Page 1

OPERATING MANUAL

PULSE CURRENT

MEASURING SYSTEM

EN

TRT-BA-PD200-HS-006-EN

PD200

Page 2

Operating manual – pulse current measuring system PD200

A - 1

EN

Table of contents

01. Safety .........................A - 01

02. Intended use ......................A - 02

03. Scope of delivery ..................A - 02

3.1 Standard scope of delivery ......... A - 02

3.2 Optional accessories .............. A - 03

3.3 Supplies .......................A - 03

04. Operating elements, displays and

connections ......................A - 04

4.1 Pulse generator PD200 G ..........A - 04

4.2 Pulse receiver PD200 E ............A - 05

05. Functional check ..................A - 05

5.1 Battery testing pulse receiver ....... A - 05

5.2 Voltage testing pulse generator ......A - 05

5.3 Checking the functional interaction

of both devices ..................A - 06

06. Leak detection ....................A - 06

6.1 General functioning ...............A - 06

6.2 Preparing the measurement ........A - 07

6.3 Preparation warm/green roof ....... A - 07

6.3.1 Installation of loop wiring .....A - 07

6.3.2 Using the gravel claw

(optional accessories) ........A - 08

6.3.3 Connecting the pulse generator A - 08

6.3.4 Connecting the pulse receiver .. A - 08

6.4 Preparation cold roof .............A - 08

6.4.1 Installation of loop wiring .....A - 08

6.4.2 Connecting the pulse generator A - 09

6.4.3 Connecting the pulse receiver .. A - 10

6.5 Detection ......................A - 10

07. Avoiding measurement errors ........A - 10

7.1 Shielding ...................... A - 10

7.2 Supposed leak at the centre

of the measuring surface ..........A - 11

7.3 Prolonged drought ...............A - 11

7.4 Earthed metal parts .............. A - 11

08. Checking of lined ponds and swimming

pools with non-conducting sealing

....

A - 11

09. Troubleshooting

...................

A - 12

10. Maintenance and service

............

A - 12

10.1 Battery change ................. A - 12

10.2 Maintenance and service of

the device .................... A - 12

11. Technical data

.....................

A - 12

11.1 Pulse generator PD200 G. ........A - 12

11.2 Pulse receiver PD200 E ..........A - 12

11.3 Particular equipment features ...... A - 13

12. Miscellaneous

.....................

A - 13

12.1 Operational reliability ............ A - 13

12.2 Seminars ..................... A - 13

12.3 Disposal ...................... A - 13

This release replaces all previous releases. No part of this publication may be reproduced

without written permission. The same applies for electronically processing, duplicating or

spreading the publication. Subject to technical changes. All rights reserved. Trademarks are

used without guarantee that they may be used freely and primarily following the spelling of

the manufacturer. The product names used are registered and should be treated appropriately.

Changes to construction in the interests of constant improvements to the product, as well as

changes to the shape and colour are reserved. Scope of delivery may vary from product images.

This document was produced with all due care. We accept no liability whatsoever for mistakes

or omissions. © TROTEC

®

The measuring device at hand was built according to

current state-of-the-art technology and fulfils valid

European and national directives. This conformity has

been tested and the corresponding declarations and

documents are kept on file by the manufacturer.

To keep this condition and ensure safe operation,

as a user, you must observe the following safety

instructions:

01. Safety

We accept no liability for damages caused by nonobservance of this manual or unprofessional

handling. Any warranty claims are voided in such

cases!

m Before starting the measuring device for the

first time, read this manual from cover to

cover!

Page 3

Operating manual – pulse current measuring system PD200

EN

A - 2

For reasons of safety and conformity (CE), any

unauthorised change made to the device construction

or components which are to be used with the

measuring device are prohibited!

Before using the device, observe the following:

• Never measure live parts.

• The only party responsible for determining

measured results to be valid, drawing conclusions

and deriving actions is the user! The correctness

of the results presented is excluded from any

liability or guarantee. Liability for damages which

have been caused by utilising the presented

measured results is strictly excluded.

02. Intended use

The PD200 system is a professional measuring device

based on the pulse current method for the pinpoint

location of grounded leaks in non-conducting plastic

foils.

Fields of application i.a.:

• warm roofs, cold roofs and greened flat roofs

• roof-top terraces

• balconies

• lined ponds, swimming pools

• plastic covered landfills, dumps

The power supply has to comply with the device

type and the mains connection must be provided

with a proper protective earth conductor. The device

may only be used for the given intended use while

complying with the specified technical data.

Any other use is considered misuse and contrary to

the intended use.

03. Scope of delivery

3.1 Standard scope of delivery

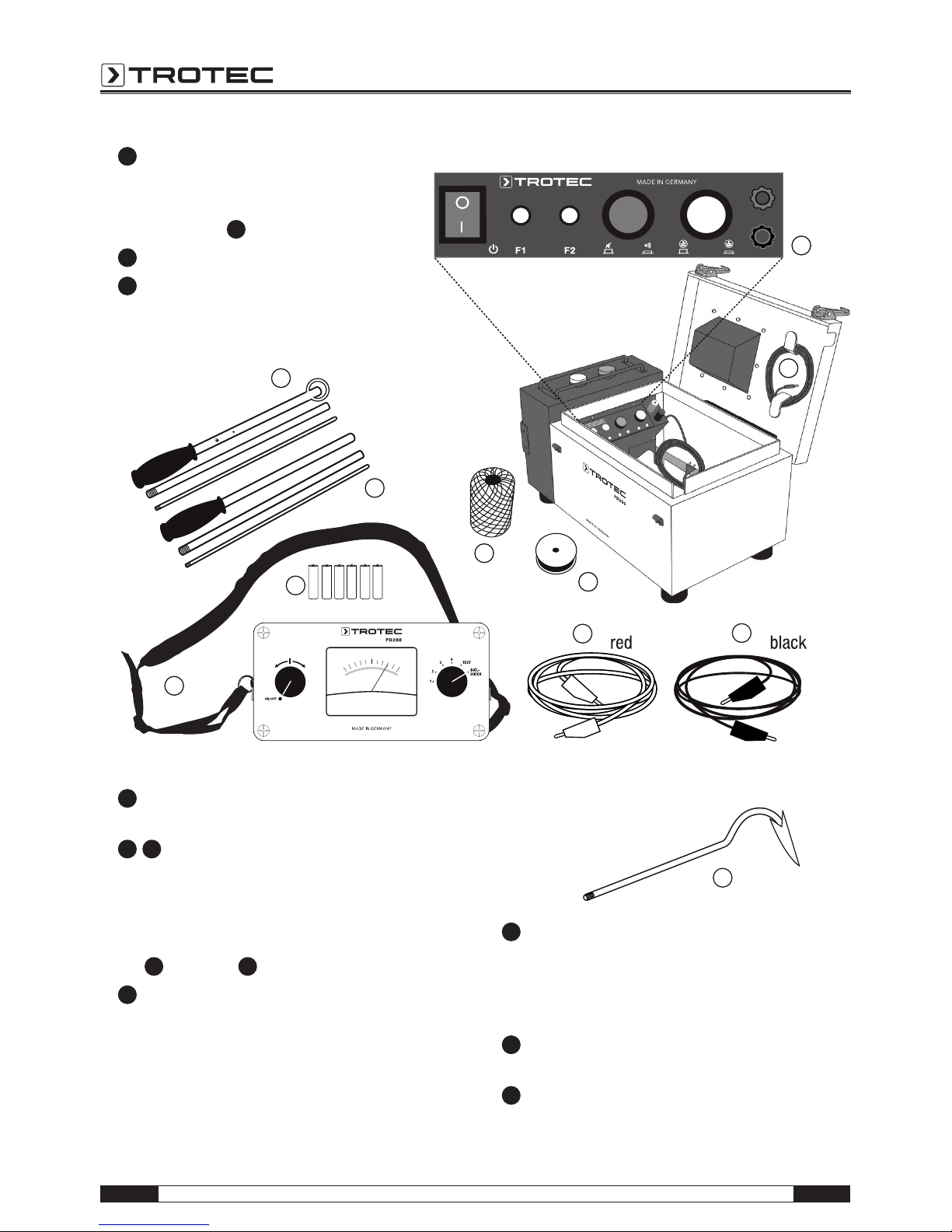

•

1

transport case with carrying handle

and 2 safety locks

1

Page 4

Operating manual – pulse current measuring system PD200

A - 3

EN

0

µA

50

+–

50

40 40

30 30

20 20

10 10

+

–

• 2 integrated pulse generator PD200 G

with power cable

• 1 x connection cable with clip terminal

in the lid, black

3

length 8 m

•

4

1 x reel PD200 loop wiring, length 200 m

•

5

1 x reel PD200 earth cable

extension with banana jack,

red, length 25 m

•

6

compact, battery-powered pulse receiver

PD200 E with carrying strap

•

7 8

2 x take-apart measuring rods with rubber

grip (3-part, length: 1.00 m) incl. 1 x clamping

spring and 1 x integrated uncoiling aid for loop

wiring

• 1 x connecting cable each for the measuring rods,

red

9

and black

10

•

11

6 x batteries of type LR06 / AM-3 | AA | Mignon

3.2 Optional accessories

•

12

gravel claw for a simplified laying of loop wiring

under the gravel fill

(art. no. 3.510.010.003)

3.3 Supplies

•

4

1 x spare reel of PD200 loop wiring,

length 200 m (art. no. 3.510.010.005)

•

5

1 x spare reel of PD200 earth cable extension,

red, length 25 m (art. no. 3.510.010.004)

3

2

4

6

7

8

5

9

11

12

10

Page 5

Operating manual – pulse current measuring system PD200

EN

A - 4

+

–

04. Operating elements, displays and connections

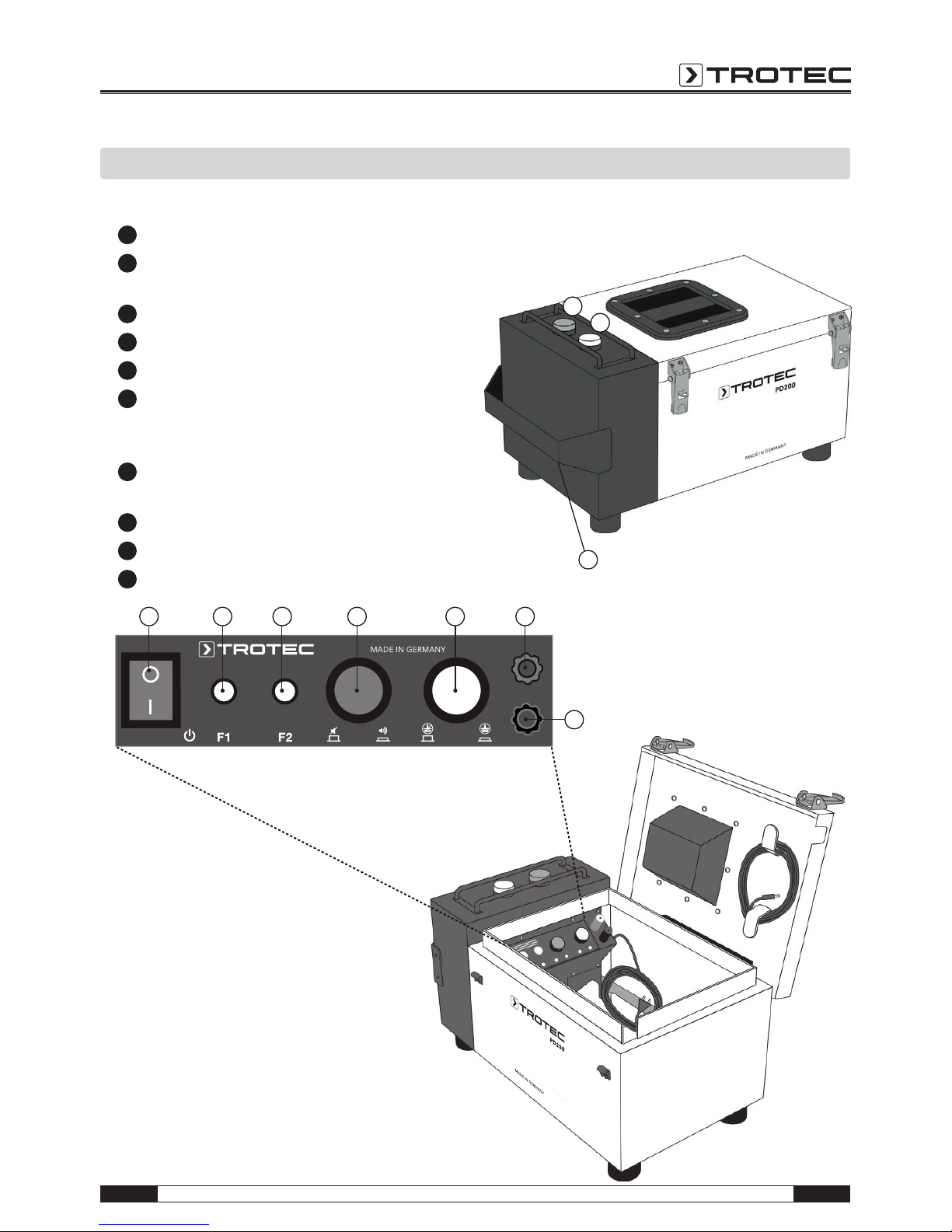

4.1 Pulse generator PD200 G

•

A

red warning light for earthing control

•

B

green lamp for visual control of

current pulses (flashes green)

•

C

rocker switch with indicator light, green

•

D

primary fuse (PTC) F1

•

E

secondary fuse (PTC) F2

•

F

pressure switch, red, for activation of an additional acoustic signal for acoustic control of current

pulses

•

G

pressure switch, green, for switching on the

external earthing

•

H

positive connector, red

•

I

negative connector, black

•

J

transport handle

A

B

DC E F G H

I

J

Page 6

Operating manual – pulse current measuring system PD200

A - 5

EN

+

–

0

µA

50

+–

50

40 40

30 30

20 20

10 10

05. Functional check

5.1 Battery testing pulse receiver PD200 E

Do not switch on the receiver. Set the right rotary

switch to "BAT.-CHECK". If the needle on the

indicating instrument [µA]

L

deflects to the right to at

least 30 µA, the battery capacity is sufficient and the

device ready for use. Then turn the right rotary switch

to position "4".

5.2 Voltage testing pulse generator PD200 G

Plug the power cable into an earthed safety socket.

Flip the rocker switch

C

to position "I" and the green

indicator light indicates the mains connection.

4.2 Pulse receiver PD200 E

•

K

rotary switch "ON/OFF", adjustment for

"0" position

•

L

analogue indicating instrument [µA]

•

M

rotary switch with 6 settings:

attenuation 1-4, 1 = without resistance,

2 = minimum

resistance ... 4 = maximum resistance

test setting (TEST)

battery check (BAT.-CHECK)

•

N

carrying strap

• red

O

and black P connectors for connection

of connection cables with measuring rods

K

M

N

L

L

C

P

O

0

µA

50

+–

50

40 40

30 30

20 20

10 10

Page 7

Operating manual – pulse current measuring system PD200

EN

A - 6

+

–

0

µA

50

+–

50

40 40

30 30

20 20

10 10

5.3 Checking the functional interaction

of both devices

m Before checking, switch off both devices. Set

the rotary switch of pulse receiver PD200 E

M

to "TEST". If the switch is in a different

position, the receiver might be damaged

when switching on pulse generator PD200 G.

Use the red

9

and black 10 connection cables to

connect the pulse receiver to the receptacles of the

pulse generator

H

I. Ensure the correct colour

assignment black/red.

Switch on the generator. Then switch on the receiver

and use the rotary switch

K

to adjust the indicator

to "0".

The needle of the analogue indicating instrument [µA]

L

must deflect to the right in the pulse frequency.

Also check the pulses by means of the green lamp

B

in the transport case. Switch on the acoustic

signal of the pulse generator

F

.

Interchange the two measuring lines at the pulse

receiver – black cable to red connector and red cable

to black connector – and repeat the procedure. The

needle should now deflect to the left.

+G-

pulse generator

loop wiring

potential lines

leak

06. Leak detection

6.1 General functioning

The method is based on the fact that there is water

both on top of and also underneath the sealing sheet.

This water or moisture serves as conductor. Therefore, leak detection always requires a damp and

hence electrically conducting sealing sheet, regardless of whether the surface is wet to various degrees,

gravelled or greened.

The PD200 pulse generator gives of current pulses

with a voltage of 40 V. The current finds its path to the

point of leakage via the moisture. The PD200 receiver

is used to measure the potential difference. The

needle of the indicating instrument deflects to the

direction with the higher potential, indicating the

direction for the locator. This way you are led to the

leak, to the position where moisture enters.

F H

I

K M

L

Page 8

Operating manual – pulse current measuring system PD200

A - 7

EN

6.3 Preparation warm/green roof

6.3.1 Installation of loop wiring

Figure: sectional drawings warm roof

loop wiring

fill

loop wiring

fill

Before measuring, the bare cord 4 (loop wiring)

is to be laid as closed circuit around the roof

area to be examined observing a minimum

distance of 0.5 m to the roof edge. Current can only

flow when the wire is placed directly on the roof

seal. If the fill consists of gravel or other granulated

material, we recommend the gravel claw (art.

no. 3.510.010.003) as optional accessory. In case

of thicker coatings, e.g. soil or greening, the roof

seal has to be exposed to enable direct contact

of loop wiring and roof seal.

At any rate, the roof seal to be checked must be sufficiently damp to conduct the current pulses. The roof

seal may have to be watered additionally.

6.2 Preparing the measurement

The basic distinction of flat roofs is made

between warm, cold and greened roof. Their

different composition necessitates a different

preparation.

Figure: schematic cross-section warm roof

gravel fill

roof seal

thermal insulation

vapour barrier

supporting structure

(solid ceiling)

greening

vegetation layer

filter layer

drainage layer

roof seal

thermal insulation

vapour barrier

supporting structure

(solid ceiling)

roof trim

gravel fill

roof seal

roof boarding

roof beam

timber rafter

thermal insulation

vapour barrier

ceiling boarding

wall

roof trim

Figure: schematic cross-section

greened roof

Figure: schematic cross-section

greened roof

Figure: schematic cross-section

cold roof

Page 9

Operating manual – pulse current measuring system PD200

EN

A - 8

6.3.2 Using the gravel claw (optional accessories)

The gravel claw serves the purpose of simplified

laying of loop wiring under the gravel fill.

Screw the gravel claw (art. no. 3.510.010.003) to

the bottom part of the measuring rod, which is not

intended for uncoiling the loop wiring (measuring rod

1). Now push the loop spindle onto the handle part

of the other measuring rod (measuring rod 2), which

serves as uncoiling aid, and secure the spindle by

means of the corresponding clamping spring.

Uncoil some of the loop wiring (approx. 1 m) and

attach it to a fixed position on the roof in a way that it

cannot shift, e.g. by weighting it down with an object.

Now tighten the wire and thread it into the eye of

the gravel claw. Hold spindle and gravel claw as

illustrated below. Carefully insert the claw in the

gravel by pulling and move backwards one step at a

time, so that the loop wiring disappears underneath

the gravel fill. On a sample basis check that the loop

is placed directly on the roof membrane.

m Always ensure sufficient protection for

all works on the (flat) roof! Particularly in

close proximity to the roof edge there is the

ever-present risk of falling!

0

µA

50

+–

50

40 40

30 30

20 20

10 10

6.3.3 Connecting the pulse generator

Connect the pulse generator to the mains. For this,

the device must be switched off. Make sure that the

earthing is switched on at the pressure switch

G

:

The red positive connector and the red

connection cable are not being used here.

Earthing is effected via the earthing contact

of the mains plug. The black connection cable

3

is connected to the loop wiring by use of the clip

terminal.

6.3.4 Connecting the pulse receiver

Both measuring rods are screwed together and

connected to the pulse receiver by use of the red and

black connecting cables.

6.4 Preparation cold roof

Timber structures are electrically non-conducting.

Therefore, the preparations differ.

6.4.1 Installation of loop wiring

Please proceed as described in point 6.3.1.

Page 10

Operating manual – pulse current measuring system PD200

A - 9

EN

6.4.2 Connecting the pulse generator

Connect the pulse generator to the mains. For

this, the device must be switched off. Make

sure that the earthing is switched off at the

pressure switch

G

.

Plug the end of the red connection cable

5

into the

red positive connector

H

. Now attach the bare end

of the wire to the wet ceiling area underneath the flat

roof.

loop wiring

connection cable, black (negative)

pulse generator PD200 G

leak

nail

connection cable, red (earthing)

window

If required, drive a nail into the ceiling at this place.

The black connection cable

3

is connected to the

loop wiring by use of the clip terminal.

6.4.3 Pulse receiver

Please proceed as described in point 6.3.3.

Page 11

Operating manual – pulse current measuring system PD200

EN

A - 10

6.5 Detection

First switch on the pulse generator and then the pulse

receiver.

Position yourself parallel to a roof side, seize the

two measuring rods by the rubber grips and with a

distance of approx. 1.5 m push them carefully through

the fill (gravel, greening) onto the roof seal.

m Avoid applying too much force, for

otherwise you will inadvertently puncture

the roof membrane!

m Measuring will only be possible when there

is contact to the roof seal, otherwise no

current flows through the receiver.

Pulses will now be indicated on the pulse receiver's indicating instrument. Should the deflection be

hardly discernible, reduce the resistance at the pulse

receiver by use of the rotary switch from "4" to "3"

or lower.

m Relevant for detection is NOT the degree of

needle deflection, ONLY the direction.

Start locating. If the needle now deflects e.g. to the

right, then move another step to the right. Keep going

like this until the needle deflects to the left for the

first time. At this point turn your body by 90° and

again follow the needle deflection. When the needle

deflection again changes its direction, reduce the

space between the measuring rods and repeat

the above procedure until you detect the precise

location of the leak. Having removed the fill, the leak

should be visible and can be repaired.

07. Avoiding measurement errors

By earthing the positive pole (see 6.3.3) on the roof,

everything grounded will be indicated. As a result

you are easily led to a lightning arrester, because it

contacts the fill. To avoid this you can either prevent

the connection of grounded parts to the roof e.g. by

placing insulating tape or foil underneath or neutralize

the earthing of these parts e.g. by disconnecting the

lightning protection. Earthed drains (metal drains) are

to be shielded.

7.1 Shielding

If insulation or the removal of an earthing is not an

option, as is the case for e.g. drains or ventilation

shafts, this area is to be shielded. To do so, a closed

loop is installed around this area and connected to the

outer main loop. This way it is also possible to shield

leaks which have already been detected in order to

then proceed with another detection process.

+G-

+G-

pulse generator

main loop

loop

(shielding)

shaft

drain

Page 12

Operating manual – pulse current measuring system PD200

A - 11

EN

7.2 Supposed leak at the centre of the measuring

surface

If with a decreasing deflection you are led toward the

middle M1 of the indicated field, there probably is no

leak. To check this, install some test wiring which is

connected to the loop approx. 1 m beside the measured spot M1. If the previously determined point of

leakage M1 shifts away from the test wiring toward

M2, there is no leak.

7.3 Prolonged drought

In case of prolonged drought the fill is to be prepared

for measurement by means of generous watering. On

roofs without fill a moisture film is all it takes, as long

as it covers the entire area. Cold roofs might necessitate a certain waiting period.

7.4 Earthed metal parts

In order to ascertain whether the metal parts on the

roof are grounded, use the black connection cable

3

and briefly contact the clip terminal to the respective

surface of the metal part. Make sure that the earthing

is switched on at the pressure switch

G

. If a loud

acoustic signal is emitted and the warning

light

A

lights up in red, the metal part is

grounded.

08. Checking of lined ponds and swimming

pools with non-conducting sealing

First measure the floor area of swimming pools.

Following the floor, the walls can be checked for leaks

one by one. For this purpose the loop wiring is affixed

by use of adhesive tape. Lined ponds, too, can be

examined with a loop around the outer rim. However,

the foil here has to be visibly exposed. The measurement is effected by applying the same method as on

the roof. Here, too, sufficient moisture covering the

entire area is required for the measurement.

+

G

1m

M

1

-

M

2

pulse generator

loop wiring

test wiring

cross-section pool

Page 13

Operating manual – pulse current measuring system PD200

EN

A - 12

09. Troubleshooting

Fault description Potential cause

Green indicator light

of pulse generator

PD200 G [4.1

C

] is not

illuminated.

Check mains

connection, fuses

[4.1 D, E].

Indicating instrument at

pulse receiver PD200

E [4.2

L

] does not

deflect to the right

during battery check.

Wrong switch setting,

low battery

Indicating instrument

at pulse receiver

PD200 E [4.2

L

] does

not deflect during the

measurement.

Attenuation set too high;

fill too dry, missing

protective earth

conductor of the mains

supply of the pulse

generator

Red warning light of

pulse generator PD200

G [4.1

A

] lights up and

an acoustic signal is

emitted (current value

of more than 1 A).

Loop wiring in contact

with grounded metal

parts.

10. Maintenance and service

10.1 Battery change

You can check the battery voltage according to

point 5.1.

Required for the operation of pulse receiver

PD200 E are 6 customary batteries of type

LR06 / AM-3 | AA | Mignon.

Detach the 4 screws, lift off the cover, remove the

empty batteries and replace them with new ones.

Please observe the correct polarity when inserting the

batteries.

It is also possible to use rechargeable batteries. If so,

make sure that at least 2000 mA NiMH batteries of

type 06 or AM-3 | AA | Mignon 1.2 V are used. Do

not dispose of used batteries in the household rubbish

or throw them in the fire; instead, dispose of them

according to the relevant legal requirements.

10.2 Maintenance and service of the device

• If required, clean both devices by means of a

slightly damp, lint-free cloth.

• Do not use any aggressive detergents, but only

clean water to moisten the cloth.

• When not in use for a longer period of time, it is

recommended to remove the batteries from pulse

receiver PD200 E.

11. Technical data

11.1 Pulse generator PD200 G

Pulse generator PD200 G

Article number 3.510.010.010

External dimensions

L x W x H

470 x 240 x 250 mm

Weight complete with

standard accessories

8.6 kg

Mains connection 220-240 V, 50-60 Hz

11.2 Pulse receiver PD200 E

Pulse receiver PD200 E

Article number 3.510.010.011

External dimensions

L x W x H

160 x 80 x 55 mm

Weight (incl. batteries) 550 g

Battery voltage 9 V (6 x 1.5 V)

Page 14

Operating manual – pulse current measuring system PD200

A - 13

EN

11.3 Particular equipment features

• compact case to transport the required accessories

• robust, splash-proof design

• easy handling of pulse receiver PD200 E due to less

operating elements

• green signal lamp [4.1

B

] for visual control and

selectable acoustic signal [4.1

F

] for acoustic

control of current pulses from the PD200 G

• alarm signal in the event of a short circuit

12. Miscellaneous

12.1 Operational reliability

Without prior express authorization by Trotec

the device must not be opened or repaired by

unqualified persons. Both the warranty and

operating permit expire when removing or changing

nameplates or labels.

12.2 Seminars

We offer practical seminars for an optimum

application of the PD200. Information ca be obtained

by phone via our information line +49 2452 962-333

or else online via www.trotec.de.

12.3 Disposal

The icon with the crossed-out waste bin

on waste electrical or electronic equipment

stipulates that this equipment must not be

disposed of with the household waste at

the end of its life. You will find collection

points for free return of waste electrical and electronic equipment in your vicinity. The addresses can be

obtained from your municipality or local administration. For further return options provided by us please

refer to our website www.trotec24.com.

The separate collection of waste electrical and electronic equipment aims to enable the re-use, recycling

and other forms of recovery of waste equipment as

well as to prevent negative effects for the environment and human health caused by the disposal of

hazardous substances potentially contained in the

equipment.

You are responsible for deleting any personal data

stored on the waste equipment to be disposed of.

In the European Union, batteries and accumulators

must not be treated as domestic waste, but must be

disposed of professionally in accordance with Directive 2006/66/EC of the European Parliament and of

the Council of 6 September 2006 on batteries and

accumulators. Please dispose of batteries and accumulators according to the relevant legal requirements.

Manufacturer:

Trotec GmbH & Co. KG

Grebbener Straße 7

D-52525 Heinsberg

Phone: +49 2452 962-400

Fax: +49 2452 962-200

E-Mail: info@trotec.com

Heinsberg, Juli 2015

Managing Director: Detlef von der Lieck

Page 15

Operating manual – pulse current measuring system PD200

EN

A - 14

Notes

Page 16

Trotec G mbH & Co. KG

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-0

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...