OPERATING MANUAL

OIL HEATING UNITS

IDS 900

EN

TRT-BA-IDS900-HS-003-EN

Table of contents

02. Description

01. Safety .......................................A - 1

02. Description ...................................A - 1

03. Instructions for the installer .......................A - 2

04. Start-up .....................................A - 4

05. Care and maintenance ..........................A - 6

06. Transport and repositioning .......................A - 7

07. Faults and troubleshooting .......................A - 7

08. Functional diagram and control panel ...............A - 9

09. Circuit diagram ...............................A - 11

10. Technical data ................................A - 12

11. Available accessories ..........................A - 13

This release replaces all previous releases. No part of this publication may be reproduced without written

permission. The same applies for electronically processing, duplicating or spreading the publication. Subject

to technical changes. All rights reserved. Trademarks are used without guarantee that they may be used freely

and primarily following the spelling of the manufacturer. The product names used are registered and should be

treated appropriately. The right to make construction changes in the interests of constant product improvement

as well as changes to the shape and colour is reserved. The scope of delivery may vary from product images.

This document was produced with all due care. We accept no liability whatsoever for mistakes or omissions.

®

© TROTEC

01. Safety

The applicable laws and regulations concerning the use of air heaters must be observed for the installation, regulation and use of this

device.

Please observe the following instructions:

• Strictly adhere to the instructions contained in this operating

manual.

• Avoid positioning air heaters in rooms with explosion hazard or

where fire is prohibited.

• Do not store combustible materials near the device (minimum

distance 3m).

• Take the necessary fire protection measures.

• Provide for sufficient ventilation of the room where the air heater

is positioned.

• Position the device near a chimney and an electrical supply control

panel complying with the specified parameters.

• Check the device prior to start-up and regularly during operation.

In particular, make sure that children or animals cannot approach

the device unnoticeably.

• Always remove the plug from the socket after operation. Furthermore, pay attention to the operating conditions of the air heater,

particularly:

• Do not exceed the maximum thermal output of the heater

("TECHNICAL DATA").

• Make sure that the air supply is not below the nominal air

supply. Therefore check that there are no obstacles or obstructions

in the inlet and/or outlet pipes, such as cloths or blankets

placed on the device, or walls or large objects situated in the

immediate vicinity of the device. If the air flow rate is

insufficient, the combustion chamber will heat up and the overheating

protection thermostat L1 will switch the device on and off

continuously ("FAULTS AND TROUBLESHOOTING"). .

The air heaters of the IDS series are designed for heating

medium-sized and large rooms requiring a fixed or mobile heating

source. They heat the air by emitting the thermal energy generated

by combustion via the metal surfaces of the combustion chambers

and via the heat exchanger. The air passage duct and the smoke

passage duct are hermetically sealed from each other.

The combustion air, i.e. the air required for combustion, is directly

sucked in by the integrated burner in the following way:

• from outdoors via the air inlet nozzle (available as accessory) to

avoid reducing the oxygen content of the room to be heated or

• directly from the room to be heated. In the latter case the room must

be adequately ventilated to guarantee a sufficient air exchange.

The hot air flow is moved by the motor-driven high-performance fan.

The fresh air is heated by the combustion gases via the dense metal

surface of the combustion chamber. The combustion gases are

directed to an exhaust gas duct so that they can escape via a

chimney or chimney pipe with sufficient dimensions to ensure the

discharge of the flue gases.

The end piece of the hot air outlet duct can be replaced by the

following ducts:

• with 2 or 4 outlet openings, all of which are kept open.

The air heater IDS 900 can be operated with burners running on

diesel fuel, natural gas (G20) or liquid gas LPG (butane, G30, and

propane, G31) with ON-OFF operating mode.

m

Only the burners selected and supplied by the manufacturer

may be used.

The CE label on the device becomes obsolete

if the burner is replaced with a non-original burner, even

if the latter has similar characteristics.

The IDS900 is equipped with an electronic flame monitoring system

and the following equipment:

• Safety equipment (safety thermostat with manual reset, flame

monitoring, air pressure switch) responding in case of severe

operational disruptions and triggering a safety shutdown: in this

case the air heater switches off, the burner display(h) is permanently illuminated in red and operation can only be continued after

the cause of the failure has been identified and eliminated.

• Control equipment (temperature controller for regulating the air

outlet temperature, fan thermostat and burner thermostat, voltage

monitoring) triggering in case of minor malfunctions or disruptions

in the power supply and causing a temporary shutdown of the air

heater. In this case the air heater resumes operation automatically

once the normal operating conditions have been restored.

If one of these safety devices is triggered, always identify the cause

and repair the damage before pressing the corresponding restart

button to switch the air heater back on ("FAULTS AND TROUBLESHOOTING").

In the event of an overheating of the combustion chamber, the overheating thermostat responds. It switches the device off and switches

it back on after the device has cooled down (light (h) turns on and

off again).

A - 1 Operating manual – IDS 900 EN

03. Instructions for the installer

m All operations described in this chapter must be carried out

by appropriately qualified personnel.

3.1 POWER CONNECTIONS AND SETTINGS

The standard version of the air heater contains all control and

safety equipment required for operating the device. The electric

switch panel, burner, fan thermostat, overheating thermostat and

safety thermostat with manual restart are already connected.

Connect the power cable to a properly secured socket. On construction

sites, there must be an RCD upstream of the socket according to

VDE 0100/0105.

Before commissioning the air heater and thus before connecting the

device to the electricity grid check that the values of the electricity

grid correspond to the specifications on the identification plate.

m All activities listed under this section may only be carried

out by specialists.

3.2 FLOOR OR CEILING INSTALLATION

The air heater can be mounted as follows:

• on the floor in a stable position

• suspended from the ceiling using ropes and/or chains with a

suitable size and length fastened to the four suspension points

NO

The minimum distance to walls, to the floor and/ or to the ceiling

should be at least 1m.

m Make sure that the angle of the ropes and/or chains to

the vertical axis does not exceed 5°, that the ropes do not

cross each other and that a different rope is used for each

hook.

3.3 CONNECTION TO THE HOT AIR FEED DUCTS

The air heater is designed for direct air distribution. The hot air

opening can be replaced with a 2-way or 4-way distributor head

in order to divide the hot air flow by means of flexible channel

modification. In such a case, you have to disassemble the original

outlet nozzle and replace it with the 2-way or 4-way distributor head.

The equipment mentioned above can be connected to ducts with

the corresponding diameter whenever this is required for special

applications. In this case or if there are substantial changes in the

hot air distribution circuit (change of the length or diameter of the

pipe, number of curves etc.), checks and adjustments are required.

In any case you have to:

• Check that the power consumption of the fan motor does not

exceed the specified value.

• Check that the air flow rate corresponds to the nominal flow rate.

EN Operating manual – IDS 900 A - 2

3.4 CONNECTION TO THE FUEL SUPPLY

Always observe the installation, adjustment and operating

regulations stipulated by the local and/or national laws regarding

the use of air heaters.

• Before planning the exhaust system, inform the responsible

chimney sweep according to DIN18160.

• Risk of injury due to poisoning!

• Improper installation of the exhaust system can cause health

problems.

• Have the device installed by an expert technician!

• Have the exhaust emission of the burner checked at regular

intervals.

In order to connect the device to the fuel oil pipe, the fuel oil tank can

be connected to the burner pump:

• directly using the fuel oil pump of the burner while observing

the dimensions and lengths specified in the burner's operating

manual included in the annex of this operating manual;

• indirectly using an auxiliary pump for the fuel oil.

In this case please contact the technical service for a proper

dimensioning of the system.

Connect the end of the air intake pipe with the wall duct. The

pipe must be fitted with a protective grid so that small animals or

rubble cannot enter it.

3.5 CONNECTION OF THE BURNER'S AIR INLET

The combustion air inlet(3) can be connected to the outdoor area

of the room to be heated so that fresh air can be sucked in without

reducing the oxygen content of the room.

A pipe must be provided for this purpose to prevent narrowing due

to the negative pressure of the intake air. The pipe should have a

diameter of at least 100mm and a length not exceeding 6m.

m Shorten pipes which are too long. There must be no kinks

and/or curves which might obstruct the intake of air.

Connecting the air inlet of the burner:

• Remove the cover(1) of the burner housing.

• Remove the end plate(2) of the burner housing.

• Guide the air hose(3) through the hole in the end plate(2) and

fasten it to the air intake snorkel(4) of the burner.

• Slide the cover(1) of the burner housing along the air hose(3)

and attach it to the burner housing. While doing so, make sure

that the air hose(3) does not slip off the air intake snorkel(4).

• Fasten the plate(1) to the air inlet of the burner. It must be rotated so that the air hose(3) is blocked.

m Adjust the burner air according to the "TECHNICAL DATA"

table.

3.6 CONNECTION TO THE SMOKE OUTLET DUCT

The smoke outlet ducts must be made of steel and in accordance

with EN1443.

The combustion efficiency and the proper burner operation depend

on the chimney draught. For connection to the chimney pipe, the

applicable legal regulations and the following provisions must be

observed:

• The chimney connection must be as short as possible and

ascending (minimum height 1m);

• There must be no sharp curves or reductions in cross-section;

• Always provide a wind shield to prevent the penetration of rain

water or clogging of the smoke outlet due to wind;

• The draught of the chimney pipe must not be lower than the

nominal value;

• Every air heater must have its own chimney;

The following image shows how to position the chimney:

A - 3 Operating manual – IDS 900 EN

A) Minimum distance 1 m

B) As short as possible

C) Minimum distance 1 m

D) H-shaped chimney cowl

m The use of concentric pipes for smoke outlet or intake of

combustion air is expressly prohibited for these devices.

It can severely and permanently affect their functioning.

04. Start-up

m The initial start-up must always be carried out by a

specialist who verifies whether the combustion

parameters are correct.

m The burners are preset at the factory. This setting may

deviate from the required setting. It must therefore be

checked and, if necessary, corrected during start-up.

The settings (fuel oil pressure of the burner, combustion head

position, air regulation) can be found in the "TECHNICAL DATA" table.

The probe used for regular checks of the combustion and exhaust

gas temperature must be inserted as follows:

NO

The combustion is stable and clean if the combustion parameters

have the following values:

Bacharach index: 0 (white)

CO

: 11 ÷ 12.5 %

2

Oxygen (O

CO

): 4.5 ÷ 6 %

2

max: 500 ppm

Depending on the fuel used and on the installation conditions (height

level, combustion air intake with or without air inlet etc.), readjustment of

the burner may be required if the combustion parameters are incorrect.

After completion of the acceptance inspections, the hole for inserting

the probe must be sealed with a material that is heat-resistant and

guarantees tightness of the duct.

4.1 SWITCH-ON

• Lift the panel(n) of the control box.

• Make sure that the switch(a) is set to "0".

• Switch on the air heater using the circuit breaker at the control

box. The green power indicator light(b) lights up.

• Turn the switch(a) to "H" or "V+H": the burner starts the starting

or pre-purging cycle. Then the flame is ignited. After the

combustion chamber has been preheated for several minutes, the

main fan switches on.

EN Operating manual – IDS 900 A - 4

m In V+H operating mode, the fan runs continuously. This

also applies when the burner switches off after reaching

the predefined room temperature.

m In H operating mode, the fan only operates when the

combustion chamber is sufficiently heated. When the

predefined room temperature is reached, the burner

switches off and the fan keeps running until the combustion

chamber has cooled down completely.

In case of a failure of the air heater during start-up or operation,

please refer to the "FAULTS AND TROUBLESHOOTING" chapter to

find the cause for the malfunction.

m After a safety shutdown of the burner, the lamp/button

(m) lights up and the burner reset button (m) must be

pressed and held for three seconds to be able to restart

the air heater.

m After a safety shutdown caused by the safety thermostat

(indicator light h), you have to press the reset button(i) to

be able to restart the air heater.

m Never carry out more than two consecutive restarts.

Unburned fuel oil can accumulate in the combustion

chamber and might suddenly ignite during the

subsequent restart.

4.2SWITCH-OFF

To switch the device off in case of manual operation, set the main

switch (a) to "0". For automatically operated devices, the room

thermostat must be used.

The burner stops (indicator light h goes out) while the fan keeps

running. The fan switches on and off several times until the combustion

chamber has cooled down completely.

m The air heater's operation must not be stopped by simply

removing the plug from the supply control panel. The

electrical supply may only be interrupted after the fan has

come to a standstill.

4.3VENTILATION

If you want to use the air heater for continuous ventilation only, set

the switch(a) to "V".

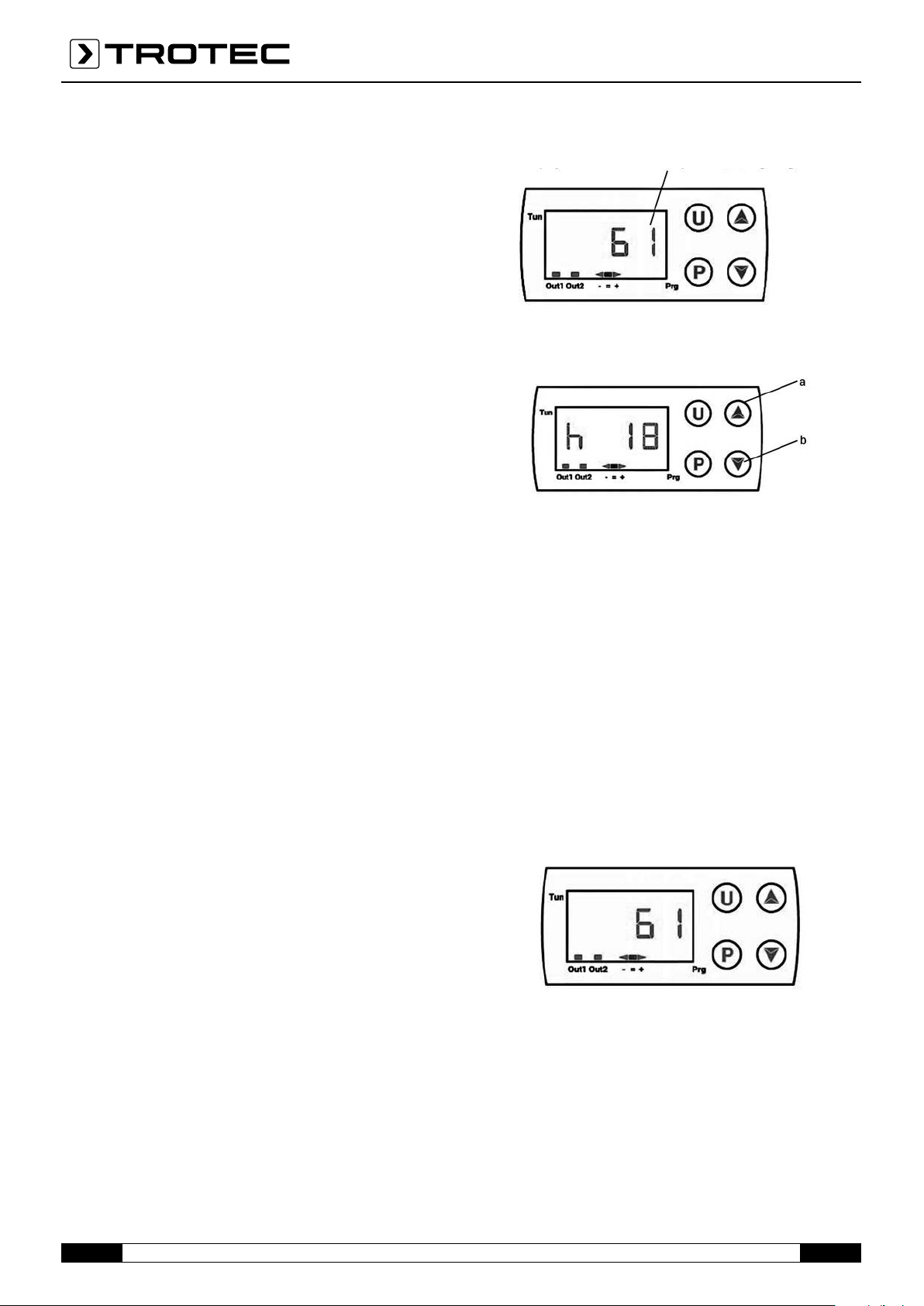

Detection of the air outlet temperature

The detected temperature [°C] is shown on the display:

Recording of the operating hours

If you press the button (a) twice, the operating time in hours[h] will

be displayed:

m The indicated time is not the effective heating time but

the time during which the device has been supplied with

current and switched on.

Proceed as follows to reset the counter:

• Turn the device's main switch to "0" (OFF).

• Press and hold the P button of the temperature controller for at

least three seconds. The word "PASS" flashes for five seconds.

• Enter the code "-481". To do so, repeatedly press the button(b)

until the desired character appears. Then press the P button to

confirm and move to the next character.

• Finally, press the U button: The air outlet temperature is displayed

again.

4.5 CONTROL OF THE TRIGGER TEMPERATURE OF THE FAN

THERMOSTAT

Control of the trigger temperature of the fan thermostat

4.4TEMPERATURE CONTROLLER

The air heater is equipped with a temperature controller (g) with

LCD display that can be used to display and control the following

parameters:

• Detection of the air outlet temperature

• Recording of the operating hours

• Control of the trigger temperature of the fan thermostat

• Control of the trigger temperature of the burner thermostat

The temperature controller is programmed in a way that it

automatically switches the main fan on or off depending on the

temperature set for the combustion chamber. This prevents cold air

from being blown out when the burner starts and the combustion

chamber is not yet sufficiently heated.

It also guarantees a discharge of the internal residual heat upon

switch-off.

The default temperature setting is 35°C with a hysteresis of 5°C.

A - 5 Operating manual – IDS 900 EN

The red "OUT1" LED indicates the operating condition of the fan

thermostat:

• When it is illuminated, the fan is running (ON);

• When it is not illuminated, the fan is switched off (OFF).

4.6 CONTROL OF THE TRIGGER TEMPERATURE OF THE BURNER

THERMOSTAT

Control of the trigger temperature of the burner thermostat

• Proper operation of the device requires regular maintenance

activities. Make sure that you disconnect the air heater from

the electrical power supply before starting these activities.

Maintenance

Measure

Check the air heater

Check the fuel oil supply line

Daily Weekly

x

x

Semi-

annually

Annually

The temperature controller is programmed in a way that it

automatically switches the burner on or off depending on the

maximum temperature set for the combustion chamber. This

prevents overheating of the combustion chamber and thus triggering

of safety thermostat L2, which would switch off the air heater (see

also "Faults and troubleshooting" chapter).

The default thermostat setting for the maximum temperature of the

combustion chamber is 95°C with a hysteresis of 5°C.

The red "OUT2" LED indicates the operating condition of the burner

thermostat: The LED sequence "- = +" indicates the current

temperature compared to the set temperature:

• If the red arrow above the "-" symbol lights up, the temperature

is below the set value and thus the thermostat enables operation

of the burner.

• If the green LED above the "=" symbol lights up, the temperature

equals the set value.

• If the red arrow above the "+" symbol lights up, the temperature

is above the set value and thus the thermostat disables operation

of the burner.

m The trigger temperatures of the fan thermostat and burner

thermostat can be modified. However, this should only

be done if it is absolutely necessary. For this purpose,

please contact the Trotec service to obtain the information

required for reprogramming the temperature controller.

Clean the outside of the device

Clean the motor and fan

Check the electrical connections

Check and test the burner

Check the thermostats

Clean the inside of the device

Inspect and clean the combustion

chamber

x

x

x

x

x

x

x

5.1 CHECKING THE AIR HEATER AND THE FUEL OIL SUPPLY LINE

Please check the following:

• Make sure that the device is not positioned in areas with a high

risk of fires or in potentially explosive atmospheres

• Make sure to maintain a safety distance from flammable

• substances

In case of fuel oil leaks:

• Close the fuel oil shut-off valve

• Locate and repair the fuel oil leak

• Do not use the machine until the removed panels have been

reattached

• Make sure that the room to be heated is sufficiently ventilated

• Make sure that the air intake and outlet pipes are not blocked in

any way

• Make sure that there are no sheets or blankets placed on the

device

• Make sure that the device is in a firm and stable position

• Make sure that the air heater is regularly monitored

during operation and checked prior to start-up

05. Care and maintenance

For a smooth operation of the device, the following tasks must be

performed regularly. Please note that the power supply of the air

heater must be interrupted beforehand.

m All operations described in this chapter must be carried out

by appropriately qualified personnel. Before starting work,

make the following preparations:

• Switch off the device as described above in the "SWITCHOFF" section.

• Cut off the power supply using the circuit breaker.

• Wait until the device has cooled down.

5.2 CLEANING THE OUTSIDE OF THE DEVICE

For a failure-free operation, we recommend that you clean the following parts:

• Burner:

- Thoroughly remove dirt and residues

- Make sure that the air inlet is not clogged

• Clean the housing, lines, pipes, connectors and joints with a cloth

• Air inlet/outlet:

- Thoroughly remove dirt and residues

- Make sure that the air inlet is not clogged

EN Operating manual – IDS 900 A - 6

5.3 CLEANING THE MOTOR AND THE FAN

To clean the fan wheel and the motor, please proceed as follows:

• Loosen the fastening screws of the fan and remove the fan.

• Clean the motor with compressed air.

• Clean the fan wheel with a hard brush.

• Reinstall the fan.

5.4 CHECKING THE ELECTRICAL CONNECTIONS

After unplugging the power supply cable, check all electrical

connections as follows:

• Make sure that the connections are intact and properly seated.

• Remove any dirt and corrosion or replace the connections if

necessary

• Replace damaged wires or connectors if necessary

5.5 CHECKING AND TESTING THE BURNER

To access the burner:

5.8 CLEANING THE HEAT EXCHANGER AND THE COMBUSTION

CHAMBER

To maintain the device's high efficiency, the cleaning work

described here must be performed at least once at the end of

each operating season, or several times in case of excessive soot

formation. The latter can occur, for instance, if the chimney draught

is not ideal, if low quality fuel is used, if the burner is improperly

adjusted, or if the device is switched on and off frequently.

06. Transport and repositioning

Hold the front handles when repositioning or transporting the device.

The heater will move on its rear wheels.

m Before repositioning the device, make the following prepara-

tions:

• Switch off the device.

• Interrupt the power supply by removing the plug from the

socket.

• Wait until the heater has cooled down.

• Unscrew the fastening screw of the burner

• Pull out the burner and perform the inspection and cleaning work

according to the instructions in the burner's operating manual

• Reattach the burner unit

• Perform the work steps required to measure the combustion

parameters and ensure a stable and clean combustion, which are

described in chapter4

5.6 CHECKING THE THERMOSTATS

Proceed as follows to check the thermostats:

• Remove any connection ducts from the air outlet

• Locate the thermostats mounted on the inner wall of the air heater

• Clean the thermostats with a dry cloth and pay attention not to

kink or damage the capillary tube

5.7 CLEANING THE INSIDE OF THE DEVICE

For thorough cleaning the air heater can be washed with water both

on the inside and on the outside.

However, you have to observe the following:

• The power cable must be removed from the socket

• All inspection panels must be completely closed

• When cleaning with a water jet, the maximum permissible

pressure is 70 bar with a distance below 30 cm

• All parts must have dried completely before the power cable is

reconnected

Only use the provided lifting gear for lifting the device. Attach ropes

or chains to the four lifting points. Before lifting the device make sure

that the lifting gear used is actually suited to lift the device. You will

find the weight of the device in the technical data table.

m Do not try to lift the device with pure muscle power: The

heavy weight can cause serious physical damage.

07. Fault and troubleshooting

In case of a severe operational disruption, various safety devices can

cause a safety shutdown of the device. This is signalised as follows:

• at the control box

This is the block signal indicating that safety thermostatL2

has triggered. The reset button is located inside the burner

housing.

• at the burner

Safety shutdown signal indicating that the burner's flame

monitoring has triggered.

m In the event of a safety shutdown, do not carry out two

consecutive restarts. Unburned fuel components can accumulate in the combustion chamber and might suddenly

ignite during the subsequent restart.

If the inspections and corrective measures do not produce any results, please contact your nearest sales and service centre.

A - 7 Operating manual – IDS 900 EN

Malfunction Cause Troubleshooting

• Device does not start

• No power supply

• Incorrect main switch position

• Room thermostat only functions

sporadically

• The safety system (burner,

thermostat L2, thermal relay of

the fan) was not reset after repair

• Overheating of the combustion

chamber

• Tripping of thermostat L2 (warning

light (9) lights up)

• Tripping of thermal relay RM

(light (10) lights up)

• Overheating of the combustion

chamber

• Excessive power consumption of

the fan motor

• Check the functioning and position of the

switch

• Check the characteristics of the electrical line

• Check the electrical connections

•

Check whether the fuses are intact

• Set to the right position

• Check and correct the thermostat position

• Check whether the thermostat is operational

• Press the reset button:

• Burner (button on control system)

• Thermostat L2 (button (6))

• Thermal relay of the fan (button (11))

• Check fuel supply• Tripping of thermostat L1

• Check the correct positioning of any flaps,

nozzles etc.

• Remove any parts which might be stuck in the air

ducts or ventilation grilles

• Check as described above

• If unsuccessful, please contact your supplier

• Heater with axial fan: Remove any obstacles from

the air intake. Reduce the lengths of the air ducts

• The burner starts, the flame does

not ignite and the reset indicator on

the control system is illuminated

• The fan does not start or starts with a

delay

• The fan makes noises or vibrates

• Irregular operation of the burner

• No power supply

• Thermostat F damaged

• Motor winding burnt or

interrupted

• Motor capacitor burnt

(Mod. "M")

• Motor bearing blocked

• Foreign objects on fan blades

• Insufficient air circulation

• Heater with centrifugal fan: Check the fan belt

setting as described in the "CONNECTION TO

AIR DUCTS" chapter

• In any case check that the power consumption is

lower than the value indicated on the nameplate

• Should this situation reoccur after pressing the

restart button and starting the device, please contact

the technical customer service

• Check whether the fuses are intact

• Check the electrical connections

• Check, adjust or exchange the thermostat

• Exchange fan motor

• Exchange capacitor

• Exchange bearing

• Remove foreign objects

• Remove any obstacles affecting air circulation

• Insufficient heating

• Insufficient heat output of the

burner

• Please contact the technical customer service

EN Operating manual – IDS 900 A - 8

08. Functional diagram and control panel

1 USCITA ARIA CALDA

SORTIE AIR CHAUD

WARMLUFTAUSTRITT

HOT AIR OUTFLOW

SALIDA DE AIRE CALIENTE

ВЫХОДГОРЯЧЕГОВОЗДУХА

2 CAMINO

CHEMINEE

SCHORNSTEIN

CHIMNEY

CHIMENEA

ДЫМОХОД

3 VENTILATORE RAFFREDDAMENTO

VENTILATEUR REFROIDISSEMENT

KÜHLVENTILATOR

COOLING FAN

VENTILADOR DE ENFRIAMIENTO

ВЕНТИЛЯТОРОХЛАЖДЕНИЯ

4 CAMERA DI COMBUSTIONE

CHAMBRE DE COMBUSTION

BRENNKAMMER

COMBUSTION CHAMBER

CÁMARA DE COMBUSTIÓN

КАМЕРАСГОРАНИЯ

5 BRUCIATORE

BRULEUR

BRENNER

BURNER

QUEMADOR

ГОРЕЛКА

6 SCAT OLA TERMOSTATI L2

BOITIER THERMOSTATS L2

THERMOSTATGEHÄUSE L2

THERMOSTATS L2 BOX

CAJA DE TERMOSTATOS L2

КОРОБКАТЕРМОВЫКЛЮЧАТЕЛЕЙL2

7 STAFFE DI SOLLEVAMENTO

ÉTRIERS DE LEVAGE

TRAGWANGEN

HOISTING BRACKETS

SOPORTES DE ELEVACIÓN

ПОДЪЕМНЫЕКРОНШТЕЙНЫ

8 PIEDE / MANIGLIA

SUPPORT/POIGNEE

STUTZE/HANDGRIFF

SUPPORT/HANDLE

AYUDA Y MANIJA

НОЖКА/РУЧКА

9 RUOTA

ROUE

RAD

WHEEL

RUEDA

КОЛЕСО

10 SCATOLA BRUCIATORE

BOÎTIER BRÛLEUR

BRENNERGEHÄUSE

BURNER BOX

CAJA DEL QUEMADOR

КОЖУХГОРЕЛКИ

11 PARAURTI

PARE-CHOCS

PUFFER

BUFFER

PARACHOQUES

АМОРТИЗИРУЮЩИЕПРОКЛАДКИ

12 SCATOLA QUADRO ELETTRICO

BOÎTIER TABLEAU ÉLECTRIQUE

SCHALTKASTEN

ELECTRICAL PANEL BOX

CAJA DEL CUADRO ELÉCTRICO

КОЖУХЭЛЕКТРОШКАФА

A - 9 Operating manual – IDS 900 EN

a INTERRUTTORE RISCALDAMENTO-VENTILAZIONE

INTERRUPTEUR CHAUFFAGE-VENTILATION

SCHALTER HEIZUNG-LÜFTUNG

HEATING-VENTILATION SWITCH

INTERRUPTOR CALEFACCION/VENTILACION

ПЕРЕКЛЮЧАТЕЛЬНАГРЕВА-ВЕНТИЛЯЦИИ

b LAMPADA TENSIONE

TEMOIN TENSION

LEUCHTE SPANNUNG

VOLTAGE LAMP

TESTIGO TENSIÓN

ИНДИКАТОРНАПРЯЖЕНИЯ

c LAMPADA TERMOSTATI DI SICUREZZA L2

TEMOIN THERMOSTATS DE SURCHAUFFE, L2

KONTROLLLEUCHTE SICHERHEITSTHERMOSTATE L2

OVERHEAT THERMOSTATS CONTROL LAMP, L2

TESTIGO TERMOSTATOS DE SEGURIDAD, L2

ИНДИКАТОРПРЕДОХРАНИТЕЛЬНЫХ

ТЕРМОВЫКЛЮЧАТЕЛЕЙL2

d PRESA PER TERMOSTATO AMBIENTE

PRISE THERMOSTAT D’AMBIANCE

RAUMTHERMOSTAT STECKDOSE

ROOM THERMOSTAT PLUG

ENCHUFE TERMOSTATO AMBIENTE

РАЗЪЕМДЛЯТЕРМОСТАТАОКРУЖАЮЩЕЙСРЕДЫ

e PRESA PER FILTRO PRERISCALDO

PRISE POUR FILTRE PRÉCHAUFFAGE

ANSCHLUSS FÜR FILTER VORWÄRMANLAGE

INTAKE FOR PRE-HEAT FILTER

TOMA PARA FILTRO DE PRECALENTAMIENTO

ГНЕЗДОДЛЯФИЛЬТРАПОДОГРЕВА

f PRESSACAVO PER CAVO ALIMENTAZIONE

PRESSE-CÂBLES POUR CÂBLE D‘ALIMENTATION

KABELDURCHFÜHRUNG FÜR STROMVERSORGUNGSKABEL

CABLE CLAMP FOR POWER CABLE

PRENSACABLE PARA CABLE DE ALIMENTACIÓN

КАБЕЛЬНАЯВТУЛКАДЛЯСИЛОВОГОКАБЕЛЯ

g TERMOREGOLATORE

THERMORÉGULATEUR

TEMPERATURREGLER

TEMPERATURE CONTROLLER

TERMORREGULADOR

ТЕРМОРЕГУЛЯТОР

h LAMPADA BRUCIATORE

VOYANT BRÛLEUR

BRENNERANZEIGE

BURNER LIGHT

TESTIGO DEL QUEMADOR

ИНДИКАТОРГОРЕЛКИ

LAMPKA SYGNALIZACYJNA PALNIKA

i PULSANTE DI RIARMO TERMOSTATO DI SICUREZZA, L2

POUSSOIR DE RÉARMEMENT THERMOSTAT DE SÉCURITÉ, L2

ENTSTÖRTASTE DES SICHERHEITSTHERMOSTATEN, L2

SAFETY THERMOSTAT RESET BUTTON, L2

BOTÓN DE REARME DEL TERMOSTATO DE SEGURIDAD, L2

КНОПКАСБРОСАПРЕДОХРАНИТЕЛЬНОГОТЕРМОВЫКЛЮЧАТЕЛЯ,L2

l LAMPADA BLOCCO VENTILATORE (solo per modelli trifase)

TÉMOIN BLOCAGE VENTILATEUR (uniquement pour modèles triphasés)

KONTROLLLEUCHTE SICHERHEITSABSCHALTUNG DES VENTILATORS (nur Modelle mit

3-Phasen-Betrieb)

FAN BLOCK LAMP (for 3-phase models only)

TESTIGO BLOQUEO VENTILADOR (sólo para modelos trifásicos)

ИНДИКАТОРБЛОКИРОВКИВЕНТИЛЯТОРА(толькодлятрехфазныхмоделей)

m LAMPADA / PULSANTE DI RIARMO BRUCIATORE

TÉMOIN / POUSSOIR DE RÉARMEMENT

BRÛLEUR

LAMPE / ENTSTÖRTASTE BRENNER

BURNER RESET BUTTON / LAMP

TESTIGO/BOTÓN DE REARME DEL QUEMADOR

ИНДИКАТОР/КНОПКАСБРОСАГОРЕЛКИ

n PANNELLO SCATOLA QUADRO ELETTRICO

PANNEAU BOÎTIER TABLEAU ÉLECTRIQUE

ABDECKUNG SCHALTKASTEN

ELECTRICAL PANEL BOX PANEL

PANEL DE LA CAJA DEL CUADRO ELÉCTRICO

ПАНЕЛЬКОЖУХАЭЛЕКТРОШКАФА

o QUADRO ELETTRICO

TABLEAU ÉLECTRIQUE

SCHALTKASTEN

ELECTRICAL PANEL

CUADRO ELÉCTRICO

ЭЛЕКТРОШКАФ

EN Operating manual – IDS 900 A - 10

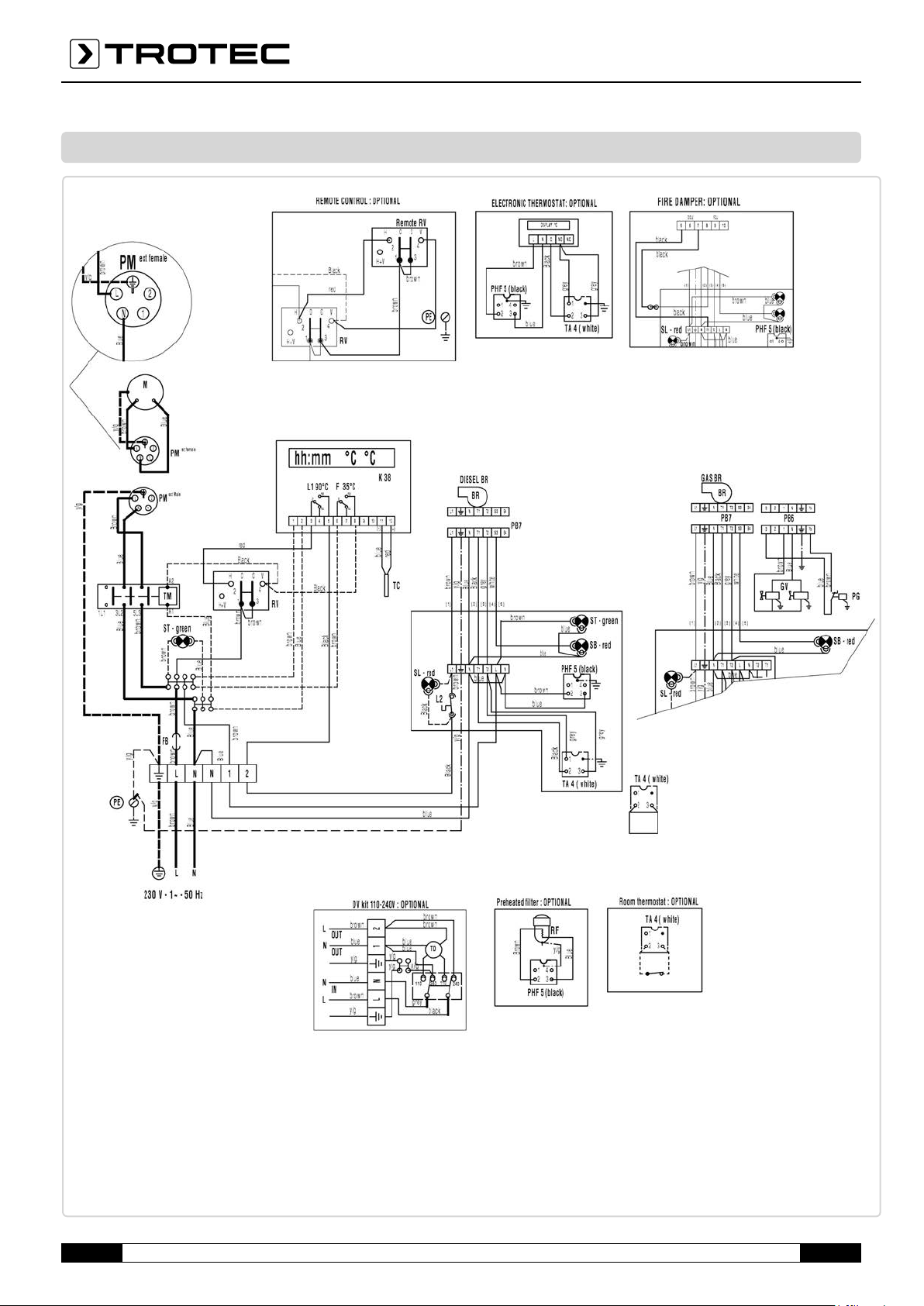

09. Circuit diagram

C Capacitor

M Fan motor

F Air controller

FB Fuse for burner 6A

TM Remote switch for fan

RM Thermal relay for fan

ST Indicator light

SB Fan "OFF" indicator light

A - 11 Operating manual – IDS 900 EN

BR Burner

TA Room thermostat

PB Burner

L1 Overheating protection thermostat, L1

L2 Safety thermostat with manual release, L2

RV Switch heating-stop-ventilation

SL Overheating protection indicator light, L1, L2

10. Technical data

Article number

Air flow rate

Fan

Max. nominal heat input

Nominal heat output

Temperature increase* (ΔT)

Input voltage

Current consumption

Max. oil consumption

Air transport hose connector ø

Chimney connection ø

Thermostat connection

Tank contents

Sound level (distance 1m)

Length

Width

Height

Weight kg

Combustion

1.430.000.160

Type IDS 900

12,500 m³/h

axial fan

235 kW

221 kW (181,427 kcal)

47 °C

230 V / 50 Hz

12 A

21.67 l/h

1 x 700 mm** 2 x 600 mm** 4 x 400 mm**

200 mm

standard

208 l

81.3 dB(A)

2,245 mm

982 mm

1,584 mm

351 kg

indirect

* ΔT indicates the temperature increase. The outlet air temperature is calculated from ΔT + ambient temperature.

** Optionally available accessories required.

EN Operating manual – IDS 900 A - 12

11. Available accessories

Accessory Article number

Hose

connector

Two-way

hose distributor

Four-way

hose distributor

Thermostat

with 10 m cable

Connection kit

for external oil tank

Oil pre-heating

Filler neck oil filter

1 x ø 700 mm,

standard equipment

2 x ø 600 mm,

Article no. 6.100.006.174

4 x ø 400 mm,

Article no. 6.100.006.175

Article no.

6.100.007.016

Standard equipment

Article no.

6.100.006.177

Article no.

6.100.006.161

Oil tank pedestal IDS900,

capacity 208 litres

Exhaust gas pipe rigid,

length 1 m

90° arc connection

for exhaust gas pipe

Exhaust gas pipe

rain cover

Air hose Tronect

SP-C³, length 7.6m

Article no.

6.100.006.176

Article no.

6.100.006.214

Article no.

6.100.006.220

Article no.

6.100.006.226

Article no.

6.100.001.273

A - 13 Operating manual – IDS 900 EN

EN Operating manual – IDS 900 A - 14

Trotec GmbH & Co. KG

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...