Page 1

DH 30 VPR+ / DH 60 VPR+

EN

OPERATING MANUAL

DEHUMIDIFIER / CLIMATE

MANAGER

TRT-BA-DH30VPR+-DH60VPR+-TC-002-EN

Page 2

Table of contents

Notes regarding the operating manual.................................1

Safety .....................................................................................2

You can download the current version of the operating manual

and the EU declaration of conformity via the following link:

Information about the device................................................4

Transport, assembly and preparation for start-up .............6

Important information regarding the dehumidification

performance and drying rate ................................................8

Operation .............................................................................10

Errors and faults..................................................................15

Maintenance ........................................................................17

Technical annex...................................................................20

Disposal ...............................................................................22

Notes regarding the operating manual

Symbols

Warning of electrical voltage

This symbol indicates dangers to the life and health of

persons due to electrical voltage.

DH 30 VPR+

http://hub.trotec.com/?id=39535

DH 60 VPR+

http://hub.trotec.com/?id=39536

Warning

This signal word indicates a hazard with an average

risk level which, if not avoided, can result in serious

injury or death.

Caution

This signal word indicates a hazard with a low risk

level which, if not avoided, can result in minor or

moderate injury.

Notice

This signal word indicates important information (e.g.

material damage), but does not indicate hazards.

Info

Information marked with this symbol helps you to carry

out your tasks quickly and safely.

Follow the manual

Information marked with this symbol indicates that the

operating manual must be observed.

1 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 3

Safety

Read this manual carefully before starting or using the

device. Always store the manual in the immediate vicinity

of the device or its site of use!

Warning

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future

reference.

This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

• Do not use the device in potentially explosive rooms.

• Do not use the device in aggressive atmosphere.

• Let the device dry out after a wet clean. Do not operate it

when wet.

• Do not use the device with wet or damp hands.

• Do not expose the device to directly squirting water.

• Never insert any objects or limbs into the device.

• Do not sit on the device.

• This appliance is not a toy! Keep away from children and

animals. Do not leave the device unattended during

operation.

• Do not cover or transport the device during operation.

• Check accessories and connection parts for possible

damage prior to every use of the device. Do not use any

defective devices or device parts.

• Ensure that all electric cables outside of the device are

protected from damage (e.g. caused by animals). Never

use the device if electric cables or the power connection

are damaged!

• The electrical connection must correspond to the

specifications in chapter Technical data.

• Insert the mains plug into a properly secured mains

socket.

• Observe the technical data when selecting extensions to

the power cable. Completely unroll the extension cable.

Avoid electrical overload.

• Before carrying out maintenance, care or repair work on

the device, remove the mains plug from the mains socket.

Hold onto the mains plug while doing so.

• Switch the device off and disconnect the power cable from

the mains socket when the device is not in use.

• Do not under any circumstances use the device if you

detect damages on the mains plug or power cable.

If the supply cord is damaged, it must be replaced by the

manufacturer, his service agent or similarly qualified

persons in order to avoid a hazard.

Defective power cables pose a serious health risk.

• Observe the storage and operating conditions (see chapter

Technical data).

• Ensure that the air inlet and outlet are not obstructed.

• Ensure that the side of the device where the air inlet is

found is kept free of dirt and loose objects.

• Only transport the device in an upright position with an

emptied condensation tank or drain hose.

• Discharge the collected condensate before transport and

storage. Do not drink it. Health hazard!

Intended use

Only use the device as a stationary dehumidifier for drying and

dehumidifying room air as well as for odour elimination

(ionization) whilst adhering to the technical data and safety

instructions.

Intended use comprises:

• protecting valuables and movables in museums, galleries,

libraries or garages against moisture,

• odour neutralization in garages, archives, wine cellars,

cellar vaults, storage facilities or rooms that are neither

inhabited nor used by persons,

• drying and dehumidifying:

– production plants, underground rooms

– store rooms, archives, laboratories

• keeping dry of:

– instruments, devices, files

– electrical control centres

– moisture-sensitive goods, loads, etc.

Improper use

Do not place the device on wet or flooded ground.

Do not use the device outdoors.

Do not place any objects, e.g. wet clothing, on the device for

drying.

Any unauthorised modifications, such as alterations or structural

changes to the device, are forbidden.

EN 2

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 4

Personnel qualifications

People who use this device must:

• be aware of the dangers that occur when working with

electric devices in damp areas.

• have read and understood the operating manual, especially

the Safety chapter.

Maintenance tasks which require the housing to be opened

must only be carried out by specialist companies for cooling and

air-conditioning or by Trotec.

Residual risks

Warning of electrical voltage

Work on the electrical components must only be

carried out by an authorised specialist company!

Warning of electrical voltage

Before any work on the device, remove the mains plug

from the mains socket!

Hold onto the mains plug while pulling the power cable

out of the mains socket.

Warning

Dangers can occur at the device when it is used by

untrained people in an unprofessional or improper way!

Observe the personnel qualifications!

Behaviour in the event of an emergency

1. In an emergency, disconnect the device from the mains

feed-in:

Pull the mains plug.

2. Do not reconnect a defective device to the mains.

Warning

A falling device can cause injuries! Always transport

and assemble the device with the help of other

persons. Never stand below the device when it is

suspended. Ensure adequate stability of the device's

wall fixing.

Warning

Risk of suffocation!

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

Warning

Ozone formation!

In case of improper use the device generates a minor

concentration of ozone when operating at stage 5.

In general, ozone may cause or intensify fire, it may be

fatal if inhaled and irritating to eyes, respiratory system

and skin!

Endeavour to prevent the formation of ozone. Hence,

never leave the device running at stage5 in continuous

operation!

Notice

Do not operate the device without an inserted air filter!

Without air filter the inside of the device will be heavily

contaminated, this could reduce both the

dehumidification performance and odour elimination

and result in damage to the device.

3 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 5

Information about the device

Value Protection Range technology (VPR+)

If properly dimensioned and operated, the dehumidifiers of the

VPR+series keep the humidity level steady around the clock

and, if needed, neutralize a great number of offensive smells.

The humidity is automatically regulated to the set level that

reliably prevents corrosion, condensation and mould formation.

A relative humidity between 45 and 50% provides better

protection than any other measure against corrosion and rust.

Rust mainly occurs at inaccessible, hardly visible spots.

In addition to the dehumidification and odour elimination, the

process air is further freed from dust and/or soot depending on

the used filter model.

The integrated pump ensures the discharge of the accumulating

condensate even over differences in height.

The fan comes with two stages to adjust the device

performance to the contaminations and conditions in the room.

Description of the device

The dehumidifiers of the VPR+ series use the principle of

condensation to automatically dehumidify rooms.

The fan sucks damp room air through the air inlet(3), the

evaporator and the condenser located behind it. The air is

cooled at the cold evaporator until it is below the dew point.

Water vapour contained in the room air precipitates on the

evaporator fins as either condensation or rime. The

dehumidified, cooled air is rewarmed at the condenser and

blown out at a temperature of approx. 5 °C above room

temperature.

The drier air thus conditioned mixes with the air in the room via

the air outlet(1). The humidity in the room where the device is

positioned is reduced as air constantly circulates through the

device. Depending on the air temperature and the relative

humidity, the condensed water either drops into the

condensation tray continuously or only during the defrost

phases.

To set the desired humidity level, a hygrostat with control

dial(8) is provided in the device's interior. This control dial can

be easily accessed once the filter flap(3) has been removed.

The device can reduce the relative humidity of a room to approx.

30%.

At a room temperature of 15°C, the devices emit 1.6 to 3 times

of their power consumption to the room air in form of heat (see

chapter Technical data, COP). Because of the heat dissipation,

which develops during operation, the room temperature can

therefore rise by approx. 1 to 3°C.

A high humidity level in the air (starting at 70%RH) provides

the perfect breeding ground for mould. However, the room air

must not be too dry either (<40%RH). Materials such as

leather or rubber become porous, and wood becomes brittle and

fissured.

For the storage of vehicles we recommend a relative humidity

between 45 and 50%. For other material-specific humidity

values please refer to the respective manufacturer's instructions

for the stored goods.

Additionally, the device comes equipped with an ionizer which

eliminates odours and bacteria from the room air, if required.

Depending on the model an integrated filter absorbs dust and /

or soot in the room air.

The incorporated pump helps to discharge condensate; in doing

so, it is possible to overcome a difference in altitude of up to

10m. That way, it is possible to discharge condensate across

several storeys.

EN 4

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 6

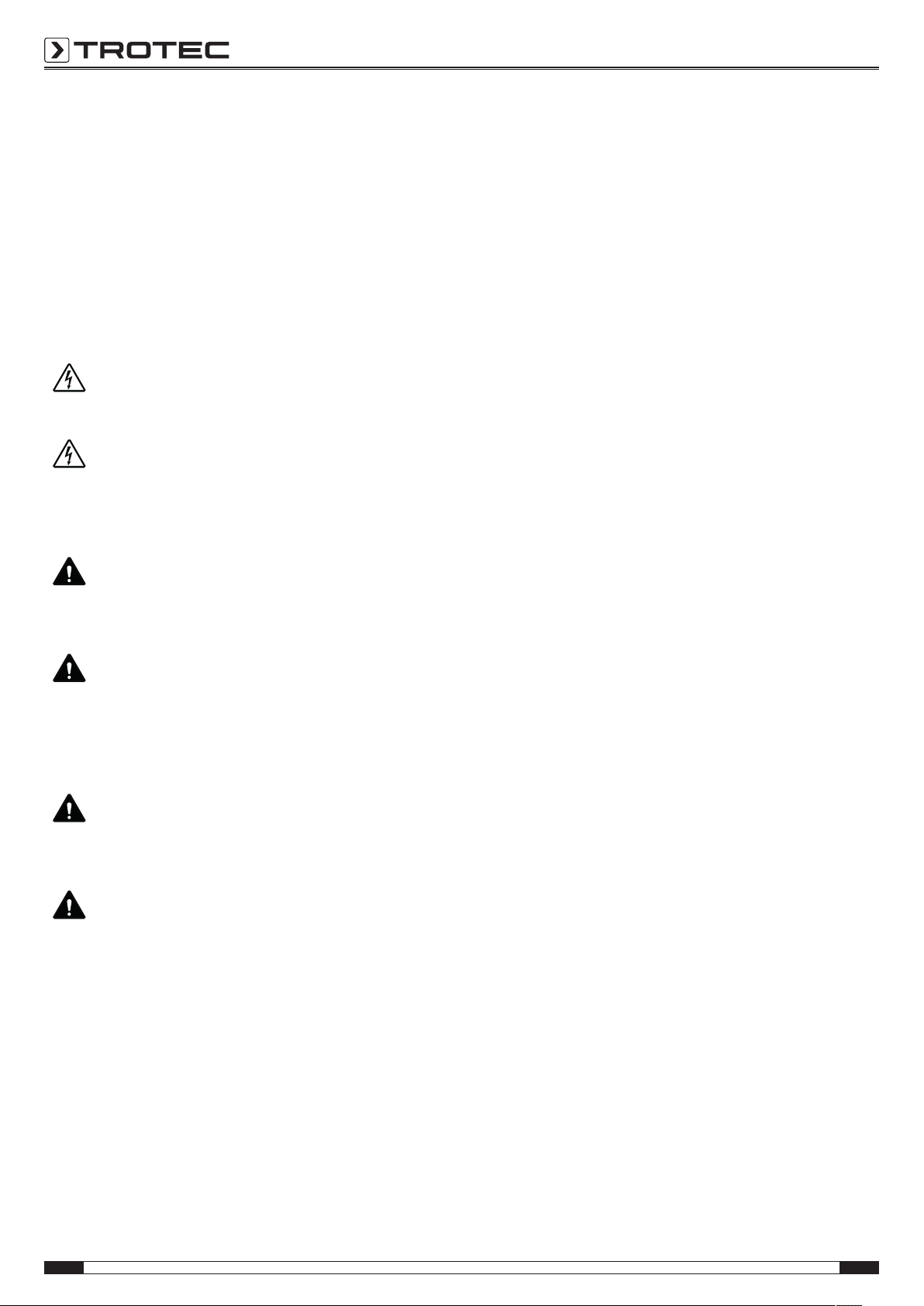

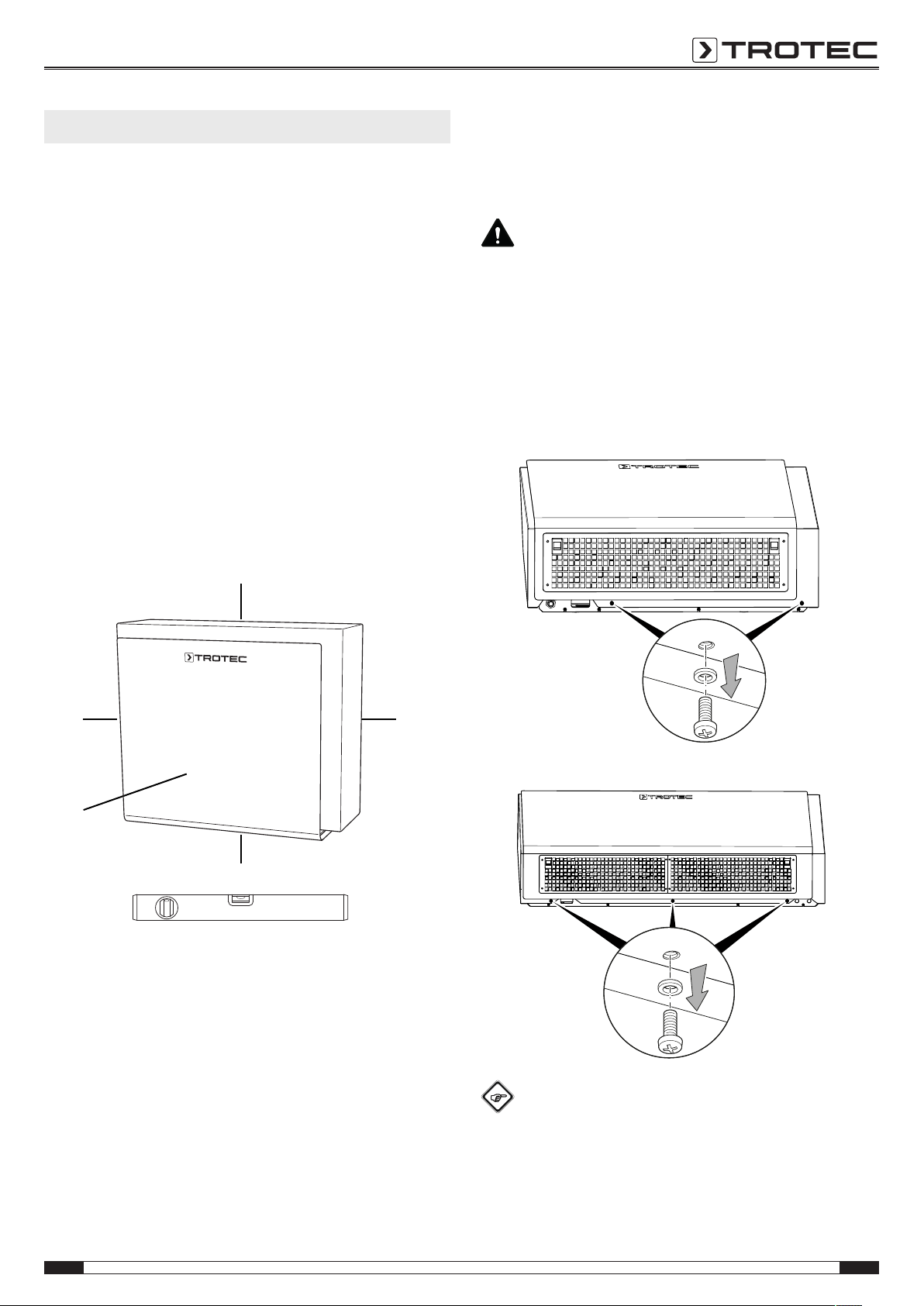

Device depiction

1

2

4

6

3

7, 8

5

6

1

2

6

3

7, 85

6

6

4

DH30VPR+

DH60VPR+

No. Designation

1 Air outlet (behind faceplate)

2 Housing

3 Air inlet with filter flap

4 Wall holder

5 Hose connector for condensation drain hose

6 Suspension

7 Ionizer control panel (tamper-proof installation inside the device)

8 Control dial hygrostat (tamper-proof installation inside the device)

Scope of delivery

• Dehumidifier

• Wall holder

• Air filter (combination filter)

• Air filter (standard)

• Condensation drain hose, ø 5mm (inside), l = 10m

• Power cable with CEE 7/7 Schuko plug

• Operating manual

Available accessories

• Combination filter DH30VPR+ (5pieces): art. no.

7.710.000.926

• Standard air filter DH30VPR+: art. no. 7.710.000.925

• Combination filter DH60VPR+ (5pieces): art. no.

7.710.000.929

• Standard air filter DH60VPR+: art. no. 7.710.000.930

5 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 7

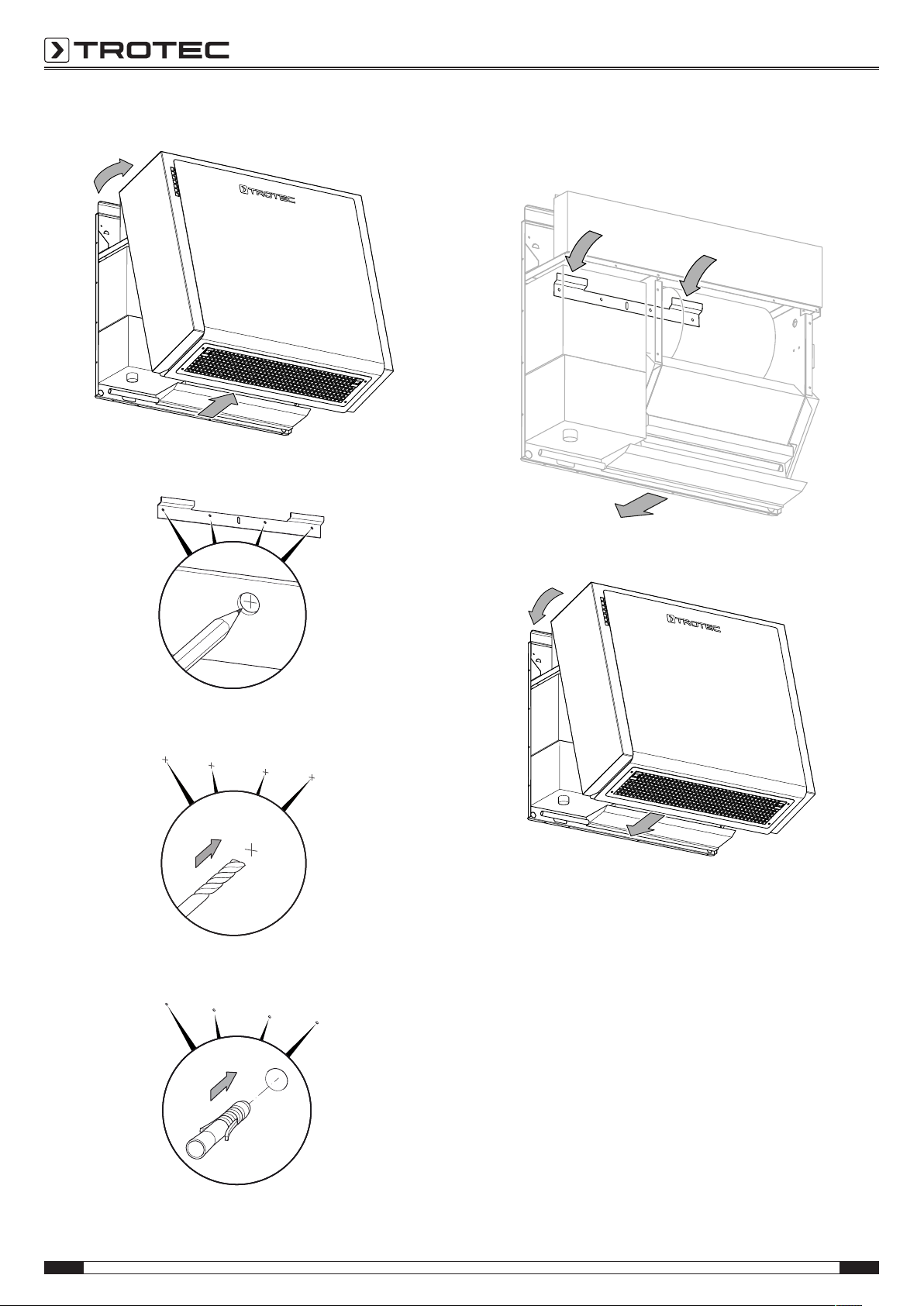

Transport, assembly and preparation for start-up

C

C

A

B

D

DH 30 VPR+

DH 60 VPR+

Always utilize the help of another person to transport and

assemble the DH30VPR+. Always utilize the help of two other

persons to transport and assemble the DH60VPR+. Do not try

to assemble the device without the help of another person. To

lift the device, use a forklift or an elevating truck as appropriate.

Observe the following instructions:

• When assembling the device, keep a sufficient distance to

heat sources.

• When assembling the device, especially in wet areas,

secure the device locally with an RCD (Residual Current

protective Device) which complies with the relevant

regulations.

• Make sure that extension cables are completely unrolled.

• Insert the mains plug into a properly secured mains

socket.

• When assembling the device, observe the minimum

distance from adjacent walls or other objects as described

in the Technical Data chapter.

Assembly

Assemble the device as follows:

Select screw and dowel sizes suitable for the weight of the

device (see technical data) and the structure of the wall.

Warning

A falling device can cause injuries! Always transport

and assemble the device with the help of other

persons. Never stand below the device when it is

suspended. Ensure adequate stability of the device's

wall fixing.

1. The table or floor on which you should now unpack the

device must be clean.

2. Open the screw connection at the housing.

EN 6

Info

The principle of hanging up the DH60VPR+ is the

same as for the DH30VPR+. But the DH60VPR+

comes with a longer suspension rail.

The following steps will be illustrated by using the

DH30VPR+ as example.

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 8

3. Remove the housing.

4. Mark the position for the bore holes.

8. Suspend the device from the wall holder by means of the

mounting brackets. Utilize the help of one or two other

persons as well as suitable lifting gear to do so.

9. Put the housing back on the device.

5. Drill the holes into the wall.

6. Insert suitable dowels into the bore holes.

10. Fasten the housing to the device.

Storage

Drain any possibly remaining condensate.

When the device is not being used, observe the following

storage conditions:

• in an upright and stable position.

• dry and protected from frost and heat.

• protected from dust and direct sunlight.

• with a cover to protect it from invasive dust, if necessary.

7. Fasten the wall holder in place.

7 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 9

Important information regarding the dehumidification performance and drying rate

The dehumidification performance depends on:

• the layout of the room

• the individual usage behaviour

• the room temperature

• the relative humidity

The higher the room temperature and relative humidity, the

greater the dehumidification performance or drying speed at

which a wet vehicle dries.

For use in living rooms, a relative humidity of approx. 50% is

sufficient. In store rooms and archives, the humidity should

generally not exceed a level of approx. 50%.

Dehumidification of garages

For the storage of vehicles we recommend a relative humidity

between 45 and 50%. For other material-specific humidity

values please refer to the respective manufacturer's instructions

for the stored goods.

How the room temperature influences the dehumidification

performance?

In the winter at decreasing mean temperatures of below 15°C

the dehumidifier's capacity and thus the room volumes to be

covered are disproportionately reduced.

This circumstance results from the physical correlations

between the room air's moisture absorption capacity at low

temperatures and the performance curve of condenser dryers

that may appear complex to the layman. In order to render these

complex correlations comprehensible for the typical user we

endeavour to briefly describe the recommended course of action

on the subject of capacity and performance limits of the DH-VPR

+ devices at low temperatures:

Correlation between the temperature in the garage

and duration of the drying process

Mean temperature in a gar-

age during the

winter

starting at

19°C

Approximate drying

duration of wet

vehicles*

using a DH-VPR+

climate manager

less than 1day

The drying period

can be reduced

through additional

ventilation**

drying

16 – 19 °C approx. 1day

accelerated by

approx. 50 – 70%

12 – 15 °C 1 – 2 days

8 – 11 °C 3 – 5 days

4 – 7 °C more than 5days

drying

accelerated by

approx. 30 – 50 %

* The time for drying moisture

accumulated in the car body,

at the underbody and inside

the engine compartment as

well as in ribbings and

hollows could even be

significantly extended if there

is no air circulation!

Rule of thumb:

The higher the room temperature, the sooner will the

dehumidifier DH-VPR+ have "dried" the room air and therefore

all the vehicles in the garage. In contrast, the lower the room

temperatures, the longer will it take to completely dry wet

vehicles. To be sure, even at low temperatures the DH-VPR+

can quickly dry the air in the garage to the desired level, the car

and floor however remain moist.

On principle, it takes a disagreeably long time to dry wet

vehicles at temperatures below 15°C (up to several days), this

is particularly problematic considering the instant corrosion. It is

not due to the dehumidifier DH-VPR+ that the vehicle will not

dry, but rather the physical circumstances of humidity combined

with the evaporation behaviour (drying rate) of water.

A consequence of low temperatures is that on surfaces water

evaporates very slowly even at an ideal room climate of

50%RH. In simplified terms, this is due to the fact that at low

temperatures – insofar as relative humidity (%RH) is concerned

– the gradient of vapour pressure between the dry room air and

the water surface is very large, in terms of the absolute

humidity (g/m³), however, it is very small.

As a result, the water at wet vehicles situated in cold garages

evaporates very slowly even though the DH-VPR+ devices are

running at full capacity.

** Additional ventilation has a

favourable impact on the drying

duration for residual moisture

accumulated in the car body, at

the underbody and inside the

engine compartment as well as

in ribbings and hollows.

EN 8

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 10

Here a worst-case scenario:

A modern car wet with rain is parked in a garage along with a

classic vehicle. The room temperature is 4°C. Attributable to

evaporation of water at the still warm, wet vehicle, the relative

humidity in the garage quickly rises to 95%.

95% of relative humidity at 4°C mean that in absolute terms

only about 6g of water are bound in a cubic metre of air, for

that is the physical limit that can be absorbed.

For comparison:

At a room temperature of 21°C and 95%RH, 17g of water

are retained by a cubic metre of air. In other words, for every

100m³ of room air in the garage the air contains over 1litre

more of pure water (than at 4°C) in the form of water vapour.

This quickly adds up to several litres of water in the garage! And

it results in the DH-VPR+ withdrawing next to none of the water

from the room air at these low temperatures, because it is

unable to extract any. Hardly any water is bound in the room air,

rendering dehumidification a physical impossibility.

The higher the room temperature, the more moisture

can be absorbed by the room air

Temperature in the

garage:

Relative humidity:

4 °C 21 °C

50 % 95 % 50 % 95 %

3 g/m³ 6 g/m³ 9 g/m³ 17 g/m³

Moisture retained

by the room air:

(absolute humidity)

Consequence for

drying wet

vehicles:

With 95% the relative humidity given in our example is rather

high. The vehicle's corrosion and the mould formation at the

walls started immediately. It does not take a great amount of

absolute humidity in the air to get the processes of corrosion

and mould growth going. It is enough if water is bound as

vapour, even though expressed in absolute terms (g/m³) the

values are not very impressive.

Vapour pressure

difference:

3 g/m³

Low drying speed

(minor vapour pressure

difference)

Vapour pressure

difference:

8 g/m³

High drying speed

(great vapour pressure

difference)

And there is another aspect:

Due to the minor absolute vapour pressure differences, the

drops of water on the wet car do not evaporate. It stays wet

despite the DH-VPR+ operation. And the situation is the same:

Low temperatures --> minor differences in the air's moisture

content with regard to the absolute humidity level (g/m³) in spite

of large differences regarding the relative humidity.

Even at low temperatures, the DH-VPR+ keeps the room climate

at the desired level. If new water enters the scene at these low

room temperatures by way of a wet vehicle and the temperature

remains low, the wet vehicle will dry very slowly, hence causing

the humidity inside and at the car to rise to a corrosion-prone

level. Dry keeping is not a problem. Quick drying, however, is a

physical impossibility.

Conclusion:

Using DH-VPR+ devices classic cars can be stored and

showcased during the winter to a temperature of 0°C. Yet the

capacity is disproportionately reduced (see table Correlation

between the temperature in the garage and duration of the

drying process).

However, if both the storage and a quick drying of wet vehicles

are required – also during the winter – you will additionally have

to ensure heating in order to increase the drying rate for wet

vehicles so as to effectively prevent corrosion and mould

growth.

So, if the classic car garage is used all through the year and/ or

there are often wet cars inside, we recommend room

temperatures of at least 15°C. If water only sporadically enters

the garage, there is no need for permanent heating. It will be

sufficient to heat the garage to a level between 15°C and 20°C

during the drying phase lasting several days. On these grounds,

we recommend a general on-demand heating option to achieve

a reasonable temperature for drying the garage quickly.

Depending on the temperature, a heating phase of 3 to 7days

should normally suffice to ensure a fail-safe drying process.

This period can be considerably reduced by the use of fans.

Especially for a quick drying in the car body, at the underbody

as well as in ribbings and hollows we always recommend the

use of fans for wet classic cars (see table Correlation between

the temperature in the garage and duration of the drying

process).

The more frequently and extensively the cars are used, the

higher should be the average temperature in the garage so as to

attain a quick and fail-safe drying process and thus to prevent

corrosion and mould.

9 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 11

Operation

NORMAL

DRIER

8

9

10

11

12

13

DH 30 VPR+

DH 60 VPR+

• Once the device has been switched on, the drying function

works fully automatically.

• The ionization function may be started manually as

needed, see chapter Ionization.

• To make sure that the built-in sensor can determine the

humidity correctly and that the room air is permanently

filtered, the fan continues to operate until the device is

switched off.

• Avoid open doors and windows.

Info

The possible dehumidification performance of the DHVPR+ climate managers is directly tied to the room

temperature.

The higher the room temperature, the more moisture

can be withdrawn from the room air.

The lower the room temperature, the less moisture can

be withdrawn from the room air.

For more information please read the chapter

Important information regarding the

dehumidification performance and drying rate. The

physical correlations are illustrated elaborately by way

of example scenarios and the recommended course of

action.

No. Designation

8 Control dial hygrostat

9 Fusing 6.3 A / T (time delay)

10 Power Ionization button

11 Ionizer control dial

12 Warning light

13 Fan stage switch

Installing the condensation drain hose

1. Connect one end of the condensation drain hose to the

bulkhead coupling.

Operating elements

Info

You can access the operating elements by opening the

filter flap at the device, see chapter Maintenance.

The control panel of the DH30VPR+ is located on the

left-hand side, in case of the DH60VPR+ it can be

found on the right.

The depiction of the operating elements features the

device DH60VPR+ by way of example. In case of the

DH30VPR+, the individual operating elements can be

located elsewhere but with identical labelling.

2. Place the other end of the condensation drain hose in a

sufficiently dimensioned container (at least 50litres for the

DH30VPR+, 90 for the DH60VPR+) or lead the hose end

to a drain.

3. Avoid kinking.

EN 10

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 12

Notes regarding the condensation drain hose:

NORMAL

DRIER

8

NORMAL

DRIER

8

9

10

11

12

13

• The maximum pump height amounts to 10m for the

DH30VPR+ and to 15m for the DH60VPR+.

• The condensation drain hose should be no longer than

25m.

• The end of the condensation drain hose must always be

free and may not protrude into the water.

• While laying the condensation drain hose, make sure that

– even at low temperatures – the water inside the hose

cannot freeze.

Switching the device on

1. Ensure that the condensation drain hose has been laid and

connected properly. Do not create tripping hazards.

2. Ensure that the condensation drain hose is not bent or

jammed and that there are no objects on the condensation

drain hose.

3. Ensure that the condensation can run off properly.

4. Insert the mains plug into a properly secured mains socket.

Regulating the room humidity level

1. Set the desired humidity level via the control dial(8) of the

hygrostat.

2. Turn the control dial to the middle of the word NORMAL.

After 2days a humidity level between 50 and 55% should

be reached.

3. Then check the humidity level by means of a

thermohygrometer. If the air is too dry (insufficient humidity

level), turn the hygrostat control approx. 1cm to the left, if

the air is too humid (excessive humidity), turn it approx.

1cm to the right (towards the word DRIER).

4. Every time you have changed the hygrostat setting wait for

2days, then repeat the procedure until the desired humidity

level is reached.

Automatic defrost

If the room temperature is lower than 15°C, the heat exchanger

will freeze during dehumidification. The device will then carry

out an automatic defrost. The duration of the defrost process

can vary depending on the room temperature. The lower the

temperatures, the longer the defrost period.

Ionization

Ex factory, the dehumidifier DH-VPR+ comes equipped with a

special, high-quality NTP air purification unit. In its plasma zone,

airborne odours, pollutants and microorganisms, as are found

primarily in the recommended fields of application for the VPR

+series, can be neutralized efficiently through oxidative

conversion.

When contaminated air flows through the ionizer unit, it is

neutralized by means of electrical excitation to form singlet

oxygen with broken down hydrogen and oxygen molecules,

which are harmless for humans and nature.

The ionizers employed in the VPR+series are able to

continuously neutralize most types of these application-specific

odorous substances in the room air. As a consequence the

odour nuisance is reduced slowly, but steadily.

Ionization control

The ionization function can be switched on via button10. When

the ionization function is activated, the button(10) is

illuminated.

The device comes with a controller for 5intensity levels(11).

With the settings 1 to 4 the production of singlet oxygen can be

ð Upon reaching the desired humidity value, the compressor

switches off automatically.

ð The fan keeps running to ensure a permanent air circulation

for filtering the air, neutralizing possible odours and

monitoring the humidity level.

ð If the set humidity level is exceeded, the compressor will

automatically be activated to dehumidify the room air once

again.

11 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

adjusted from the minimum to the maximum value for the

standard permanent treatment.

Beyond that, an additional 5th level is available for short-time

intensive treatments.

When using this fifth setting, a small amount of ozone is

generated inside the device, however, if used as intended,

this concentration is neither a health hazard nor is it

damaging to the material.

Page 13

Recommended procedure for standard treatment

(settings 1-4)

The perception of odours is subjective. Besides, fluctuating

climate parameters such as the humidity level and room

temperature influence not only the diffusion of odour particles in

the room, but also the reaction potential for the oxidative

conversion of airborne odours and pollutants.

For this reason it is not possible to specify a linear reference

value e.g. depending on the room size. Instead we recommend

an individual, active levelling geared to the local circumstances

and your personal requirements:

1. Before the first application, air the room out thoroughly.

2. To begin with, set the ionizer to level3 and the fan to

stage1 and let the device run with these settings for up to

7days.

3. During or at least at the end of the treatment there should

be either a perceivable reduction of the odour intensity

and/or a slight ozone odour.

If so, you can now turn the ionizer down by 1level and, if

required, repeat this step according to your odour

perception until you have reached level1.

4. If after a period of 7days you cannot observe a reduction of

the odour intensity or an ozone smell, increase the

operating level one by one up to max. level4 and treat the

room again for up to 7days. Before using level5 (intensive

treatment), first read the Procedure for intensive treatment.

Note:

• Any time you reduce or increase the setting by one level,

wait for at least 7days before making another change.

After every interval and before any level adjustment air the room

out exhaustively!

For the standard treatment the fan should be set to stage1.

Procedure for intensive treatment

In case of considerable odour nuisance – e.g. from long-lasting

sources such as drains, fuel odours or the smell of mould or

intensive one-time sources like tobacco, animal smells or musty

odours in the car etc. – and if the previously performed standard

treatment was not successful, it is appropriate to carry out a

short-time intensive treatment at level5 to effectively eliminate

the cause.

1. Make sure that all surfaces in the room to be treated are

freely accessible for the circulatory air of the DH-VPR+

(open windows, boot and bonnet of vehicles, open wardrobe

doors, shut the curtains to provide the best possible

effective surface). If possible, remove car mats and carpets

in the passenger compartment and boot and spread them

out on the floor of the garage. The better the air circulation

at the surfaces to be treated, the better the chances for a

successful odour elimination. To achieve optimum results,

the room temperature during the intensive treatment should

be in a range of 20 to 25°C. This generally serves to ensure

a diffusion of the odorous substances. During the intensive

treatment the room temperature must not exceed 28°C!

2. Set the ionizer to level5 and the fan to stage2 and let the

device run with these settings for 24hours.

3. After this treatment period set the intensity switch from 5

back to a lower level and see to a thorough 15-minute

ventilation (rush airing) of the room. The ozone smell is

usually evaporated after 2 to 3 intermittent ventilation

processes.

4. If after the 24-hour treatment the reduction in odour

intensity is not satisfactory, repeat step2 up to five times as

the circumstances require.

5. After a successful odour reduction repeat step3 and

continue with the standard treatment (levels1-4).

6. Also set the fan to at least stage1.

Small amounts of ozone are generated within the device during

the intensive treatment. In the room air the ionizer does not

produce ozone concentrations exceeding the generally

applicable limit values. For reasons of safety and due to

individual sensitivities however, there must be no person or

animal present in the room to be treated. Entering the room as

well as brief visits to switch the device on and off are as

harmless as the short-term exposure to the ozone smell that is

sometimes subjectively perceived as intense.

Note:

• If an ozone odour becomes noticeable in the room (not just

at the outlet opening) during the standard treatment,

gradually turn the intensity down until the smell is no

longer perceivable (Remember to air the room every time

you lower the intensity level).

EN 12

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 14

Ozone smell

If used as intended and for appropriate room sizes in inhabited

rooms such as basements, garages, halls or libraries our ionizer

does not produce harmful concentrations exceeding the max.

allowable concentration at the workplace (MAC limit value) even

if set to the highest level(5).

And yet, even this low concentrated ozone odour is often

perceived as very disagreeable. The factor between the odour

threshold perception of 40µg/m³ and the valid exposure limit

values at the workplace based on the MAC value (maximum

allowable concentration) of 0.2mg (200µg)/m³ of room air

amounts to 5.

With ozone concentrations of as little as 40µg/m³ or slightly

above many a person perceives this ozone smell as offensive

and very disagreeable. Up to the MAC limit value variations in

the ozone concentration can hardly be discerned by way of

smell, which means that even with completely uncritical

concentrations the reek of ozone is distinctive.

However it also indicates that at the same time strong

odoriphores are being effectively neutralized, e.g. tobacco,

animal or mould odours diffusing from leather, textiles, carpets,

wood or other porous materials.

Room temperatures and odours

Also important for a successful application beside the correct

dosing is the temperature at which the treatment takes place.

Heat increases the rate at which odorous substances diffuse

from materials. Once the odour is in the air, it is bound by

oxygen.

If during the wintertime the room temperature is too low (below

12°C), the odour might come back all of a sudden in the

summer. Additional heating in the cold season helps to improve

the release of not yet diffused odour particles. Hence, the

correct temperature for an effective treatment is to be attained

by trial and error.

It is easily conceivable, that you only need to use the ionizer

after the winter season, when the fuel evaporation of vehicles

with carburettor increases, odours from textile coverings begin

to diffuse or else only after extreme precipitation periods, when

the basement begins to smell musty owing to the increasing

moisture penetration in the brickwork.

Individual odour perception

The odour perception and rating differs from one individual to

another.

Because of this individual perception, a general across-theboard recommendation for dosage and usage is not feasible,

therefore every user can only achieve his odour balance by

actively and patiently levelling out the intensity levels.

Whether it concerns the smell of mould in a vault cellar, fuel

odours in the garage or the musty smell in a historical library –

every person feels differently about it. Mostly, it is not the smell

per se that is regarded as bothersome, but the intensity.

Subtle smells, generally associated with the respective

collector's item, are often desirable and even perceived as

quaint – an automobile enthusiast for instance might just love a

whiff of gas in the garage whereas his wife will probably take to

her heels once a certain intensity is reached. For an oenophile

an old wine cellar may well smell a little musty and old, but

never foul. There are many other examples we could add to the

list.

To ensure an adequate efficiency of the device as well as your

individual satisfaction, active tuning of the intensity level over

several weeks bringing it closer to your personal odour balance

cannot be avoided.

An odour neutraliser is no odour improver

Nevertheless, you should always bear in mind that this device is

an odour neutraliser, not an odour improver as may be

commonly used for the active scent marketing in department

stores. Pure neutralization through the electrical oxidation or

chemical bonding of odours does not imply a subsequent

fragrance or pleasant smell in the air.

From experience: in some cases it is also possible that after the

successful neutralization of primary odours other smells, which

have previously gone unnoticed, become apparent and are then

in turn individually perceived as objectionable.

Odour is and will remain an extremely distinct issue greatly

influenced by the personal sense of smell and the perceptual

sensitivity.

With a device of the VPR+series you have chosen a

professional tool to improve the storage conditions for your

valuables.

We are not in a position to improve the existing state of

materials and objects, but, if applied correctly, our products can

contribute to their permanent preservation by protecting your

valuables from corrosion, dust, mould and bacterial

decomposition.

13 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 15

Ozone treatment for similar applications

A (highly concentrated) ozone treatment is carried out for

example in the professional car valeting. Especially in case of

pre-owned cars, unpleasant odours inside the passenger

compartment (e.g. former smoker's vehicle) can be eliminated

in this manner.

The oxidising effect of ozone turns odorous substances into

odourless substances. Germs and odour-causing bacteria are

killed in this process – even at otherwise inaccessible locations

such as under seats or in ventilation openings. As a result of this

treatment the vehicle is disinfected and usually odour-free.

The ozone treatment is also a worldwide standard method for

odour neutralization and disinfection in the hotel industry, used

in smoking rooms or for other substantial odour nuisances.

In the sector of fire, water and sewage damage restoration

ozonization has been the most commonly used standard method

for many years.

Employed for these applications are however pure ozone

generators with concentrations of 5g/m³ and more, which

cannot be compared with the NTPgenerator built into the

VPR+series.

Should you have similar requirements or be unable to get the

odour sources under control despite the application of the

VPR+ionizer, please contact our specialist consultants. We'd be

happy to advise you and we offer ozone generators of every

performance class for the professional odour neutralization. If

necessary, we will refer you to proven experts in your region.

Neutralization of fuels

Generally, the fuel odour in garages can be neutralized

sufficiently. Within 2weeks the objective of a sufficient

neutralization rate is usually achieved.

With extreme evaporation rates however (many sources of

evaporation, sports carburettor, leaky tank lines or gaskets and

high room temperatures) in some cases the neutralization

performance of the (or an) ionizer is not sufficient to produce the

desired success. An ozone concentration well beyond the max.

allowable concentration at the workplace (MAC limit value)

would have to be emitted in the room.

Leaving aside the fact that fuel vapours of this concentration are

hazardous to health, low-dose ionizers can solve this special

problem only in part.

In order to successfully eliminate such extreme fuel odours,

mechanical and chemical bonding of the vapours has to be

effected in addition to the electrical neutralization.

For this purpose we offer mechanical air cleaners that have

activated carbon filters specifically designed for extreme fuel

odours. Combined with the ionizer we achieve a satisfactory

solution in 99% of cases with extreme fuel odours. Often

another separate ionizer can also be helpful in such cases.

Please contact our consultants as needed.

Air filter

As standard, devices of the VPR+series are delivered with 2air

filters:

• 1 x air filter dust (standard)

• 1 x air filter dust/soot (combination filter)

The technical data given for the air volume freely blowing refers

to the air volume at the device outlet without filter. Every air

filter applied reduces the amount of circulated air depending on

the type of filter and its filtration efficiency.

All filters are adapted for the devices of the VPR+series and

work together perfectly.

Owing to the more efficient 2-stage filter ladder, the dust/soot

combination filter reduces the amount of exhaust air to a greater

extent than the standard air filter. The circulating air

performance depends on the contamination level of the

combination filter: with a new air filter it is reduced by 15%, if

the filter is heavily contaminated with soot the circulating air

performance will be reduced by up to 99%. Soot contains oily

products from incomplete combustion and clogs the filter

surface excessively – especially when combined with the dust

from the room air. On these grounds and in case of a high dust

and soot pollution it is especially important to regularly check

the air filter for dirt and to replace it if necessary.

The two stages of the fan permit an individual adjustment of the

circulating air performance to the respective room size and

odour nuisance. The selected filtration method must be

observed, since the attainable air flow rate varies depending on

the used filter type (standard or combination filter). The table

below contains the model-specific air flow rates for the fan

stages1 and 2 including all filter combinations:

DH30VPR+:

Fan stage Freely blowing Standard filter Combination filter

Stage 1 502 m³/h 455 m³/h 420 m³/h

Stage 2 745 m³/h 685 m³/h 635 m³/h

DH60VPR+:

Fan stage Freely blowing Standard filter Combination filter

Stage 1 745 m³/h 675 m³/h 590 m³/h

Stage 2 1,065 m³/h 985 m³/h 900 m³/h

In garages with modern vehicles, where corrosion is of minor

importance, in museums, libraries or wine cellars, thus all

rooms in which the emission of soot can normally be ruled out

and where the prevention of mould and bacteria is paramount, it

is advisable to use the standard air filter. The standard air filter

has less impact on the reduction of circulated air volume than

the combination filter. Consequently a higher air circulation is

achieved when using the standard air filter. Albeit, for the filter

change the same rules apply as for the combination filter.

A dirty air filter significantly reduces the dehumidification

performance, the equipment's lifetime and the efficiency of

odour neutralization.

EN 14

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 16

Shutdown

DH 30 VPR+

DH 60 VPR+

Warning of electrical voltage

Do not touch the mains plug with wet or damp hands.

1. Hold onto the mains plug while pulling the power cable out

of the mains socket.

2. If necessary, remove the condensation drain hose and any

residual fluid from it.

3. Clean the device according to the Maintenance chapter.

4. Store the device according to the Storage chapter.

Errors and faults

The device has been checked for proper functioning several

times during production. If malfunctions occur nonetheless,

check the device according to the following list.

The device does not start:

• Check the power connection (230 V/1~/50 Hz).

• Check the power cable for damages.

• Check the on-site fusing.

• Have the electrics checked by a specialist company for

cooling and air-conditioning or by Trotec.

An alarm signal is emitted:

• The pump attempts to pump off a larger quantity of water.

The device will be switched off completely. As soon as the

water is gone, the device will restart and the alarm dies.

• If the emitted alarm signal is a continuous tone, the

condensate pump inside the device needs to be checked.

To do so, please proceed as follows:

1. Hold onto the mains plug while pulling the power cable out

of the mains socket.

2. Open the screw connection at the housing.

The device is running, but there is no formation of

condensate:

• Check whether the condensation drain hose is positioned

correctly.

• Check the room temperature. Observe the device's

permissible operating range according to the technical

data (see chapter Important information regarding the

dehumidification performance and drying rate).

• Ensure that the relative humidity complies with the

technical data (see chapter Important information

regarding the dehumidification performance and drying

rate).

• Check the preselected humidity level at the hygrostat's

control dial(8). The humidity in the room must be above

the selected range. Reduce the desired humidity level by

turning the control dial(8) to the right (towards the word

DRIER).

• Check the condensate pump for proper functioning or

unusual vibrations and sounds. Remove external dirt (see

chapter Maintenance).

• Check the air filter for dirt. If necessary, clean or replace

the air filter (see chapter Maintenance).

The device is loud or vibrates:

• Check whether the device is mounted horizontally.

• Check whether the air filter has been inserted correctly.

15 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 17

3. Remove the housing.

4. Check whether the float in the container floats. If required,

fill a little water into the condensation tray. If the float is

stuck and does not float, it could help to lightly tap the side

of the container.

5. Check whether water has accumulated in the condensate

collection container or the condensation tray.

8. Fasten the housing to the device.

9. Plug the power cable back into the mains socket.

If the alarm signal continues despite these measures, please

contact Trotec.

The device gets very warm, is loud or loses power:

• Check the air filter for dirt. Remove external dirt.

• Check the inside of the device for dirt. If necessary, clean

the interior of the device using compressed air.

Your device still does not operate correctly after these

checks?

Have the device repaired by authorised expert staff or by Trotec.

6. If so, clean the drain hoses.

7. Put the housing back on the device.

EN 16

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 18

Maintenance

Maintenance intervals

Maintenance and care interval before every

start-up

Check air inlets and outlets for dirt and

foreign objects and clean if necessary

Clean the exterior X X

Visually check the inside of the device for

dirt

Check for damage X X

Check the attachment screws X X

Test run X

Replace air filter X

Replace air filter (in case of a high dust

and/or soot pollution)

Empty the condensate pump, condensation

tray and/or condenser dryer

X X

as needed at least every 2

weeks

X X

every 2 months at

the latest

X

at least every 4

weeks

at least every 6

months

at least annually

Maintenance and care log

Device type: .............................................

Maintenance and care interval 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Check air inlets and outlets for dirt and

foreign objects and clean if necessary

Clean the exterior

Visually check the inside of the device for

dirt

Check for damage

Check the attachment screws

Check the condensate pump and tank, and

clean if necessary

Test run

Comments

Device number: ....................................

1. Date: ................................

Signature: ............................

5. Date: ................................

Signature: ............................

9. Date: ................................

Signature: ............................

13. Date: ..............................

Signature: ............................

17 EN

2. Date: ................................

Signature: ............................

6. Date: ................................

Signature: ............................

10. Date: ..............................

Signature: ............................

14. Date: ..............................

Signature: ............................

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

3. Date: ................................

Signature: ............................

7. Date: ................................

Signature: ............................

11. Date: ..............................

Signature: ............................

15. Date: ..............................

Signature: ............................

4. Date: ................................

Signature: ............................

8. Date: ................................

Signature: ............................

12. Date: ..............................

Signature: ............................

16. Date: ..............................

Signature: ............................

Page 19

Activities required before starting maintenance

DH 30 VPR+

DH 60 VPR+

• Do not touch the mains plug with wet or damp hands.

• Before any work, remove the mains plug!

Warning of electrical voltage

Maintenance tasks at the electrical equipment or the

air-conditioning technology must only be carried out by

specialist companies for cooling and air-conditioning or

by Trotec.

Cleaning the housing

Clean the device with a soft, damp and lint-free cloth. Ensure

that no moisture enters the housing. Protect electrical

components from moisture. Do not use any aggressive cleaning

agents such as cleaning sprays, solvents, alcohol-based or

abrasive cleaners to dampen the cloth.

2. Remove the housing.

Cleaning the inside of the device

Perform this activity once a year.

1. Open the screw connection at the housing.

3. Clean the hose lines at the pump and remove any dirt.

4. Put the housing back on the device.

EN 18

5. Fasten the housing to the device.

6. Plug the power cable back into the mains socket.

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 20

Refrigerant circuit

3

• The entire refrigerant circuit is a maintenance-free,

hermetically sealed system and may only be maintained or

repaired by specialist companies for cooling and airconditioning or by Trotec.

Replacing the air filter

Perform this activity every 6 months. In case of a high dust and/

or soot pollution the air filter has to be replaced after 2months

at the latest.

Notice

Ensure that the air filter is not worn or damaged. The

corners and edges of the air filter must not be

deformed or rounded. Before reinserting the air filter,

make sure that it is undamaged and dry!

Notice

A dirty air filter obstructs the air current. This can lead

to damages at the refrigerant circuit and ionizer.

During operation with a dirty air filter there will be

neither dehumidification nor ionization.

2. Remove the air filter.

3. Install the new air filter. In doing so, make sure that the

white side of the combination filter faces outwards.

The air filter's frame must line up precisely with the corners

and edges of the cut-out to prevent unfiltered air flows!

1. Open the filter flap(3).

4. Dispose of the used filter according to the national

regulations.

5. Refit the filter flap(3).

19 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 21

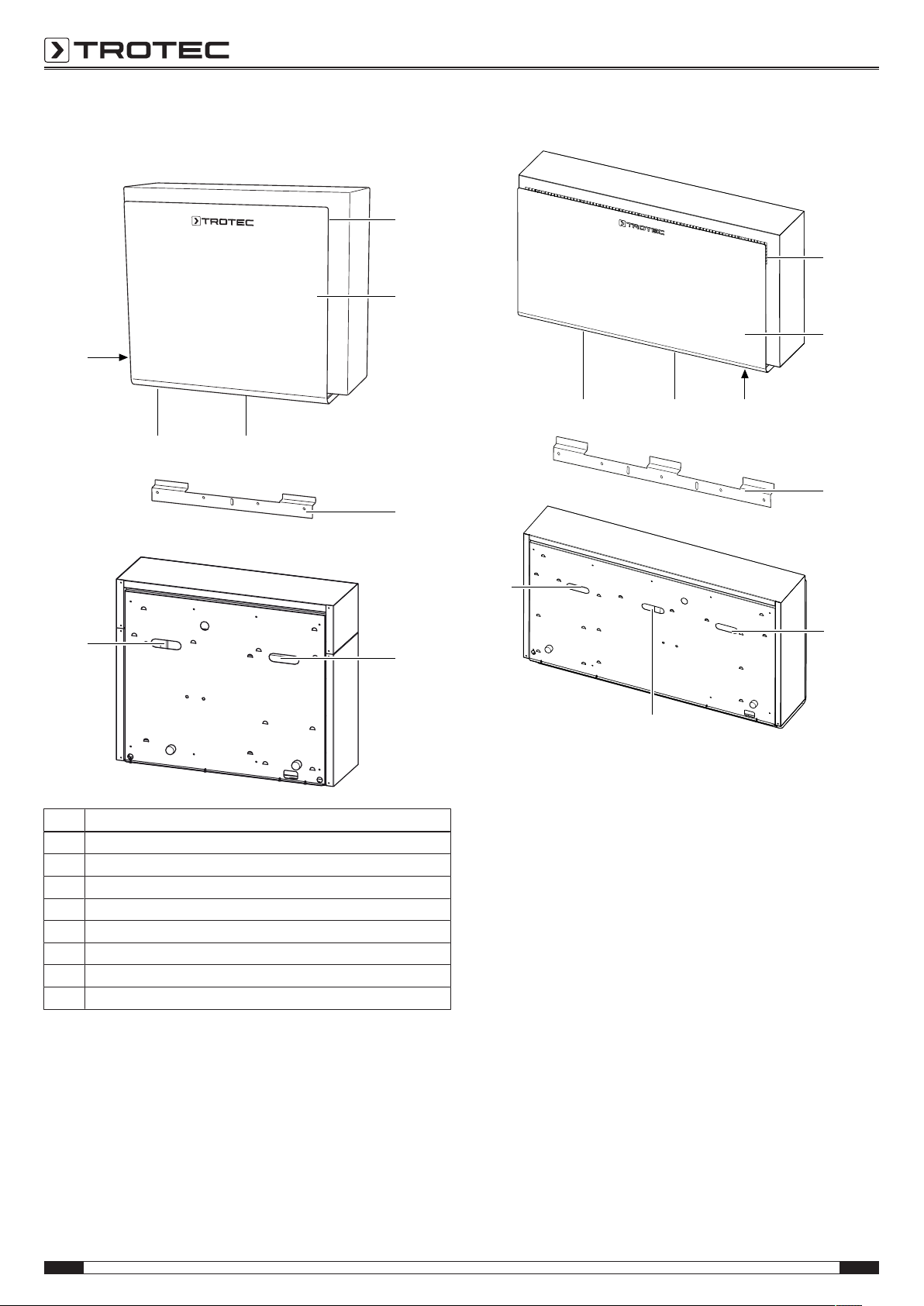

Technical annex

l / 24 h

35

30

25

20

15

10

°C

1) 2)

40 % 50 %

30 %

60 % 70 %

80 %

0 10 20 30 40 50 60

2,15

1,90

1,70

1,50

1,35

1,20

0,80

0,75

0,70

0,65

0,60

0,55

DH 30 VPR

DH 30 VPR+

l / 24 h

35

30

25

20

15

10

°C

1) 2)

40 % 50%

30 %

60 % 70%

80 %

0 20 40 60 80 100 120

4,1

3,5

3,1

2,6

2,3

1,9

1,3

1,2

1,1

1,0

0,9

0,8

DH 60 VPR

DH 60 VPR+

Technical data

Parameter Value

Model

DH30VPR+ DH60VPR+

Dehumidification performance see dehumidification diagrams

Mains connection 1/N/PE~ 230 V / 50 Hz

Power cable CEE 7/7 / l = 3.5 m

Power input dehumidification 0.75 kW 1.2 kW

Power input ventilation 88 W 85 W

Nominal/peak current 4.4 A / 15.8 A 7.5 A / 30 A

Heat emission at 15°C 1.35 kW 2.3 kW

Coefficient of performance (COP *) 2.5 2.9

Refrigerant R-407C R-407C

Amount of refrigerant 0.5 kg 0.8 kg

GWP (Global Warming Potential) 1774 1774

Air flow rate (freely blowing, stage2) 745 m³/h 1,065 m³/h

Sound pressure level (3 m distance) 52 dB(A) 54 dB(A)

Operating range temperature 0to 40°C 0to 40°C

Setting range relative humidity 30 % to 60 % RH

Max. permissible relative humidity 90 % RH

Max. pump height of the condensate pump 10 m 15 m

Condensation drain hose ø 5 mm (inside), l = 10 m

Weight 57 kg 90 kg

Dimensions (width x depth x height)

787 x 280 x 690 (mm) 1,255 x 280 x 690 (mm)

incl. wall holder

Standard faceplate steel, white powder-coated

Minimum distance to walls or other objects:

A: top:

B: bottom:

C: side:

D: front:

12.5 cm

12.5 cm

12.5 cm

12.5 cm

12.5 cm

12.5 cm

12.5 cm

12.5 cm

* The COP is the ratio of the generated cooling capacity or heat output to the electrical power input.

Dehumidification chart

EN 20

No. Designation

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

1) Heat emission in kW at 60 %RH

2) Power input in kW at 60 %RH

Page 22

Refrigerant circuit diagram

COMPRESSOR

SOLENOID VALVE

AIR CONDENSER

EVAPORATOR

DRIER

CAPILLARY

INSULATION

PROCESS PORT

21 EN

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 23

Disposal

The icon with the crossed-out waste bin on waste

electrical or electronic equipment stipulates that this equipment

must not be disposed of with the household waste at the end of

its life. You will find collection points for free return of waste

electrical and electronic equipment in your vicinity. The

addresses can be obtained from your municipality or local

administration. For further return options provided by us please

refer to our website www.trotec24.com.

The separate collection of waste electrical and electronic

equipment aims to enable the re-use, recycling and other forms

of recovery of waste equipment as well as to prevent negative

effects for the environment and human health caused by the

disposal of hazardous substances potentially contained in the

equipment.

You are responsible for deleting any personal data stored on the

waste equipment to be disposed of.

The device is operated with fluorinated greenhouse gas which

can be dangerous for the environment and contribute to global

warming when emitted to the atmosphere.

Further information is provided on the nameplate.

Dispose of the refrigerant appropriately and according to the

national regulations.

EN 22

Operating manual – dehumidifier / climate manager DH 30 VPR+ / DH 60 VPR+

Page 24

Trotec GmbH & Co. KG

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...