Instruction Handbook

Advanced

LP 4140 | 4151

Laser Printer b/w

Contents

Content s

1 Handling Paper .. ... ... .... .......................................... ... ... ... .... ... .....................................................1-1

General Guidelines ...................................... ... ... .... ... ... .......................................... ... .... ... ...........1-2

Special Paper ..............................................................................................................................1-9

Media Type ................................................................ ... ... .... ... ... ... .............................................1-13

Loading Paper ...........................................................................................................................1-14

2 Using the Operation Panel........................................................................................................2-1

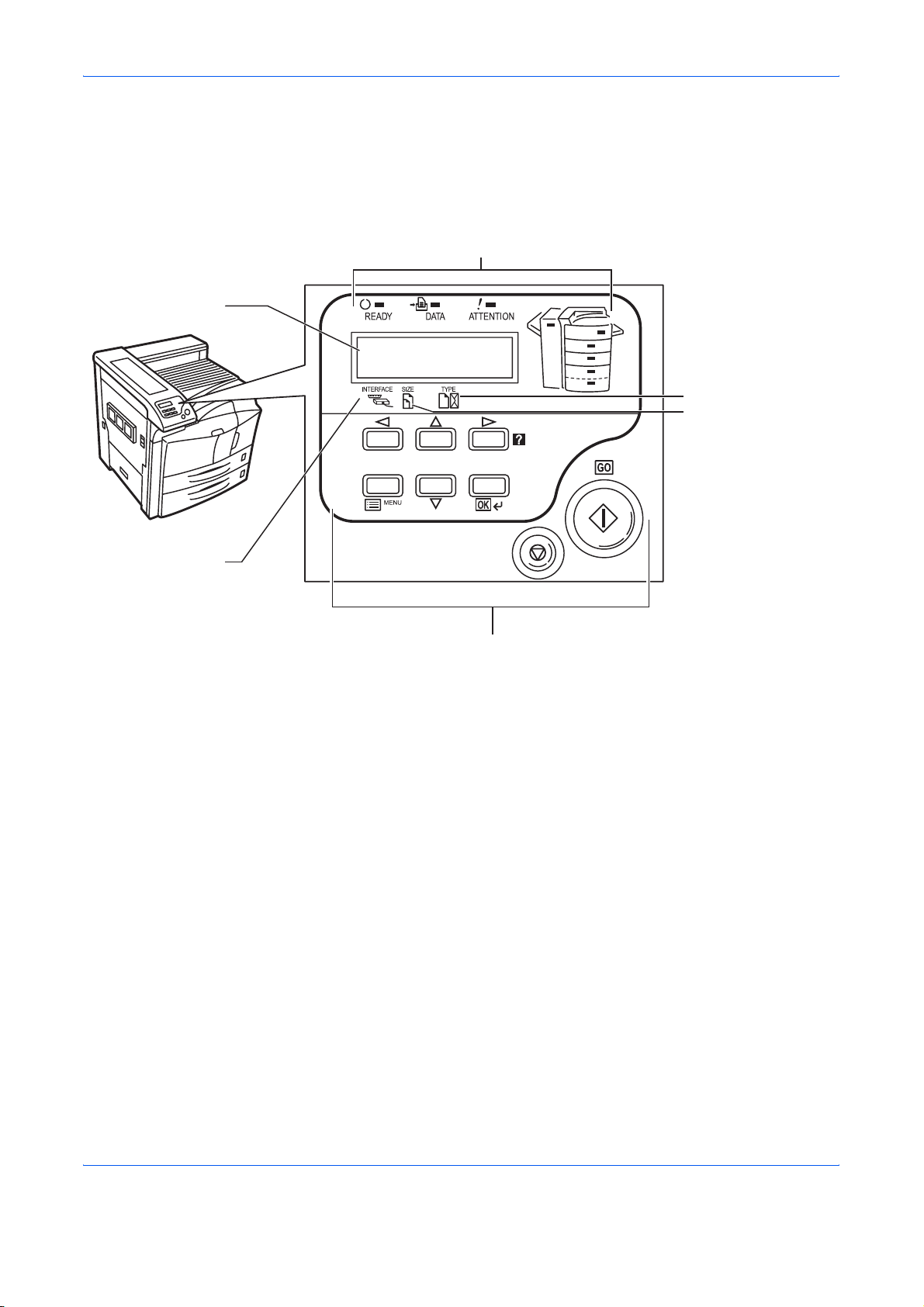

Understanding the Operation Panel ............................................................................................2-2

Canceling a Printing Job .................................................................. ... ... ... ... .... ... ... ... .... ............2-10

Using the Operation Panel ................. .... ... ... ... .......................................... ... .... ... ... ... .... ... ... ... ...2-11

Using the Menu Selection System ......................... ... ... ............................................. .... ... ... ......2-19

Status Pages .............................................................................................................................2-20

e-MPS .......................................................................................................................................2-23

Changing the Interface Parameters ..........................................................................................2-35

Making Default Settings ............................................................................................................2-42

Pagination .................................................................................................................................2-51

Setting Print Quality .................................. ... ... ... .... ... ... ... .... ... ...................................................2-58

Operating the Storage Device ...................................................................................................2-62

Paper Handling ......................................... ... ... ... .... ... ... .......................................... ... .... ............2-73

Reading Life Counters ..............................................................................................................2-86

Other Modes ................................... ... .... .......................................... ... ......................................2-87

3 Fonts ...........................................................................................................................................3-1

List of Fonts .................................................................................................................................3-2

4 Options........................................................................................................................................4-1

General Information ..................................... ... ... .... ... ... ... .... ... ... ... .... ...........................................4-2

Network Interface ........................................................................................................................4-6

Hard Disk ....................................................................................................................................4-8

CompactFlash (Memory) Card ........................... .... ... ... ... .... ... ... ... .... ......................................... 4-10

USB Flash Memory ............... .... ... ... .......................................... ... .... ... ... ... ... .... ... ... ...................4-11

Expansion Memory Modules ........ ...... .... ... ... ... ..........................................................................4-12

HDD Security Function ..............................................................................................................4-15

5 Computer Interface.............. .... ... ... ... .... ... ... ... ... .... .......................................... ... ... ... .... ... ...........5-1

General Information ..................................... ... ... .... ... ... ... .... ... ... ... .... ...........................................5-2

Parallel Interface ....................... .......................................... ... ... ... .... ... ... ... ... .... ...........................5-3

USB Interface ........ ... .... .......................................... ... ... ... .... ... ... ... .... ... ........................................5-5

Serial Interface (Option) ..............................................................................................................5-6

RS-232C Protocol .......................................................................................................................5-7

RS-232C Cable Connection ......................................................................................................5-10

Glossary.........................................................................................................................................1

Index...............................................................................................................................................1

ADVANCED OPERATION GUIDE i

Contents

ii ADVANCED OPERATION GUIDE

Introduction

This guide has the following chapters:

• 1 Handling Paper

Explains how to choose, handle and load paper.

• 2 Using the Operation Panel

Explains how to use the operation panel to configure the printer.

• 3 Fonts

Shows the available fonts.

• 4 Options

Shows the available options.

• 5 Computer Interface

Describes the possible connections between the printer and

your computer.

• Glossary

A Glossary of terms used is provided here.

ADVANCED OPERATION GUIDE iii

Conventions

This manual uses the following conventions:

Convention Description Example

Italic Typeface Used to emphasize a key

word, phrase or references to

additional information.

Courier Typeface Used to denote messages or

names displayed on the

operation panel.

Bracket Bold Text

Typeface

Bold Typeface Used to emphasize button or

Notes Used to provide additional or

Important Used to provide important

Caution Cautions are statements that

Used to denote operation

panel keys.

items to be selected in dialog

boxes, and titles displaying in

dialog boxes.

useful information about a

function or feature.

information.

suggest mechanical damage

as a result of an action.

Close the top cover.

Refer to Toner Container

Replacement on page 3-3.

Replace the waste toner box when

the Check waste toner box

message is displayed.

Press [Go].

Click Next.

NOTE: For information about storing

the pin, refer to step 10.

IMPORTANT: Ensure paper is not

folded, curled, or damaged.

CAUTION: Do not pull the cassette

out when holding the front of the

machine.

Warning Used to alert users to the

possibility of personal injury.

iv ADVANCED OPERATION GUIDE

WARNING: High voltage is

present in the charger section.

1 Handling Paper

This chapter explains the following topics:

• General Guidelines...................................................... 1-2

• Special Paper.............................................................. 1-9

• Media Type................................................................ 1-13

• Loading Paper........................................................... 1-14

ADVANCED OPERATION GUIDE 1-1

Handling Paper

General Guidelines

Paper Availability

The printer is designed to print on high-q uality copier bond paper (the kind

used in ordinary dry copier machines), but it can also accept a variety of

other types of paper within the limits specified below.

NOTE: The manufacturer assumes no liability for problems that occur

when paper not satisfying these requirements is used.

Selection of the right paper is important. Using the wrong paper ca n result

in paper jams, misfeeding, curling, poor print quality, and paper waste, an d

in extreme cases can damage the printer. The guidelines given below will

increase the productivity of your office by ensuring efficient, trouble-free

printing and reducing wear and tear on the printer.

Most types of paper are compatible with a variety of machines. Paper

intended for xerographic copiers can also be used with the printer.

There are three general grades of paper: economy, standard, and

premium. The most significant difference between grades is the ease with

which they pass through the printer. This is affected by the smoothness,

size, and moisture content of the paper, and the way in which th e paper is

cut. The higher the grade of paper you use, the less risk there will be of

paper jams and other problems, and the higher the level of quality your

printed output will reflect.

Differences between paper from different suppliers can also affect the

printer’s performance. A high-quality print er canno t pr od uc e hig h- q ua lity

results when the wrong paper is used. Low-priced paper is not economical

in the long run if it causes printing problems.

Paper in each grade is available in a range of basis weights (defined later ).

The traditional standard weights are 16, 20, and 28 pounds (60 to

105 g/m

2

).

1-2 ADVANCED OPERATION GUIDE

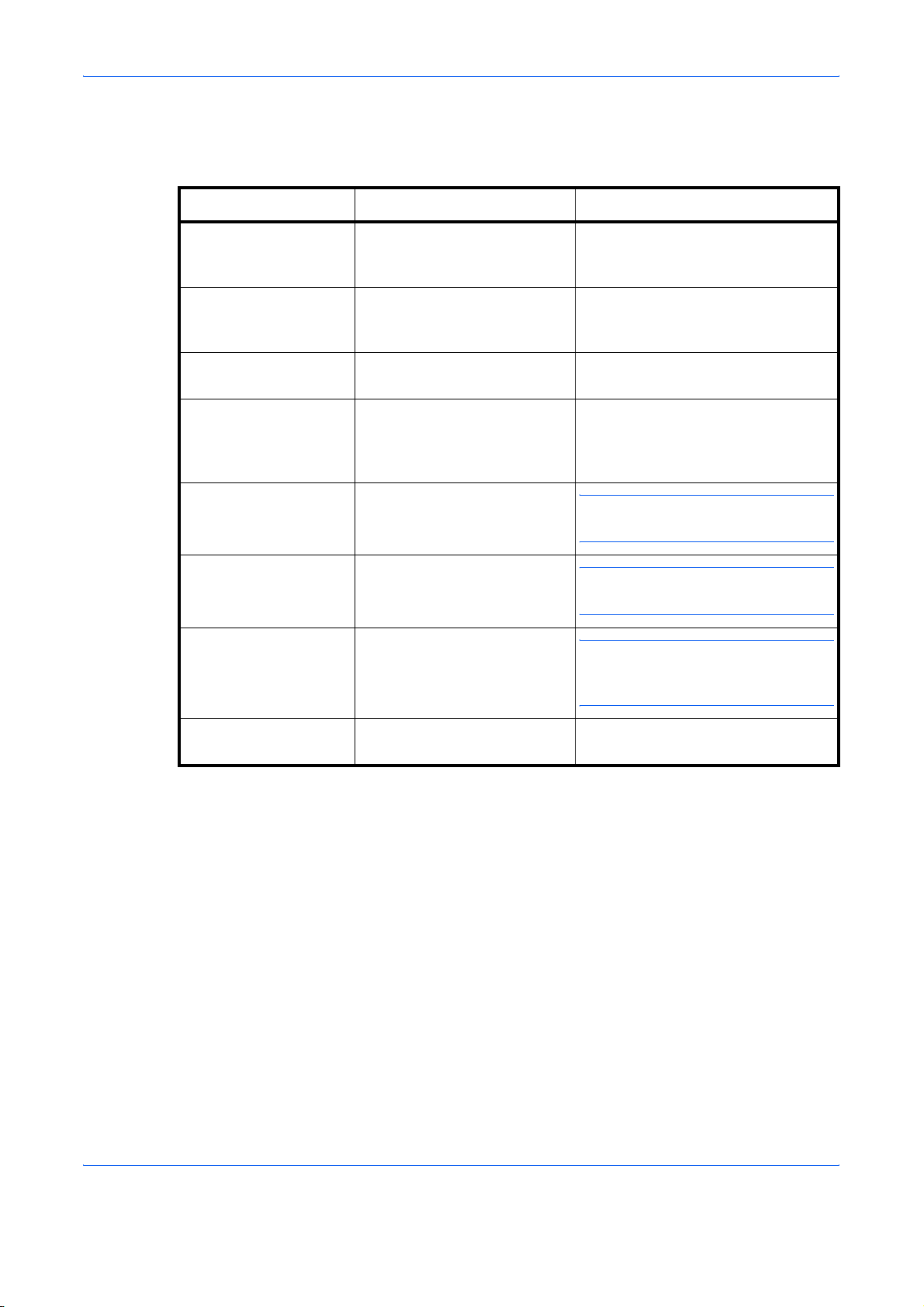

Paper Specifications

The following table summarizes the basic paper specifications. Details are

given on the following pages.

Handling Paper

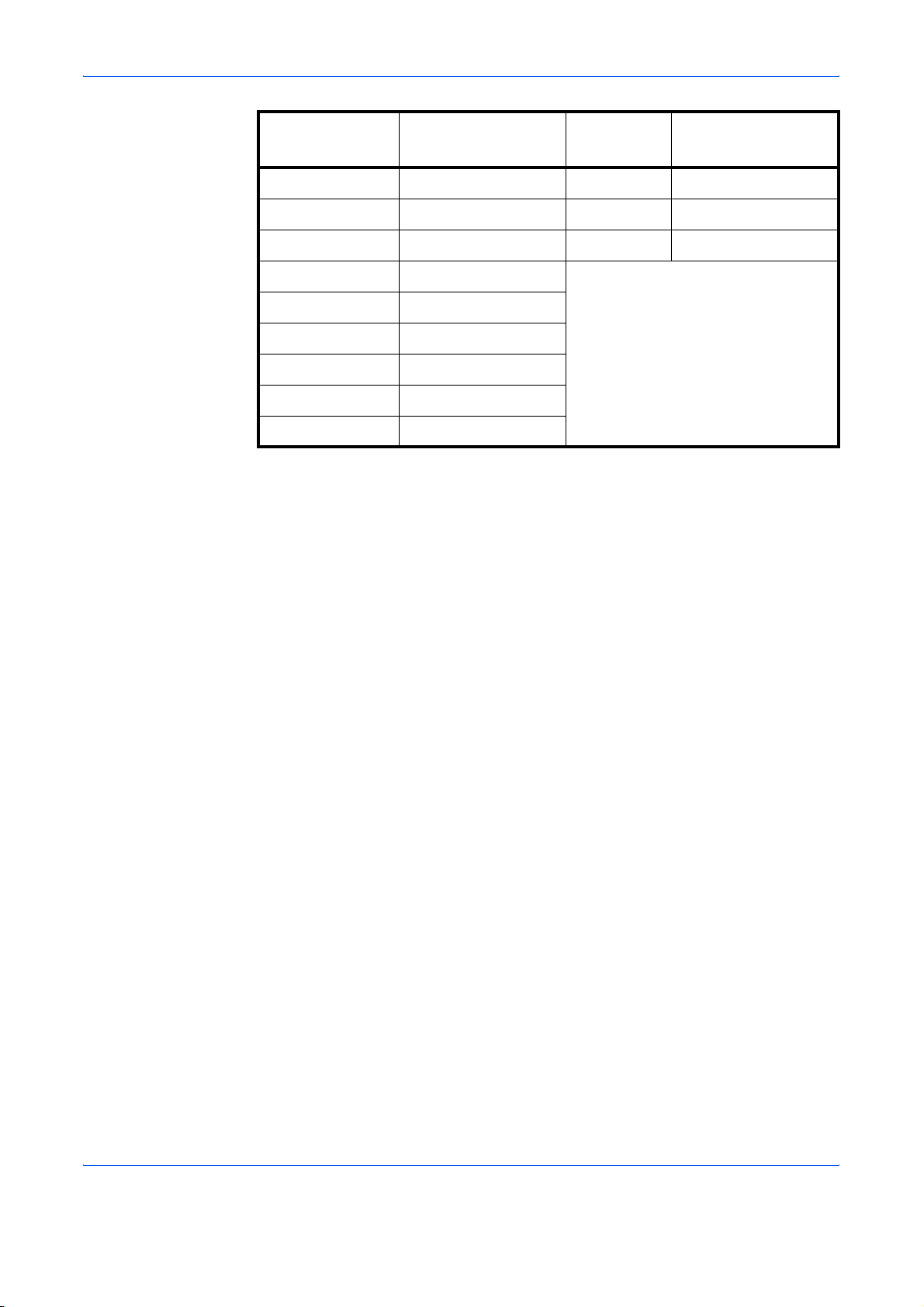

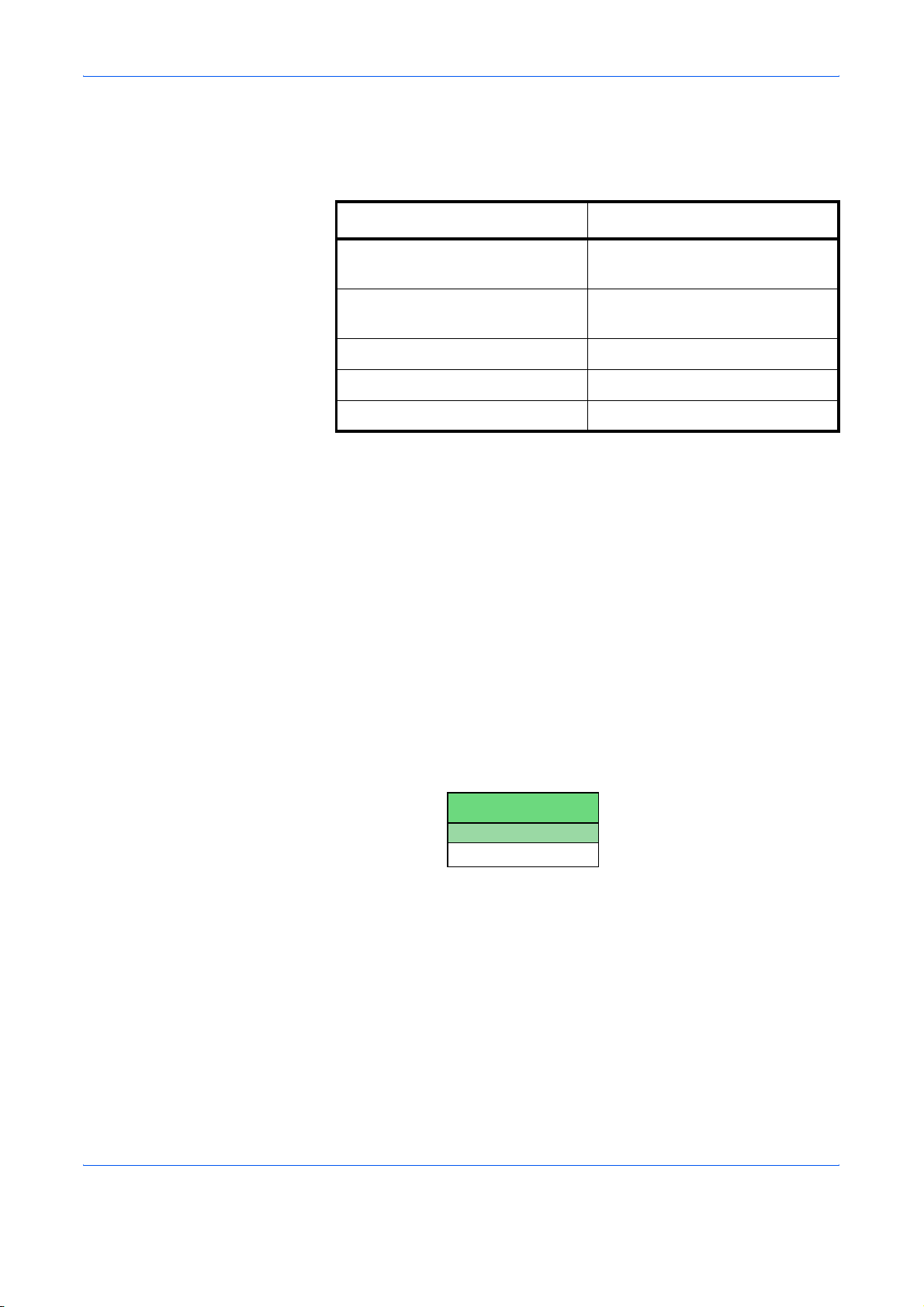

Item Specification

Weight Cassette: 60 to 105 g/m

Thickness 0.086 to 0.110 mm (3.4 to

Dimensional accuracy ±0.7 mm (±0.0276 inches)

Squareness of corners 90° ±0.2°

Moisture content 4 to 6 %

Direction of grain Long grain

Pulp content 80 % or more

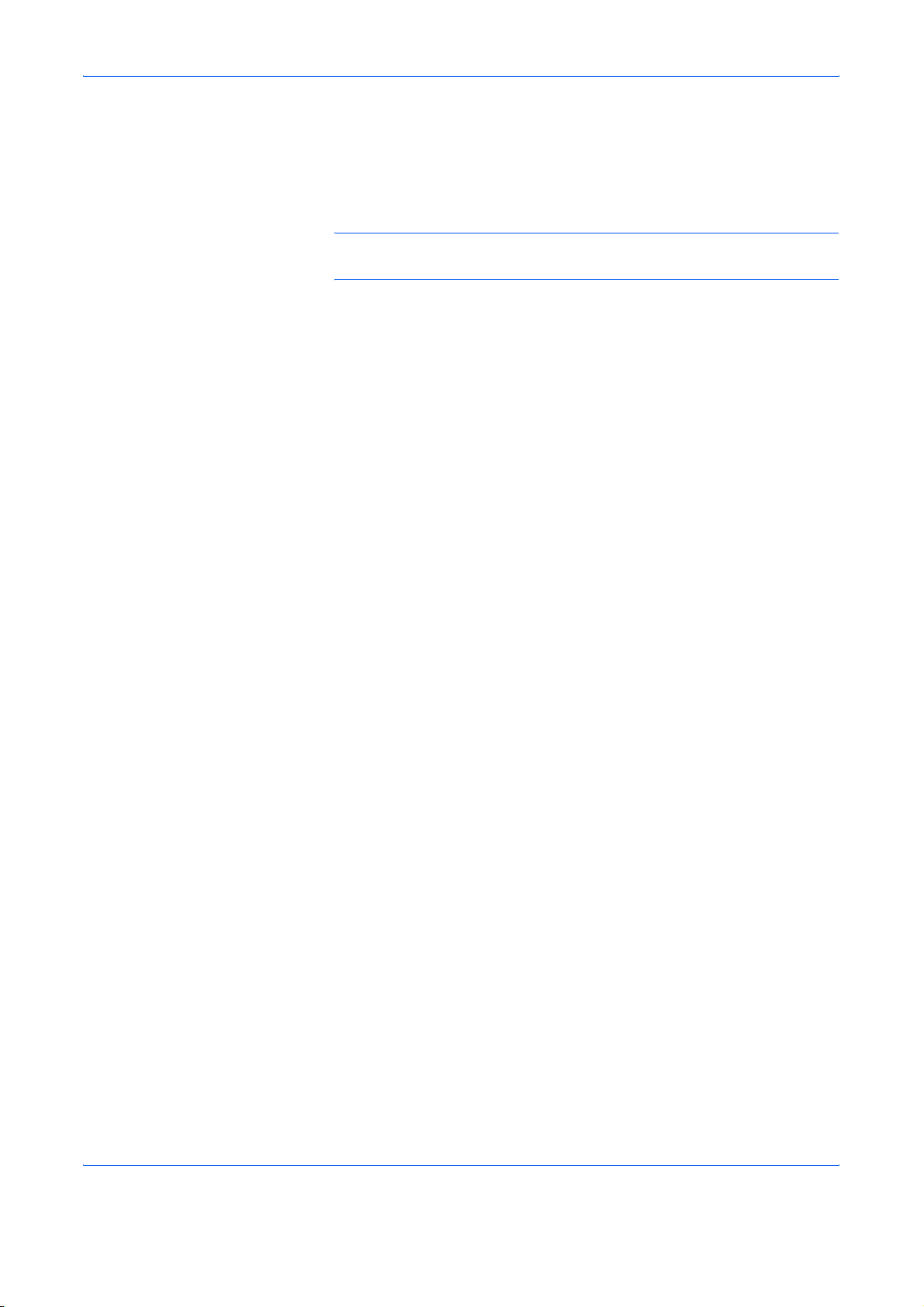

Minimum and maximum paper sizes

The minimum and maximum paper sizes are as follows. For non standard

paper such as cut-sheet, the MP (multi-purpose) tray must be used.

Paper Cassette

(16 to 28 lb/ream)

MP tray: 45 to 200 g/m

(12 to 53 lb/ream)

4.3 mils)

MP Tray

2

2

Minimum

Paper

Size

Minimum

Paper

Size

148 mm

5-13/16 inches

88 mm

3-7/16 inches

297 mm

11-11/16 inches

432 mm

17 inches

210 mm

8-1/4 inches

148 mm

5-13/16 inches

297

mm

11-11/16 inches

450 mm

18 inches

ADVANCED OPERATION GUIDE 1-3

Handling Paper

Selecting the Right Paper

Laser printing is a process involving laser light, electrostatic discharge,

toner, and heat. In addition, as the paper passes through the printer it

undergoes considerable sliding, bending, and twisting motions. A highquality printing paper matching the printer’s requirements withstands all

these stresses, enabling the printer to turn out clean, crisp printed copies

consistently.

Remember that all paper is not the same. Some of the factors to consider

when selecting paper for the printer are as follows:

Condition

Avoid using paper that is bent at the edges, curled, dirty, torn , embosse d,

or contaminated with lint, clay, or paper shreds.

Use of paper in these conditions can lead to illegible printing, misfeeding,

and paper jams, and can shorten the life of the printer. In particular , avoid

using paper with a surface coating or other surface treatment. The paper

should have as smooth and even a surface as possible.

Composition

Do not use paper that has been coated or surface-treated and contains

plastic or carbon. The heat of fusing can cause such paper to give off

harmful fumes.

Bond paper should contain at least 80 % pulp. Not more than 20 % of the

total paper content should consist of cotton or other fibers.

Paper Sizes

Cassettes and an MP tray are available for the paper sizes listed in the

table below. The dimensional tolerances are ±0.7 mm (±0.0276 inch es) for

the length and width. The angle at the corners mu st be 90° ±0. 2°.

MP tray Size

Envelope

Monarch

Envelope #10 4-1/8 × 9-1/2 inches Legal 8-1/2 × 14 inches

Envelope #9 3-7/8 × 8-7/8 inches Letter 8-1/2 × 11 inches

Envelope #6 3-5/8 × 6-1/2 inches Statement 5-1/2 × 8-1/2 inches

3-7/8 × 7-1/2 inches Ledger 11 × 17 inches

Cassette or

MP tray

Size

Envelope DL 110 × 220 mm Folio 210 × 330 mm

Envelope C5 162 × 229 mm A3 297 × 420 mm

A6 105 × 148 mm A4 210 × 297 mm

B6 128 × 182 mm A5 148 × 210 mm

1-4 ADVANCED OPERATION GUIDE

Handling Paper

MP tray Size

Cassette or

MP tray

Size

ISO B5 176 × 250 mm B4 257 × 364 mm

Executive 7-1/4 × 10-1/2 inches B5 182 × 257 mm

Envelope C4 229 × 324 mm Oficio II 8-1/2 × 13 inches

Hagaki 100 × 148 mm

Oufuku Hagaki 148 × 200 mm

Youkei 2 114 × 162 mm

Youkei 4 105 × 235 mm

8K 273 × 394 mm

16K 197 × 273 mm

Paper with other sizes (custom sizes) can also be fed from the MP tray.

The minimum size paper for manual feed is 88 × 148 mm (3-1/2 × 5-13/16

inches), fed lengthwise. The maximum size is 297 × 450 mm (11-11/16 ×

17-3/4 inches).

Smoothness

The paper should have a smooth, uncoated sur face. Paper with a rough or

sandy surface can cause voids in the printed output. Paper that is too

smooth, however, can cause multiple feeding and fogging problems.

(Fogging is a gray background effect.)

Basis Weight

Basis weight is the weight of a standard quantity of paper. In the traditional

system, the standard quantity is a ream consisting of 500 sheets

measuring 17 × 22 inches each. In the metric system the standard quantity

is 1 square meter.

Paper that is too light or too heavy can cause misfeeding, jams, and

premature wear of the printer. Uneven paper weight can cause multiple

feeds, print defects, poor toner fusing, blu rr i ng , an d ot he r pr int qua lity

problems. The proper weight is 60 to 105 g/m

45 to 200 g/m

2

for the MP tray.

2

for the paper cassette, and

ADVANCED OPERATION GUIDE 1-5

Handling Paper

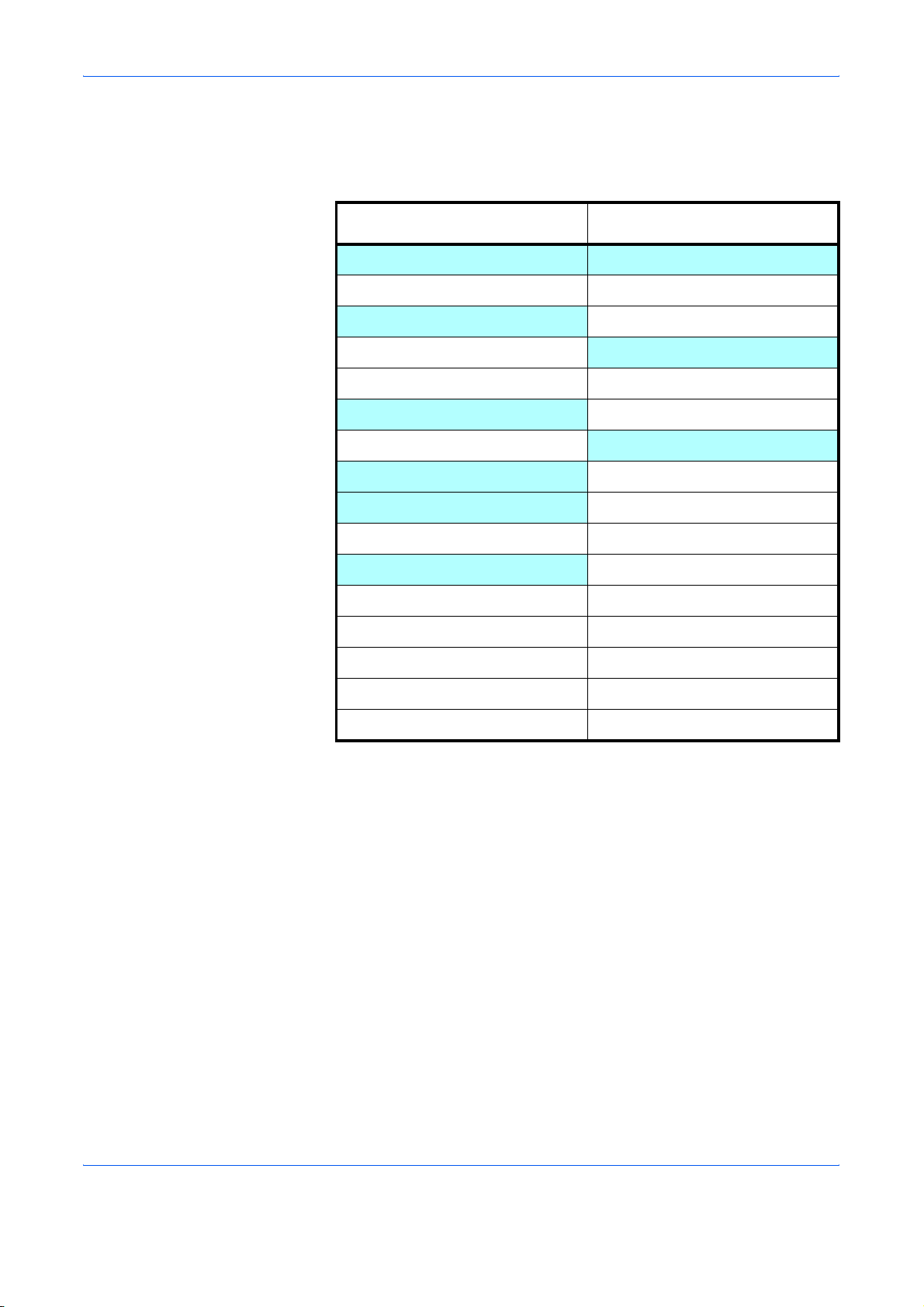

Paper Weight Equivalence Table

The paper weight is listed in pounds (lb) and metric grams per square

2

meter (g/m

). The shaded part indicates the standard weight.

U. S. Bond Weight (lb)

16 60

17 64

20 75

21

22 81

24 90

27

28 105

32 120

34 128

36 135

39 148

42 157

43 163

Europe Metric Weight (g/m

80

100

2

)

Thickness (Caliper)

Thick paper is referred to as high-caliper paper and thin paper as lowcaliper paper. The paper used with the printer should be n either extremely

thick nor extremely thin. If you are having problems with paper jams,

multiple feeds, and faint printing, the paper you are using may be too thin.

If you are having problems with paper jams and blurred printing, the paper

may be too thick. The proper thickness is 0.086 to 0.110 mm (3.4 to

4.3 mils).

47 176

53 199

1-6 ADVANCED OPERATION GUIDE

Moisture Content

Moisture content is defined as the percent ratio of moisture to the dry mass

of the paper. Moisture can affect the paper’s appearance, feedability, curl,

electrostatic properties, and toner fusing characteristics.

The moisture content of the paper varies with the relative humidity in the

room. When the relative humidity is high and the paper absorbs moisture,

the paper edges expand, becoming wavy in appea rance. When the relative

humidity is low and the paper loses moisture, the edges shrink and tighten,

and print contrast may suffer.

Wavy or tight edges can cause misfeeding and a lignment anomalie s. The

moisture content of the paper should be 4 to 6%. To ensure the proper

moisture content, it is important to store the paper in a controlled

environment. Some tips on moisture control are:

• Store paper in a cool, dry location.

• Keep the paper in its wrapping as long as possible. Rewrap p aper that

is not in use.

• Store pape r in its original carton. Place a pallet, etc., under the carton

to separate it from the floor.

• After removing paper from stora ge, let it stand in the same ro om as the

printer for 48 hours before use.

• Avoid leaving paper where it is exposed to heat, sunlight, or damp.

Handling Paper

Paper Grain

When paper is manufactured, it is cut into sheets with the grain running

parallel to the length (long grain) or parallel to the width (short grain). Short

grain paper can cause feeding problems in the printer. All paper used in

the printer should be long grain.

Other Paper Properties

Porosity: Refers to the density of the paper structure; that is, ho w openly

or compactly the fibers are bonded.

Stiffness: Limp paper can buckle inside the printer, while pape r that is too

stiff may bind. Either way the result is a paper jam.

Curl: Most paper has a natural tendency to curl in one direction. The paper

should be loaded so that the natural curl is downward, to counteract the

upward curl imparted by the printer. Printed sheets will then come out flat.

Most paper also has a top and bottom surface. Loading instructions are

usually given on the paper package.

NOTE: If the paper is considerably curled in one direction, e.g. when the

paper was used to print on one side, try to roll the paper in the opposite

direction to counteract the curl. Printed sheets will then come out flat.

ADVANCED OPERATION GUIDE 1-7

Handling Paper

Electrostatic properties: During the printing process, the paper is

electrostatically charged to attract the toner. The paper must be able to

release this charge so that printed sheets do not cling together in the

output tray.

Whiteness: T he contrast of the printed page depends on th e whiteness of

the paper. Whiter paper provides a sharper, brighter appearance.

Quality control: Uneven sheet size, corners that are not square, ragged

edges, welded (uncut) sheets, and crushed edges an d corners can cause

the printer to malfunction in various ways. A quality pa pe r supp lier should

take considerable care to ensure that these problems do not occur.

Packaging: Paper should be packed in a sturdy carton to protect it from

damage during transport. Quality paper obta ined from a reputable supplier

is usually properly packaged.

1-8 ADVANCED OPERATION GUIDE

Special Paper

Handling Paper

This section explains printing on special paper. The page printer can use

the following types of special paper. In this case, set the media type

according to the table below.

Paper type to be used Media type to be selected

Colored paper Color

Preprinted paper Preprinted

Overhead projector

transparencies

Postcards Cardstock

Envelopes Envelope

Label Labels

When using the above types of paper, be sure to use products that are

specified for use with photocopiers and/or page printers. Feed paper other

than colored paper or preprinted paper from the MP (multi-purpose) tray.

Use paper that is sold specifically for use with copiers (heat-fusing type).

Label paper and envelopes should not be placed in the cassette.

Since the composition and quality of special paper vary considerably,

special paper is more likely than white bond paper to give trouble during

printing. No liability will be assumed if moisture, etc., given off in printing on

special paper causes harm to the machine or opera to r.

Transparency

NOTE: Before purchasing any type of special paper, test a sample on the

printer and check that print quality is satisfactory.

Specifications for each type of special paper are given below.

ADVANCED OPERATION GUIDE 1-9

Handling Paper

Transparency

Transparency must be able to withstand the heat of fusing during the

printing process. It should satisfy the conditions given in the table below.

Item Specification

Tolerance of heat Must tolerate at least 190 °C

(374 °F)

Thickness 0.100 to 0.110 mm (3.9 to

4.3 mils)

Material Polyester

Dimensional accuracy ±0.7 mm (±0.0276 inches)

Squareness of corners 90° ± 0.2°

If transparency jams frequently, pull the top of the sheet very gently as it

leaves the printer.

Adhesive-Backed Labels

The basic rule for printing on adhesive labels is that the adhesive must

never come into contact with any part of the printer. Adhesive paper

sticking to the drum or rollers will damage the printer.

Label paper must be manually fed.

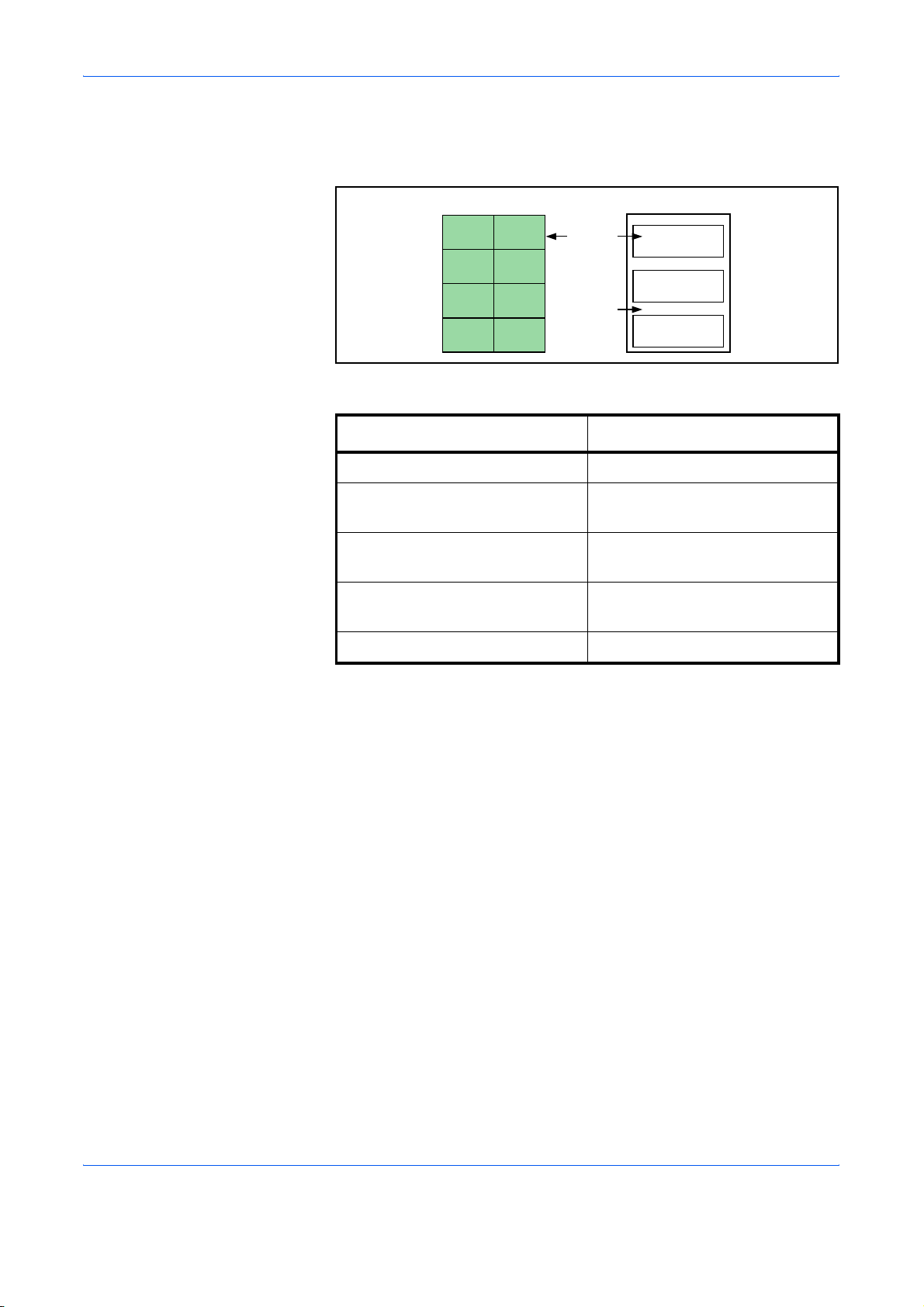

Label paper has a structure comprised of thre e lay er s, as shown in the

figure below. The top sheet is printed on. The adhesive layer consists of

pressure-sensitive adhesives. The carrier sheet (also called the linear or

backing sheet) holds the labels until use. Due to the complexity of its

composition, adhesive-backed label paper is particularly likely to give

trouble in printing.

Adhesive label paper must be entirely covered by its top sheet, with no

spaces between the individual labels. Labels with spaces in between are

apt to peel off, causing serious paper jam problems.

Top sheet (White

bond paper)

Adhesive

Carrier sheet

1-10 ADVANCED OPERATION GUIDE

Handling Paper

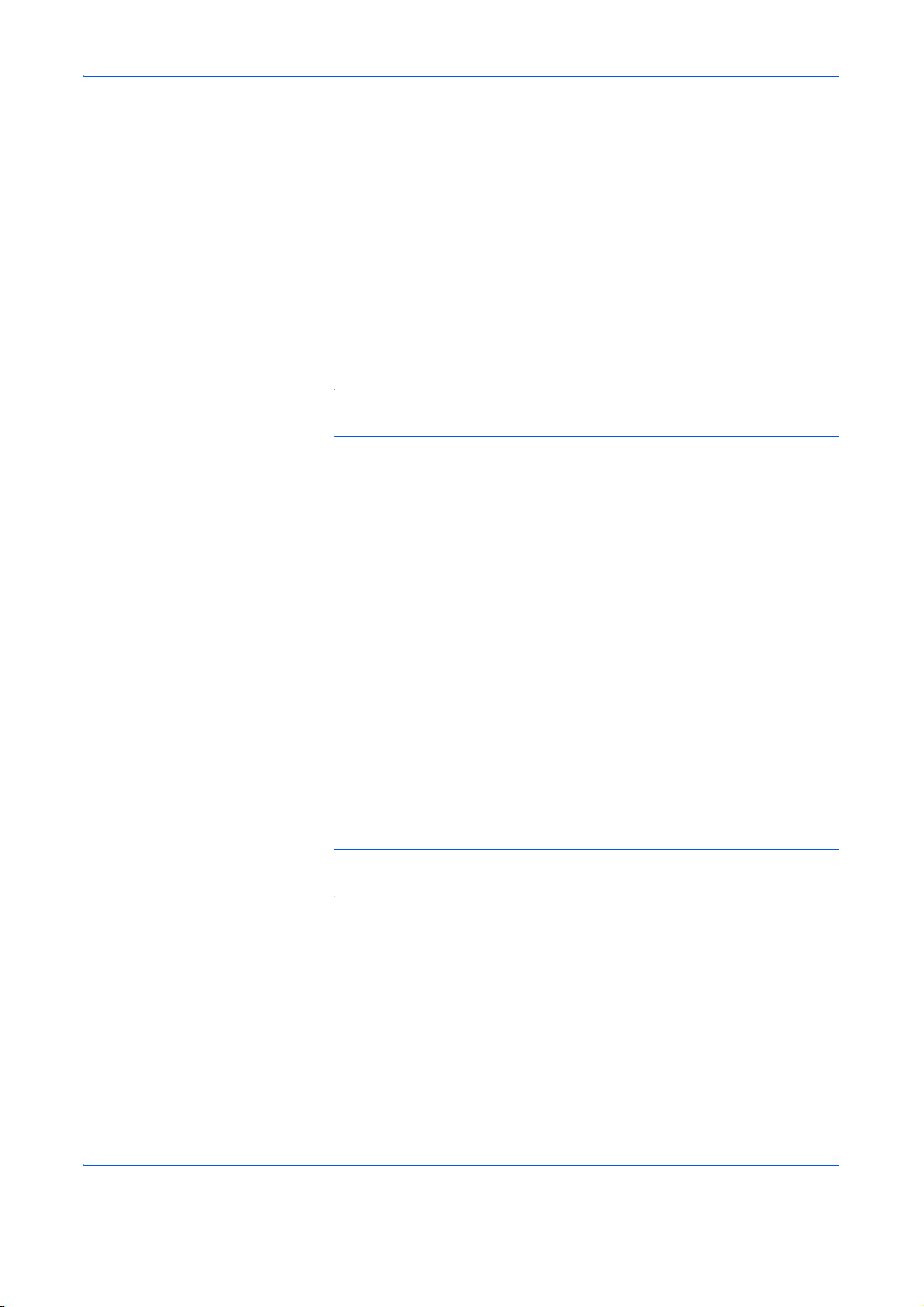

Some label paper is manufactured with an extra margin of top sheet

around the edge. Do not remove the extra top sheet from the carrier sheet

until after printing is finished.

Acceptable

Top

sheet

Carrier

sheet

Unacceptable

The table below lists the specifications for adhesive label paper.

Item Specification

Weight of top sheet 44 to 74 g/m

Composite weight 104 to 151 g/m

2

(12 to 20 lb/ream)

2

(28 to 40 lb/ream)

Thickness of top sheet 0.086 to 0.107 mm

(3.9 to 4.2 mils)

Composite thickness 0.115 to 0.145 mm

(4.5 to 5.7 mils)

Moisture content 4 to 6 % (composite)

Postcards

Fan the stack of postcards and align the edges before loading them in the

MP tray. Make sure the postcards you are going to set are not curled.

Feeding curled postcards may cause paper jams.

Some postcards have rough edges on the back (those are created when

the paper is cut). In this case, put the postcards on a flat place and rub the

edges with, for example, a ruler to smooth them.

Envelopes

The printer can print on envelopes using paper with a basis weight of 60 to

79 g/m

An envelope is a more complex object than a single sheet of paper. For this

reason, it may not be possible to obtain consistent print quality over the

entire envelope surface.

Many envelopes have a diagonal grain orientation (Refer to Paper

Grain on page 1-7). This orientation is more likely to wrinkle and crease on

its way through the printer. Before purchasing envelopes for use with the

printer, test a sample to verify the envelope’s suitability.

2

(16 to 21 lb/ream). Envelopes must be manually fed.

ADVANCED OPERATION GUIDE 1-11

Handling Paper

Do not use envelopes that have an encapsulated liquid adhesive.

Avoid long printing runs consisting of envelopes only. Extensive envelop e

printing can cause premature printer wear. To avoid jamming due to curled

envelopes, do not leave more than approximately 10 printed envelopes

stacked in the paper trays during multiple envelope printing.

Thick Paper

Fan the stack of paper and align the edges before loading them in the MP

tray. Some types of paper have rough edges on the back (those are

created when the paper is cut). In this case, put the paper on a flat place

and rub the edges once or twice with, for example, a ruler to smooth them.

Feeding rough edged paper may cause paper jams.

NOTE: If the paper jams even after you smooth it out, load the paper in

the MP Tray with the leading edge raised up a few millimeters.

Colored Paper

Colored paper should satisfy the same conditions as white bond paper,

listed in Paper Specifications on page 1-3. In addition, the pigments used

in the paper must be able to withstand the heat of fusing during the printing

process (up to 200 °C or 392 °F).

Preprinted Paper

Preprinted paper should have a bond paper base. The preprinted ink must

be able to withstand the heat of fusing during the printing process, and

must not be affected by silicone oil.

Do not use paper with any kind of surface treatment, such as the type of

paper commonly used for calendars.

Recycled Paper

Select recycled paper that meets the same specifications as the white

bond paper (refer to Paper Specifications on page 1-3) except whiteness.

NOTE: Before purchasing recycled paper, test a sample on the printer

and check that the print quality is satisfactory.

1-12 ADVANCED OPERATION GUIDE

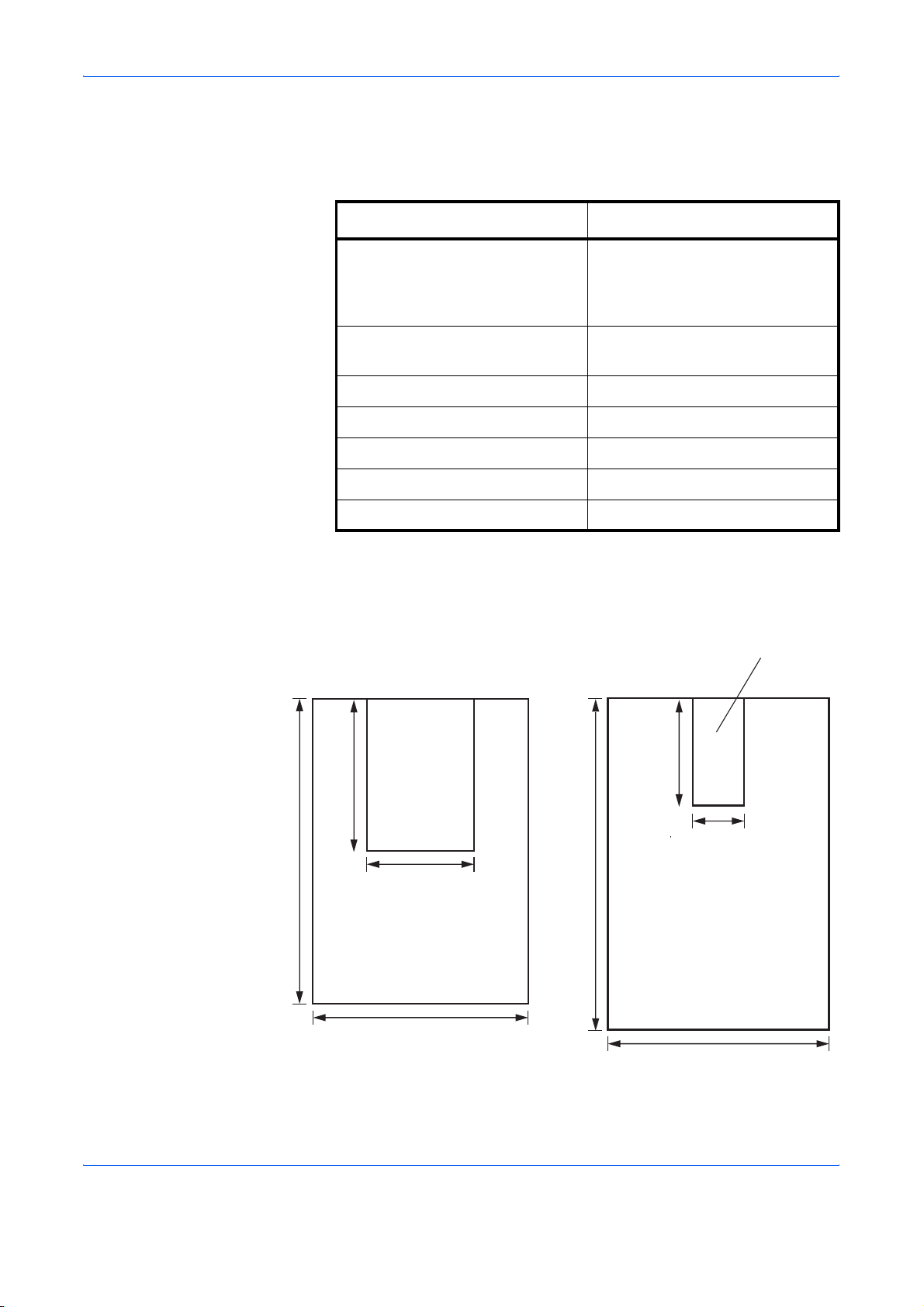

Media Type

Handling Paper

The printer is capable of printing under the optimum setting for the type of

paper being used.

Setting the paper type for the paper source from the printer’s operation

panel will cause the printer to automatically select the paper source and

print in the mode best suited to that type of paper.

A different paper type setting can be made for each paper source including

the MP tray. Not only can preset paper types be selected, but it is also

possible for you to define and select customized paper types. Refer to

Creating Custom Paper Type on page 2-82.

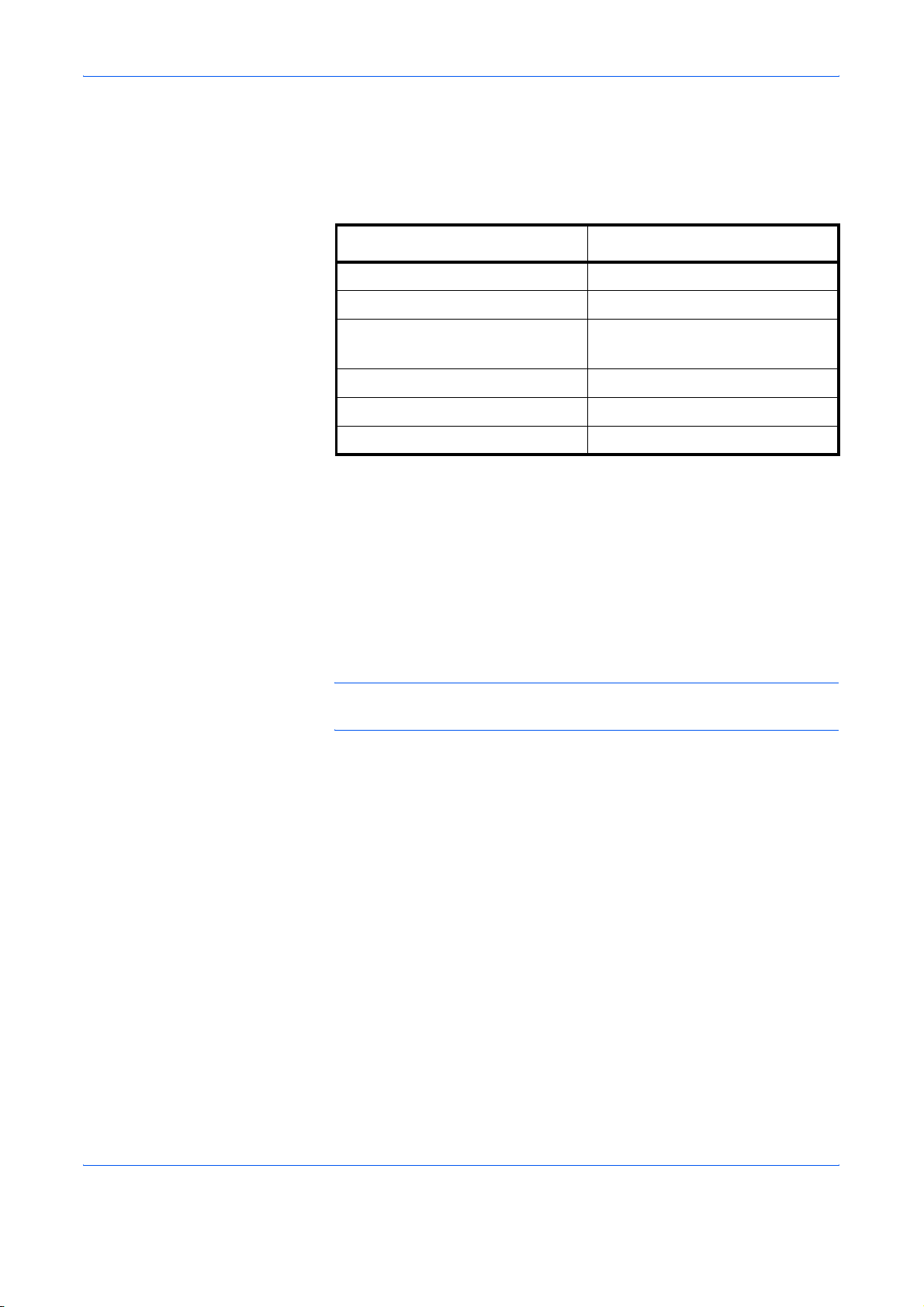

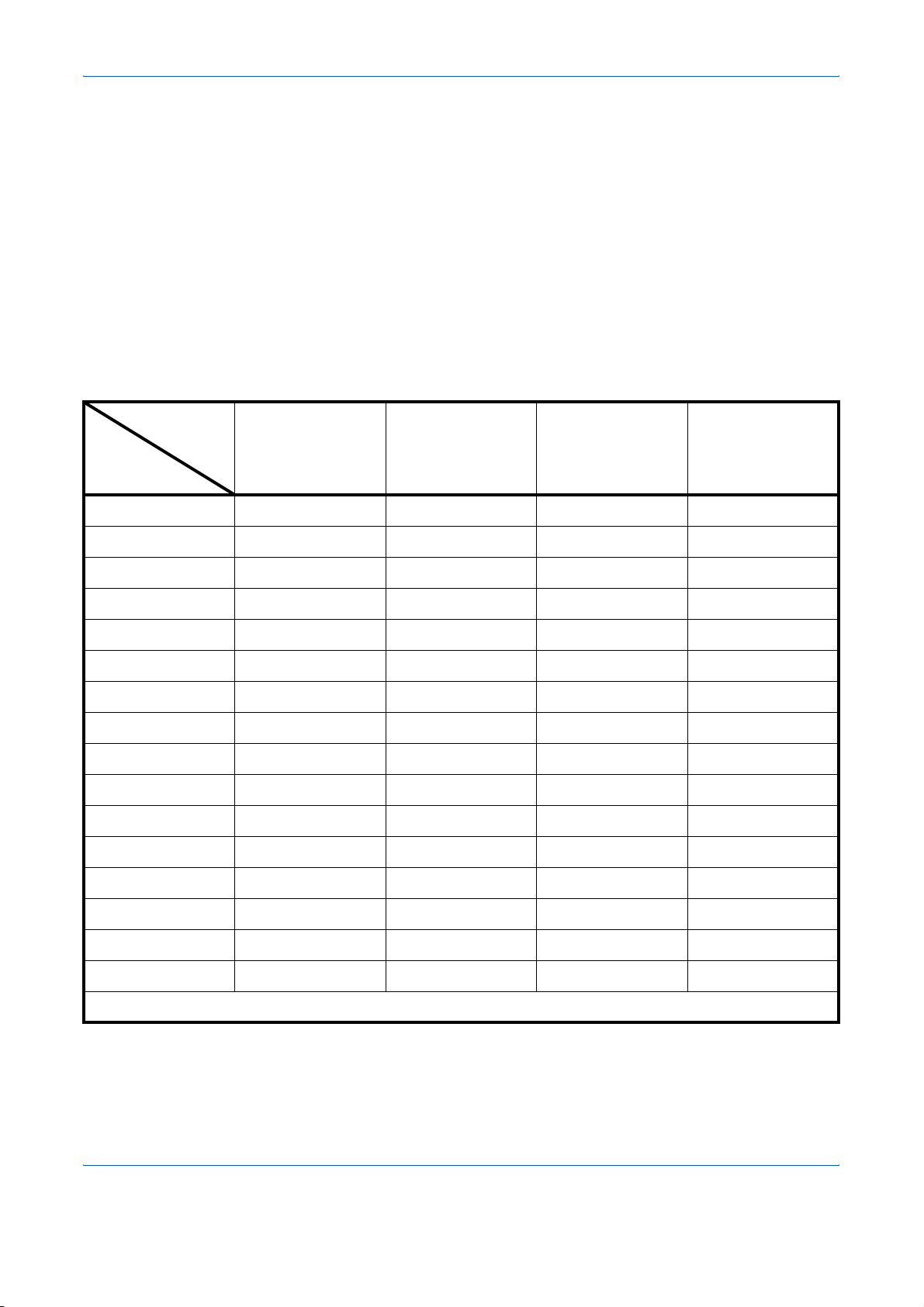

The following types of paper can be set.

Paper source

MP tray Paper Cassette Paper Weight

Media Type

Plain Yes Yes Normal 2 Yes

Transparency Yes No Extra Heavy No

Preprinted Yes Yes Normal 2 Yes

Labels Yes No Heavy 1 No

Bond Yes Yes Normal 3 Yes

Recycled Yes Yes Normal 2 Yes

Vellum Yes Yes Light No

Rough Yes Yes Normal 3 Yes

Letterhead Yes Yes Normal 2 Yes

Color Yes Yes Normal 2 Yes

Prepunched Yes Yes Normal 2 Yes

Envelope Yes No Heavy 2 No

(MP tray available

only in Cassette

Duplex path

mode)

Cardstock Yes No Heavy 2 No

Thick Yes No Heavy 2 No

High quality Yes Yes Normal 2 Yes

Custom 1 (to 8)* Yes Yes Normal 2 Yes

Yes: Can be used No: Cannot be used

* This is a paper type defined and registered by the user. Up to eight types of user settings may be

defined. For details, refer to Creating Custom Paper Type on page 2-82.

ADVANCED OPERATION GUIDE 1-13

Handling Paper

Loading Paper

Loading Paper into the Paper Cassette

The following explains the produre for loading paper. Paper can be loaded

into the two paper cassettes and the MP tray.

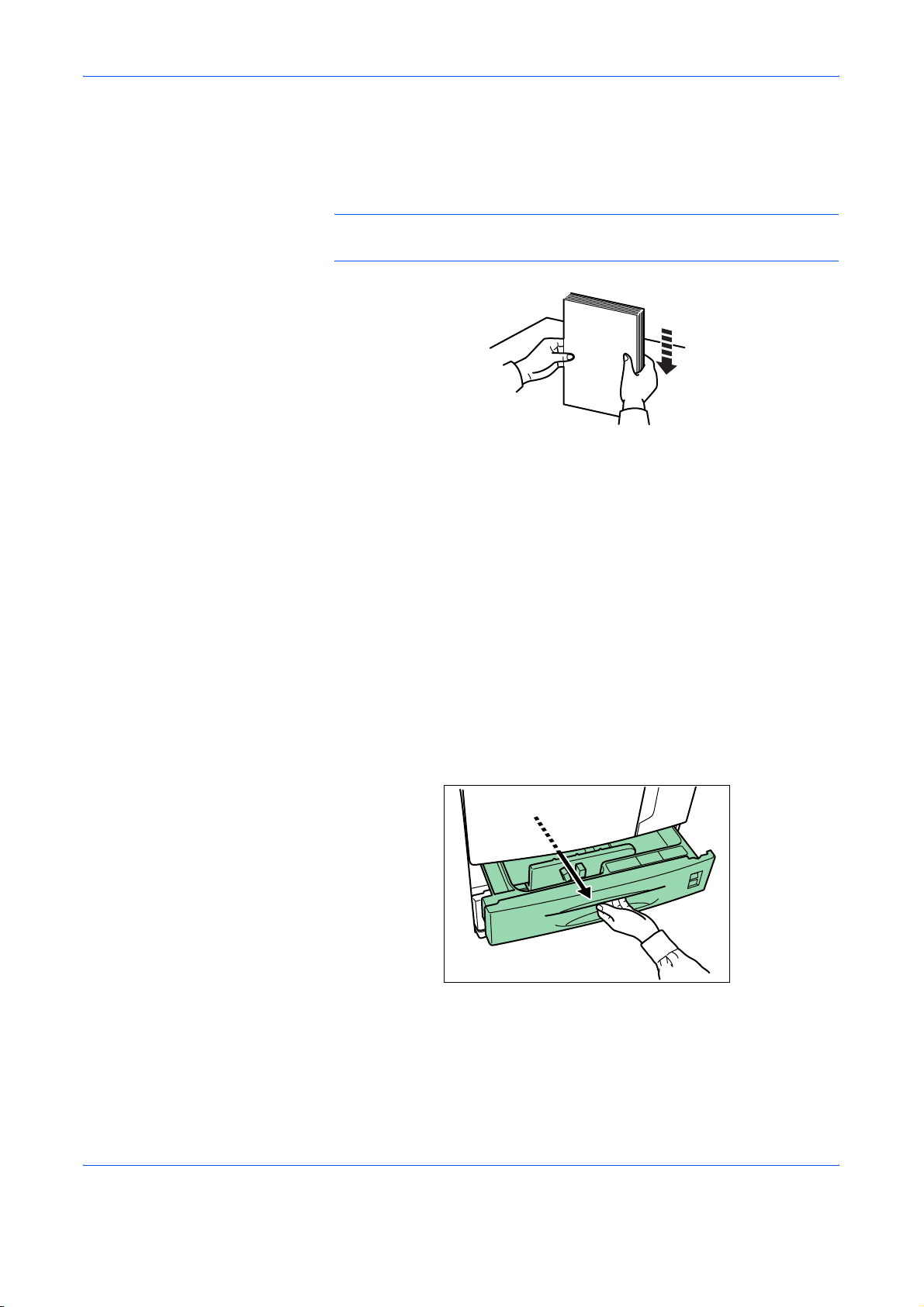

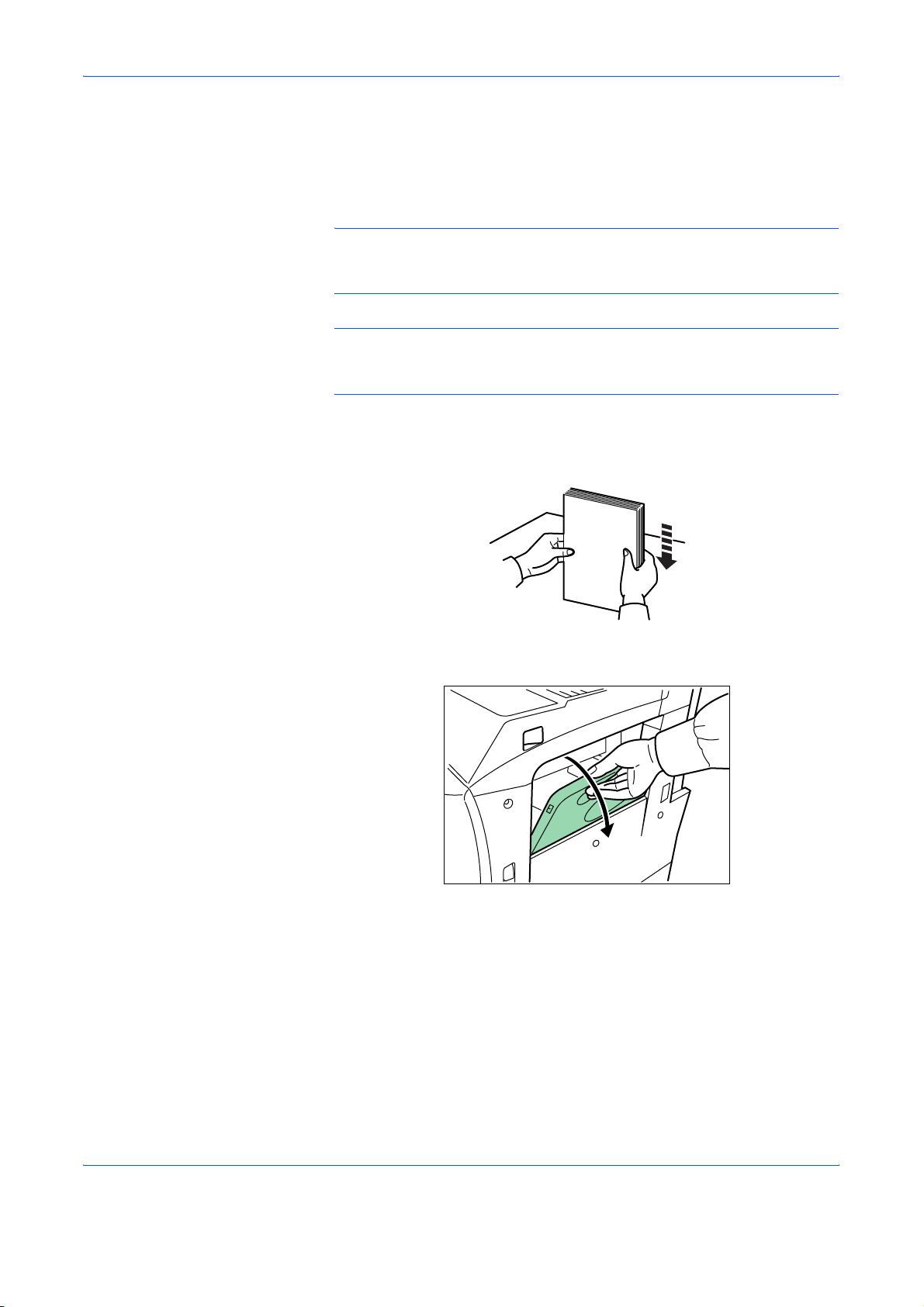

IMPORTANT: Fan the paper, then tap it on a level surface. This avoid

media jams or skewed printing.

Up to about 500 sheets of standard paper (80 g/m2) can be loaded into the

each paper cassette.

Inch specifications

Each paper cassette can be set to hold paper of any desired size from 1 1

× 17 to 5-1/2 × 8-1/2".

Metric specifications

Each paper cassette can be set to hold paper o f any desired size from A3

to A5R.

Pull the paper cassette out toward you as far as it will go. Do not pull more

1

than one paper cassette out at a time.

1-14 ADVANCED OPERATION GUIDE

Handling Paper

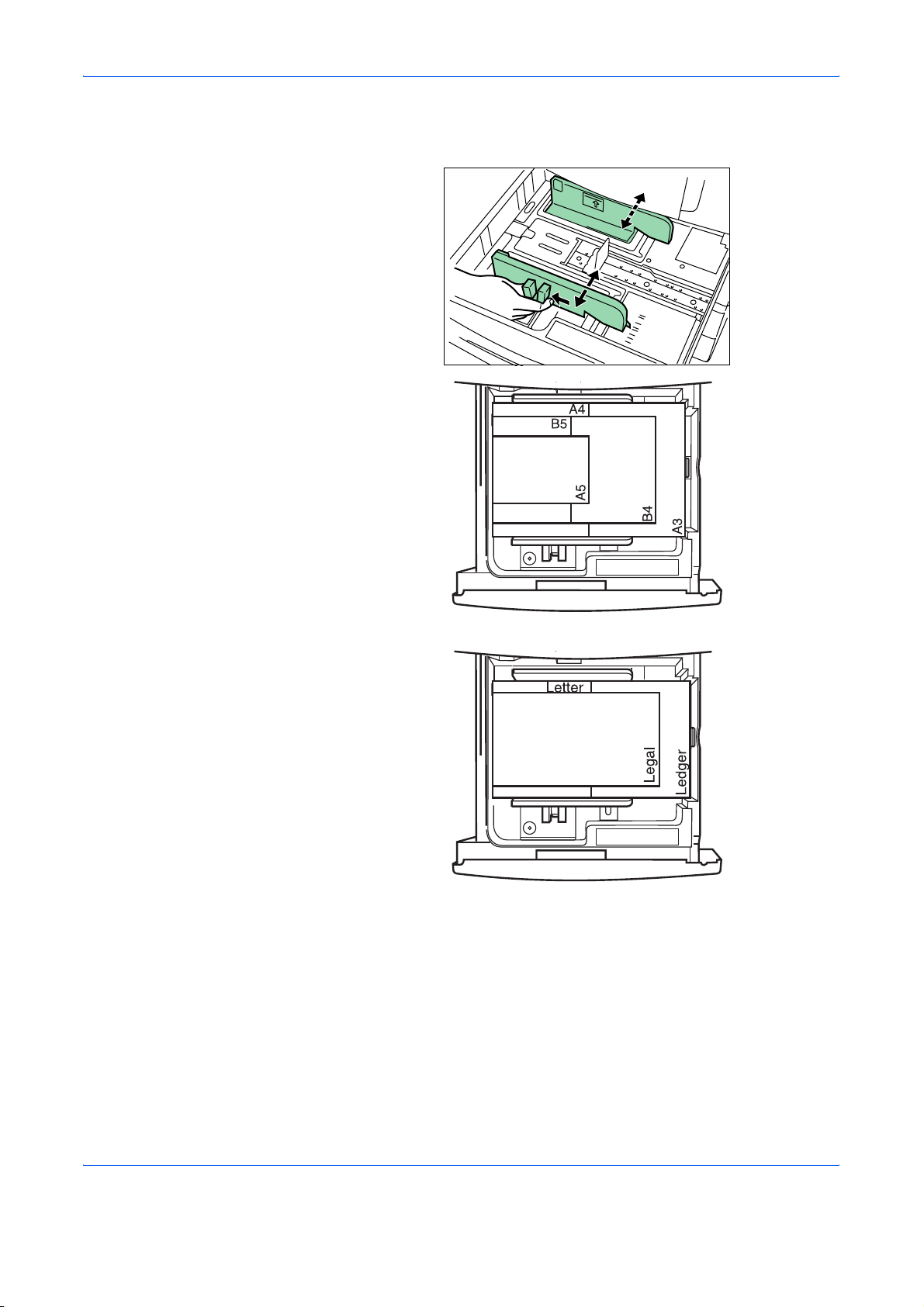

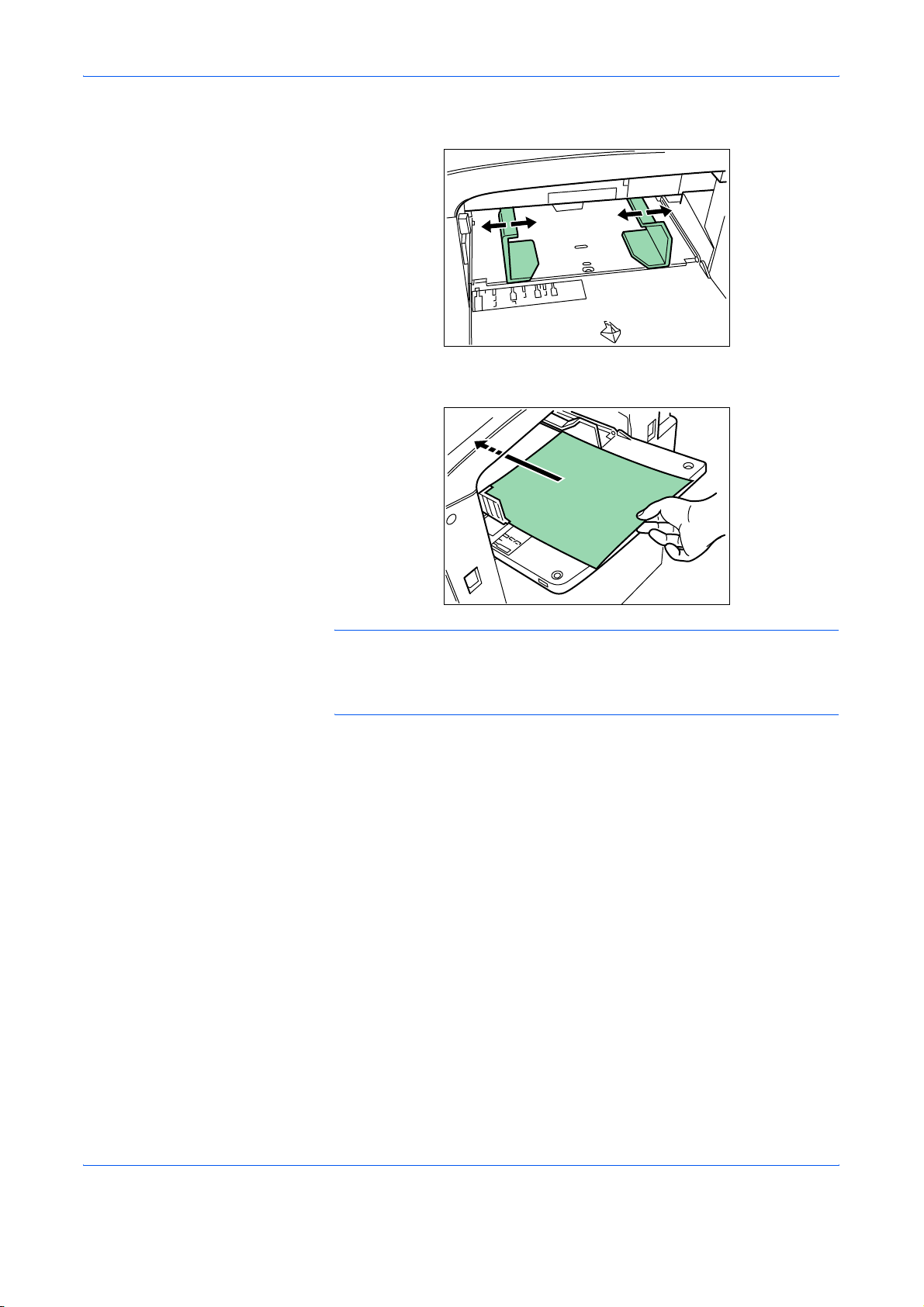

Hold the paper guide and move it to align the paper guide with the r equired

2

paper width. Paper sizes are marked inside the paper cassette.

ADVANCED OPERATION GUIDE 1-15

Handling Paper

Hold the paper stopper and move it to align with the required paper length.

3

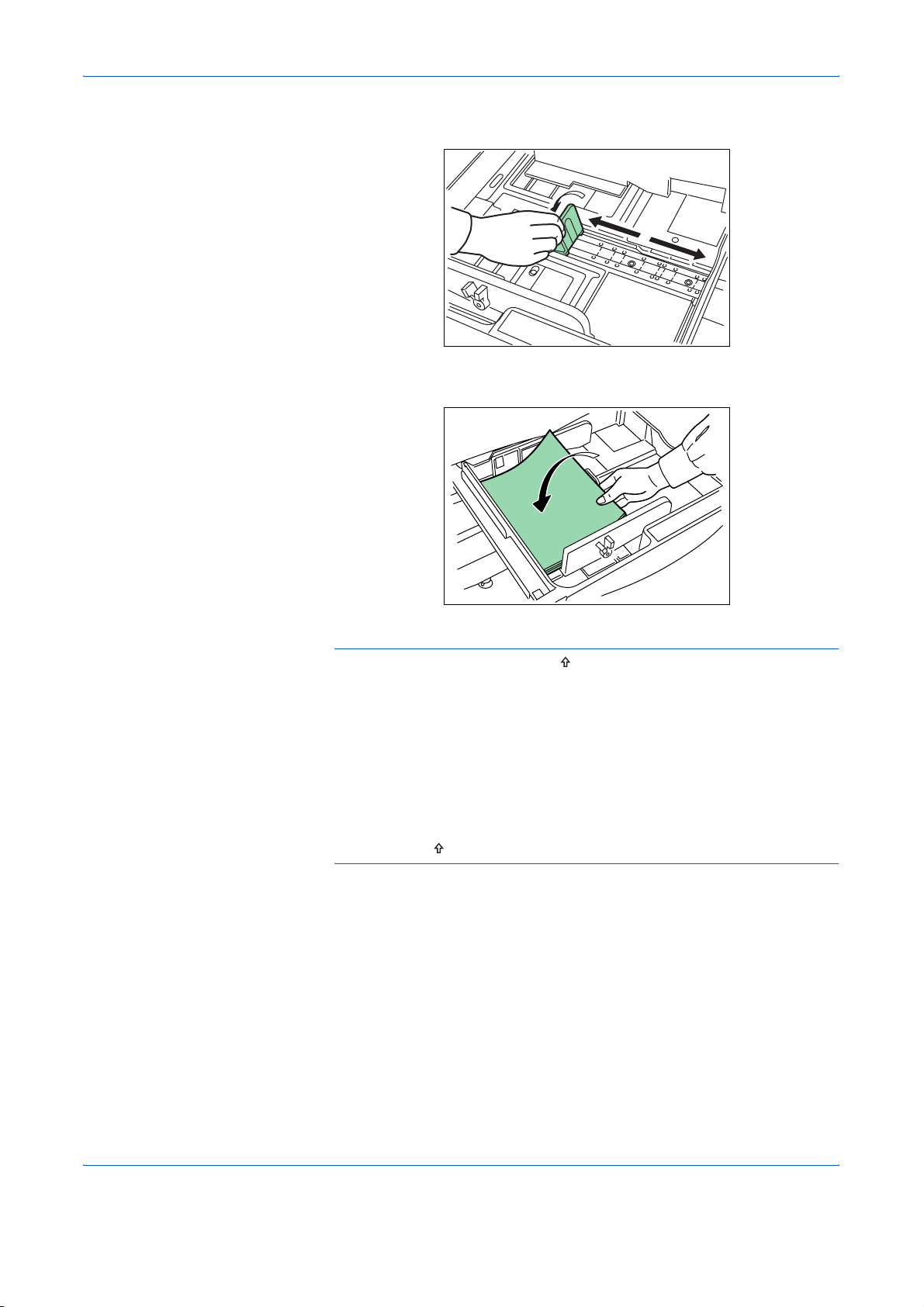

Set the paper flush against the left-hand wall of the paper cassette.

4

IMPORTANT:There is a sticker ( in the illustration) indicating paper

capacity attached to the inside of the paper cassette. Do not load paper

above this limit.

When loading paper into the paper cassette, make sure that the print side

is facing upward. (The print side is the side facing upward when the

package is opened.)

Check that the paper guide makes secure contact with the paper. If there

is a gap, adjust the position of the paper guide.

If small-size paper jams occur frequently under high temperature and high

humidity conditions, reduce the number of sheets to the level line indicated

on the sticker .

1-16 ADVANCED OPERATION GUIDE

Handling Paper

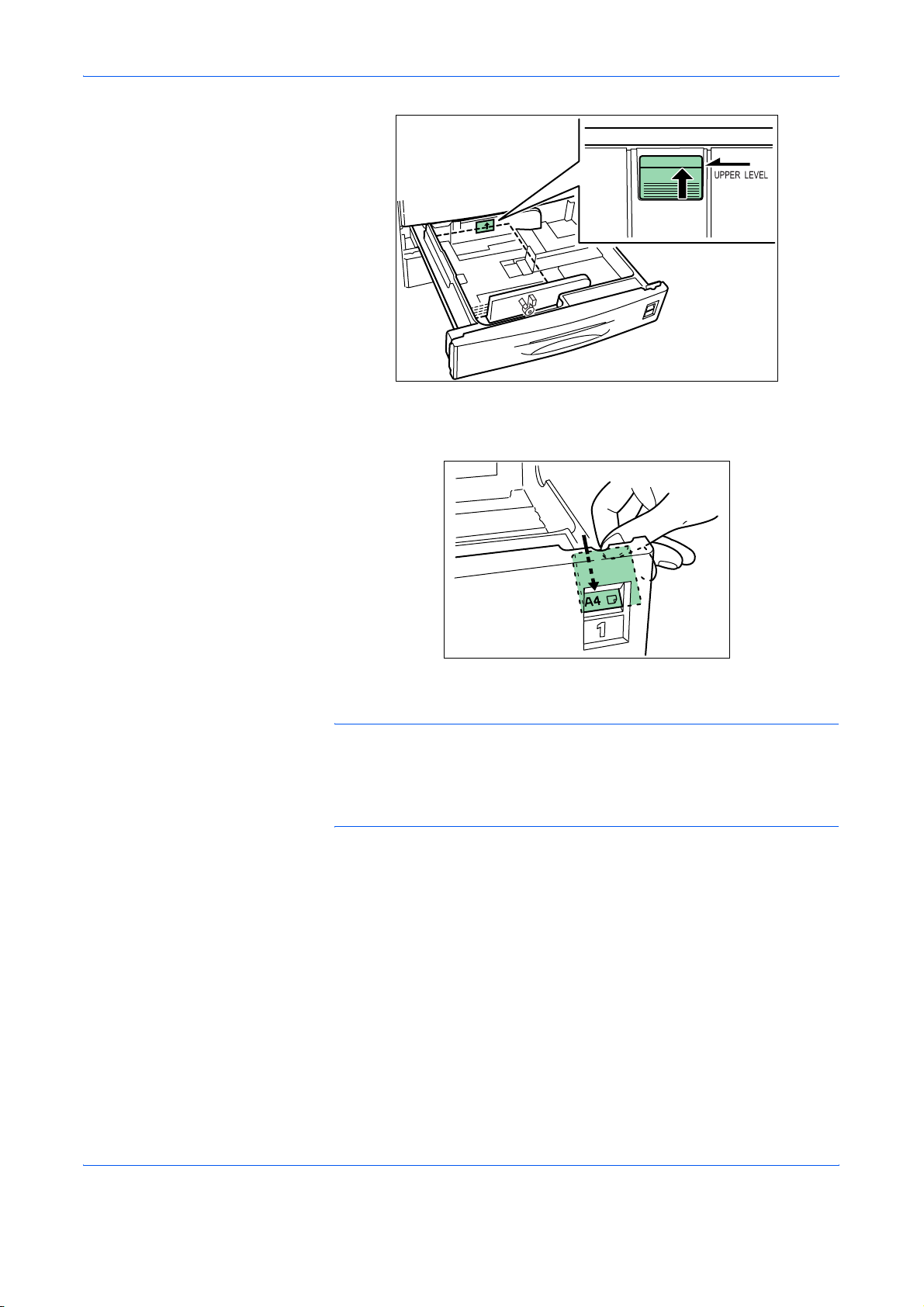

Set the supplied paper size plate so that the size of the paper loaded can

5

be checked by looking at the front of the paper cassette.

Push the paper cassette back until it stops.

6

NOTE: Before leaving the printer in disuse for a prolonged period of time,

remove the paper from the paper cassette(s) and seal it in its original

packaging to protect from moisture. Also, when storing paper in a high

temperature and high humidity environment, seal it in a moisture-proof

bag.

ADVANCED OPERATION GUIDE 1-17

Handling Paper

Loading Paper into the MP (Multi-Purpose) Tray

Special paper as well as standard paper can be loaded into the MP tray.

When printing onto transparencies or thick paper, be sure to use the MP

tray.

IMPORTANT: When setting special paper, such as transparencies and

thick paper, into the MP tray, select the type of paper by referring to Media

Type on page 1-13.

NOTE: The number of sheets of standard paper th at can be loaded in the

MP tray at a time is approximately 200. When using transparencies, load

a single sheet at a time.

Fan the paper, then tap it on a level surface to avoid media jams or skewed

1

printing.

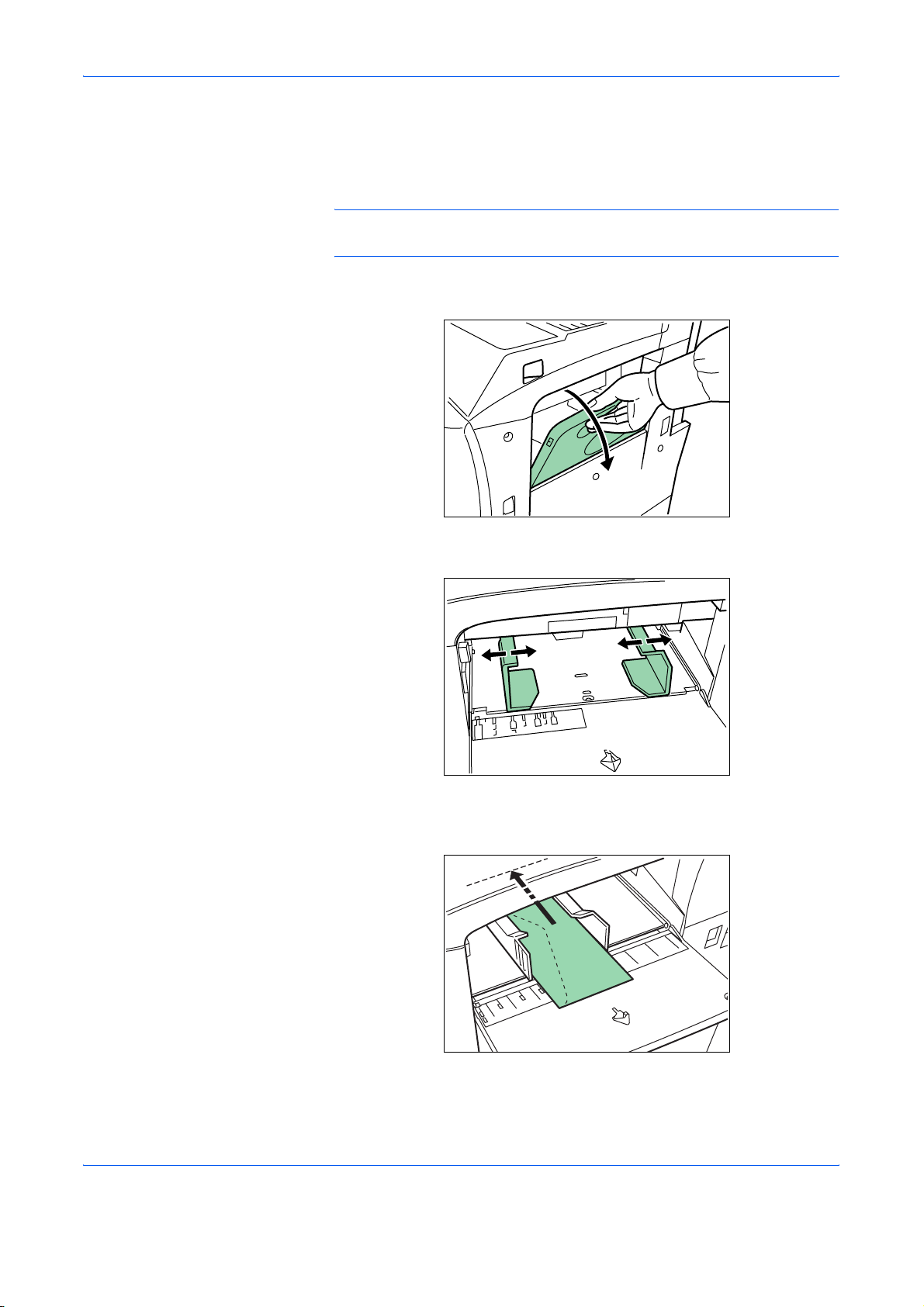

Open the MP tray.

2

1-18 ADVANCED OPERATION GUIDE

Adjust the insert guides to the size of the paper to be loaded.

3

Insert the paper along the guides as far as it will go.

4

Handling Paper

IMPORTANT: When loading paper into the MP tray, make sure that the

print side is facing upward. (The print side is the side facing upward when

the package is opened.) If the leading edge of the paper is curled,

straighten it out before loading the paper in the MP tray.

ADVANCED OPERATION GUIDE 1-19

Handling Paper

Setting Envelopes

When using the optional printer function, envelopes can be set in the MP

tray.

NOTE: Do not print on envelopes with flap adhesive exposed. This can

cause printer malfunction.

Open the MP tray.

1

Align the insert guides with the envelope size.

2

Position the envelope against the insert guides with the print side facing

3

upward, and insert it as far as it will go.

1-20 ADVANCED OPERATION GUIDE

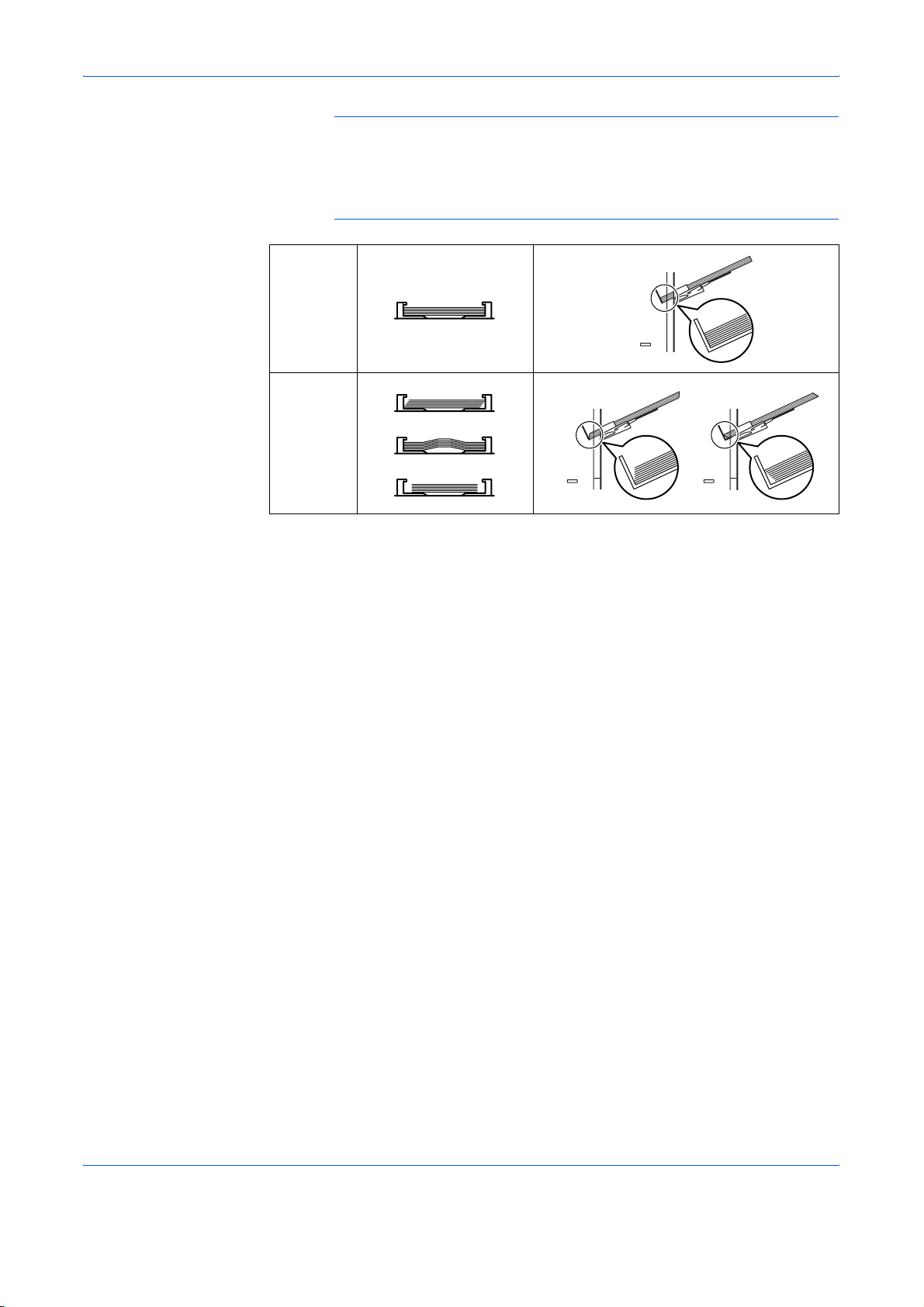

NOTE: Do not load more paper than will fit under the load limits on the

inside of the MP tray. If the paper is considerably curled in one direction,

for example, if the paper is already printed on one side, try to roll the

paper in the opposite direction to counteract the curl. Printed sheets will

then come out flat.

Correct

Incorrect

Handling Paper

ADVANCED OPERATION GUIDE 1-21

Handling Paper

1-22 ADVANCED OPERATION GUIDE

2 Using the Operation

Panel

This chapter explains the following topics:

• Understanding the Operation Panel............................ 2-2

• Canceling a Printing Job ........................................... 2-10

• Using the Operation Panel......................................... 2-11

• Using the Menu Selection System ............................ 2-19

• Status Pages............................................................. 2-20

• e-MPS ....................................................................... 2-23

• Changing the Interface Parameters .......................... 2-35

• Making Default Settings ............................................ 2-42

• Pagination ................................................................. 2-51

• Setting Print Quality................................................... 2-58

• Operating the Storage Device................................... 2-62

• Paper Handling.......................................................... 2-73

• Reading Life Counters............................................... 2-86

• Other Modes.............................................................. 2-87

ADVANCED OPERATION GUIDE 2-1

Using the Operation Panel

Understanding the Operation Panel

The operation panel has an LCD message display, indicators, and eight

keys.

Operation Indicators (Refer to page 2-3)

Message Display

(Refer to page 2-4)

Ready

A4 PLAIN

- - -

Paper Type Indicator

(Refer to page 2-7)

Paper Size Indicator

(Refer to page 2-5)

Interface Indicator

(Refer to page 2-5)

Keys (Refer to page 2-8)

2-2 ADVANCED OPERATION GUIDE

Loading...

Loading...