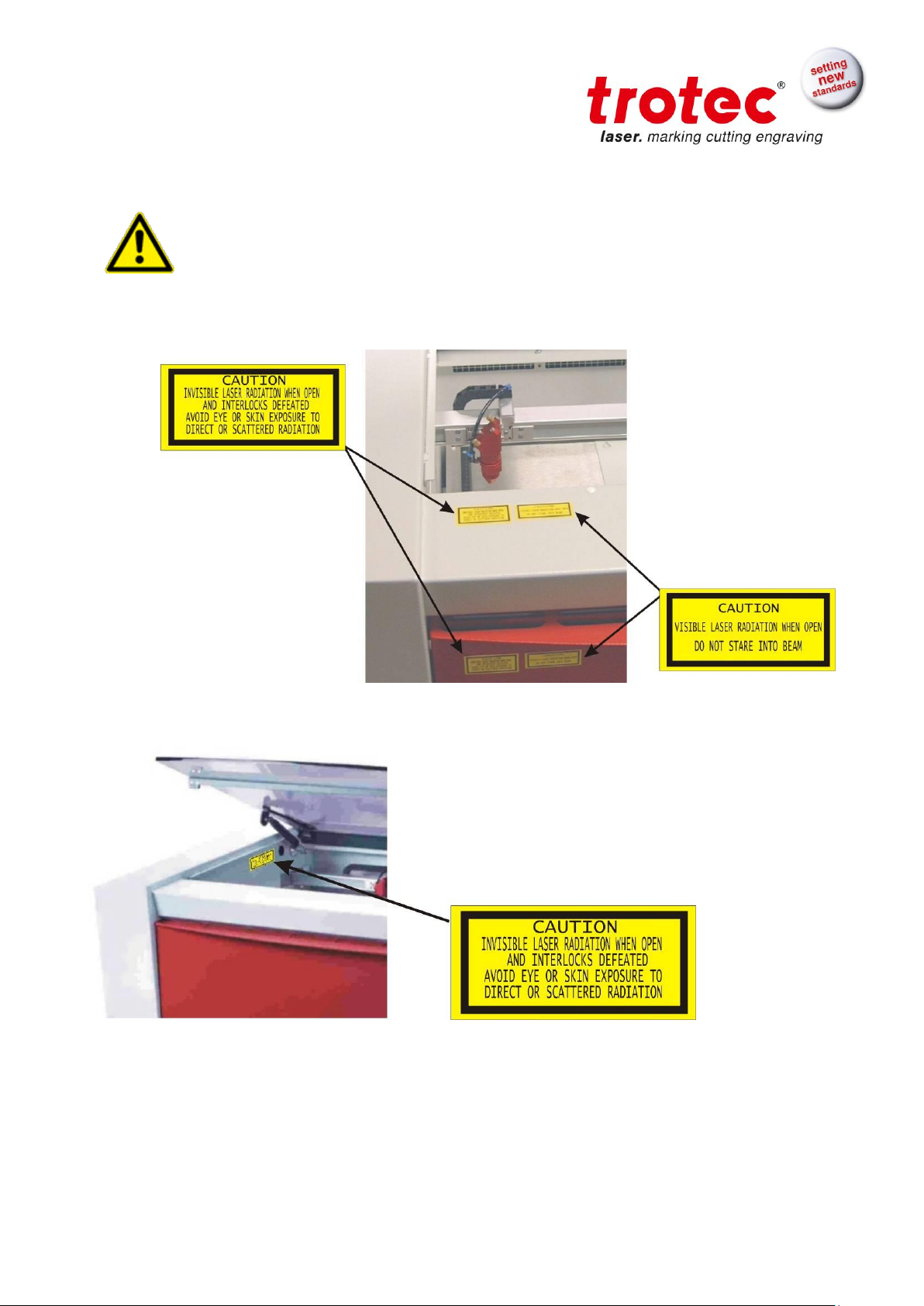

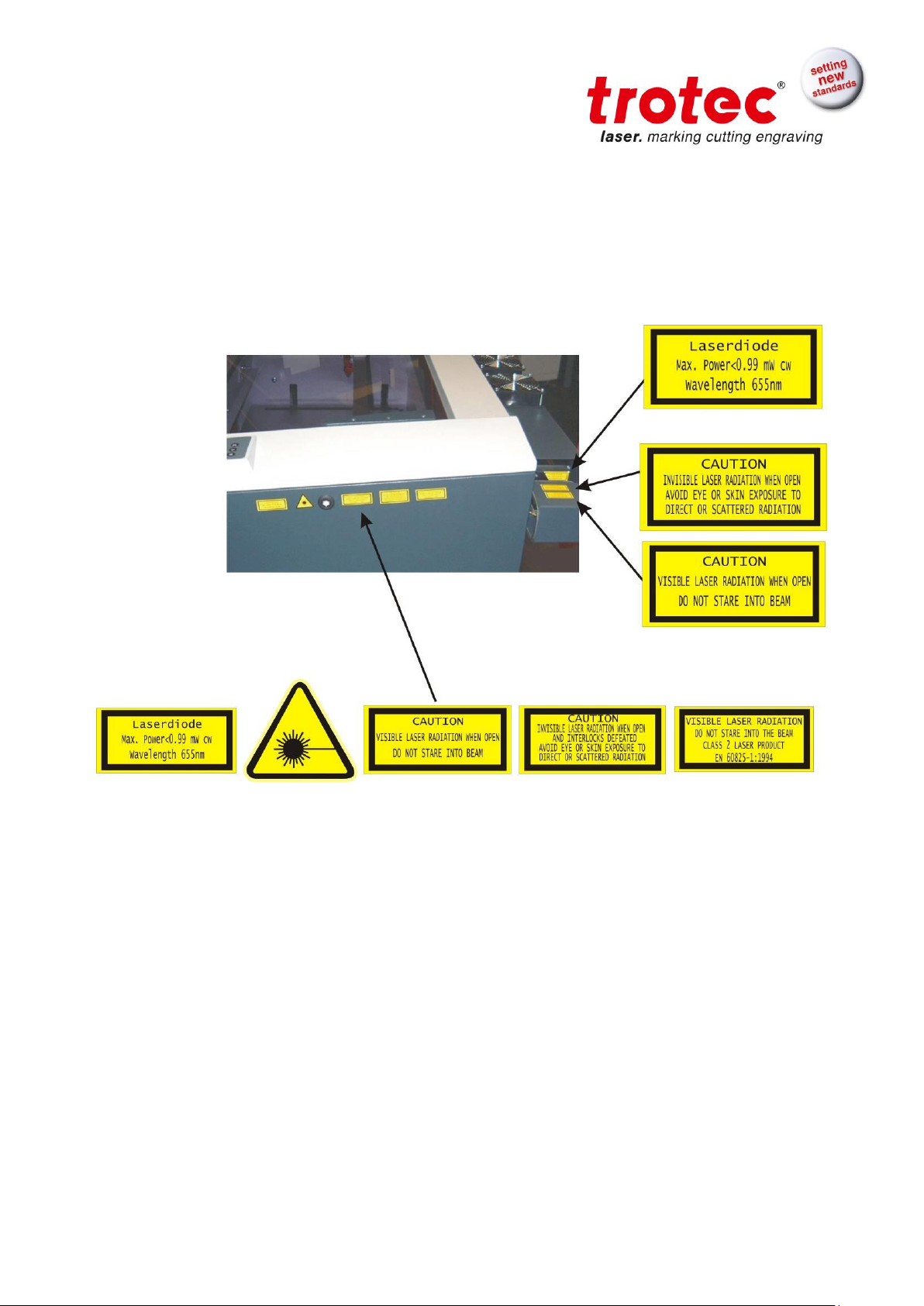

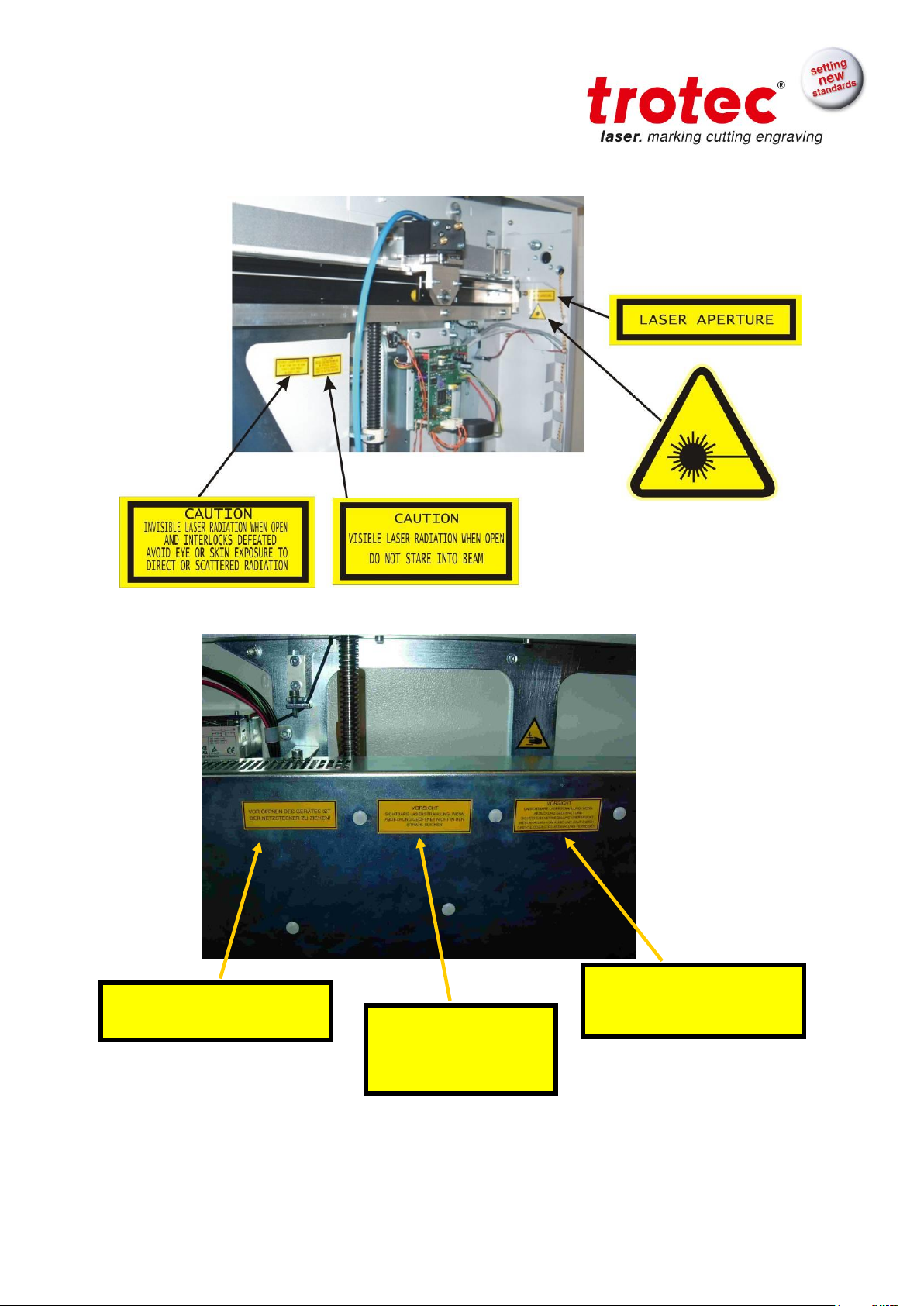

2.4 Warning and Information Labels ............................................................................................................ 16

3 BEFORE OPERATION ................................................................................................... 19

3.1 Unpacking ................................................................................................................................................ 19

3.2 Contents of Delivery ................................................................................................................................ 20

3.3 Location .................................................................................................................................................... 21

3.4 Electrical – Requirements ....................................................................................................................... 22

3.5 Exhaust System – Requirements ........................................................................................................... 23

3.6 Computer – Requirements ...................................................................................................................... 23

3.7 Connections ............................................................................................................................................. 24

3.7.1 Connecting the Mains ......................................................................................................................... 24

3.7.2 Connecting the Computer ................................................................................................................... 25

3.7.3 Connecting the Exhaust System ......................................................................................................... 26

4 OPERATION .................................................................................................................. 27

4.1 Machine view and connections .............................................................................................................. 27

4.2 ON/OFF Switch ......................................................................................................................................... 33

4.3 Keypad ...................................................................................................................................................... 34

4.4 First Steps before Engraving ................................................................................................................. 38

4.5 First Engraving Tests .............................................................................................................................. 42

4.6 Rotary Engraving Attachment ................................................................................................................ 45

4.7 Tips and Tricks for Laser Engraving ..................................................................................................... 49

4.8 Tips and Tricks for Laser Cutting .......................................................................................................... 51

BA 8010_3.0_EN (10/2016) 3 / 68

Page 4

4.9 Tips and Tricks for the Production of Rubber Dies ............................................................................. 52

5 MAINTENANCE ............................................................................................................. 53

5.1 Cleaning the System ............................................................................................................................... 53

5.2 Cleaning the Optical Parts ...................................................................................................................... 54

5.2.1 CLEANING THE LENS ....................................................................................................................... 54

5.2.2 CLEANING THE MIRRORS #2 AND #3 ............................................................................................. 56

5.3 Maintenance Plan .................................................................................................................................... 59

6 ADDITIONAL INFORMATION ....................................................................................... 60

6.1 Tips for Troubleshooting ........................................................................................................................ 60

6.2 Options ..................................................................................................................................................... 61

6.2.1 Lateral Air Assist ................................................................................................................................. 61

6.3 TRAINING SCHEDULE............................................................................................................................. 64

6.4 Response Form ........................................................................................................................................ 65

6.5 How to create a Service File ................................................................................................................... 66

BA 8010_3.0_EN (10/2016) 4 / 68

Page 5

1 GENERAL

1.1 Operation Manual Use – General Information

Caution:

Please read and follow this Operation Manual carefully, before installation and operation.

Damage to persons and/or material can result from not following individual points of the

Operation Manual!

Operation of the system is only permitted with equipment and spare parts supplied or listed

in the spare parts and consumables lists.

Auxiliary equipment must be adjusted to the base machine (any queries to dealer or

manufacturer).

The following symbols are used for easier understanding of the Operation Manual:

If the Operation Manual is not observed, this area represents a particular

danger for the operating personnel or the personnel responsible for

maintenance.

Caution: This component is under voltage. In these areas strictly observe

the safety instructions regarding electricity. Care is to be taken in particular

during maintenance and repair work.

Caution: In this area pay attention to the possible dangers of the laser beam.

Note or information on individual components of the device, that simplify

the use or make it more understandable.

BA 8010_3.0_EN (10/2016) 5 / 68

Page 6

1.2 Designated Use

The Trotec Speedy 100, is used for engraving and cutting of signs, stamps and suchlike.

A wide variety of materials such as rubber, acrylic, coated metal, tin, special steel, anodized

aluminum, cork, cardboard, glass, leather, marble, several plastics and wood can be

processed on the laser.

The engraving process must only be performed with a perfectly adjusted

machine (see also Section 4 OPERATION).

For cutting applications from 45W the use of the cutting table is absolutely

necessary.

Use of the system in other areas is against the designated use. The

manufacturer does not admit liability for damage to personal and/or equipment

resulting from such use.

The system must only be operated, maintained and repaired, by personnel

that are familiar with the designated field of use and the dangers of the

machine!

Non-observance of the instructions for operation, maintenance and repair

described in this Operation Manual excludes any liability of the manufacturer

if a defect occurs.

Caution when processing conductive materials (carbon fibers,…)! Conductive

dust or particles in the ambient air might damage electrical components and

lead to short circuits. Bear in mind that those defects are NOT warranted.

1.3 Disposal remarks

Do not dispose the machine with domestic waste!

Elektronic devices have to be disposed according to the regional directives

on electronic and electric waste disposal.

In case of further questions, please ask your supplier. He might take care of

proper disposal.

BA 8010_3.0_EN (10/2016) 6 / 68

Page 7

1.4 Technical Data / Device Specification

Working area

24“ x 12“/ 610 x 305 mm

Max. height of work piece

6,7 inch / 170 mm with 1,5 inch lens

6,2 inch / 157 mm with 2,0 inch lens

5,7 inch / 144 mm with 2,5 inch lens

Max. engraving speed

71 inch/sec. / 180 cm/sec. Standard

110 inch/sec / 280 cm/sec. Performance

Cutting speed

depending on material, thickness, laser power

Motor

Brushless DC servo

Encoder

Increment

Work piece table

Solid metal (Ferro-magnetic)

Max. load of work piece table

22 lbs / 10 kg

Lenses available

1,5”, 2,0” or 2,5”

Standard:

Laser pointer (655nm, < 0,99mWcw), Ferro-magnetic table, 2” lens, USB connection, Interchangeable

exhaust connector, JobControl Basic software

Optional:

Electro-Optic Autofocus, Honeycomb Cutting Table, Rotary Attachment, Air Assist including

Compressor, Stand with Storage Area, Laser Power Upgrade, Performance Upgrade, JobControl

software Upgrade (Advanced, Expert), MCI Pad Production, Data import MAC

Laser power

Adjustable from 0 - 100% (typically 10-100%)

Interface Hardware

RS-232-C: Data Rate 19.200 -115.200 Baud

USB: Data Rate 460.800 Baud

Interface Software

JobControl, HPGL

Laser tube

Sealed off CO2 Laser, maintenance free

Laser power: 12W – 60W

Wavelength

10,6µm

Air cooling system

12W – 60W unit air-cooled

12W – 60W units

Single phase 230V / 50Hz or 115V / 60 Hz

Power consumption

1400W for 60W unit

Recommended fuse

10A for 12W – 60W 230V unit

10A for 12W – 30W 115V unit

15A for 40W – 60W 115V unit

1.4.1 Technical Data Speedy 100

Mechanics

Features

Control System

Laser Equipment

Cooling System

Electricity, Power, Fuse

BA 8010_3.0_EN (10/2016) 7 / 68

Page 8

Dimensions

Width/depth/height (approx.)

38,3 inch / 30,1 inch / 18 inch; 974mm/765mm/457mm

Weight (approx.)

194 lbs / 88 kg for 25W unit

Ambient temperature

+15°C to +25°C / 59°F to 77°F

Humidity

40% to max. 70%, not condensing

Laser class

CDRH Laser Safety

Laser Class 2(M)

CE compliant, FDA approved

Interlock

Double Interlock safety system

Ambient Conditions

Laser Safety

SUBJECT TO CHANGE WITHOUT PRIOR NOTICE! APRIL 2012

BA 8010_3.0_EN (10/2016) 8 / 68

Page 9

1.4.2 Technical Data Speedy 100R

Working area

24“ x 12“ / 610mm x 305mm

Max. height of work piece

6,7 inch / 170 mm with 1,5 inch lens

6,2 inch / 157 mm with 2,0 inch lens

5,7 inch / 144 mm with 2,5 inch lens

Max. engraving speed

71 inch/sec. / 180 cm/sec. Standard

Cutting speed

depending on material, thickness, laser power

Motor

Brushed DC servo

Encoder

Increment

Work piece table

Solid metal (Ferro-magnetic)

Max. load of work piece table

22lbs / 10 kg

Lenses available

1,5”, 2,0” or 2,5”

Standard:

Laser pointer (655nm, < 0,99mWcw), Ferro-magnetic table, 2” lens, USB connection, Interchangeable

exhaust connector, JobControl Basic software

Optional:

Electro-Optic Autofocus, Honeycomb Cutting Table, Rotary Attachment, Air Assist including

Compressor, Stand with Storage Area, Laser Power Upgrade, JobControl software Upgrade

(Advanced, Expert), MCI Pad Production, Data import MAC

Laser power

Adjustable from 0 - 100%

Interface Hardware

RS-232-C: Data Rate 19.200 -115.200 Baud

USB: Data Rate 460.800 Baud

Interface Software

JobControl, HPGL

Laser tube

Sealed off CO2 Laser, maintenance free

Laser power: 12W – 60W

Wavelength

10,6µm

Air cooling system

12W – 60W unit air-cooled

12W – 60W units

Single phase 230V / 50Hz or 115V / 60 Hz

Power consumption

1400W for 60W unit

Recommended fuse

10A for 12W – 60W 230V unit

10A for 12W – 30W 115V unit

15A for 40W – 60W 115V unit

Mechanics

Features

Control System

Laser Equipment

Cooling System

Electricity, Power, Fuse

BA 8010_3.0_EN (10/2016) 9 / 68

Page 10

Dimensions

Width/depth/height (approx.)

38,3 inch / 30,1 inch / 18 inch; 974mm/765mm/457mm

Weight (approx.)

194 lbs / 88 kg for 25W unit

Ambient temperature

+15°C to +25°C / 59°F to 77°F

Humidity

40% to max. 70%, not condensing

Laser class

CDRH Laser Safety

Laser Class 2 (M)

CE compliant, FDA approved

Interlock

Double Interlock safety system

Ambient Conditions

Laser Safety

SUBJECT TO CHANGE WITHOUT PRIOR NOTICE! APRIL 2012

BA 8010_3.0_EN (10/2016) 10 / 68

Page 11

1.5 Manufacturer's Label

The manufacturer's label is located on the back of the device (see Figure below).

It is recommended to enter data such as serial number and year of manufacture into the

manufacturer's label below so that you always have this data handy if you have problems

with your device or require spare parts.

BA 8010_3.0_EN (10/2016) 11 / 68

Page 12

1.6 EU – Declaration of conformity

(Machine directive 2006/42/EG, appendix II A)

Manufacturer:

Trotec Laser GmbH.

Linzer Straße 156,

A-4600 Wels

Authorized person for the compilation of technical documentation:

Gerhard KREMPL, Trotec Laser GmbH., Linzer Straße 156, A-4600 Wels

We hereby certify that

SPEEDY 100

Modell N° 8010 Speedy 100

in its conception, construction and form put by us into circulation is in accordance with all the relevant

essential health and safety requirements of the EC machinery directive 2006/42/EEC.

Further valid guidelines/regulations for the product:

2006/95/EG Low Voltage Directive

2004/108/EG EMC Guideline

Applied harmonized standards:

- EN ISO12100 Machine Safety

- EN 60335-1/2007 Safety of Household and similar Appliances

- EN 55014-1/2006, EN 55014-2/1997 Electromagnetic Compatibility

- EN 60204-1 Machine Safety – electr. Equipment

- EN 60825-1/2007, EN 60825-4/2006 and EN 60825-14/2006 Safety of Laser Equipment

- EN 55022/2008, EN 55024/2003 Electromagnetic Compatibility

Place, Date:

Wels, 30.03.2011

Personal data of the signer:

Stephan FAZENY, Head of Research and Development

Signature:

BA 8010_3.0_EN (10/2016) 12 / 68

Page 13

2 SAFETY

2.1 General Safety Information

All personnel involved in installation, set-up, operation maintenance and repair of the machine, must

have read and understood the Operation Manual and in particular the "Safety" section. The user is

recommended to generate company-internal instructions considering the professional qualifications

of the personnel employed in each case, and the receipt of the instruction/Operation Manual or the

participation at introduction/training should be acknowledged in writing in each case.

Safety-conscious Working

The machine must only be operated by trained and authorized personnel.

The scopes of competence for the different activities in the scope of operating the machine must be

clearly defined and observed, so that under the aspect of safety no unclear questions of competence

occur. This applies in particular to activities on the electric equipment, which must only be performed

by special experts.

For all activities concerning installation, set-up, start-up, operation, modifications of conditions and

methods of operation, maintenance, inspection and repair, the switch-off procedures that may be

provided in the Operation Manual must be observed.

Safety Information for the User and/or Operating Personnel

No working methods are permitted that affect the safety of the machine.

The operator must also ensure that no unauthorized persons work with the machine (e.g. by

activating equipment without authorization).

It is the duty of the operator, to check the machine before start of work for externally visible

damage and defects, and to immediately report changes that appear (including behavior during

operation) that affect the safety.

The user must provide that the machine is only operated in perfect condition.

The user must guarantee the cleanness and accessibility at and around the machine by

corresponding instructions and controls.

Principally, no safety components may be removed or disabled (already here we emphasize the

imminent dangers, for example severe burns, loss of eye-sight). If the removal of safety

components is required during repair and service, the replacement of the safety components

must be performed immediately after completion of the service and repair activities.

BA 8010_3.0_EN (10/2016) 13 / 68

Page 14

Preparation, retooling, change of work piece, maintenance and repair activities must only

performed with equipment switched off, by trained personnel.

It is forbidden to perform unauthorized modifications and changes to the machine. It is

emphasized, that any unauthorized modifications to the machine are not permitted for safety

reasons.

2.2 Laser Safety Information

To assess the potential dangers laser systems pose, they are classified into 5

safety classes: 1, 2, 3a, 3b and 4. Speedy 100 is a device of class 2 (USA:

Class II). This is guaranteed by the protective housing and the safety

installations.

Please note that improper operation of the device can override the status of

safety class 2 and can cause the emission of harmful radiation.

This laser engraving system contains a carbon dioxide (CO2) laser of class 4

that emits intensive and invisible laser radiation. Without safety precautions

the direct radiation or even diffuse reflected radiation is dangerous!

Without safety precautions, the following risks exist with exposure to laser

radiation:

Eyes: Burns to the cornea

Skin: Burns

Clothing: Danger of fire

Never try to modify or disassemble the laser and do not try to start up a

system that had been modified or disassembled!

Dangerous radiation exposure can result from the use of operation or

adjustment equipment other than that described here, and if different

operational methods are performed.

Service technicians defeating the interlock safety circuit are required to wear

standard laser safety glasses for CO2 lasers (wavelength 10.6 µm).

BA 8010_3.0_EN (10/2016) 14 / 68

Page 15

2.3 Safety Precautions when Operating the Device

In your Speedy 100, a closed safety system is integrated which immediately switches off

the power to the laser tube when the protection cover is opened. Consequently an

incomplete engraving can occur if the cover is opened during operation. Therefore, first

press the "PAUSE" button, if you want to interrupt an engraving process.

Please remember the following safety precautions when working with this device:

A fire extinguisher must always be handy as the laser beam can ignite flammable materials.

Do not store any flammable materials in the inside of the device or in the immediate vicinity

of the device. Particularly leftovers of produced materials have to be removed to prevent fire

hazard.

Unsupervised operation of the system is not permitted.

Because of their low absorption many metals, in particular un-coated aluminum, copper,

silver and gold cannot be processed with the laser and lead to high reflections of the laser

beam. Such materials must not be inserted into the beam, as a directed reflection could

destroy the protection cover.

Adjustment of the beam path must be performed only by especially trained personnel. An

improper setting can lead to uncontrolled emission of the laser radiation.

Before processing materials the user must verify, whether harmful materials can be

generated and whether the filter equipment of the exhaust system is suitable for the

harmful materials. We emphasize that it is the responsibility of the user, to consider the

national and regional threshold values for dust, fogs and gases when selecting the filters

and the exhaust system. (The values for the maximum workplace concentration must not

be exceeded.)

Please refer to the manual of the exhaust system on how and in what intervals you need to

replace filters.

PVC (polyvinyl chloride) must under no circumstances be processed with the laser.

Should you have further questions before starting work, please contact your dealer or

Trotec.

BA 8010_3.0_EN (10/2016) 15 / 68

Page 16

2.4 Warning and Information Labels

The warning and information labels are attached in such positions of the

device that could represent a source of danger during set-up and operation.

Therefore, follow the information on the labels. If labels are lost or damaged,

they must be replaced immediately.

BA 8010_3.0_EN (10/2016) 16 / 68

Page 17

BA 8010_3.0_EN (10/2016) 17 / 68

Page 18

BEFORE OPEN UNPLUG THE

MACHINE FIRST

CAUTION

VISIBLE LASER RADIATION

WHEN OPEN DO NOT STARE

INTO BEAM

CAUTION

INVISIBLE LASER RADIATION WHEN OPEN

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED RADIATION

BA 8010_3.0_EN (10/2016) 18 / 68

Page 19

3 BEFORE OPERATION

3.1 Unpacking

You receive your Trotec Speedy 100 packed in a cardboard box or wooden box, which

contains the laser and additional accessories. The following steps give you an overview of

the unpacking and assembly of the laser. Please follow these steps carefully.

Keep the packing box. You will require it in case of a return.

Dispose all waste according to the applicable waste disposal law.

1. Remove the cover. Please do not forget to store this box in a dry place.

2. Carefully remove the foam material, which protects the viewing window of the cover,

and the tape that holds this cover in place.

3. Lift the laser machine out of the box. For this you will require two persons. Position the

laser machine on a stable table, on the delivered stand (optional) or on the ride-on

exhaust (optional).

4. Remove the accessories box which contains all accessory parts required for the

installation of the laser machine.

5. Open the accessories box.

BA 8010_3.0_EN (10/2016) 19 / 68

Page 20

3.2 Contents of Delivery

1 5 7 2 6 8

3

4

Transport and service packaging

Laser including optics

Stand (optional)

Accessories box, which contains the following parts:

1. CD Trotec software / engraver driver incl. Operation Manual

2. Mains cable

3. Computer connection cable USB

4. Computer connection cable serial (optional)

5. Cleaning kit for optics

6. Additional lenses (optional)

7. Focus tool(s)

8. Allen key set 1.5 - 10 mm

BA 8010_3.0_EN (10/2016) 20 / 68

Page 21

3.3 Location

Before you install the laser system, you should select an appropriate location. Follow the

guidelines shown below:

Avoid locations where the system is exposed to high temperatures, dust and

high humidity. (The humidity must not exceed 70% and the temperature must

not be close to the dew point.)

Avoid locations, where the system is exposed to mechanical shocks.

Fuse protection:

Do not connect other devices via the laser fuse, as the laser system requires

the full amperage.

Avoid locations with poor air circulation.

Select a location, whose room temperature is between 15 °C and 25 °C (59°

– 77° F). Avoid higher ambient temperatures and strong exposure of the

engraver to the sun. Use blinds, if required.

Select a location close to ventilation (if available).

Select a location that is not more than 2.50 m away from your computer (max.

cable length to avoid disturbing interferences).

Try to place a working table or a place to put things next to it. This shall avoid,

that the machine is misused as a table.

BA 8010_3.0_EN (10/2016) 21 / 68

Page 22

3.4 Electrical – Requirements

Make sure that your electrical outlet is capable of providing the proper

voltage, frequency and amperage that the laser system requires.

We recommend having individual circuits for

Lasermachine and PC

Extractor

Recommended fuse: compare “Electricity, Power, Fuse” in section “1.4

Technical Data / Device Specification”.

Please install your computer to the same circuit as the laser marker to prevent

electromagnetic interactions.

DAMAGES FROM AN INADEQUATE OR INAPPROPRIATE POWER

SOURCE ARE NOT COVERED UNDER WARRANTY.

Noisy or unstable electricity as well as voltage spikes can cause interference

and possible damage to the electronics of the laser system. It is better to

connect the laser system to a dedicated electrical line.

It is highly recommended that you use a surge suppression plugs to protect

your computer equipment.

If electrical power fluctuations, brown outs or constant power outages are a

problem in your area, an electrical line stabilizer, UPS (Uninterruptible Power

Supply) or backup generator might be required. If installing any of these

devices, make sure that they meet the electrical requirements of the laser

system.

It is your responsibility to provide a suitable electrical supply.

BA 8010_3.0_EN (10/2016) 22 / 68

Page 23

3.5 Exhaust System – Requirements

To guarantee the right ventilation during the engraving of rubber, an exhaust

system with a minimum suction power of 300 m³/h is required. The device

must be equipped with a fine dust filter (generation of rubber dust) as well as

an activated carbon filter (neutralization of smells). A good filtering of the

outgoing air is also required when cutting plastics or engraving wood. If only

anodized plates are engraved, the suction power can be reduced.

Connection - see section 3.7.3 Connecting the Exhaust System.

Do not start the machine without an adequate exhaust system.

3.6 Computer – Requirements

The following recommendation represents the minimum requirements.

When using a more powerful computer the graphics are generated and

displayed faster and the computing times and the data transfer to the laser are

reduced. To use the newest software version, you might have to abide other

requirements.

Windows 7 32/64-bit or

Windows Vista 32/64-bit (with Service Pack 1 or later) or

Windows XP 32/64-bit (with Service Pack 2 or later)

Microsoft .NET framework 3.5

Adobe Reader 9.0 or later

Local administrative privileges (for required software installations)

GHz processor or faster

GB RAM or greater (Windows 7, Windows Vista) or

1 GB RAM or greater (Windows XP)

80 GB hard drive or larger

1024 x 768 resolution monitor or greater

true color graphics card (24-bit color depth)

1 free USB interface

CD-ROM drive

Mouse

BA 8010_3.0_EN (10/2016) 23 / 68

Page 24

3.7 Connections

INPUT POWER

100-120VAC 60HZ

INPUT POWER

220-240VAC 50HZ

1

Perform the connections exactly in the order described, otherwise electrostatic

charging can damage your computer and/or the electronics of the laser

system.

3.7.1 Connecting the Mains

Connect one end of the mains cable with the connection socket (1) at the rear side

of the laser device (see Figure below) and the other end with a protected power

outlet.

Mains voltage and operating voltage must correspond (AC 230 V/50 Hz

or AC 115 V/60 Hz) – see information label beside the connection

socket.

Under no circumstances switch on the device if the voltages do not

correspond.

BA 8010_3.0_EN (10/2016) 24 / 68

The main fuses are located inside the connection socket and are

accessible from the exterior.

Page 25

3.7.2 Connecting the Computer

2

1

The computer must be switched off and connected to the mains voltage.

Connect the laser (see Figure below) to a free serial interface (1) or USB port (2) on your

computer.

BA 8010_3.0_EN (10/2016) 25 / 68

Page 26

3.7.3 Connecting the Exhaust System

Exhaust connection hose

to Laser (2)

Exhaust connection cable

Mains cable to mains socket (1)

Connect your exhaust system to the mains socket (1).

Make sure that the mains voltage corresponds with the voltage

allocated for the exhaust system.

Plug the ends of the exhaust duct into the allocated connection (2). The position

of the connector depends on the type of exhaust system.

When using the Trotec exhaust system, also connect it with the cable included

to the remote control connector of the laser (3).

Also follow the operation and maintenance instructions in the Operation Manual of

the exhaust system.

BA 8010_3.0_EN (10/2016) 26 / 68

to Laser (3)

Page 27

4 OPERATION

1

Top lid

11

Cooling fan

2

Autofocus sensor

12

Exhaust hose connector

3

Service access panel

13

Manufacturers label

4

Connection Socket for Rotary

14

Laser tube cover

5

Focusing head

15

Power supply

6

X-axis

16

Power socket and fuses

7

Ruler

17

PC connection cable (Serial)

8

Working table

18

Exhaust connection cable

9

Keypad

19

PC connection cable (USB)

1 2 8 6 7 3 4

10 9 11

12

14

16

17

18

15

13

5

19

4.1 Machine view and connections

BA 8010_3.0_EN (10/2016) 27 / 68

Page 28

10

Maintenance panel

BA 8010_3.0_EN (10/2016) 28 / 68

Page 29

1 Top lid

If the Top lid is opened, no data is processed. After closing the Top lid,

the device is not ready to process commands for 5 seconds. If the

protection cover is opened during operation, the motion system is

stopped and laser source is turned off.

Please note, that the laser tube is switched off immediately and

consequently the result of the engraving is incomplete. During

processing of commands the protection cover must only be opened

after pressing the "Pause" button.

2 Light Barriers – Autofocus sensor

Used for the automatic focusing of the work piece (optional).

Do NOT use this option when processing transparent materials.

3 Service Access Panel

Only to be opened by trained technical service personnel.

4 Connection Socket for Rotary Engraving Attachment

Connector for the rotary engraving attachment (option).

Supplies the rotary engraving attachment with the required electric

signals.

5 Focusing head

The lens that focuses the laser beam onto the material is mounted

inside the focusing head.

6 X axis

The motion system is that part that performs the mechanical

movements in X direction (horizontal) and Y direction (vertical). The X

axis is visible in the working area.

7 Ruler

BA 8010_3.0_EN (10/2016) 29 / 68

Page 30

Used to align material and measure it.

BA 8010_3.0_EN (10/2016) 30 / 68

Page 31

8 Working Table

The work pieces to be processed are put onto the working table. To

facilitate orientation, a horizontal and a vertical ruler are located on the

engraving table. The table is ferromagnetic for easier fixation of work

pieces.

9 Keypad

The Keypad contains multiple buttons and displays for controlling the

device.

See section 4.3 Keypad for further information.

10 Maintenance Panel

Has to be opened with a 10mm Allen key to maintain optics.

11 Cooling Fan

Air cooled laser tubes are equipped with cooling fans on the laser tube

or the laser tube cover.

12 Exhaust hose connector

13 Manufacturer's Label

Shows important data of the machine like serial number or

manufacturing date.

14 Laser Tube cover

All laser tubes are equipped with a cover.

15 Power Supply

Changes the main power to power types suitable for the mechanic and

electronic parts of the machine.

BA 8010_3.0_EN (10/2016) 31 / 68

Page 32

16 Power Socket

To connect the main power according the information on the

manufacturers label. In the Power Socket are the fuses.

17 PC connection cable (Serial)

18 Exhaust connection cable

19 PC connection cable (USB)

BA 8010_3.0_EN (10/2016) 32 / 68

Page 33

4.2 ON/OFF Switch

Switches the mains supply ON/OFF.

The following conditions must be fulfilled for correct start up:

- unrestricted freedom of motion of the mechanics

- no materials under the engraving table

- protection covers closed

If the top lid or any other interlock secured cover (mainenance panel)

is open, an acoustic signal sounds and the status display flashes fast

in green.

Íf all interlock-secured covers are closed, immediately after being

switched on, the device starts the referencing process. When the

referencing process is completed correctly, an acoustic signal sounds

and the device is ready for operation. The readiness for operation is

additionally displayed by green (slow) flashing of status display.

Before switching on the device, the user must make sure that no

objects of any kind are located inside the operating space, which could

limit or obstruct the mechanics of the device.

When switching off the mains supply, all processing data is lost.

BA 8010_3.0_EN (10/2016) 33 / 68

Page 34

4.3 Keypad

When both keys are pressed simultaneously, the material is

focused automatically (only with light barriers = option).

The automatic focus option might not work on transparent

materials or materials which are not flat

If the position of the air assist nozzle has been adjusted for a ≥ 2.5"

lens, the light barrier autofocus is not possible as this would cause a

head crash (working head hits material or working table).

Bear in mind that machine defects from head crashes are not

warranted..

1

2 3 4 5 6 7 8

9

1 POSITIONING KEYS Z

When pressing one of these two keys the engraving table moves in

Z direction (upwards or downwards).

Use these positioning keys to move the work piece manually.

Before the automatic focus- move is started, the head is moved

backward in line with the light barriers. If the light barrier is broken, e.g.

by an air assist nozzle, the upward move will ne suppressed to prevent

a collision between the nozzle and the table.

BA 8010_3.0_EN (10/2016) 34 / 68

Page 35

By pressing the “Shift” key and a Z- positioning key an automatic

move to the corresponding end- positions is performed:

Shift + Down: the table moves down to the lowest possible position

Shift + Up: the table moves up to the autofocus- position.

Note: Shift + Up will cause the head moving backwards to the light

barriers (according simultaneous pressing of both z-keys).

If any of positioning keys X and Y are pressed, no moves in Z are

possible.

An automatic move of the Z- axis can be stopped by pressing any

of the positioning keys (1 or 2).

2 POSITIONING KEYS X/Y

Use the positioning keys to manually move the lens holder into the

indicated directions.

When you press two keys simultaneously, the lens holder moves

diagonally.

When you press the "Shift" key and one of the positioning keys

simultaneously, a movement to the corresponding end position is

performed.

If all panels are closed, the movement is done with the maximum

velocity, if opened, the speed is 1/4th of the maximum.

While the Z- axis is in movement (e.g. autofocus), no cursor moves in

X and Y axis are performed.

The status display (8) of the device is located in the center of the key

pad.

3 PAUSE

Used to stop the current working process (key lights up). As soon as

the last processing command is finished, the motion system stops.

If this key is pressed a second time, the key illumination goes off, the

interrupted working process is continued.

BA 8010_3.0_EN (10/2016) 35 / 68

Page 36

STANDBY

Switches the device into Standby mode (Laser ready) – key lights up.

By pressing the key again the device is switched back to Ready mode.

If the Standby button is pressed while the Z- axis is in an automatic

move (e.g. autofocus), the Standby mode is entered after finishing the

Z- axis- move (Z- axis move can be stopped by pressing any of the Zaxis keys).

Additionally the cooling fans of 12W, 25W and 30W units are turned off.

4 EXHAUST

Used to manually switch the exhaust system on and off.

The key illumination shows the status of the exhaust system.

When the key is illuminated, the exhaust system is switched on.

After completing the engraving process, the exhaust system can only

be switched off after some seconds (follow-up time).

5 “SHIFT” (TEST) key for 2nd function key level

For additional Operations. When this key is pressed together with the

following keys, the functions indicated are activated:

- Exhaust (5):

Air assist on/off

- Pause (3)

Stops the job program immediately

- Positioning keys X/Y/Z (2):

These keys drive the laser head to the end position

- Repeat

Tests the laser source for proper function (acoustic signal sounds

simultaneously)

6 START (REPEAT)

By pressing “Start (Repeat)”, the jobs which are currently positioned

on the selected plate in the Trotec JobControl are started.

If the jobs have been processed before, they will be reset

automatically.

7 STATUS INDICATOR LASER BEAM

Indicates, that a laser beam is currently being emitted.

8 STATUS DISPLAY

BA 8010_3.0_EN (10/2016) 36 / 68

Page 37

green, flashing slowly (0.5 Hz)

9

Machine is ready

green, flashing fast (2 Hz)

9

Cover has been opened

green permanent light /

Pause mode

9

Data available in the machine

red permanent light

8

Laser beam is being emitted

green/red flashing alternately

8+9

Cover open during switch-on process,

simultaneously acoustic signal -

no referencing

Indicates the current status of the device:

BA 8010_3.0_EN (10/2016) 37 / 68

Page 38

4.4 First Steps before Engraving

To prepare your laser for the first engraving tests, perform the following steps:

1. Switch machine on with the ON / OFF switch.

2. The working table automatically references in X/Y/Z direction.

3. Open the protection cover and place work piece on the working table.

Usually you position the work piece into the upper left-hand corner of the

engraving table against the horizontal and vertical rulers. However, any other

position on the engraving table is also possible.

4. Focusing the Laser Beam

For the laser beam in your laser system to be able to engrave and cut

precisely, the energy is focused with a lens system, which is mounted on the

motion system in a lens holder.

The focusing point of the laser beam (for the mid-resolving lens, which is part

of the delivery) is located 5.08 cm (2.0 inch) below the lens.

For optimal processing the surface of the material that you want to engrave or

cut, has to be adjusted to this point.

BA 8010_3.0_EN (10/2016) 38 / 68

Page 39

BA 8010_3.0_EN (10/2016) 39 / 68

Page 40

There are three methods to focus the laser beam:

1

A: Manual focusing

B: Focusing by software

C: Automatic focusing by means of light barriers (optional)

To A – Manual focusing:

A1. Move the processing head over the material to be engraved by means

of the positioning keys X/Y

A2. Hang the focus tool on the external ring of the working head so that the

focus tool can move unhindered. Move the working table upwards by

pressing the Z positioning key (1). While doing this carefully observe the

focus tool.

Before the focus tool reaches the work piece, move the working table

upwards only very slowly and step by step by briefly tapping the

positioning key, until the tool tilts to the side. Now the lens is focused

onto the surface of the material.

BA 8010_3.0_EN (10/2016) 40 / 68

Page 41

To B – Focusing by software:

1

B1. Click the icon “focus laser” in the Trotec JobControl

The working table moves in Z direction.

The following values are used to determine the focus position and

therefore always have to be checked before using this focus option:

- material thickness (specify the value as accurate as possible)

- table height (check if right table is selected in Options)

- lens type (specify the according lens)

To C – Automatic focusing by means of light barriers (optional):

The automatic focusing is only possible if the work piece is thicker than

the rulers.

The Autofocus option might not work on transparent materials or

materials which are not flat.

Bear in mind that defects from head crashes (working head hits

material or working table) are NOT warranted.

C1. By pressing the two keys for Z positioning (1) of the working table

simultaneously, the laser beam is automatically focused onto the work

piece (If you don’t have the autofocus-option, the table will go down to

Z = 0).

BA 8010_3.0_EN (10/2016) 41 / 68

Page 42

4.5 First Engraving Tests

The following steps describe, how to successfully engrave a first pattern. Please follow the

individual steps:

1. First switch on the computer, then the Laser.

2. Put the object to be engraved into the laser and move into the desired position on the

engraving table. Usually the object is positioned in the upper left-hand corner. Use the

rulers to determine the dimensions of the object to be engraved.

3. With the positioning keys the lens is positioned over the material to be engraved. You

focus with the help of the focus tool or by auto focus (see page 38 ongoing).

BA 8010_3.0_EN (10/2016) 42 / 68

Page 43

BA 8010_3.0_EN (10/2016) 43 / 68

Page 44

4. Generate a graphic with the help of your graphics software. The size of the graphic

does not matter as the printer driver adjusts it to the work piece automatically if

requested.

Also consult the Software Manual for further information.

5. Select "File Print", to access the printer driver, where you can perform work piece and

material settings as well as specify a job name or a job number.

This file is automatically transferred into Trotec JobControl.

6. After the engraving material, the engraving direction, die orientation of the work piece

and the orientation of the plate have been specified in the Trotec JobControl under

"Plate, Setup Plate", the job can be positioned on the plate with a double-click. If

necessary, the job can be positioned at any position on the plate by dragging with the

mouse. The position of the job corresponds with the engraving position on the

engraving table.

Make sure that on engraving flammable materials the air assist is on (e.g. rubber

engraving)!

7. Establish a connection with the engraver by clicking on the button "Establish

Connection" in JobControl.

8. Switch on the exhaust system. When using an original Trotec exhaust system with

installed connection cable, this happens automatically – check only, whether in the

indicator "Exhaust Ready" is green in the Engraver Control of the JobControl.

9. Finally press the START button (green arrow) in the Control of the JobControl, to start

the engraving process.

10. While the laser is engraving, you can generate the next graphic.

11. When the engraving is complete, the JobControl offers you the following possibilities:

- delete the job

- Job Reset and placing back in to the waiting list for later repeat of the engraving.

- Job Reset and immediate repeat

BA 8010_3.0_EN (10/2016) 44 / 68

Page 45

4.6 Rotary Engraving Attachment

1

The rotary engraving option in the printer driver is used in combination of the

rotary engraving attachment, to engrave cylindrical objects.

To compensate for the different diameters of different objects, the image must

be adjusted. This is performed automatically by the engraving driver, by

selecting the rotary engraving option and entering the diameter of the object to

be engraved.

Never plug or unplug the rotary engraving attachment while the machine is

turned on. If this is not observed, there insists the danger of irreparable

damage on the prints!

The rotary engraving attachment permits engraving of cylindrical objects with a diameter

from 30mm to 118 mm, a length of up to 350 mm at a maximum weight of 3 kg.

To install and set-up the rotary engraving attachment proceed as described as follows:

1. Move the working table to the lower position, switch off the laser and open the top

lid.

2. Put the rotary engraving attachment onto the working table and connect the rotary

engraving attachment to the working table. Before you fix the rotary engraving

attachment, align it so that its sides are parallel to the rulers. The rulers offer a visual

aid for placing the graphic.

BA 8010_3.0_EN (10/2016) 45 / 68

Page 46

3. Connect the rotary engraving attachment via the control cable with the connector of

1

the motion system. The connector is located inside the left front of the interior.

Mounting the work piece:

4. Before you mount the object into the rotary engraving attachment, measure the

diameter of the object at the position to be engraved with a sliding caliper or a similar

tool. Write down this value.

5. Adjust and fix the slider with lever 1 to make the work piece fitting into the rotary

engraving attachment.

BA 8010_3.0_EN (10/2016) 46 / 68

Page 47

6. Now switch on the laser and wait until the referencing is finished. Position the working

head over the object at the position, where you want to engrave. Now focus the object

with the focus tool.

BA 8010_3.0_EN (10/2016) 47 / 68

Page 48

Engraving:

Also consult the Software Manual for further information.

7. Generate a graphic with the help of your graphics software. The size is not important,

as the graphic can be adjusted to the dimensions of the work piece by the printer

driver.

8. Then perform the settings for size and orientation in the JobControl under "Plate,

Setup Plate" and, if necessary, select the engraving material. Please note especially,

that you can determine the orientation of the graphic on the object with "Job

Orientation”.

9. In the "Options" menu of the JobControl select "Rotary Engraving Attachment" and

enter the diameter of the object.

10. Double-click on the previously generated job in the waiting list to place it on the plate.

11. Use the mouse to drag the job to the position of the plate, at which the desired

engraving area is located on the object. Use the rulers in the machine and in

JobControl for orientation and move the lens holder directly over the desired position,

after you have connected the computer with the laser, and position the job on the

screen according to the position of the lens.

12. Establish the connection to the laser.

13. Switch on the exhaust system (only necessary if you do not use an original Trotec

exhaust system).

14. Activate the START button in the Engraver Control of the JobControl and start the

engraving process.

BA 8010_3.0_EN (10/2016) 48 / 68

Page 49

4.7 Tips and Tricks for Laser Engraving

The engraving depth can easily be varied through the laser power or the speed. To increase

the engraving depth, reduce the speed or increase the power setting. This way you increase

the amount of energy per area unit. Engraving too deep, however, reduces the quality of the

details. With coated materials the required power depends of the kind and thickness of the

coating. With power set too high the individual lines become too thick and a sharp picture

cannot be achieved. The resolution of the graphics should usually be at 500 dpi. The dpi

setting (number of laser dots per inch) depends on the material. The lower this setting is,

the lower the resolution of the engraved picture will be. This, however, reduces flaming and

increases the energy of a pulse, which can improve the overall result (e.g. when engraving

some sorts of plastic materials).

Protection foil:

Remove the protection foil from the engraving area. However, leave the protection foil on

the area that is not engraved, to avoid scratching of the material.

Plastics:

Plastics for engraving are available in many different colors and thicknesses and with many

different coatings and surfaces. The majority of available plastics can be well engraved and

cut with the laser. Plastics with a micro-porous surface seem to give the best result, because

less surface material needs to be removed. As most plastic materials have a low melting

point, a low ppi setting should be selected to reduce the danger of melting.

BA 8010_3.0_EN (10/2016) 49 / 68

Page 50

Acrylic:

There are two different types of acrylic – cast and extruded. The cast acrylic becomes white

or mat after engraving, the extruded acrylic remains clear. Use extruded acrylic for

engravings that are filled with paint and cast acrylic for normal engravings. Cast acrylic can

be best engraved without protection foil. It is better to engrave the entire surface with a low

energy setting.

Engraving photographs:

Engraving photographs can be quite a challenge at the beginning. But as soon as you

understand the basics it will become easier for you. Scan the desired picture with a

resolution of 300 dpi. Adjust brightness and contrast so that lighter colors become lighter

and darker colors become darker. The photo might look better if you use a filter, which

sharpens the contours. The next step is the selection of a raster. Usually the software offers

a selection of different rasters with a specified number of lines per inch and different raster

angles. Use a raster with between 20 and 100 lines per inch. Increasing the number of lines

per inch decreases the size of the points. Try which raster you think looks best. With one

material large dot look better, with another material smaller points look better. If you cannot

select rasters with your software, the machine will select the raster automatically.

BA 8010_3.0_EN (10/2016) 50 / 68

Page 51

4.8 Tips and Tricks for Laser Cutting

Distance to the Surface of the Work piece

If you want to achieve very good results, when laser-cutting acrylic or wood, we recommend,

that the plate be attached at least some millimeters above the engraving table. By doing this

the smoke and the melting residuals underneath the plate can escape unhindered. A slight

moistening of the plate will reduce the area of heat influence. Generally the protection foil

should be removed, except when there is considerable development of fumes. During laser

cutting the Hz setting (pulses per second) should be set to low, in particular for flammable

materials.

Multiple cutting (insert logo)

Often a clearer contour can be achieved by cutting twice rather than cutting only once.

BA 8010_3.0_EN (10/2016) 51 / 68

Page 52

4.9 Tips and Tricks for the Production of Rubber Dies

The various mixtures and densities of rubber plates cause a slightly varying engraving depth.

The settings in the overview table give a good indication. Since engraving a standard rubber

material requires a relatively high laser power, the laser power is principally set to 100% and

only the speed is varied.

Due to their lower density, so-called micro porous rubber materials allow a significantly

higher engraving speed. Test the rubber first, to find out the correct speed setting.

The Trotec JobControl software simplifies the creation of a stamp significantly. Mirroring as

well as converting is performed automatically and a cone-shaped shoulder is generated

around each letter. Due to the wider base the letters are stabilized during stamping and

therefore the imprint becomes clearer. If you engrave rubber dies without using this option,

the letters will have no shoulders making them very thin and unstable.

To avoid flaming, we recommend a low HZ setting near 1000 Hz for cutting the rubber die.

The laser pulses are set apart from each other and their edges just touch. This results in a

perforation. The rubber die stays connected to the rubber plate but can be torn off easily.

The advantage of this method is that there is practically no further risk of deformation or

melting of the material. Furthermore, the entire plate can be removed from the laser at one

time instead of having to collect all dies individually.

Engraving rubber produces a considerable amount of dust. Therefore a well-dimensioned

exhaust system and its regular maintenance are very important. The appropriate Trotec

exhaust system is absolutely recommended.

BA 8010_3.0_EN (10/2016) 52 / 68

Page 53

5 MAINTENANCE

5.1 Cleaning the System

Caution – use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous laser radiation exposure.

Before starting cleaning and maintenance work always switch off the device

and unplug the mains plug.

You should check at least once a day, whether dust has accumulated in the

engraving system. In case of soiling the machine must be cleaned.

The cleaning interval strongly depends on the material that is being processed

and the operating time of the device. Please bear in mind that only a clean

machine guarantees optimal performance and reduces the service costs.

CAUTION: Always keep the system clean, as flammable parts in the working

area or exhaust area rise the fire hazard.

General Cleaning:

1. Move the engraving table into a position in which it is easiest for you to clean the surface

with a window cleaning agent and paper towels.

2. Make sure, that the device is switched off and unplugged. Open the protective cover.

3. Thoroughly remove all loose dirt particles and deposits in the interior of the machine.

4. Clean the cover of the laser tube.

5. You can clean the viewing window with a cotton cloth. Do not use paper towels as they

could scratch the acrylic.

BA 8010_3.0_EN (10/2016) 53 / 68

Page 54

5.2 Cleaning the Optical Parts

1

Trotec recommends to use following cleaning material:

Lens tissues Part number 69249

Lens cleaner Part number 69248

The lens has a durable multi-coating and won’t be damaged by correct and careful cleaning.

You should inspect the mirrors and the lens according the maintenance plan. If you discover

a veil of haze or dirt, you must clean them.

Follow the instructions below for the cleaning of optical parts:

5.2.1 CLEANING THE LENS

1. Move the engraving table to a distance approx. 10 cm under the lens holder.

2. Move the working head into the center of the working surface and put a cloth under the

lens holder (so that the lens is not damaged if it accidentally falls out of its holder).

3. Now you can unscrew the lens holder (1).

4. Once positioned over a clean lens cleaning tissue, remove the lens from the lens holder

by carefully turning the lens holder and letting the lens and the O-ring drop onto the

cleaning cloth.

5. Examine the O-ring and, if necessary, clean it with a cotton bud and a lens cleaning

tissue.

6. Remove the coarse dust as good as possible by blowing air onto the lens surface.

7. Check the surface and if necessary clean the lens with the lens cleaning liquid and lens

tissue.

BA 8010_3.0_EN (10/2016) 54 / 68

Page 55

8. Hold the lens assembly by its edge with a lens cleaning tissue and use a drop of lens

cleaning liquid from the little bottle which you received as an accessory delivered with

the laser. While holding the lens on an angle, flush both surfaces of the lens, to wash

away coarse soiling.

9. Put the lens on a clean lens cleaning tissue. Put some lens cleaning liquid on one side

of the lens. Leave the liquid to take effect for approximately one minute and then gently

wipe it away with lens cleaning tissues soaked with lens cleaning liquid.

10. Finally, dry this side of the lens with dry lens cleaning tissues and repeat the cleaning

process on the other side of the lens.

Never use a cleaning tissue twice. Dust accumulated in the cleaning tissue

could scratch the lens surface.

11. Examine the lens. If it is still soiled, repeat the cleaning process until the lens is clean.

12. Carefully insert the lens into the lens holder.

Ensure, that the rounded side (= convex) of the lens is facing upwards.

Then put the O-ring on top of the lens.

13. Carefully assemble the lens in reverse order.

BA 8010_3.0_EN (10/2016) 55 / 68

Page 56

5.2.2 CLEANING THE MIRRORS #2 AND #3

1

2

There are two mirrors in the operating area of the laser, which may have to be

cleaned if they are soiled. To clean the mirrors, follow the instructions below.

MIRROR #2

1. The mirror #2 is located on the right-hand side of the machine. To be able to access

mirror #2, you must remove the right maintenance panel.

The laser must be switched off before the panel is removed!

2. The mirror #2 is attached by means of two Allen screws (1), which are located on the

mirror holder. Open the screws and remove the lens holder together with the mirror. Do

not touch the milled screws while doing this (2).

Make sure that you do not touch the mirror surface with your fingers as this

reduces the mirror's working life significantly.

3. Use a drop of lens cleaning liquid from the accessories box and, while holding the mirror

on an angle, flush the surface of the mirror, to wash away coarse soiling.

4. Put the mirror on a working surface. Put some drops of lens cleaning liquid on the mirror

and leave the liquid take effect for approximately 1 minute.

5. Use a folded piece of lens cleaning tissue soaked with lens cleaning liquid and wipe

gently over the mirror only once. Use a fresh lens cleaning tissue soaked with lens

cleaning liquid each time and again wipe over the mirror only once. Then wipe the mirror

dry with a new dry lens cleaning tissue. Never use a cleaning tissue twice, as it could

carry dust particles, which can scratch the mirror surface.

6. Examine the mirror and repeat the cleaning process, if necessary.

BA 8010_3.0_EN (10/2016) 56 / 68

Page 57

7. Replace the mirror and fix it again with the two Allen screws.

BA 8010_3.0_EN (10/2016) 57 / 68

Page 58

MIRROR #3

1

1. While holding the mirror, loosen the big screw (1) and lift the mirror from the laser head

Pay attention that the mirror doesn't grind over the mirror holder, as it can be

scratched very easily.

2. Use a drop of lens cleaning liquid from the accessories box and, while holding the mirror

on an angle, flush the surface of the mirror, to wash away coarse soiling.

3. Put the mirror on a working surface. Put some drops of lens cleaning liquid on the mirror

and leave the liquid to take effect for approximately 1 minute.

4. Use a folded piece of lens cleaning tissue soaked with lens cleaning liquid and wipe

gently over the mirror only once. Use a fresh lens cleaning tissue soaked with lens

cleaning liquid each time and again wipe over the mirror only once. Then wipe the mirror

dry with a new dry lens cleaning tissue. Never use a cleaning tissue twice, as it could

carry dust particles, which can scratch the mirror surface.

5. Examine the mirror and repeat the cleaning process, if necessary.

6. Re-insert the mirror into the mirror holder by setting it straight onto the holder and

tightening the screw.

BA 8010_3.0_EN (10/2016) 58 / 68

Page 59

5.3 Maintenance Plan

daily

weekly

monthly

yearly

Laser

Lens, mirror 3

Check

Cleaning if

required

Mirror 2

Check

Cleaning if

required

Engraving table and

rulers

Cleaning

Cover of the laser tube

and housing

Cleaning

Entire working area –

general cleaning

Cleaning

Exhaust System

Bag filter

According to the operation manual

of the exhaust system

Filter mat

Particle filter

Activated carbon filter

For detailed information on the maintenance activities on exhaust systems please

refer to the respective manual.

BA 8010_3.0_EN (10/2016) 59 / 68

Page 60

6 ADDITIONAL INFORMATION

6.1 Tips for Troubleshooting

The machine does not react after activating the "ON" key.

Check the mains connection.

Check the main fuses. They are located next to the mains connection socket.

Replace defect fuses with fuses of the same type and value.

No referencing is performed after switching on the machine.

No acoustic signal can be heard.

Check if the top lid and other interlock-secured covers (maintenance panel) are

tightly closed.

The following error message is displayed when trying to establish a connection

between the JobControl and machine:

”Could not build up connection to the laser.”

Check the cable connection between computer and machine.

Make sure that you are actually using the correct serial interface COM 1 to COM 10

of your computer and that it is functional.

Check the interface selection in "Options" in the "Settings" menu of JobControl.

After starting a job the exhaust system is not switched on.

Check whether the exhaust system is connected with the mains socket.

Check the cable connection between the machine and the exhaust system.

A job, which was created with the graphics software, does not appear in the JobControl

waiting list.

Check whether the sorting function "Kind" and "Resolution" are activated in the

waiting list.

Make sure that the directory ”Spool” has been created in the directory of JobControl

(”Trotec”) and that the correct path to this directory has been set under "Options" in

the "Settings" menu.

A job transferred to JobControl does not contain any graphics,

Use the "Fit to page" option in the printer menu of your graphics software.

BA 8010_3.0_EN (10/2016) 60 / 68

Page 61

6.2 Options

1,5'' lens

2'' lens

2,5'' lens

Nozzle positions

AF

possible

possible

not possible

If the air assist nozzle is adjusted to a 2,5'' lens or bigger, automatic focusing

with the light barrier is not possible. This would lead to a collision of the laser

head with the workpiece or with the working table ("head crash").

In this case please use the manual focusing method or use a different position

for the air assist nozzle. The damage of the machine by a collision is excluded

from warranty.

6.2.1 Lateral Air Assist

During laser engraving and laser cutting, the supply of compressed air can significantly influence

and improve results. Air assist is often used with vector cutting applications to derive heat and

flammable gases from the cutting surface. Through a constant airflow over the whole cutting

surface, fire sources will be removed and fume is reduced. In addition, air assist improves

engraving dust removal.

According to used lens the position of the air assist nozzle must be adapted accordingly.

Small leads on the holder mark the single positions.

BA 8010_3.0_EN (10/2016) 61 / 68

Page 62

Cutting table: Honeycomb table especially for cutting tasks, is placed onto the

standard table, during cutting the residuals of the material fall through

the honeycombs onto the table, reverse side of the material remains

clean, cutting lines are cleaner.

BA 8010_3.0_EN (10/2016) 62 / 68

Page 63

Acceptance report

Dear customer!

Please check applicable items:

We request your confirmation of

properly completed transfer of the

machine

Machine parts checked for shipping damage

Machine parts checked against delivery note

Setup of the machine discussed

Startup of the machine discussed

Operation of the machine discussed

Maintenance of the machine discussed

Electrical voltage checked

Safety Instructions discussed

Trial run performed

Deficiencies determined

The machine with the

Please transmit a copy of this

document – filled out and signed

by an authorized company

representative – to an employee of

our sales affiliate for forwarding to

the manufacturer.

Thank you very much.

machine designation: Speedy 100

has been checked according to the listed items and has been

transferred properly.

City, Date

Company stamp / Signature

BA 8010_3.0_EN (10/2016) 63 / 68

Page 64

6.3 TRAINING SCHEDULE

Employee/Trainee:

Trainer:

Date of Training:

The above mentioned Employee received instruction on the operation of the Speedy 100

Lasersystem.

Especially the following topics are covered:

- Machine Function

- Danger Area

- Warnings

- Interlock System

- Taking into Service and Shutdown

- Work Flow

- Announcement of unexpected working result and the resulting procedure

- Announcement of Failure and instituting Procedure

- Responsibility on remedial measure

- Operation Manual and its depository for inspection

- Cleaning and Maintenance

............................................................... ...............................................................

Signature of Trainer Signature of Trainee

BA 8010_3.0_EN (10/2016) 64 / 68

Page 65

6.4 Response Form

Date

Machine Details

Contact Details

Serialnumber

Name

JobControl Version

Country

Driver Version

Phone Number

Layout Software

Email address

Firmware Version

Problem Description

Does an Error message show up on the PC, if so which one?

What happened before the error showed up? (Thunderstorm, Windows-Update,…)

What was tried to solve the problem?

If you face any trouble with the machine, please provide the following information and add a

Servicefile (procedure is described on the following pages).

Please send the information to your sales representative or to techsupport@troteclaser.com.

BA 8010_3.0_EN (10/2016) 65 / 68

Page 66

6.5 How to create a Service File

1. Start JobControl.

2. Position the job (which possibly caused a failure) on the plate.

3. Run the job and leave the job on the plate.

4. Go to “Settings” > “Create Service File”.

5. The window „Save Service File to“ shows up. Please select a directory to save the file and

click on „Save“.

BA 8010_3.0_EN (10/2016) 66 / 68

Page 67

BA 8010_3.0_EN (10/2016) 67 / 68

Page 68

6. The window „Add Layout File“ shows up. Please select the layout file, which was sent most

recently to JobControl and possibly caused a failure (example: Corel file, Photoshop file,

AutoCAD file,…). Click on „Open“.

7. The following window confirms, that the Service File (ServiceLog.txt) was created

successfully.

8. Please send the Service File together with a picture of the bad result and detailed

description to your sales representative or to techsupport@troteclaser.com.

BA 8010_3.0_EN (10/2016) 68 / 68

Loading...

Loading...