Triumph 1978, 1978 Bonneville 750, 1978 T140E Owner's Handbook Manual

O\N

ClassicBike.biz

ERS

ANDBOOK

FOR

{

....

197

,----NNEVI E

140

PART

U.

L

NO.

.A.

MODEL

715D

99-7007

EDITION

Specialthanksto

Walter

forcontributing

thismanual

T

ClassicBike.biz

OWNER'S HANDBOOK

FOR

BO EVILLE 750

UNIT CONSTRUCTION TWIN

1978

MODEL

© Copyright

AI!

rights reserved. No part of this publication

may be reproduced without permission.

Meriden

Motorcycles Ltd., Meriden Works, Allesley, Covemry, England.

Air filter......... ....... ....

ClassicBike.biz

..........

INDEX

............... .......

.....

.......

....

........................ 33

Page

Brakes............

8rake adjustment .

Carburetor .......... .

Chain adjustment.. ................. ............... .......

Cleaning your motorcycle........

Controls......

Electrical equipment....

Fron t forks............... .................................. ....................................... 22

General description

Guarantee arrangements ..... .................

Ignition timing... .................... .................. ...................

Lubrication

Oil changing............................ ....

Rear suspension .............

Routine maintenance

....................

...

...

......

.................

....

...

......................

......

...................

..

..........

... ... ...

.......... ... ............... .

.......

....... ..... ............. ................... ......

...

.......

..

.............................

...

....

..

.............

...

.....................................................................

......

................

...

............................

... ~ ... :

.. ~ ...

..

....

~~'.~~1

;.

...

~.r~'.~

.....

................................

...

.....................

.... .........

....

:....................... .....

..

.....

..... ................. .......

....

.......

...

....

.........

...

..................

..

................

.....

~~;~..

..........

...

.....

..........................

.....

. .

............. .........

....

...

..............

....

..............

...................

.....

..

26

15

....... .....

....

....... ........ 10

.............. 28

.......

.

.... .......

....

. 34

..

........

41,42

....

....

.......

32

19

30

30

23

40

9

4

Breaking-in .............

Sparking plug .........................

Starting.........................

Tires ...............

Useful data.. ........ ...............

Valve adjustment................. ... ........

Wheels

...

...

...................

...

...........................

............................. :........... ........... .............

.......

........ ...............

........

............................................................ 12

...

...................

...

......

.......

..............

...

.......

...........................................................

2

....

.................

...

..... ..................

....

.......

....

................. .......

....

........

........

.....

............. .. 13

...... 13

29

....

.

26

6,

7,

....

24

~

,

8

ILLUSTRATION INDEX

ClassicBike.biz

Fig. Page

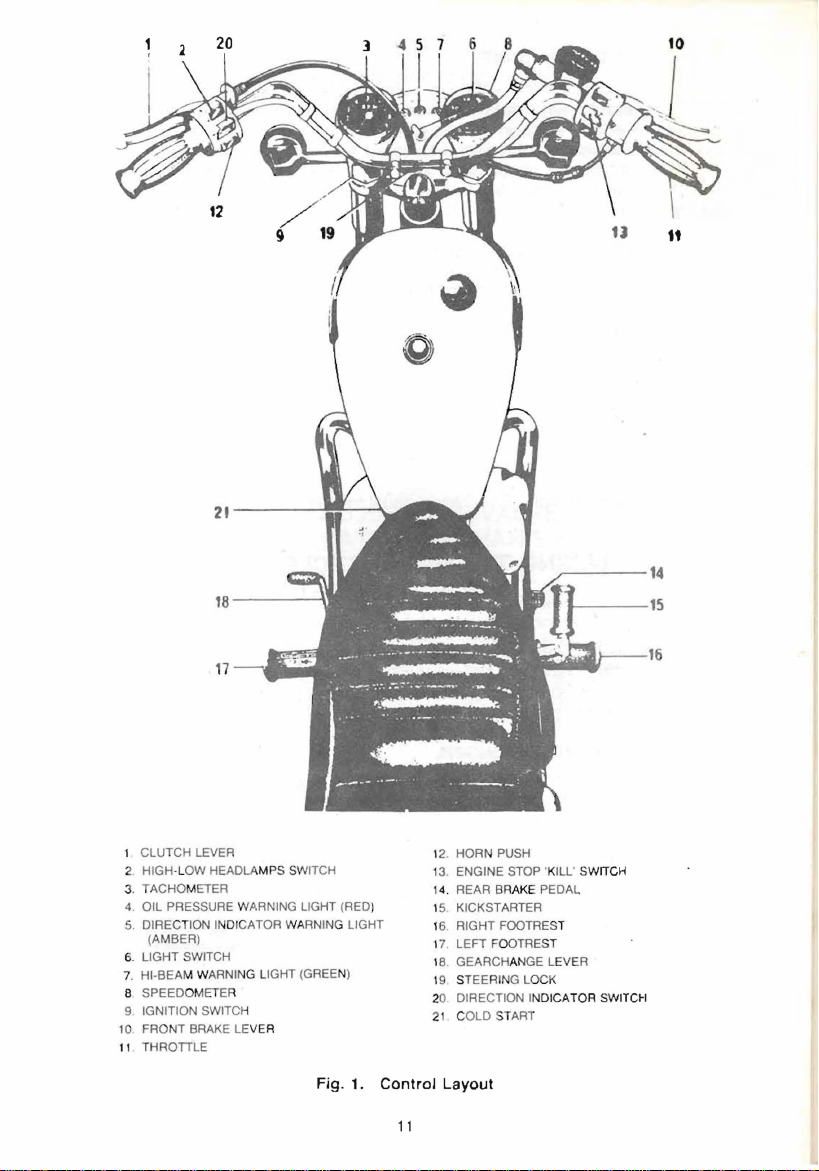

1 Control layout ..................................

.............

...

...

"'.

.. ....

.....

........

11

2 To adjust valve operating mechanism ...................

3 Showing arrangement for bleeding the front brake....

............

......

4 Showing the brake reservoir fluid level and cap .................

5 To adjust rear brake..

6 To adjust the primary chain......

7 To adjust the rear suspension springs ........... . ..........

8 Contact breaker..................................

9 Gearbox drain and level plugs ...... ......

10 Amal concentric carburetor ................

11

To secure the rectifier............ .......

12

Zener diode, model ZD71S.. ........

13 Wiring diagram......................

14 Lubrication pOints .....

...

.....

....

........ ................... ........................

...

.........

............... .....

..

...............................

.....

...

...

.......... .......... .................

...

...

..................................

......

...

...........................

...

...

........

...

......

...

......... ..

....

................

...

....

.......

.....................................

....

............ .....

.. ..

.. .. ..

......

...

.........

...

.....

...

..... ....

..

........

...........

...

...

....

...

...

14

16

17

18

20

23

28

31

~13

37'

38

39

41

3

INTRODUCTION

ClassicBike.biz

The Owner's Handbook includes all the information that the majority of

owners

there is

having basic

Workshop

we

individual customers.

will require.

available a Workshop Manual but this is intended for those

mechnical knowledge and workshop facilities. To obtain the

Manual order from your local Triumph dealer or distributor as

do

not supply parts or service literature direct from the factory to

If

you require more information for major repairs

Where specialised advice is required beyond the

then you should write to your distributor who will act on our behalf. Unless

the full engine number is quoted it

motorcycle and give a

bearing on the subject

additions or alterati ons to the standard equipment.

Where a gu arantee

who may

be

claims in respect of prop

dealer to his distributor.

The terms of the

dealer.

be

able to provide a replacement to enable your motorcycle to

use

d whilst the defective part

helpful reply. Any information which may have a

should be included, particularly details of any

claim is involved, consul your dealer or distributor

ri

etary components should be forwarded by your

U.S. Triumph guarantee can be obtained from your

is

often difficult to identify the type of

is returned

ability of the dealer ,

to his distr ibutor. Guarantee

4

ClassicBike.biz

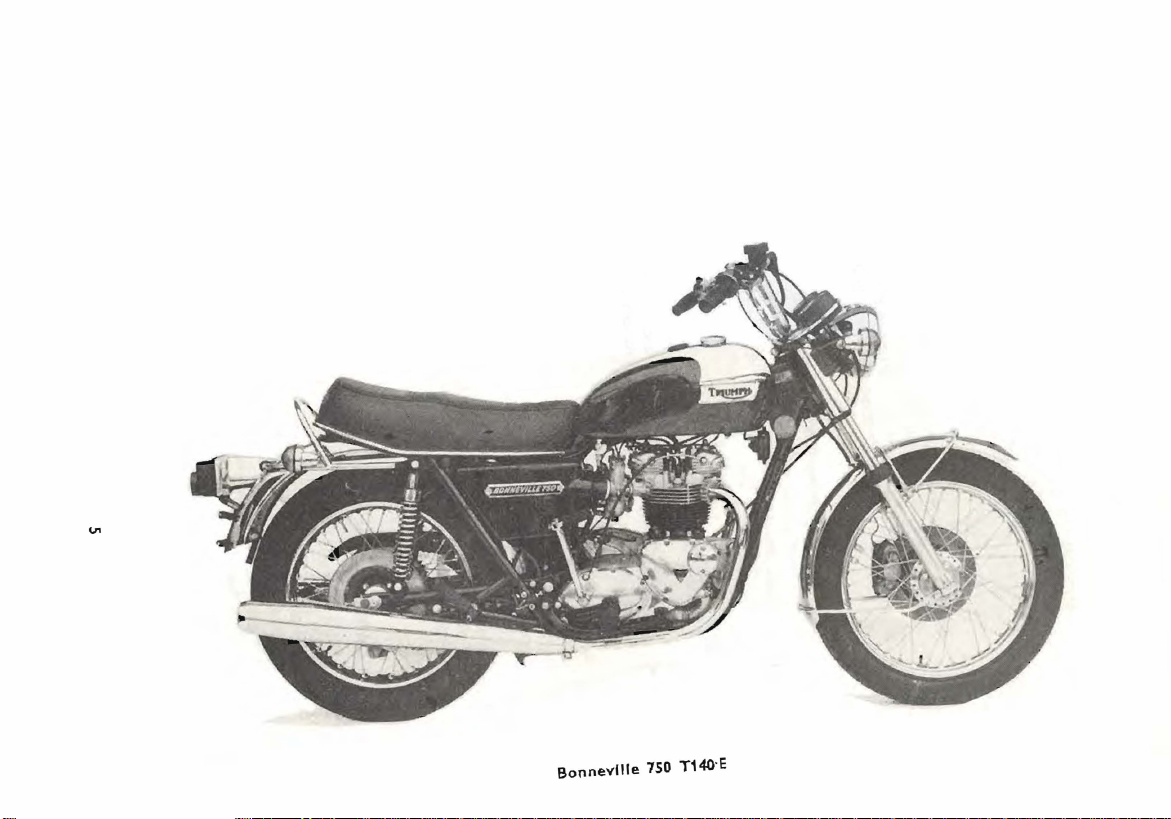

Bonneville

750 T140-E

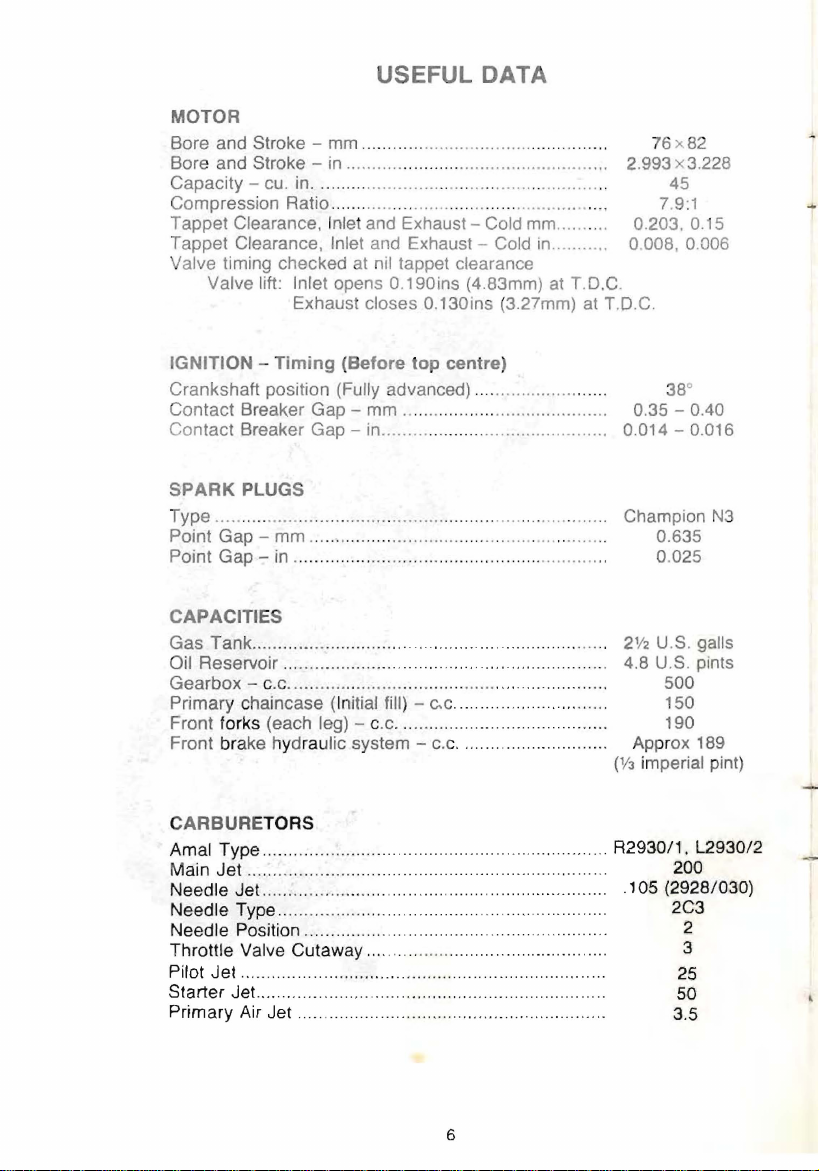

USEFUL DATA

ClassicBike.biz

MOTOR

Bore and Stroke - mm ..............................................

Bore and Stroke -

Capacity - cu. in .....

Compression Ratio .

Tappet Clearance,

Tappet Clearance,

Valve timing checked at nil tappet clearance

Valve lift: Inlet opens 0.190ins (4.83mm) at T.D.C.

in

......................

................

......

..................

Inlet and Exhaust - Cold mm .......

Inlet and Exhaust - Cold

Exhaust closes 0.130ins (3.27mm) at

...

......................

...

.. ..

........................... . .

............................ ,

in

.........

..

..

..

2.993 x3.228

..

.

0.203,0.15

..

o

T.O.C.

76 x

45

7.9:1

OOB,

82

0.006

IGNITION - Timing (Before top centre)

Crankshaft position (Fully advanced) .... ...................... 38

Contact Breaker Gap - mm ........... ............................. 0.35 - 0.40

Contact Breaker Gap - in.............

............................... 0.014 - 0.016

0

SPARK PLUGS

Type ............

Point Gap Point

...............................................

mm ... ....

Gap - in ......................... ...

....

...........................

........

................. Champion

..................

...

..

.......

...........

..

..

0.635

0.025

CAPACITIES

Gas Tank ........................ .......

Reservoir

Oil

Gearbox -c.

Primary

Front forks (each leg) - c.c.

Front brake hydraulic system -

...

... ......... ................

c. ..........

chaincase (Initial fill) - e.c..... .

.. ..

.. ..

.............

................... ...................

...

.. ..

.............

C.

c. ........................... .

.... ....

... .....

....

..............

.. .. ..

......

................ 150

.. ..

...................

..

2V2

U.

... ...

... 4.B U.S. pints

.......

..

Ap

prox 189

(1fJ

imperial pint)

S.

500

190

galls

CARBURETORS

Amal Type ....... ...................... ....................... ...........

Main

Jet....... ...... ................

Needle Jet .........

Needle Type.. .................

Needle Position..............

Throttle Valve Cutaway..........

Pilot Jet

Starter Jet.......... ....... ..... ..............................................

Primary Air

...

.......

............. ............................ ...... ..................

Jet..

........................ .................................. 3.5

..

.......

............ ...............

.. ..... ............

..................................... ........ 2C3

.....

.................. ... ..

.... ..................... .105 (2928/030)

...

....... ................... ...... 3

...

..

"

...

..

....

..

.. ..

...

....... 2

...

R2930/1,

200

L2930/2

25

50

N3

6

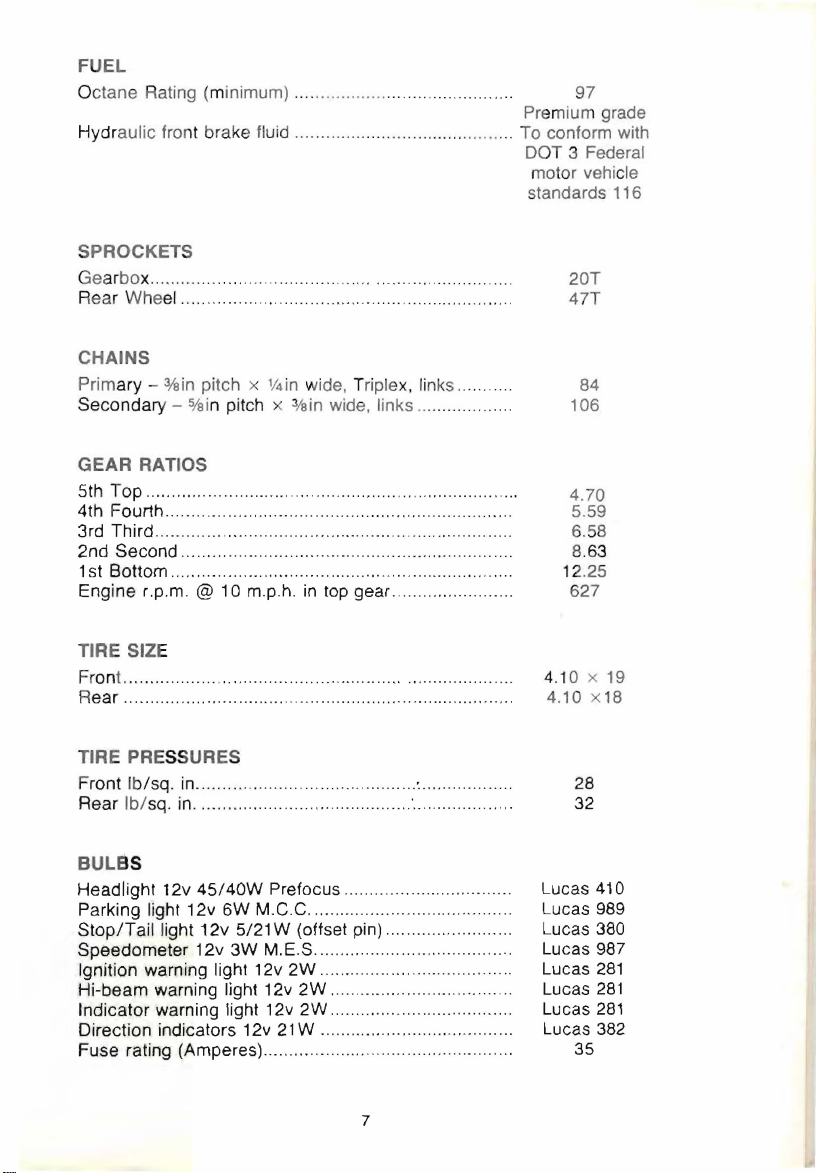

FUEL

ClassicBike.biz

Octane Rating (minimum)

Hydr

aulic fro nt brake fluid .

SPROCKETS

Ge

arbo x........ ..........

Rear

Wheel..

... ...

...........

................

CHAINS

Primary Secondary -o/ai

3/

in

pitch x V4in wide, Triplex, links

a

n pitch x

...

.................. ....

...

...............

..... .. ...... .......

...

........

......................

3/sin

wide, links ....

. ..........

...

.... 97

........................ To conform with

...

...

.........

.........

...

.. .. ..

Premium grade

DOT 3 Federal

motor vehic

standards 116

...

..

.. .. ..

.

..

...... 106

20T

47T

le

84

GEAR

5th

4th Fourth ..........

3rd Third

2nd

1 st Bottom..

Engine r.p.m. @

RATIOS

Top

................................... ...................................

...........

Second .......

...

.... ,........... ..............................

..

............ .... . ...........

..

...

......

..........................................

...................... .

10 m.p.h.

in

top gear

....

TIRE SIZE

Front...............

ear..

........ ...... ....

R

...

..................

.. ....

.......... ......

........ ......................................... 4.10 x

TIRE PRESSURE S

Front /b/sq

Rear

BUL

Headlight 12v

Parking light 12v 6W M.C.C ........

Stop/Tail

Speedometer 12v

Ignition warning light 12v

Hi-beam warning light 12v

Indicator warning light 12v

Direction indicators 12v

Fuse rating (Amperes) ...................

. in.....

..

Ib/

sq.

.............. .........

in

.......................

..................

BS

45/40W

light 12v 5/21 W (offset pin) ....... .......

Prefocus .............

3W

M.E.S ..................................

2W .......

2W

................................

2W

.........

21 W ..

................. ............

.........

.........

...........

.. ..

.. ..

..

.............

.'.........

..............................

..........................

...

..........

......... .................. .

......... 5.59

...

..

.......... .....

.......

.. ..

........ 12.25

....

.. .. .. ..

......

.....

....

.......... 4.10 x 19

....

...........

....

.. ..

...

....

.......

...

.. ..

.... .

...

...

............

...

..

4.70

.... 8.63

..

. 28

...

..

.

..

..

..

..

..

..

..

..

..

..

6.58

627

32

Lucas 410

Lucas 989

Lucas

Lucas 987

Lucas

Lucas

Lucas

Lucas 382

35

18

380

281

281

281

7

OVERALL

ClassicBike.biz

Length -in. ................................

Width - in ....... ..... .........

Seat

Weight -lb. (unladen) ......

DIMENSIONS

height -in. ".......

..

...... " ....................... .............. 33.0

............... ..... ...............

.................

......... ............. .... . .

...

..

....

.. ..

" .................

...

".

..

87.5

31.0

39 5

..:..

8

exhaust

ClassicBike.biz

frame.

where

returned

it

is

~f'~:\,U)nrlt:ll1

to

the reservoir.

NOTE - The

DO!:illl\I8

side of the is

9

to

earth.

LAYOUT OF CONTROLS

ClassicBike.biz

Clutch lever - On left handlebar. The clutch couples

the gearbox and rear wheel. Pull the leve towards the handlebar

disengage the clutch.

Kill button - On right handlebar. Depress

off the ignition and remove the key when parking.

Direction indicator switch -

operate the flashing indicators. Move right for right indication and left for

left indicatio n.

Front brake lever -

handlebar

to

apply the front brake.

On

On

right handlebar. Pull he lever toward ' the

to

stop engine. Always switch

left handlebar. Use the switch to

the

engine drive

to

to

Throttle control - Twist the right handlebar grip towards you to increase

to

the engine speed. Twist it away from you

reduce speed.

Horn push - On left handlebar. Press to sound the horn.

Dipper switch - On left handlebar. Use the lever to change the headlight

between

"high" and "Iow" beam.

peedometer - Indicates the speed and regist- 5 total and trip mileage.

To set the trip indicator to zero twist the knob clockwise.

knob as

Tachometer - Indicates the engine speed

lighting

position

second notch for

it

is

a snap fit

in

the speedometer.

in

revolutions per minute.

switch - Operated by a three position switch. From "off"

on

left, move

swi1ch

right to first notch for parking lights

full headlamp.

Do

not PUL the

and

to

Oil pressure warning light - (Red). Frtted into headlamp shell, it illumin-

is

ates as the ignition

running as oil pressure builds up.

beyond tiekover, stop the engine and investigate the cause.

switched

Hi-beam warning light -

selected.

on and should extinguish with the engine

If it fails

(G

reen). Shows as the headlight hi-beam is

to

extingui

sh

with the engine

Direction indicator warning light - (Amber). Illuminates when the

.e

tion indicators are operating.

dire

10

1 CLUTCH

ClassicBike.biz

2.

3.

4. OIL PRESSURE W

5.

6. LIGHT

7.

8

9. IGNITION SWITCH

10

. FRONT BRAKE LE

11 THROTILE

LEVER

HIGH-LOW

TACHOM

DIRECT

(AMBER)

HI-BEAM W

SPEEDOMETER

HEADLAMPS SWITCH

ETER

ION INDICATOR WARNIN

SWITCH

ARNING LI

P.RNING

GHT

VER

LIGHT (RED)

G LIGHT

(GREE

N)

12 HORN

13

1

15 KICKSTARTER

16. RIGHT FOOTREST

17 LEFT FOOTRE

' 8 , GEARCHAN

19

20 DIRECTION INDICATOR

21

PUSH

. ENGINE STOP 'KILL'

4.

REAR B

RAKE

PEDAL

ST

STEERING LOCK

COLD START

GE

SWITCH

LEVER

SWITCH

Fig. 1.

Control

11

Layout

ON

ClassicBike.biz

THE

MACHINE

Ig

ni

tion sw

Turn the key closkwise to switch

Gas

taps

right tap for normal running. When the reserve is required turn up the

lever on the left tap. Always turn off both taps when parking. otherwise

the motor will become flooded.

Note

acceleration, i.e. maximum throttle opening both taps must be used

simultaneously to ensure that a sufficient quantity of fuel

FOOT

Brake

wheel brake.

itc

h -

On

lett hand headlamp bracket operated by a key.

- At the rear underneath the tank. Turn down the lever

: When the machine is used for continual high speeds or maximum

CONTROLS

pedal -

In

front of right footrest. Press down

on

ignition.

to

is

available.

apply

the

on

the

rear

Gearchange

lower gear or pull up to change to a higher gear. The lever is spring

loaded and

St

art

er

lever -In

always returns to t

front of left footrest. Press down

he

central positio

pedal - The folding pedal behind

n.

the

right footrest.

to

change

to

TAKING THE MOTORCYCLE ON THE ROAD

THE FIRST TIME

FOR

In

most

primary chaincase and reservoir,

dry-charged battery;

a suitable grade of fuel and the motorcycle

TO S

1. Select the neutral position between first and seco

2.

3. Turn

4.

5. Press down the starter pedal

6.

cases the dealer will have checked the oil levels

if

in

doubt check again. Replenish the gas tank with

TART

THE ENGINE

Pull

in

the clutch lever and operate the starter pedal sever

free the clutc

on

lev

er

Place the key

position.

then press harder with the throttle

should start. .

Open

h.

the

gas

tap marked main

at top of carburettor

the cold start as soon

in

the ignition switc h and turn clockwise

ch

ecked the tire pressures and filled the

is

R/H side and depress co

LlH

side.

genlly until you feel some resistance;

sl/ightly open when the engine

as

the engine will allow it without

ready for starting.

nd

in

the

gear.

gearbox,

al

times

ld start

to

the

staIHn:g.

-ON'

a

to

12

RUNNING IN YOUR NEW MOTORCYCLE

ClassicBike.biz

Al

though the new parts are machined

rt

moving pa

'·b roken~in".

s need to mate with ea

At a low constant speed this would take a considerable

age, therefore the ideal method of

as

accurately as possible the

ch

other or become what is known

breaking~in

gressively the load and length of time the load

machines

opening

throttle opening, even

will travel at 50m.p.h. (80Km/h) with only a small throttle

on

a level road without harm when new but any use of a large

in

a lower gear, other than for a very short time

may cause damage .

is

to increase pro-

is

maintained. These

as

mile~

Change gear frequently

neither pulling hard

extra use of the gearbox helps

difficult

to

quote a set mileage but provided that the running-in

intelligently it should

so

in

that the engine is always working easily,

a high gear nor revolving fast

to

run-in

all the transmission parts. It

be

possible

to use

maximum performance after

in

a low gear. The

is

done

1,500 miles (2.500Km). Whenever the maximum performance is used

is a good plan to snap shut the throttle for a moment occasionally

sucks a certain amount of

oil up the cylinders.

as

this

TO ADJUST THE VALVE

OPERATING MECHANISM

There are four adjuste

re

moving the two inspection ca

of the correct thickness can be inserted u

The clearance must always be chec

easiest

to

find the correct

if you put the machine

remove the spa rking plugs. By turning

the crankshaft and position the valves.

Inlet

valves

(towards

Turn the rear wheel until one of the inlet rockers moves downwards, thus

opening

the

valve. When this

of the other inlet valve

clearance can now

is

0.008in and is correct when a feeler gauge of this thickness

sliding fit between the valve tip and the adjuster. Tighten the locknut and

recheck

the

clearance. Having adjusted one inlet valve turn

wheel until the valve which you have adjusted is now

repeat the procedure

rs

on the rockers which are accessible after

ps fro

m the rocker boxes. A feeler gauge

nd

er each roc

ked when the engine

pOi

nt of t

he

stroke

to

adjust t

on the centre stand, engage top gea

th

e rear wheel you can then turn

the

rear

of

the

engine)

valve

is

will be seated

be

checked and adjusted

for

the other inlet valve.

fully open the operating mechanism

on

the

base of

if

necessary. The clearance

ker,

see

is

cold. It will be

he

valve clearance

r,

and then

the

cam and the

is a ti

the

fully open and

Fig. 2.

ght

rear

is

it

13

Loading...

Loading...