SEARAILS RR-XXX

0-4-0 STEAM LOCOMOTIVES

ASSEMBLY MANUAL

T R Knapp Model Engineering

30 March 2015

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

1

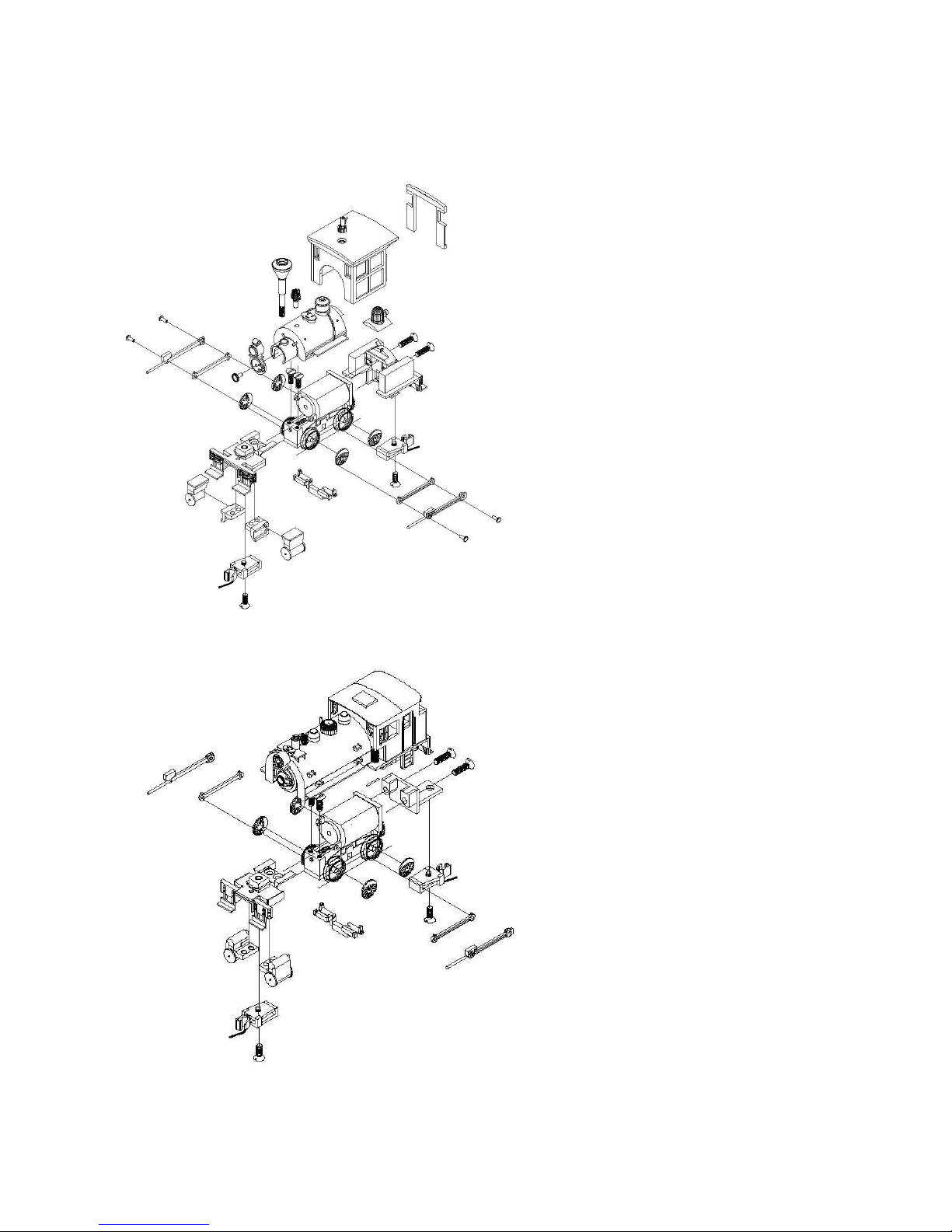

This diagram shows basic

assembly of Nn3/Z Porter 0-4-0T

2

This diagram shows basic

assembly of Baldwin

“Dockside” 0-4-0T

3/30/15 T R Knapp Model Engineering 1

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

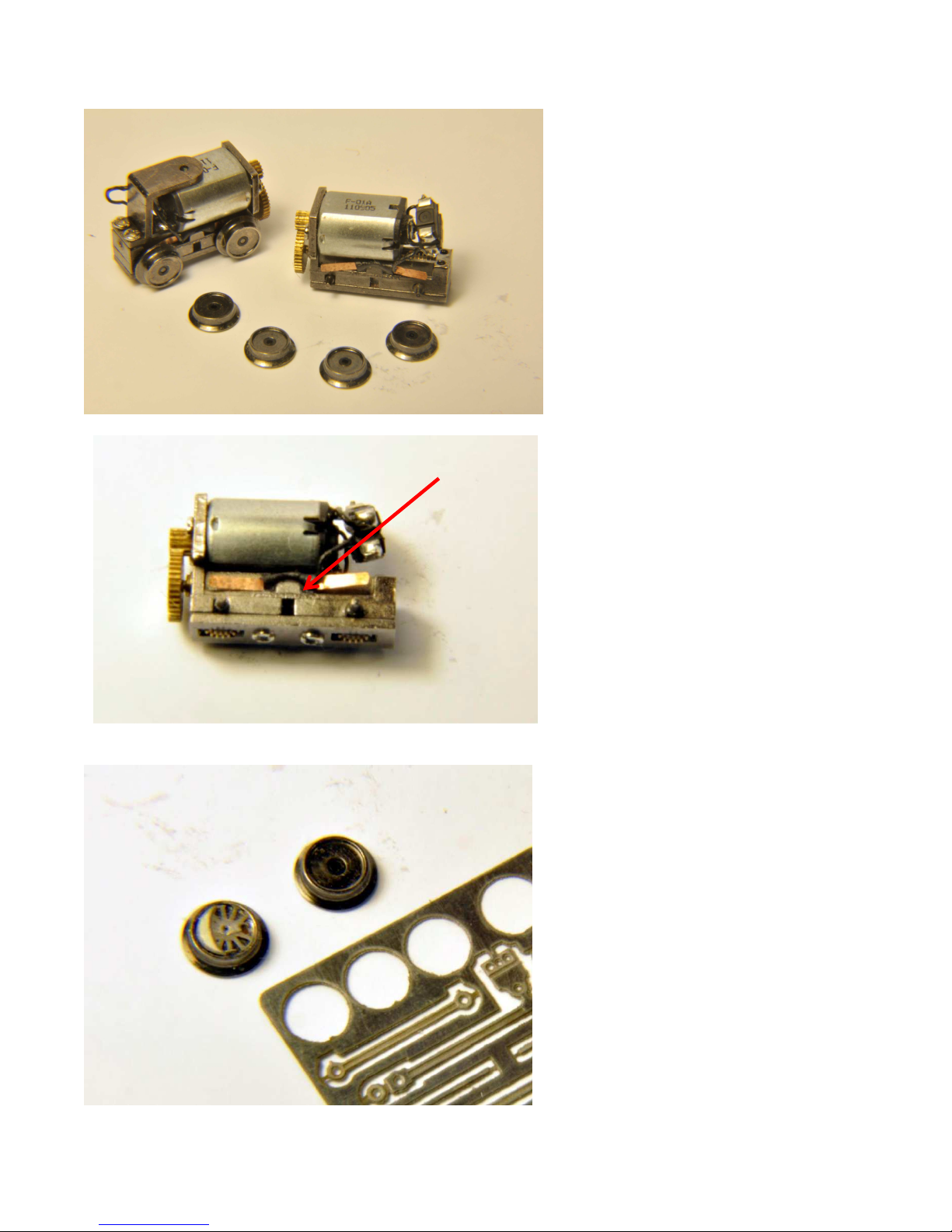

3

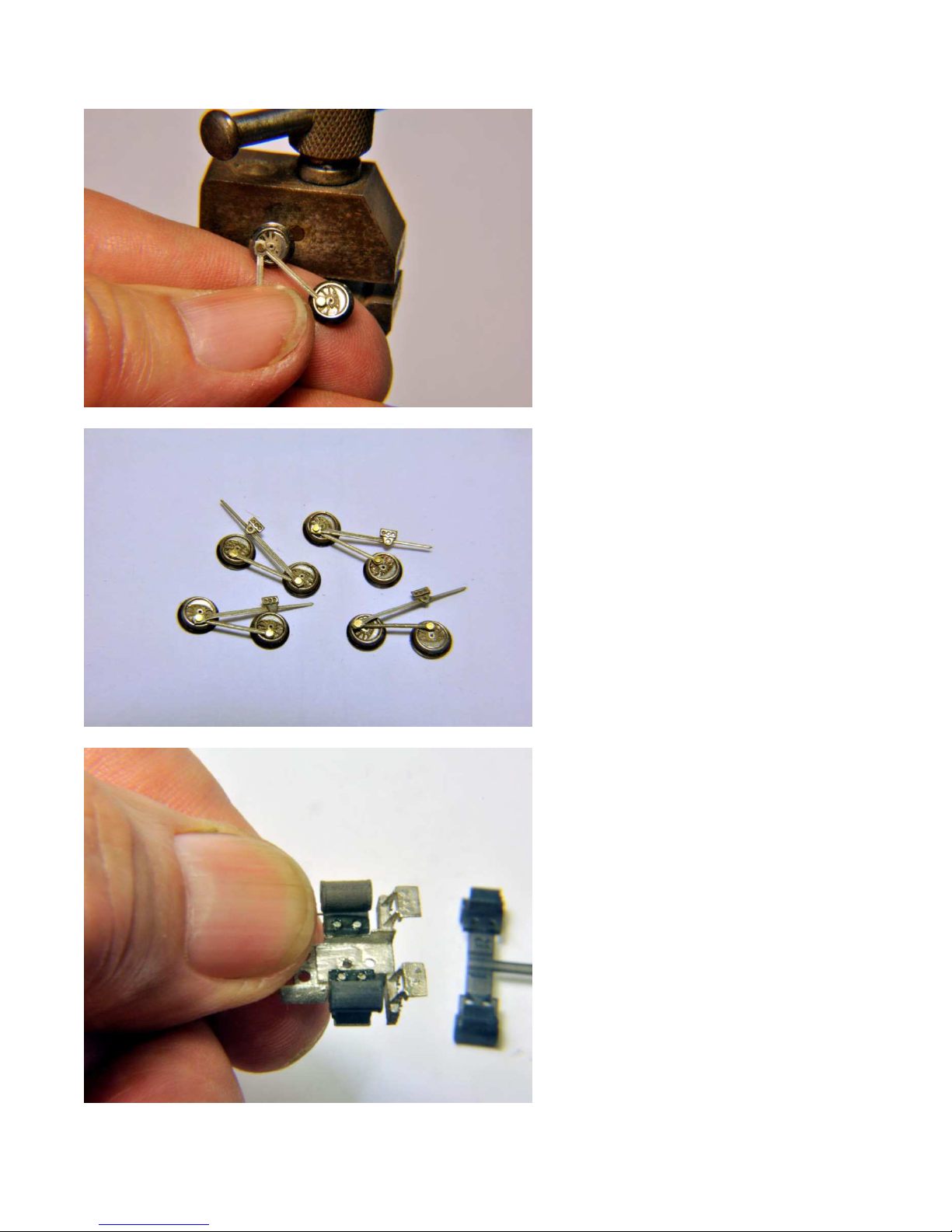

Pull drivers from ends of axles

with axles still in PowerMAX!

chassis.

4

Apply drop of CA to wiper

insulating bushing to fix in place

3/30/15 T R Knapp Model Engineering 2

5

Cut driver center from etching

fret; glue driver center etch in

driver using SMALL drop of ACC

glue.

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

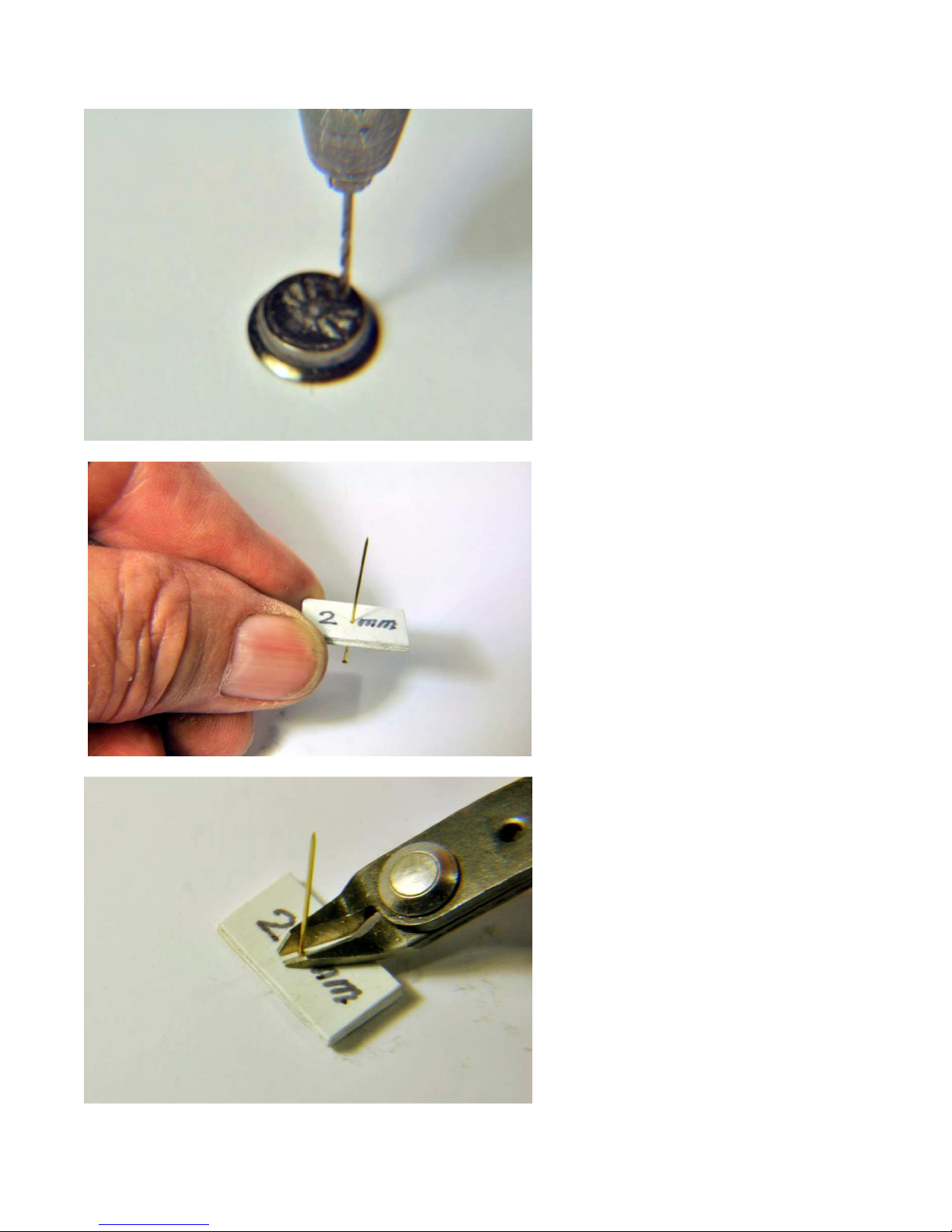

6

Drill with No. 76 (.5mm) drill.

WORK SLOWLY – the hole

intersects the stepped recess

for the insulating bushing – if

you are too aggressive, you will

break the drill bit off in the hole,

and then you are screwed!.

Cranks pins are to be made

7

from brass pins (supplied.) It is

suggested a jig be made from

laminated styrene as shown.

Place pins in jig, set jig on flat

8

surface, and cut 2mm long

crank pins

3/30/15 T R Knapp Model Engineering 3

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

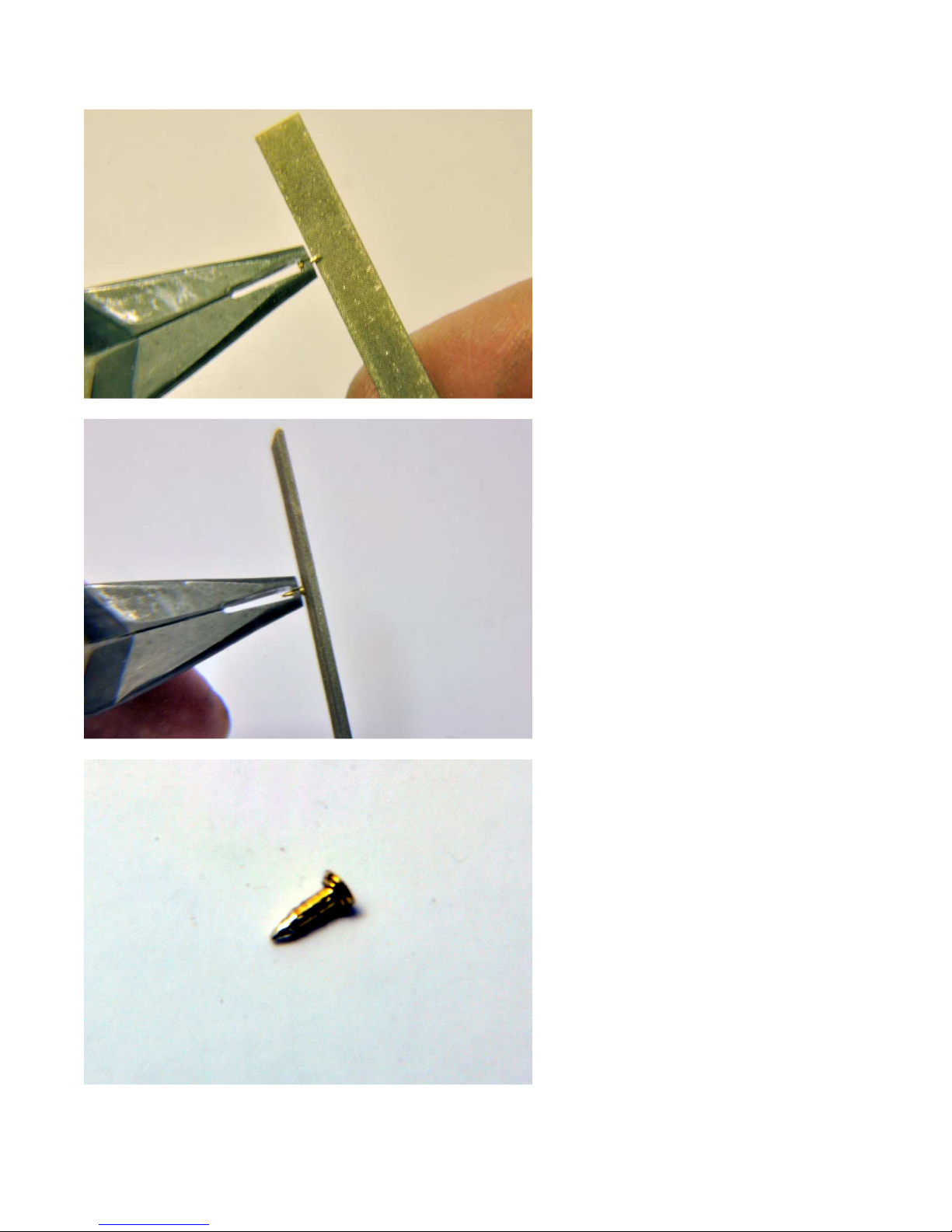

9

File end of crank pin into point.

File face of pin flat.

10

11

3/30/15 T R Knapp Model Engineering 4

Finished crank pin

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

12

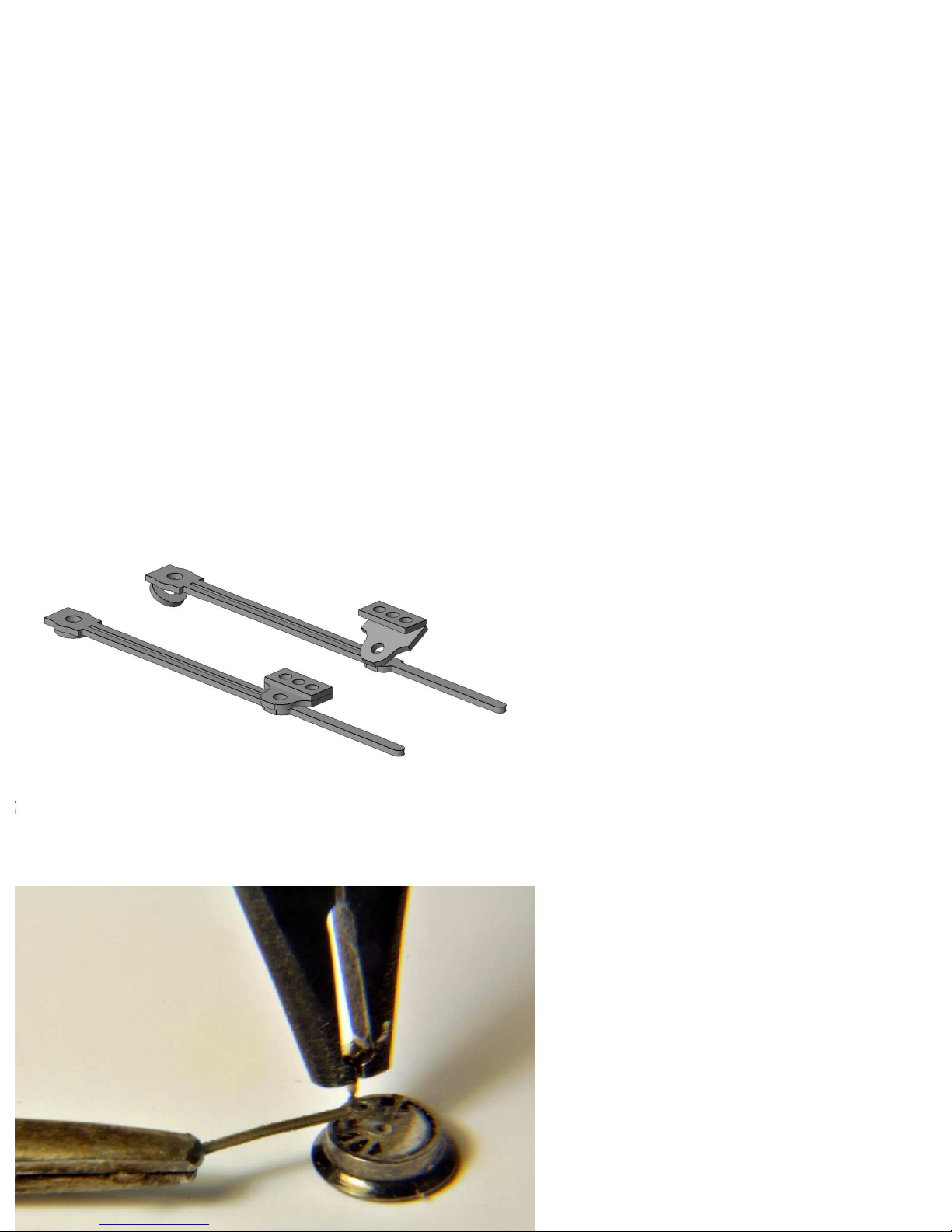

Cut main and side rods from

etching fret; fold main rod as

shown above, and secure with

CA adhesive.

13

Press crank pin into hole in

driver through hole in etched

rod.

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

15

Crank pins pressed into drivers

through side rod and main rod;

there should be a little slop in

the assembly.

16

Rods and driver subassemblies;

note slight offset bent into main

rod to assure clearing crank pin

in front axle.

17

Press cylinder castings onto

pilot casting; DO NOT FORCE –

if too tight a fit, ream holes in

cylinders.

3/30/15 T R Knapp Model Engineering 6

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

18

Press crosshead guide supports

into chassis holes each side;

apply SMALL drop of ACC to

edge of hole to fix in place

19

Press drivers onto ends of axles

orienting each wheel to match

crankpin location; offset

opposite side by 90°.

3/30/15 T R Knapp Model Engineering 7

20

Slide piston rods into holes in

cylinders as pilot is fitted to front

of chassis. (Note: add etched

crosshead guide and wire

valve rod after step 20 at right.)

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

21

Fix front pilot in place with

screws; cut length of wire and

slip into valve rod hole on

cylinder casting and glue in

place at aft end; slip etched

crosshead guide into slots and

glue in place at aft end only.

12

Test ALL LED lamps with

N’gineering LED tester.

(N’gineering LEDs have colorcoded leads. Richmond

controls LEDs will need to be

marked after trimming to 1-1/2”

length.)

Solder LEDs together in pairs,

anode (+) to cathode (-).

3/30/15 T R Knapp Model Engineering 8

Solder LEDs together in pairs,

13

anode(+) to cathode (-)

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

Test paired LEDs

14

3/30/15 T R Knapp Model Engineering 9

15

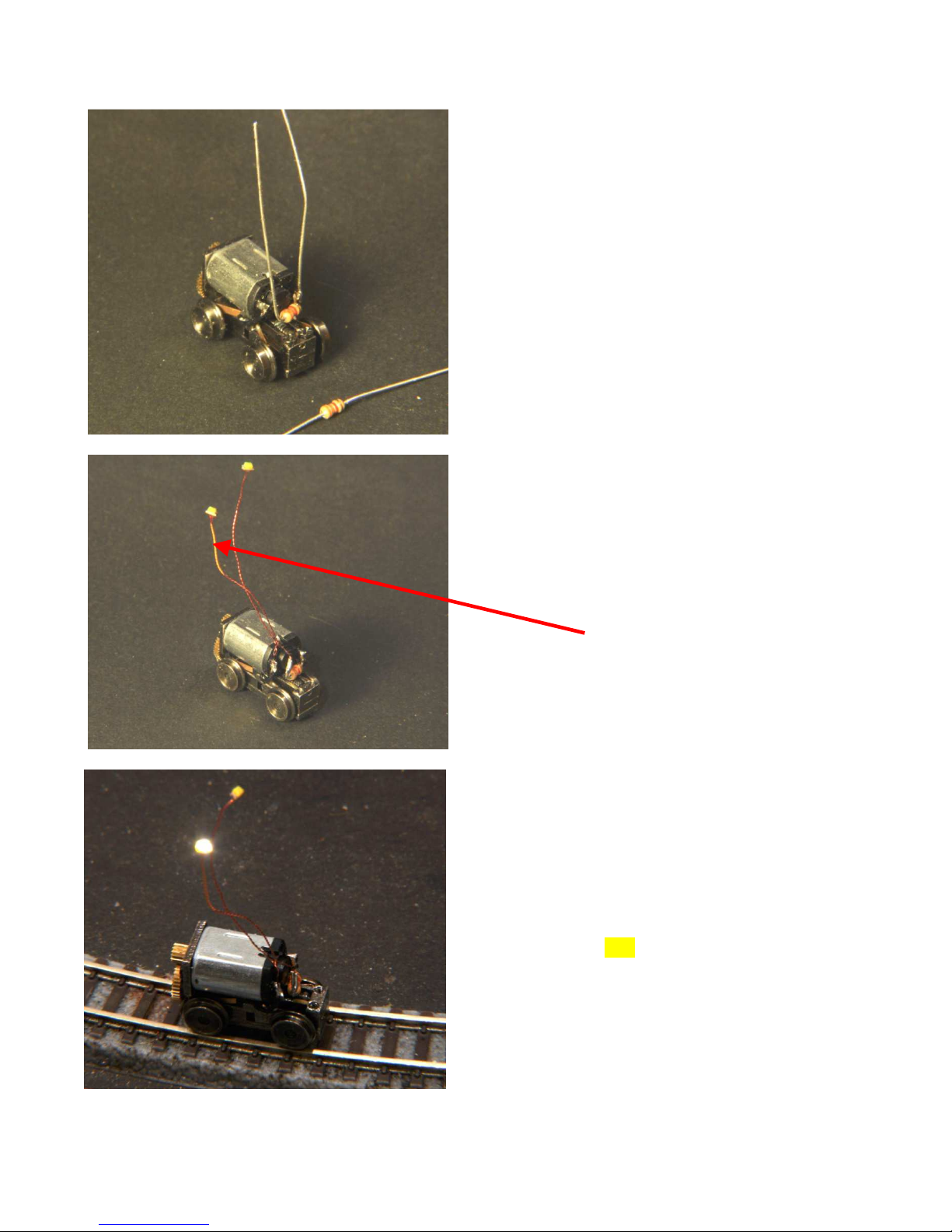

Test run each PowerMAX! both

directions – set aside for repair

any units which run erratically,

unevenly or stall on turnout

points; remove the two screws

on the top of the chassis and

save for future use.

Lubricate with AeroCar ACT2112 or ACT-3753 at drive gears

and lay shaft bearings. Run to

work oil around friction

surfaces.

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

Bend resistor leads to form “U”,

16

and solder to one pole of

motor; trim leads as shown in

photo in step 17

Solder one lead from LEDs to

17

resistor, and one to opposite

pole of motor; make sure there

is adequate separation

between end of resistor and

motor pole. (Note: Unit in this

photo has already been tested

and color-coded per Step 18.)

Test again, and mark LEDs for

18

correct orientation; after

testing, insulate LED solder pads

with CA adhesive, Pacer

Canopy Glue or Gallery Glass

coating.

3/30/15 T R Knapp Model Engineering 10

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

19 Fit fuel tanks: for Version 1, slide

spigot into rectangular hole in

side of chassis; for Version 2,

hold chassis upside down in

jeweler’s vice, remove cover

plate screws, remove cover

plate and install new cover

plate and fuel tank casting

using original screws

21

22

Apply drop of CA adhesive in

20

headlamp opening from inside,

and slide rectangular LED into

rectangular opening, holding

until CA sets. (Use accelerator

to speed up this process.)

After both lamps are in place,

slip chassis up into body shell

carefully, taking care not to

pinch any of the fine LED leads,

and making sure the leads do

not foul the drive gears; attach

chassis with two 00-90 x 3/16”

flathead screws through fuel

tanks

Test run locomotive to make

sure lamps work correctly, and

locomotive is level on rails

Trim one MTL 905 coupler box

back to paper thin with motor

tool, or cut away completely;

mount this coupler to end of

locomotive with large lay-shaft

gears using MTL Z/Nn3 coupler

mounting screw, making sure

there is clearance between

coupler box and gear; attach

another MTL 905 to opposite

end of locomotive.

Test run locomotive again.

PAINTING OPTION 2: Mask

3/30/15 T R Knapp Model Engineering 11

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

wheels and headlamps and

paint after assembly.

After paint cures, remove

masking and Test run

locomotive again.

3/30/15 T R Knapp Model Engineering 12

ASSEMBLY MANUAL – SEARAILS RR-XX – 0-4-0 SYTEAM LOCOMOTIVES

F0090B188

RR-540 Parts List

EMD40 - Z (6.5mm gauge)

description part number qty source remarks

1 brass body casting 1 Udell

2 brass tank connector castings 1 Udell

3 PowerMAX-6.5 RR-153S 1 KK

4 resistor 3.3KEBK-ND 1 Digikey

5 pre-wired 0603 LEDs don't know number 2 N'gineering 1-1/2" wire leads

6 couplers (and screws) 002 02 021 2 MTL 1/2 package

7 screws 00-90 x 3/16

8 instructions insert

9 die-cut package insert

2

J I Morris Co 144 per package

3/30/15 T R Knapp Model Engineering 13

Loading...

Loading...