Page 1

PJSS 10-230V

EN

OPERATING MANUAL

850W PENDULUM ACTION

JIGSAW

TRT-BA-PJSS10-230V-TC-001-EN

Page 2

Table of contents

Notes regarding the operating manual.................................1

Notice

This signal word indicates important information

(e.g. material damage), but does not indicate hazards.

Safety .....................................................................................2

Information about the device................................................7

Transport and storage...........................................................9

Start-up................................................................................10

Operation .............................................................................14

Available accessories..........................................................17

Errors and faults..................................................................17

Maintenance ........................................................................18

Disposal ...............................................................................18

Notes regarding the operating manual

Symbols

Warning of electrical voltage

This symbol indicates dangers to the life and health of

persons due to electrical voltage.

Info

Information marked with this symbol helps you to carry

out your tasks quickly and safely.

Follow the manual

Information marked with this symbol indicates that the

operating manual must be observed.

Wear ear protection

Information marked with this symbol indicates that you

should wear hearing protection.

Wear safety glasses

Information marked with this symbol indicates that you

should wear eye protection.

Wear a protective mask

Information marked with this symbol indicates that you

should wear a protective mask.

Wear protective gloves

Information marked with this symbol indicates that you

should wear protective gloves.

You can download the current version of the operating manual

and the EU declaration of conformity via the following link:

Warning of hot surface

This symbol indicates dangers to the life and health of

persons due to hot surface.

Warning of laser radiation

This symbol indicates dangers to the health of persons

due to laser radiation.

Warning of sharp object

This symbol indicates dangers to the life and health of

persons due to pointed objects.

Warning of hand injuries

This symbol indicates dangers to the health of persons

due to hand injuries.

Warning

This signal word indicates a hazard with an average

risk level which, if not avoided, can result in serious

injury or death.

Caution

This signal word indicates a hazard with a low risk

level which, if not avoided, can result in minor or

moderate injury.

PJSS 10-230V

http://hub.trotec.com/?id=39835

1 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 3

Legal notice

This release replaces all previous versions. No part of this

publication may be reproduced without written permission from

TrotecGmbH&Co.KG. The same applies for electronically

processing, duplicating or spreading the publication. Subject to

technical changes. All rights reserved. Trademarks are used

without guarantee that they may be used freely and primarily

following the spelling of the manufacturer. Product names are

registered.

Changes to construction in the interests of constant

improvements to the product, as well as changes to the shape

and colour are reserved.

The scope of delivery may vary from product images. This

document was created with all due care.

TrotecGmbH&Co.KG accepts no liability whatsoever for

possible mistakes or omissions.

© TrotecGmbH&Co.KG

Warranty and liability

The device complies with the fundamental health and safety

requirements of the applicable EU regulations and was tested at

the factory for perfect functionality multiple times.

However, if faults in the functionality occur and cannot be

remedied with the measures in the chapter Errors and faults,

please get in touch with your dealer or distributor.

When making a warranty claim, supply the device number

(see the side of the device).

When manufacturer's instructions or legal regulations have not

been followed, or after unauthorised changes to the device are

made, the manufacturer is not responsible for the resulting

damages. Changes to the device or unauthorised replacement

of individual parts can drastically impact the electrical safety of

this product and will result in the loss of the warranty. Liability

does not extend to damages to people or property caused by the

device being used other than as described in the instructions in

this operating manual. Subject to changes to technical design

and model changes as part of constant development and

product improvement without prior notice.

No liability is accepted for damages resulting from improper

use. In such a case, any warranty claims will be voided also.

Safety

Read this manual carefully before starting or using the

device. Always store the manual in the immediate vicinity

of the device or its site of use!

Warning

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future

reference.

This appliance can be used by children aged from

8 years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

The term power tool used in the safety warnings refers to both

mains-operated and battery-powered electric tools (with/

without power cable).

General Power Tool Safety Warnings – Work area

safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

• Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

EN 2

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 4

General Power Tool Safety Warnings – Electrical

safety

General Power Tool Safety Warnings – Personal

safety

• Power tool or power adapter plugs must match the

outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will reduce

risk of electric shock.

• Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

• Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

• Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a residual current device(RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

• Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention

while operating power tools may result in serious personal

injury.

Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites

accidents.

• Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

• Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. The use of a dust

extraction system may reduce dust-related hazards.

3 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 5

General Power Tool Safety Warnings – Power tool

use and care

Device-specific safety warnings for jigsaws

• Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the

job better and safer at the rate for which it was designed.

• Do not use the power tool if the switch does not turn it

on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

• Disconnect the plug from the power source and / or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

• Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to

bind and are easier to control.

• Use the power tool, accessories and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

General Power Tool Safety Warnings – Service

• Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Warning of laser radiation

Laser class2, P max.: > 1mW, λ: 650nm,

EN 60825-1:2014

Do not look directly into the laser beam or the opening

from which it emerges.

Never point the laser beam at people, animals or

reflective surfaces. Even brief eye contact can lead to

eye damage.

Examining the laser output aperture by use of optical

instruments (e.g. magnifying glass, magnifiers and the

like) entails the risk of eye damage.

When working with a laser of class2, observe the

national regulations on wearing eye protection.

• Hold the device by its insulated gripping surfaces

when performing an operation where the insertion tool

may contact hidden wiring or its own cord. Contacting

a live wire might energize exposed metal parts of the

device and lead to an electric shock.

• Use appropriate detection equipment to track down

concealed supply lines or consult the local utility

companies. Contact with electrical lines may result in fire

and electric shock. Damaging a gas line may lead to an

explosion. Penetrating a water line causes property

damage and may cause an electric shock.

• Vibrations can be harmful to the human hand-arm

system. Keep the vibration exposure time to a minimum.

• Secure the workpiece. The grip of tensioning devices or a

vice is more secure than holding the workpiece only by

hand.

• Clean the shank of the saw blade before inserting it.

A dirty shank cannot be fastened securely.

• Check the saw blade for tight fit. A loose saw blade

could fall out and injure you.

• Before switching on the power tool, ensure that the

insertion tool can move freely. If the device is switched

on with a jammed insertion tool, the resulting forces can

be extreme causing the device to kick out sideways.

• Do not work on moistened material or moist surfaces.

• Only hold the power tool against the workpiece when

the tool is switched on and running. Otherwise there is

a risk of kickbacks.

• Make sure that the base plate is positioned securely

on the contact face during sawing. A jammed saw blade

could break or cause a kickback.

• Keep your hands out of the sawing area. Do not reach

underneath the workpiece. Risk of injury upon contact with

the saw blade.

EN 4

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 6

• Keep your hands away from lifting rod and quickrelease chuck. Crushing hazard upon contact with these

components.

• Ensure sufficient ventilation.

• Regularly check the quick-release chuck for wear or

damage.

• Only use intact, flawless saw blades. Bent and blunt

saw blades could break or cause a kickback.

• Do not attempt to slow down the saw blade movement

by pressing against the blade from the side once the

device is switched off. The saw blade could be damaged,

break or cause a kickback.

• Switch off the power tool when your operation is

completed, but do not remove the saw blade from the

kerf until it has come to a standstill. This serves to

avoid a kickback, then you can put the power tool down

safely.

• Immediately switch off the power tool if the insertion

tool gets jammed. The power tool can lash out to the side

owing to the forces that build up consequently.

• Wait until the power tool has come to a standstill,

before putting it down. The insertion tool could get

caught resulting in a loss of control of the power tool.

Intended use

Only use the device PJSS 10-230V:

• for straight and curved cuts at angular workpieces made of

wood, plastic and light metal while keeping base plate

contact,

• for mitre cuts up to an angle of 45° at angular workpieces

made of wood, plastic and light metal,

whilst adhering to the technical data (see operating manual).

We recommend using the power tool with original Trotec

accessories.

Improper use

• The device is not intended for processing damp wood.

• The device is not intended for processing glass or stone.

• The device is not intended for freehand operation without

base plate contact.

Personnel qualifications

People who use this device must:

• have read and understood the operating manual, especially

the Safety chapter.

Personal protective equipment

Wear hearing protection.

Excessive noise can lead to hearing loss.

Wear eye protection.

With it you protect your eyes from splintering, falling

and flying pieces which could cause injuries.

Wear a dust mask.

It saves you from inhaling harmful dusts generated

when processing workpieces.

Wearing protective gloves.

They protect your hands from burns, crushing injuries

and skin abrasions.

5 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 7

Residual risks

Warning of electrical voltage

Electric shock from insufficient insulation.

Check the device for damages and proper functioning

before each use.

If you notice damages, no longer use the device.

Do not use the device when the device or your hands

are damp or wet!

Warning of electrical voltage

Work on the electrical components must only be

carried out by an authorised specialist company!

Warning of electrical voltage

Before any work on the device, remove the mains plug

from the mains socket!

Hold onto the mains plug while pulling the power cable

out of the mains socket.

Warning of electrical voltage

There is a risk of a short-circuit due to liquids

penetrating the housing!

Do not immerse the device and the accessories in

water. Make sure that no water or other liquids can

enter the housing.

Warning of laser radiation

Laser class2, P max.: > 1mW, λ: 650nm,

EN 60825-1:2014

Do not look directly into the laser beam or the opening

from which it emerges.

Never point the laser beam at people, animals or

reflective surfaces. Even brief eye contact can lead to

eye damage.

Examining the laser output aperture by use of optical

instruments (e.g. magnifying glass, magnifiers and the

like) entails the risk of eye damage.

When working with a laser of class2, observe the

national regulations on wearing eye protection.

Warning of hand injuries

Crushing hazard near saw blade and base plate if

handled without due care.

Wear protective gloves!

Warning of sharp object

Parts of the saw blade are sharp. Risk of injuries if

handled without due care.

Wear protective gloves!

Warning of hot surface

The insertion tool might still be hot after the

application. Burn hazard when touching the insertion

tool.

Do not touch the insertion tool bare-handed!

Wear protective gloves!

Warning

Toxic dusts!

The harmful / toxic dusts produced during operation

pose of risk to the health of the operator and persons

in the vicinity.

Wear eye protection and a dust mask!

Warning

Do not process materials containing asbestos.

Asbestos is considered carcinogenic.

Warning

Make sure not to hit power, gas or water lines when

working with a power tool.

If necessary, use a pipe detector to check the wall you

want to drill in or slit open.

Warning

Risk of injuries caused by flying parts or bursting tool

heads.

Warning

Dangers can occur at the device when it is used by

untrained people in an unprofessional or improper way!

Observe the personnel qualifications!

Warning

The device is not a toy and does not belong in the

hands of children.

Warning

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

Caution

Vibration emissions can cause a health hazard if the

device is used for an extended period of time or if it is

not properly handled and maintained.

Caution

Keep a sufficient distance from heat sources.

Notice

If you store or transport the device improperly, the

device may be damaged.

Note the information regarding transport and storage of

the device.

EN 6

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 8

Behaviour in the event of an emergency

1. Switch off the device.

2. Disconnect the device from the mains feed-in:

Hold onto the mains plug while pulling the power cable out

of the mains socket.

Information about the device

Device description

The device PJSS 10-230V is suited for varied sawing operations

with a quick sawing progress due to the adjustable pendulum

action.

The anti-splinter guard ensures tear-free cuts.

The pendulum action can be set to 3 levels, or switched off if

required.

The saw blades can be exchanged without tools.

The base plate can be adjusted without tools and allows for

cutting angles of 15°, 30° and 45°.

The stroke rate can be easily adjusted between 0 and

3,000 spm using the integrated setting wheel.

The work area can be illuminated thanks to an LED. For an

improved guidance, a laser can be switched on in addition,

which indicates the current cutting path.

Furthermore the device is equipped with a fan function for a

cutting line without sawdust and with an integrated connection

for effective external vacuum cleaning.

7 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 9

Device depiction

1

2

4

3

5

6

17

16

18

15

19

7

12

13

14

8

9

10

11

No. Designation

1 Stroke rate setting wheel

2 On/off switch

3 Dust extraction connection

4 Splinter blow-off/suction selector switch

5 Pendulum action selector switch

6 Base plate with removable sliding block

7 Protective pin

8 Rip fence

9 Saw blade set

10 Adapter for dust extraction

11 Anti-splinter guard

12 Guide roller

13 Quick-change chuck

14 Base plate lock

15 Locking screws for rip fence

16 Protective cover

17 Laser, LED work lamp

18 Button for laser and LED work lamp

19 Lock-on switch continuous operation

Scope of delivery

• 1 x Pendulum action jigsaw

EN 8

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

• 1 x Rip fence

• 3 x Saw blade HCS wood

• 1 x Saw blade HSS metal

• 1 x Adapter for dust extraction

• 1 x Anti-splinter guard

• 1 x Sliding block

• 1 x Manual

Page 10

Technical data

Transport and storage

Parameter Value

Model PJSS10-230V

Mains connection 1/N/PE ~ 230 V/ 50 Hz

Power input 0.85 kW

Idle stroke speed 0 – 3,000 spm

Cutting angle 0° / 15° / 30° / 45°

Cable length 3 m

Protection class

Weight 2 kg

Vibration information according to EN 60745

Total vibration emission value:

Sawing chipboards a

Uncertainty K

Sawing sheet metal a

Uncertainty K

Sound values according to EN 60745

Sound pressure level L

Sound power L

Uncertainty K 3 dB

h,B

h,B

pA

WA

II /

9.5 m/s²

1.5 m/s²

11.2 m/s²

1.5 m/s²

88 dB(A)

99 dB(A)

Wear hearing protection.

Excessive noise can lead to hearing loss.

Information on noise and vibration:

• The vibration level specified in these instructions was

determined by means of a measuring method standardized

in EN 60745 and can be used for a device comparison. The

specified vibration emission value may also be used for a

preliminary assessment of the exposure.

Caution

Vibration emissions can cause a health hazard if the

device is used for an extended period of time or if it is

not properly handled and maintained.

• The vibration level will change depending on the

application of the power tool and may in some cases differ

from the value specified in these instructions. The vibration

load may be underestimated if the power tool is used

regularly in such a way. For a precise estimation of the

vibration load during a certain work period, it is also

important to consider the periods during which the device

is switched off, or is running but not actually employed.

This can reduce the vibration load over the entire work

period significantly.

Notice

If you store or transport the device improperly, the

device may be damaged.

Note the information regarding transport and storage of

the device.

Transport

Before transporting the device, proceed as follows:

• Switch off the device.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

• Allow the device to cool down.

• Remove the tool from the tool holder.

• If attached, disconnect the dust extraction system from the

device.

Storage

Before storing the device, proceed as follows:

• Switch off the device.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

• Allow the device to cool down.

• Remove the tool from the tool holder.

• Clean the device as described in the Maintenance chapter.

When the device is not being used, observe the following

storage conditions:

• dry and protected from frost and heat,

• ambient temperature below 40 °C,

• protected from dust and direct sunlight.

9 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 11

Start-up

16

13

12

Unpacking the device

• Take the device out of the packaging.

Warning of electrical voltage

Electric shock from insufficient insulation.

Check the device for damages and proper functioning

before each use.

If you notice damages, no longer use the device.

Do not use the device when the device or your hands

are damp or wet!

• Check the contents for completeness and look for

damages.

Warning

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

• Dispose of the packaging material according to the

national regulations.

Changing the saw blade

Warning of electrical voltage

Before any work on the device, remove the mains plug

from the mains socket!

Hold onto the mains plug while pulling the power cable

out of the mains socket.

2. Turn the quick-release chuck(13) to the side and hold it in

this position.

Wear protective gloves

Wear appropriate protective gloves when inserting or

exchanging tools.

As standard, the device is supplied with 3saw blades for cutting

in wood and one saw blade for cutting in light metals.

Please proceed as follows to remove or insert a saw blade:

1. Detach the protective cover(16).

3. If a saw blade is inserted, remove the saw blade from the

quick-release chuck.

4. Insert the saw blade into the quick-release chuck. Make

sure that the teeth of the saw blade point to the front and

that the saw blade is seated in the guide roller(12).

5. Push the saw blade into the quick-release chuck up to the

stop. Use a suitable sawblade with single lug shank.

EN 10

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 12

6. Let go of the quick-release chuck.

20

21

6

6

11

ð The quick-release chuck must return to its initial

position.

7. Check whether the saw blade is properly locked in place.

8. Reattach the protective cover(16).

Mounting / removing the sliding block

To protect the surface of the material to be processed, the

sliding block is already preassembled. You may remove the

sliding block if required.

1. Release the two fastening clips(20) at the rear.

2. Slowly push the sliding block(21) forward while carefully

detaching the front part of the sliding block from the base

plate(6).

3. Pull the sliding block(21) downwards carefully.

Mounting / removing the anti-splinter guard

The anti-splinter guard serves to avoid tearing of the surface

when sawing in wood. The anti-splinter guard can only be used

in combination with certain types of saw blades and at a cutting

angle of 0°. You may remove it if required, e.g. if you want to

make a mitre cut.

The anti-splinter guard is already preassembled.

1. First remove the sliding block (see Mounting / removing the

sliding block).

2. Remove the anti-splinter guard(11) from the base plate(6)

by carefully pushing the anti-splinter guard outwards.

3. To reinsert the anti-splinter guard(11), carefully push it into

the recess of the base plate from below until the antisplinter guard locks in place. When doing so, make sure

that the smooth side of the anti-splinter guard points away

from the device.

4. To reattach the sliding block(21), first push it onto the front

part of the base plate(6).

5. Then let the fastening clips(20) lock in place at the rear.

6. Check the sliding block(21) for tight fit.

11 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 13

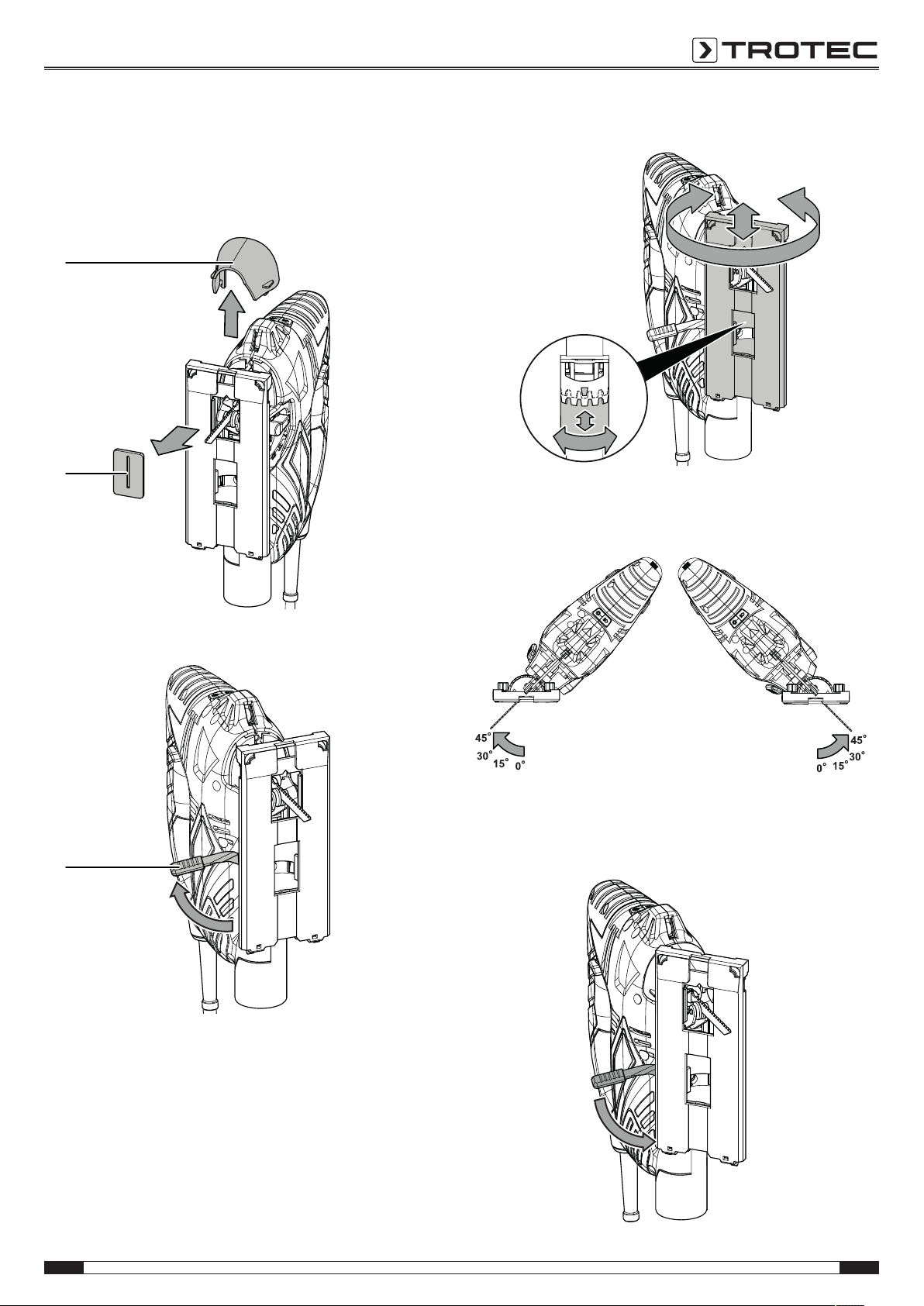

Adjusting the cutting angle

16

11

14

The cutting angle can be adjusted to the left or right at angles of

0° / 15° / 30° / 45°.

1. First, remove the anti-splinter guard(11) and the protective

cover(16).

3. Slide the base plate to the rear until it can be freely rotated.

4. Set the desired cutting angle. The number of degrees to be

set is engraved on the base plate.

2. Push the base plate lock(14) to the front.

5. Slide the base plate back to the front until the toothing

engages.

6. Push the base plate lock(14) to the rear.

EN 12

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 14

7. Check the base plate for tight fit.

15

8

1

Info

The anti-splinter guard and the protective cover cannot

be used for mitre cuts.

Mounting the rip fence

The rip fence can be fastened on both sides of the device.

1. Loosen the locking screws(15) at the slot. Make sure not to

unscrew the locking screws completely.

Selecting the stroke rate

The required stroke rate depends on the material and the

operating conditions and can be determined by way of fieldtesting.

The setting range covers the levels 1 – 6 (0 – 3,000spm). You

can change the preselected stroke rate level at any time.

1. Turn the setting wheel(1) to the desired stroke rate level.

2. Slide the rip fence(8) into the slot with the marking pointing

up.

3. Move the rip fence(8) into the desired position.

4. Tighten the locking screws(15).

13 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 15

Adjusting the pendulum action

I

II

III

0

5

You can adjust the pendulum movement of the saw blade.

Levels 1 to 3 allows for a faster work progress and level0

(pendulum movement off) enables fine and clean cutting edges.

The ideal pendulum level for the respective application can be

determined by way of field-testing. Please observe the following

instructions:

• If you want to obtain a fine and clean cutting edge,

preferably select a low pendulum level or switch off the

pendulum action completely.

• Switch off the pendulum action when processing thin

materials.

• Work at a low pendulum level when processing hard

materials.

• For soft materials or when sawing wood with the grain you

can work with the maximum pendulum level.

1. Set the pendulum action selector switch(5) to the desired

level. The higher the level, the larger the pendulum stroke.

The pendulum action can also be adjusted during operation.

Operation

Tips and notes on handling the jigsaw

General information:

• Keep the venting slots clear to prevent the motor from

overheating.

• Check the tool in the tool holder for proper fit before every

application. The tool must be firmly locked in place in the

designated holding fixtures on the tool holder.

• Before every application, make sure that you have selected

the correct tool for the intended use.

Sawing:

• Only use intact, flawless saw blades. Bent, blunt or

otherwise damaged saw blades could break.

• When sawing lightweight construction materials, make

sure to observe the legal regulations and

recommendations of the material manufacturers.

• Before sawing wood, chipboards, building materials etc.

with HCSblades, check the above for foreign objects,

e.g. nails, screws or similar. If required, remove the foreign

objects or use HSS saw blades.

• Use a narrow saw blade when sawing tight curves.

• The saw blade should not be longer than required for the

intended cut.

Connecting the power cable

1. Insert the mains plug into a properly secured mains socket.

EN 14

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 16

Switching the LED work lamp and laser on and off

1 x =

2 x =

3 x =

4 x =

18

19

2

6

The device is equipped with an LED work lamp to illuminate the

workpiece and with a laser to mark the cutting path. The laser is

best suited for cuts with a 0° cutting angle.

Warning of laser radiation

Laser class2, P max.: > 1mW, λ: 650nm,

EN 60825-1:2014

Do not look directly into the laser beam or the opening

from which it emerges.

Never point the laser beam at people, animals or

reflective surfaces. Even brief eye contact can lead to

eye damage.

Examining the laser output aperture by use of optical

instruments (e.g. magnifying glass, magnifiers and the

like) entails the risk of eye damage.

When working with a laser of class2, observe the

national regulations on wearing eye protection.

The LED work lamp and laser can be switched on and off in the

following combinations:

• LED work lamp and laser on

• LED work lamp on, laser off

• LED work lamp off, laser on

• LED work lamp and laser off

1. Press the button for laser and LED work lamp(18) until the

desired combination is set.

Switching the device on and off

Wear your personal protective equipment when working with

the device.

1. Check whether the fixed saw blade, the set stroke rate, the

pendulum action and the cutting angle are suitable for the

intended application.

2. Check whether the workpiece is secured and the worktop

prepared correspondingly.

3. Check whether the fixed saw blade, the set stroke rate, the

pendulum action and the cutting angle are suitable for the

intended application.

4. Position the base plate with the sliding block(6) on the

workpiece.

5. Press the on/off switch(2) and hold it during operation.

ð The device operates with the previously selected

settings.

6. Let go of the on/off switch(2) to stop the device.

15 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 17

Switching continuous operation on and off

4

16

3

10

4

When continuous operation is activated, the on/off switch does

not have to be held permanently, which makes working more

comfortable.

1. Proceed as described in the chapter Switching the device

on and off, steps 1 to 4.

2. Push the lock-on switch(19) to the left or right with your

thumb until the lock-on switch is completely pushed in on

one side.

3. Let go of the on/off switch(2) and continue holding the

device.

ð The device keeps running and continuous operation is

activated.

4. Press the on/off switch(2) to stop continuous operation.

ð The lock-on switch automatically returns to centre

position.

5. Let go of the on/off switch(2) to stop the device.

Setting the splinter blow-off/suction function

You can choose whether the splinters shall be blown off towards

the front or sucked off with an optionally connectable vacuum

cleaner.

1. Make sure that the protective cover(16) is mounted.

2. Slide the blow-off/suction function selector switch(4) to the

left to suck the splinters in using an external vacuum

cleaner, or to the right to blow the splinters away.

Connecting the dust extraction system

You can connect a vacuum cleaner to the device. The adapter

included in the scope of delivery allows to connect smaller pipe

diameters.

Caution

Use a special vacuum cleaner to suck off harmful or

toxic materials.

1. If required, attach the adapter(10) to the connection for the

dust extractionsystem(3).

2. For an optimum dust extraction, insert the anti-splinter

guard if possible.

3. Connect a suitable vacuum cleaner (e.g. industrial vacuum

cleaner) to the dust extraction.

4. Slide the splinter blow-off/suction selector switch(4) to the

left to the position for dust extraction.

EN 16

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 18

Available accessories

Warning

Only use accessories and additional equipment

specified in the operating manual.

Using insertion tools or accessories other than those

specified in the operating manual may cause a risk of

injury.

The device becomes hot:

• Make sure not to exert too much pressure on the device

during sawing.

• To select a low stroke rate, turn down the setting wheel for

stroke rate selection.

• Check whether the chosen saw blade is suitable for the

task to be carried out.

• Keep the venting slots clear to prevent the motor from

overheating.

Designation Article number

Jigsaw blade set for wood, 10-piece 6.215.001.101

Jigsaw blade set for metal, 10-piece 6.215.001.131

Errors and faults

The device has been checked for proper functioning several

times during production. If malfunctions occur nonetheless,

check the device according to the following list.

Troubleshooting tasks which require the housing to be opened

must only be carried out by a specialist dealer or by Trotec.

Slight smoke or odour are emitted during first use:

• This is not a fault. These phenomena disappear after a

brief runtime.

The device does not start:

• Check the power connection.

• Check the power cable and mains plug for damages.

• Check the on-site fusing.

Info

Wait for at least 10 minutes before switching the

device back on.

Info

Wait for at least 10 minutes before switching the

device back on.

Notice

Wait for at least 3 minutes after maintenance and

repair work. Only then switch the device back on.

Your device still does not operate correctly after these

checks?

Please contact the customer service. If necessary, bring the

device to an authorized specialist electrical company or to

Trotec for repair.

The saw blade is loose:

• Make sure that the saw blade is firmly locked in place in

the designated recesses of the quick-release chuck.

• Make sure that the quick-release chuck is locked.

The saw blade experiences difficulties penetrating the

material to be processed or the sawing performance is

insufficient:

• Check the set stroke rate; it must be suitable for both the

saw blade and the material.

• To select a higher stroke rate, turn up the setting wheel for

stroke rate selection.

• Check whether the pendulum action setting is suitable for

the material to be processed.

• If the saw blade is worn, replace it with a new one.

• Check whether the chosen saw blade is suitable for the

material to be processed.

17 EN

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 19

Maintenance

Activities required before starting maintenance

Disposal

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

• Switch off the device.

• Hold onto the mains plug while pulling the power cable out

of the mains socket.

• Allow the device to cool down completely.

Warning of electrical voltage

Maintenance tasks which require the housing to be

opened must only be carried out by authorised

specialist companies or by Trotec.

Notes on maintenance

Inside the device, there are no parts that need to be maintained

or lubricated by the user.

Cleaning

The device should be cleaned before and after each use.

Note:

The device does not have to be lubricated after cleaning.

Warning of electrical voltage

There is a risk of a short-circuit due to liquids

penetrating the housing!

Do not immerse the device and the accessories in

water. Make sure that no water or other liquids can

enter the housing.

• Clean the device with a soft, damp and lint-free cloth.

Ensure that no moisture enters the housing. Protect

electrical components from moisture. Do not use any

aggressive cleaning agents such as cleaning sprays,

solvents, alcohol-based or abrasive cleaners to dampen

the cloth.

• Dry the device and the saw blades with a soft cloth, lintfree cloth.

• Remove any abrasive dust and, if applicable, wood chips

from the quick-release chuck.

• Keep the ventilation openings free from dust deposits to

prevent overheating of the motor.

The icon with the crossed-out waste bin on waste

electrical or electronic equipment stipulates that this equipment

must not be disposed of with the household waste at the end of

its life. You will find collection points for free return of waste

electrical and electronic equipment in your vicinity. The

addresses can be obtained from your municipality or local

administration. For further return options provided by us please

refer to our website www.trotec24.com.

The separate collection of waste electrical and electronic

equipment aims to enable the re-use, recycling and other forms

of recovery of waste equipment as well as to prevent negative

effects for the environment and human health caused by the

disposal of hazardous substances potentially contained in the

equipment.

You are responsible for deleting any personal data stored on the

waste equipment to be disposed of.

EN 18

Operating manual – 850W pendulum action jigsaw PJSS 10-230V

Page 20

Trotec GmbH & Co. KG

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...