Page 1

LD6000

EN

OPERATING MANUAL

COMBINATION DETECTOR

TRT-BALD6000-WM-04-EN

Page 2

Table of Contents

1. Safety Instructions 3

2. Intended Use 3

3. Scope of Delivery 3

4. Control Elements and Connecting Ports 4

5. Powering Up and Operating the Device 4

5.1. Microphone Jack and Sensor Port . . . . . . . . . . . . . . . . . . . . . . . . .4

5.1.1. Connecting the Microphones for Acoustic Leak Detection .4

.1.2. Connecting the Hydrogen Sensor for Trace Gas Detection .5

5

5.2. Powering On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6. Navigation and Menu Structure 5

6.1. Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.2. Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.3 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.4. Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.4.1. Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.4.2. Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.4.3. Power Off Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.4.4. Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.4.5. Frequency Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.4.6. Hearing Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.4.7. Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.4.8. Clear Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7. Acoustic leak and pipe detection 6

7.1. Parameter Settings in the Acoustic Modes . . . . . . . . . . . . . . . . . . .7

7.1.1. Manual sensor sensitivity adjustment . . . . . . . . . . . . . . . .7

7.1.2. Automatic sensor sensitivity adjustment . . . . . . . . . . . . .7

7.1.3. Selecting the Filter Presetting . . . . . . . . . . . . . . . . . . . . .7

7.1.4. Volume Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

7.2. Smart Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.2.1. Mode Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.2.2. Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.2.3. Measuring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.3. F&V Mode (Frequency and Volume) . . . . . . . . . . . . . . . . . . . . . . . .9

7.3.1. Mode Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.3.2. Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.3.3. Measuring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.4. V Mode (Level Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.4.1. Mode Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.4.2. Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.4.3. Measuring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.5. PULSE mode

(acoustic pipe detection using a pulse wave generator) . . . . . . . .10

7.5.1. Mode description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

7.5.2. Mode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

7.5.3. Measuring operation . . . . . . . . . . . . . . . . . . . . . . . . . . .10

7.5.4. Filter settings in PULSE mode . . . . . . . . . . . . . . . . . . . . .10

7.6. Clear Current Measurement Series . . . . . . . . . . . . . . . . . . . . . . .10

7.7. Adjusting the filter and switching on the acoustic function . . . . .11

7.7.1. Manual filter frequency adjustment . . . . . . . . . . . . . . . .11

7.7.2. Automatic filter frequency adjustment . . . . . . . . . . . . . .11

.7.3. Switching on the acoustic function

7

during filter adjustment . . . . . . . . . . . . . . . . . . . . . . . . .11

8. Acoustic Long-Term Measuring 11

8.1. Parameter Settings for Acoustic Long-Term Measuring . . . . . . . .12

8.2. Measuring Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

9. Trace Gas Detection 12

9.1. Putting the Device into Operation . . . . . . . . . . . . . . . . . . . . . . . .12

9.2. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

9.3. Normal Measuring with Acoustic Feedback . . . . . . . . . . . . . . . . .13

9.4. Defining Alarm Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

9.5. Measuring with Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . .14

9.6. Clearing the Measurement Series / Clearing Zero Calibration . . .14

10. Saving and Loading Measuring Data 15

11. Transferring Measuring Data To A PC 15

12. Troubleshooting 16

Trace Gas Detection – List of possible errors or faults . . . . . . . . . . . . . .16

Acoustic leak detection – List of possible errors or faults . . . . . . . . . . .16

13. Changing the Battery, Cleaning and Maintenance 17

Changing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Cleaning and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

LD6000 Measuring Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

LD6000 H2 hydrogen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

14. Technical Data 17

15. Information for Use in the Field 18

15.1. Acoustic Leak Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

15.1.1. How Sound Is Created . . . . . . . . . . . . . . . . . . . . . . . . . .18

15.1.1.1. Ground-Borne Sound . . . . . . . . . . . . . . . . . . . .18

15.1.1.2. Structure-Borne Sound . . . . . . . . . . . . . . . . . . .18

15.1.1.3 Current Induced Sound . . . . . . . . . . . . . . . . . . .18

15.1.1.4 Interference Factors . . . . . . . . . . . . . . . . . . . . .19

15.1.2. Schematic Leak Detection . . . . . . . . . . . . . . . . . . . . . . .19

15.1.2.1 Narrowing Down the Leak Using

a Stick Microphone . . . . . . . . . . . . . . . . . . . . . .19

15.1.2.2 Pinpointing the Leak Using a Ground Microphone

. .

19

15.1.2.3 Pipe Detection with Pulse Wave Generator . . . .19

15.2. Leak Detection with Trace Gas . . . . . . . . . . . . . . . . . . . . . . . . . .19

15.2.1 Functioning Principle . . . . . . . . . . . . . . . . . . . . . . . . . . .19

15.2.2 How to Carry Out Leak Detection with a Forming Gas . . .19

15.2.3 Determining Correct Quantities Using

Experience Gained in the Field . . . . . . . . . . . . . . . . . . . .19

This publication replaces all previous publications. No part of this publication may be reproduced, processed using

electronic systems, replicated or distributed in any way without prior written authorisation by us. Subject to technical

modifications. All rights reserved. Names of goods are used without guarantee of free usage and used for the most

part according to the manufacturers‘ syntax. The names of goods used are registered and should be considered as such.

We reserve the right to modify the design in the interest of ongoing product improvement, such as shape and colour

modifications. The scope of delivery may vary from that in the product description. All due care has been taken in

compiling this document. We accept no liability for errors or omissions. © TROTEC

®

2

LD6000 Operating Manual

EN

Page 3

LD6000

This measuring device was designed and manufactured in line with the latest technological advancements and complies

with the requirements as laid down in existing European and national guidelines. Conformity has been certified.

The relevant declarations and documents are in the manufacturer’s possession.

As the user you must read and adhere to the following safety instructions in order to ensure that this

condition is maintained and that no danger results from the use of this device:

1. Safety Instructions

We do not accept any liability for any damages which might occur as a result

of improper use or the non-observance of these instructions. The guarantee

expires with immediate effect in such cases!

These instructions must be read in full before the device

is put into operation for the first time!

For reasons of safety and CE compliance you may on no account carry out any

changes or modifications on either the device itself or any other components

which may be used in connection with this measuring device!

The following instructions must be adhered to before the device is taken into use:

• Do NOT carry out measurements on live components.

• Please observe the measuring range of the measuring sensor.

• Please observe the operating and storage conditions.

• Do NOT immerse the sensor head of the hydrogen sensor in standing water

or any other liquids and do not dip into sludge or any sludge-like substances.

• Do NOT bring the sensor head of the hydrogen sensor into contact

with fine powder or powdery substances.

• The user is solely responsible for determining whether he or she considers

the measuring results to be valid and for any conclusions that are reached or

any measures that are taken as a result thereof. We can neither guarantee

the validity of any measuring results nor can we accept liability for any such

results. We are on no account able to accept liability for any damage which

may be caused as a consequence of the use of these measuring results.

2. Intended Use

The LD6000 is a combo detector designed to allow the user to carry out electroacoustic leak detection in pipe systems and to perform non-destructive pinpoint leak detection in systems which have been previously flooded with trace

gas using the indicative measurement of different hydrogen concentrations.

The device may be used for this purpose only and only within the

technical data parameters as specified.

Any other use is considered to be not intended for this purpose.

In accordance with the EU (European Union) Directives on Waste

Electrical and Electronic Equipment (WEEE), electronic equipment

must not be treated as domestic waste, but must be disposed of

professionally in accordance with Directive 2002/96EU of the

EUROPEAN COUNCIL AND PARLIAMENT of 27 January 2003

regarding old electrical and electronic equipment.

Please dispose of this appliance in a manner appropriate to the

relevant legal requirements at the end of its product life.

3. Scope of Delivery

The following components are included in the

standard scope of delivery:

• LD6000 measuring device

• LD K – sound blocking headphones

• LD6000 BM – universal microphone with magnet adapter

• LD6000 DA – tripod adapter

• LD6000 VL – stick extension with tip

• LD6000 TG – shoulder strap

• PC connecting cable, USB

• LD6000 transport case

The following components are available

as optional accessories:

• LD6000 BMW – wind protected ground microphone

(with dead-man’s button)

• LD6000 VK – connecting cable

• LD6000 BMW DA – tripod adapter for LD6000 BMW ground microphone

• LD6000 H2 – hydrogen hand sensor

• LD6000 H2 – hydrogen ground sensor with integrated pump

• LD6000 transport case V

EN

LD6000 Operating Manual

3

Page 4

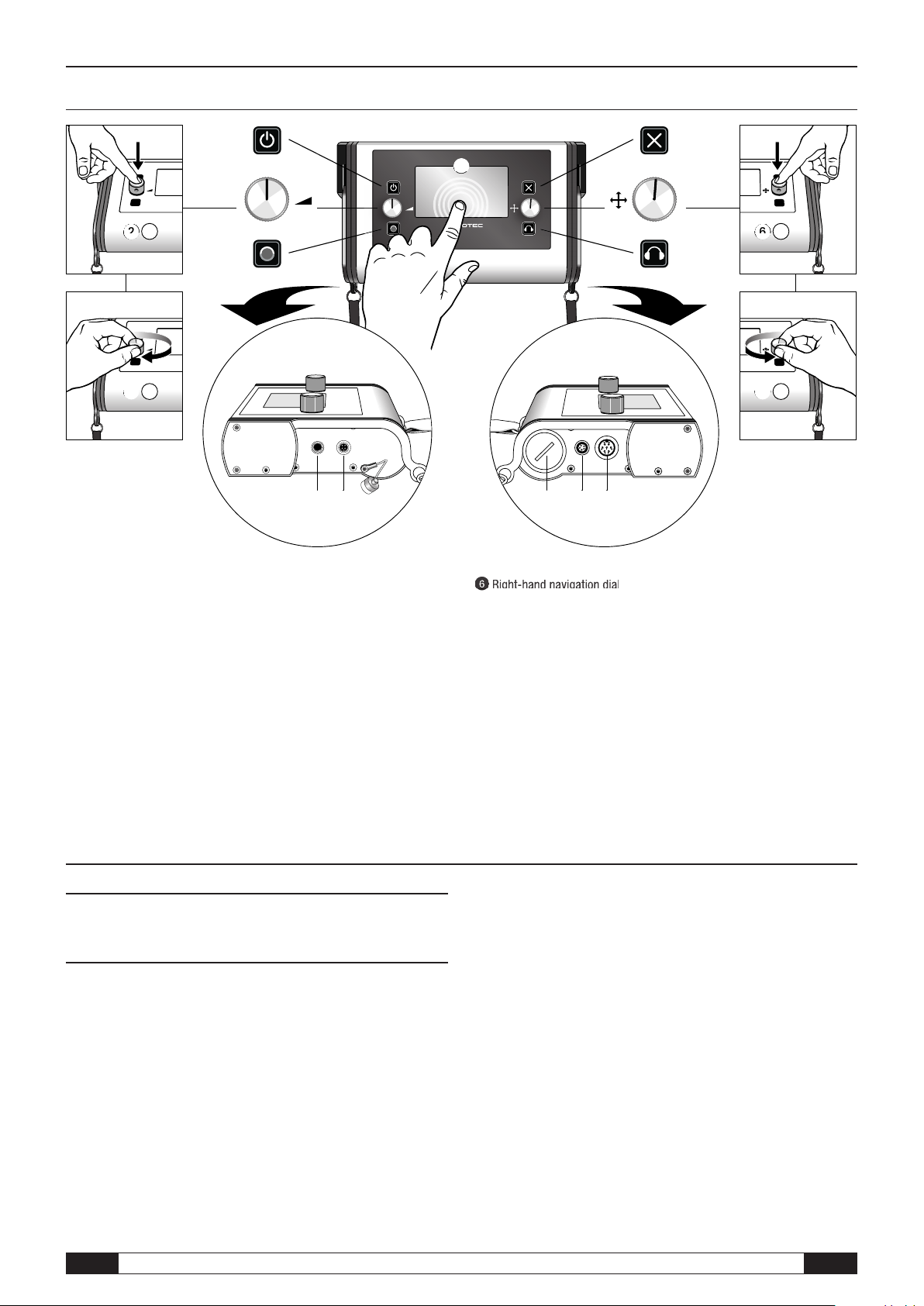

4. Control Elements and Connecting Ports

6

000

A

A

B

B

On/Off key

Left-hand volume dial

This dial has two functions: you can either press A or turn B

the dual function dial. Turn the dial to adjust the volume of your

headphones while measuring is being carried out. Press the dial

to clear the current measurement series.

Record button

Touch display

You can also use the high resolution colour touch screen to carry out

adjustments to the measuring device in place of the dial.

Cancel key

5. Powering Up and Operating

the Device

5.1. Microphone Jack and Sensor Port

First place the batteries into the battery compartment of the LD6000 and connect

all the components which you require to perform your specific measuring operation.

Headphones:

Connect the headphones to the headphone jack of the LD6000 if necessary

(see chapter 4, legend item

The headphones have been designed specifically for use with the LD6000

and for carrying out acoustic leak detection. The state-of-the-art electronics

incorporated in the high-quality hearing protector capsule ensure optimal results

while providing excellent soundproofing qualities.

). Use the supplied LD K headphones only.

Right-hand navigation dial

This dial has two functions: you can either press A

or turn

Turn the dial to access menu and setting functions and to specify selected settings.

Press the dial to confirm selections and settings. The navigation dial on the right

can also be used to execute a variety of settings which will be dealt with more

closely in the following chapters.

B the dual function dial.

Headphone key

Headphone jack

Connection for PC cable

Screw-on battery compartment lid

LD6000 H2 hydrogen sensor connecting port

Microphone jack

5.1.1. Connecting the Microphones for

Acoustic Leak Detection

Please be sure to use one of the following microphones only when carrying

out acoustic leak detection with the LD6000.

LD6000 BM universal microphone

The LD6000 BM is a universal microphone which can be either be used as a

probe microphone or a contact microphone. Connect the LD6000 VL extension

kit to the universal microphone and use as a probe microphone to pinpoint leaks

or screw on the optionally available magnet and use as a contact microphone

when carrying out leak detection where ferromagnetic pipes, for example, are

involved. The contact microphone can then be used in connection with the LD6000

DA tripod adapter as a ground microphone to locate any potential leaks.

Using the LD6000 BMW Ground Microphone

The LD6000 BMW is a wind-protected ground microphone which can be used when

carrying out leak detection on solid, stable surfaces. The LD6000 BMW can be

combined with the LD6000 DM tripod magnet for use on loose or unstable surfaces.

4

LD6000 Operating Manual

EN

Page 5

Depending on the type of acoustic measurement, the microphones

24-01-11 17:00

Help

H

2

24-01-11 17:00

HelpMenu

Date / Time

24-01-11

17:00

Level

3

Language Power off time Backlight

Freq. range Ear protection Touch screen

Clear Memory

can be connected to the LD6000 as follows:

The LD6000 BM as a Ground Microphone:

Connect the LD6000 DA tripod adapter to the base of the LD6000 BM

and connect the microphone to the microphone jack (see chapter 4,

legend item

he LD6000 BM as a Contact Microphone:

T

Connect the magnet base to the base of the LD6000 BM and connect

the microphone to the microphone jack (see chapter 4, legend item

of the LD6000.

The LD6000 BM as a Probe Microphone:

Connect the tip of the LD6000 VL to the base of the LD6000 BM either with or

ithout the extension piece and connect the microphone to the microphone jack

w

(see chapter 4, legend item

LD6000 BMW Ground Microphone:

onnect the LD6000 DM tripod magnet to the base of the LD6000 BMW if

C

necessary. Connect the LD6000 VK connecting cable to the microphone and

plug the microphone into the microphone jack (see chapter 4, legend item

of the LD6000.

) of the LD6000.

) of the LD6000.

)

5.1.2. Connecting the Hydrogen Sensor for

Trace Gas Detection

The LD6000 H2 hydrogen sensor can be connected to the LD6000 to carry out

non-destructive leak detection in systems that have previously been flooded

with trace gas. Connect the sensor to the hydrogen sensor port (see chapter 4,

legend item

You will find instructions on how to carry out measuring in chapter 9 and

further practical information guidelines regarding the use of trace gas

in leak detection in chapter 15.2.

) of the LD6000.

5.2. Powering On and Off

Press the On/Off key to power on (see chapter 4, legend item ). The start

screen appears and changes to the main menu as soon as the measuring device

is ready for use.

Press the On/Off key and hold for approx. 3 seconds to power off

(see chapter 4, legend item

).

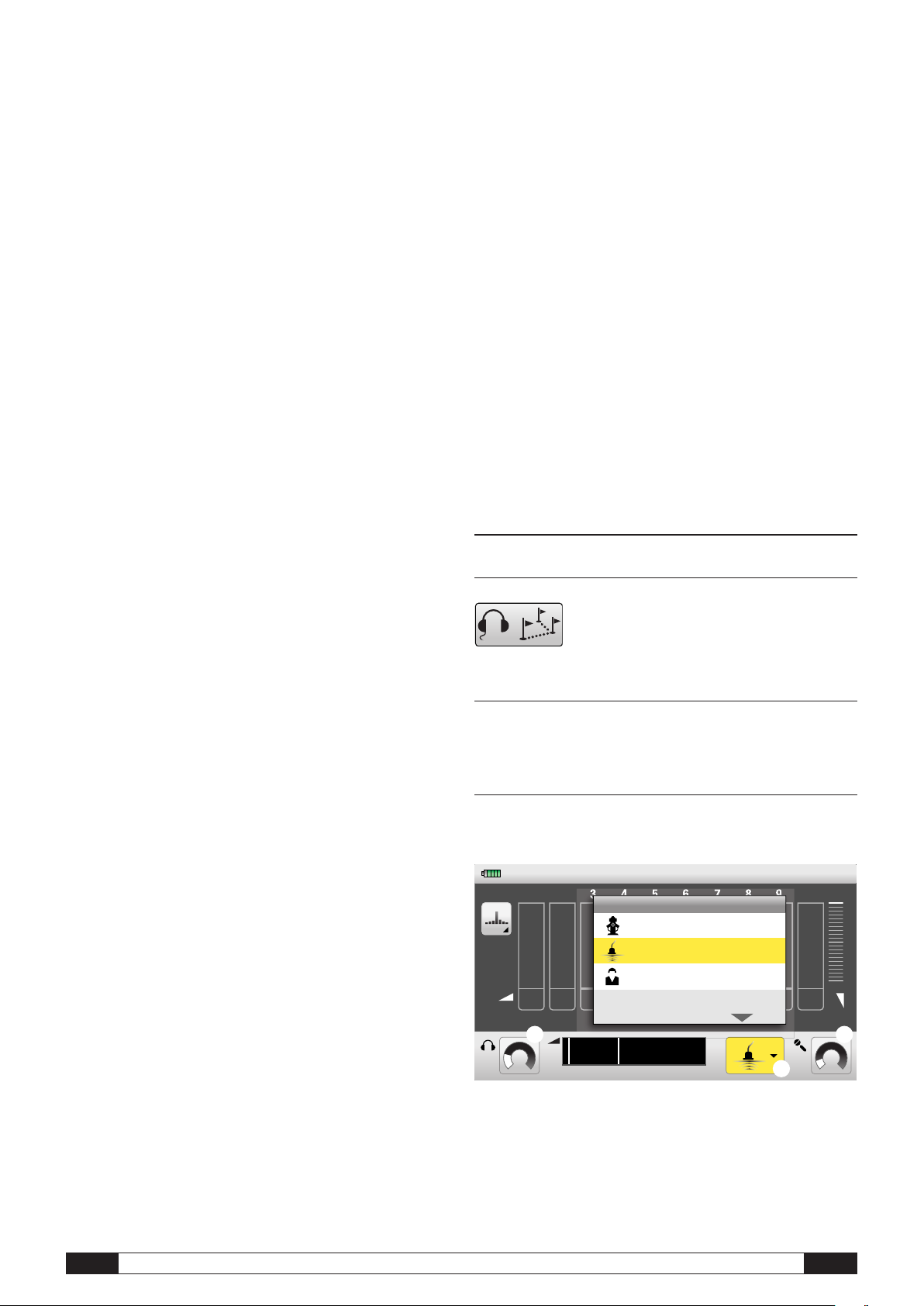

.2. Main Menu

6

You are in the main menu when you power on the LD6000 for the first time.

You can navigate to the following sectors from there:

• Help menu

• Setting menu

• Measuring operation with acoustic leak and pipe detection

)

• Measuring operation acoustic long term measurements

• Measuring operation trace gas detection

• PC data transfer

Press menu in the upper screen bar or the cancel key to return to

the main menu from the selected sector.

(chapter 6.3)

(chapter 6.4)

(chapter 11)

(chapter 9)

(chapter 8)

6.3 Help

The LD6000 is equipped with an integrated help function which can be accessed

from either side. Navigate to the menu item Help in the upper menu bar as

described in chapter 6.1. to get to the Help main page. Scroll to the Help topic

which you would like to find out more about and confirm your selection by

pressing the dial on the right to get to the help text you need.

Press the door symbol within the help sector to navigate back out of the

help sector step by step. Return to the Help main page from a Help text

by pressing the door symbol. Press the door symbol to return to the

main menu from the Help main page.

Press the cancel key to leave the help sector immediately.

You will then return to the main menu.

(chapter 7)

6. Navigation and Menu Structure

6.1. Navigation

The LD6000 has a number of menu and selection boxes which you can select

by either using the touch screen or the navigation dial on the right. When using

the touch screen, simply briefly place your finger on the menu or selection box

you wish to select.

You can also turn the dial either clockwise or anticlockwise

continuously to go through all the menu or selection boxes

in order to get to the box you wish to select.

Active menu items or selection boxes are highlighted in yellow.

which was confirmed.

Press the cancel key to leave the menu or selection box

which is just being shown and return to the last command line

EN

Press the dial when you are finished to confirm your

selection. The menu or selection box which you have

selected will now be shown.

6.4. Settings

Navigate to the settings you wish to select and carry out your selection in order

to perform the following configurations:

LD6000 Operating Manual

You can reach the menu Settings via the Settings symbol

in the main menu.

5

Page 6

.4.1. Time and Date

24-01-11 17:00

SaveHelpMenu

12345678910

100500

3

Mode

Fittings

Ground

User

20 10

%%

05001000

Hz

6

Use the dial on the right to navigate to the selection field of your choice. The

selection field you have chosen will be marked with a red border. Press the

dial on the right to confirm your selection. The field you have selected is now

active and highlighted in yellow.

Press the dial again or press the cancel key to deactivate the field

you have selected.

When the selection field is active, you can enter a value by turning the dial on

the right and pressing the dial to confirm that the value you have entered is

correct. You can now navigate to the next selection field.

To enter the value via the touch screen, first press your finger against the selection field which you wish to activate and then enter the value using the number

pad. Press OK to confirm that the value you have entered is correct and press

DEL to clear the value.

Press the cancel key or the door symbol on the screen to leave the setting menu.

6.4.2. Languages

You can select from one of several display languages. Scroll down to the language

ou wish to select and press the dial on the right to conform your selection.

y

Press the Cancel key or the door symbol on the screen to leave the setting menu.

6.4.3. Power Off Time

You can conserve battery power by selecting a time between 1 and 60 minutes

after which the device then automatically powers off when not in use.

Repeat the procedure as described in Time and Date (see chapter 6.4.1.) to

enter the length of time you have selected.

.4.7. Touch Screen

6

You can use this setting window to deactivate the touch screen function or to

carry out a calibration or performance check.

Use the dial on the right to navigate to the selection field of your choice

and confirm your selection by pressing the dial.

If on/off has been selected, you can activate or deactivate the touch screen

function respectively by pressing the dial.

To leave the setting menu either press the dial or press the Cancel key

r the door symbol on the screen.

o

6.4.8. Clear Memory

You can clear two different memory values in this window setting.

Clear Memory clears all the values that have been saved into the device.

Clear Parameter Memory clears all the user-defined configurations for the high

pass filter, low pass filter and the maximum breadth of the frequency spectrum

in the window setting Frequency Range (see chapter 6.4.5.).

You can also use the touch screen to clear the memory or use the dial on the

right to navigate to the selection field you have chosen before pressing the

dial to confirm your choice. A tick symbol will appear to acknowledge that the

memory has been cleared.

To leave the setting menu either press the dial or press the cancel key or the

door symbol on the screen.

7. Acoustic leak and pipe detection

6.4.4. Backlight

The brightness of the display can be adjusted from 0 to 100 % to suit your

individual requirements. There is also a scale with three individual colour segments which show you just how much battery power the brightness setting

you have selected consumes.

The batteries will last longest when the scale is green and used up

fastest when the scale is red.

Turn the dial on the right to increase or dim the brightness and leave the menu

by either pressing the dial or by pressing the cancel key or the door symbol on

your screen.

6.4.5. Frequency Range

With the LD6000 a frequency range of 0-4,000 Hz can be analyzed. Each of the

measuring modes that can be used during acoustic leak detection has both a

selection of predefined filters as well as a selection of user-defined filters which

can be configured in the setting window Frequency Range.

The settings of the high pass filter (HP), the low pass filter (LP) and the maximum

breadth of the colour spectrum can all be changed.

Repeat the procedure as described in Time and Date (see chapter 6.4.1.) to enter

the configuration you have selected.

6.4.6. Hearing Protection

The LD6000 is equipped with an automatic sound absorber which ensures that

hearing protection guidelines according to BGV B3 (formerly VBG 121) (BGV Accident Prevention & Insurance Association) are complied with when used with

the headphones included in the scope of delivery.

The noise protection intensity of the headphones can be adapted individually to

suit the user. The intensity ranges from 0 (relatively low) to 3 (maximum). Each

of the three stages complies with the requirements as laid down in VBG 121.

The configuration corresponds to the procedure for setting the time

and date as described in chapter 6.4.1.

In order to be able to carry out acoustic leak detection with

the LD6000, first activate the symbol for your acoustic leak

detection measuring operation in the main menu and confirm

your selection.

How to get to the display.

Your measuring device is preset to Smart mode. In addition to the

☞

volume) and the V mode (level mode) or the pipe detection PULSE mode

(acoustic pipe detection using the pulse wave generator). The individual

measuring modes will be explained in detail in chapters 7.2 to 7.5.

Regardless of the measuring mode you have selected, the following parameters

can be set for all the measuring modes that can be used to carry out leak detection

in the same consistent manner:

Smart mode, you may choose to select the F&L (frequency and

Sensor sensitivity setting

Selection of predefined filter settings

Volume setting

6

LD6000 Operating Manual

EN

Page 7

.1. Parameter Settings in the Acoustic Modes

24-01-11 17:00

SaveHelpMenu

12345678910

100500

11 17:

0

0

Save

Help

Menu

234

5

678910

20 0

%

%0 10 20 30 40 50 60 70 80 90 100

%

06001200

H

z

24-01-11 17:00

SaveHelpMenu

12345678910

100500

2

40111 17

:

0

0

Help

Menu

1

234

5

678

9

20 10

%

%0 10 20 30 40 50 60 70 80 90 100

%

06001200

Hz

24-01-11 17:00

SaveHelpMenu

1

2345678910

100500

3

Mode

Fittings

Ground

User

20 10

%%

05001000

H

z

7

7.1.1. Manual sensor sensitivity adjustment

To set the sensitivity of the sensor which is connected to your leak detection

evice, navigate in the display window to the symbol for the sensor sensitivity

d

setting

The sensor sensitivity settings window opens.

T

on a scale from 0 to 100 %. Turn the dial on the right or touch the touch screen

and pull your finger to the sensitivity value which you would like to select.

The sensitivity value is ideal when the control bar

shown. Press the cancel key to leave the window without changing the sensitivity value.

Press the dial on the right to confirm the new setting or press the cancel key.

You can also confirm the setting change by pressing the symbol for the sensor

sensitivity

Important: The current measurement series will be cleared when any

changes are carried out to the sensitivity settings!

The sensitivity value you have selected will either be displayed as a number

or in the form of a tachometer in the symbol for the sensitivity setting

, activate the symbol and confirm your selection.

he microphone amplification factor that has been currently selected is displayed

on the left is half red, as

on the touch screen.

.

7.1.2. Automatic sensor sensitivity adjustment

In addition to the manual adjustment function, the LD6000 is also equipped with

an automatic adjustment function which enables you to set the sensor sensitivity

independently to the optimum setting.

To use this automatic function, navigate to the symbol for the sensor sensitivity

settings in the display

The sensor sensitivity setting window

Press the record button and keep pressed until

you hear a signal tone.

The acoustic signal tells you that the amplification has been automatically set

to the optimum setting.

To close the settings window, press the right-hand dial or the cancel key.

Alternatively you may close the window by pressing the sensor sensitivity

setting symbol

, activate the symbol and confirm your selection.

on the touchscreen.

opens.

To select one of the predefined filter settings, navigate to the filter mode symbol

on the display, activate the symbol and confirm your selection.

The window for the filter presetting selection opens.

There are three presettings to choose from:

• Fittings

• Ground

• User

To carry out the setting, navigate in the window to the presetting

which you wish to select, activate the setting and confirm your selection by

pressing the dial on the right. The window then closes and the symbol for the

selected filter setting appears as the filter mode symbol

Press the cancel key to leave the window without changing the filter setting.

Important: The current measurement series will be cleared when any

changes are carried out to the filter settings!

In addition to the predefined filters, you can change the predefined filter settings

manually in all the measuring modes at any time between individual measurements while leak detection is being carried out. In order to do so, follow

the instructions as described in chapter 7.7.

There is a predefined frequency range from 0 to 2,000 Hz with a

200 Hz high pass filter and an 800 Hz low pass filter which are

ideal for checking the status of fittings and hydrants.

There is a predefined frequency range from 0 to 1,000 Hz with a

50 Hz high pass filter and a 400 Hz low pass filter which are ideal

for checking the status of pipe runs. This is the factory default setting and

therefore the setting when the device is put into operation for the first time.

This presetting uses the filter range which you, the user, defined according

to your own specific filter preferences (see chapter 6.4.5). When this

product leaves the factory the frequency range is from 0 to 1,200 Hz

with a 100 Hz high pass filter and an 800 Hz low pass filter.

,

or

.

7.1.4. Volume Setting

7.1.3. Selecting the Filter Presetting

You can select one of three filters when carrying out acoustic leak detection.

Each of the filters can be changed individually during measuring.

EN

You can adjust the volume of the headphones to suit your requirements. The

volume does not depend on the predefined hearing protection intensity (see

chapter 6.4.6.) which you may have selected.

LD6000 Operating Manual

7

Page 8

The volume you have selected will either be displayed as a number or in the

24-01-11 17:00 SaveHelpMenu

12345678910

100500

20 10

%%

06001200

Hz

Mode

Smart mode

F & V mode

V mode

PULSE mode

ƒ

24-01-11 17:00

S

aveHelpMenu

12345678910

100500

20919826

1

4

1414

20

9

999

888

999

27 29

%%

0

500 1200

H

z

, activate

.

form of a tachometer in the symbol for the volume of the headphones

Changing the Volume Before or After Measuring:

To change the volume of your headphones before or after measuring, navigate

in the window to the symbol for selecting the headphone volume

the symbol and confirm your selection.

The window for selecting the headphone volume opens.

he volume that has been selected for your headphones is displayed on a scale

T

from 0 to 100 %. Turn the dial on the right or touch the touch screen and pull

your finger to the volume which you would like to select.

Press the Cancel key to leave the window without changing the

volume setting.

Press the dial on the right to confirm the new setting or press the Cancel key.

You can also confirm the setting change by pressing the symbol for the headphone volume

A change in volume has no affect on the measuring curve and the current

measurement series is not cleared.

Changing the Volume During Measuring:

on the touch screen.

You can change the volume at any time during

measuring by either turning the dial clockwise if you

would like to turn up the volume or anti-clockwise

if you wish to turn down the volume.

7.2. Smart Mode

7.2.1. Mode Description

The Smart Mode displays a double bar comprising a noise level indicator

and the smart indicator for enhanced leak detection.

The smart indicator is based on a complex calculation and analysis system which

includes factors like frequency, sound levels and evaluations.

This algorithm has been tried and tested and is especially effective when

background noise levels are high and the sound emitted by the leak is very quiet.

7.2.2. Mode Selection

.2.3. Measuring Procedure

7

Press the record button to start measuring. Keep the button pressed for the

duration of the measuring operation. The device will stop measuring when the

record button is no longer pressed.

The display can show a measurement series which is made up of the last ten

individual measurements.

The first measurement is displayed on Position 1. Each further measurement –

beginning with Position 2 – will be placed on an ascending position. When

Position 10 has been reached, the oldest of the ten measurements, i.e. the

measurement on Position 1 will be cleared so that the last measurement that

was taken last is always on Position 10.

The double bar can be used to visualise the following information

in smart mode:

The right-hand, thin bar

from 0 to 100. The grey bar represents the minimum measured value, i.e. the

quietest sound that is relevant for the detection of the leak. This value is also

displayed as a number below the bar

In addition the sound value that is currently being measured is displayed as

such on the bar

The left-hand, broad bar

on a complex set of calculations and analysis methods (see chapter 7.2.1).

The higher the smart indicator value, the more reliable the information on the

leak. The smart indicator bar also displays the colour of the frequency which

was used for the calculation that is required to provide an indication on the

whereabouts of the leak. According to the rule of thumb, the closer the leak,

the higher the smart indicator bar value and the lighter the colour.

The smart indicator bar value is also displayed as a number next to

the actual bar

The symbol of a waterdrop

level in the measurement series and therefore the point at which a leak is

most likely.

.

shows the sound amplitude on a sound level scale

.

.

is the smart indicator. The smart indicator is based

is used to denote the highest minimum sound

Because the measuring values determined during leak detection

☞

a specific mode, measuring modes can be changed between individual

measurements and the measurements that were taken prior to the

The measuring mode symbol on the display shows which mode

has been set.

If the smart mode has not already been set, navigate to the measuring mode

symbol

The window for selecting the measuring mode will then open.

To set the smart mode, navigate to the list item smart mode and confirm your

selection by pressing the right-hand dial.

The window will close and the smart mode symbol will be shown

, activate the symbol and confirm your selection.

8

.

LD6000 Operating Manual

mode change can be either analysed or measuring can be continued.

The measurement series remains unaffected and is not cleared.

are not determined using a specific mode, but only shown in

EN

Page 9

.3. F &V Mode (Frequency and Volume)

24-01-11 17:00

S

aveHelpMenu

12345678910

100500

Hz

20 10

%%

06001200

Hz

1

234

5

6

7

Mode

Smart mode

F & V mode

V

mode

ƒ

ƒ

P

ULSE mode

24-01-11 17:00

SaveHelpMenu

12345678910

100500

Hz

20

160191702619020160

160160160

170170170

190190190

160160160

05001000

Hz

ƒ

27 29

%%

24-01-11 17:00 SaveHelpMenu

12345678910

100500

%

20 10

%%

06001200

Hz

1

234

5

6

7

Mode

Smart mode

F & V mode

V mode

ƒ

PULSE mode

24-01-11 17:00

SaveHelpMenu

12345678910

100500

%

20 19 26 20

05001000

Hz

27 29

%%

7

.3.1. Mode Description

7

The sound amplitude of the minimum measured value (bar height) and

the frequency range with the highest sound amplitude (bar colour) are

displayed as a bar in F& V mode.

.3.2. Mode Selection

7

The measuring mode symbol on the display shows which mode has been

set. If the F& V mode has not already been set, navigate to the measuring mode

symbol

selecting the measuring mode will then open.

To set the F &V mode, navigate to the list item F & V mode and confirm your

selection by pressing the right-hand dial. The window will close and the F & V

mode symbol will be shown

, activate the symbol and confirm your selection. The window for

.

The symbol of a waterdrop is used to denote the highest minimum sound

level in the measurement series and therefore the point at which a leak is most

likely.

Because the measuring values are not determined using a

☞

modes can be changed between individual measurements and the measurements that were taken prior to the mode change can be either analysed or measuring can be continued. The measurement series remains

unaffected and is not cleared.

specific mode, but only shown in a specific mode, measuring

7.4. V Mode (Level Mode)

7.4.1. Mode Description

In V mode, the measured minimum value only is

displayed as a single bar.

7.4.2. Mode Selection

7.3.3. Measuring Procedure

The measuring mode symbol on the display shows which mode is currently

being used. If the V mode has not been set, navigate to the measuring mode

symbol

The window for selecting the measuring mode will then open.

To set the V mode, navigate to the list item V mode and confirm your selection

by pressing the right-hand dial.

The window will close and the V mode symbol will be shown

, activate the symbol and confirm your selection.

7.4.3. Measuring Procedure

Press the record button to start measuring. Keep the button pressed for the

duration of the measuring operation. The device will stop measuring when the

record button is no longer pressed.

The display can show a measurement series which is made up of the last ten

individual measurements. The first measurement is displayed on Position 1.

Each further measurement – beginning with Position 2 – will be placed on

an ascending position. When Position 10 has been reached, the oldest of the

ten measurements, i.e. the measurement on Position 1 will be cleared so that

the last measurement that was taken last is always on Position 10.

The single bars are used to visualise the following information

in F&V mode:

As is the case in V mode, the height of the bar shows the sound amplitude on a

sound level scale from 0 to 100. In addition, the colour of the bar visualises the

frequency range with the highest noise amplitude. The brighter the colour, the

higher the frequency.

The sound level

under the bars.

In addition, the sound value that is currently being measured is displayed

in the form of a bar

EN

and frequency are also shown as a number

.

LD6000 Operating Manual

Press the record button to start measuring. Keep the button pressed for the

duration of the measuring operation. The device will stop measuring when the

record button is no longer pressed. The display can show a measurement series

which is made up of the last ten individual measurements.

The first measurement is displayed on Position 1. Each further measurement –

beginning with Position 2 – will be placed on an ascending position. When

Position 10 has been reached, the oldest of the ten measurements, i.e. the

measurement on Position 1 will be cleared so that the last measurement that

was taken last is always on Position 10.

.

9

Page 10

When in V mode, the height of the bar shows the noise amplitude of the

24-01-11 17:00 SaveHelpMenu

12345678910

100500

%

20 10

%%

06001200

Hz

1

234

5

6

7

Mode

Smart mode

F & V mode

V mode

ƒ

PULSE mode

24-01-11 17:00 SaveHelpMenu

1

2345678910

100500

%

3

5463050

20 10

%%

0

sec

4

0-1000

Hz

measured minimum value on a sound level scale from 0 to 100.

In addition, the value that is being currently measured is displayed

o

The symbol of a waterdrop

sound level in the measurement series and therefore the point at

which a leak is most likely.

☞

mode, measuring modes can be changed between individual measurements and the measurements that were taken prior to the mode change

can be either analysed or measuring can be continued. The measurement

series remains unaffected and is not cleared.

n the bar

.

is used to denote the highest minimum

Because the measuring values during leak detection are not

determined using a specific mode, but only shown in a specific

7.5. PULSE mode (acoustic pipe detection using a

pulse wave generator)

7.5.1. Mode description

The pulse wave generator produces a pressure wave which is repeated

periodically and can be picked up further down the pipe by the LD6000

and a connected ground microphone. This enables you to detect non-metallic

water pipes up to a depth of 2 metres without first having to interrupt any services

or turn off any water supplies.

7.5.2. Mode selection

In addition, the current measurement is displayed as a bar value .

The bar which shows the actual value is a practical aid for detecting pipes

because it clearly shows the impulse which the LD-PULS is generating. The

olume and frequency of the impulse are at their highest directly above the pipe.

v

The interval and intensity of the impulses are displayed visually in a four-second

window on the bottom time axis

.

7.5.4. Filter settings in PULSE mode

In contrast to the leak detection filter presettings (see chapter 7.1.3.), a filter

mode symbol

There is a predefined frequency range with a 0 Hz high pass filter and a 1,000

Hz low past filter. This is the factory setting which you would use for your first

measurement.

The frequency range can be adjusted at any time to suit your individual

requirements. To adjust the frequency range, navigate to the filter mode symbol

, activate the symbol and confirm your selection.

The acoustic filter adjustment window opens.

Follow the instructions for adjusting the filter frequencies as described in

chapter 7.7.1.

which is only available in this mode appears in PULSE mode.

The measuring mode symbol displayed in the display shows you which mode

has been currently selected. If the PULSE mode has not already been selected,

navigate to the measuring mode symbol

your selection.

The measuring mode selection window opens.

To set the PULSE mode, navigate to the list item PULSE mode and confirm your

selection by pressing the right-hand dial.

The window closes and the PULSE mode symbol is displayed as a measuring

mode symbol

.

7.5.3. Measuring operation

Press the record button to start a measurement and release the record button

to stop the measurement. The measurement will last for as long as you keep

the record button pressed.

The last ten individual measurements can be displayed as a measurement series

in the display. The first measurement is displayed on position 1 and each new

measurement is displayed in ascending form from position 2 upwards. When

the tenth measurement has been carried out, the first position, ie. the oldest

measurement will be deleted and the last measurement will be displayed on

position 10.

In PULSE mode, the height of the bar shows the sound amplitude of the measured

minimum value on a scale of 0 to 100.

, activate the symbol and confirm

We recommend that you do NOT use the automatic function

☞

adjust the filter frequencies manually. As a rule, the following applies: the

greater the distance between the LD6000 and the LD-PULS, the lower the

frequency you should select. A frequency window ranging from 0 - 350 Hz

has proved to be particularly effective when working in the field.

(chapter 7.7.2.) in PULSE mode. Instead we recommend that you

7.6. Clear Current Measurement Series

As many as 10 single measurements can be carried out with the LD6000 and

used as a measurement series which can then be seen on the display. This series

remains in the memory – even when the device is powered off – unless certain

parameters are changed.

This function is of a particular advantage in the field as this means that the last

measuring value can then be “carried over” to the next measuring point where

the measurement series can then be continued.

It must be pointed out that the measurement series will be cleared as soon as

the sensor sensitivity settings or the predefined filter settings are changed.

Follow the instructions in chapter 10 to find out more on how the measurement

series can be saved permanently.

To clear the individual measurements or the measurement

series shown on the display, press the dial on the left and

keep pressed for 3 seconds. All 10 positions on the display have now been cleared and are empty.

10

LD6000 Operating Manual

EN

Page 11

.7. Adjusting the filter and switching

24-01-11 17:00

SaveHelpMenu

100500

12345678910

20919826

1

1209

990192620

88

1111

99

05001000

Hz

01000

5

0400

27 29

%%

A

B

24-01-11 17:00

SaveHelpMenu

100500

12345678910

209198261120

9

990192620

88

1111

99

05001000

Hz

01000

50 400

27 29

%%

A

B

24-01-11 17:00

SaveHelpMenu

100500

12345678910

20919826

1

1

20

9

990192620

88

1111

99

05001000

H

z

01000

5

0400

27 29

%%

7

on the acoustic function

7.7.1. Manual filter frequency adjustment

You can change the preselected filter frequencies at any time between individual

measurements in each of the three acoustic leak detection measuring modes.

Navigate to the frequency range display

confirm your selection.

The window for the acoustic filter adaption will then open.

The high pass filter, the low pass filter, the frequency spectrum and the status

symbol for the acoustic activation are all presented on the display.

The frequency spectrum is also presented as a colour gradient.

Dark colours indicate low frequency sounds and bright colours

indicate high frequency sounds.

The preset high pass filter is active. This is indicated by the red high pass filter

value field

A and the red high pass filter bar B in the frequency band.

To change the frequency value of the high pass filter, turn the right-hand dial or

touch the touch screen and pull the high pass filter bar to the position where

you would like it to be.

, activate the display and

When working in the field, the setting for

the low pass filter is ideal when all the high

frequency sounds lie within the selected range

and the high pass filter is set so that the bottom

rong filter adaptation

W

left-hand sector of the selection box is on

he right-hand sloping flank of the biggest

t

part of the spectrum.

ress the cancel key to leave the window.

P

ight filter adaptation

R

7.7.2. Automatic filter frequency adjustment

In addition to the manual adjustment function, the LD6000 is also equipped with

an automatic adjustment function which enables you to set the frequency ranges

independently to the optimum setting.

To use this automatic function, navigate to the frequency range display

the display and confirm your selection.

The acoustic filter adjustment window

opens.

Press the record button and keep pressed until you hear a signal tone.

The acoustic signal tells you that the frequency values for the high pass filter

and the low pass filter have now been automatically set to the optimum setting.

To close the window, press the cancel key.

in

To change the frequency value of the low pass filter, press the right-hand dial

once. The low pass filter is now active. This is indicated by the red high pass

filter value field

A and the red high pass filter bar B in the frequency band.

To set the frequency value of the high pass filter, turn the right-hand dial or

touch the touch screen and pull the high pass filter bar to the position where

you would like it to be.

7.7.3. Switching on the acoustic function during

filter adjustment

The LD6000 is equipped with a function which allows you to activate the acoustics

while the filter is being adapted.

This function can be turned on or off by pressing the headphone key. The status

symbol for the acoustic activation function in the window

shows the current

function status.

When this function is active, the sound from the microphone is passed

on through to the headphones while the filter is being adapted.

This means that you can either enter numerical values to set the limits for the

frequency ranges you wish to select or you can set the limits using the acoustic

method.

8. Acoustic Long-Term Measuring

You can carry out long-term measuring with the LD6000 in

order to determine over a longer period whether a certain

sound can be attributed to either a leak or a sound that is

coming from the surrounding area (noises generated by a canal, pump etc.)

To select the acoustic long-term measuring mode, activate the symbol for

acoustic long-term measuring in the main menu and confirm your selection.

You will then arrive at the display.

EN

LD6000 Operating Manual

11

Page 12

.1. Parameter Settings for

24-01-11 17:00

SaveHelpMenu

100500

20 35

%%

0

500 1000

Hz

sec 0 50 100 150 200 250 300

24-01-11 17:00

S

aveHelpMenu

100500

20 35

%%

0

500 1000

Hz

sec 0 50 100 150 200 250 300

H

2

24-01-11 17:00

SaveHelpMenu

100 050 00

5 4 3 2 1

100 050 00

1

0

000

0

8

Acoustic Long-Term Measuring

.2. Measuring Procedure

8

You can set the following parameters and carry out the

following actions on the display:

:

:

:

• Set the sensor sensitivity

• Select the filter presetting

• Adapt the filter and activate the acoustics manually

• Set the volume

• Set time intervals for long-term measuring

• Start long-term measuring (chapter 8.2)

• Clear the display (chapter 8.2)

• Stop/continue long-term measuring (chapter 8.2)

Setting the sensor sensitivity

To set the sensor sensitivity, perform the same steps as described for current

measurements in chapter 7.1.1.

Selecting the filter presetting

To select the filter presetting, perform the same steps as described for current

measurements in chapter 7.1.2.

Adapting the filter and activating the acoustics manually :

To adapt the filter and activate the acoustics manually, perform the same

steps as described for current measurements in chapter 7.6.

Setting the volume

To select the volume for long-term measuring, perform the same steps as

described for current measurements in chapter 7.1.3.

In addition, the volume function for long-term measuring can be

deactivated at any time by pressing the headphone key.

The volume that has been set is not affected by the mute function. The mute

function mutes the headphones.

Press the record button or the record symbol on the display to start

long-term measuring. The measurement begins and ends with the

preselected times.

You can interrupt the recording at any time by pressing the pause symbol

the record symbol

pause symbol, the record symbol or the record button.

or the record button. Continue measuring by pressing the

To clear the long-term measurement series on the

display, press either the left-hand dial and keep pressed

for 3 seconds or by pressing the clear symbol

on the display.

9. Trace Gas Detection

The LD6000 is excellently-suited for detecting leaks together with the optionally

available LD6000 H2 hydrogen sensor and the formation gas type 95/5, which

comprises 95 % nitrogen and 5 % hydrogen.

To select the trace gas detection, activate the symbol

for the trace gas detection in the main menu and

confirm your selection.

You will then arrive at the display.

9.1. Putting the Device into Operation

,

Selecting the time intervals for long-term measuring

There are four predefined time intervals available for selection:

5, 15, 30 and 60 minutes.

To select a time interval, navigate to the time interval symbol

on the display and confirm your selection.

The window for setting the time interval will open.

Navigate to the time interval you wish to select by pressing the right-hand dial

or by touching the touch screen and confirm your selection by pressing the

right-hand dial or press the cancel key.

The time scale

that has been selected.

on the display will now display the time interval

:

As soon as you change to trace gas detection on the display when the hydrogen

sensor is connected, the device recognises the sensor and warms it up to

operating temperature.

This warm-up phase takes approximately 3 minutes and is displayed as a

blue progress bar

The sensor self-calibrates during the warm-up phase. This self-calibration is

designed to determine the base value for the different hydrogen concentrations

that are detected during measuring.

below the numerical display.

LD6000 Operating Manual

12

EN

Page 13

The sensor calibrates independently according to the existing hydrogen con-

24-01-11 17:00

SaveHelpMenu

100 050 00

5 4 3 2 1

20 35 11

100 050 00

1

300

0

300

H2

24-01-11 17:00

SaveHelpMenu

100 050 00

5 4 3 2 1

100 050 00

1

250

0

250

H2

centration in the surrounding air.

This is why it is especially important that you ensure that the sensor is not near

hydrogen source during the warm-up phase.

a

We therefore recommend that you either go outside into the open with the

LD6000 during the warm-up phase or remain in place where you know that

the hydrogen concentration is lower (< 1 ppm H

As soon as the sensor has reached its operating temperature the warm-up

bar disappears and the LD6000 is ready to use.

).

2

9.2. Display

You can read and adjust the following parameters and carry out the following

actions on the display for trace gas detection:

• Bar display

current value underneath it.

• Preset alarm value

• Digital display with the current measuring value

• Five position bars for the bar display and the numerical display

of the previous 5 measurements beginning with Position 1 for the last measurement up to Position 5 for the fifth of the last previous

5 measurements.

• Start / Stop symbol

• Perform zero calibration

• Switch the measuring tone on and off

• Define the alarm threshold

• Record symbol for the measurement operation

The functions and setting possibilities of these parameters will be explained in

detail in the following chapters.

and the number which displays the

to start and stop a measurement

9.3. Normal Measuring with Acoustic Feedback

Information on the displayed values:

☞

The LD6000 H2 hydrogen sensor is able to detect highly resolved hydrogen

concentrations from 10 to 20,000 ppm.

The LD6000 displays the detected hydrogen concentrations as digits but

without an accompanying value in a range from 0 to 1,000 digits.

Important: The correlation from display and H

but logarithmic. The displayed digital value does not automatically

correspond with the ppm value!

concentration is not linear,

2

Starting Measuring:

Press the start/stop symbol

to begin a measurement. The measurement and will be continued until one of

the keys is pressed to discontinue measuring.

A pulsating record symbol

The current measuring value is either displayed as a number on the digital dis-

play

or as both as a number and a bar on the right-hand red bar display .

The display value increases if you get closer to an area with a higher hydrogen

concentration. The value decreases again when you move away from this area

or enter adjoining areas with lower hydrogen concentrations.

There is a hydrogen concentration of 250 digits on the display as

shown in the example.

Activating the Acoustic Feedback:

As it may become difficult to keep an eye on the display the whole time while

trying to detect the direction which the biggest trace gas increase is coming

from, the LD6000 is also equipped with an acoustic feedback to help you during

leak detection.

The LD6000 is equipped with a signal display which is connected to a piezo

element and additionally able to transmit a signal tone to the connected LD K

headphones.

The acoustic feedback is initially set to “deactivated”.

To activate the acoustic feedback, navigate to the measuring tone symbol

with the right-hand dial and activate the symbol by either pressing the dial or

by directly touching the touch screen where the measuring tone symbol

When the acoustic feedback is activated, the sound is emitted via both the

connected headphones as well as the internal piezo element.

The sound is emitted in the same volume and the same frequency via the

piezo element. The tone sequence increases when the measuring values increase and decreases when the measuring values decrease.

The sound is emitted in the same volume as a continuous tone via the

headphones. The frequency depends on the measuring value. The frequency

increases when the measuring values increase (the tone becomes higher) and

decreases when the measuring values decrease (the tone becomes higher).

on the touch screen or press the record button

indicates that measuring is being carried out.

is.

EN

LD6000 Operating Manual

13

Page 14

.4. Defining Alarm Thresholds

24-01-11 17:00

SaveHelpMenu

100 050 00

5 4 3 2 1

20 35 11

100 050 00

1

0

0

2

40111 17

:

0

0

Help

Menu

543

212

035

11

Digits

02004006008001000

9

In order to allow you to identify certain hydrogen concentrations more easily,

the LD6000 is equipped with a permanent alarm function with alarm thresholds

that can be configured individually. The factory setting is 500 digits.

An acoustic alarm sounds when the alarm threshold is exceeded. The warning

tone sounds different than the standard feedback signal.

When the alarm tone sounds via the piezo element, the signal changes

constantly in a tone sequence with long tones in short intervals.

When the alarm tone sounds via the headphones, the continuous tone is

emitted without interruption with maximum frequency when the predefined alarm

hresholds have been exceeded.

t

To set the alarm threshold which you wish to select, navigate in the display

window to the symbol for the threshold setting

confirm your selection.

The window for setting the alarm threshold will then open.

The current alarm threshold is displayed on a step scale ranging from 0 to

1,000 digits.

You can select a new threshold value by either turning the dial on the right

or placing a finger on the touch screen and pulling it to the value which

you wish to select.

Press the cancel key to leave the window without changing the

threshold value.

Press the dial on the right to confirm your selection or press the cancel key.

, activate the symbol and

The digit display now shows two values: the relative measured value (relative

to the defined reference value, 000-display at the point of zero calibration) as

large digits in the middle of the digit display and the measured absolute measured value as reference value when zero calibration was carried out in the lower

right-hand area of the digital display.

The displayed value changes as follows when the hydrogen concentration

increases: the relative measured value shows the increasing values in relation

to the defined reference value. The absolute measured value shows the actual

existing hydrogen concentration.

The relative measured value is not only displayed on the digital display but

also on the red bar display as well as on the numerical display below.

If the hydrogen concentration sinks below the defined reference value, the

displayed relative measured value no longer changes (000), but the absolute

easured value still displays the existing hydrogen concentration.

m

Here an example to explain how this works:

There are different hydrogen concentrations in three fictive adjoining zones. The

concentration in Zone 1 is 200 digits, the concentration in Zone 2 is 300 digits

the concentration in Zone 3 is 100 digits.

First measuring is carried out in Zone 1.

The measured value on the display is 200 digits.

Now a zero calibration is carried out in Zone 1 and the existing

hydrogen concentration (200 digits) is defined as the reference

value. When a second measurement is carried out in Zone 1,

the digital display now shows a relative measured value of 000

and an absolute measured value of 200.

A new measurement is carried out in Zone 2. The digital

display now shows a relative measured value of 100

and an absolute measured value of 300.

Then measuring is carried out in Zone 3. After the measurement

has been carried out, the digital display only shows the absolute

measured value 100 and no measuring value (000).

9.5. Measuring with Zero Calibration

It may become necessary to use the zero calibration function to define a reference

value during measuring so that fluctuating hydrogen concentrations at different

measuring points can be defined more clearly.

As soon as a reference value has been defined a value that is relative to the

newly defined reference value appears on the display.

This can be of particular advantage when sections of pipe are measured in areas

with high hydrogen concentrations, because it allows you to narrow down the

position of the leak on a step-by-step basis.

To determine a reference value, navigate to the zero calibration symbol

with the right-hand dial and activate the symbol by pressing the dial. You

can also activate the zero calibration symbol by touching the symbol on touch

screen.

Important: The current measurement series is cleared when zero

calibration is performed!

When you perform a zero calibration you are defining the existing hydrogen

concentration, i.e. the current measuring value, as the new reference value.

This in turn changes the displayed measurement value when compared to the

normal measurement with zero calibration.

Important: The defined alarm thresholds are always set with regard to the

relative measured value! An alarm threshold of 150 digits, as shown in the

example above, would only trigger a signal after the first measurement in Zone

1 before zero calibration was carried out, even though the absolute measured

value that was measured in Zone 1 (after zero calibration) and also in Zone 2

was above the alarm threshold.

9.6. Clearing the Measurement Series /

Clearing Zero Calibration

You can use the clear function to clear both the measurement series and the

zero calibration in trace gas mode.

Either of the two cannot be cleared individually. You can either clear both of

them or neither of them.

Press the left hand dial to clear both the zero calibration

and the current measurement series. Both memory

parameters are now cleared. There are now no measuring

To save measurement series permanently into the memory,

follow the instructions as described in chapter 10.

values and no reference value.

14

LD6000 Operating Manual

EN

Page 15

10. Saving and Loading

24-01-11 17:00

H

elpMenu

S

elect memory

1

2

3

4

5

24-01-11 17:00

HelpMenu

Select memory

1 24-01-11 17:00

2

3

4

5

24-01-11 17:00

HelpMenu

Measuring Data

Any measurement reading and any measurement series can be saved to the

internal memory of the LD6000 permanently and either called up at a later point

or transferred to your PC.

The menu item “save” is only visible when you are in a measuring mode.

To save a measurement or a measurement series into the memory, navigate to

the menu item “save” with the right-hand dial and press the dial to confirm your

selection.

You can also use the touch screen to select the memory item “save”.

The display now changes to the memory page.

Saving Measuring Data

You can also confirm your selection directly by pressing the symbol

Load Measuring Data on the touch screen.

You can then call up the measuring data you have saved from any one of the

emory spaces. Turn the right-hand dial to navigate to the memory space you

m

wish to select and confirm your selection by pressing the display symbol Load

Measuring Data

The measuring value you have selected is now displayed.

.

11. Transferring Measuring Data

To A PC

The measuring values which you have saved to your internal memory can be

transferred to your PC for further assessment or documentation.

You will need the PC connecting cable included in the scope of delivery and a

software tool which you can download free of charge at www.trotec.com.

The software tool which you may choose to download is absolutely

☞

The software is provided without any form of support and any form of

guarantee. The intuitive user interface is exceptionally easy to work with

and understand. Further information regarding the software and its use can

be found in the application included.

free of charge and is not a part of the standard scope of delivery.

To save your measuring data, navigate to the display symbol Save Measuring

Value

You can also confirm your selection directly by pressing the symbol Save

Measuring Value on the touch screen.

The measuring values can then be saved to any memory space you wish. Turn

the right-hand dial to navigate to 1 of the 20 memory spaces and confirm your

selection by pressing the display symbol Save Measuring Value

The measuring value is now on the memory space which you

previously selected.

You can navigate to memory spaces outside the touch screen display

by touching the navigation symbols

You can either leave the memory page by pressing the cancel key

or the door symbol on the display.

Loading Measuring Data

and confirm your selection by pressing the right-hand dial.

.

.

To transfer your data to the PC, navigate to the main menu and select

the Data Transfer display symbol (see chapter 6.2).

The display now changes to the memory transfer page.

Please ensure that your PC is connected to the LD6000 and then navigate to

the display symbol Data Transfer . Confirm your selection and follow the

instructions as shown on your PC.

To call up any data that you have previously saved, navigate to the display symbol

Load Measuring Data

dial.

EN

and confirm your selection by pressing the right-hand

LD6000 Operating Manual

15

Page 16

12. Troubleshooting

Acoustic leak detection – List of possible errors or faults:

Error⁄Fault Description Possible Cause Recommended Action

No sound in the headphones

The screen remains blank.

1. The sound receiver or the

headphones are not connected

properly

2. Wrong filter settings

3. The cable that connects the

sound receiver and the unit

appears to be defective.

4. The cable that connects the

headphones to the unit appears

to be defective (in such a case

the sound level indicator on the

display still works properly!)

5. Memory settings

1. The batteries are empty

2. The unit is defective Please contact our Customer Support Centre.

Check the connections between the connected sound receiver and the

connected headphones and the LD6000.

Select a broader frequency range, e.g. 50 to 2,000 Hz and generate a clearly

audible sound by scratching a surface or turning on a radio, for example.

If the action you have carried out causes the numerical or bar display to change

and these sounds can be clearly heard in your headphones, then you can be

sure that the headphones and microphone are working properly.

Now carry out the measurement again and adapt the frequency range

to suit the measuring operation.

• Check the connections between the connected sound receiver

and the LD6000.

• Replace the cable with a spare cable if possible or use the cable from a

second LD6000 to check to see if the sound receiver is working properly.

• Check the connections between the connected headphones and the LD6000.

• Connect a spare pair of headphones which you may have or another pair

from a second LD6000 to the unit and check the function again.

If the actions that you have carried out have not been successful, then go to

“Clear memory” in the menu and clear the parameter memory.

If you can still not hear anything over the headphones, then please contact

our Customer Support Centre.

Replace the batteries inside your unit with new ones of the

same high quality and type.

1. The brightness setting has not

been set correctly.

Display brightness too dim

2. Battery power very low

The company logo remains on the display 1. The unit is defective Please contact our Customer Support Centre.

Go to the menu item “Settings” and increase the display brightness.

Replace the batteries inside your unit with new ones of the

same high quality and type.

Trace Gas Detection – List of possible errors or faults:

Error ⁄Fault Description Possible Cause Recommended Action

1. The sensor cable has not been

connected properly.

You cannot commence measuring,

the cross symbol above the function key

does not disappear,

the sensor does not warm up

No or hardly any display of existing

gas concentrations

Reaction time too long 1. Sensor is not working properly Please contact our Customer Support Centre.

2. Port ⁄ Jack or plug defective

3. Cable defective

4. Sensor defective Please contact our Customer Support Centre.

1. Sensor was connected to the

unit in a room with existing

gas concentrations

2. Sensor defective Please contact our Customer Support Centre.

• Check the connections between the connected H2 sensor and the LD6000.

• Replace the sensor with a spare sensor if possible or use the sensor from a

second LD6000 to check to see if the sensor is working properly.

• Check the connections between the connected H2 sensor and the LD6000.

• Replace the sensor with a spare sensor if possible or use the sensor from a

second LD6000 to check to see if the sensor is working properly.

• Check the connections between the connected H2 sensor and the LD6000.

• Replace the sensor with a spare sensor if possible or use the sensor from a

second LD6000 to check to see if the sensor is working properly.

Leave the room and go somewhere where existing hydrogen levels are normal,

e.g. out in the open. Power up the unit AGAIN and then return to the room

which you had previously left.

16

LD6000 Operating Manual

EN

Page 17

13. Changing the Battery, Cleaning and Maintenance

Changing the Battery

There is a battery symbol above the menu bar on the left-hand side of the display that shows you how much power you batteries have left. The more green

segments there are, the higher the battery capacity. If there is only one red

segment left, then the batteries need to be replaced very soon.

s soon as the battery voltage drops below the strength that is required to

A

power the unit, a warning symbol starts to blink in the middle of the display.

The batteries should be replaced immediately.

hange the batteries as follows:

C

Power off the unit. Unscrew and remove the battery compartment lid (see chapter

4, legend item

), take out the used batteries and replace them with new ones.

Please make sure that the poles of the batteries you are inserting are properly

aligned with the poles inside the battery compartment.

To power the LD6000, you may either choose to use high quality batteries type

LR14 C 1.5 V (recommended capacity ≥ 4,500 mAh) or rechargeable batteries.

When using rechargeable batteries, you must make sure that you only use

NIMH rechargeable batteries, type HR14 1.2 V.

Do not dispose of batteries in household waste. Do not throw into water or fire.

Please make sure that you dispose of your used batteries according to existing

government guidelines and regulations.

14. Technical Data

Cleaning and Maintenance

LD6000 Measuring Device

Use a slightly moist, lint-free cloth only to clean the main unit. Do NOT use any

detergents or cleaning fluids. Use clean, clear water only.

We recommend that you remove the batteries from the battery compartment

when you are not planning on using your measuring device for a longer period.

LD6000 H2 hydrogen sensor

The measuring tip of the hydrogen hand sensor is equipped with a brass-coloured

hexagonal protection cap (sinter filter) which is designed to protect the sensor

system.

Use compressed air to remove any dirt particles which might happen to settle

on the sinter filter.

Unscrew the sinter filter from the measuring tip and direct the jet of compressed

air from behind – from the direction of the inner thread of the filter – towards