Page 1

BB20

EN

OPERATING MANUAL

LAYER THICKNESS

MEASURING DEVICE

TRT-BA-BB20-TC2019-05-001-EN

Page 2

Table of contents

Notes regarding the operating manual................................. 2

Safety .....................................................................................2

You can download the current version of the operating manual

and the EU declaration of conformity via the following link:

Information about the device................................................3

Transport and storage...........................................................5

Operation ...............................................................................5

Menu structure ....................................................................10

PC software..........................................................................11

Errors and faults..................................................................11

Maintenance and repair ......................................................11

Disposal ...............................................................................12

Notes regarding the operating manual

Symbols

Warning of electrical voltage

This symbol indicates dangers to the life and health of

persons due to electrical voltage.

Warning

This signal word indicates a hazard with an average

risk level which, if not avoided, can result in serious

injury or death.

Caution

This signal word indicates a hazard with a low risk

level which, if not avoided, can result in minor or

moderate injury.

Note

This signal word indicates important information (e.g.

material damage), but does not indicate hazards.

Info

Information marked with this symbol helps you to carry

out your tasks quickly and safely.

Follow the manual

Information marked with this symbol indicates that the

operating manual must be observed.

BB20

https://hub.trotec.com/?id=43284

Safety

Read this manual carefully before starting or using the

device. Always store the manual in the immediate vicinity

of the device or its site of use!

Warning

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may

result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future

reference.

This appliance can be used by children aged from

8years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved.

Children shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

• Do not use the device in potentially explosive rooms.

• Do not use the device in aggressive atmosphere.

• Protect the device from permanent direct sunlight.

• Do not remove any safety signs, stickers or labels from the

device. Keep all safety signs, stickers and labels in legible

condition.

• Do not open the device.

• Observe the storage and operating conditions as given in

the Technical data chapter.

Intended use

Only use the device for coating thickness measurements.

Observe and comply with the technical data.

To use the device for its intended use, only use accessories and

spare parts which have been approved by Trotec.

2 EN

layer thickness measuring device BB20

Page 3

Improper use

1

2

8

7

9

5

4

3

10

6

Do not use the device in potentially explosive atmospheres, for

measurements in liquids or at live parts. Trotec accepts no

liability for damages resulting from improper use. In such a

case, any warranty claims will be voided. Any unauthorised

modifications, alterations or structural changes to the device are

forbidden.

Personnel qualifications

People who use this device must:

• have read and understood the operating manual, especially

the Safety chapter.

Residual risks

Warning

Risk of suffocation!

Do not leave the packaging lying around. Children may

use it as a dangerous toy.

Warning

The device is not a toy and does not belong in the

hands of children.

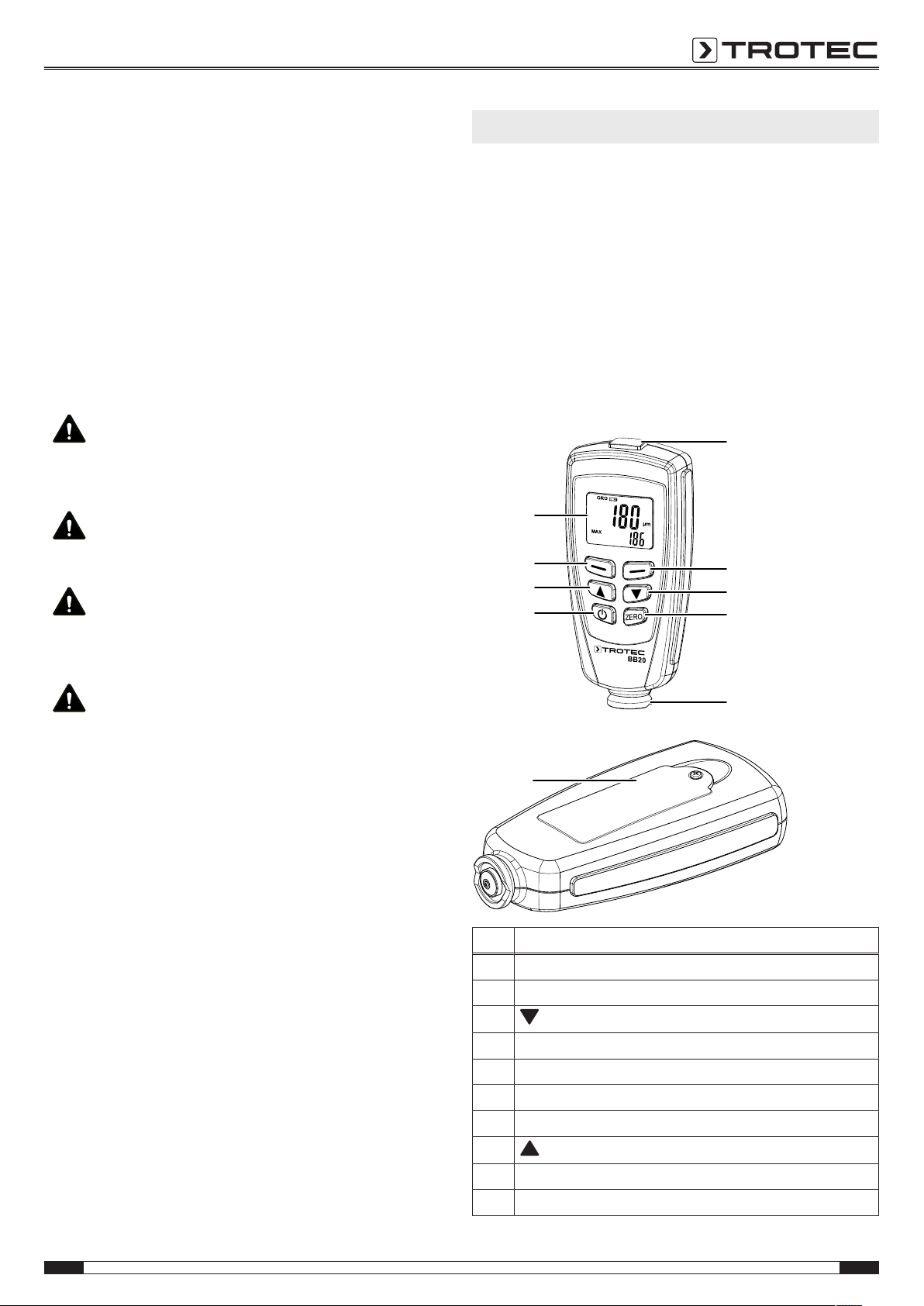

Information about the device

Device description

The deviceBB20 is used to determine the coating thickness on

ferromagnetic and non-ferromagnetic metal surfaces. The

measuring device functions according to the magnetic induction

principle (for coatings on ferromagnetic surfaces) or the

turbulent flow principle (for coatings on non-ferromagnetic

surfaces).

The BB20 is a compact and versatile device suitable for quick,

precise and non-destructive measurements of coating

thicknesses.

Device depiction

Warning

Dangers can occur at the device when it is used by

untrained people in an unprofessional or improper way!

Observe the personnel qualifications!

Caution

Keep a sufficient distance from heat sources.

Note

To prevent damages to the device, do not expose it to

extreme temperatures, extreme humidity or moisture.

Note

Do not use abrasive cleaners or solvents to clean the

device.

No. Designation

1 USB interface

2 Blue button (back/ cancel)

3

button

4 ZERO button

5 Sensor

6 Battery compartment with cover

7 Power button

8

button

9 Red button (select/ confirm)

10 Display

EN 3

layer thickness measuring device BB20

Page 4

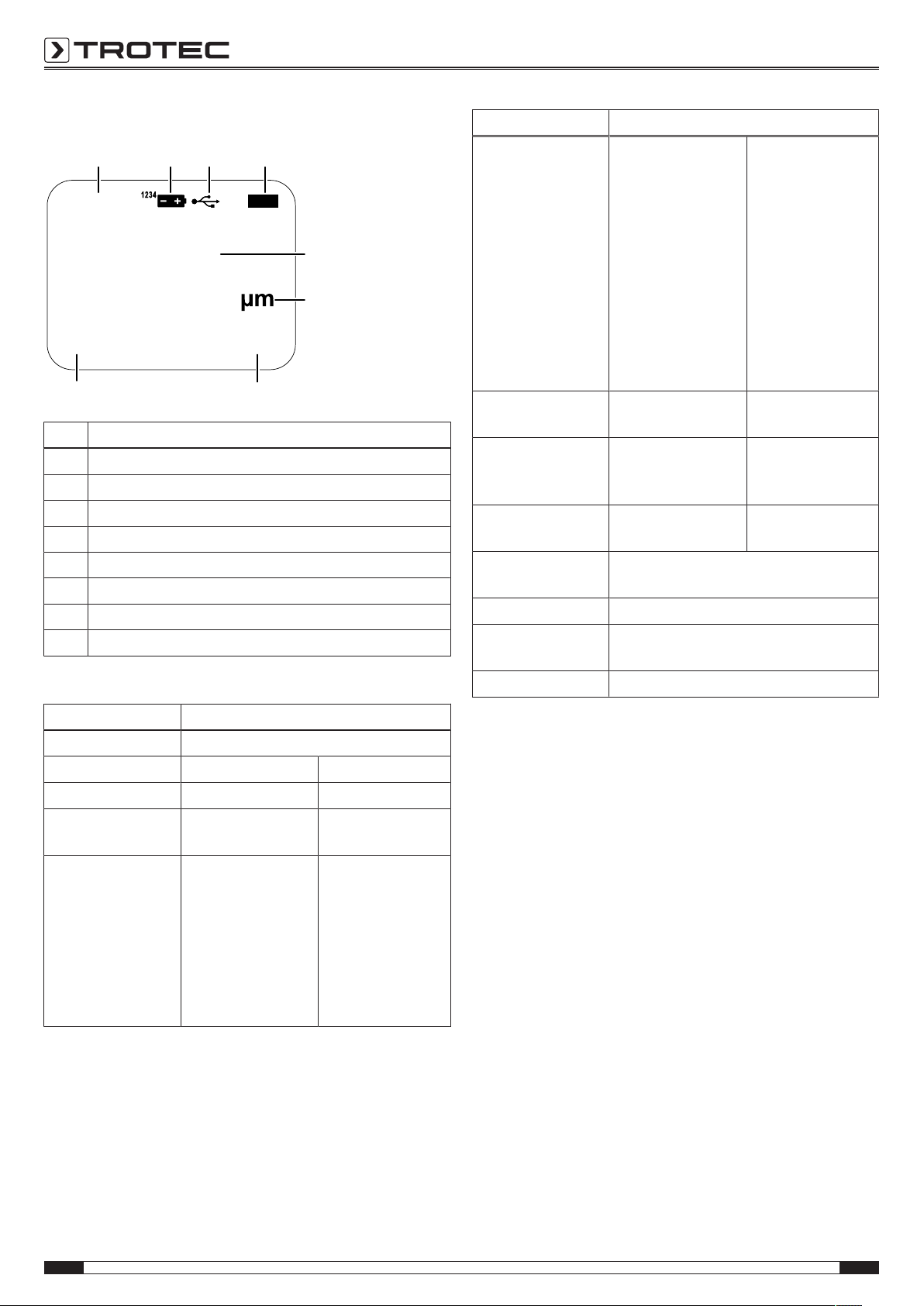

Display

DIR GRO

NO=3 MAX=63

NFe

58

18 17

16

15

14

13

11

12

No. Designation

11 Working mode display

12 Battery indication

13 PC access display

14 NFe/Fe display

15 Indication of the unit

16 Layer thickness display

17 Statistical data display: AVG, MAX, MIN, SDEV

18 Number of measured values

Technical data

Parameter Value

Accuracy 0 to 50μm

(0.1μm)

50 to 850μm

(1μm)

850 to 1250μm

(0.01mm)

0 to 1.968mils

(0.001mils)

1.968 to 33.46mils

(0.01mils)

33.46 to 49.21mils

(0.1mils)

Minimum bending

radius

Diameter of the

smallest measuring

surface

Critical primary layer

thickness

Ambient temperature

Power supply 2 batteries 1.5 V AAA

Dimensions (length

x width x height)

Weight 152 g

1.5 mm 3 mm

7 mm 5 mm

0.5μm 0.3μm

0 to 40°C (32 to 104°F) at 20 to

90%RH

114x 27x 54 mm

0 to 50μm

(0.1μm)

50 to 850μm

(1μm)

850 to 1250μm

(0.01mm)

0 to 1.968mils

(0.001mils)

1.968 to 33.46mils

(0.01mils)

33.46 to 49.21mils

(0.1mils)

Parameter Value

Model BB20

Sensor

Functional principle Magnetic induction Turbulent flow

Measuring range 0 to 1250 μm

Guaranteed

tolerance (of the

measured value)

F N

0 to 49.21 mils

0 to 850μm

(±3 % ±1μm)

850 to 1250μm

(±5 %)

0 to 33.46mils

(±3 % ±0.039mils)

33.46 to 49.21mils

(±5 %)

0 to 1250 μm

0 to 49.21 mils

0 to 1000μm

(±3 % ±1.5μm)

850 to 1250μm

(±5 %)

0 to 33.46mils

(±3 % ±0.059mils)

33.46 to 78.7mils

(±5 %)

Scope of delivery

• 1 x Layer thickness measuring device BB20

• 2 x 1.5 V batteries AAA

• 1 x Transport case

• 1xSteel and aluminium base plate with different film

thicknesses for calibration

• 1 x USB cable

• 1x Operating manual

• 1x PCsoftware

4 EN

layer thickness measuring device BB20

Page 5

Transport and storage

Operation

Note

If you store or transport the device improperly, the

device may be damaged.

Note the information regarding transport and storage of

the device.

Transport

For transporting the device, use the transport case included in

the scope of delivery in order to protect the device from external

influences.

Storage

When the device is not being used, observe the following

storage conditions:

• dry and protected from frost and heat

• protected from dust and direct sunlight

• For storing the device, use the transport case included in

the scope of delivery in order to protect the device from

external influences.

• The storage temperature is the same as the range given in

the Technical data chapter.

• Remove the batteries from the device.

Inserting the batteries

• Insert the supplied batteries before first use.

1. Loosen the screw and open the battery compartment(6).

2. Insert the new batteries in the battery compartment(6)

with correct polarity.

3. Place the cover back on the battery compartment(6) and

reinsert the screw.

Switching the device on

Info

Note that moving from a cold area to a warm area can

lead to condensation forming on the device's circuit

board. This physical and unavoidable effect can falsify

the measurement. In this case, the display shows

either no measured values or they are incorrect. Wait a

few minutes until the device has become adjusted to

the changed conditions before carrying out a

measurement.

1. Press the Power button(7).

ð The display will be switched on and the device ready for

operation.

Menu

Press the Red button(9) to open the main menu.

Press the (3) or button(8) to select the desired menu

item.

In order to confirm the selected menu item, press the Red

button(9) again.

Press the Blue button(2) to return to the previous menu item.

EN 5

layer thickness measuring device BB20

Page 6

Setting the measuring mode

To adjust the measuring mode, please proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Measure mode menu item, then, select the

desired mode. Confirm with the Redbutton(9).

Single mode:

After every measurement, an acoustic signal will be emitted. All

measurements are automatically saved.

Continuous mode:

The sensor must not be lifted between the individual

measurements. No acoustic signal will be emitted after the

measurement. All measurements are automatically saved.

Setting the working mode

To set the working mode, please proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Working mode menu item, then, select the

desired mode. Confirm with the Redbutton(9).

The device offers two different working modes:

DIRECT:

This mode is suitable for quick and easy measurements.

Measurements are cached during a measurement series.

Once the device is switched off or changes into another working

mode, the measurement results will be deleted. The statistical

analysis programme is able to assess80measurements. Once

the memory is full, the oldest measurements will be overwritten.

GROUP:

The GROUP mode comprises group1to4. In each group,

80individual and 5statistical measurements can be saved.

Calibration and limit values can be adjusted and saved

individually.

Once the memory is full, current measurements will no longer

be saved. Measurements can be carried out as usual.

Setting the sensor mode

To adjust the sensor mode, please proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Used probe menu item, then, select the desired

mode. Confirm with the Redbutton(9).

• AUTO:

The sensor automatically selects a measuring mode.

• Fe:

The sensor operates according to the magnetic induction

principle if it is placed on a magnetic surface.

• Not Fe:

The sensor operates according to the turbulent flow

principle if it is placed on non-magnetic metals.

Units

You can choose between metric (μm and mm) and

imperial(mils) units.

If the measured value exceeds850μm, the device switches to

mm.

To change the unit, proceed as follows:

1. Press the Red button(9) to open the main menu.

2. In the menu, select the menu item Options and confirm by

pressing the Red(9) button.

3. Select the Unit setting menu item, then, select the desired

unit. Confirm with the Redbutton(9).

Reset

Resetting deletes the entire data in all memories. In order to

carry out a reset, follow these steps:

1. Switch the device off.

2. Simultaneously press the Zero button(4) and the Power

button(7).

ð sure to reset will be displayed.

3. Press the Red button(9) to confirm or the Blue button(2) to

cancel the process.

The device automatically switches back on.

Background illumination

In the menu, you can control the background illumination using

Options and Backlight, during a measurement, use the

Bluebutton(2).

6 EN

layer thickness measuring device BB20

Page 7

Indication of statistics

In the menu item LCD Statistic, you can choose between the

following indications:

• Average

• Maximum

• Minimum

• Standard deviation (Sdev.)

The selected indication appears in the bottom right corner of the

display in the statistical data indication(17).

Statistics of the measured values appear on the bottom left

corner in the display in the measured values indication(18).

To view all statistical values of the respective groups, go to the

menu and select Statisticview.

Measured value indication

To view all measured values of the respective groups, go to the

menu and select Measureview.

Automatic switch-off

The device switches off after 3 minutes of inactivity. To

deactivate automatic switch-off, go to the Options section in the

menu and select the Auto poweroff function. Select Disable and

confirm by pressing the Red(9) button.

Device calibration

Carry out a calibration before each measuring operation.

You can perform the calibration e.g. at an untreated or uncoated

spot of the object to be tested or use the set included in the

scope of delivery.

Calibration mode

1. Press the Red button(9) to open the main menu.

2. Select the Calibration menu item, then select Enable.

ð You return automatically back to Calibration.

3. Press the Blue button(2) to return back to the start screen.

Calibration is carried out here.

ð The following messages appear on the display:

• cal zero: There is no one-point or two-point calibration.

• cal1to2: There is a one-point or two-point calibration.

• zeroy: There is a zero-point calibration.

Info

Please bear in mind that the device at hand is a

precision measuring device that can determine coating

thicknesses of no more than a few micrometres (1µm

is equivalent to one thousandth of a millimetre).

The surface condition of most measuring objects is

hardly ever perfectly even and homogeneous, even

though it might appear differently to the naked eye.

Observed under the microscope, even the smoothest

surface looks much like a mountain and valley

landscape. The teensiest of scratches, cavities or

contaminations can therefore already have a negative

effect on the expected measurement result, seeing as

they will also be a part of the measurement to a

greater or lesser extent. It does, however, not affect

the accuracy of the device. Even after the calibration

unexpected measurement deviations of a few

micrometres always have to be regarded in this

context.

Hence it is important to handle the supplied calibration

accessories with care to avoid scratches and dirt on

their respective surface as far as possible.

EN 7

layer thickness measuring device BB20

Page 8

Zero point calibration

ü An uncoated sample is required.

1. Place the sensor onto an uncoated sample. The calibration

sample is to be identical with the actual sample in terms of

material composition, shape and surface condition.

ð The following message will be displayed:

<x.x μm>

2. Lift the sensor again and keep it away from the sample (at

least 10cm).

3. Press and hold the Zero button(4) for approx. 2seconds.

ð The following result appears on the display:

<0.0μm>

CAL1

ZeroY

ð The calibration is terminated.

One-point calibration

This calibration is suited for high-precision measurements, e.g.

for thin coatings.

ü A calibration film, a coated and an uncoated sample are

required.

1. Activate the calibration mode as described before.

2. Carry out a zero-point calibration.

3. Place the calibration film on an uncoated sample.

4. Place the sensor on the sample.

ð The measurement is effected.

5. Lift the sensor again.

6. Adjust the required film thickness by using the Down/

Right(3) or the Up/Left(8) button. The film thickness

should be at least the size of the estimated coating

thickness.

7. Repeat this step several times.

8. Now carry out the measurement on a coated sample.

9. Press the Zero button(4) to adopt the current calibration.

10. To exit the current calibration, press the Blue button(2).

Two-point calibration

This calibration is especially suited for measurements on rough

surfaces or for high-precision measurements.

ü You need two films of different film thickness. The thicker

film should be approx.1.5 times thicker than the thinner

film.

1. At first, carry out a zero-point calibration.

2. Using the first film, carry out a one-point calibration.

3. Repeat this step with the second film.

4. Place the sensor onto the coating that is to be measured.

After a brief acoustic signal is emitted, you can lift the

sensor again.

ð The measured value appears on the display.

Calibration on radiated surfaces

Values of layer thickness measurements carried out on radiated

surfaces are usually too high. The average thickness can be

determined as follows:

Method A

1. Carry out the steps for one-point and two-point calibration

as described above. Use a smooth sample with the same

surface curvature and material type as the measuring

object that is to be used later on.

2. In order to determine the average value Xo, carry out

approx.10 measurements on the uncoated sample.

3. Afterwards, carry out approx.10 measurements on the

coated sample to determine the average value Xm.

ð The difference between both average values is the

average coating thickness Xeff. Take the standard

deviation of both values Xm and Xo into account.

Xeff= (Xm - Xo)±S

Method B

1. Carry out a zero calibration with approx.10measurements

on an uncoated sample.

2. Afterwards, carry out a film calibration on the uncoated

sample.

3. Repeat this calibration with films of different thicknesses

(max. thickness50μm). Together, these films should be as

thick as the assumed layer thickness.

ð The layer thickness can be read from the display.

Method C

1. Carry out the steps for two-point calibration with two films

as described above.

2. Use several 50μm films to approach the actual surface as

precisely as possible.

ð The layer thickness can be read from the display.

8 EN

layer thickness measuring device BB20

Page 9

General information on measurements

If the calibration has been carried out correctly, the measured

value lies within the guaranteed measuring tolerance. Incorrect

measured values can be deleted in the menu. The last value

results from the statistical calculation and the guaranteed

degrees of tolerance of the measured value.

Strong electrical or electromagnetic fields can influence the

measured values.

The measuring tip is to be cleared of contamination prior to

each calibration.

Wait for at least 4seconds after each measurement before

proceeding to the next measurement as the device does not

respond to measurement sequences carried out too quickly.

Deleting functions

In order to delete measured values, select Delete in the menu,

then select the measured values you would like to delete.

• Current Data

Deletes the last measured value.

• All Data

All data can be deleted during the respective working

mode.

• Group Data

Comprises Delete all data. In addition, the limit values and

one-point and two-point calibration values will be deleted.

Statistical measurements

The device is able to calculate statistics based on

80measurements. A total of 400measured values can be

saved.

No measured values are saved in direct mode, however,

calculating statistics is possible.

If you change between the different working modes or if the

device is switched off, statistics are deleted from the direct

mode.

The following statistical values are calculated:

• NO.: Number of measured values in working mode

• AVG: Average

• Sdev.: Standard deviation

• MAX: Maximum value

• MIN: Minimum value

Memory space full

If the memory space is full in group mode, statistics will no

longer be updated. However, measurements can still be carried

out. These measurements will not be part of the statistics.

In single measurement mode, FULL appears on the display.

If the memory space is full in direct mode, old measurements

are replaced by new ones and statistics will be updated.

Limit value functions

Limit values can be entered using the Limit function. It is

possible to enter limit values before, during or after carrying out

measurement series.

1. Press the Red button(9) to open the main menu.

2. Select the Limit menu item, then select Limit setting.

ð Using the (3) and (8) buttons, you can

determine the upper limit value in the High limit section

and the lower limit value in the Low limit section.

Each measured value beyond the fixed tolerance limit appears

on the display as follows:

H: Measured value is above upper limit value.

L: Measured value is below lower limit value.

EN 9

layer thickness measuring device BB20

Page 10

Menu structure

Main menu Submenu 1 Submenu 2

Statistic view

(Statistic view)

Options Measuring mode Single mode

Limit values (Limit) Limit value settings

Average view

Minimum view

Maximum view

Number view

Standard deviation

view (Sdev.view)

Working mode

(Working mode)

Used probe

(Used probe)

Units

(Unit setting)

Background illumination (Back-

light)

LCD Statistic

LCDStatistic

Automatic switchoff (Autopoweroff)

(Limitsettings)

Delete limit value

(Delete limit)

-

Continuous mode

Direct

Group 1

Group 2

Group 3

Group 4

AUTO

Fe

Not Fe

μm

mils

mm

On

Off

Average

Maximum

Minimum

Standard deviation

Activate

Deactivate

Upper limit value

Lower limit value

-

Main menu Submenu 1 Submenu 2

Delete Current data -

All data

Group data

Measured value

- indication (Measure

view)

Calibration Activate (Enable) -

Deactivate

(Disable)

Delete zeroN

Delete zeroF

10 EN

layer thickness measuring device BB20

Page 11

PC software

Errors and faults

Using the software CoatingThicknessTester stored

measurement data can be called up and saved via USB cable.

The software is available for download at www.trotec.de.

Info

The supplied free software is designed for useful basic

functionalities. Trotec assumes no liability with regard

to this free software and also provides no support on

that score. Trotec accepts no liability concerning the

use of this free software and is under no obligation to

make adjustments or to further develop updates or

upgrades.

Installation requirements

Ensure that the following minimum requirements for installing

the PC software are fulfilled:

• Supported operating systems:

– Windows 7

– Windows 8

– Windows 8.1

– Windows 10

• Hardware requirements:

– Standard USB interface

– Min. 7MB of free hard disk space

– Recommended resolution: 1280*1024 with16bit

– .NET Framework 2.0 or higher

The device has been checked for proper functioning several

times during production. If malfunctions occur nonetheless,

check the device according to the following list.

The device does not switch on:

• Check the charging status of the batteries. Change the

batteries, if required.

• Check that the batteries are properly positioned. Check the

polarity is correct.

• Never carry out an electrical check yourself; instead,

contact your Trotec customer service.

Table of faults

The following error codes can be displayed:

Error code Cause of error

Err1, Err2, Err3 Faulty contact between sensor and

mainboard

Err1 Faulty signal of eddy-current sensor

Err2 Faulty signal of magnetic induction sensor

Err3 Faulty signals of both sensors

Err4, Err5, Err6 No meaning, reserved for later versions of

the device

Err7 Faulty measurement. There might be a

hardware problem.

Installing the PC software

1. Insert the data medium with the software into the drive or

download the current software from the Service area of

Trotec download centre.

2. Double-click the installation file Setup.exe.

3. Follow the instructions of the installation wizard.

Starting the PC software

1. Connect the device to the PC using the supplied USB cable.

2. Start the PC software.

ð The software connects to the device.

ð Data stored on the device can now simply be visualised

in form of a chart or graphic.

Saving measured values (export)

You can export a selected group as csv or txt file and save it on

your PC. There the table looks as it does in the software.

1. Open the desired file.

2. You select either Save *.TXT or Save *.CSV.

Maintenance and repair

Battery change

A battery change is required, when the battery indication(12)

lights up or the device can no longer be switched on. See

chapter Operation

Cleaning

Clean the device with a soft, damp and lint-free cloth. Make

sure that no moisture enters the housing. Do not use any

sprays, solvents, alcohol-based cleaning agents or abrasive

cleaners, but only clean water to moisten the cloth.

Repair

Do not modify the device or install any spare parts. For repairs

or device testing, contact the manufacturer.

EN 11

layer thickness measuring device BB20

Page 12

Disposal

The icon with the crossed-out waste bin on waste

electrical or electronic equipment stipulates that this equipment

must not be disposed of with the household waste at the end of

its life. You will find collection points for free return of waste

electrical and electronic equipment in your vicinity. The

addresses can be obtained from your municipality or local

administration. For further return options provided by us please

refer to our website https://de.trotec.com/shop/.

The separate collection of waste electrical and electronic

equipment aims to enable the re-use, recycling and other forms

of recovery of waste equipment as well as to prevent negative

effects for the environment and human health caused by the

disposal of hazardous substances potentially contained in the

equipment.

In the European Union, batteries and accumulators must not be

treated as domestic waste, but must be disposed of

professionally in accordance with Directive 2006/66/EC of the

European Parliament and of the Council of 6September 2006

on batteries and accumulators. Please dispose of batteries and

accumulators according to the relevant legal requirements.

12 EN

layer thickness measuring device BB20

Page 13

Trotec GmbH

Grebbener Str. 7

D-52525 Heinsberg

+49 2452 962-400

+49 2452 962-200

info@trotec.com

www.trotec.com

Loading...

Loading...