Triumph TR6R Tiger 650, TR6C TROPHY 650, T120R Bonneville 120, T12OR BONNEVILLE 120 Replacement Parts Manual

REPLACEMENT

PARTS

CATALOGUE

No.

7

UNIT CONSTRUCTION

40

cu.

ins.

TWINS

TR6R TIGER 650

TR6C TROPHY 650

Tl2OR BONNEVILLE 120

From

engine

No.

DU

85904

TRIUMPH ENGINEERING COMPANY LIMITED

MERIDEN WORKS . ALLESLEY

.

COVENfRY

.

ENGLAND

TELEPHONE MERIDEN

331

TELEGRAMS "TRUSTY COVENTRY"

PUBLISHED SEPTEMBER 1960 REF. SPC.7.

TRIUMPH GUARANTEE

1.

in this Guarantee the word "machine" refers to the motor cycle, scoorer, motor cycle combination

or sidecar as the case may be, purchased by the Purchaser.

2.

In order to obtain the benefit of this Guarantee, the Purchaser must have correctly completed the

3

registration form and returned

it

to us within fourteen days of the purchase.

1

3.

We will supply, free of charge, a new part in exchange for, or, if we consider repair sufficient, will

repair free of charge any part proved within six months of the date of purchase of any new machine,

(three months overseas) or within three months of its renewal or repair in the case of a part already

renewed or repaired, to be defective by reason of our faulty workmanship or materials.

We do not

undertake to bear the cost of fitting such new or repaired part

or

accessory.

4.

Any part considered to be defective must be sent to our Worlcs, carriage paid, accompanied by the

following information:-

(a)

Name of purchaser and his address;

(b) Date of purchase of machine;

(c) Name of dealer from whom the purchase was made;

'

(d) Engine number and model.

5.

This Guarantee shall not extend to defects or damage appearing after misuse, neglect, abnormal stress

or

strain, or the incorporation or affixing of unsuitable attachments or parts and in particular:-

(a) Hiring out;

(b) Racing and Competitions;

(c) Adaptation or alteration of any part

or

parts after leaving our Works;

(d) The attaching of a sidecar in a manner not approved by us or to an unsuitable

motor cycle.

This Guarantee shall not extend to machines whose trade mark, name or manufacturing number has

been altered or removed, or in 'which has been used any part not supplied or approved by us, or to

ryres, saddles, chains, speedometers, revolution counters and electrical equipment or to parts supplied

to the order of the Purchaser and different from our standard specification.

6.

Our liability and that of our dealer who sells the machine, shall be limited to that set out in this guarantee,

and no other claims including claims for consequential damage or injury to person or property, shall

be admissible. Ail other conditions and warranties statutory or otherwise and whether express or

implied are hereby excluded and no guarantee other than that expressly herein contained applies to

the machine to which this Guarantee relates or any accessory or part

thereof.

7.

We reserve the right to modify or deviate from the Published Specification without notice,

REPAIRS GUARANTEE

1.

Whilst the highest standard of workmanship and maierials is aimed at, we cannot accept liability for

any defects appearing more than three months after the machine, assembly or component has left our

Worlcs after being repaired.

2.

We will repair or replace at our option free of charge any defective work, materials or parts relating

to the repairs carried out by us appearing within that time but shall not be under any further

or

other

liability for any other loss or damage whether direct or consequential and our liability shall be limited

to

the cost of so making good. We do not undertake to bear the cost of fitting any replacement or

repaired part.

3.

We do not accept liability in respect of parts of proprietary manufacture, e.g. tyres, saddles, chains.

speedometers, r?volution counters and electrical equipment which may be used by us in effecting a

repair. Ali other conditions and warranties statutory

or

otherwise expressed or implied are hereby

excluded.

TRIUMPH SPARES

HOW

TO

ORDER.

Every part is indicated by number, and this should be quoted together with

the description. In order to assist customers, dimensions have been given in many cases where parts are

similar. Parts where possible have been listed in order of assembly and a number of the illustrations show

the assembly order also. With these aids there should be no

dificulty in identifying the parts you require

Always head your order with the engine number, stamped on the left side of the crank case

underneath the cylinder flange, together

with

the prefix letters.

WHERE

TO

OBTAIN. Triumph Spare Parts can only be obtained from an authorized Triumph

Dealer, and we recommend our customers to place their orders with the Triumph Dealer in their district.

When parts not usually asked for are required, and for which the Dealer may have to write or obtain

specially, the postage or carriage incurred becomes payable.

Triumph Spares are not supplied to private owners direct from the factory.

If

difficulty

is experienced

in

obtaining the required parts, the matter should be taken up directly

with

the

Triumph Spares Department.

Customers are warned against the risk incurred by purchasing parts that are not of genuine Triumph

manufacture. This risk is eliminated if parts are ordered as instructed from recognised Dealers.

PATTERNS AND PARTS FOR REPAIR.

It

is not necessary to send patterns if the part number

is quoted. The sending of patterns often delays the order

as

parcel post or rail takes longer than letter post.

Parts sent to Coventry for repair, replacement, or

as

patterns should bear the sender's name and address

and clear instructions should accompany the parts.

In your own interest send a copy of the advice note

under separate cover. All

pans must be fowarded carriage paid and care should be taken to ensure that

all

remittances are sent separately and not enclosed with the parts. Fragile units such as cylinders, etc.,

should always be boxed to avoid damage in transit. Complete machines should have all fitments such

as

windscreens, driving mirrors, tools, etc., removed by the sender before despatch, as

it

is impossible for us

to accept responsibility in the event of loss in transit. We are always pleased to give estimates for over-

hauling and repairs, but should an estimate not be accepted, a charge

will be made covering cost of dismantling

and re-assembling, if carried out.

Communications relating to Parts should be addressed to the SPARES DEPARTMENT and for repairs.

guarantee claims and technical advice to the SERVICE DEPARTMENT. Triumph Engineering Co. Ltd.,

Meriden

Works, Allesley, Coventry. In order to facilitate quick reference, the quoting of any number, invoice

number or reference from previous communications is essentizl. Accessories not of our manufacture

should be sent direct to the actual makers, whose names and addresses appear below.

PROPRIETARY GROUP

Ancillary equipment which

is

fitted to our motor cycles

is

of the highest quality and is guaranteed by

the manufacturer and not by ourselves. Any repairs

or

claims should be made to the actual makers or their

local agents who will always give owners every possible assistance. The following are the addresses of the

various manufacturers:-

CARBURETTERS SPARKING PLUGS

Messrs. Amal Lid., Champion Sparking Plug Co. Ltd..

Holdford Rd.. Witton, Birmingham

6.

Feltham. Middlesex.

CHAIFIS

Renold Chains Ltd.,

Wythenshawe. Manchester.

ELECTRICAL EQUIPMENT

Messrs.

J.

Lucas Ltd.,

Gt. Hampton St., Birmingham,

18

SPEEDOMETERS

Messrs. Smiths Industries Ltd.,

Cricklewood Works. London.

N.W.2.

SUSPENSION UNITS

Messrs. Girling Ltd.,

Birmingham Road, West Bromwich. Staffs,

TYRES

Dunlop Rubber Co. Ltd..

Fort Dunlop. Birmingham,

24

INDEX

Page

Page

AIR FILTER

...

...

...

...

57

ALTERNATOR

...

...

...

...

13 . 33

...

AUTO-ADVANCE UNIT

...

23

......

BATTERY CARRIER

...

57

BRAKE SWITCHES

......

...

65

CAMSHAFT. INLET AND EXHAUST 13

CAPACITOR. IGNITION

...

...

75

CARBURETTER

...

...

...

69 . 71

CARTON PACKS

... ...

...

9

CENTRE STAND

...

...

...

35

CHAINS

......

...

...

...

33

CHAINCASE

......

...

...

33

CLUTCH

...

...

...

...

31

CLUTCH LEVER ASSEMBLY

...

29

COIL

... ...

...

...

.

.

77

CONDENSER PACK

......

...

77

CONNECTING RODS

...

...

13

CONTACT BREAKER

......

...

23

CONTROL CABLES

......

...

65

CONTROL LEVERS

......

...

63

CRANKCASE

......

...

...

15

CRANKCASE UNDERSHIELD

...

39

CRANKSHAFT

......

...

...

13

CYLINDERS

...

...

...

...

19. 21

CYLINDER HEAD

...

...

...

19. 21

....

ENGINE PLATES

...

...

...

39

ENGINE TORQUE STAY

...

...

39

EXHAUST

PIPES

...

...

...

41.43

EXHAUST PIPE ADAPTOR

......

19.21

FENDERS

...

...

...

...

61

FOOTRESTS

...

...

...

...

39. 67

FRAME

...... ...

...

...

35

FRONT BRAKE

...

...

...

49

FRONT FORKS

...

...

...

45

FRONT WHEEL

...

... ...

49

FUSE ASSEMBLY

...

...

...

57

GAS TANK

... ...

...

...

53

......

GASKET SET

...

...

9

...

GEARBOX

...

...

25. 27. 29

HANDLEBARS

......

...

HANDLEBAR MOUNTINGS

...

HEADLAMP

...

...

...

HEAT SINK

...

...

...

HORN

......

... ...

KICKSTARTER

......

...

MANIFOLD

... ...

...

MUFFLERS

...

...

...

OIL PUMP

...

...

...

OIL TANK

...

...

...

PISTONS

...

...

...

PROP STAND

......

...

PUSH RODS

......

...

REAR WHEEL

......

...

RECTIFIER

...

...

...

REFLECTORS

......

...

ROCKERS

... ...

...

SIDE PANEL

......

...

SPARKING PLUG

...

...

SPEEDOMETER

......

...

SPEEDOMETER GEARBOX

...

STEERING DAMPER

......

STEERING RACES

...

...

SUSPENSION UNITS

......

SWINGING FORK

...

...

SWITCHES

...

...

...

TACHOMETER

......

...

TACHOMETER GEARBOX

...

TAIL LAMP

...

...

...

TAPPETS

...

...

...

TIMING GEARS

...

...

TOOLKIT

...

...

...

TWIN SEAT

......

...

VALVES

......

...

...

VALVE GUIDES

...

...

WIRING HARNESS

ZENER DIODE

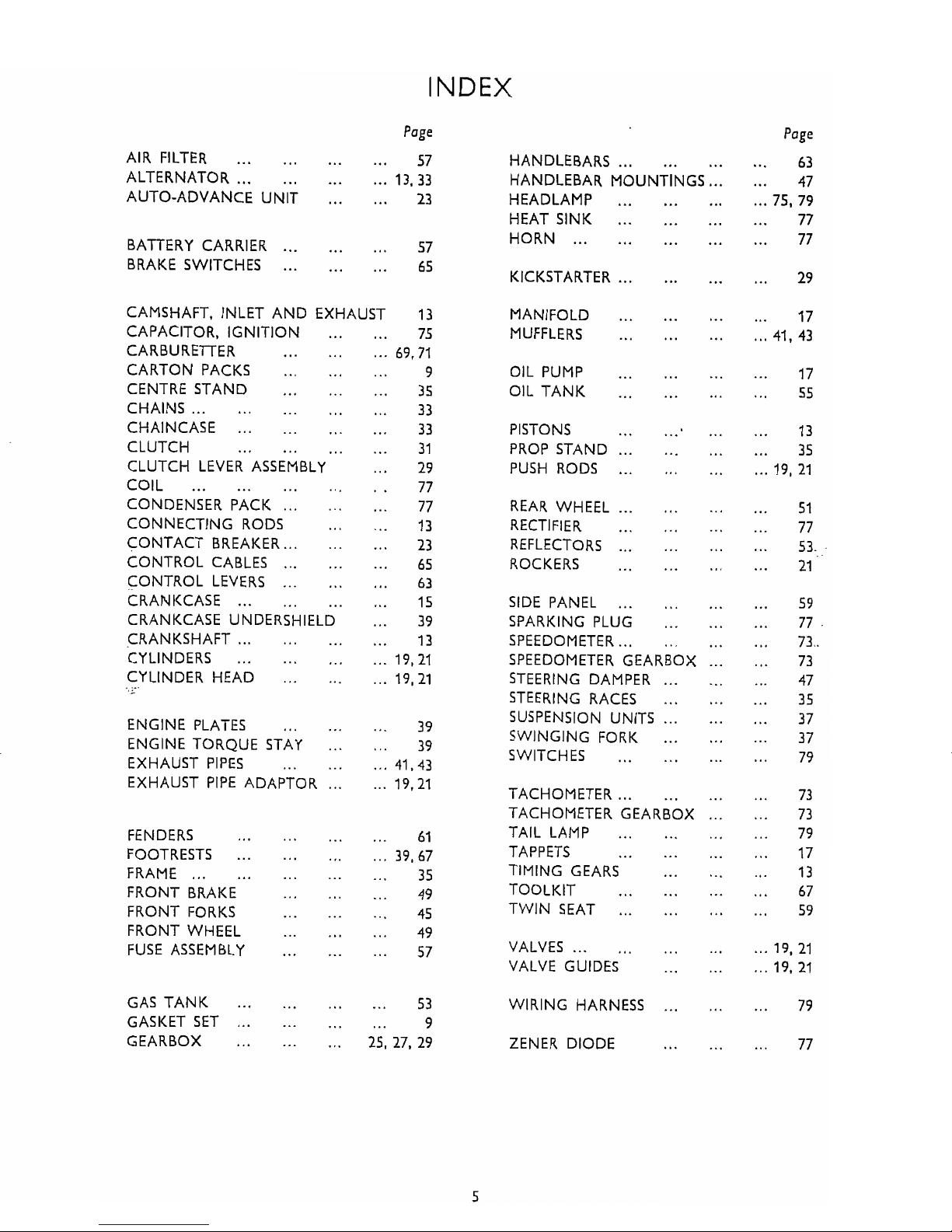

TIGER 650 (TR6R) TECHNICAL DATA

Bore and stroke

......

. , .

...

... ...

...

...

...

...

71 x 82

rnrn.

2.79 x 3.23

ins.

Capacity

...... ...

...

... ...

...

... ...

...

...

649

C.C.

(40

cu. ins.)

Compression ratio

Spark plugs

...

Carburetter

...

Gearbox sprocket

Chains

... ...

Capacities

...

Brakes

...

...

Tire

size

......

.

.

...

...

... ...

Main jet

... ...

Needle jet

...

...

Throttle valve

......

Front

...

...

...

Rear

... ...

...

... ...

Gas Tank

...

...

Oil Tank

...

...

Gearbox

...

...

Primary Chaincase

...

Front Forks (each leg)

...

...

Front, diameter

...

...

Rear, diameter

...

..

Front

...

...

...

Rear

...

...

...

Champion

N3

...

...

...

Amal Concentric

930

...

...

...

230

...

...

...

.I 06

...

...

...

No.

3+

19

teeth

...

...

...

+"

Duplex x

84

links

...

...

...

%"

x x

104

links

...

...

...

3$

U.S.

galls.

(16

litres)

...

...

...

6

U.S.

pints

(2.8

litres)

...

...

...

$

pint

(500

c.c.)

...

...

...

2

pint

(350

c.c.)

...

...

...

f

pint

(200

c.c.)

...

...

...

8" (20.32

cm.)

...

...

...

7" (17.78

cm.)

Bore and stroke

...

TROPHY

650

(TR6C) TECHNICAL DATA

Capacity

......

Compression ratio

Spark plugs

...

Carburetter

...

Gearbox sprocket

Chains

...

...

Capacities

...

Brakes

...

...

Tiresize

......

...

... ...

...

Main jet

...

...

...

Needle jet

...

......

Throttle valve

Front

...

...

...

Rear

...

...

...

Gas Tank

... ...

Oil Tank

...

...

Gearbox

...

. .

,

Primary Chaincase

...

Front Forks (each leg)

...

...

Front, diameter

......

Rear, diameter

.

.

...

Front

... ...

...

Rear

...

...

...

71 x 82 mm.

2.79

x

3.23 ins.

...

...

...

649

C.C.

(40

cu. ins.)

Champion

N3

...

...

...

Amal Concentric 930

...

...

...

230

...

...

...

.I

06

...

...

...

No. 3f

...

...

...

+''

Duplex x 84 links

... ...

...

$"x+"xl04links

...

...

...

2$ U.S. galls. (11 litres)

...

...

...

6

U.S.

pints (1.8 litres)

...

...

...

pint (500

c.c.)

...

...

...

$

pint (350

c.c.)

... ...

...

f

pint (200 c.c.)

...

...

...

8"

(20.32 cm.)

... ...

...

7" (17.78 cm.)

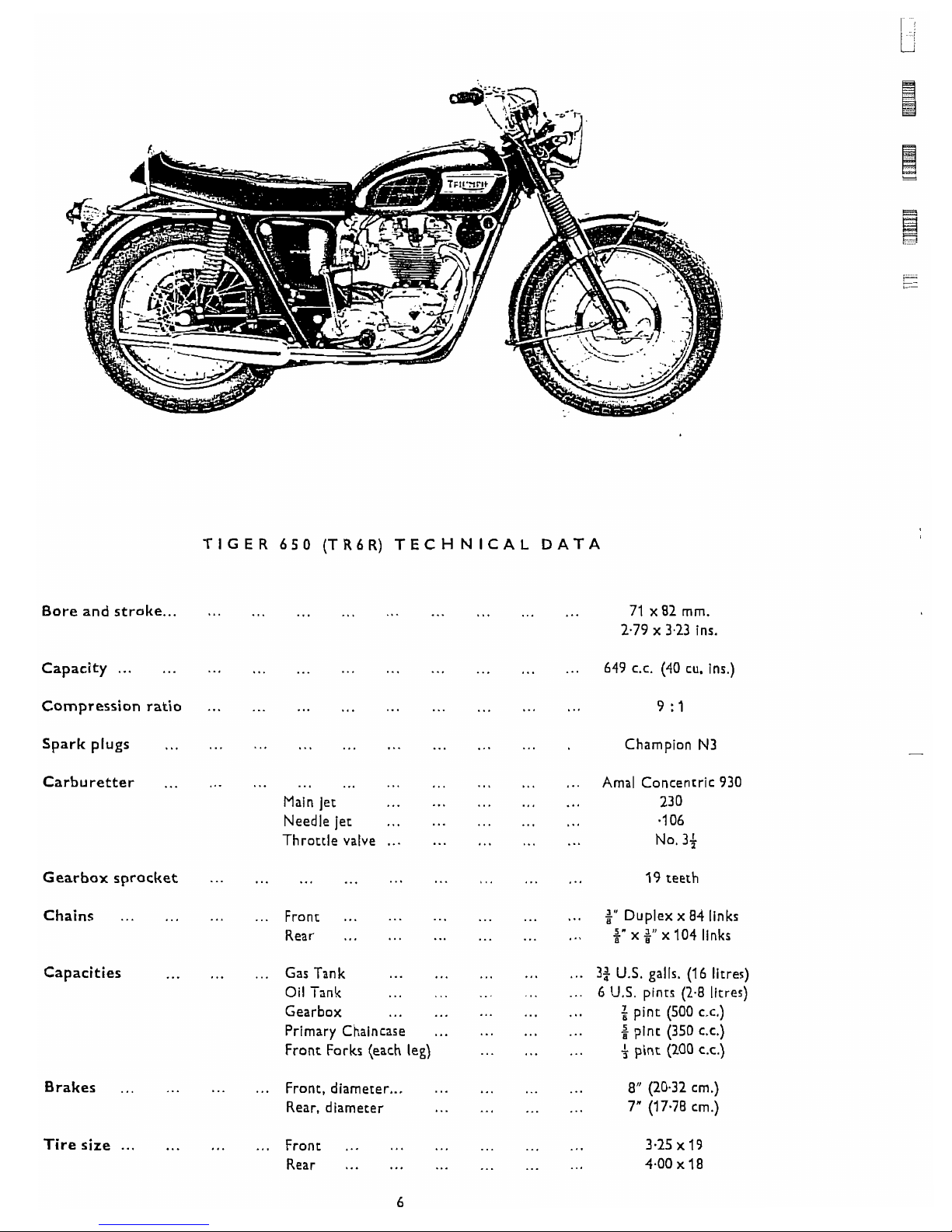

BONNEVILLE (T12OR) TECHNICAL DATA

...

Bore and stroke

Capacity

......

Compression ratio

Spark plugs

...

Carburetters

...

Gearbox sproclcet

Chains

...

...

Capacities

Brakes

... ...

Tire

Size

......

...

...

...

...

Main jet

...

...

Needle jet

...

...

Throttle valve

......

...

...

...

...

...

Front

Rear

...

...

...

...

Gas Tank

...

...

Oil Tank

...

Gearbox

...

...

...

Primary Chaincase

Front Forks (each leg)

...

Front, diameter

......

Rear, diameter

...

Front

...

...

...

...

Rear

...

...

...

71

x 82 mm.

2.79

x

3.23 ins.

...

...

...

649

C.C.

(40 cu. ins.)

... ... ...

9

:I

Champion N3

...

...

...

2 Amal Concentric 930

...

...

...

190

...

...

...

.I

06

...

...

...

No. 3

...

... ...

19 teeth

...

...

...

+"

Duplex x 84 links

... ...

...

x x 104 links

...

...

...

2;

U.5, galls. (11 litres)

...

...

...

5

U.5. pints (2.8 litres)

... ...

...

+

pint (500 LC.)

...

...

...

5

pint (350 c.c.)

...

...

...

f

pint (200 c.c.)

... ...

...

8" (20.32 cm.)

... ...

...

7"

(17.78 cm.)

4

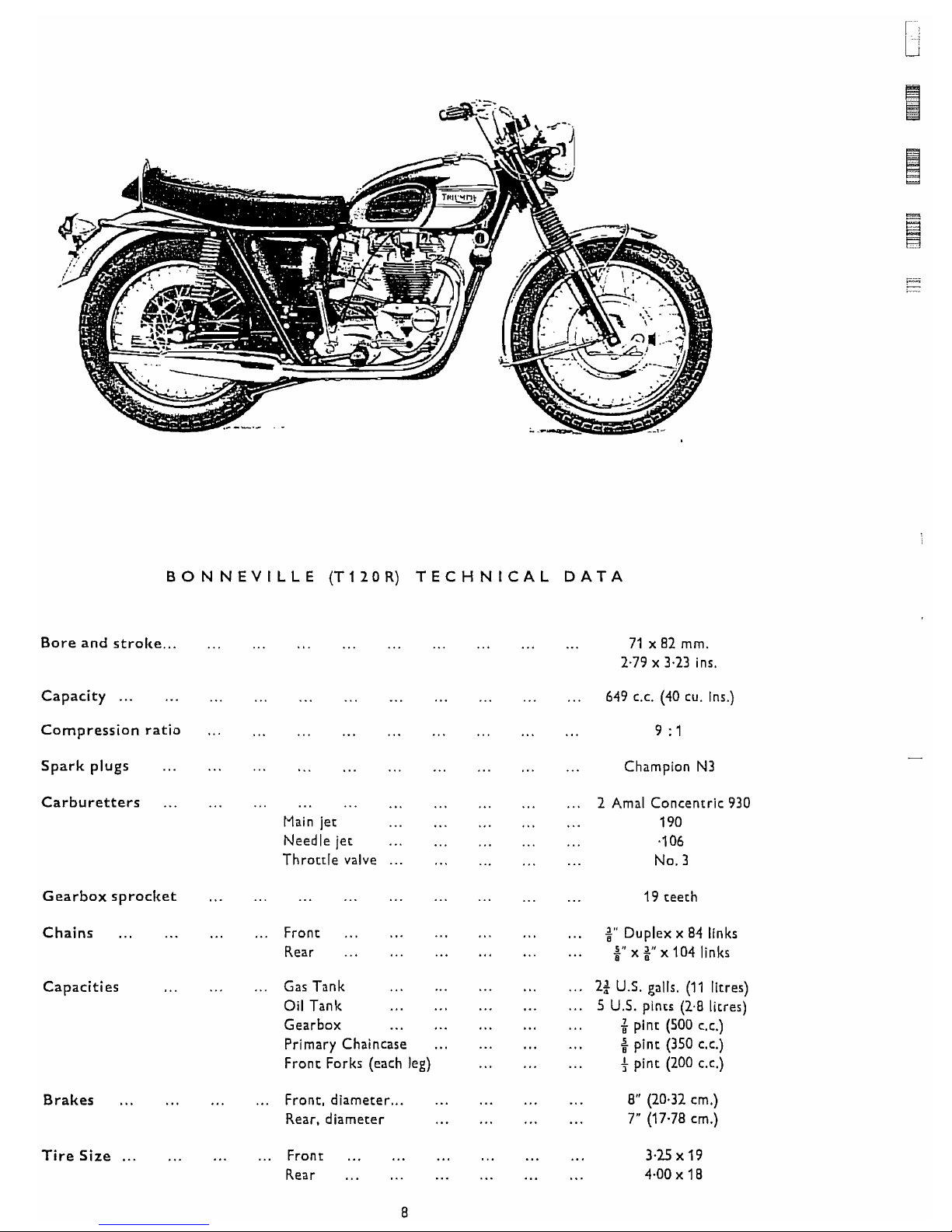

CARTON PACK LIST

1

The following sub-assemblies are supplied in carton packs under the C.P: part number stated. The

contents of these carton packs are preserved and will not deteriorate under adverse conditions.

Part

No.

Contents

Brake Lining

C.P.38/A.M.2

......

2

......

...

NW243

......

...

Brake lining

16

......

...

W129

......

...

Rivet

Pistons (complete with rings, gudgeon pins and circlips). These are in effect "carton pack" assemblies.

E6868

......

...

...

...

...

9

:

1

CR.

...

...

Standard

E6867

......

...

...

...

...

11

:I

CR.

...

...

Competition use only

All the above pistons are available in oversizes of 0.010 ins., 0.020 ins., 0.040 ins., (0.25 mm.,0.5 mm..lmm.)

De-coke Gasket Set All models

......

...

...

... ...

DGS7

Overhaul Gasket Set Ail models

......

...

...

...

...

GS/B/66/67

Fork Service pack

...

...

... ...

...

...

...

CP168,64T

Steering Race Kit

C.P.156

......

...

2...

...

...

HI11

...

... ...

Cups

1

......

...

H439

...

... ...

Cone

1

......

...

HI018

......

...

Top cone

40

......

...

570-3

...

...

...

Ball

HOW TO USE THIS PARTS CATALOGUE

First check that the engine number of your machine is subsequent to that quoted on the title page.

Next consult the index on Page

4

for the parts or group of parts which you wish to locate.

When

you have located the parts make sure from the end columns that the part you have located does apply to

your machine.

List the quantities required

as

single units; do not ask for "2 pairs" or

"3

dozen".

I.

Proprietary components e.g. electrical equipment, carburetters, suspension units etc. are listed in the

first column~nder~rium~h part numbers (prefixed either D-or99-) whereverthey are stocked atthe factory.

If proprietary parts are listed only under manufacturers part numbers, they are not available from,the factory.

In case of painted items always state the colour required.

Painted parts are available only in the colours

or alternatives specified

for

that model of that particular year.

Model

TR6 all cond~tions

T12OR

Colour

Trophy Red/Silver

Olympic Flame/Silver

N.B.

Trophy Red and Olympic Flame are both flamboyant finishes applied over Silver.

Paint is available only in Aerosol containers.

PLEASE NOTE

i

THROUGHOUT THIS LIST, ASSEMBLIES ARE PRINTED IN CAPITALS AND THE COMPONENTS

INCLUDED IN THAT ASSEMBLY ARE INDENTED IN THE DESCRIPTION COLUMN, REVERTING

TO THE ORIGINAL ALIGNMENT WHEN THE ASSEMBLY IS COMPLETE. TO ORDER THE COMPLETE

ASSEMBLY IT

IS

NECESSARY ONLY TO QUOTE THE ASSEMBLY NUMBER. ANY COMPONENT

PARTS LISTED MAY ALSO BE OBTAINED SEPARATELY IF REQUIRED.

SPECIAL WORKSHOP TOOLS

A COMPLETE LIST OF WORKSHOP TOOLS CAN

BE MADE AVAILABLE BY EITHER CONTACTING

YOUR DEALER OR APPLYING DIRECT TO THE TRIUMPH SERVICE DEPARTMENT.

IN MOST CASES

THESE TOOLS ARE VERY COSTLY AS THEY ARE MADE ENTIRELY FOR WORKSHOP USE. AND

THEREFORE, IT

IS NOT RECOMMENDED THAT THE PRIVATE OWNER PURCHASES THE TOOLS IN

ORDER TO AID SERVICING THE MACHINE ONCE OR TWICE ONLY. IN THESE CIRCUMSTANCES

IT

IS

FAR MORE ECONOMICAL TO GET IN TOUCH WITH A RECOGNISED DEALER.

UNIFIED THREAD FORM

NEW PARTS HAVING THREADED FIXINGS INTRODUCED IN THIS CATALOGUE HAVE THE UNIFIED

FORM OF SCREW THREADS. THIS CHANGEOVER WlLL BE CONTINUED AS AND WHEN NEW PARTS

ARE INTRODUCED. EVEN WHERE PARTS ARE SIMILAR IN APPEARANCE NEW PART NUMBERS

WlLL BE ALLOCATED TO IDENTIFY THE UNIFIED THREADS. ALL NUTS, BOLTS AND STUDS

HAVING THIS THREAD ARE IDENTIFIED BY MARKINGS. BOLTS HAVE A CIRCULAR RECESS IN

THEIR HEADS. STUDS A CIRCULAR GROOVE ON THE END. AND NUTS HAVE INTERLOCKING

CIRCLES ON THE SIDE.

i

I

41 19

io

21 22 23

24

2s

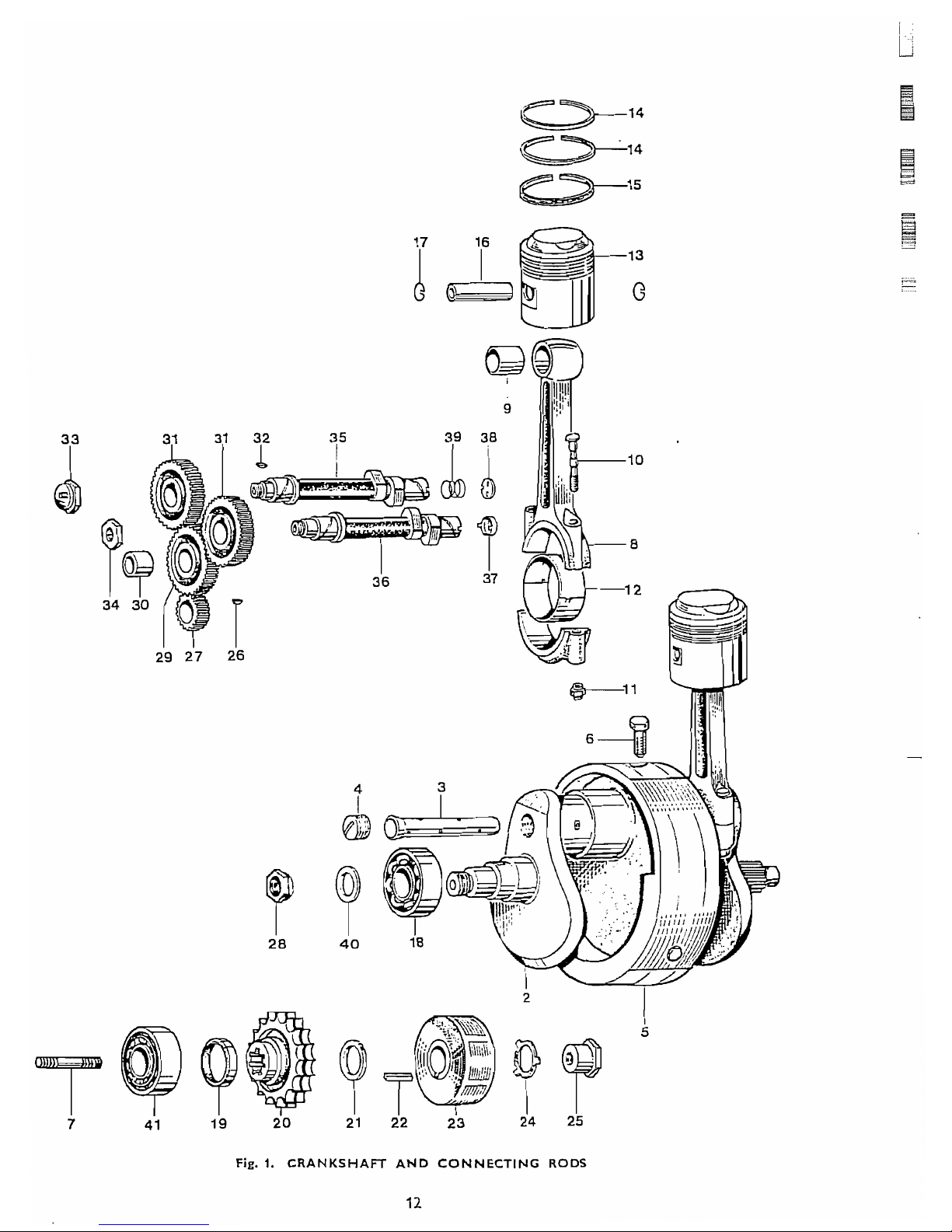

Fig.

1.

CRANKSHAFT AND CONNECTING RODS

Ref

.

No

.

I

-

Part No

.

"E9686

E4643

E3903

E3905

"'E9687

*E9307

E3114

E9S25

El 51 1

E6576

5549

E3586

E6868

E6867

E6864

E6865

E6863

E6869

El 591

E3876

E5446

E4573

E3974

99-0739

E3975

E3977

El580

E4564

E4565

E6159

E400

E4562

El558

El 463

E4563

El

0040

El 0041

i

E4700

E5316

E2256

E3300

E2879

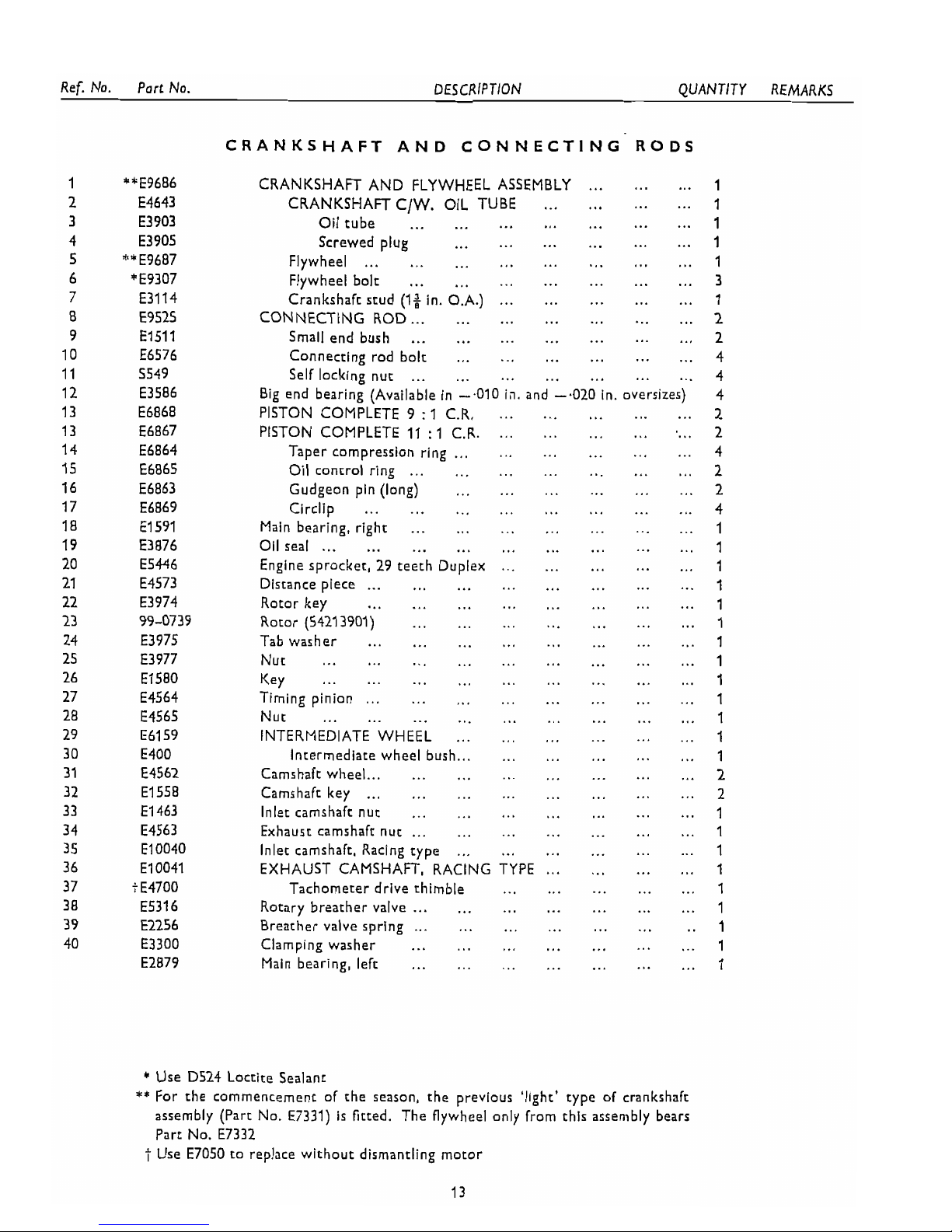

OESCRIP TlON QUANTITY REMARKS

CRANKSHAFT AND CONNECTING RODS

CRANKSHAFT AND FLYWHEEL ASSEMBLY

......

...

1

...

...

CRANKSHAFT

C/W

.

OIL TUBE

...

...

1

... ...

...

...

...

Oil tube

... ...

1

...

...

...

... ...

Screwed plug

...

1

...

...

...

...

...

Flywheel

......

...

1

...

...

... ... ...

Flywheel bolt

... ...

3

... ...

Crankshaft stud (I+ in . O.A.)

......

...

1

...

...

CONNECTING ROD

......

...

...

...

2

...

...

...

...

...

Small end bush

...

...

2

...

...

Connecting rod bolt

...

...

...

...

4

...

...

...

Self locking nut

......

...

...

4

Big end bearing (Available in -.010 in

.

and -.020 in . oversizes) 4

...

...

PISTON COMPLETE 9 : 1 C.R.

...

...

...

2

...

....

PISTON COMPLETE 11 : 1 C.R.

......

...

2

...

...

...

Taper compression ring

......

...

4

...

...

...

...

Oil control ring

......

...

2

...

...

Gudgeon pin (long)

...

...

...

...

2

...

...

...

Circlip

...

...

...

...

...

4

...

...

...

Main bearing. right

...

...

...

...

1

...

...

Oil seal

...

... ...

...

...

... ...

1

...

...

Engine sprocket, 29 teeth Duplex

... ... ...

1

...

...

Distance piece

......

...

...

... ...

1

...

...

...

Rotor key

...

...

...

...

...

1

...

...

...

Rotor (54213901)

...

...

...

...

1

...

...

...

Tab washer

...

...

...

...

...

1

...

...

...

...

...

Nut

...

...

... ...

1

...

...

Key

... ...

...

...

... ... ...

1

......

...

...

Timing pinion

... ...

...

...

1

...

...

Nut

...

...

...

...

... ...

...

1

...

...

...

INTERMEDIATE WHEEL

...

...

...

1

...

...

Intermediate wheel bush

......

...

...

1

...

...

...

Camshaft wheel

......

...

...

...

2

... ...

...

...

...

Camshaft key

... ...

...

2

...

...

...

...

...

...

Inlet camshaft nut

...

1

...

...

...

Exhaust camshaft nut

......

...

...

1

...

...

...

...

Inlet camshaft. Racing type

...

...

1

EXHAUST CAMSHAFT. RACING TYPE

......

...

...

1

...

...

Tachometer drive thimble

...

...

...

1

...

...

...

Rotary breather valve

......

...

...

1

...

Breather valve spring

......

...

...

... ..

1

...

...

...

Clamping washer

...

... ...

...

1

...

...

...

...

...

Main bearing. left

...

...

1

'

Use D524 Loctite Sealant

**

For the commencement of the season. the previous 'light' type of crankshaft

assembly (Part No

.

E7331)

is

fitted . The flywheel only from this assembly bears

Part No

.

E7332

i.

Use E7050 to replace without dismantling motor

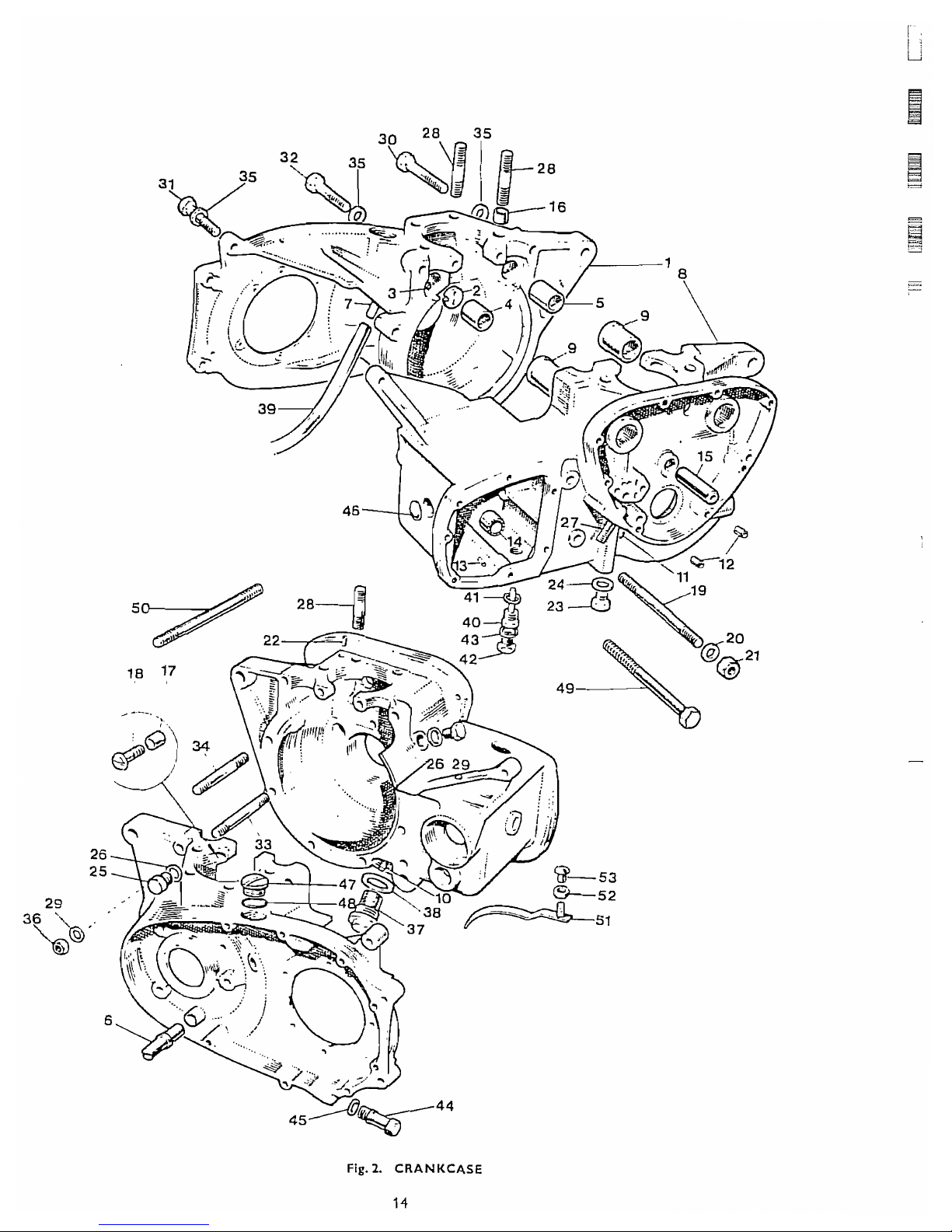

Fig.

2.

CRANKCASE

14

DESCRIPTION

CRANKCASE

...

CRANKCASE DRIVE SIDE

...

Breather disc

...

...

...

Locating pin-at disc

... ...

Inlet camshaft bush

...

...

Exhaust camshaft bush

......

Chain rensioner abutment

...

Breather pipe (metal)

...

...

CRANKCASE TIMING SIDE

...

Camshaft bush

...

...

...

Scavenge pipe

...

...

...

Locating peg (at oil pipes)

...

Hollow dowel

...

...

...

Locating peg (L/S at thrust washer)

Needle roller bearing. layshaft

...

Intermediate wheel spindle

...

Hollow dowel

......

...

...

Hollow dowel

......

...

...

Screw

(s

in . U.H.)

... ...

...

Stud (4f in . O.A.)

...

...

...

Plain washer

...

...

...

...

Nut

...

...

...

...

...

Hollow dowel. tappet oil feed

...

Oilway plug

...

...

...

...

Copper washer

......

...

...

Tachometer drive plug (L.H. thread)

Fibre washer

...

...

...

...

Oil pipe stud (If in . O.A.)

......

Cylinder stud (1: in . O.A.)

......

Plug. timing hole

...

... ...

Bolt (2f in . U.H.) UN

......

...

Bolt (1; in . U.H.) UN

......

...

Bolt (1; in . U.H.) UN

......

...

Stud (5-h in . O.A.)

...

...

...

Stud (3;

in

.

O.A.)

...

...

...

Plain washer

...

...

... ...

Nut

...

...

...

... ...

Crankcase filter UN

......

...

Copper washer

......

...

...

Breather extension pipe

...

...

Drain plug (with level tube) UN

...

F~bre washer

...

...

... ...

Level plug UN

...... ...

...

Copper washer

......

...

...

Drain and adiuzter plug

...

...

Fibre washer

... ...

...

...

Bianting plug

...

...

... ...

Filler plug UN

......

...

...

Fibre washer

... ...

...

...

Bolt (4 in . U.H.) UN

......

...

Stud (4) in . O.A.)

...

...

...

...

Protection blade

...

...

Self locknut UN

... ...

...

Rubber plug (for protection blade stud

I

QUANTITY REMARKS

...

I

...

2

...

Reference only

...

Reference only

...

2

...

1

...

1

....

1

...

1

...

1

...

2

...

1

...

2

...

2

...

2

...

I

...

2

(TR6C 3 off)

...

11

...

8

...

1

...

1

...

I

...

1

...

1

...

2

...

2

...

1

...

1

(Except TR6C)

...

1

... 1

...

1

TR6R. T12OR

ASSY

13

16

24

18

23

20

21

22

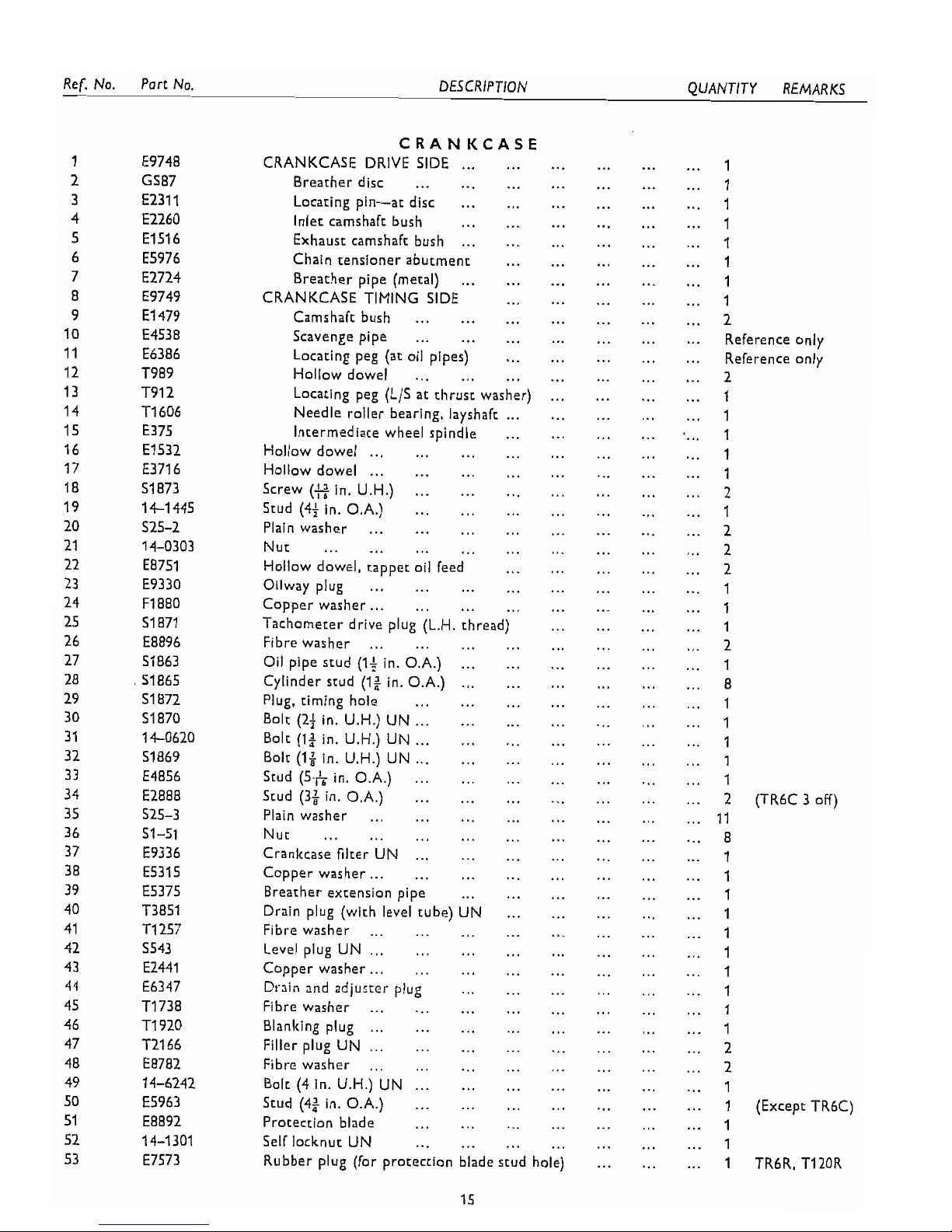

Fig.

3.

OIL PUMP. RELEASE VALVE, MANIFOLD AND TAPPETS

16

1

I

Ref . No . Port No

.

DESCRIPTION QUANTITY REMARKS

1

OIL PUMP. RELEASE VALVE. MANIFOLD AND TAPPETS

E6928

Reference only

GS153

E6681

E495

570-7

E403

E2360

E3730

51 864

E3887

51 906

E6595

E7590

GS251

E6596

GS254

E7591

El 670

51

876

E5660

E5512

525-1 3

51 877

E2962

NA43A

£491 8

525-3

El310

£9352

E9353

El612

HZ00

E3059R

£8801

E7563

...

... ...

...

OIL PUMP

...

... ...

...

1

...

...

...

...

Pump body

......

...

...

1

...

Feed plunger

...

...

...

...

...

...

1

... ...

...

Scavenge plunger

...

... ... ...

1

...

...

...

...

...

...

Drive block

...

1

...

...

Valve ball

(6

in . dia.)

...

...

...

...

2

...

...

Valve spring

...

...

...

... ...

2

...

... ...

...

...

Screwed plug

...

...

2

...

...

...

...

Joint washer

...

... ...

...

1

... ...

Oil

pump stud

(I*

in

.

U.H.)

...

...

...

2

...

...

...

...

...

...

Serrated washer

...

2

...

...

... ...

...

...

...

Nut

...

...

2

....

OIL RELEASE VALVE

...

...

...

...

...

1

...

...

Valve body

...

...

...

... ...

1

...

...

... ... ...

...

Piston

...

...

1

...

...

Cap

......

...

...

...

...

...

1

...

...

Fibre washer

...

...

... ...

...

1

...

... ...

Main spring

...

...

...

...

1

...

...

... ...

...

...

...

Fibre washer

...

1

...

...

...

Stud

(1E

in . O.A.)

......

... ...

4

...

...

...

...

...

...

...

Joint washer

...

2

......

... ...

...

...

Inlet manifold

...

...

...

...

Plain washer

... ...

...

...

...

...

...

...

Nut

...

...

... ...

...

...

...

Stud (I& in . O.A.)

...

...

...

...

...

...

Joint washer

...

... ... ...

...

...

...

...

...

...

~6 1

&

TR6C

insulating bloclc

...

...

1

...

...

...

Plain washer

... ...

...

...

...

2

...

...

...

... ...

...

Nut

...

... ...

2

... ...

...

...

...

Inlet tappet guide

...

...

1

...

...

Exhaust tappet guide

......

...

...

...

1

...

...

...

...

Serrated washer

...

...

...

2

...

...

...

...

...

Set bolt

......

...

...

2

...

...

...

...

Inlet tappet

...

...

...

...

2

......

...

...

Exhaust tappet

...

...

...

...

2

...

...

...

...

"O-ring

... ...

...

...

2

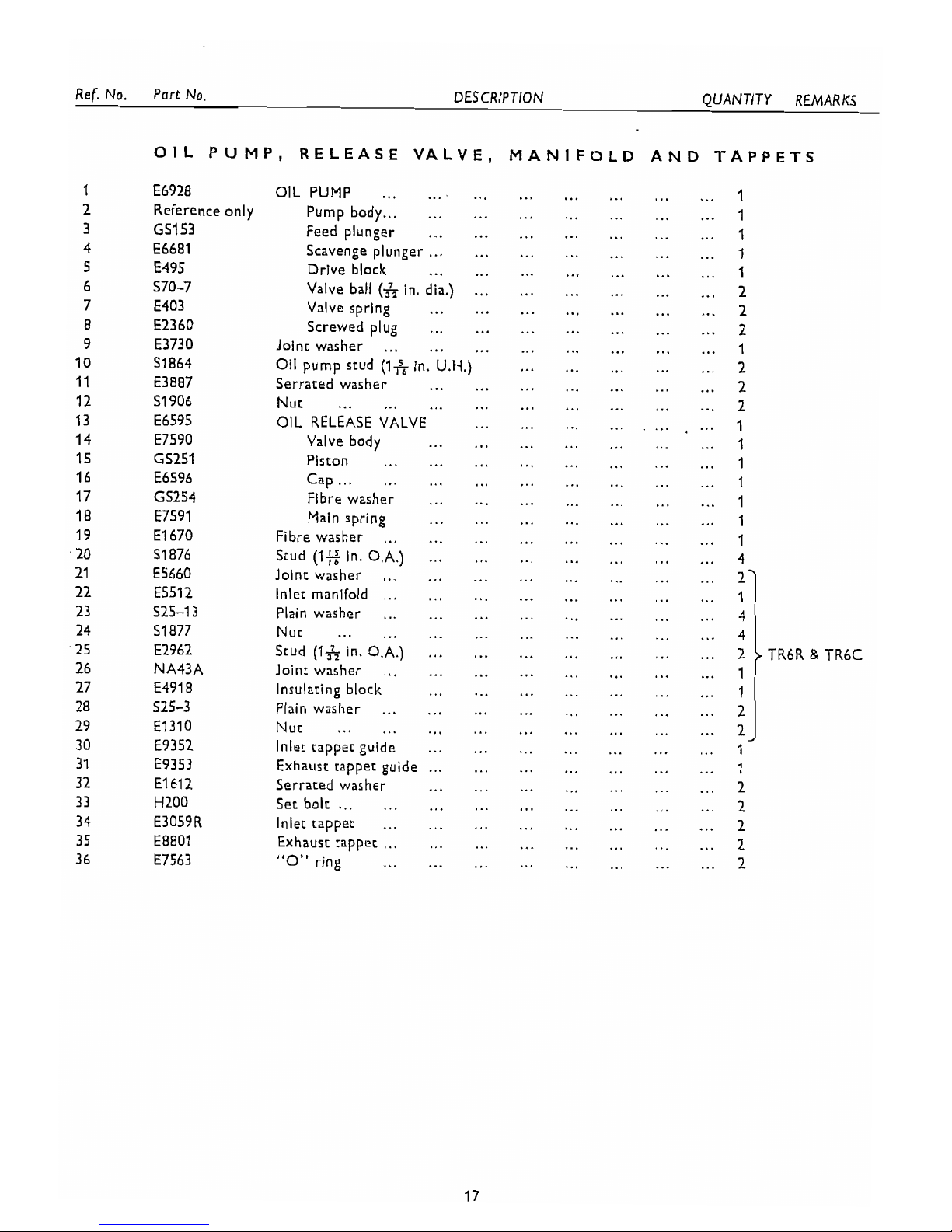

Fig.

4.

CYLINDER BLOCK AND HEAD, TR6

18

i

Ref. No

.

Part

No

.

DESCRIPTION QUANTITY REMARKS

CYLINDER BLOCK AND HEAD. TR6R. TR6C

Cylinder base washer

......

...

......

Cylinder block

...

...

Cylinder base nut

...

...

...

... ...

Push rod

...

...

Cover tube

... ...

...

...

...

Rubber washer

......

...

Cylinder head gasket

......

...

...

CYLINDER HEAD c/w GUIDES

...

Inlet valve guide

...

...

Exhaust valve guide

...

...

...

Exhausr pipe adaptor

...

...

...

Inlet valve

...

...

Exhausr valve

......

...

. . .

...

...

...

Botrom cup

...

......

Inner valve spring (red spot)

...

Ourer valve spring (green spot)

...

Top collar

...

...

...

...

Split cotrer

...

...

...

.

...

Cylinder head bolt (3i in

U.H.)

...

...

Plain washer

...

...

Bolt (3 in . U.H.)

...

...

...

...

...

...

Plain washer

...

...

Sealing ring

...

...

...

Inlet rocker box

...

...

...

Exhausr rocker box

...

...

...

Joint washer

...

...

...

...

.

...

Rocker box stud

(E

in O.A.)

......

Rocker box nut

...

...

Plain washer

...

...

...

...

.

...

Rocker box bolt (2& in U.H.)

...

Plain washer

...

...

...

Cylinder head bolt (lor torque stay)

...

lnspeccion cap

......

...

...

...

Joint washer

...

...

Locking spring

......

...

...

...

Fibre washer

...

...

...

...

Screw

(i

in . U.H.)

...

...

...

ROCKER (right exhaust. lelt inlet)

...

ROCKER (lelt exhaust. right inlet)

...

Rocker ball pin

...

...

Rocker adjusting pin

......

...

...

Adjuster lock nut

...

...

....

Thrust washer. $ in

...

...

....

Thrust washer. + in

...

...

Spring washer

......

...

...

...

...

Rocker spindle

...

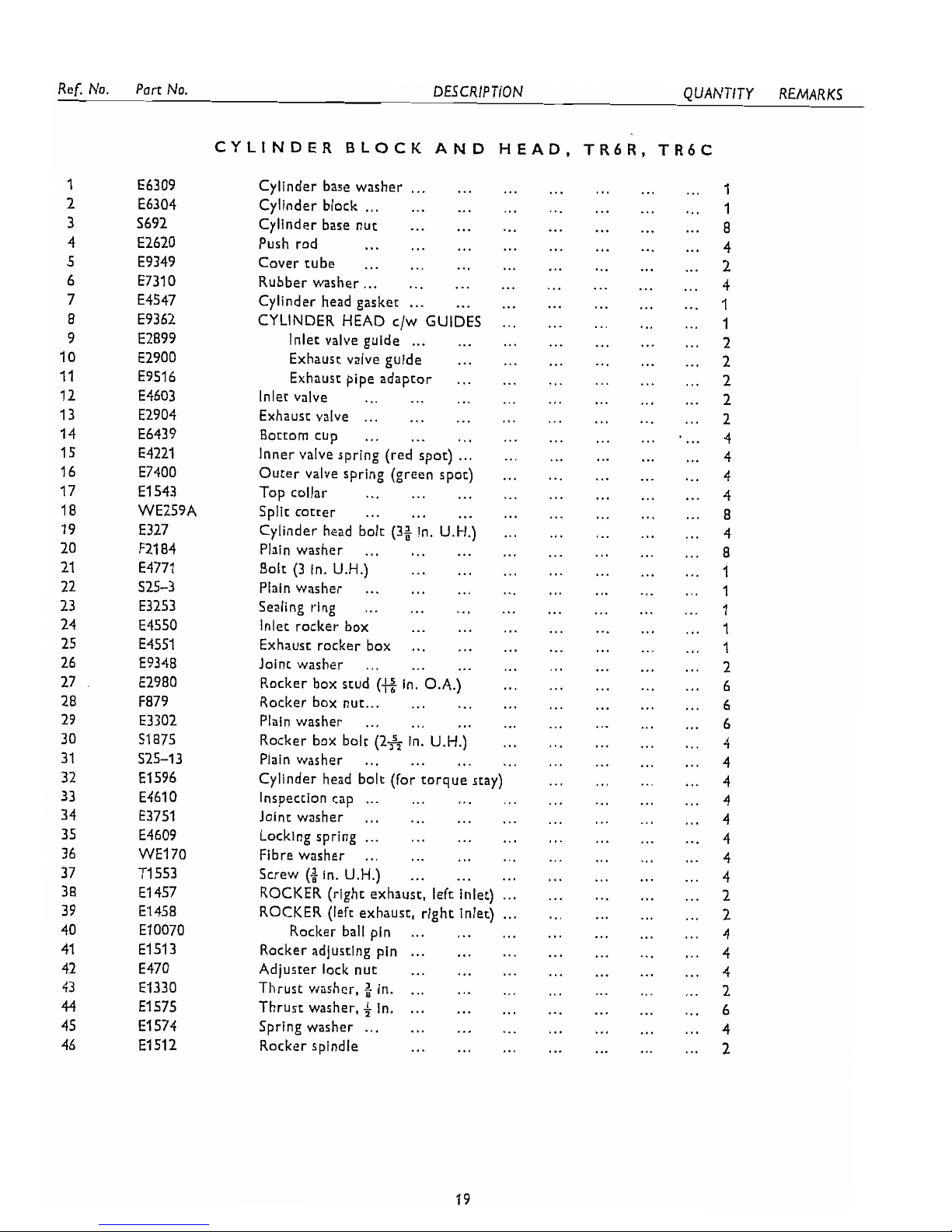

Fig.

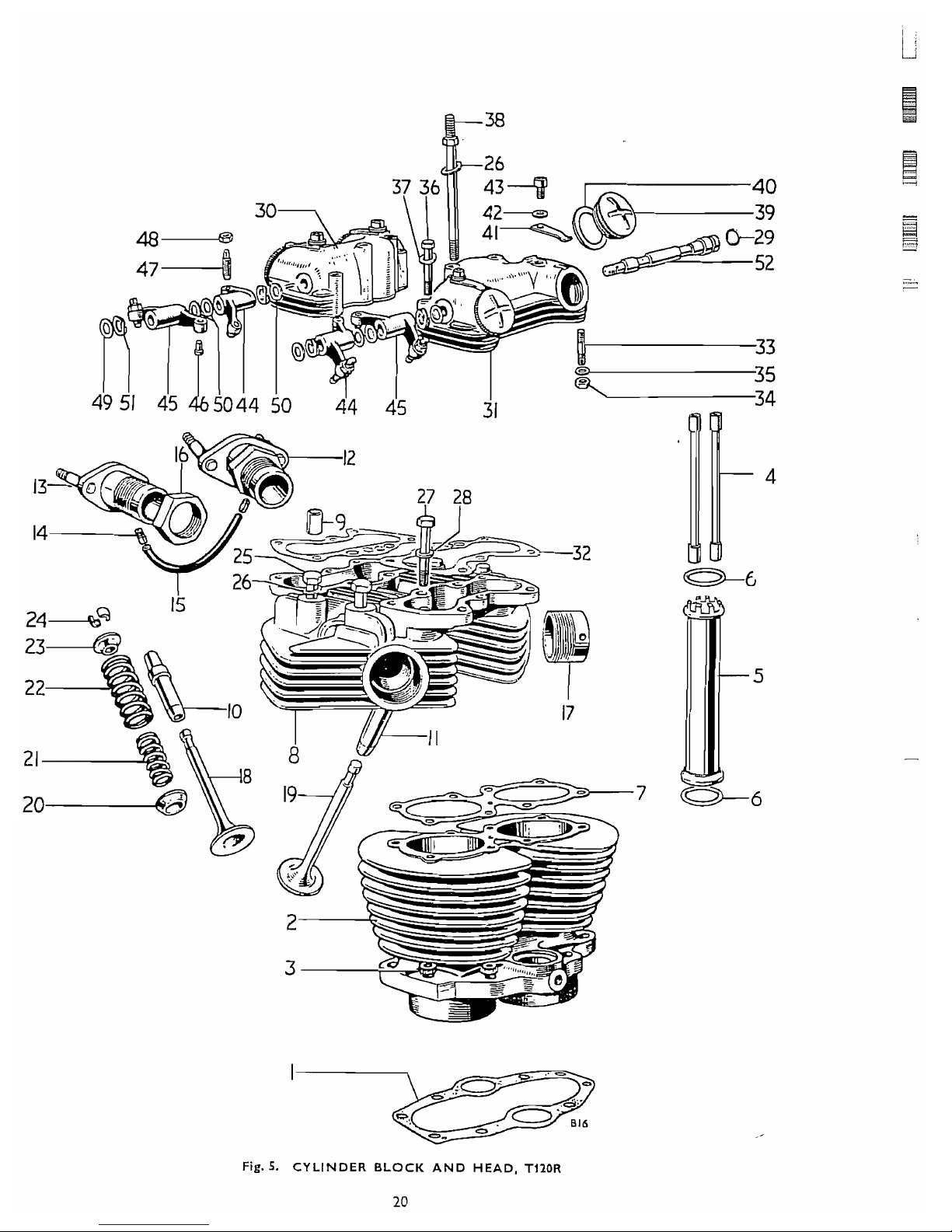

5.

CYLINDER BLOCK AND HEAD, TIIOR

20

DESCRIPTION QUANTITY REMARKS

CYLINDER

BLOCK

AND HEAD. '~120~

Cylinder base washer

......

...

...

...

... ...

1

Cylinder block

......

......

...

...

... ...

1

Cylinder base nut

...

......

...

...

...

...

8

...

...

...

...

...

Push rod

... ...

...

4

......

...

...

...

Cover tube

... ...

...

2

...

...

...

...

Rubber washer

......

...

...

4

Cylinder head gasket

......

... ... ... ... ...

1

...

CYLINDER HEAD c/w GUIDES

...

...

... ...

1

...

Sleeve for head bolts passing through inlet tracts

2

Reference only

...

Inlet valve guide

......

...

...

...

...

...

2

Exhaust valve guide

...

...

...

...

...

...

2

Carburetter adaptor. left

...

...

...

...

...

1

Carburetter adaptor. right

...

...

...

...

...

1

...

...

...

...

...

Connector

......

...

2

...

...

...

...

Balance pipe

... ...

....

1

Adaptor locking nut

...

...

...

... ...

...

2

...

Exhaust pipe adaptor

...

...

...

...

...

2

...

...

...

...

...

...

...

Inlet valve

...

2

...

...

...

...

Exhaust valve

......

... ...

2

...

...

...

...

Bottom cup

...

... ...

...

4

Inner valve spring (Red spot)

...

...

...

...

...

4

...

Outer valve spring (green spot)

...

...

...

...

4

...

...

...

Top collar

...

...

...

...

...

4

...

...

...

...

Split cotter

...

...

... ...

8

Cylinder head bolt (3t In . U.H.)

... ... ...

... ...

4

...

...

...

...

...

Plain washer

...

...

...

8

...

... ...

...

Bolt (3 in . U.H.)

...

...

...

1

...

... ...

...

...

Plain washer

...

...

...

1

...

...

...

...

...

...

Sealing ring

...

...

2

...

...

...

...

Inlet rocker box

...

...

...

1

...

...

Exhaust rocker box

...

...

...

...

...

1

...

...

...

...

Joint washer

...

...

...

...

2

...

Rocker box stud

(e

In . O.A.)

...

...

...

...

6

... ... ...

...

...

...

Nut

...

...

...

6

...

...

...

...

...

...

Plain washer

...

...

6

...

Rocker box bolt (2& in . U.H.)

...

...

...

...

4

...

...

...

...

Plain washer

... ...

...

...

4

...

...

Cylinder head bolt (for torque stay)

...

...

4

......

...

...

Inspection cap

...

...

...

...

4

...

...

...

...

...

Joint washer

... ...

...

4

Locking spring

......

... ...

...

...

... ...

4

...

...

...

... ...

Fibre washer

...

... ...

4

...

Screw

(+

in . U.H.)

...

...

...

...

...

...

4

......

ROCKER (right exhaust. left inlet)

...

...

...

2

...

ROCKER (left exhaust. right inlet)

......

...

...

2

Rocker ball pin

... ...

...

...

...

... ...

4

Rocker adjusting pin

......

...

...

...

...

...

4

...

Adluster lock nut

...

... ...

...

... ...

4

Thrust washer

.

$

in

....

...

...

... ...

...

...

2

Thrust washer. 4 in

....

...

...

...

...

...

...

6

...

...

Spring washer

......

...

... ... ...

4

...

...

Rocker spindle

...... ...

...

...

...

2

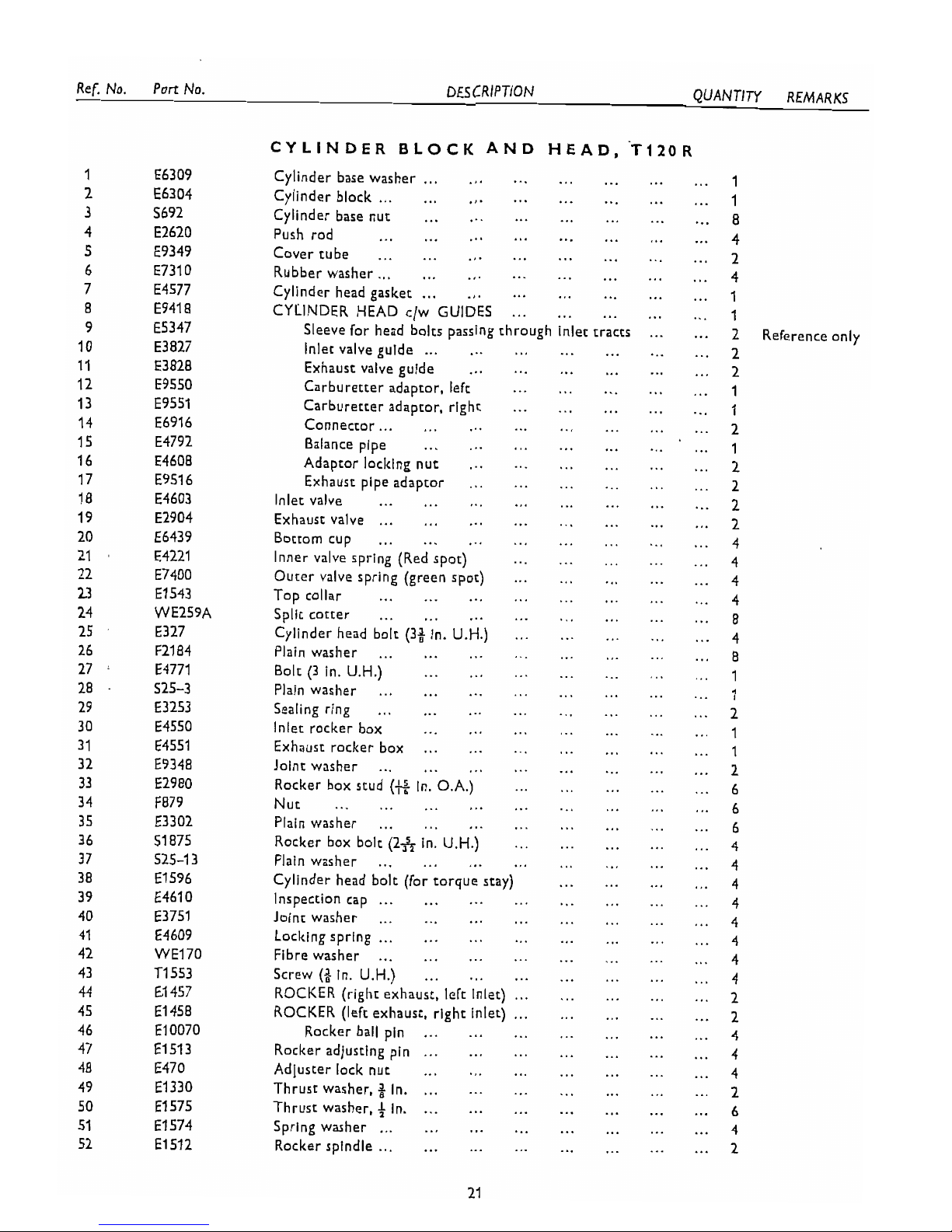

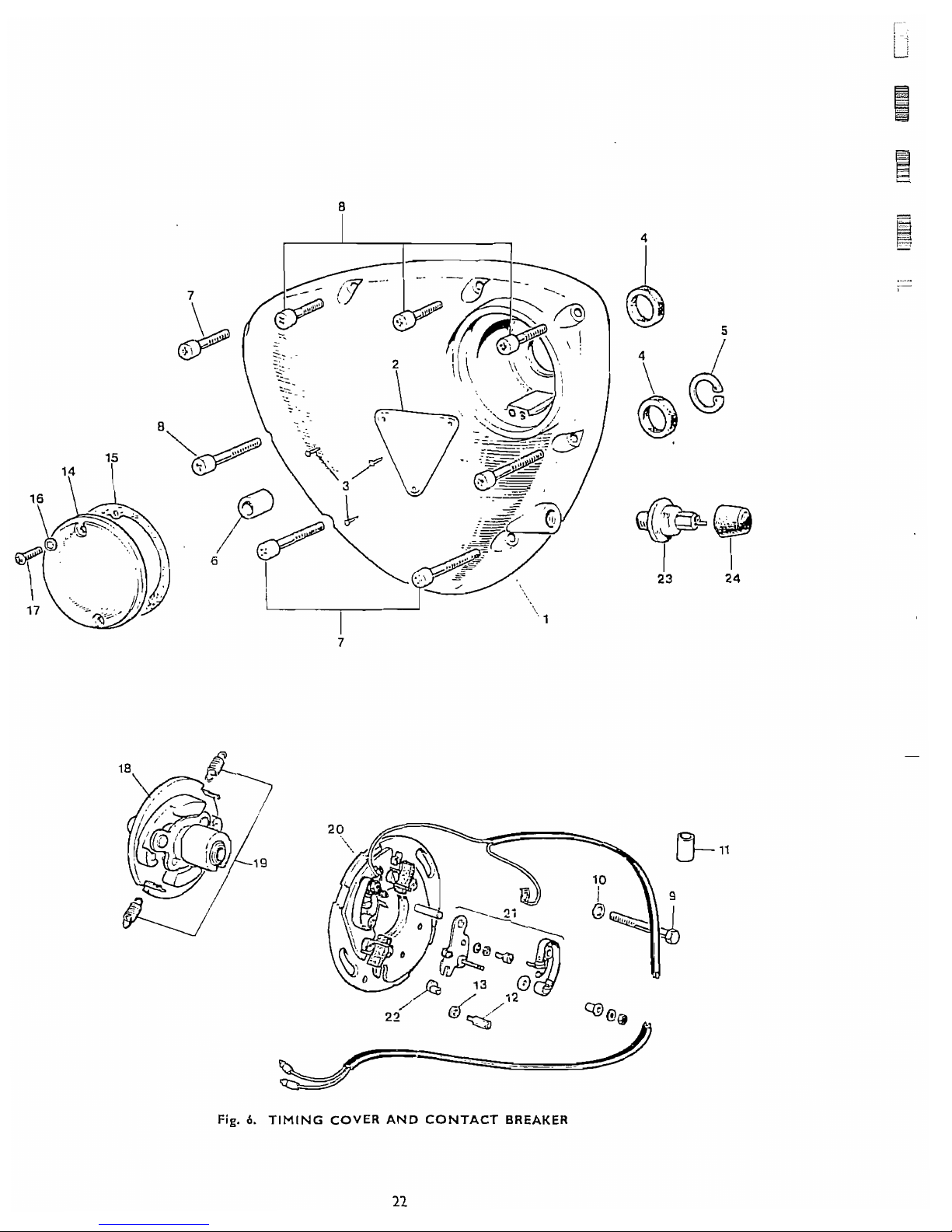

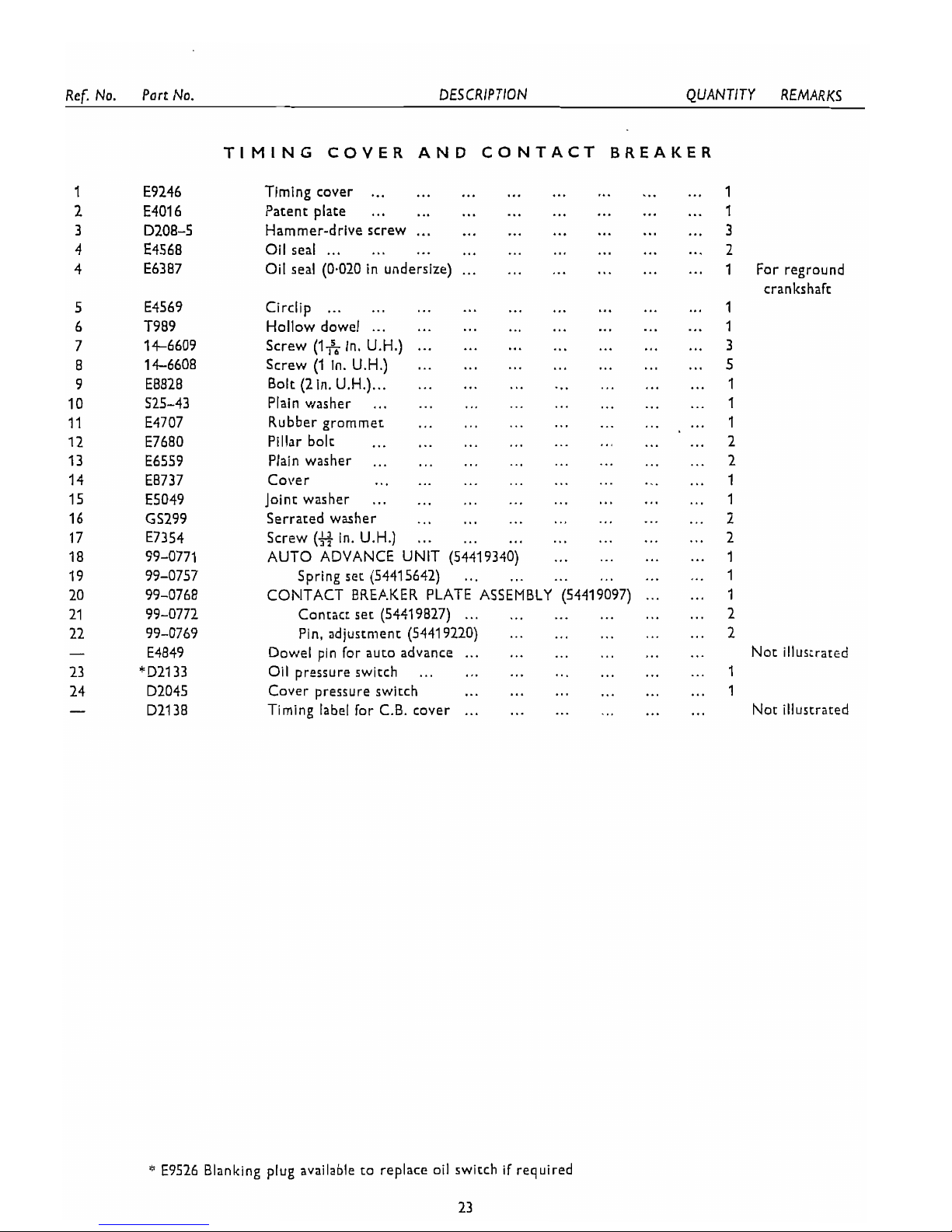

Fig.

6.

TIMING COVER AND CONTACT BREAKER

I

Ref . No . Port No

.

DESCRIPTION QUANTITY REMARKS

TIMING COVER AND

CONTACT

BREAKER

...

...

...

...

Timing cover

... ...

...

...

1

...

... ...

Patent plate

...

... ...

...

...

1

......

...

...

...

Hammer-drive screw

...

...

3

...

...

... ...

...

Oil seal

...

...

...

...

2

Oil seal (0.020 in undersize)

...... ...

...

...

...

1

For reground

crankshaft

...

...

... ...

... ...

Circlip

...

...

...

1

...

...

... ...

Hollow dowel

......

...

...

1

...

...

Screw (Iff In . U.H.)

...

...

...

...

...

3

...

... ... ...

Screw (1 in . U.H.)

...

...

...

5

.

......

...

...

...

Bolt (Zin U.H.)

...

...

...

1

...

...

...

...

...

...

Plain washer

...

...

1

...

...

...

...

...

Rubber grommet

...

...

1

...

...

...

...

...

... ...

Pillar bolt

...

2

... ...

...

...

...

Plain washer

... ...

...

2

...

...

...

...

...

...

Cover

......

1

...

... ...

...

...

...

Joint washer

...

...

1

...

...

...

...

...

Serrated washer

...

...

2

...

... ...

Screw

(5

in

. U.H.)

...

...

...

...

2

...

AUTO ADVANCE UNIT (54419340)

...

...

...

1

...

... ...

...

...

Spring set (54415642)

...

1

......

CONTACT BREP.KER PLATE ASSEMBLY (54419097)

1

......

Contact set (54419827)

...

...

...

...

2

...

...

...

Pin. adjustment (54419220)

...

...

2

Dowel pin lor auto advance

......

...

...

...

...

Not illustrated

... ...

...

...

...

Oil pressure switch

...

...

1

...

...

...

...

...

Cover pressure switch

...

1

Timing label lor C.B. cover

......

...

...

... ...

Not illustrated

*

E9526 Blanking plug available to replace

oil

switch if required

23

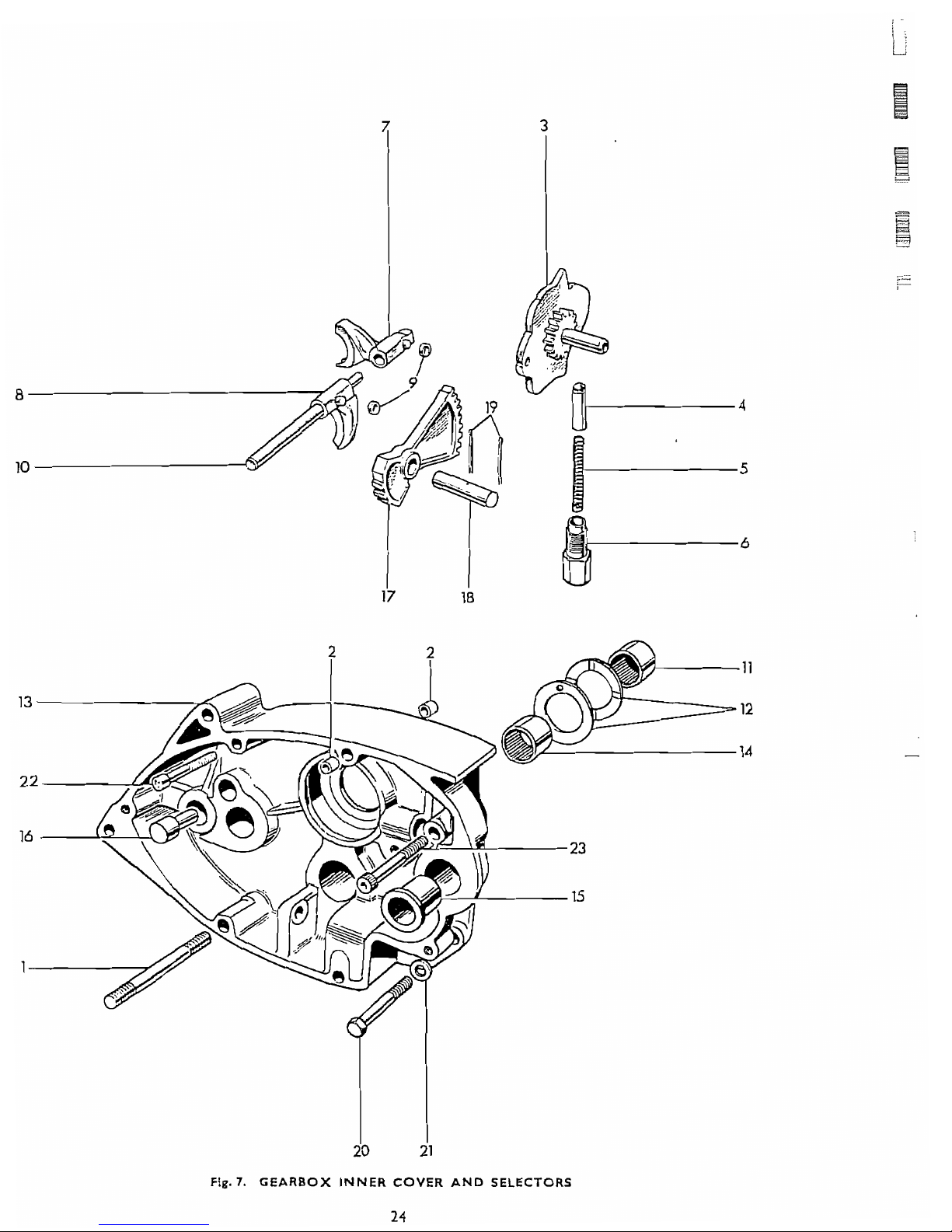

Fig.7.

GEARBOX INNER COVER AND SELECTORS

24

Loading...

Loading...