Trojan Flooded, AGM, Gel User Manual

USER’S GUIDE

Congratulations

on your purchase from Trojan Battery Company, the manufacturer of the

world’s most trusted deep-cycle batteries. The battery you purchased was

engineered by Trojan to deliver superior power, performance, durability

and reliability for use in a broad range of demanding applications. From the

T2 Technology™ in our ooded batteries to the C-Max Technology™ in the

Reliant™ AGM line, our goal is to provide clean and reliable energy storage

solutions that enhance the way people live and work around the world.

This User’s Guide

was created by Trojan’s application engineers and contains vital information

regarding proper care and maintenance of your new battery. Please read through

this User’s Guide carefully and completely before using your battery. It will help

you achieve optimum performance and long life from your new investment.

800-423-6569 Ext. 3045 / +1-562-236-3045

TECHNICAL SUPPORT

Contents

01 Safety . . . . . . . . . . . . . . . . . . 5

02 Equipment Needed. . . . . . . . . . . . 5

03 Battery Installation . . . . . . . . . . . 6

3.1 Battery Connections . . . . . . . . . . . . . 6

3.2Terminal Types . . . . . . . . . . . . . . . 6

3.4Cable Size . . . . . . . . . . . . . . . . .10

3.5Torque Values . . . . . . . . . . . . . . . .11

3.6Terminal Protection . . . . . . . . . . . . .12

3.7Connecting Batteries to Increase System Power . . .12

3.8Ventilation . . . . . . . . . . . . . . . . .13

3.9Battery Orientation. . . . . . . . . . . . . .13

3.10Battery Environment . . . . . . . . . . . .13

3.11Temperature. . . . . . . . . . . . . . . . 13

04 Preventative Maintenance . . . . . . . . 14

4.1Inspection . . . . . . . . . . . . . . . . .14

4.2Watering . . . . . . . . . . . . . . . . . 14

4.3Cleaning. . . . . . . . . . . . . . . . . .16

4.4Charging & Equalizing. . . . . . . . . . . . .16

4.4.1Boost Charging . . . . . . . . . . . . . .16

4.4.2Charging . . . . . . . . . . . . . . . .18

4.4.3Equalizing . . . . . . . . . . . . . . . .22

05 Storage . . . . . . . . . . . . . . . . . 24

5.1 Storage in Hot Environments . . . . . . . . . .24

5.2Storage in Cold Environments . . . . . . . . .24

06 How to Maximize the Performance of your

Trojan Battery . . . . . . . . . . . . . . 24

07 What to Expect from your Trojan Battery . 25

08 Trouble-Shooting. . . . . . . . . . . . . 26

8.1Preparation for Testing . . . . . . . . . . . .26

8.2On-Charge Voltage Testing . . . . . . . . . . .26

8.3Specic Gravity . . . . . . . . . . . . . . .27

8.4Open Circuit Voltage Testing . . . . . . . . . .27

8.5Discharge Testing . . . . . . . . . . . . . .28

09 Battery Recycling . . . . . . . . . . . . 29

10 Battery Acronyms . . . . . . . . . . . . 30

5

USER’S GUIDE

5

01 Safety

Since batteries deliver large amounts of power that can cause injury and even death, observing safety

rules is of paramount importance. For your safety and the safety of those around you, please observe the

following checklist when working on or around batteries.

Always Never

Always wear protective clothes, gloves & safety goggles Never smoke near batteries

Always use insulated tools when working on batteries Never wear jewelry or other metal objects when working on

or around batteries

Always check connections for proper torque Never make direct contact with the electrolyte (sulfuric acid). If this occurs,

ush with large amounts of water.

Always charge batteries in well-ventilated areas Never place objects on top of batteries, which can cause a short circuit

Always keep sparks and ames* away from batteries Never add acid to a battery

Always use largest cable size of shortest length to minimize voltage drop Never charge a frozen battery

Always ensure plates are covered in water before charging Never charge a ooded battery without securing vent caps on the cells

Always make sure charger is set for the appropriate battery type (ooded,

AGM or gel)

Never charge a battery when the temperature is above 122° F (50°C)

Always charge batteries before installing Never store batteries unless they are fully charged

Always neutralize acid spills with baking soda and water Never leave an acid spill unattended

WARNING Risk of re, explosion, or burns. Do not disassemble, heat above 70° C (160° F),

or incinerate.

02 Equipment Needed

Before installation or maintenance of your batteries, have the following equipment available:

î Proper personal protective equipment

(eye protection and acid resistant gloves)

î Distilled or treated water (deionized or

reverse osmosis)

î Insulated wrench

î Baking soda

î Terminal protector spray

î Voltmeter

î Hydrometer (deep-cycle

ooded/wet batteries)

î Discharge tester (if available)

î Battery charger

TROJAN BATTERY

6

03 Battery Installation

To ensure you install your batteries properly and safely, please use the following guidelines.

3 .1 Battery Connections

Battery cables provide the link between the batteries, equipment and charging system. Faulty

connections can lead to poor performance and terminal damage, meltdown or re. To ensure proper

connections, please use the following guidelines for cable size, torque values and terminal protection.

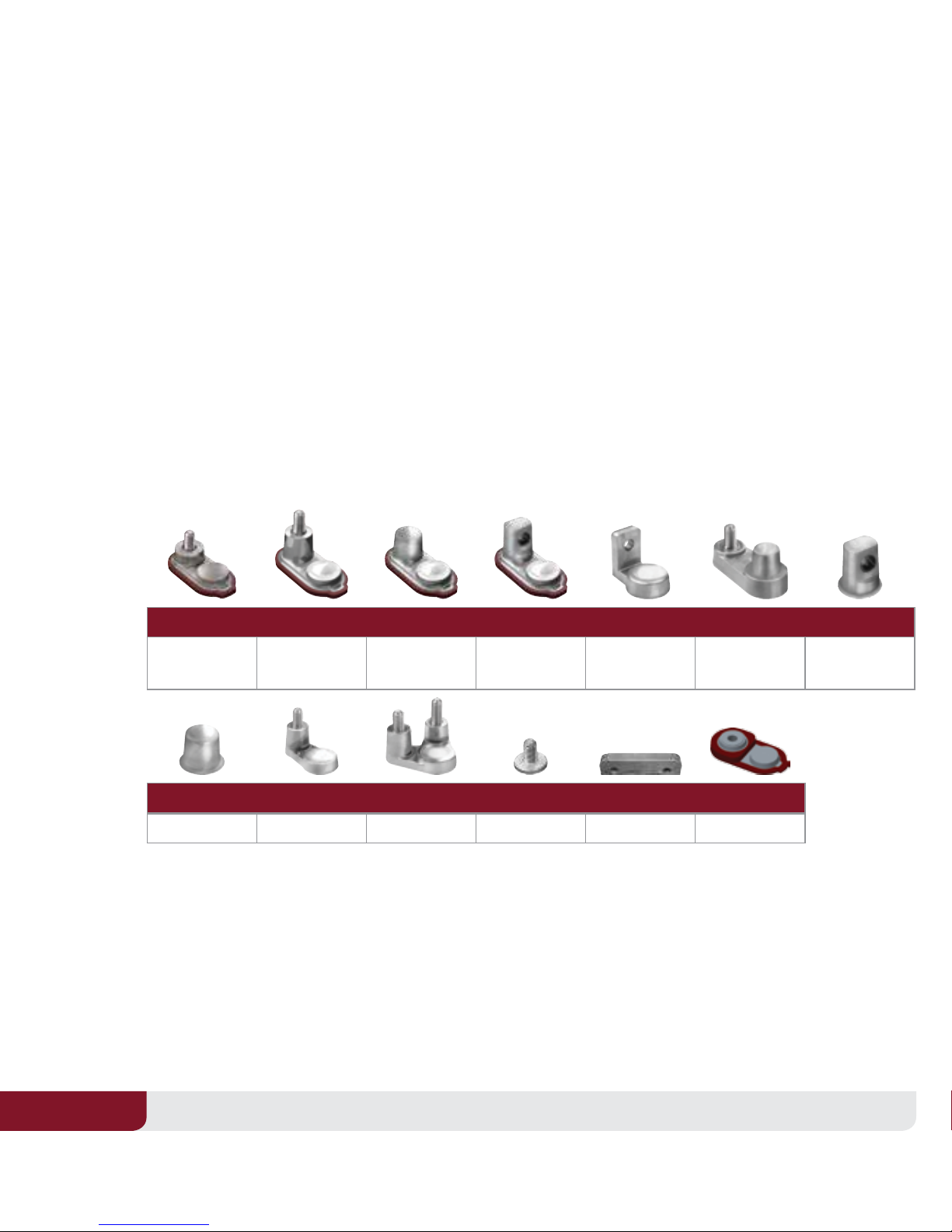

3.2 Terminal Types

Below are the various terminal types found on Trojan batteries. Refer to the appropriate terminal type

when determining proper torque in Section 3.5 below.

1 ELPT 2 EHPT 3 EAPT 4 EUT 5 LT 6 DT 7 UT

Embedded Low

Prole

Embedded High

Prole

Embedded Auto

Post

Embedded

Universal

L-Terminal Automotive Post

& Stud

Universal

8 AP 9 WNT 10 DWNT 11 ST 14 IND 15 M6/M8 15

Automotive Post Wingnut Dual Wingnut Stud Industrial

6mm/8mm Insert

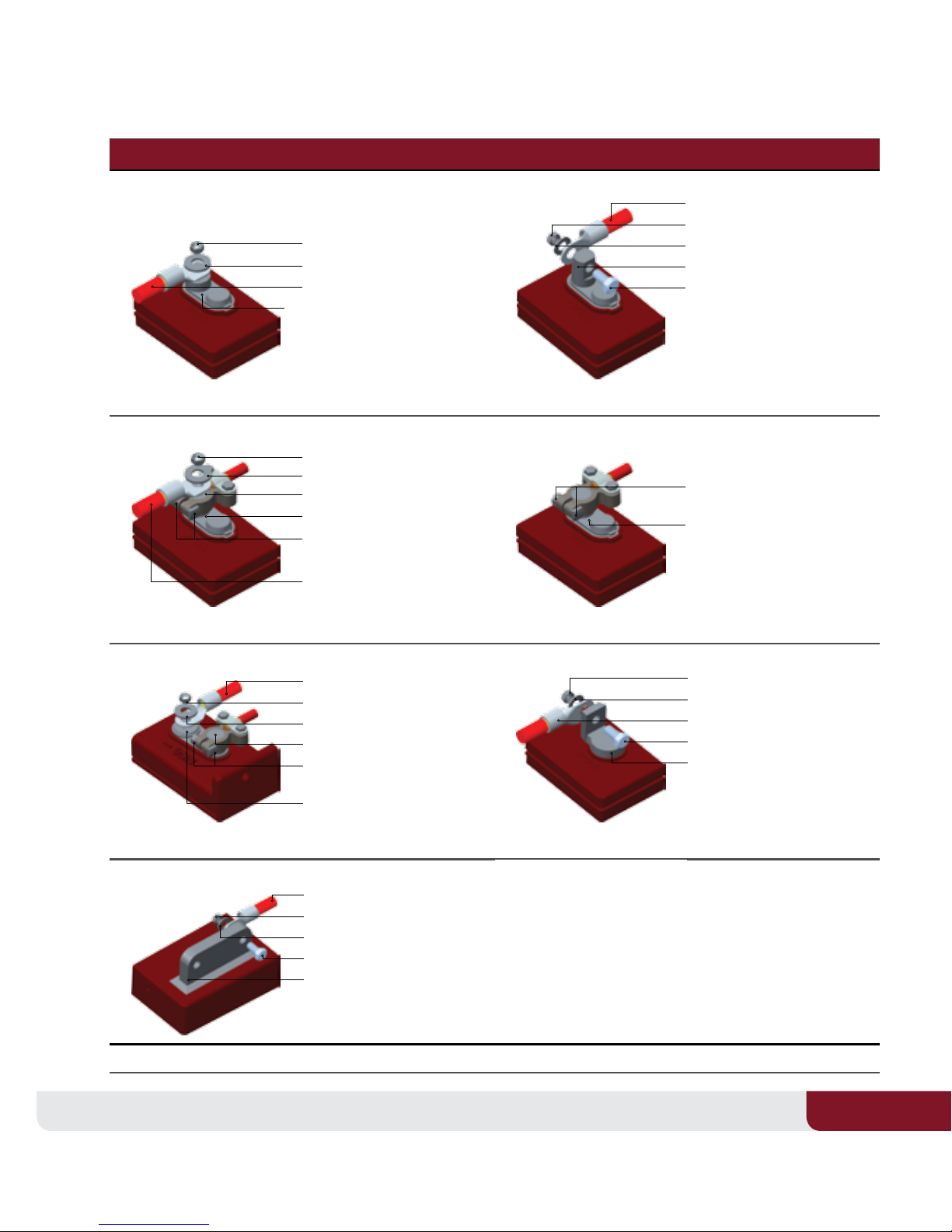

3.3 Correct Hardware* Installation

If using at washers, it is very important to ensure the battery cable lug connection is contacting the lead

surface of the terminal, and the washer is placed on top of the wire connection. Do not place washer

between the battery terminal and the battery wire, which creates high resistance and can cause

terminal meltdown. It is important that fasteners be tightened to the appropriate torque for each

terminal type, as dened in Table 2.

7

USER’S GUIDE

7

Flooded

ELPT EUT

EHPT EAPT

DT LT

IND

Images shown reect correct hardware placement. *Hardware not supplied by Trojan Battery Company.

Nut - Torque to 95 -105 in -lbs (11-12 Nm)

Nut - Torque to 95 -105 in -lbs (11-12 Nm)

Washer*

Washer*

AP Connector

Torque to 5 0-70 in-lbs (6 -8 Nm)

Cable Lug

Cable Lug

Terminal

Terminal

Stud Portion

Cable Lug

Nut - Torque to 95 -105 in -lbs (11-12 Nm)

Washer*

Terminal

Bolt

Nut - Torque to 95 -105 in -lbs (11-12 Nm)

Washer*

Cable Lug

Bolt

Terminal

Cable Lug

Nut - Torque to 10 0-120 in-lbs (11-14 Nm)

Washer*

Bolt

Terminal

Terminal

AP Connector

Torque to 5 0-70 in-lbs (6 -8 Nm)

Cable Lug

Nut - Torque to 95 -105 in -lbs (11-12 Nm)

Washer*

AP Terminal

AP Connector

Torque to 5 0-70 in-lbs (6 -8 Nm)

Stud Terminal

TROJAN BATTERY

8

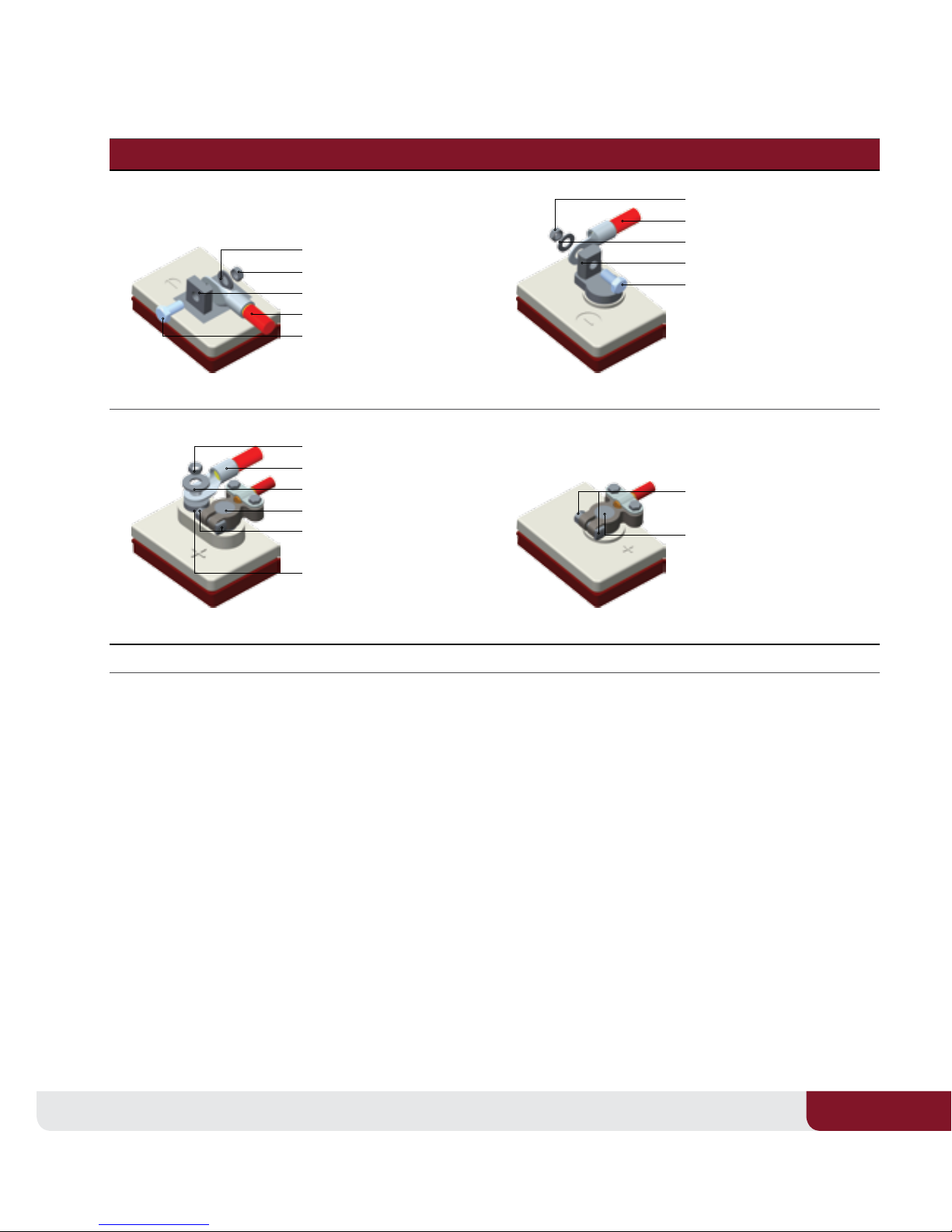

AGM

LT DT

M6 M8

AP (RELIANT) AP

ST

Images shown reect correct hardware placement. All hardware supplied for Reliant AGM. Hardware for non Reliant AGM is optional.

Nut - Torque to 55-70 i n-lbs (6-8 Nm) Nut - Torque to 95 -105 in -lbs (11-12 Nm)

Washer Cable LugLock Washer

Cable Lug Lock Washer

Bolt - 20 mm AP Terminal

M8 Terminal

AP Connector

Torque to 5 0-70 in-lbs (6 -8 Nm)

Bolt - 16mm - Torque t o 85-95 in-l bs (10-11 Nm)

Washer

Lock Washer

Stud Terminal

AP Connector

Torque to 5 0-70 in-lbs (6 -8 Nm)

Lock Washer

Bolt - Torque to 85 -95 in-lbs (10 -11 Nm)

Washer

Cable Lug

Terminal

Lock Washer

Bolt - Torque to 2 5-35 in-lbs (3- 4 Nm)

Washer

Cable Lug

Terminal

LT Adapter

AP Adapter

Torque to 8 5-95 in-lbs (10 -11 Nm)

M8 Terminal

Nut

- Torque to 120 -180 i n-lbs (14-20 Nm)

Cable Lug

Terminal

AP Connector

Torque to 4 4-62 in- lbs (5-7 Nm)

Terminal

9

USER’S GUIDE

9

Gel

LT UT

DT AP

Images shown reect correct hardware placement. *Hardware not supplied by Trojan Battery Company.

Washer*

Nut - Torq ue to 95-105 in -lbs (11-12 Nm)

Nut - Torq ue to 95-105 in -lbs (11-12 Nm)

Nut - Torq ue to 95-105 in -lbs (11-12 Nm)

Cable Lug

Cable Lug

Terminal

Washer*

Washer*

Cable Lug

Terminal

AP Connector

Torque to 5 0-70 in-lbs (6 -8 Nm)

Terminal

Bolt

Bolt

AP Connector

Torque to 5 0-70 in-lbs (6 -8 Nm)

Stud Terminal

AP Terminal

TROJAN BATTERY

10

3.4 Cable Size

Battery cables should be sized to handle the expected load. Refer to Table 1 for the maximum amps

based on the cable/wire gauge size.

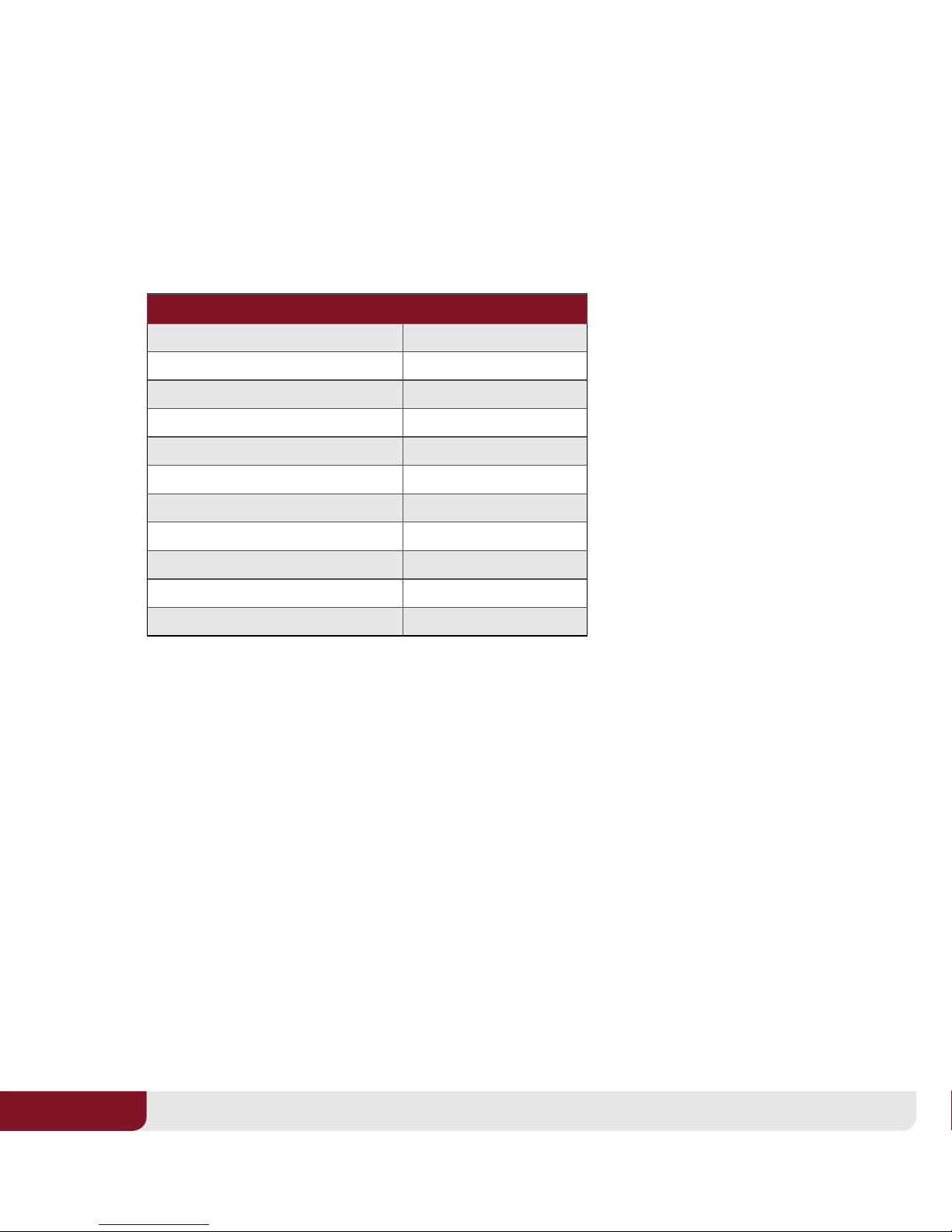

Table 1

Cable/Wire Gauge Size (AWG) Ampacity (amps)

14 25

12 30

10 40

8 55

6 75

4 95

2 130

1 150

1/0 170

2/0 265

4/0 360

Table values are for cable lengths

less than 6 feet (1829 mm). In

series/parallel battery banks, it

is preferable for all series cables

to be the same length, and all

parallel cables to be the same

length.

For more information refer to the

National Electric Code for correct

cable/wire size, which can be

located at www.nfpa.org.

Loading...

Loading...