Page 1

QUBE+

EN

ORIGINAL INSTRUCTIONS

INSULATION DRYING UNIT

TRT-BA-QUBE-TC2015-27-010-EN

Page 2

Table of contents

Notes regarding the instructions ..........................................2

Safety .....................................................................................2

Information about the device................................................4

Transport and storage...........................................................7

Follow the manual

Information marked with this symbol indicates that the

instructions must be observed.

You can download the current version of the instructions and

the EUdeclaration of conformity via the following link:

Assembly and installation.....................................................8

Start-up................................................................................10

Operation .............................................................................11

Errors and faults..................................................................13

Maintenance ........................................................................15

Technical annex...................................................................22

Disposal ...............................................................................26

Declaration of conformity ...................................................26

Notes regarding the instructions

Symbols

Warning of electrical voltage

This symbol indicates dangers to the life and health of

persons due to electrical voltage.

Warning of hot surface

This symbol indicates dangers to the life and health of

persons due to hot surface.

Warning

This signal word indicates a hazard with an average

risk level which, if not avoided, can result in serious

injury or death.

Caution

This signal word indicates a hazard with a low risk

level which, if not avoided, can result in minor or

moderate injury.

Note

This signal word indicates important information

(e.g. material damage), but does not indicate hazards.

Info

Information marked with this symbol helps you to carry

out your tasks quickly and safely.

Qube+

https://hub.trotec.com/?id=40717

Safety

Read this manual carefully before starting or using the

device. Always store the manual in the immediate vicinity

of the device or its site of use!

• Do not use the device in potentially explosive rooms.

• Do not use the device in aggressive atmosphere.

• Set the device up in an upright and stable position.

• Make sure that the air inlet and outlet are not obstructed.

• Make sure that the suction side is kept free of dirt and

loose objects.

• Never insert any objects or limbs into the device.

• Do not cover or transport the device during operation.

• Ensure that all electric cables outside of the device are

protected from damage (e.g. caused by animals). Never

use the device if electric cables or the power connection

are damaged!

• Observe the device's power input, cable length and

intended use when selecting extensions to the power

cable. Completely unroll extension cables. Avoid electrical

overload.

• Switch the device off and disconnect the power cable from

the mains socket when the device is not in use.

• Do not under any circumstances use the device if you

detect damages on the mains plug or power cable.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Defective power cables pose a serious health risk!

• Insert the mains plug into a properly secured mains

socket.

2 EN

insulation drying unit Qube+

Page 3

Intended use

The Qube+ is to be used in low pressure mode for insulation

drying of floating screeds, flat roofs (warm roof constructions)

and hollow floorings. It is intended to transport non-aggressive

and non-explosive gaseous media.

Improper use

The device is not suitable for the inflation of bouncy castles or

similar objects.

The device is not designed to suck in large quantities of water.

If, during insulation drying, you notice that there are large

amounts of water left in the insulation layer, the water must be

sucked off with a water extractor before using the device.

The device is not suitable for the intake of frothing or foaming

media, aggressive cleaning agents and acetone-based fluids.

Media other than those listed as intended use must not be

conveyed.

Personnel qualifications

People who use this device must:

• be aware of the dangers that occur when working with

electric devices in damp areas.

• have read and understood the instructions, especially the

Safety chapter.

Warning

Risk of suffocation!

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

Note

Do not operate the device without an inserted air filter!

Without the air filter, the inside of the device will be

heavily contaminated. This could reduce the

performance and result in damage to the device.

Note

Overheating of motor electronics

Permanent or repeated overheating may destroy the

motor electronics. Avoid overheating the device and

provide sufficient air circulation. If necessary, direct the

warm air out of the room. Room temperatures above

35°C are to be avoided during operation.

Also observe the information in the Set-up chapter.

Note

Observe the overvoltage protection.

The device comes equipped with an overvoltage

protection. When checking for electrical safety, please

bear in mind that the test voltage has to be reduced to

250V.

Residual risks

Warning of electrical voltage

Work on the electrical components must only be

carried out by an authorised specialist company!

Warning of electrical voltage

Before any work on the device, remove the mains plug

from the mains socket!

Hold onto the mains plug while pulling the power cable

out of the mains socket.

Warning of hot surface

Risk of injury due to hot surfaces at the outlet opening.

Warning

Small objects and particles can be sucked in and lead

to injuries.

Make sure that no person is standing near the inlet or

outlet opening while the device is running.

Warning

Dangers can occur at the device when it is used by

untrained people in an unprofessional or improper way!

Observe the personnel qualifications!

Note

Damage to the turbine due to sucked-in particles.

If impurities enter into the turbine, this might damage

the turbine. The turbines are suited for transporting

clean air only.

Behaviour in the event of an emergency

1. Switch off the device.

2. In an emergency, disconnect the device from the mains

feed-in: Hold onto the mains plug while pulling the power

cable out of the mains socket.

3. Do not reconnect a defective device to the mains.

EN 3

insulation drying unit Qube+

Page 4

Information about the device

Device description

The Qube+ consists of only one device and is 50% lighter and

50% smaller than a comparable MultiQube tower.

A multi-device installation with complex hose connections can

be omitted without replacement. Just set it up, plug it in, switch

it on – all done! No further equipment technology is required.

The device comes ready for connection with all integrated parts:

a powerful fan motor, a water separator, a 4-stage filter system

and an efficient silencer – ultra-compact, united in a robust,

stackable aluminium construction, offering clearly more

advantages and at the same time causing considerably less

costs than multi-device solutions.

Globally unique integral solution:

• VX 5 turbine

• Water separator WA 4i

• HEPA filter module

• Silencer NR 19

Equipment features:

• Adaptronic power control for flexible low-pressure surface

drying operations ranging from 8m2 to 85m

• Globally unique HiDry automatism for all power stages

• Optiflow NT multi-function display

• Non-wearing touchscreen control panel

• Counter for operating hours and energy consumption

(MID-compliant)

• Night operation – whisper mode

• 2 TTKwic quick couplings for drainage connection of

dehumidifiers

• Flexible 4-stage filter system

• DA4 interface

• Efidry humidity sensor connection

• Residual water draining

• Connection for discharge of hot process air

• Service socket (tamper-proof)

• Cable holder

• Key lock to prevent maloperation

• ECO level (stage1) for small surfaces

• Height-adjustable telescopic push handle

2

The device is equipped with a touch screen with LC display.

It provides information on the operating stage, air flow rate etc.

The background colour of the LC display changes according to

the traffic light principle to indicate how suitable your drying

installation is. An optimal air flow rate is indicated by a green

background colour during operation. If the display is illuminated

in yellow, this means that the installation is OK but the flow

conditions for the dry air are not optimal. Drying can be carried

out without any difficulties while the display is yellow. A red

background indicates an uneconomic operation. The

compressor should not be permanently operated in this

condition.

Practical benefits:

• The most light, compact and powerful system unit on the

market

• 50% smaller than a comparable MultiQube installation, up

to 75% smaller than constructions from competitors

• Flexible filter system with optional HEPA filter usage

• Total weight only 27kg

• Stackable

With the device all negative time factors can be eliminated in

one sweep – this way less devices are needed and moved,

stock requirements are reduced, more equipment can be

transported to the damage site per tour, less time is needed for

set-up and disassembly as well as for cleaning. All in all, your

working, space and warehouse productivity can be increased

many times over by using the Qube+!

4 EN

insulation drying unit Qube+

Page 5

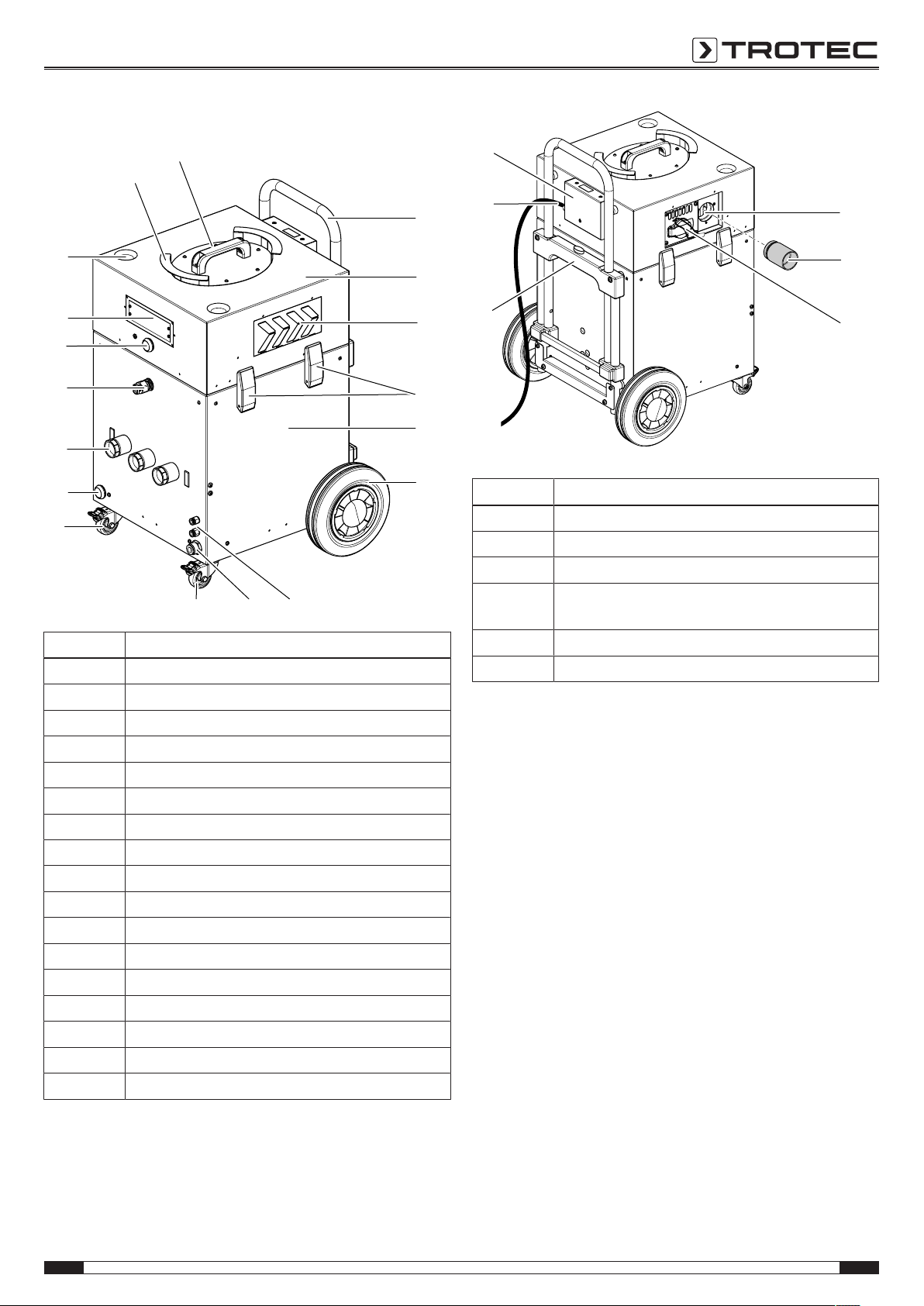

Device depiction

1

3

17

4

16

15

14

13

12

11

10

6

8 79

9

2

5

18

19

21

22

20

23

No. Designation

1 Telescopic push handle

2 Upper part with turbine

3 Air inlet for cooling

4 Tension lock

5 Lower part with pump

6 Wheel

7 TTKwic connection

8 Drain hose connection

9 Castor with parking brake

10 Residual water draining button

11 Hose connectors

12 DA4 sensor connection

13 Power button and communication port

14 Touchscreen control panel

15 Castor retainer (for storage)

16 Power cable retainer

17 Carrying handle upper part

No. Designation

18 Connection for discharge of process air

19 Connector 50 mm

20 Service socket (tamper-proof)

21 Holder for storage with release button for the

height-adjustable telescopic push handle

22 Power cable

23 MIDmeter

EN 5

insulation drying unit Qube+

Page 6

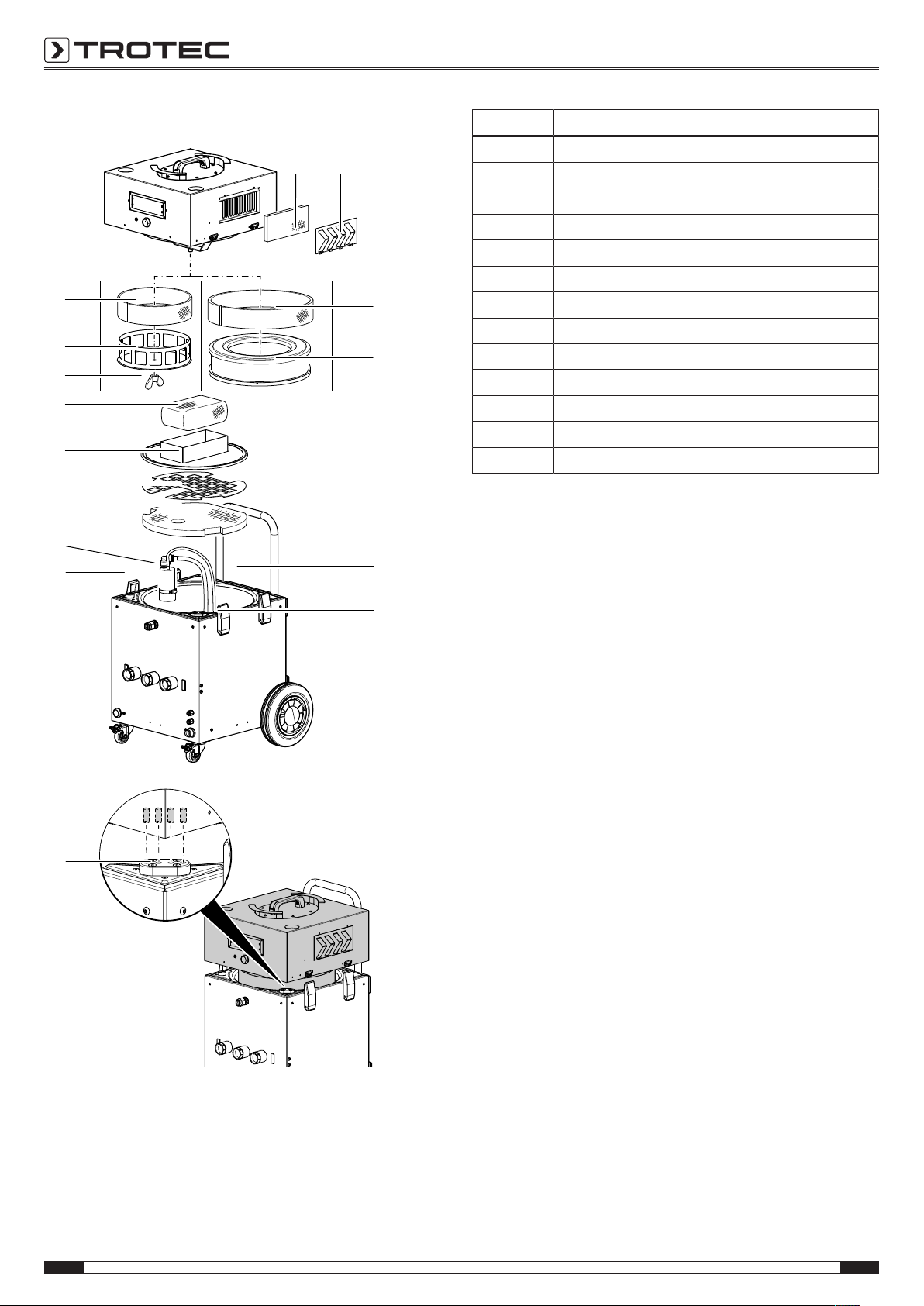

Schematic detail view with filters

A

B

24

34

31

30

27

4

28

23

4

4

25

26

32

33

29

35

No. Designation

23 F7 air filter

24 Air filter cover

25 F8 filter sleeve for HEPA filter (optional)

26 HEPA filter (optional)

27 Pump

28 Coarse filter

29 Coarse filter fixation grid

30 Demister holder

31 Demister

32 Wing nut

33 Cage

34 G4 filter sleeve

35 Spring contacts for electrical connection

6 EN

insulation drying unit Qube+

Page 7

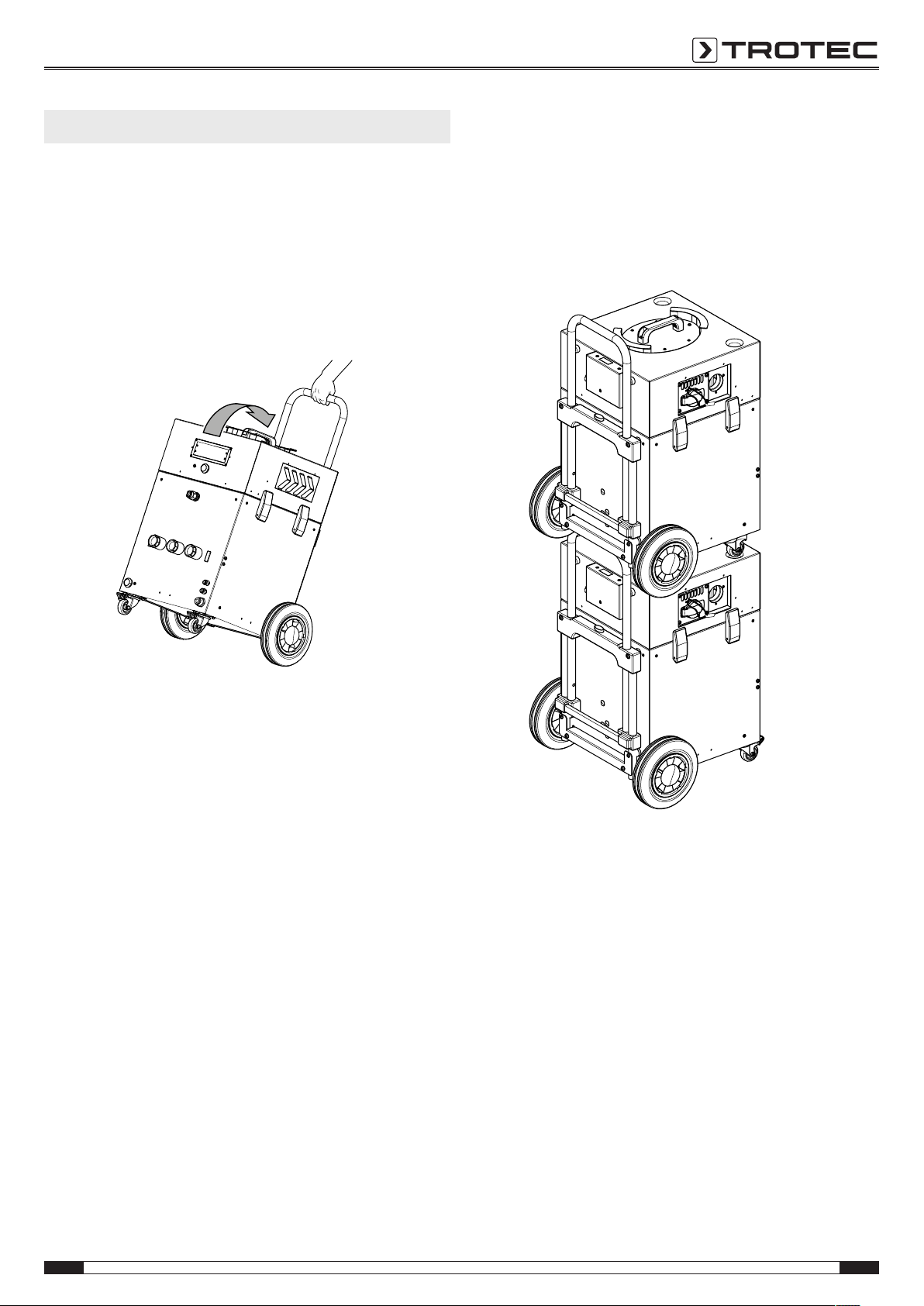

Transport and storage

Note

If you store or transport the device improperly, the

device may be damaged.

Note the information regarding transport and storage of

the device.

Transport

To make the device easier to transport, it is fitted with a

transport handle and two wheels.

Storage

Before storing the device, proceed as follows:

• Empty and clean the condensation tank prior to storage.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

The devices can also be stacked on top of one another for

storage.

Before transporting the device, proceed as follows:

• Switch off the device at the mains switch.

• Remove the mains plug from the mains socket.

• Drain any residual water from the device.

• Remove the connected hoses and components.

• Prior to every transport check whether the upper and lower

part of the device are firmly connected via the tension

locks.

• Do not incline the device by more than 45°, for otherwise

the device could be damaged.

When the device is not being used, observe the following

storage conditions:

• dry and protected from frost and heat

• in an upright position where it is protected from dust and

direct sunlight

• with a cover to protect it from invasive dust, if necessary

EN 7

insulation drying unit Qube+

Page 8

Assembly and installation

21

Scope of delivery and accessories

Accessories and supplies contained in the scope of delivery of

the Qube+:

Quantity and designation Art. no.

1 x water separator bottom filter mat 7.160.000.206

1 x G4 filter sleeve 7.160.000.214

1 x F7 Z-line filter for filtering the sucked-in

motor cooling air

1 x 50 mm hose connection for process air

discharge

1 x drain hose, length 5m, Ø12mm 7.331.000.476

1 x coarse filter fixation grid 7.241.001.245

Further accessories and supplies:

Accessories Art. no.

38 mm connector 7.200.000.002

HEPA filter module, H13 high-efficiency

particulate air filter as per DIN EN 1822-1,

filtration efficiency > 99.97% / 0.3µm,

incl. F8 prefilter sleeve (DIN EN 779)

F8 filter sleeve for HEPA filter module, filter

class 8 (DINEN779)

F8 filter sleeve 7.160.000.216

connection cable VX-DA for data

transmission to the DA4

sound protection hood 6.100.000.070

protective cover 6.100.003.15

7.160.000.213

7.200.000.001

7.160.000.221

7.160.000.215

7.333.000.015

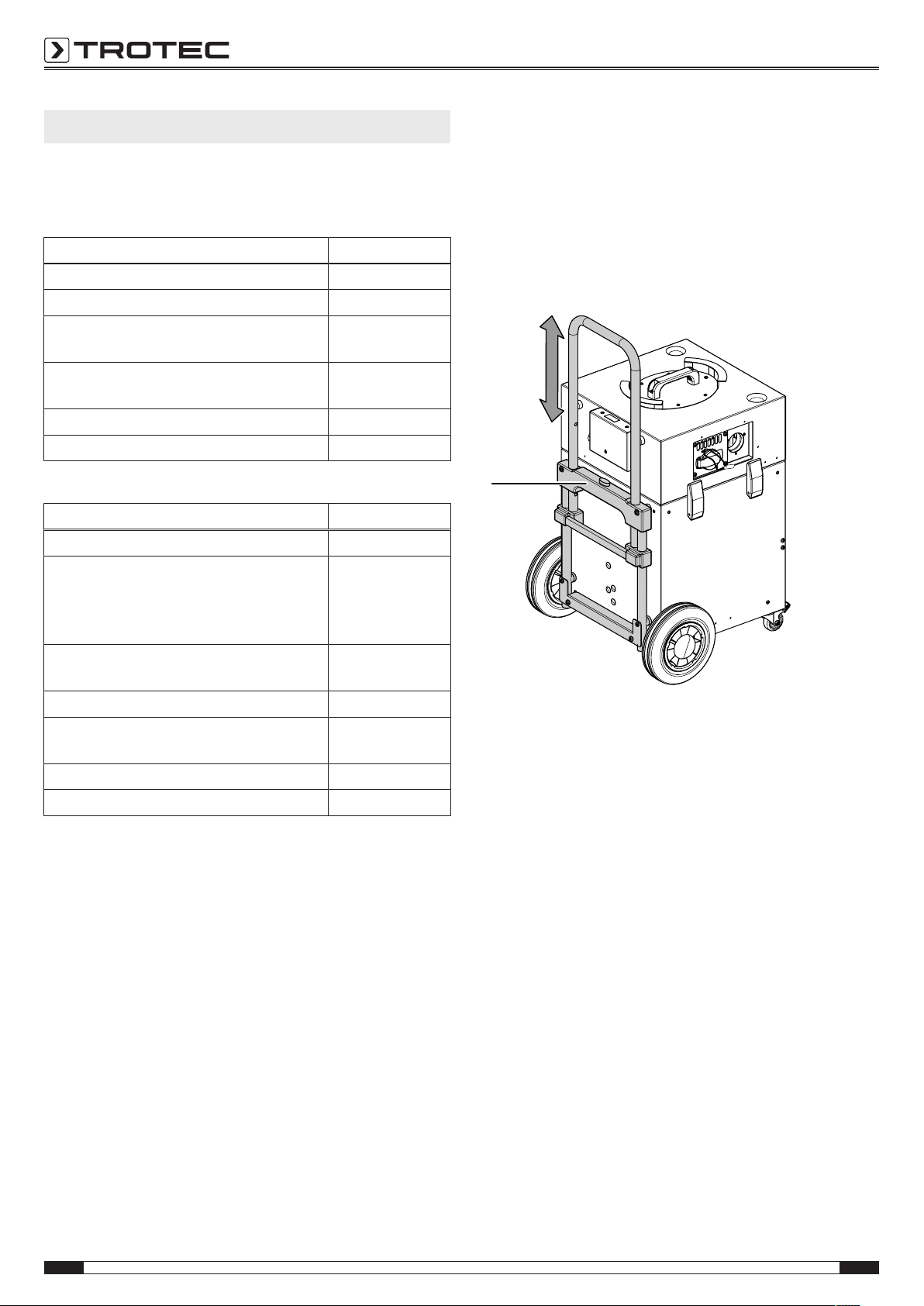

Assembly

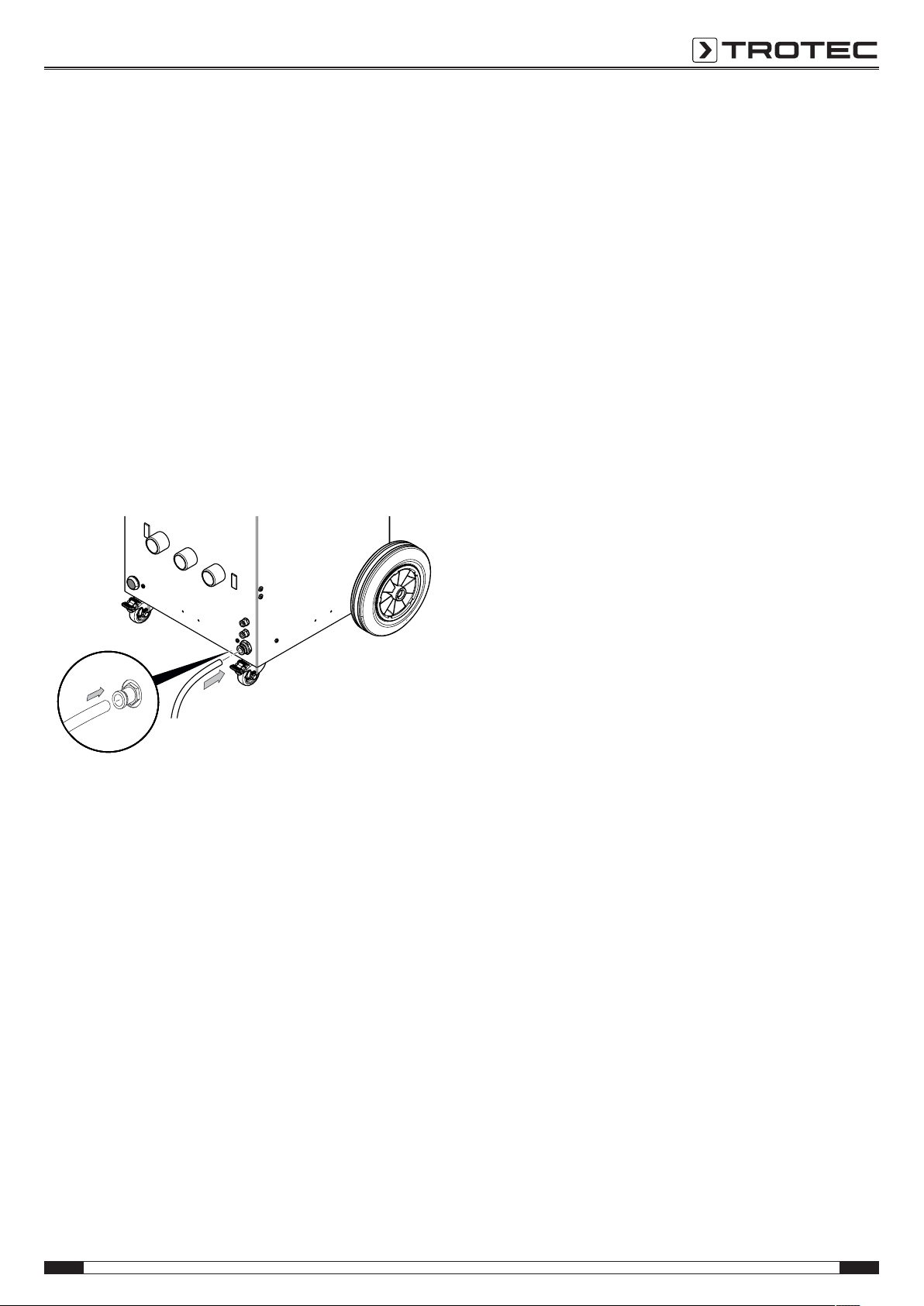

Remove the packaging. Remove any transport locks from the

supply connections.

The wheels are already preassembled.

The telescopic push handle is preassembled and can be

adjusted in height:

Press and hold the height adjustment button(21) to adjust the

extendable length of the telescopic push handle.

8 EN

insulation drying unit Qube+

Page 9

Connecting the drain hose

The device must be connected to an appropriate drain or

collection container via a drain hose so that the device can drain

the accumulated water from the water tank if required.

Observe the following when connecting the drain hose:

• Please note that the collection container must be

sufficiently dimensioned. The end of the drain hose should

not extend into the water.

• Please note that only unpolluted water may be discharged

into the drain.

• The drain must be able to take the respective water

quantity.

• Height differences of up to 10m are permissible.

• Dispose of contaminated water in accordance with the

national regulations.

1. Connect the drain hose (Ø12mm) to the water discharge

connection.

TTKwic quick couplings

As standard, the device comes with two integrated TTKwic

quick couplings(7), where condensate discharge hoses of up to

two used dehumidifiers plus condensate pump can be

connected. The entire water discharge is then taking place

centrally via the drain hose of the device.

Note

When using the TTKwic connections of the device,

please make sure that the device is switched on.

If the device is switched off, the accumulated

condensation will not be pumped out and may

overflow.

Should the device – while using the TTKwic

connections – create much less noise during operation

or stop working altogether, set the device to a lower

performance level or switch on TTKwic mode, see

chapter Operation.

2. Guide the other hose end to a drain or collection container.

• Regularly inspect the drain hose and hose connection for

kinks and dirt. Remove kinks and clean the drain hose,

if required.

EN 9

insulation drying unit Qube+

Page 10

Positioning the device

When setting up the device, make sure that the warm air

generated by the device is discharged. The room temperature

should not exceed 35°C.

If condenser dryers are operated at temperatures above 35°C

and at high humidity levels permanently, the pressure in the

refrigerant circuit will rise. Consequently the compressor will

permanently run at its limit, which leads to increased wear and

tear.

• If required, ensure that the process air is discharged by

connecting a suitable discharge hose to the process air

discharge connection(18).

• Provide sufficient fresh air supply by ventilating the room

at regular intervals.

• Should the discharge of warm air not be an option, the

device can also be installed outside of the room to be dried

and the hose connection can be established by means of a

PlanoPro door gap nozzle (art.no. 6.100.000.160).

Such an installation may look like this, for example:

Start-up

• Use suitable hoses (observe number and diameter) to set

up the drying installation.

• Remove the sealing caps from the connectors to which you

want to connect a hose. If a connector is not needed, the

sealing cap must remain on the connector.

Note

Connectors without a sealing cap or a connected hose

may cause water to escape and thus result in water

damages.

Carefully check the connectors before switching the

device on.

• For drying operations, only use cables and sockets

complying with the regulations. In addition to the 16A

fuse, the socket should also be secured by a 30mA

residual current device (RCD).

Note

We recommend using a suitable mat if the Qube is

placed on sensitive ground.

The device comes equipped with an overheating protection.

This serves to prevent excessive ambient temperatures.

It protects the materials and devices located in the room.

Inserting the filters

Check whether the filters have been properly inserted into the

device:

• G4 filter sleeve or optional F8 filter sleeve or HEPA filter

with F8 filter sleeve

• demister

• coarse filter (filter mat) with coarse filter fixation

• pump filter

Info

The coarse filter fixation should rest on the coarse filter

to prevent the coarse filter from floating

unintentionally.

Mains connection

• Plug the mains plug into a sufficiently fused socket.

Switching the device on

Press the power button(42) to switch the device on.

The following working stages are available:

• 4 power stages 1-4

• stage 5: boost stage

• whisper mode

• TTKwicmode

Check the installation via the LC display:

• green: optimal air volume flow

• yellow: limit range

• red: air flow rate too low – installation must be optimized

10 EN

insulation drying unit Qube+

Page 11

Operation

36 37 38

40 39

14

42

41

12

Operating elements

Setting the power stages and operating modes

The device comes with 4 power stages, a boost mode, a

whisper mode and the TTKwic mode.

Whisper mode can be activated by pressing the whisper mode

button(40).

Setting the power stages and the boost mode

In boost mode, the motor runs at its maximum performance.

Choose from the power stages1 to 4 or boost mode by pressing

the buttons plus(38) or minus(37).

Setting whisper mode

In whisper mode, the compressor runs with a max. motor power

of 60%, thus reducing the noise emission (e.g. at night).

Whisper mode is automatically left after 10h and the

compressor starts to run at its previously chosen power stage

again. Selecting another stage via the control panel will also

stop the whisper mode.

Press the whisper mode button(40) to activate or deactivate

whisper mode.

• A countdown(10h) on the control panel indicates the

remaining whisper mode duration.

• Pressing a button on the control panel deactivates whisper

mode. This only applies if the key lock is disabled.

No. Designation

12 DA4 sensor connection

14 Touchscreen control panel

36 LC display

37 Minus button (decrease power stage)

38 Plus button (increase power stage)

39 Operating hours button

40 Whisper mode button

41 Communication port

42 Power button

Setting TTKwic mode

In this operating mode the device's motor is turned off and only

the pump operates. So if a dehumidifier transports water into

the device by means of a condensate pump, the accumulated

water will be pumped off when the tank's maximum filling level

is reached.

Press the whisper mode button(40) followed by minus(37) to

activate or deactivate TTKwic mode.

Info

In whisper mode you can enable or disable TTKwic

mode at any time.

The whisper mode duration(10h) also applies to the

TTKwic mode.

EN 11

insulation drying unit Qube+

Page 12

Key lock

To prevent an accidental maladjustment of the device settings,

the device is fitted with a key lock function.

Simultaneously press and hold the plus(38) and minus(37)

buttons for approx. 5s to enable or disable the key lock. Pay

attention to the indication on the display.

The key lock indication in the top right corner of the LC display

changes according to the selected setting:

• Padlock closed: The key lock is activated.

• Padlock open: The key lock is deactivated.

Example for an enabled key lock function:

Example for a disabled key lock function:

Info

The key lock will be activated automatically after

approx. 10min of non-use.

Displaying the operating hours

Pressing the operating hours button(39) while the device is

switched on allows you to see the number of operating hours.

The energy consumption can be read at the rear of the Qube+.

The counter has an MIDcertificate qualifying it for billing

purposes.

In accordance with calibration regulations, restoration

companies are so-called "meter users" or "users of

measurement readings", which binds them to observe the

German Weights and Measures Act (MessEG). The MessEG

regulates the recording and transfer of measurement readings

based on which the power consumption costs of the devices

shall be determined.

Emptying the tank

Info

The drain hose must be connected and guided to an

appropriate drain or collection container.

Filling level sensors inside the tank control the automatic

operation of the pump. Once a certain filling level is reached in

the tank, the pump will start to operate automatically:

• The message abpumpen... appears on the LC display.

• The pump drains the accumulated water via the connected

drain hose.

• If the pump cannot drain the water fast enough, the

motor’s fan will be switched off. The message Behaelter

voll! appears on the LC display. The maximum tank filling

level has been reached. The pump drains the accumulated

water.

• Once the tank has been emptied, the fan motor will switch

back on and the drying operation will continue.

Shutdown

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

• Remove the residual water by pressing the button for

residual water draining(10).

• Press the power button(42) to switch the device off.

• Wait until the motor has come to a standstill.

• Remove any hose connections.

• Reinsert the sealing plugs removed during start-up.

Info

If a load is connected to the service socket, its energy

consumption will also be measured by the energy

meter.

Connecting the DA4 (external control unit)

The communication port(41) is used for data transfer to the

DA4 control unit. The data may then be forwarded (USB and

modem or USB only).

Additionally, the internal sensor of the DA4 must be connected

via the sensor connection(12).

12 EN

insulation drying unit Qube+

Page 13

Errors and faults

The device has been checked for proper functioning several

times during production. If malfunctions occur nonetheless,

check the device according to the following list.

The device does not start:

• Check the power connection.

• Check the power cable and mains plug for damages.

• Check the on-site fusing.

• Check whether the overheating protection has tripped.

The device comes equipped with an overheating

protection. If the temperature within the device exceeds

the permissible value, the air flow rate will be reduced

automatically. Temperatur 1! will be displayed. If the

temperature increase continues nonetheless, the device

will be switched off and Temperatur 2! appears on the

display.

If necessary, direct the warm air out of the room. A room

temperature of more than 35°C is to be avoided during

operation. Also observe the information in the Set-up

chapter.

Little or no air is sucked in or blown out:

• Check the installation and add relief openings to improve

the air circulation and to operate the compressor within its

operating range if necessary.

Motor switches off during operation or its performance is

reduced:

• The device has been overheated due to improper operation

and switched off by the thermal protection of the motor.

This may be due to the following causes:

– High counter pressure on the outlet side has led to

overheating.

– Too strong flow resistance on the suction side has led

to overheating in suction mode.

• Wait until the motor has cooled down. Then switch the

device back on.

• Check the installation and add relief openings to improve

the air circulation and to operate the compressor within its

operating range if necessary.

• Check whether the air filter of the turbine is soiled or

clogged.

• If the room temperature exceeds 35°C, provide better

ventilation. If necessary, guide the warm air out of the

room.

Your device still does not operate correctly after these

checks?

Please contact the customer service. If necessary, bring the

device to a specialist company for cooling and air-conditioning

or to Trotec for repair.

Motor is not running:

• Check the display. If Behaelter getrennt! is indicated, the

upper part may not be correctly positioned on the lower

part. Check whether the upper and lower part are properly

connected to one another.

• Check whether voltage is applied.

• Check the electrical connections and safety installations.

EN 13

insulation drying unit Qube+

Page 14

Fault messages

The following fault messages may appear on the LC display:

Fault message Cause Remedy

Behaelter getrennt!

(tank disconnected)

The electrical

contact between

the upper and

lower part is

disrupted. The

motor switches

off.

Check whether the

upper and lower part of

the device are firmly

connected via the

tension locks. Check

the contacts of the

upper and lower part.

Clean if necessary.

Pumpe

Abkuehlphase..

(cooling phase

pump)

The pump is in

continuous

operation mode

and has no time

to cool down.

No action required.

The cooling phase lasts

15min. Then the

device starts up again

and resumes operation

with the previously

selected settings.

Behaelter voll!

(tank full)

The water tank is

full.

No action required.

The pump drains the

accumulated water via

the drain hose. The

motor switches off. The

motor will only switch

back on and the Qube

will only continue to

operate once the water

has been drained.

Pumpe pruefen!

(check pump)

The pump is

blocked and can

no longer operate.

Press the button for

draining residual

water(10). If the pump

is still blocked, switch

the device off. Clean

tank and pump

thoroughly.

The pump is in

operation but

there is no water

in the tank.

Switch the Qube off

and back on. If the

message appears

again, check the water

level sensor and clean

this area thoroughly.

Too much water

in the insulation

layer or an

unconnected

drain hose causes

the pump to

operate

continuously.

Check the drain hose

for proper fit. There

must be no kinks or

loops in the hose that

could prevent the water

from being drained off.

Check for potential

leakage.

Fault message Cause Remedy

abpumpen...

(pumping off)

The pump drains

the accumulated

water.

No action required.

If the pump is to run

permanently, the water

should be removed

with an industrial

suction unit in a first

step.

Filter wechseln!

(change filter)

The G4 or F8 filter

sleeve or the

HEPA filter is

clogged.

Exchange the filter

sleeve. In case a HEPA

filter is used and the

message continues to

be shown on the

display, the HEPA filter

itself must be

exchanged as well.

12V Netzteil

pruefen

(check 12V power

adapter)

Temperatur 1!

(temperature1)

Temperatur 2!

(temperature2)

The sensor for

monitoring the

water level is not

working properly.

The temperature

within the device

exceeds the

permissible value,

this tripped the

overheating

protection.

The temperature

within the device

exceeds the

permissible value,

this tripped the

overheating

protection. The

device has

switched off.

Please contact the

customer service.

No action required.

The air flow rate will be

adjusted automatically.

Investigate the cause

of overheating if

required to prevent

further overheating.

Investigate the cause

of overheating.

If necessary, direct the

warm air out of the

room. A room

temperature of more

than 35°C is to be

avoided during

operation. Also observe

the information in the

Set-up chapter.

14 EN

insulation drying unit Qube+

Page 15

Maintenance

Activities required before starting maintenance

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

• Switch the device off.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

Warning of electrical voltage

Tasks which require the housing to be opened

must only be carried out by authorised specialist

companies or by Trotec.

Note

Observe the overvoltage protection.

The device comes equipped with an overvoltage

protection. When checking for electrical safety, please

bear in mind that the test voltage has to be reduced to

250V.

Info

Via the following link you will find an explanation of

how to clean the Qube+ and what to observe for this

process:

https://www.youtube.com/watch?v=8_G8kCDMHIM

Cleaning the housing

Clean the device with a soft, damp and lint-free cloth. Ensure

that no moisture enters the housing. Protect electrical

components from moisture. Do not use any aggressive cleaning

agents such as cleaning sprays, solvents, alcohol-based or

abrasive cleaners to dampen the cloth.

Draining residual water

The residual water should always be drained before the device

is transported.

Press the button for residual water draining to drain the water

left in the tank.

Exchanging or removing the drain hose

The drain hose should be cleaned if dirt is visible.

If there are signs of wear or damage, the drain hose should be

exchanged.

Remove the drain hose before transporting the device.

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

1. Press the blue ring on the outside of the quick coupling

together and at the same time pull the hose.

EN 15

insulation drying unit Qube+

Page 16

2. If required, connect a new drain hose.

A

B

34

31

27

28

23

25

26

Cleaning or replacing the filters

The filters must be cleaned or replaced as soon as they are

dirty.

If the Filter wechseln! message appears on the display, the filter

inside the device (G4 or F8 filter sleeve or HEPA filter) must be

replaced as it does not allow a sufficient quantity of air to pass.

Observe the following before cleaning or replacing the filter:

• Press the power button(42) to switch the device off.

• Disconnect the device from the mains.

• Drain the residual water from the tank.

The device is equipped with different filter types:

• G4 filter sleeve(34) (F8 filter sleeve also an option here)

• F8 filter sleeve for HEPA filter, optional (25)

• HEPA filter, optional (26)

• demister (31)

• coarse filter (28)

• air filter (23)

• pump filter (part of 27)

16 EN

insulation drying unit Qube+

Page 17

Replacing the air filter

17

4

4

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

1. Remove the cover from the air filter.

2. Remove the air filter.

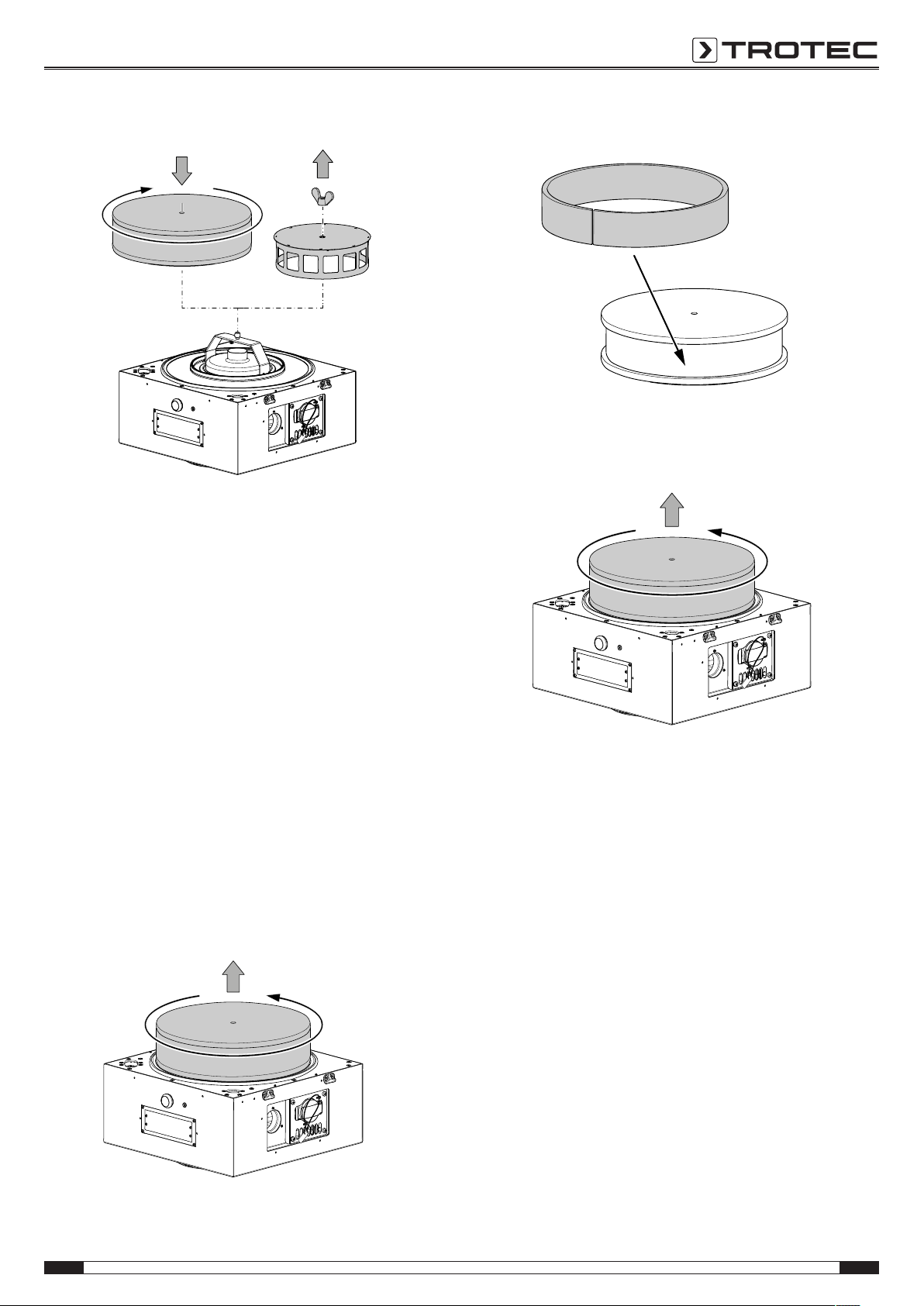

Replacing the G4 filter sleeve

If the Filter wechseln! message appears on the display, the

G4 filter sleeve inside the device must be replaced as it does not

allow a sufficient quantity of air to pass.

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

1. Open the 4 tension locks(4).

2. Lift the upper part at the carrying handle(17) and place it

onto a stable base.

3. Install a new air filter.

4. Reattach the coverto the air filter.

3. Turn the upper part so that the bottom side with the filter

points upwards.

EN 17

insulation drying unit Qube+

Page 18

4. Remove the G4 filter sleeve from the cage.

5. Place a new G4 filter sleeve around the cage and close the

Velcro® fastener. Make sure that the sleeve surrounds the

cage completely.

6. Put the upper part back on the device and close the

tension locks.

Cleaning the demister

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

ü The upper part has been removed (see Replacing the

G4 filter sleeve).

1. Take the demister out of the holder in the lower part of the

device.

2. Rinse the demister under running water.

ð Exchange the demister if required (e.g. in case of

damages).

3. Put the demister back into the holder.

4. Put the upper part back on the device and close the

tension locks.

18 EN

insulation drying unit Qube+

Page 19

Cleaning the pump filter

43

44

45

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

ü The upper part has been removed (see Replacing the

G4 filter sleeve).

1. Take the demister along with the holder out of the lower

part of the device.

2. Remove the coarse filter fixation.

4. Loosen the quick coupling of the hose(43) on the tank

wall.

5. Slightly lift the sheet that is fixating the pump.

6. Take out the pump.

7. Detach the pump filter from the pump.

8. Rinse the pump filter under running water.

ð Exchange the pump filter if required (e.g. in case of

damages).

3. Loosen the connecting plug(44) of the electrical

connection on the tank wall. Close the cap(45) of the plug

connection to avoid contamination.

9. Slightly lift the sheet that is fixating the pump and refit the

pump.

10. Check the pump for tight fit.

11. Plug the hose(43) back into the quick coupling.

12. Open the cap(45) of the pump's electrical connection and

put the plug(44) back in.

13. Refit the coarse filter fixation. The coarse filter fixation

should rest on the coarse filter.

14. Refit the demister along with the holder.

15. Put the upper part back on the device and close the

tension locks.

EN 19

insulation drying unit Qube+

Page 20

Cleaning the coarse filter (filter mat)

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

ü The upper part has been removed (see Replacing the

G4 filter sleeve).

1. Take the demister along with the holder out of the lower

part of the device.

2. Remove the coarse filter fixation.

5. Rinse the coarse filter and the coarse filter fixation under

running water.

ð Exchange the coarse filter and the coarse filter fixation

if required (e.g. in case of damages).

6. Put the coarse filter back in.

7. Slightly lift the sheet that is fixating the pump and refit the

pump.

8. Check the pump for tight fit.

9. Plug the hose(43) back into the quick coupling.

10. Open the cap(45) of the pump's electrical connection and

put the plug(44) back in.

11. Refit the coarse filter fixation. The coarse filter fixation

should rest on the coarse filter.

12. Refit the demister along with the holder.

13. Put the upper part back on the device and close the

tension locks.

3. Remove the pump as described in chapter Cleaning the

pump filter, step3 to 6.

4. Remove the coarse filter.

Replacing the G4 filter sleeve by an F8 filter sleeve

(optional)

If a finer ambient air filtration is required, the G4 filter sleeve

can be replaced by an F8 filter sleeve.

1. Please proceed as described in chapter Replacing the

G4 filter sleeve.

2. Replace the G4 filter sleeve by the F8 filter sleeve

(7.160.000.216). In doing so, make sure that the coarse

fleece is positioned on the outside and the finer fleece on

the inside of the cage.

Replacing the G4 filter sleeve by a HEPA filter (optional)

If required, the G4 filter sleeve can be replaced by a HEPA filter.

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

1. Proceed as described in steps1 to 3 in the chapter

Replacing the G4 filter sleeve.

2. Loosen the wing nut and remove the cage with the

G4 filter sleeve.

20 EN

insulation drying unit Qube+

Page 21

3. Screw the HEPA filter onto the upper part.

4. Put the upper part back on the device and close the

tension locks. Make sure that the contacts of the upper

and lower part are properly aligned with one another.

4. Remove the F8 filter sleeve from the HEPA filter.

5. Place the new F8 filter sleeve around the HEPA filter. Make

sure that the sleeve surrounds the filter completely.

6. Screw the HEPA filter back onto the upper part.

Exchanging the HEPA filter and the F8 filter sleeve

(optional)

If the Filter wechseln! message appears on the display, the filter

inside the device must be replaced as it does not allow a

sufficient quantity of air to pass. Always exchange the HEPA

filter on every construction site to prevent contamination. If the

Filter wechseln! message appears on the display during

operation, you can exchange the F8 filter sleeve in a first step.

If this is not sufficient (Filter wechseln! message still displayed),

the HEPA filter must be exchanged as well.

ü The device is switched off and disconnected from the

mains.

ü The residual water has been drained.

1. Please proceed as described in steps1 and 2 in the

chapter Replacing the G4 filter sleeve.

2. Turn the upper part so that the bottom side with the

HEPA filter points upwards.

3. Unscrew the HEPA filter from the upper part.

7. Put the upper part back on the device and close the

tension locks.

EN 21

insulation drying unit Qube+

Page 22

Technical annex

Technical data

Technical data and equipment Qube+

Suitable for surfaces sized up to (low pressure) power stage 1 10m

power stage 2 25m

power stage 3 50m

power stage 4 85m

2

2

2

2

Maximum pressure (low pressure) 220 mbar

Air flow rate (freely blowing)

1

Defined volumetric flow optimum (sucking in) of the HiDry

automatism incl. HEPA filter

whisper mode 90 m

power stage 1 50 m

power stage 2 90 m

power stage 3 140 m

power stage 4 160 m

boost stage 180 m

250 m

3

3

3

3

3

3

3

Motor power (depending on the performance level) whisper mode 0.2 to 1.2 kW

Sound level (distance 3m, depending on the performance level) whisper mode 48dB(A) to 59dB(A)

Volume collection container 10 l

Input voltage 230V/ 50Hz

Weight 27 kg

Dimensions Lx Wx H (telescopic push handle down/ up) 490x 500x 735/ 925mm

Mobility carrying handle ■

stackable ■

rollable ■

carriage design ■

Hose connections insulation drying 3 x ø 38 mm

TTKwic dehumidifier quick couplings 2 x

Waste water connection ■

DA4 interface ■

Efidry humidity sensor connection ■

Service socket (tamper-proof) ■

50 mm connector for compressed air discharge ■

Residual water draining ■

Overflow sensor with automatic switch-off ■

Baffle plate for coarse filtration ■

Stainless steel demister for water separation and fine filtration ■

Robust and non-wearing touchscreen control panel design ■

Optiflow NT multi-function display ■

digital

2

2

2

2

Operating hours counter digital

Power meter, MID-compliant

3

Plain text status indication ■

Illumination for power control ■

HEPACONTROL filter change indicator ■

22 EN

insulation drying unit Qube+

Page 23

Technical data and equipment Qube+

TTKwic operating mode ■

Height-adjustable telescopic push handle ■

Cable holder with fixable plug ■

Thermal protection ■

Maintenance quick release fasteners ■

1

maximum air flow rate of the fan motor (not integrated) 2 vvia OptiflowNT multi-function display 3 What does MID-compliant mean? In some areas, the Measuring Instruments Directive (MID)

replaces the previous regulation of national authorization and subsequent calibration. As a result, all energy meters in Europe used for energy consumption-based billing have to be MID-compliant

from now on. Therefore, the Qube+ holds a separate certified, MID-compliant counter, which transmits its data to the OptiflowNT multi-function display for inspection.

EN 23

insulation drying unit Qube+

Page 24

Exploded assembly drawing

A

B

2

3

4

1

11

12

7

13

6

8

9

10

5

14

15

16

Info

The position numbers of the spare parts differ from

those describing the positions of the components

mentioned in these instructions.

24 EN

insulation drying unit Qube+

Page 25

List of spare parts

Pos. no. Article number Designation

1 7.600.000.006 swivel castor 50/19

2 P10006255 telescopic push handle

3 7.310.000.897 handle

4 7.600.000.001 plain bearing wheel 200/50 with black end cap

5 7.200.000.001 connector 50 mm aluminium

6 P10003459 housing Qube+ filter insert

7 7.160.000.221 HEPA filter module H13 incl. F8 prefilter sleeve

8 P10000203 demister insert

9 P10002223 housing Qube+ demister holder

10 P10006736 Qube+ water separator bottom filter mat

11 7.160.000.213 F7 Z-line filter

12 P10003460 housing Qube+ cover air aperture

13 7.160.000.214 G4 filter sleeve

14 7.331.000.476 drain hose (5m)

15 7.170.001.201 pump with plug

16 7.241.001.245 coarse filter fixation

Additional spare parts available on request.

EN 25

insulation drying unit Qube+

Page 26

Disposal

The icon with the crossed-out waste bin on waste

electrical or electronic equipment stipulates that this equipment

must not be disposed of with the household waste at the end of

its life. You will find collection points for free return of waste

electrical and electronic equipment in your vicinity. The

addresses can be obtained from your municipality or local

administration. For further return options provided by us please

refer to our website www.trotec24.com.

The separate collection of waste electrical and electronic

equipment aims to enable the re-use, recycling and other forms

of recovery of waste equipment as well as to prevent negative

effects for the environment and human health caused by the

disposal of hazardous substances potentially contained in the

equipment.

Declaration of conformity

The text below sets out the contents of the declaration of

conformity. The signed declaration of conformity can be found

at https://hub.trotec.com/?id=40717.

Declaration of conformity

In accordance with the ECMachinery Directive 2006/42/EC,

AnnexII, part1, SectionA

Herewith, we– Trotec GmbH&Co.KG– declare that the

machinery designated below was developed, constructed and

produced in compliance with the requirements of the

ECMachinery Directive in the version 2006/42/EC.

Product model/ Product:

Product type:

Year of manufacture as of:

Relevant EU directives:

• 2011/65/EU: 1July 2011

• 2014/30/EU: 29March 2014

Applied harmonised standards:

• EN 55014-1:2006

• EN 55014-2:2016

• EN 60335-1:2012/AC:2014

• EN60335-2-40:2003

• EN61000-3-2:2014

• EN 61000-3-3:2013

Applied national standards and technical specifications:

• None

Qube+

insulation drying unit

2018

Manufacturer and name of the authorised representative of

the technical documentation:

Trotec GmbH & Co. KG

Grebbener Straße 7, D-52525 Heinsberg

Phone: +49 2452 962-400

E-mail: info@trotec.de

Place and date of issue:

Heinsberg, 20.09.2018

Detlef von der Lieck, Managing Director

26 EN

insulation drying unit Qube+

Page 27

Trotec GmbH & Co. KG

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...