Page 1

OPERATION MANUAL

SpeedMarker 300 / ProMarker 300

This documentation with all illustrations is intellectual property of Trotec Produktions- u. Vertriebs GmbH.

The entire documentation is given to the user for personal use only. This documentation must not be reproduced or made available to others without our written permission. Any breach of law will be prosecuted.

Page 2

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 2 von 42

ProMarker 300

TROTEC PRODUKTIONS UND VERTRIEBS GMBH

Linzer Straße 156

A – 4600 Wels

AUSTRIA

Tel.: ++43/7242/239-7000

Fax: ++43/7242/239-7380

E-Mail: techsupport@troteclaser.com

www.troteclaser.com

Trotec cannot be held responsible for any direct or indirect damages, which result from using or working with the

products electric circuits or software described herein. The apparatus must be used only by trained and skilled

personnel. Before use the manual should be read and followed carefully.

Furthermore Trotec reserves the right to change or alter any product described herein without prior notice.

In case of failure, please check the device first according to section 12 Troubleshooting. If unsuccessful, please

note all data of the device (year of manufacture, software version, etc.) and call us from a telephone next to the

switched on device.

For queries or technical problems please contact your dealer or Trotec directly at the above address..

Page 3

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 3 von 42

ProMarker 300

1 Content

1 Content ............................................................................................................................................................. 3

2 Introduction ...................................................................................................................................................... 5

3 General Information ......................................................................................................................................... 5

General Instructions for Using the Operation manual ................................................................................ 6

Intended Use ............................................................................................................................................. 7

Disposal remarks ....................................................................................................................................... 7

Manufacturer's Label ................................................................................................................................. 8

EC–Declaration of Conformity ................................................................................................................... 9

4 Safety .............................................................................................................................................................. 10

General Safety Information ...................................................................................................................... 10

Laser Safety Information ......................................................................................................................... 11

Safety Precautions when Operating the Device ...................................................................................... 13

Warning and Information Labels .............................................................................................................. 14

5 Before Commissioning .................................................................................................................................. 16

General Instructions ................................................................................................................................ 16

Scope of Supply (Standard Configuration) .............................................................................................. 17

Unloading, Inspection and Reporting Faults ............................................................................................ 18

6 Technical Data ................................................................................................................................................ 19

General Description ................................................................................................................................. 19

Laser Module Dimensions ....................................................................................................................... 19

Housing Dimensions ................................................................................................................................ 20

Data Sheet .............................................................................................................................................. 21

7 System Overview ........................................................................................................................................... 22

The Laser Module.................................................................................................................................... 23

7.1.1 Laser Module Control elements (Front Side) ................................................................................ 23

7.1.2 Laser Module Interface (Reverse Side) ........................................................................................ 24

Industrial PC ............................................................................................................................................ 25

7.2.1 Industrial PC (Front Side) ............................................................................................................. 25

7.2.1 Industrial PC Interface (Reverse Side) ......................................................................................... 25

Control Elements on the Front of the SpeedMarker 300 / ProMarker 300 ............................................... 26

Processing Area Layout .......................................................................................................................... 26

Safety Devices......................................................................................................................................... 27

7.5.1 Emergency Stop Device ............................................................................................................... 27

7.5.2 Laser protection glass .................................................................................................................. 28

7.5.3 Laser protection shutter................................................................................................................ 28

Page 4

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 4 von 42

ProMarker 300

8 Installation ...................................................................................................................................................... 29

Installation Location ................................................................................................................................. 29

Electrical Installation ................................................................................................................................ 29

8.2.1 Overview - PC Interface (Reverse Side) ...................................................................................... 29

8.2.2 Power Supply ............................................................................................................................... 30

8.2.3 Overview - Laser Module Interface (Reverse Side) ...................................................................... 31

8.2.4 Interface Pin Configurations ......................................................................................................... 33

9 Commissioning .............................................................................................................................................. 34

Installation Inspection .............................................................................................................................. 34

Marking Software..................................................................................................................................... 34

Switching On/Off...................................................................................................................................... 35

Opening and closing the doorf ................................................................................................................. 35

Focusing .................................................................................................................................................. 36

Using Pass-Through Option .................................................................................................................... 37

10 Maintenance ................................................................................................................................................... 38

General Maintenance .............................................................................................................................. 38

Cleaning the Lenses ................................................................................................................................ 38

Replacing the Filter Pad .......................................................................................................................... 39

11 Transportation and Storage .......................................................................................................................... 40

Transportation Conditions ....................................................................................................................... 40

Storage Conditions .................................................................................................................................. 40

Storage Location ..................................................................................................................................... 40

12 Troubleshooting ............................................................................................................................................. 41

Problem Resolution ................................................................................................................................. 41

Possible Error Messages ......................................................................................................................... 42

Page 5

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 5 von 42

ProMarker 300

2 Introduction

The SpeedMarker 300 / ProMarker 300 is a second generation high quality galvo laser marker. The Yb fibre laser

source means the system has an extremely long life-cycle and minimal maintenance costs. The system is

maintenance free apart from the filter pad and processing lens.

The combination of a high quality galvo scanner and a fibre laser produce highly precise marking results in short

marking times.

This, together with the marking software and the available interfaces, provides a flexible and productive marking

solution of the highest quality standards.

3 General Information

Strict compliance with the safety procedures described in this operation manual and exercising extreme caution

when using the equipment are essential for avoiding and reducing the possibility of personal injury or damage to

the equipment.

The SpeedMarker 300 / ProMarker 300 is a Class 2 marking system as per DIN EN 60825-1 “Safety of laser prod-

ucts”.

All information, illustrations, tables, specifications and diagrams contained in this operation manual have been carefully compiled according to the art current at the time of going to press. No liability is accepted with regard to errors,

missing information and any resulting damage or consequential loss.

Trotec Produktions und Vertriebs Ges.m.b.H. reserves the right to update any of the information, illustrations, tables,

specifications and diagrams contained in this operation manual with regard to technical developments at any time

without notice.

Any software incorporated in this equipment should only be used for the purpose for which it was supplied by Trotec

Produktions und Vertriebs Ges.m.b.H. It is strictly prohibited for the user to undertake any alterations, conversions,

translations into another computer language or copies (except for any essential back-up copies).

Trotec Produktions und Vertriebs Ges.m.b.H. is not responsible for any personal injury or material damage, of either

an indirect or specific nature, consequential loss, loss of commercial profits, interruption to business, or loss of

commercial information resulting from the use of the equipment described in this manual.

Page 6

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 6 von 42

ProMarker 300

General Instructions for Using the Operation manual

The Operation manual describes how to handle the device correctly and safely and guides you through the necessary steps for initial use. The Operation manual also contains important information regarding system maintenance.

This Operation manual must be read and followed carefully before commissioning and operating the device. Failing

to observe individual points listed in this Operation manual may result in personal injury and/or material damage to

property!

This system may only be operated using devices and spare parts included in the scope of supply or the replacement

or wear and tear parts list.

Ancillary devices must be calibrated to meet the safety and operational requirements of the base machine (please

contact your dealer or the manufacturer with any queries).

The following symbols are used within this Operation manual to aid understanding:

If the Operation Manual is not observed, this area represents a particular danger for the operating

personnel or the personnel responsible for maintenance.

Caution: This component is under voltage. In these areas strictly observe the safety instructions

regarding electricity. Care is to be taken in particular during maintenance and repair work.

Caution: In this area pay attention to the possible dangers of the laser beam.

Note or information on individual components of the device, that simplify the use or make it more

understandable.

Page 7

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 7 von 42

ProMarker 300

Intended Use

The Trotec SpeedMarker 300 / ProMarker 300 is intended exclusively for laser marking using the supplied marking

software.

Materials such as metal, anodized aluminum, and several plastics can be processed on the laser.

The following points should also be observed as part of the intended use:

only mark approved materials using suitable parameters

The working process mustt only be performed with a perfectly adjusted machine (see also

Section 9 Commissioning)

The system must only be operated, maintained and repaired, by personnel that are familiar

with the designated field of use and the dangers of the machine!

Non-observance of the instructions for operation, maintenance and repair described in this

Operation Manual excludes any liability of the manufacturer if a defect occurs.

Use of the system in other areas is against the designated use. The manufacturer does not

admit liability for damage to personal and/or equipment resulting from such use

The use of a suitable extraction system to remove fumes, dust or other reaction products is

absolutely necessary.

observe effective safety regulations and the procedures described in this Operation manual

caution when processing conductive materials (carbon fibers,)! Conductive dust or particles

in the ambient air might damage electrical components and lead to short circuits. Bear in mind

that those defects are NOT warranted.

If the intention is to use the system for other applications, Trotec Produktions und Vertriebs Ges.m.b.H. should be

informed in advance

Disposal remarks

Do not dispose the machine with domestic waste!

Electronic devices have to be disposed according to the regional directives on electronic and

electric waste disposal. In case of further questions, please ask your supplier. He might take care

of proper disposal.

Page 8

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 8 von 42

ProMarker 300

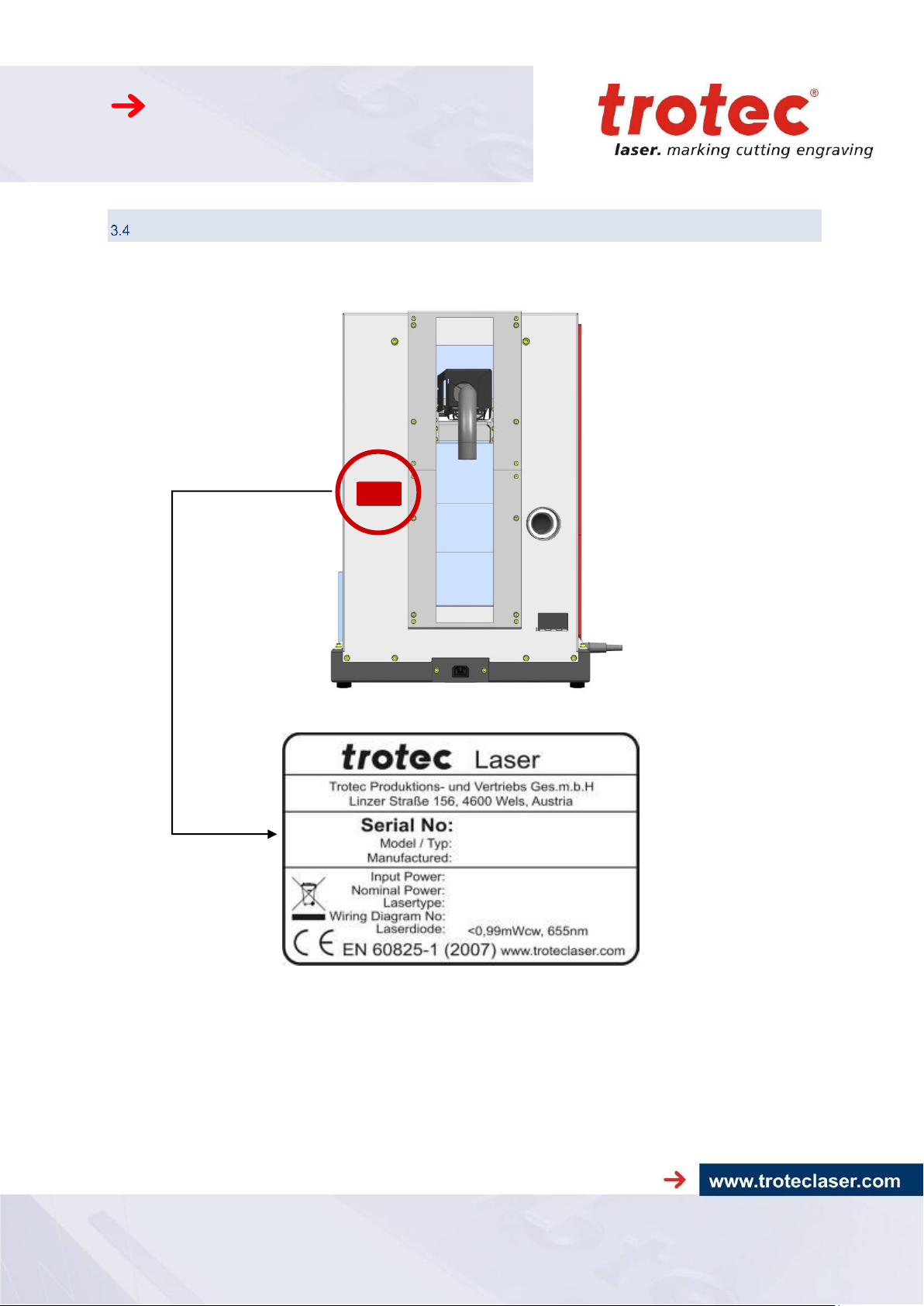

Manufacturer's Label

The Manufacturer's Label is located on the backside of the machine (see picture below)

It is recommended to enter data such as serial number and year of manufacture data sheet above so that you

always have this data handy if you have problems with your device or require spare parts.

Page 9

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 9 von 42

ProMarker 300

EC–Declaration of Conformity

(Machine directive 2006/42/EG, appendix II A)

Manufacturer:

Trotec Produktions u. Vertriebs GmbH.

Linzer Straße 156,

A-4600 Wels

Authorized person for the compilation of technical documentation:

Gerhard KREMPL, Trotec Produktions u. Vertriebs GmbH., Linzer Straße 156, A-4600 Wels

We hereby certify that

SpeedMarker 300 / ProMarker 300

ProMarker 300

Model N° 8025 SpeedMarker 300 / ProMarker 300

Model N° 8025 ProMarker 300

in its conception, construction and form put by us into circulation is in accordance with all the relevant essential

health and safety requirements of the EC machinery directive 2006/42/EEC.

Further valid guidelines/regulations for the product:

2006/95/EG Low Voltage Directive

2004/108/EG EMC Guideline

Applied harmonized standards:

- EN ISO12100 Machine Safety

- EN 60335-1/2007 Safety of Household and similar Appliances

- EN 55011 + A1/2010 Electromagnetic Compatibility

- EN 60204-1 Machine Safety – electr. Equipment

- EN 60825-1/2007, EN 60825-4/2006 and EN 60825-14/2006 Safety of Laser Equipment

- EN 61000-6-2/2005, EN 61000-3-3/2008 and EN 61000-3-2 +A1 +A2/2009 Electromagnetic Compatibility

Place, Date:

Wels, 14.10.2013

Personal data of the signer:

Stephan FAZENY, Head of Research and Development

Signature:

Page 10

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 10 von 42

ProMarker 300

4 Safety

Please read this chapter before operating or servicing a Trotec SpeedMarker 300 / ProMarker 300 laser system!

General Safety Information

All personnel involved in installation, set-up, operation maintenance and repair of the machine, must have read and

understood the Operation Manual and in particular the "Safety" section. The user is recommended to generate

company-internal instructions considering the professional qualifications of the personnel employed in each case,

and the receipt of the instruction/Operation Manual or the participation at introduction/training should be acknowledged in writing in each case.

Safety-conscious Working

The machine must only be operated by trained and authorized personnel.

The scopes of competence for the different activities in the scope of operating the machine must be clearly defined

and observed, so that under the aspect of safety no unclear questions of competence occur. This applies in particular to activities on the electric equipment, which must only be performed by special experts.

For all activities concerning installation, set-up, start-up, operation, modifications of conditions and methods of operation, maintenance, inspection and repair, the switch-off procedures that may be provided in the Operation Manual must be observed.

Safety Information for the User and/or Operating Personnel

No working methods are permitted that affect the safety of the machine.

The operator must also ensure that no unauthorized persons work with the machine (e.g. by activating

equipment without authorization).

It is the duty of the operator, to check the machine before start of work for externally visible damage and

defects, and to immediately report changes that appear (including behavior during operation) that affect

the safety.

The user must provide that the machine is only operated in perfect condition.

The user must guarantee the cleanness and accessibility at and around the machine by corresponding

instructions and controls.

Principally, no safety components may be removed or disabled (already here we emphasize the imminent

dangers, for example severe burns, loss of eye-sight). If the removal of safety components is required

during repair and service, the replacement of the safety components must be performed immediately after

completion of the service and repair activities.

Preparation, retooling, change of work piece, maintenance and repair activities must only performed with

equipment switched off, by trained personnel.

It is forbidden to perform unauthorized modifications and changes to the machine. It is emphasized, that

any unauthorized modifications to the machine are not permitted for safety reasons.

Page 11

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 11 von 42

ProMarker 300

Laser Safety Information

To assess the potential dangers laser systems pose, they are classified into 5 safety classes: 1,

2, 3a, 3b and 4. Trotec SpeedMarker 300 / ProMarker 300 fiber is a device of class 2 (USA: Class

II) and class 4 (USA: Class IV) with pass through option

Please note that improper operation of the device can override the status of safety class 2 and

can cause the emission of harmful radiation.

This laser system contains a YTTERBIUM FIBER LASER of class 4 that emits intensive and invisible laser radiation. Without safety precautions the direct radiation or even diffuse reflected radiation is dangerous!

Without safety precautions, the following risks exist with exposure to laser radiation:

Eyes: Burns to the retina for NIR (Near Infra Red) LASER

Skin: Burns

Clothing: Danger of fire

Never try to modify or disassemble the laser and do not try to start up a system that had been

modified or disassembled!

Dangerous radiation exposure can result from the use of operation or adjustment equipment other

than that described here, and if different operational methods are performed.

Service technicians using the service plug are required to wear standard laser safety glasses for

NIR (Near Infra Red) lasers (wavelength 1060 nm).

Page 12

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 12 von 42

ProMarker 300

In case of using highly reflecting materials like

blank or polished metals

metals with very high reflectivity like copper, brass, gold, silver

any materials with highly reflecting coatings

other highly reflecting materials,

especially in combination with high laser power, low processing speed and/or work pieces with curved or

inclined surfaces, laser radiation might be reflected towards the protection cover. With a very low probability this protection cover could be damaged if the reflected radiation is FOCUSSED onto the surface of

the protection cover.

Therefore visual inspection for point-like defects on the protection cover should be done if the aforementioned conditions are given.

The loss of yellow color on the protection cover indicates a damage of the protecting layer. If you detect

such effects, immediately turn off the laser machine and take care to get a new protection cover.

Also other components inside the machine may be damaged if the aforementioned conditions are given. To improve

laser safety an optional “Laser Protection Cover” is available on request.

Page 13

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 13 von 42

ProMarker 300

Safety Precautions when Operating the Device

In your SpeedMarker 300 / ProMarker 300, a closed safety system is integrated which immediately switches off the

power to the laser tube when the protection cover is opened. Consequently an incomplete engraving can occur if

the cover is opened during operation.

Please remember the following safety precautions when working with this device:

A fire extinguisher must always be handy as the laser beam can ignite flammable materials. Do not store any

flammable materials in the inside of the device or in the immediate vicinity of the device. Particularly leftovers of

produced materials have to be removed to prevent fire hazard.

Unsupervised operation of the system is not permitted.

Adjustment of the beam path must be performed only by especially trained personnel. An improper setting can lead

to uncontrolled emission of the laser radiation.

Before processing materials the user must verify, whether harmful materials can be generated and whether the filter

equipment of the exhaust system is suitable for the harmful materials. We emphasize that it is the responsibility of

the user, to consider the national and regional threshold values for dust, fogs and gases when selecting the filters

and the exhaust system. (The values for the maximum workplace concentration must not be exceeded.)

Please refer to the manual of the exhaust system on how and in what intervals you need to replace filters.

PVC (polyvinyl chloride) must under no circumstances be processed with the laser.

Should you have further questions before starting work, please contact your dealer or Trotec.

Page 14

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 14 von 42

7

1

6

4

3

5

2

3

1

2 4 5

6

7

ProMarker 300

Warning and Information Labels

The warning and information labels are attached in such positions of the machine that could represent

a source of danger during set-up and operation. Therefore, follow the information on the labels.

If labels are lost or damaged, they must be replaced immediately

Page 15

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 15 von 42

ProMarker 300

With pass through option (laser class 4):

Page 16

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 16 von 42

ProMarker 300

5 Before Commissioning

General Instructions

Read the Operation manual and ensure it is accessible at all times.

The ambient air temperature must be between +5°C und +35°C and the relative air humidity not exceed

90% (non-condensing).

A laser system consists of high quality electrical and optical components. Mechanical stresses, vibrations

and impacts must always be avoided.

If the system has been subject to significant temperature variations, it must be brought back to room tem-

perature before being commissioned.

There must be sufficient air supply to the 19” module. The accumulation of heat due to covered ventilation

slots or filter pads can damage the system.

The operating personnel must read and understand the Operation manual, in particular the chapter on

"Safety Instructions". It is recommended that the operator compiles with in-house instructions regarding

safety and operation and that the receipt of these instructions/Operation manual and the participation in

briefings/training courses is confirmed in writing.

Laser marking may generate gases, fumes and other reaction products on the surface of the material. The

operator must therefore use an effective extraction system.

Page 17

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 17 von 42

ProMarker 300

Scope of Supply (Standard Configuration)

1x SpeedMaker 300 (incl. laser module)

1x Industrial Computer

2x key for Industrial Computer

2x key for laser module

1x Connection cable set:

o cable W203 (X51 – X53).

cable W503 (X93 – X103)

back bridge Plug (X31)

X11 plug (wired)

1x CD with marking software

1x USB flash drive with Windows Backup

1x lens cleaning kits

1x Allen key set

2x IEC connector for laser module and computer

1x IEC connector for electrical Z-Axis (optional)

1x Extraction system connection cable (optional)

1x Pass-Through interlock key (optional)

2x: Additional weights when side panels released (for Pass-Through only)

Page 18

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 18 von 42

ProMarker 300

Unloading, Inspection and Reporting Faults

In the event of transportation damage or incomplete delivery:

Record all details in writing immediately.

Note all claims on the transportation documents.

Photograph any damage.

Send report to Trotec.

When unloading:

The marking head is connected to the actual laser source in the laser module via an approx. 2.1

m long fibre optic cable. The fibre optic cable is enclosed with the jumper cables in a black protective tube for protection. Avoid any unnecessary stretching or bending by a radius more then

66 mm of the fibre optic cable. This could damage the fibre optic cable.

The lens unit should only be uncovered following installation. The lenses are high quality optical

components which must be kept clean in order to ensure optimum marking results. Never touch

the lenses with bare fingers!

After unloading:

Inspect the machine and machine components for transportation damage.

Check the delivery for completeness.

Remove all transport packaging.

Page 19

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 19 von 42

ProMarker 300

6 Technical Data

General Description

All electronic components are integrated in the machine. All necessary connectors are located on the reverse side

of the laser module and PC.

Laser Module Dimensions

Page 20

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 20 von 42

ProMarker 300

Housing Dimensions

Drawing 1: interior Drawing 2: door open

Drawing 3: door closed

Page 21

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 21 von 42

Laser

pulsed Yb-fiber laser, maintenance free

Laser power

10, 20, 30 or 50 Watt, depending on model

Wavelength

1064 nm ± 8

Pulse width

110ns

Cooling

Air cooled (filters)

Marking area

F-100

F-160

F-254

70 x 70mm

120 x 120mm

190 x 190mm

Focus diameter

~ 27 µm

~ 45 µm

~ 68µm

Writing speed

640 cps (1mm single stroke with F=160mm)

Positioning speed

10m/s with F=160mm

Computer

Industrial grade PC as 19" rack unit 3RU high

Intel® Celeron Dual Core G540 (2.5 GHz each), 4 GB RAM

HDD 250GB, DVD R/W,

Operating system Windows® 7

Interfaces

USB, Ethernet, RS232, digital I/O’s (24V DC)

Marking software

SpeedMark or SAMLight

Bay width

350mm

Bay hight

383mm

Interior dimension (WxD)

350 x 350mm

Max. part hight (WxD)

300 x 300mm

Z-axis

Mechanical or software-controlled z-axis

Table

Aluminum t-slot table

Ambient conditions

Operating temperature +5 to +35° C.

Relative humidity max. 90 %.

Non-condensing

Power requirements

110-230V AC, 50/60Hz, single-phase

Power consumption

Max. 600 W

Equipment protection

IP54 (Marking head), IP20 (Laser unit)

Laser class

CDRH laser safety

Class II (Class IV with Pass-Through option)

CE certified

ProMarker 300

Data Sheet

Laser

Galvo Scanner

Control

Interior Dimensions

Mechanical Setup

Ambient Conditions

Laser Safety

Page 22

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 22 von 42

Workstation housing:

1

Safety door incl. safety glass (closed)

2

Safety door handle

3

Cable opening (interlock, mark start, rotary)

4

Extraction system connector

5

Laser safety protection elements

6

Backside of marking head incl. fibre

7

Manufacturers plate

… with mechanical Z-axis option:

8

Z-Axis adjustment wheel

… with software controlled Z-axis option:

9

Keypad

10

IEC Connector for Z-Axis

… with Pass-Through option:

11

Interlock hatch

12

Removable side panels (both sides)

13

Interlock indication lights (both sides)

14

Emergency Stop button

4

5 6 7

3

10

9

1

8

11

2

14

13

12

ProMarker 300

7 System Overview

Page 23

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 23 von 42

3 1 2

4

5 6 7 3 1 2 4 5 6

7

ProMarker 300

The Laser Module

7.1.1 Laser Module Control elements (Front Side)

Main switch

System ready – control lamp

Shutter – control lamp

Laser busy – control lamp

Emergency stop – button

Error reset – button

Key switch

Page 24

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 24 von 42

Protection tube for fiber cable

ProMarker 300

7.1.2 Laser Module Interface (Reverse Side)

X11 – Emergency Stop / Interlock / ext. Messages

X31 – External Panel

X51 – Laser Control

X61 – Extraction System

X71 – Start / Stop

Page 25

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 25 von 42

X53

X93

X103

X83

TLC2

card

Combination

board slot

ProMarker 300

Industrial PC

7.2.1 Industrial PC (Front Side)

7.2.1 Industrial PC Interface (Reverse Side)

Page 26

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 26 von 42

Z-Axis up

Z–Axis down

Laser busy

Light switch

Start button

(must be activated in

the software)

Emergency Stop

(only with Pass through option)

Keypad

(only with motorized Z- Axis option)

Manual Z-Axis handle

(only with manual Z- Axis option)

Exhaust tube

T-slot table

Z-Axis height

indication

ProMarker 300

Control Elements on the Front of the SpeedMarker 300 / ProMarker 300

Processing Area Layout

The processing area contains the axis system, extraction hose, light, t-slot table and the marking head including

lens.

Page 27

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 27 von 42

ProMarker 300

Safety Devices

The SpeedMarker 300 / ProMarker 300 is fitted with the following safety devices:

Main switch

Emergency stop button

Safety switches on the safety door

Observation window of laser protection glass

Laser protection shutter

Cover plates

Do not alter or deactivate the safety switches or protective covers on the laser head or the machine.

All safety and protection devices must be installed and fully functional every time the machine is put into operation.

7.5.1 Emergency Stop Device

There is one emergency stop button located on the laser module. With the optional Pass through option also a

second emergency stop button on the front of the SpeedMarker 300 / ProMarker 300 housing

The function of the emergency stop device is

Firstly: to prevent any risks to the operating personnel.

Secondly: to avoid any damage to/destruction of the machine/material.

The emergency stop automatically shuts off the electric circuit. The laser beam is interrupted by the shutter. All

movements are stopped.

When the emergency stop function is triggered, an error message is displayed.

Emergency stop acknowledgement

Eliminate the cause of the emergency stop

Unlock the emergency stop button

Acknowledge the error message using the "System Alarm" Button on the Laser module.

Page 28

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 28 von 42

ProMarker 300

7.5.2 Laser protection glass

The light green observation window in the front door is made of laser protection glass in accordance with DIN EN

201. The glass consists of a special material depending on the type of laser used and which absorbs the laser

radiation. The glass should be replaced if it becomes damaged.

7.5.3 Laser protection shutter

If a safety circuit in the laser cell is open, the laser protection shutter shuts momentarily. For reasons of safety this

disconnection functions via safe components. The laser is interrupted mechanically. An error message is issued.

Page 29

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 29 von 42

X53

X93

X103

X83

TLC2

card

Combination

board slot

ProMarker 300

8 Installation

Installation Location

The installation location must:

have a non-fluctuating power supply

be vibration free

have sufficient air supply for the laser module and PC

The laser module and the PC should be located next to or directly above one another if possible in order

for the modules to be connected to one another with the cables provided..

Electrical Installation

All connectors are clearly identified in order to facilitate the electrical installation. A connector marked X43 belongs

to the socket with the same denotation.

The connector denotations are also coded. The last digit of the connector denotation identifies the respective hardware components. Therefore:

X …1 Laser module

X …2 Marking head

X …3 PC

8.2.1 Overview - PC Interface (Reverse Side)

Connectors X93 and X103 are joined directly to one another via a short cable.

Connector X53 is joined to X51 on the laser module using the cable supplied.

Page 30

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 30 von 42

ProMarker 300

Connector X83 is connected to the cable from the laser module. This cable leads from the laser module via the

black tube to X82 on the marking head.

The monitor, mouse and keyboard must also be connected to the PC. (Monitor, mouse and keyboard are not normally included in the scope of supply.)

Note: the PC COM4 interface is not connected prior to delivery!

8.2.2 Power Supply

IEC connectors are located on the reverse side of the laser module and PC for the connection of the supplied IEC

power cords.

Before putting the system into operation, it is essential to check whether the laser module is configured to the

available supply voltage and frequency.

The configuration of the laser module is given on the type plate or warning sign above the IEC connector.

The laser module is fitted with different main fuses depending on the configured supply voltage:

115V AC - 1 X 6.3 A “T” speed/time-delay

230V AC - 2 x 4 A “T” speed/time-delay

The main fuses are located behind the cover, immediately adjacent to the IEC connector.

The same main fuse is used for all supply voltages on the PC.

Page 31

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 31 von 42

ProMarker 300

8.2.3 Overview - Laser Module Interface (Reverse Side)

Before the laser marker can be put into operation, the external safety circuits and the external start and stop signals

must be connected.

When making these connections, the operator must ensure that all safety circuits comply with the respective valid

national standards and guidelines for the use of laser devices. Otherwise the device may cause personal injury or

material damage.

The following connectors are available on the laser module:

X11 – Emergency Stop / Interlock / ext. Messages

The X11 connector enables the connection of external safety circuits, additional emergency stop circuits and external warning lamps.

This connector comes already wired regarding the configuration of your SpeedMarker 300 / ProMarker 300. The

precise pin configuration of the plug is provided in in 0

The maximum load of each of the digital 24V outputs on the interface X11 is 100 mA. A short

circuit of the outputs must be avoided as it will damage the respective inputs.

The digital 24V inputs (pin 14 and pin 15) should only be controlled by isolated contacts with the

24V pin 13. The input of signals with any other reference potential could result in damage to the

respective inputs.

Page 32

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 32 von 42

ProMarker 300

X31 – External Panel

The connector X31 may be used to connect an external control panel such as that located on the front of the laser

module.

If no external panel is connected, the supplied connector must be used with the bridging devices.

X51

Laser control. This is connected to X53 on the PC.

Only use the original cable supplied.

X61 – Extraction System

This connector is used to control, start and stop a Trotec extraction unit.

Only use the original cable supplied.

X71 – Start / Stop

The X71 connector is already wired regarding the configuration of your SpeedMarker 300 / ProMarker 300.

Page 33

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 33 von 42

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

24V

Emergency Stop Kreis 1

Emergency Stop Kreis 2

Interlock Cover Lid Kreis 1

Interlock Cover Lid Kreis 2

potfreier Kont. Emergency Stop

(geschl. wenn Emergency offen)

Eingang externer Abort (24V)

Eingang externer Reset (24V)

Ausgang Lampe System On (24V)

Ausgang Lampe Laser Busy (24V)

Ausgang Lampe System Ready (24V)

Ausgang Lampe Sum Alarm (24V)

Ausgang Lampe Shutter (24V)

0V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

externintern

Steckerbelegung Emergency Stop / Interlock / ext. Messages (X11)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

externintern

Steckerbelegung externes Panel (X31)

Abort

Reserve_Input_0

Schlüsselschalter

Emergency Stop Kreis 1

Reserve_Input_1

Ausgang Lampe System On (24V)

Ausgang Lampe Laser Busy (24V)

Ausgang Lampe System Ready (24V)

Ausgang Lampe Sum Alarm (24V)

Ausgang Lampe Shutter (24V)

15 15

24V

0V

Optional

Emergency Stop Kreis 2

Emergency stop circuit 1

Emergency stop circuit 1

Interlock cover lid circuit 1

Interlock cover lid circuit 2

Isol. contact. Emergency Stop

(closed if evergency open)

Input external Abort (24V)

Input external Reset (24V)

Output lamp System On (24V)

Output lamp Laser Busy (24V)

Output lamp System Ready (24V)

Output lamp Sum Alarm (24V)

Output lamp Shutter (24V)

Key switch

Abort

Reserve_input_0

Reserve_input_1

Output lamp System On (24V)

Output lamp Laser Busy (24V)

Output lamp System Ready (24V)

Output lamp Sum Alarm (24V)

Output lamp Shutter (24V)

Emergency stop circuit 1

Internal external

Internal external

Emergency stop circuit 2

ProMarker 300

8.2.4 Interface Pin Configurations

X11 – Emergency Stop / Interlock / ext. Messages

X31 – External Panel

Page 34

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 34 von 42

1

2

3

4

5

Busy (max. 24V, 100mA)

1

2

3

4

5

externintern

Steckerbelegung Start/Stop (X71)

GND Start

6 6

GND Stop

Start

Stop

Internal external

ProMarker 300

X71 – Start / Stop

9 Commissioning

Installation Inspection

In order to ensure the unit is installed correctly, the following points should be checked:

Ensure the power supply corresponds to the correct connection values and suitable fuses have

been used.

Has the mechanical and electrical installation been performed correctly and completely?

Check the mechanical and electrical installation for completeness and the correct input voltages.

Ensure that the optical components are free from dust and dirt.

Have the protective covers been removed from the focusing objective lens?

Check the environmental conditions against the technical specification.

Are you familiar with the laser safety regulations?

Have all laser safety measured been fulfilled? The system may then only be switched on once all provi-

sions for complying with laser safety have been checked by an authorised individual and confirmed to

have met the standards.

Marking Software

The marking software is already installed on the supplied PC.. It is also included in the setup on the accompanying

software CD.

For information on using the software, please read the accompanying software handbook.

Page 35

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 35 von 42

7

6

1

1

7

2

3

6

6

3 1 2

4

5 6 7

ProMarker 300

Switching On/Off

Press the master switch on the laser module.

The switch is illuminated in green and the two status lamps on the marking

head also illuminate in green (shutter closed).

Put the key in the key switch (vertically) and turn 90° to the right.

Press the “Error reset” button to reset the system to its normal state.

As soon as the door is closed …

System ready , Shutter and the two status lamps (red) on the marking head should now be illuminated.

The laser is now ready to start marking.

Start the PC. (The mains switch is located on the front behind the right hand cover. When operating the system

for the first time it may be necessary to check the master switch on the reverse side of the PC. In its normal

state this can remain in the “On” position.)

Now start the marking software on the PC

If an error occurs, the “Error Reset” button illuminates. Pressing this button acknowledges the error and the

system is then ready to continue operating.

Opening the door, while a marking process is running, will interrupt the laser beam immediately. The Error reset

button …… will illuminate and must be reset before you can continue with your marking.

We recommending using only the key switch to pause the laser.

To completely turn off the laser, the main switch must be set to O.

Opening and closing the doorf

The door of the SpeedMarker 300 / ProMarker 300 is directly connected to the Interlock circuit. Therefore starting

a marking process is only possible with the door closed.

Simply use the black handle at the door to lift it and slide it down for opening and closing.

Page 36

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 36 von 42

Lens

Focal distance (A)

F-100

~134,6 mm

F-160

~211,6 mm

F-254

~361,6 mm

B

C

A

ProMarker 300

Focusing

It is absolutely essential to maintain the correct focal distance for every laser marking process. Only when in focus will the laser beam achieve the power density necessary for permanent and clearly legible marking.

Prior to any marking it is therefore necessary to set the correct focal distance between the marking head and the

workpiece. An incorrect focal distance is the most common cause of poor or even indistinguishable markings.

The focal distance (A) is measured between the lower edge of the galvo head (B) and the upper surface of the

workpiece (C). The correct focal distance depends on the lens used (focal length).

Use the manual Z-Axis handle or the up and down buttons on the Keypad (see also 7.3 Control

Elements on the Front of the SpeedMarker 300 / ProMarker 300) to move the head in the correct

position.

Page 37

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 37 von 42

ProMarker 300

Using Pass-Through Option

Using the Pass-Through Option allowes you to mark work pieces longer then 350mm with a square of 200x165mm

Simply remove the side panels by unscrewing them from the outside and replace them with the additional weights

(shown in dark grey). The Interlock hatch must be installed to close the Interlock safety circuit.

Interlock hatch

additional weights

Page 38

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 38 von 42

ProMarker 300

10 Maintenance

General Maintenance

Before any maintenance work takes place, ensure that the power supply has been switched off and the

system is de-energised.

All maintenance work must be carried out according to the safety regulations.

In order to ensure the maximum availability and lifetime of the system, we recommend you regularly

check the filter system and ventilation and keep the surrounding area clean. A visual inspection of the

lenses is likewise recommended before switching on the system.

Cleaning the Lenses

This system is fitted with high quality optical components, which under normal operating conditions are maintenance

free for their lifetime. However, it may be necessary to clean output lenses, e.g. the scanner flat field lens (f-theta

objective) if it becomes covered in dust or fumes.

Never touch the optical components with your fingers! Oily or dirty hands may damage the

lens surfaces.

Do not use any tools or hard objects to clean the surfaces. Scratches cannot be repaired.

Laser optics are highly sensitive and their surfaces are not as hard as traditional glass.

They can also be easily damaged by cleaning. It is therefore necessary to ensure that any

dirt is removed using a suitable suction device and that the surrounding area is cleaned

regularly.

Small bellows should be used to remove dust.

Do not use compressed air as it contains small quantities of oil and water.

To remove larger pieces of dirt, only use a lens cleaning cloth with high proof (min. 98 %) alcohol.

Do not dip the cleaning cloth in the cleaning solution. This contaminates the solution and

makes it unusable. Place drops of the solution on the cloth!

Apply the cleaning solution carefully in order to avoid scratching the surface of the lens.

Do not wipe the lens with a dry cloth. Do not touch the reverse side of the cloth. Dirt and

sebum on the fingers can be transferred to the lens by the cloth and cause damage.

Distribute the cleaning fluid carefully using small circular motions. Start at the centre of the lens

and move outwards to the edge. Keep moving the cloth until the entire surface is clean.

Do not exert any pressure on the lens.

Page 39

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 39 von 42

Filter pad cover

Filter pad cover

ProMarker 300

Replacing the Filter Pad

This laser system is fitted with a ventilation system. A filter pad is used to protect the electronic components from

dust and dirt in the ambient air.

This filter pad should be checked and replaced at regular intervals in order to ensure optimum cooling.

The filter pad is located behind the ventilation slots on the front of the laser module or PC.

Laser module filter pad:

PC filter pad:

Page 40

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 40 von 42

ProMarker 300

11 Transportation and Storage

Transportation Conditions

When transporting outside, always transport in a covered vehicle or one with sufficient weather-proofing.

Protect the machine against transportation damage using straps and inserts, and leave sufficient distance

between other transported items.

Ambient temperature for transportation:

Min. temp. 10 °C

Max. temp. 40 °C

Handle the machine and machine components with care.

Do not place any heavy loads on the machine or machine components.

Avoid heavy impacts.

Take particular care when transporting electronic components.

Storage Conditions

Store the machine and machine components in a dry location.

Protect the machine and machine components against scratches.

Take particular care when packing away electronic components.

When storing for a long period of time, preserve bare metal parts (e.g. apply oil).

Ambient temperature for storage:

Min. temp. 10 °C

Max. temp. 40 °C

Storage Location

Storage room or boxed with sufficient weather-proofing. The storage location must be free from corrosive elements,

fumes and flammable materials.

Page 41

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 41 von 42

Problem

Possible cause

Resolution

Error message on loading the program

Plug or cable installed incorrectly

Check the plug and cable are installed correctly

Laser power supply switched off

Turn on main switch

Software not installed correctly

Re-install software

Software terminated irregularly

Restart PC

Laser will not switch on

Plug or cable installed incorrectly

Check the plug and cable are installed correctly

Laser power supply switched off

Turn on main switch

Faulty fuse in laser power supply

Replace fuse

Status lamps on marking head remain green

Interlock circuit not closed

Check interlock circuit

If no interlock circuit is connected, use bridging connector X11.

No laser beam

Laser not in focus

Check working distance

Shutter closed

Open shutter - if not possible check interlock

circuit

Incorrect laser parameters

Check the parameters in the program. Use

suitable parameters for the material and application

Insufficient laser output

Laser not in focus

Check working distance

Incorrect laser parameters

Check the parameters in the program. Use

suitable parameters for the material and application

Missing symbols

Focusing lens dirty

Clean focusing lens

Surface of the material dirty

Clean material surface

Other faults

Contact Trotec Support

ProMarker 300

12 Troubleshooting

This chapter should assist maintenance personnel with the identification and resolution of operational faults based

on error messages and symptoms.

Maintenance and repair work should only be carried out by Trotec Produktions und Vertriebs

Ges.m.b.H. or one of its authorised personnel under observation of the safety regulations.

Problem Resolution

Page 42

SpeedMarker 300 /

Ausgabe 1.0

Technische Änderungen vorbehalten.

TROTEC Produktions- u. Vertriebs GmbH

Linzer Straße 156, A – 4600 Wels

Seite 42 von 42

Error message

Cause

Card off line

Software has lost connection to the TLC2 controller

Scanner not connected

No connection to the galvo

Scanner X error

The galvo X-axis has identified an error

Scanner Y error

The galvo Y-axis has identified an error

Signal cable not connected

No connection to the marking head

External abort

External abort signal identified on X11

External stop

External stop signal identified on X11

Voltage error (15V)

+/- 15V power supply not functioning correctly

Voltage error (24V)

24V power supply not functioning correctly

Laser power supply error

Faulty laser source power supply

Shutter error

Shutter has not reached intended position

Cover connector opened during marking

ICL1 and ICL2 were opened during the marking process

External sum alarm

External error signal identified on X11

System locked by key switch

Key switch on laser module locked

Laser temperature

Laser source overheated

Laser power

24 V power supply outside the permissible tolerance zone

Laser not ready for emission

e.g. key switch not activated

Laser back reflection

Back reflection of the laser beam

Laser system error

Laser power supply voltage is too high or too low

Emergency stop button

Emergency stop button activated

System Failurer

ProMarker 300

Possible Error Messages

Below is a list of possible errors which may be detected by the system. These will appear in the software as messages on the display.

The Reset signal (X11) or the reset button on the laser module are used to acknowledge an error. In

order for the system to be reset, the error or the corresponding input signal must be acknowledged.

System errors which cannot be reset or which indicate a hardware error should only be resolved by Trotec Produktions und Vertriebs Ges.m.b.H. trained service personnel.

Loading...

Loading...