Triumph 1955 TR2, 1956 TR2, 1957 TR2, 1958 TR2, 1959 TR2 Service Manual

...

ars

Complete Service Manuals published

by

Robert Bentley, Inc.

Volkswagen Beetle and Karmann Ghia Official Service Manual Type 1, Model Years

1966-1969. Volkswagen of America, Inc.

Volkswagen Super Beetle, Beetle and Karmann Ghia Official Service Manual Type 1,

Model Years 1970-1976. Volkswagen of America, Inc.

Volkswagen Station

WagonIBus Official Service Manual Type 2, Model Years 1968- 1976.

Volkswagen of America, Inc.

Volkswagen

Fastback and Squareback Official

Service Manual Type 3, Model Years

1968- 1973. Volkswagen of America, Inc.

Capri Complete Service Manual,

Model Years

1970- 1974. Robert Bentley, Inc.

Complete Official Triumph TR2

&

TR3,1953- 196 1-includes Driver's Instruction Book

and Service Instruction Manual. British Leyland Motors

Complete Official Triumph TR4

&

TR4A, 196

1

-

1968-includes Driver's Handbook,

Workshop Manual, Competition Preparation Manual. British Leyland Motors

Complete Official Triumph GT6, GT6

+

Mk 111, 1967- 1973-includes Driver's Hand-

book and Workshop Manual. British Leyland Motors

Complete Official Triumph TR6

&

TR250,1967- 1975-includes Driver's Handbook and

Workshop Manual. British Leyland Motors

Complete Official Triumph Spitfire Mk 111, Mk IV

&

15 00,1968 - 1976-includes Driver's

Handbook and Workshop Manual. British Leyland Motors

MG Workshop Manual: Complete Tuning and Maintenance Por All Models from

"M"

Type to TF 1500. W.E. Blower

Complete Official MGB, Model Years

1962- 1974-includes Driver's Handbook, Work-

shop

Manual, Special Tuning Manual. British Leyland Motors

Complete Official Jaguar "E-includes Driver's Handbook, Workshop Manual, Special

Tuning Manual. British Leyland Motors

Complete Official

948cc

&

1098cc SpriteIMidget-includes Driver's Handbook, Work-

shop Manual, Special Tuning Manual. British Motor Corp.

Complete Official

1275cc SpriteIMidget, 1967- 1974-includes Driver's Handbook,

Workshop Manual, Emission Control

Supplement. British Leyland Motors

del

Years

Comprising

the

official

driver's instruct ion book

service instruct ion manual

Robert Bentley,

Inc.

872

Massachusetts Avenue

Cam bridge, Mass.

02139

Library of Congress Catalog Card Number 75-42893

ISBN 0-8376-0125-8

Manufactured in the United States of America

Copyright

Q

1976 Robert Bentley, Inc.

All rights in this book are reserved.

No responsibility accepted for the accuracy of the contents.

Taken as a whole, the Triumph TR2s and TR3s represent

one of the most successful sports car designs in history; so successful that, by the early nineteen-sixties, they had helped to

make Standard Triumph the second-best selling imported car

marque in the United States. During the late nineteen-fifties

and early nineteen-sixties, countless fledgling race drivers

gained their early experience in these machines. Among them

was three-time World Champion Jim

Clark, who owned one of

the first-if not the very first-TR3 in

Scotland.

Today, in the nineteen-seventies,

TR2s and TR3s are as

eagerly sought after as they were twenty years ago when the

cars were

in production. This should not be surprising since

there has never been a time during those twenty years when

TR2s and TR3s were not proving their worth. In 1965, fully ten

years after the TR2 was discontinued and almost five years

after the last TR3 had been built, the cars remained highly

competitive in racing. In that year, the Sports Car Club of

America's U.S. F-Production Championship was won by

Brian Fuerstenau in a TR3-with Lee Midgely's TR2 solidly in

second place.

Wise collectors began to acquire

TR2s and TR3s even before

their long and successful history had been written on the race

track.

(As recently as 1975 a TR3 made

the field for The Cham-

pion Spark Plug Road

~acin~ Classic-an event that deter-

mines the ultimate

standings in

U.S. amateur road racing.) In

1970, at a time when the newest TR3 was on the verge of

becoming a ten-year-old relic, well-maintained examples of its

predecessor, the TR2, were already being purchased by collectors for more than the cars had cost when new. The prices of

fully restored

TR3s have since begun to follow suit and will un-

doubtedly

continue to rise as fewer examples of the type

become

available on the open market.

This is as it should be; the

TIP2 and TR3 are landmarks in

the

evolution of the sports car. Before the TR2 arrived on the

automotive scene, enthusiasts of limited means had very few

cars from which to choose. The TR3 was a windfall particularly to sports car-starved Americans who, in buying a Triumph,

could acquire 100-mph capability at a cost little greater than

that required to obtain an 80-mph

MG.TF.

Because the value of TR2 and TR3 sports cars is increasing,

it is impossible to overstate the importance of correct

maintenance and repair.

Unfortunately, original workshop

manuals and owner's manuals have, since the assimilation of

Standard Triumph by British Leyland Motors, become virtual-

ly impossible to obtain. Indeed, original books are now

collec-

.

.

tor's items in their own right. No vintage Triumph enthusiast

would choose to risk one by placing it on an oil-stained

workbench or on a garage floor! A new, readily available and

easily replaceable manual that duplicates the orginal manuals'

This Manual has been compiled in order to meet that need,

thereby supplying complete, accurate, and comprehensive

maintenance and repair data to both car owners and professional mechanics. The

Driver's Instruction Book,

which comprises the first part of this Manual, is similar to the handbook

provided with every new TR3. The

Service Instruction Manual,

which comprises the second-and largest-portion of this

Manual, is the official factory manual and was originally intended for use by dealer service departments. Owners of

TR3s

and the so-called TR3A or TR3B model will find it informative

to read the Foreword to the TR3 Supplement, which appears

on page

419.

Assembly work on small, highly-tuned machines such as the

Triumph sports

cars must be carried out with greater precision

than is commonly practiced on large American cars. Particular

emphasis must be given to the proper use of torque wrenches

and to strict adherence to the tightening torque specifications

which are given in this Manual. A fastener that is too tight can

be worse than one that is too loose-especially on a lightweight

sports car. Stretched or broken bolts and distorted parts, which

result from overtightening by musclebound mechanics, become

a serious concern where the precision fitting of light alloy and

thin-wall iron castings is involved.

The importance of cleanliness cannot be overemphasized.

Under no circumstances should an engine or gearbox be

repaired on the ground or on a garage floor. Thoroughly clean

the exteriors of major components prior to disassembly in

order to keep road dirt and other grime out of the working

parts. No more than a pinch of abrasive dust in a gearbox can

cause rapid failure of the synchronizers and bearings.

During the final assembly of an engine or gearbox, the

cleaned parts should be laid out on a clean workbench that has

been covered with clean sheets of new cardboard or wrapping

paper. The engine or gearbox itself, if not mounted on a special

stand, should likewise be placed on a clean workbench. Sandpapering, valve grinding, or the use of bench grinders should

not be permitted near the area where final assembly is taking

place. If assembly cannot be completed in a day, enclose the

partially-assembled engine or gearbox in a large plastic

bag-such as a new trash bag or a dry cleaner's garment return

bag-so that dust and dirt will be excluded until assembly

work resumes.

By observing these precautions during the maintenance,

repair, or restoration of your TR2 or TR3, you will be preserving the value and the life of a car that is rapidly becoming one

of the classics among post-World War

I1

sports cars. If at any

time you lack the skills, special equipment, tools, or workshop

facilities for making repairs as they are described in this

Manual, we suggest you leave such repairs to an Authorized

contents is clearly needed.

Dealer or other qualified shop.

Note on the Table of Contents

Both the

Driver's Instruction

Book

and the

Service In-

struction Manual

are presented here exactly as originally

published by the Standard Motor Co.-including the

original page numbers. (The small numbers in the

center

at the bottom of each page are the original page

numbers.) We

have added the large, bold page numbers

at the lower outside margin of each page.

It is these large

numbers that are referred to in the Table of Contents

starting on the next page.

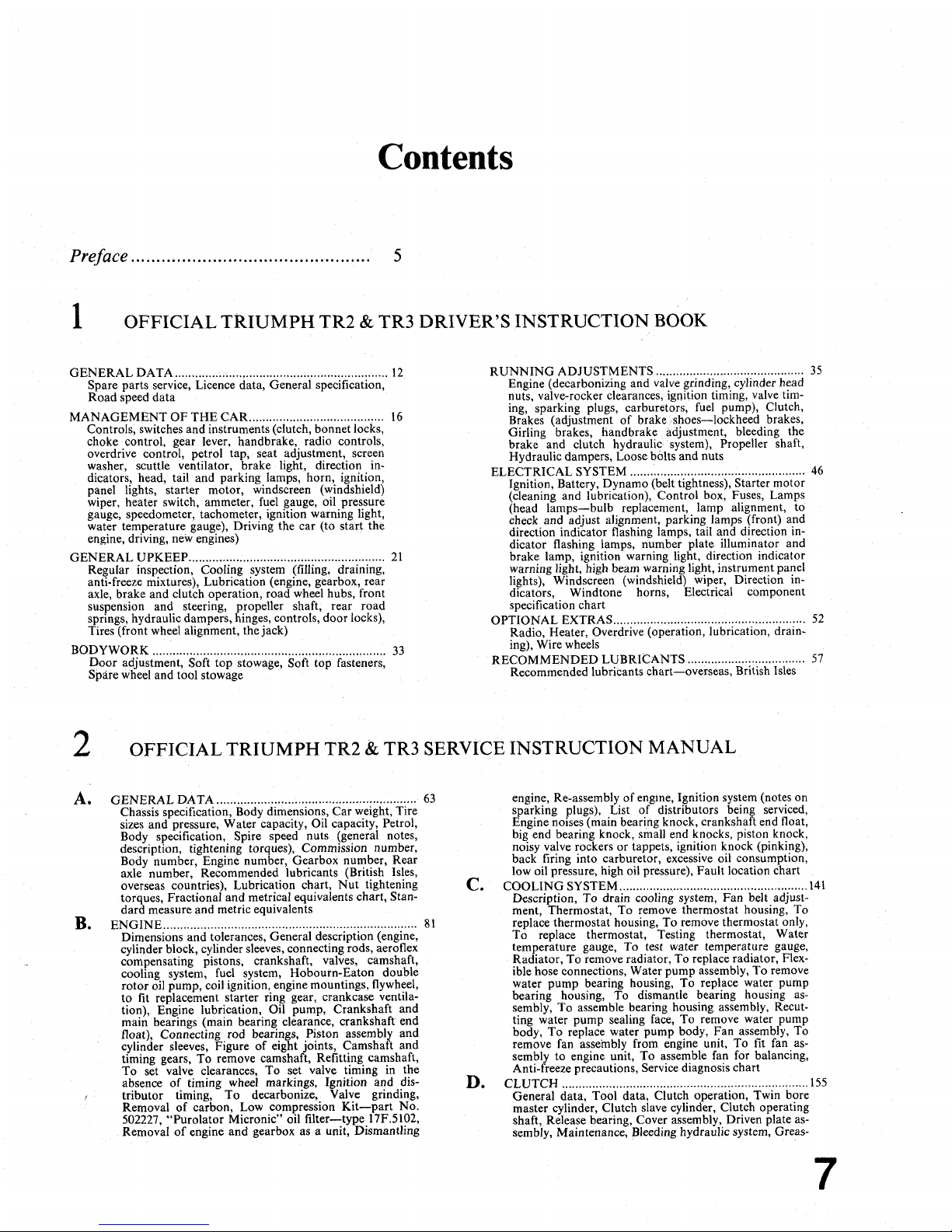

Contents

...............................................

Preface

5

1

OFFICIAL TRIUMPH TR2 & TR3 DRIVER'S INSTRUCTION BOOK

GENERAL DATA

..........................................................

12

Spare parts service, Licence data, General specification,

Road speed data

MANAGEMENT OF THE CAR

......................................

16

Controls, switches and instruments (clutch, bonnet locks,

choke control, gear lever, handbrake, radio controls,

overdrive control, petrol tap, seat adjustment, screen

washer, scuttle ventilator, brake light, direction indicators, head, tail and parking lamps, horn, ignition,

panel lights, starter motor, windscreen (windshield)

wiper, heater switch, ammeter, fuel gauge, oil pressure

gauge, speedometer, tachometer, ignition warning light,

water temperature gauge), Driving the car (to start the

engine,

driv~ng, new engines)

GENERAL UPKEEP

..........................................................

21

Regular inspection, Cooling system (filling, draining,

anti-freeze mixtures), Lubrication (engine, gearbox, rear

axle, brake and clutch operation, road wheel hubs, front

suspension and steering, propeller shaft, rear road

springs, hydraulic dampers, hinges, controls, door

Locks),

Tires (front wheel alignment, the jack)

BODYWORK

.....................................................................

33

Door adjustment, Soft top stowage, Soft top fasteners,

Spare wheel and tool stowage

RUNNING ADJUSTMENTS

............................................

35

Engine (decarbonizing and valve grinding, cylinder head

nuts, valve-rocker clearances, ignition timing, valve tim-

ing, sparking plugs, carburetors, fuel pump), Clutch,

Brakes (adjustment of brake shoes-lockheed brakes,

Girling brakes, handbrake adjustment, bleeding the

brake and clutch hydraulic system), Propeller shaft,

Hydraulic dampers, Loose bolts and nuts

ELECTRICAL SYSTEM

.................................................

46

Ignition, Battery, Dynamo (belt tightness), Starter motor

(cleaning and lubrication), Control box, Fuses, Lamps

(head lamps-bulb replacement, lamp alignment, to

check and adjust alignment, parking lamps (front) and

direction indicator flashing lamps, tail and

dnection m-

dicator flashing lamps, number plate

illuminator and

brake lamp, ignition warning light, direction indicator

warning light, high beam warning light, instrument panel

lights), Windscreen (windshield) wiper, Direction in-

dicators,

Windtone horns, Electrical component

specification chart

.......................................................

OPTIONAL EXTRAS 52

Radio, Heater, Overdrive (operation, lubrication, draining), Wire wheels

-,

RECOMMENDED LUBRICANTS

..............................

.....

57

Recommended lubricants chart-overseas, British Isles

OFFICIAL TRIUMPH TR2 & TR3 SERVICE INSTRUCTION MANUAL

GENERAL DATA

.......................................................

63

Chassis specification, Body dimensions, Car

we~ght, Tire

sizes and pressure, Water capacity, Oil

capacity, Petrol,

Body specification, Spire speed nuts (general notes,

description, tightening torques), Commission number,

Body number, Engine number, Gearbox number, Rear

axle number, Recommended lubricants (British Isles,

overseas countries), Lubrication chart, Nut tightening

torques, Fractional and metrical equivalents chart,

Stan-

C.

dard measure and metric equivalents

ENGINE

...........................................................................

81

Dimensions and tolerances, General description (engine,

cylinder block,

cyl~nder sleeves, connecting rods, aeroflex

compensating

pistons, crankshaft, valves, camshaft,

cooling system, fuel system, Hobourn-Eaton double

rotor oil pump, coil ignition, engine mountings, flywheel,

to fit replacement starter ring gear, crankcase

ventlla-

tion), Engine

lubrication, Oil pump, Crankshaft and

main bearings (main bearing clearance, crankshaft end

float), Connecting rod bearings, Piston assembly and

cylinder sleeves, Figure of eight joints, Camshaft and

timing gears, To remove camshaft, Refitting camshaft,

To set valve clearances, To set valve timing in the

absence of timing wheel markings, Ignition and dis-

tributor timing, To decarbonize, Valve grinding,

D.

Removal of carbon, Low compression Kit-part No.

502227, "Purolator Micronic" oil

filter-type,l7F.5102,

Removal of engine and gearbox as a unit, D~smantling

engine, Re-assembly

of

engme, Ignition system (notes on

sparking plugs), List

of distributors being serviced,

Engine noises (main bearing knock, crankshaft end float,

big end bearing knock, small end knocks, piston knock,

noisy valve rockers or tappets, ignition knock (pinking),

back firing into carburetor, excessive oil consumption,

low oil pressure, high oil pressure), Fault location chart

........................................................

COOLING SYSTEM 141

Description, To drain cooling system, Fan belt adjustment, Thermostat, To remove thermostat housing, To

replace thermostat housing, To remove thermostat only,

To replace thermostat, Testing thermostat, Water

temperature gauge, To test water temperature gauge,

Radiator, To remove radiator, To replace radiator, Flexible hose connections, Water pump assembly, To remove

water pump bearing housing, To replace water pump

bearing housing, To dismantle bearing housing assembly, To assemble bearing housing assembly,

Recut-

ting water pump sealing

face, To remove water pump

body, To replace water pump body, Fan assembly, To

remove fan assembly from engine unit, To fit fan assembly to engine unit, To assemble fan for balancing,

Anti-freeze precautions, Service diagnosis chart

.........................................................................

CLUTCH 155

General data, Tool data, Clutch operation, Twin bore

master cylinder, Clutch slave cylinder, Clutch operating

shaft, Release bearing, Cover assembly, Driven plate assembly, Maintenance, Bleeding hydraulic system,

Greas-

ing clutch operating shaft, Adjusting clutch, Adjusting

master cylinder, Adjusting slave cylinder, To remove

flexible hose, To fit flexible hose, Removal of slave

cylinder (with fork-rod assembly), To replace slave

cylinder, Dismantling slave cylinder, Assembly of slave

cylinder, To remove release bearing and clutch operating

shaft, To replace clutch operating shaft and release bearing, Removal of clutch from flywheel with gearbox

removed, Replacement of clutch to flywheel, Dismantling cover assembly using Churchill fixture No.

99A, As-

sembly of

cover plate assembly using Churchill fixture

No.

99A, Dismantling cover assembly without

Churchill

fixture, To assemble cover assembly without Churchill

fixture, Inspection of cover assembly, Adjusting release

levers, Condition of clutch facings, Reconditioning of

driven plate assembly, Service diagnosis chart

.....................................................................

GEARBOX 173

Dimensions and tolerances, Operation, Ratios, Bearings,

Mounting, Oil capacity, Nut and bolt data and tightening torques, To remove gearbox leaving engine in position, To replace gearbox, To dismantle, To assemble, To

dismantle top cover assembly, To assemble, Installation

of overdrive (dismantling, assembly of gearbox, fitting

overdrive unit, valve checking, valve adjustment, fitting

isolator switch, operating switch), Supplementary instructions for incorporating overdrive on "second" and

"third" gears (overdrive unit, gearbox top cover assembly)

REAR AXLE

....................................................................

205

General discription, To remove hubs, To replace hubs,

To remove hubs

(center lock type), To replace hubs

(center lock type), To remove axle shaft, To replace axle

shaft, To remove axle, To replace axle, To dismantle, To

re-assemble,

Service diagnosis

......................

FRONT SUSPENSION AND STEERING 225

Front suspension data, Description, Maintenance, Front

wheel alignment, To adjust front wheel alignment, Steer-

ing lock stops, To set steering lock stops, To remove

front hub and stub axle, To replace front hub and stub

axle, To remove front shock absorber, To fit shock absorber, To remove front road spring, To fit road spring,

To remove and dismantle front suspension unit, To assemble and replace front suspension unit, Steering, Type

and description, Maintenance, Adjustment of steering

box, To remove control head from steering wheel, To fit

control head and stator tube to steering wheel, To

remove steering wheel, To fit steering wheel, To remove

steering unit, To fit steering unit, To dismantle steering

unit, To assemble steering unit, Removal and replacement of drop arm, To remove idler unit, To fit idler unit,

Steering column bracing, Telescopic (adjustable) steering

unit (description, steering unit, steering wheel, control

head), To fit telescopic steering unit and steering wheel,

To remove telescopic steering wheel and steering unit, To

remove control head from

center of telescopic steering

wheel, To fit control head and stator tube

to telescopic

steering wheel, Steering stiffness, Assessment of accidental damage

..............

ROAD SPRINGS AND SHOCK ABSORBERS

255

Front spring (description, maintenance, to remove or

replace), Rear road springs (description, maintenance, to

remove rear road spring, to fit, rear road spring

overhaul, to dismantle, to assemble), Front shock absorber (description, maintenance, operation of telescopic

shock absorber, to remove or replace front shock absorber), Rear shock absorber (description, maintenance,

valve operation, to remove rear shock absorber, to fit

rear shock absorber)

FRAME UNIT

..................................................................

265

Description, Assessment of accidental damage, preparation of car, Checking side members for twist, Checking

side members for cradling, Checking side members for

squareness, Checking side members for bowing

PROPELLER SHAFT

......................................................

275

Description, Lubrication, Maintenance instructions,

Removal of propeller shaft, To dismantle propeller shaft,

To examine and check for wear, To assemble, To fit

propeller shaft

L.

WHEELS AND TIRES

..................................................

281

Construction of tire, Tire pressures, Repair of injuries,

Factors affecting tire life and performance (inflation

pressures, effect of temperature, speed, braking, climatic

conditions, road surface, impact fractures), Special types

of irregular tread wear ("heel and toe" or "saw tooth"

wear, "spotty" wear), Wheel alignment and its association with road camber (precautions when measuring

wheel alignment), Camber, castor and king pin inclination, Tire and wheel balance (static balance, dynamic

balance), Changing position of tires, Pressed steel wheels,

Wire wheels (to remove, to replace, examination, wheel

building)

...................................

ELECTRICAL EQUIPMENT .....297

Batteries-models GTW7A/2, GTW9A12, GT9A/2,

and GTZ9A/2 (routing maintenance, service data, servicing, preparing new unfilled, uncharged

batteries for

service, preparing GTZ "dry-charged" batteries for service, battery cable connectors), Generator-model C.39

PV/2 (general, routine maintenance, performance data,

servicing), Starting motor-model

M418G (outboard

drive)

(general, routine maintenance,

performance data,

servicing, fault diagnosis chart), Starting motor drive

(general, routine maintenance, construction, dismantling, re-assembly), Distributor-model DM2 (general,

routine maintenance, design data, servicing),

Headlamps-model F700

MK/VI (general description,

bulb

replacement, setting,

renewal of light unit), Control

box-model

RB106-1 (general, setting data, servicing),

Windscreen

(windshield)

wiper

CRT15 (general, flashing

light direction

indicators), Electric

windtone horns--

models

WT614 and WT618 (general-adjustment, inter-

nal faults, both

horns fail to operate, one horn fails to

operate), Wiring diagram, Control box-model

RB106-2

(general, setting data, servicing)

.................................

....................................

N.

BODY

..

339

Body mounting points, To remove body, To fit body,

Battery box drain, To remove and dismantle front

bumper, To fit front bumpers, To remove rear

overriders and brackets, To fit rear over-riders, To remove

front wing, To fit front wing, To remove

rear wing, To fit

rear wing, To remove bonnet lid, To fit bonnet lid, To

remove front apron, To fit front apron, Adjustment of

bonnet locks, To remove windscreen (windshield), To fit

windscreen (windshield), To fit aero-windscreen, To

remove door, To

fit door, Front door water sealing, To

remove door lock, To fit door lock,

Removal of gearbox

tunnel, To fit gearbox tunnel, To remove hood and fit-

tings, To fit hood and fittings, Water sealing of hood

seams, Adjustment of side curtains, To prepare car for

fiberglass hard top canopy, To fit fiberglass hard top

canopy, To remove fiberglass hard top canopy, To

remove luggage boot lid, To fit luggage boot lid, To dismantle spare wheel lid, To assemble spare wheel lid, To

fit Smiths circular heater

C.H.S. 92014

FUEL SYSTEM

................................................................

357

Data and description (tank capacity, petrol stop tap,

petrol pump, carburetors, air cleaners), To remove petrol

tank, To fit petrol tank, Petrol gauge, Precaution when

carrying out tests, To test dash meter, To test tank unit,

Fuel gauge fault location chart, To remove flexible petrol

feed pipe, To fit flexible petrol feed hose, Petrol stop tap,

To remove petrol stop tap, To fit petrol stop tap, Servicing petrol stop tap, To dismantle petrol stop tap, To assemble petrol stop tap, AC fuel pump type

"UP, Petrol

pump oil seal, To clean pump filter, Testing while on

engine, To remove

petrol pump from engine, To fit

petrol pump to engine, To dismantle

petrol pump, To as-

semble petrol pump, Inspection of parts,

AC

air cleaners,

To remove air cleaners, To fit air cleaners to carburetors,

Servicing air cleaners, Disconnection of carburetor controls, To remove accelerator pedal, right hand side, To fit

accelerator pedal, right hand side, To remove accelerator

pedal, left hand side, To fit accelerator pedal, left hand

side, To remove carburetor from manifold, To fit

carburetors to manifold, S.U. carburetor (description, construction), Throttle

and mixture control interconnection,

Effect of altitude and climatic extremes on standard tuning, Carburetor jet needles, To remove jet needle, To fit

needle, Centralization of jet, To assemble carburetor(s),

To adjust fuel level in float chamber,

Carburetor tuning,

Carburetor defects (pistons sticking, eccentricity of jet

and needle, flooding from float chamber or mouth of jet,

leakage from bottom of jet adjacent to adjustment nut,

dirt in carburetor, failure of fuel supply to float chamber,

sticking jet)

Q.

SPECIALIZED TOOLS

.................................................

385

Policy, Particulars of tools, Tool list

R.

BRAKES

.........................................................................

389

Description, Routine maintenance, Brake lining identifications, Data, Front brake shoe adjustment, Rear

brake shoe adjustment, Handbrake adjustment, To bleed

hydraulic system, Leakage of fluid from master cylinder,

Brake and clutch pedal adjustment, Adjusting brake

pedal, To remove front left-hand flexible hose, To fit

front left-hand flexible hose, To remove front right-hand

flexible hose, To fit front right-hand flexible hose, To

remove rear flexible hose, To fit rear flexible hose, Twin

bore master cylinder (description), To remove master

cylinder, To fit master cylinder, To dismantle master

cylinder, To assemble master cylinder, Front wheel

cylinders, To remove front wheel cylinders, To fit front

wheel cylinders, To dismantle front wheel cylinders, To

assemble front wheel cylinders, Rear wheel cylinder, To

remove rear wheel cylinder, To fit rear wheel cylinder, To

dismantle rear wheel cylinder, To assemble rear wheel

cylinder, To remove hydraulic pipe line from rear axle,

To fit hydraulic pipe line to rear axle, Fitting replace-

ment brake shoes, To remove pedal assembly, To fit

pedal assembly, To dismantle pedal assembly, To assemble pedals, To remove handbrake lever, To fit handbrake

lever, To dismantle handbrake assembly, To assemble

handbrake assembly, To remove handbrake cables, To

fit handbrake cables

................

....................................

S.

EXHAUST SYSTEM

....

411

Description, Maintenance, To remove and dismantle exhaust system, To fit exhaust system, To remove

manifolds. To fit manifolds

SUPPLEMENT FOR TR3 MODELS

..............................

417

Foreword, General data, Engine (cylinder block,

aluminum pedestals for rocker shaft, pistons, combustion head, engine oil filter, sump), Clutch (clutch driven

plate assembly, hydraulic operating mechanism), Rear

axle (general, lubrication of rear hub bearings, axle shaft,

wheel bearings and oil seals, differential and pinion as-

semblies, high speed and competition work), Front

suspension and steering (nylon bearings, lower inner

wishbone attachment), Body (specification, reveal

molding and grille, stainless steel wing beading, pas-

senger seat, occasional rear seat, to remove reveal

molding and grille, to refit reveal molding and grille, to

remove or fit wing beading, to remove passenger seat

squab, to fit passenger seat squab, to fit occasional seats,

to remove occasional seat, TR2

&

TR3 "hard top" installation-car preparation, hard top preparation,

windscreen (windshield) attachment brackets, bridge

pieces, rear

cappings, drip channels, sealing rubbers, to

fit hard

top, rear

window light), Fuel system (petrol tank,

flexible fuel pipes, carburetors, air cleaners, inlet

manifold, to remove flexible fuel hose assembly, to fit

flexible fuel hose assembly, carburetor details, air

cleaners, inlet manifold), Brakes (Girling brakes and

hydraulic clutch-from chassis No. TS.13101, front

brakes, discs, rear brakes, running adjustments,

hydraulic clutch operation, clutch slave cylinder, general

maintenance, general advice on hydraulic components),

Exhaust system

Issued

by

STANDARD-TRIUMPH SALES LTD.

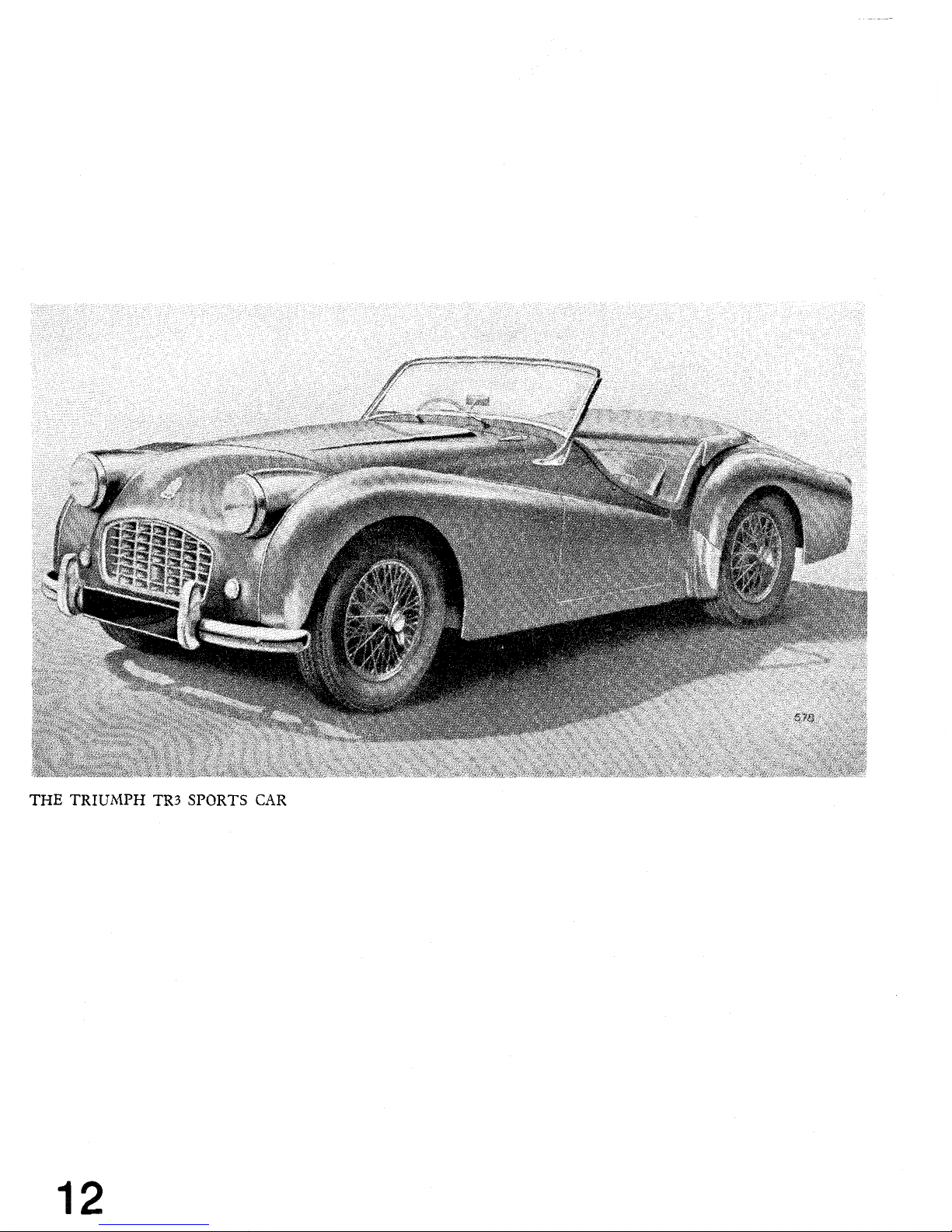

THE

TRIUMPH TR3 SPORTS

CAR

FOREWORD

The vehicle has been designed so that a minimum of attention is required to

keep it in satisfactory running order. There are, however, certain maintenance

operations which must be undertaken regularly, and the object of this instruction

book is to assist even the non-technical owner to understand the various

operations required, and so ensure that the vehicle receives regular and correct

attention.

If in any doubt about the vehicle's performance the owner should at once

consult a Triumph dealer, preferably the one from whom the car was purchased.

Triumph dealers are very carefully selected and are suitably equipped to give

satisfactory and expert after sales service.

There is

a

Service School at the factory at which our dealers' representatives

acquire a first hand knowledge of up-to-date service procedure.

Valuable

information is given regarding special methods and equipment which greatly

assists in getting the various operations performed more expeditiously.

SPARE PARTS SERVICE

To ensure the best possible service on replacement parts it is important to

note the following points

:-

(a) The policy of the Triumph Motor Company is not to supply spare

parts direct to the general public, but

all supplies are directed

through

Distributors who, in turn, will supply their Dealers. The name and

address of the Distributors and Dealers can be obtained from the

Service and Spares Directory included with each motor vehicle.

(b) It is recommended that only

C6Stanparts

"

(i.e.,

genuine Standard/

Triumph spare parts)

are used, only these carry a guarantee.

Experience gained by the manufacturers ensures that only highest

quality material is used and the strictest accuracy maintained in

manufacture.

(c) If in doubt about a particular part required, it is always advisable to

give the vehicle commission number and engine number, in addition

to the fullest description possible.

THE STANDARD CAR REVIEW

is a journal published monthly which

gives authentic information regarding the activities and products of The

Standard

&

Triumph Motor Co. Ltd. It is obtainable from most Triumph

dealers. Please write to the Publicity Department

for a free specimen

COPY.

Owners of this model who wish to be kept informed of modifications and

competition tuning hints should register as

a

member of the Triumph Sports

Owners' Association

;

details are given in the booklet enclosed with this

literature, or apply to the Publicity Dept., Triumph Motor Co.

(1945)

Ltd.,

Canley, Coventry, for a copy of the book, together with

enrolment form.

The Company reserves the right, on the sale of any vehicle, to make before

delivery, without notice, alterations to or departures from the specification,

design or equipment, detailed, described or illustrated in this or other

Company publications.

3

SPORTS

CAR

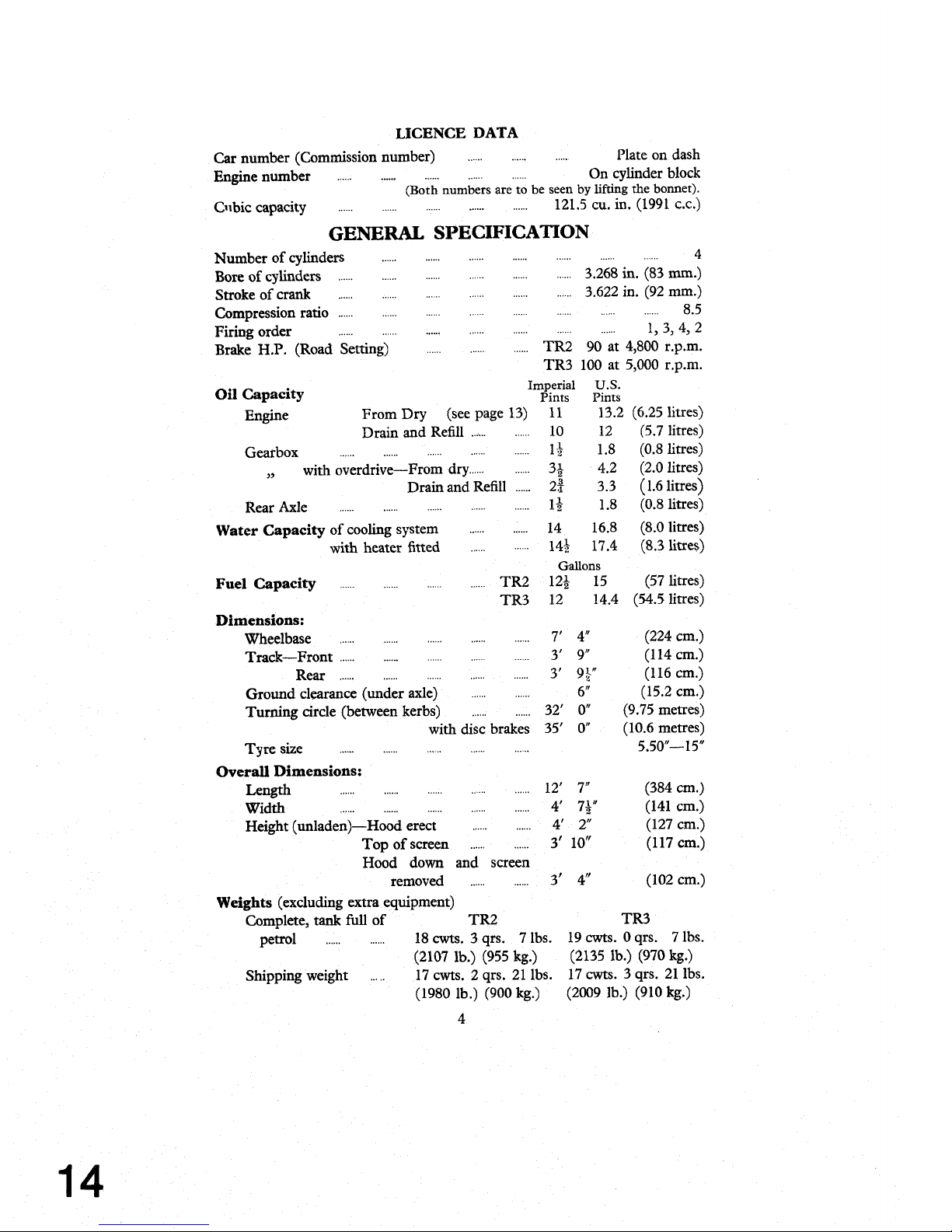

LICENCE

DATA

.....

......

Car number (Commission number)

......

Plate on dash

......

Engine number

........................

On cylinder block

(Both numbers are to be seen by lifting the bonnet).

..................

......

Cnbic capacity ...... 121.5 cu,

in.

(1991

CL.)

GENERAL SPECIFICATION

......

......

......

......

............

Number of cylinders

......

4

.....

......

......

Bore of cylinders ............

......

3.268 in. (83 mm.)

......

......

......

.....

......

Stroke of crank

......

3.622 in. (92 mm.)

......

......

......

......

......

......

......

Compression ratio

......

8.5

......

......

......

......

Firing order ..................

1,

3,

4,

2

......

......

Brake H.P. (Road Setting) ...... TR2 90 at 4,800 r.p.m.

TR3 100 at 5,000 r.p.m.

Imperial

U.S.

Oil Capacity

Pints Pints

Engine From

Dry

(see page 13) 11

13.2

(6.25 litres)

......

Drain and Refill ...,.. 10 12 (5.7 litres)

......

......

............

......

Gearbox

11 1.8 (0.8 litres)

,,

with overdrive-From dry ............ 34 4.2 (2.0 litres)

......

Drain and Refill 22 3.3 (1.6 litres)

......

......

......

......

Rear Axle

......

1i

1.8 (0.8 litres)

............

Water Capacity

of cooling system 14 16.8 (8.0 litres)

......

with heater fitted

......

14Q 17.4 (8.3litres)

Gallons

......

............

Fuel

Capacity

......

TR2 124 15 (57 litres)

TR3 12 14.4

(54.5 litres)

Dimensions:

......

......

......

......

Wheelbase

......

7' 4"

(224 cm.)

......

......

......

Track-Front ............ 3' 9" (1 14 cm.)

......

Rear

............

............

3' 9

$"

(116 cm.)

......

Ground clearance (under axle)

......

6" (15.2 cm.)

......

Turning circle (between kerbs)

......

32'

0"

(9.75 metres)

with disc brakes

35'

0"

(10.6 metres)

......

......

......

......

Tyre size

......

5.50"-15"

Overall Dimensions:

......

......

......

......

......

Length 12' 7" (384 cm.)

......

......

......

......

......

Width

4'

7;" (141 cm.)

......

Height (un1aden)-Hood erect ...... 4' 2" (127 cm.)

......

Top of screen

......

3'

10" (117 cm.)

Hood down and screen

removed

......

...... 3'

4"

(102 cm.)

Weights

(excluding extra equipment)

Complete, tank full of

TR2

TR3

......

petrol

......

18

cwts.

3

qrs. 7 lbs. 19 cwts. 0 qrs. 7 lbs.

(21071b.)(955kg.) (21351b.)(970kg.)

.....

Shipping weight

17

cwts. 2 qrs. 21 lbs.

17

cwts.

3 qrs. 21 lbs.

(1980 lb.) (900 kg.)

(2009 lb.) (910 kg.)

4

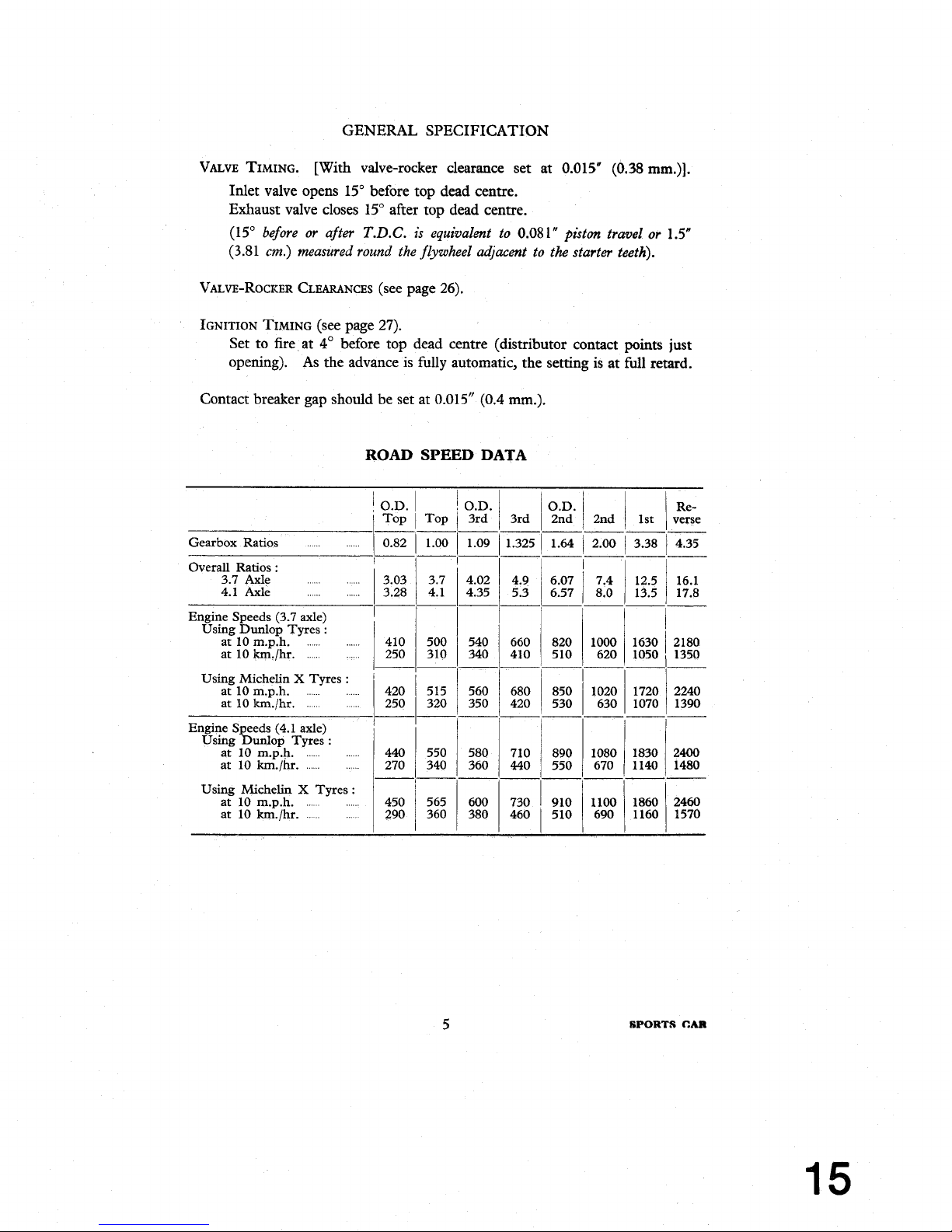

GENERAL SPECIFICATION

VALVE

TIMING.

[With

valve-rocker clearance set at 0.015" (0.38 mm.)].

Inlet valve opens 15" before top dead centre.

Exhaust valve closes 15" after top dead centre.

(15"

before or after

T.D.C.

is equivalent to

0.08

1"

piston travel or

1

S"

(3.81

cm.)

measured round the flywheel adjacent to the starter teeth).

VALVE-ROCKER CLEARANCES (see page 26).

IGNITION

TIMING

(see page 27).

Set to fire at

4' before top dead centre (distributor contact

points just

opening). As the advance is fully automatic, the semng is at

full

retard.

Contact breaker gap should be set at 0.015" (0.4

mm.).

ROAD

SPEED

DATA

1

O.D.

Gearbox Ratios

-

O.D.

3rd

1

.O9

Re-

verse

4.35

-

16.1

17.8

2180

1350

O.D.

3rd

/

2nd

1

2nd

--p

1.325 1 1.64 / 2.00

---

4.9

/

6.07

1

7.4

5.3

6.57 8.0

Overall Ratios

:

3.7 Axle

.

. .

. . . . . . . .

4.1

Axle

.

. . .

. . . . . . . .

l

-1-

l

Engine Speeds (3.7 axle)

Using

Dunlop Tyres

:

at 10 m.p.h.

at 10

!un./hr.

Using Michelin

X

Tyres

:

at 10 m.p.h.

at 10

km./hr.

Engine Speeds (4.1 axle)

Using

Dunlop Tyres

:

at 10 m.p.h.

at 10

km./hr.

Using Michelin

X

Tyres

:

at l0 m.p.h.

...

....,.

at 10 km./hr.

.....

....

SPORTS

CAR

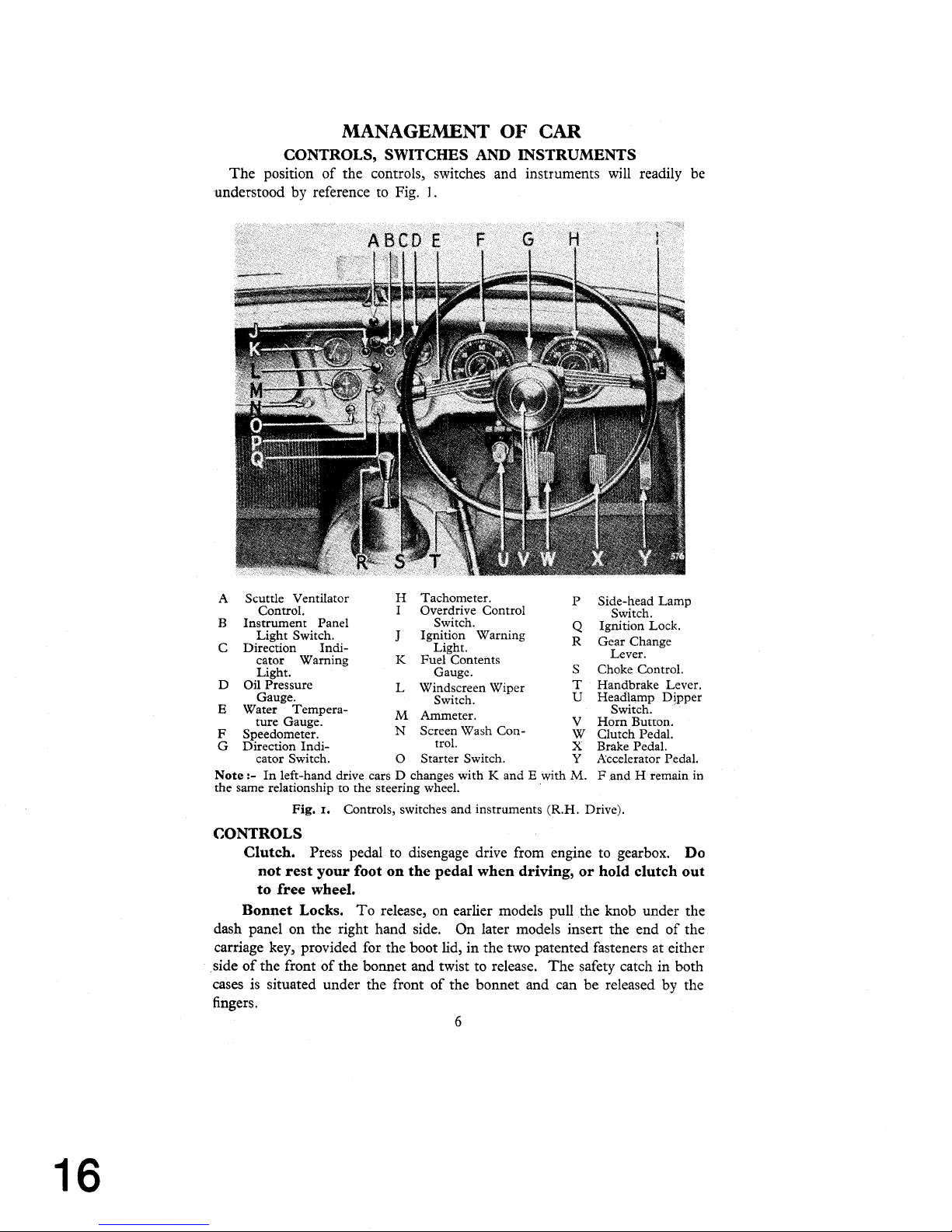

MANAGEMENT

OF

CAR

CONTROLS, SWITCHES AND INSTRUMENTS

The position of the controls, switches and instruments will readily be

understood by reference

to

Fig.

l.

Scuttle Ventilator

Control.

Instrument Panel

Light Switch.

Direction Indi-

cator Warning

Light.

Oil Pressure

Gauge.

Water Tempera-

ture Gauge.

Speedometer.

Direction Indi-

cator Switch.

Note

:-

the same relationship to the steering wheel.

In left-hand drive cars D changes with K and E with

Fig.

Controls, switches and instruments (R.H. Drive).

I.

Tachometer.

Overdrive Control

Switch.

Ignition Warning

Light.

Fuel Contents

Gauge.

windscreen Wiper

Switch.

Ammeter.

Wash Con-

Screen

trol.

Starter Switch.

Side-head Lamp

Switch.

Ignition Lock.

Gear Change

Lever.

Choke

Control.

Handbrake Lever.

Headlamp Dipper

Switch.

Horn Button.

Clutch Pedal.

Brake Pedal.

Accelerator Pedal.

M.

F and H remain in

CONTROLS

Clutch.

Press pedal to disengage drive from engine to gearbox.

Do

not rest your foot on the pedal when driving, or hold clutch out

to free wheel.

Bonnet Locks.

To relezse, on earlier models pull the knob under the

dash panel on the right hand side. On later models insert the end of the

carriage key, provided for the boot lid, in the two patented fasteners at either

side of the front of the bonnet and twist to release. The safety catch in both

cases is situated under the front of the bonnet and can be released by the

fingers.

6

MANAGEMENT OF

CAR-Controls, Switches and Instruments

Choke Control.

See page 9 for full instructions.

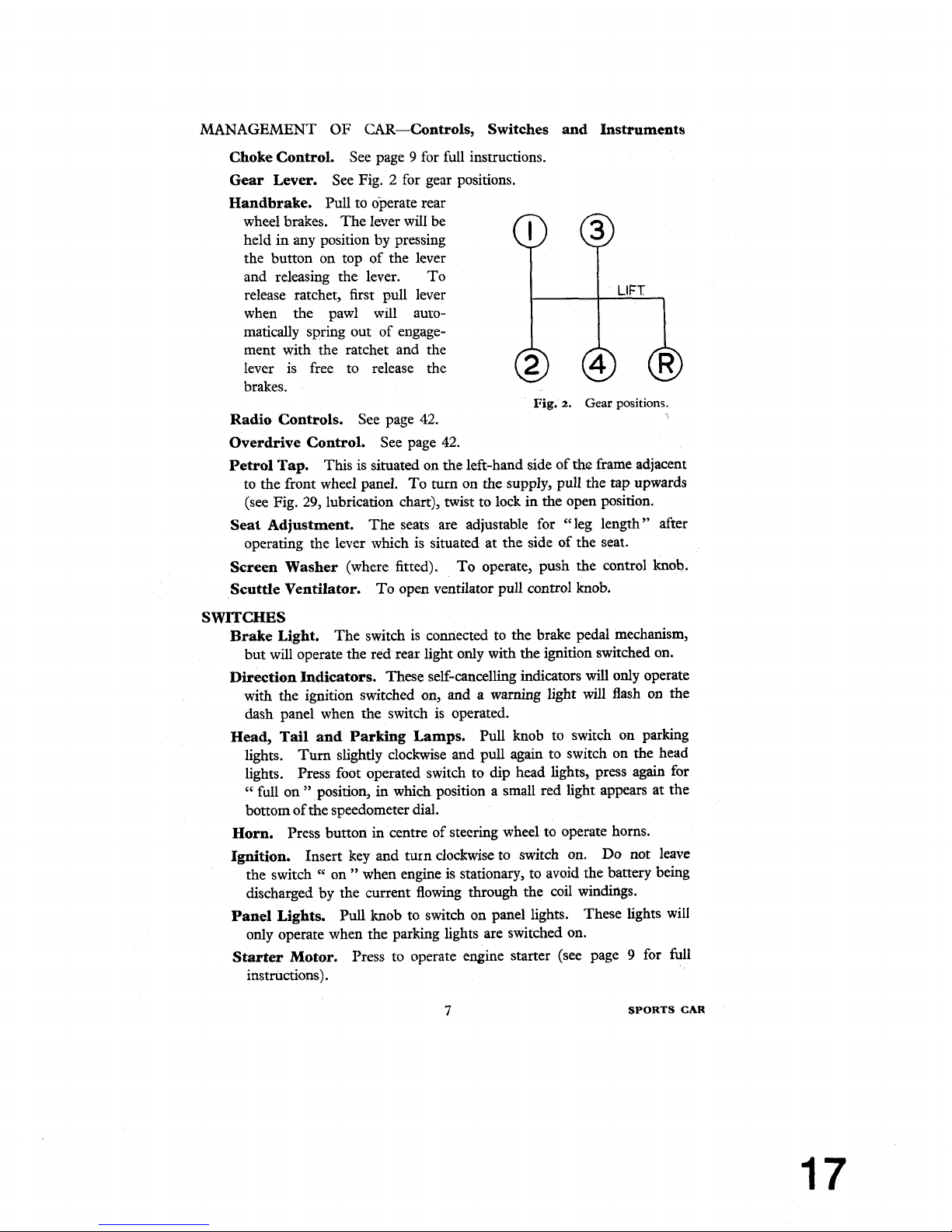

Gear Lever.

See Fig. 2 for gear positions.

Overdrive Control.

See page 42.

Handbrake.

Pull to operate rear

wheel brakes. The lever will be

held in any position

by pressing

Petrol Tap.

This is situated on the left-hand side of thc frame adjacent

to the front wheel panel. To turn on the supply, pull the tap upwards

(see Fig. 29, lubrication chart), twist to lock in the open position.

the button on top of the lever

and releasing the lever. To

release ratchet, first pull lever

when the pawl will

aulo-

matically spring out of engage-

Seat Adjustment.

The seats are adjustable for "leg length" after

operating the lever which is situated at the side of the seat.

LIFT

Screen Washer

(where fitted).

To operate, push the control knob.

Scuttle Ventilator.

To open ventilator pull control knob.

ment with the ratchet and the

lever is free to release the

brakes.

@ @

Fig.

2.

Gear

positions.

Radio Controls.

See page 42.

S

WITCHES

Brake Light.

The switch is connected to the brake pedal mechanism,

but will operate the red rear light only with the ignition switched on.

Direction Indicators.

These self-cancelling indicators will only operate

with the ignition switched on, and a warning light will flash on the

dash panel when the switch is operated.

Head, Tail and Parking Lamps.

Pull knob to switch on parking

lights.

Turn slightly clockwise and pull again to switch on the

head

lights. Press

foot operated switch to dip head lights, press again for

cc

full on " position, in which position a small red light appears at the

bottom of the speedometer dial.

Horn.

Press button in centre of steering wheel to operate horns.

Ignition.

Insert key and turn clockwise to switch on. Do not leave

the switch

cc

on " when engine is stationary, to avoid the battery being

discharged by the current flowing through the coil windings.

Panel Lights.

Pull knob to switch on panel lights. These lights will

only operate when the parking lights are switched on.

Starter Motor.

Press to operate engine starter (see page 9 for full

instructions).

7

SPORTS

CAR

MANAGEMENT

OF CAR-Controls, Switches and Instruments

Windscreen Wiper.

Pull

to operate wipers ; they will only function

when the ignition is switched on. Push to stop when arms are in the

desired parking position.

Heater Switch. See page

42.

INSTRUMENTS

Ammeter. Indicates the flow of current into or out of the battery.

Fuel Gauge. Registers the amount of fuel in the tank.

It

operates

automatically when the ignition is switched on.

Oil

Pressure Gauge. Indicates pressure of oil being pumped to the

bearings.

The gauge should read

70

Ib./sq. in. (4.9 kg./sq. cm.) minimum

when the car is

travelling at normal speeds and the oil is hot. Only

a low pressure may be registered when the engine is idling or running

at low speeds

;

this is quite normal.

Speedometer. Registers vehicle's speed and total distance covered,

and is fitted with a trip which is cancelled by pushing up the serrated

knob (situated under the instrument) and turning anti-clockwise.

Tachometer. Indicates the speed of rotation of the engine in revo-

lutions per minute. (See page

10).

Ignition

Warning Light. Glows red when ignition is switched on

with the engine idling or stopped.

It is

an indication that current is

being drawn from the battery for the ignition circuit, or other purposes

that are controlled

by

the ignition switch.

Water Temperature Gauge. The gauge shows the temperature of

the cooling water at the thermostat. Under normal motoring conditions the water temperature should not exceed

185".

MANAGEMENT

OF

CAR.

DRIVING

THE

CAR

TO

START THE ENGINE

IMPORTANT-When starting the engine at any time

:

If the engine does not start when the starter is operated,

do not re-

operate until both starter motor and engine have come to rest.

This is to avoid damage to the starter pinion.

Starting when Engine is Cold

Place the gear lever in the neutral position and see that the handbrake is

on. Pull the carburettor choke control out to the stop, switch on the

ignition and press the starter switch button. When the engine has become

sufficiently warmed up, turn the choke control and allow the control

to spring back to the

half-out

position and turn to lock in this position.

After one or two minutes driving, as the engine warms up, it will be

possible to permit the control to return home without causing the engine

to run with undue hesitation. If the battery has been allowed to get

into a run-down condition, it is better to use the starting handle. When

the engine fails to start, do not keep the choke control out too long or the

sparking plugs will become wet with petrol and it will be necessary to

remove and dry them. When the car has been left standing for some

considerable time, the fuel level in the carburettor float chambers may

have become rather low, due to evaporation. The hand primer on the fuel

pump can be used under such circumstances, before the starter is operated,

(see page

29).

When starting in very cold conditions, the clutch pedal may be depressed

when operating the starter to relieve the motor of the considerable drag

in the gearbox.

Starting with Engine Warm or Hot

When restarting the engine while it is

still

hot the accelerator pedal should

be depressed to about one-third of its travel before pressing the starter

button, the choke control should not be used.

Warming

up

In order to minimise cylinder wear the engine should be warmed up

quickly when starting from cold in winter

;

the engine may be " idled

"

for a minute to let the oil circulate, but it should not be allowed to idle for

long periods, neither should the engine be raced up to high speeds.

An engine speed of approx.

1,500

r.p.m. may be regarded as a desirable

warming up speed.

9

SPORTS

CAR

DRIVING THE

CAR-The Engine

DRIVING

Gear Changing

For a smooth gear change into a synchronised gear (4th, 3rd & 2nd) the

movement should be slow and deliberate. The gear lever must always be

moved right home to secure full engagement. First and reverse gears are

not synchromesh, gear engagement being achieved by sliding the

respective gear into mesh. To avoid a noisy change do not engage

first gear with the car stationary and the engine revving at a speed greater

than 800

r.p.m., or when

travelling in access of

15

m.p.h.

Do not attempt to engage reverse gear whilst the car is travelling forward,

Desirable Speed Limits (Particularly in gears lower than top)

The engine is capable of" revving " very fast, yet the driver should avoid

continued

"

over-revving," which is most likely to occur in the lower gears.

We strongly recommend that in all gears the driver shall not drive

the car continuously at engine speeds above

4,500 r.p.m. How-

ever, during acceleration in the gears it is permissible to

attain

5,000 r.p.m. for short periods, which speed is indicated

by the red mark on the tachometer.

NEW ENGINES (see running adjustments)

During the early stages of a new vehicle's life, for at least the first 500 miles

(800

km.), the working surfaces of the engine will be bedding down. The

power and performance will improve only if during the running-in period

the vehicle is carefully driven at moderate speeds.

We recommend that the engine should be driven at speeds not exceeding 3,500

engine

r.p.m. during this period, and suggest that

"

running-in " should be

progressive. No harm is done if the engine is allowed to

"

rev " fairly fast

so long as it is thoroughly warm and provided it is not

pulling hard.

Do not

let the engine pull hard at low speeds, always select a lower gear.

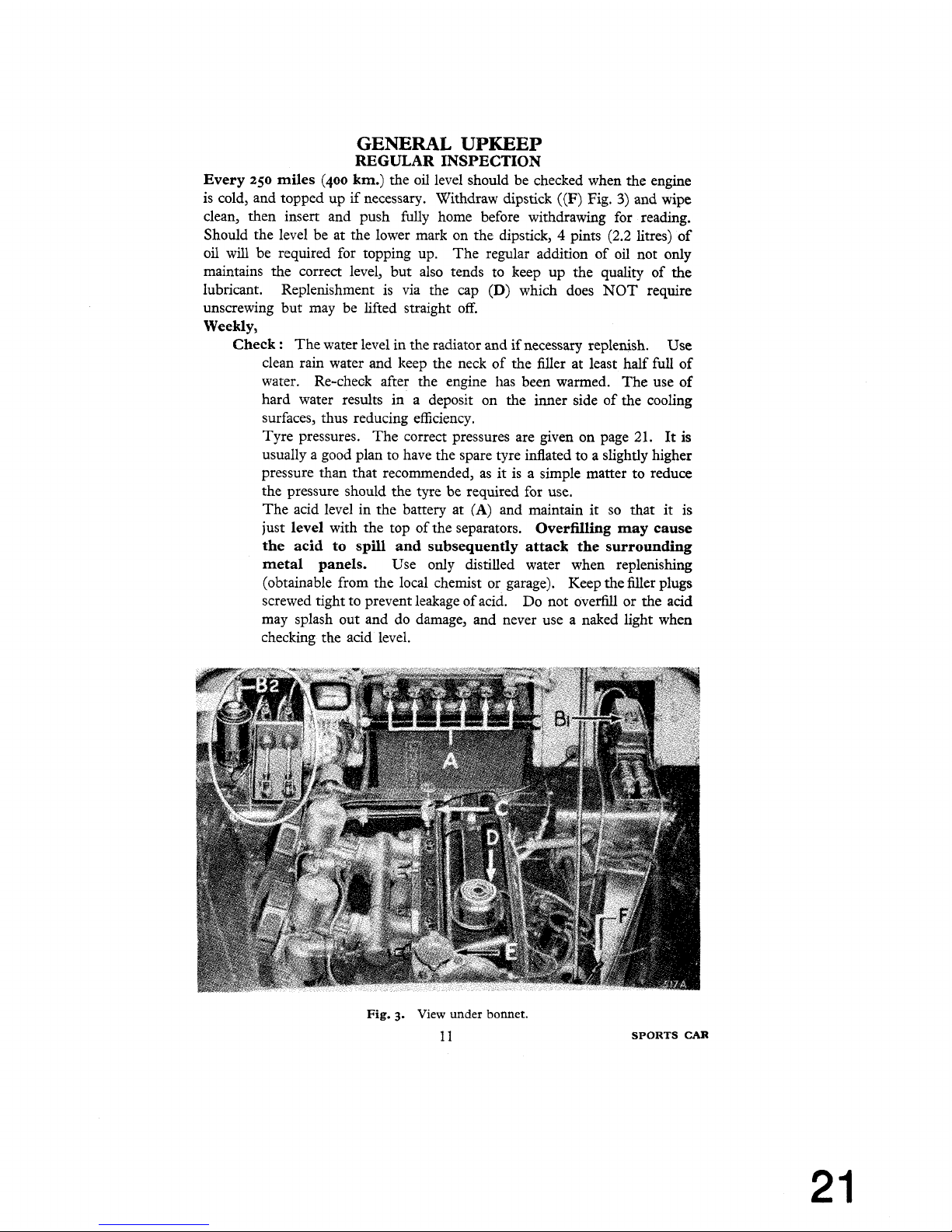

GENERAL UPKEEP

REGULAR INSPECTION

Every

250

miles

(400

km.)

the oil level should be checked when the engine

is cold, and topped up if necessary. Withdraw dipstick

((F)

Fig.

3)

and wipe

clean, then insert and push fully home before withdrawing for reading.

Should the level be at the lower mark on the dipstick,

4

pints

(2.2

litres) of

oil

will

be required for topping up. The regular addition of oil not only

maintains the correct level, but also tends to keep up the quality of the

lubricant. Replenishment is via the cap

(D)

which does

NOT

require

unscrewing but may be lifted straight off.

Weekly,

Check

:

The water level in the radiator and if necessary replenish.

Use

clean rain water and keep the neck of the filler at least half full of

water.

Re-check after the engine has been warmed. The use of

hard water results in a deposit on the inner side of the cooling

surfaces, thus reducing efficiency.

Tyre pressures. The correct pressures are given on page

21.

It

is

usually a good plan to have the spare tyre inflated to a slightly higher

pressure than that recommended, as it is a simple matter to reduce

the pressure should the tyre be required for use.

The acid level in the battery at

(A)

and maintain

it

so that it is

just

level

with the top of the separators.

Overfilling may cause

the acid to spill and subsequently attack the surrounding

metal panels.

Use only distilled water when replenishing

(obtainable from the local chemist or garage).

Keep the filler plugs

screwed tight to prevent leakage of acid. Do not

overfill or the

acid

may splash out and do damage, and never use a naked light when

checking the acid level.

Fig.

3.

View

under

bonnet.

11

SPORTS

CAR

GENERAL

UPKEEP-Cooling System and Lubrication

COOLING

SYSTEM

Filling

(see page 11).

Draining

For the purpose of draining, taps are provided in the bottom tank of the

radiator and at the rear of the cylinder block on the right-hand side. As

the cooling system is pressurised it will be necessary, when draining, to

remove the radiator

cap

(E),

Fig.

3.

If a heater is fitted, ensure that the cock is open before draining.

Anti-Freeze Mixtures

We recommend the use of Smith's " Bluecol," Duckham's Anti-freeze,

Esso Anti-freeze or Shell

"

Snowflake " Anti-freeze (inhibited Glycol

base compound) in order to protect the cooling system during frosty

weather and reduce corrosion to a minimum. The cooling system is

fitted with a thermostat and there is a risk of the radiator block freezing

while the engine is running during the warming up period when the

thermostat is shut, even though the car has been left in a warm garage

and water is not frozen at the start of the

run.

We recommend that you provide for the cooling system ample protection

against a sudden fall in temperature down to

0"

F.

(-18"

C.)

during

frosty weather by using

3

pints of anti-freeze.

In countries where sub-zero temperatures prevail, consult your Triumph

dealer regarding the quantity of anti-freeze required.

It is inadvisable to use anti-freeze for more than one season since

the inhibitor becomes exhausted and the components in contact

with the cooling water may corrode.

LUBRICATION

This

is

one of the most important subjects

in

connection with the upkeep of

a

car, and careful attention to the following instructions will be amply repaid by

the results obtained

For the recommended periods of lubrication, see the lubrication chart

folded inside the rear cover of this book.

The

correct lubricants to be

used are given on pages

51

and

52.

GENERAL UPKEEP-Lubrication

Draining

To drain the engine, gearbox and rear axle, remove the plug provided

beneath each unit. This process is assisted by opening the filler to allow

ingress of air and by draining when the oil is hot,

i.e.,

immediately after

a run.

ENGINE

Only first quality oils are recommended for use in the engine sump. These are

each of the correct viscosity and character to

afford complete

lubrication

protection.

Additives which dilute the oil or otherwise impair this protection

must not be used.

After many thousands of

miles

running the rate of oil

consumption

will increase. When the rate becomes higher than 1 gallon per

1,000 miles

(1

litre per 400 km.), it will be desirable to use the next heavier

grade of the brand of oil you normally employ.

Engine

Oil

Drain Period

The frequency of the drain period should be related to the driving

conditions to which the vehicle is subjected. A period of

3,000

miles

(5,000 km.) is recommended as the interval for average driving conditions

as defined below.

It

should be reduced for unfavourable conditions

and may

be

extended for definitely favourable conditions.

Favourable

Long distance journeys,

with

little or no engine idling, on well surfaced

roads, reasonably free from dust.

Average

Medium length journeys on well surfaced roads with a small

proportion

of stop/start operation.

Unfavourable

Any of the following

:

(a)

Frequent stop/start driving.

(b)

Operation during cold weather, especially when appreciable

engine idling is involved.

(c)

Where much driving is done under dusty conditions.

We have found the use of an upper cylinder lubricant to be an advantage,

particularly in new engines, and recommend the use of such

a

lubricant,

particularly

until

the engine is thoroughly

cc

run-in." The lubricant should

be mixed with the fuel in the proportions given on the container. Such

lubricants

may

be used with advantage throughout the life of the vehicle,

particularly during wintry weather.

13

SPORTS

CAR

GENERAL UPKEEP-Lubrication

Carburettors

Every 6,000 miles (10,000

km.)

unscrew the brass hexagon plug

in the top of each of the carburettors and top up with current

engine oil to the level of the

inner hollow shaft. Apply oil

also to the throttle linkages on

the engine, do not oil the bearings of the transverse rod attached to the scuttle as this will

seriously deteriorate the sealing

composition.

The

Oil Cleaner

The oil cleaner has been designed to filter the oil to a very

fine degree and the only attention it requires is to see that the

filtering cartridge

(B)

is removed and that a new replacement cartridge is fitted at periods

not exceeding 6,000 miles

(10,000

km.).

Later models

employ a

"

full-flow " cleaner,

and since a very

"fine"

filter

Fig.

4.

Oil

Cleaner

"

full-flow"

type.

cartridge is fitted it is important that this operation is carried out,

otherwise, as the filter becomes choked,

unfiltered oil will be passed to

the engine via the balance valve in

the cleaner. To renew the cartridge,

unscrew the securing

bolt and remove the container, the cartridge can

then be withdrawn. On some models it may be necessary to unclip and

swing the crankcase breather tube rearwards to provide sufficient room

for container removal.

Wipe out the container to remove foreign matter trapped by the filter,

using a non-fluffy cloth, and inspect afterwards to make certain that no

cloth fibres remain.

It may be desirable to discard the old container washer

(A),

replacing it

with a new one each time the cartridge is renewed. When re-assembling

the container, ensure that the washer is correctly positioned in the groove

in the filter body. Do not tighten the bolt

(C)

more than is necessary

to obtain an oil-tight joint.

Approximately one pint of oil will be lost due to the removal of the con-

tainer, and the sump should be topped up with new oil after assembly.

GENERAL UPKEEP-Lubrication

The container should not be disturbed until cartridge renewal is required

;

as the accumulated dirt on the outside of the container may fall inside

and thus be carried into the bearings when the engine is re-started.

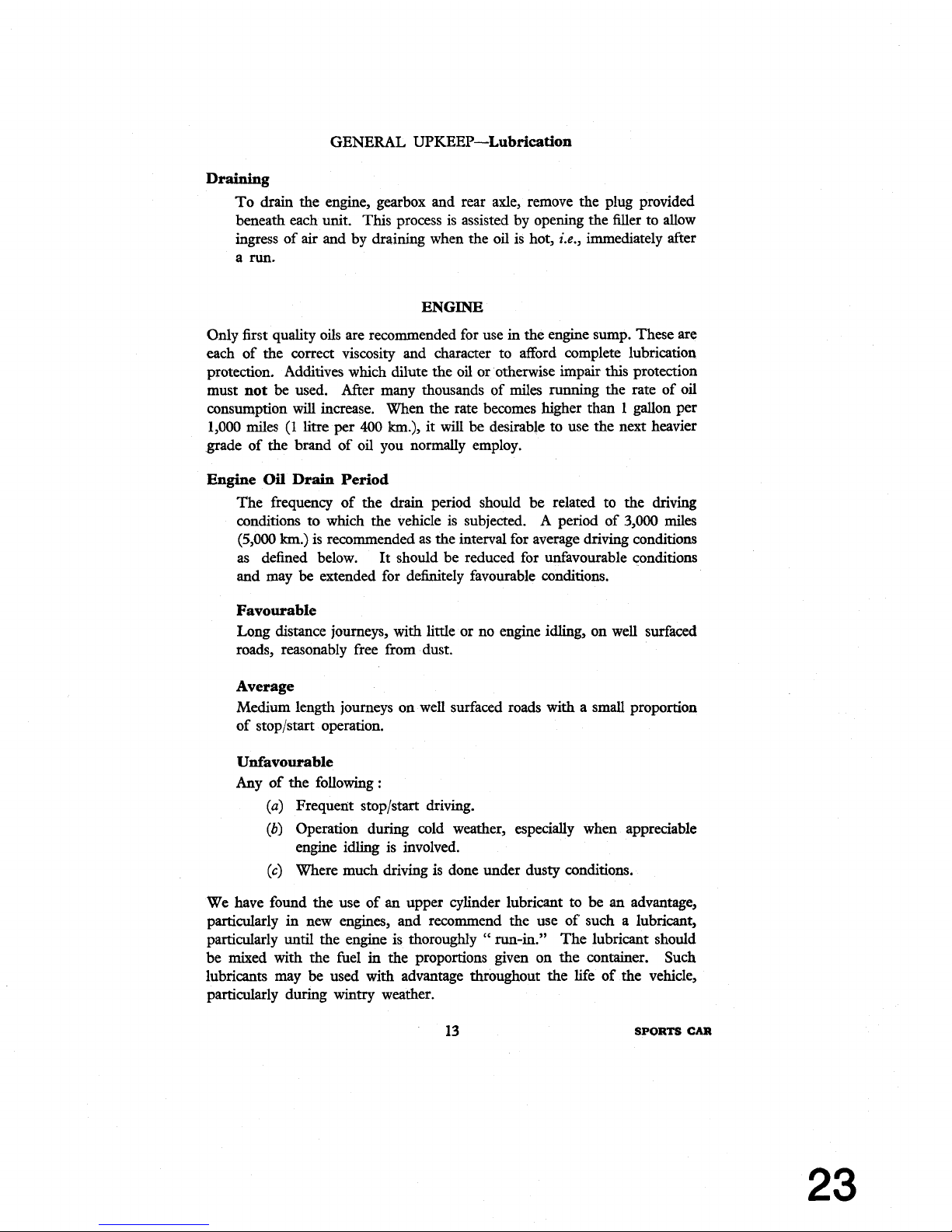

Ignition Distributor

(see Fig.

5)

Every 6,000 miles (10,000 km.), the cam

(B)

should be smeared lightly

with engine oil.

A

pronounced squeak occurs when the cam is quite dry.

Withdraw the moulded rotor arm from the top of the spindle and apply a

few drops or

thin

machine oil around the edge of the screw

(A)

to

lubricate the cam bearings and distributor spindle.

At

the same time, place

a single drop of clean engine oil on the pivots

(C)

and

(D).

Fig.

5.

Ignition distributor.

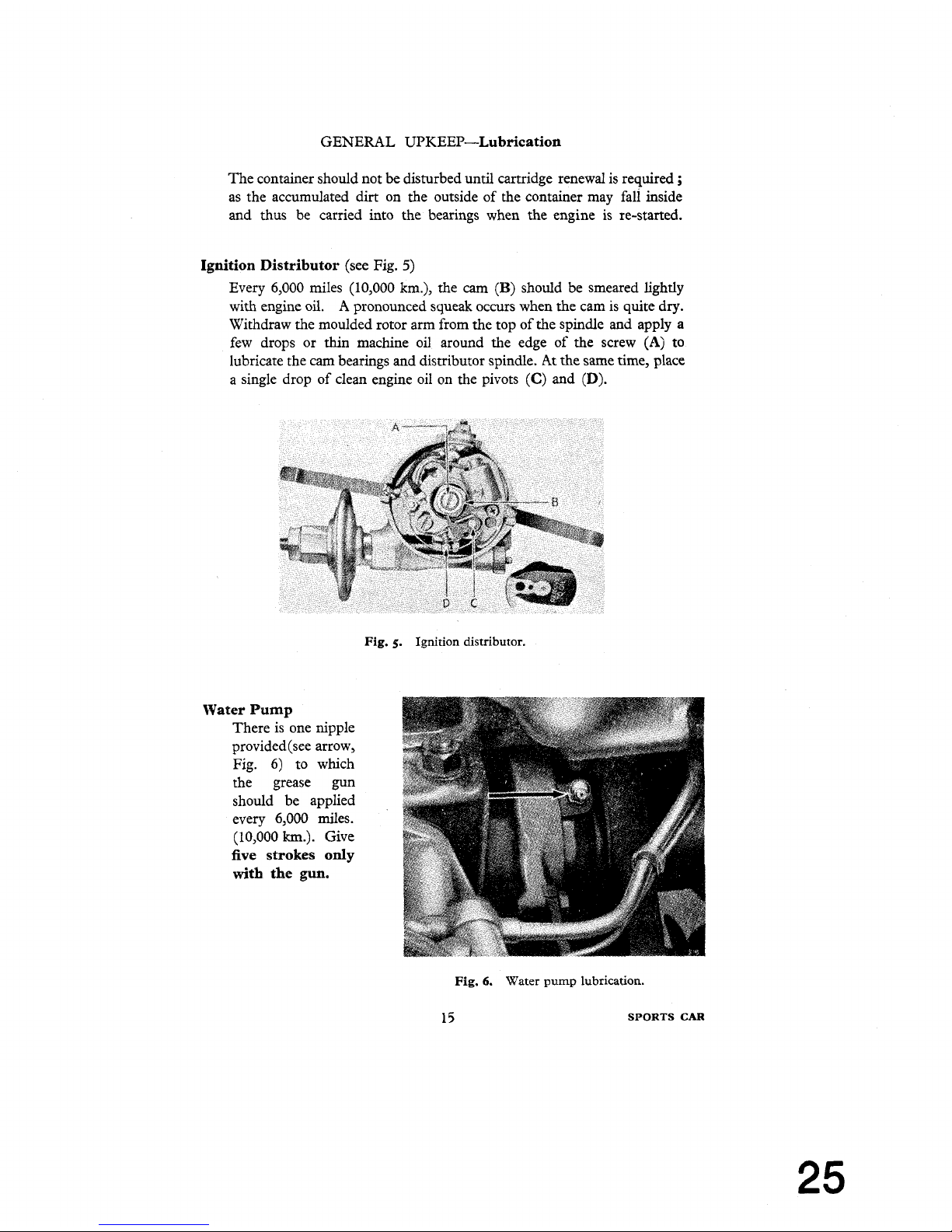

Water

Pump

There is one nipple

provided (see arrow,

Fig. 6) to which

the grease gun

should be applied

every 6,000 miles.

(10,000

km.).

Give

five strokes only

with

the

gun.

Fig.

6.

Water

pump

lubrication.

15

SPORTS

CAR

GENERAL UPKEEP-Lubrication

Dynamo and Starter

The dynamo front bearing is packed with grease before leaving the works,

and after a considerable mileage the dynamo should be removed for cleaning, adjustment and repacking of the bearing with grease. This

should

be done preferably by the nearest Triumph or Lucas Service Depot. Every

12,000 miles (20,000 km.) pour a few drops of engine oil through the hole

in the centre of the rear end cap. The hole

is sealed from dust with a

small rubber plug.

The Starter is fitted with special bearings which require no lubrication.

Air

Cleaners. Every 6,000 miles (10,000 km.) it is advisable to remove the

air cleaners and wash in petrol, particularly the gauzes, after which soak

the gauzes in oil and allow to drain before finally wiping over

and refitting.

It

is very important to refit the air cleaners in the correct manner. Ensure

that the holes immediately above the setscrew holes in the carburettor

are lined up with the similarly positioned holes in the cleaner.

Oil

Filler Cap. Every 6,000 miles (10,000 km.) remove and swill the cap

in fuel, dry off and re-fit.

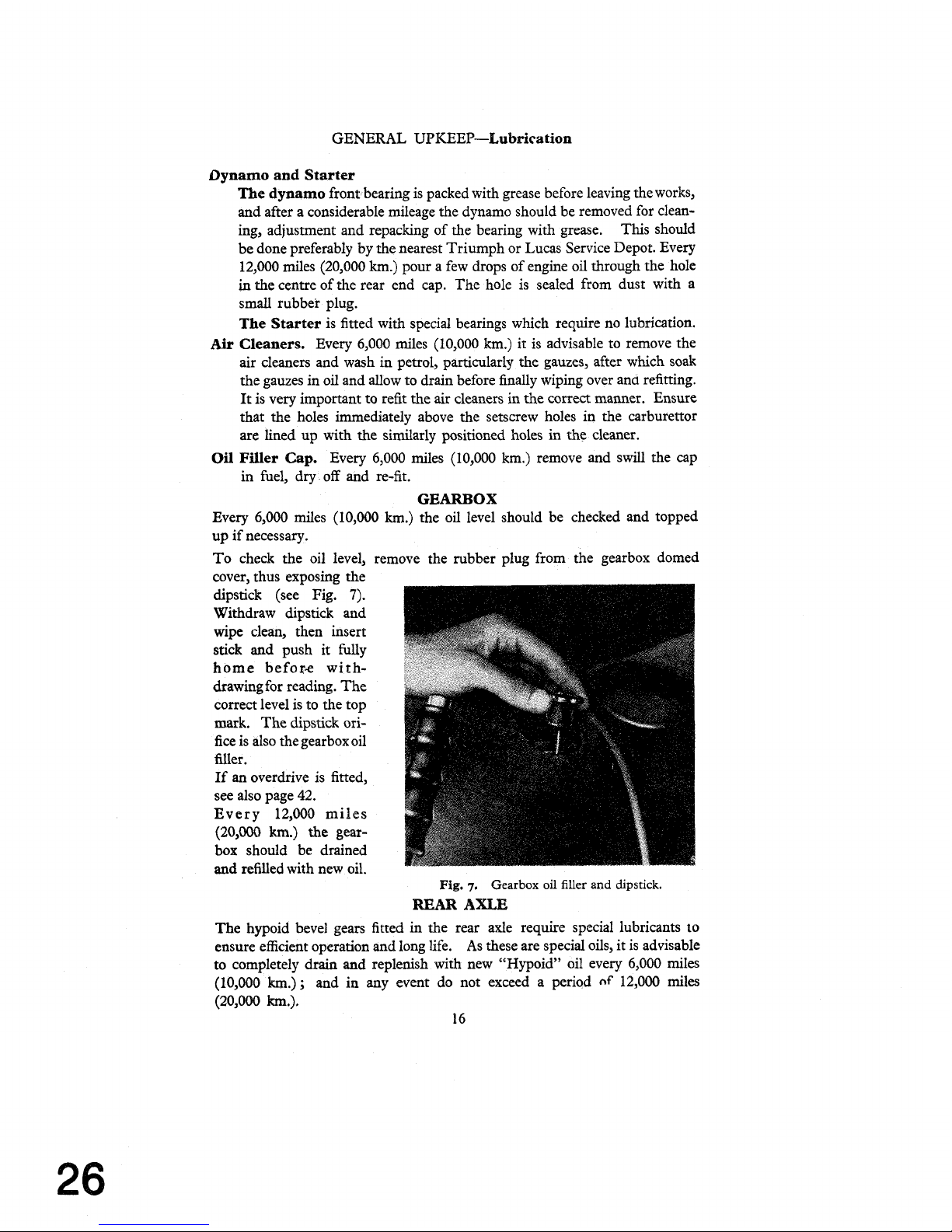

GEARBOX

Every 6,000 miles (10,000 km.) the oil level should be checked and topped

up if necessary.

To check the oil level, remove the rubber plug from the gearbox domed

cover, thus exposing the

dipstick (see Fig.

7).

Withdraw dipstick and

wipe clean, then insert

stick

and push it fully

home before withdrawing

for

reading. The

correct level is to the top

mark. The dipstick orifice is also the gearbox oil

filler.

If

an overdrive is fitted,

see also page 42.

Every 12,000 miles

(20,000

km.)

the gear-

box should be drained

and

refilled with new oil.

Fig.

7.

Gearbox oil filler and

dipstick.

REAR

AXLE

The hypoid bevel gears fitted in the rear axle require special lubricants to

ensure efficient operation and long life.

As these are special oils, it is advisable

to completely drain and replenish with new

"Hypoid" oil every 6,000

miles

(10,000

km.);

and in any event do not exceed a period

nf

12,000 miles

(20,000

km.).

16

GENERAL UPKEEP-Lubrication

It is advisable to have the oil level checked during this period, and especially

after the first 1,000 miles, and replenish if necessary to level with the bottom

of the threads in the filler orifice. Should a top-up be necessary, investigate

the cause of

oil

loss. The filler plug is accessible from underneath the

car,

being fitted to the rear axle cover (see arrow A Fig.

8).

Clean away mud

before unscrewing the filler plug to avoid grit

falling

into the axle.

BRAKE

AND

CLUTCH OPERATION

It is important that the filler cap on the combined hydraulic fluid reservoir,

integral with the master cylinders (see arrow BI or B2 Fig.

3,

page ll),

should be removed every 6,000 miles (10,000

km.),

the fluid level checked and

topped up

if

necessary. The reservoir should be filled to within one inch

(2.5

cm.) of the top, and never less than half

full

(see page 51 or 52 for the

correct fluid).

Later models with disc brakes have a circular reservoir which has an inner

chamber

;

this supplies the clutch operation mechanism. The correct fluid

level is to the top of this

inner chamber.

As

the cups in the master and all operating cylinders are pure rubber, it is

imperative to use only the recommended special fluid. Mineral oils would,

in

a very short time, distort and ruin them.

Clutch Shaft Bearings

The grease

gun

should be applied to the clutch shaft bearing grease nipples

(one at each side of the clutch housing) every 6,000 miles (10,000

km.).

One

shot only is sufficient. The nipples are accessible from underneath the

car.

[See arrow

(C),

Fig.

19,

page

311.

Clutch

and

Brake Pedal Bearings

The oil

can

should be applied to the various pivots, etc., of the pedal linkages,

both under the

bowet and

in

the driving compartment.

Fig,$.

Rear

axle

oil filler and handbrake compensator.

17

SPORTS

CAR

GENERAL

UPKEEP-Lubrication

Handbrake Cable Conduit

A

grease nipple is fitted in the conduit, as shown in the lubrication chart, to

which the grease gun should be applied every 6,000

miles (10,000 km.).

During the winter

months it is very important to keep the cable regularly

lubricated, as this prevents the entry of water which on cold nights will freeze,

thus locking the brake cable.

When lubricating the cable, grease is forced both ways and the gun should be

pumped until grease exudes at the end of the conduit.

Handbrake Compensator

Two grease nipples are provided on the compensator which is situated on

the rear axle casing (see arrow

B,

Fig.

8).

Front

ROAD

WHEEL HUBS

Recharging the hubs with grease on later models involves removing

the hubs, washing the bearings to remove all traces of the old grease

before liberally coating the rollers and races with new grease. This

should be carried out every 12,000 miles (20,000 km.). Where disc

brakes are fitted do not disturb the pipe unions but unbolt and move

the complete caliper, to

allow the hub and

disc to be removed, taking

care not to loose shims which may be fitted between the caliper and

the vertical link.

When replacing, ensure that the

inner race is tight against its shoulder.

Tighten the hub

nut until resistance is felt to hub rotation, then slacken

off

the nut by one flat of the hexagon and fit the split pin. This work

should

be preferably undertaken by your local Triumph agent who has

the necessary equipment for the task.

If

disc brakes are fitted

and the car is being used in competitions,

slacken off the hub nut one half flat and insert the split pin through one of

the two holes provided.

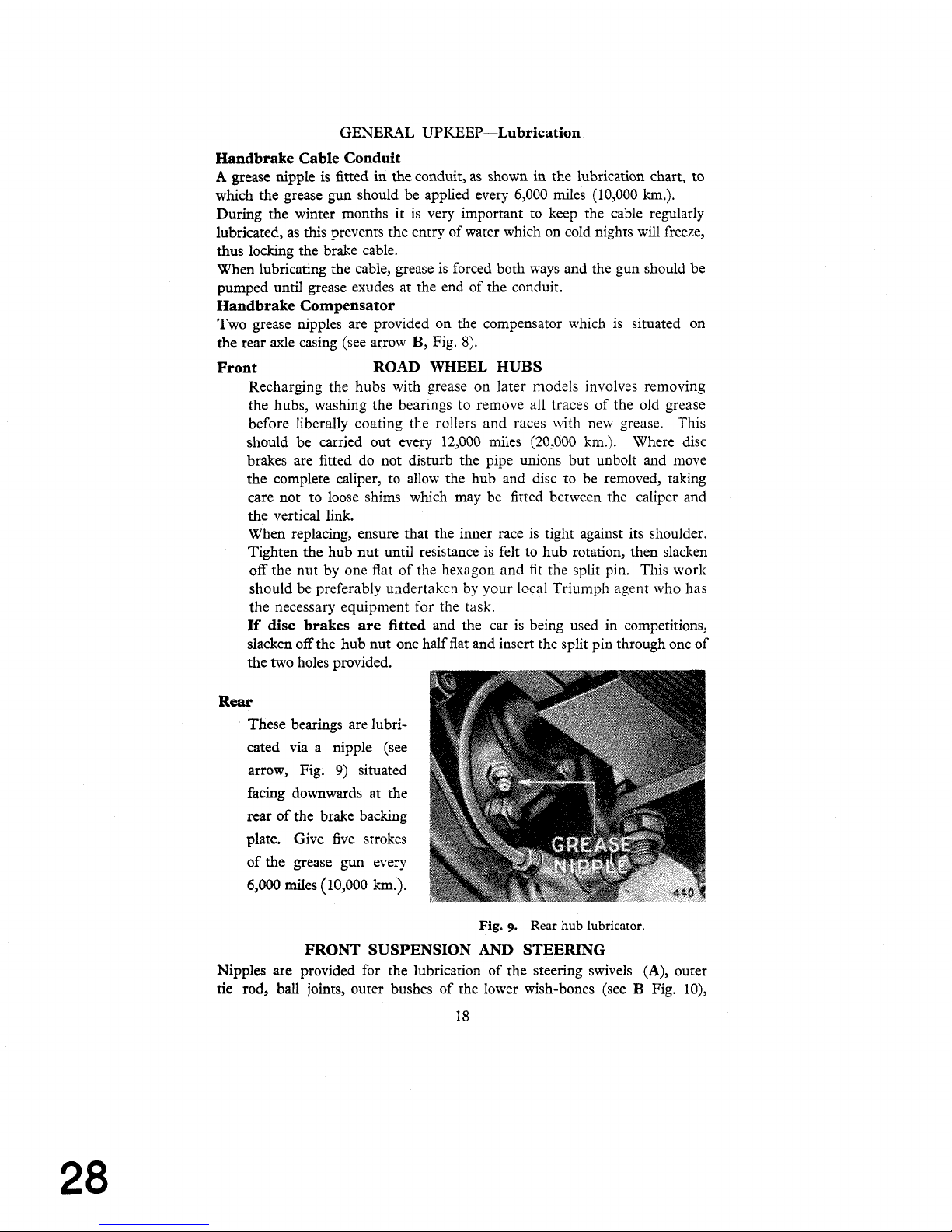

Rear

These bearings are lubricated via a nipple (see

arrow, Fig.

9)

situated

facing downwards at the

rear of the brake backing

plate. Give five strokes

of the grease

gun

every

6,000

miles

(10,000

km.).

Fig.

9.

Rear hub lubricator.

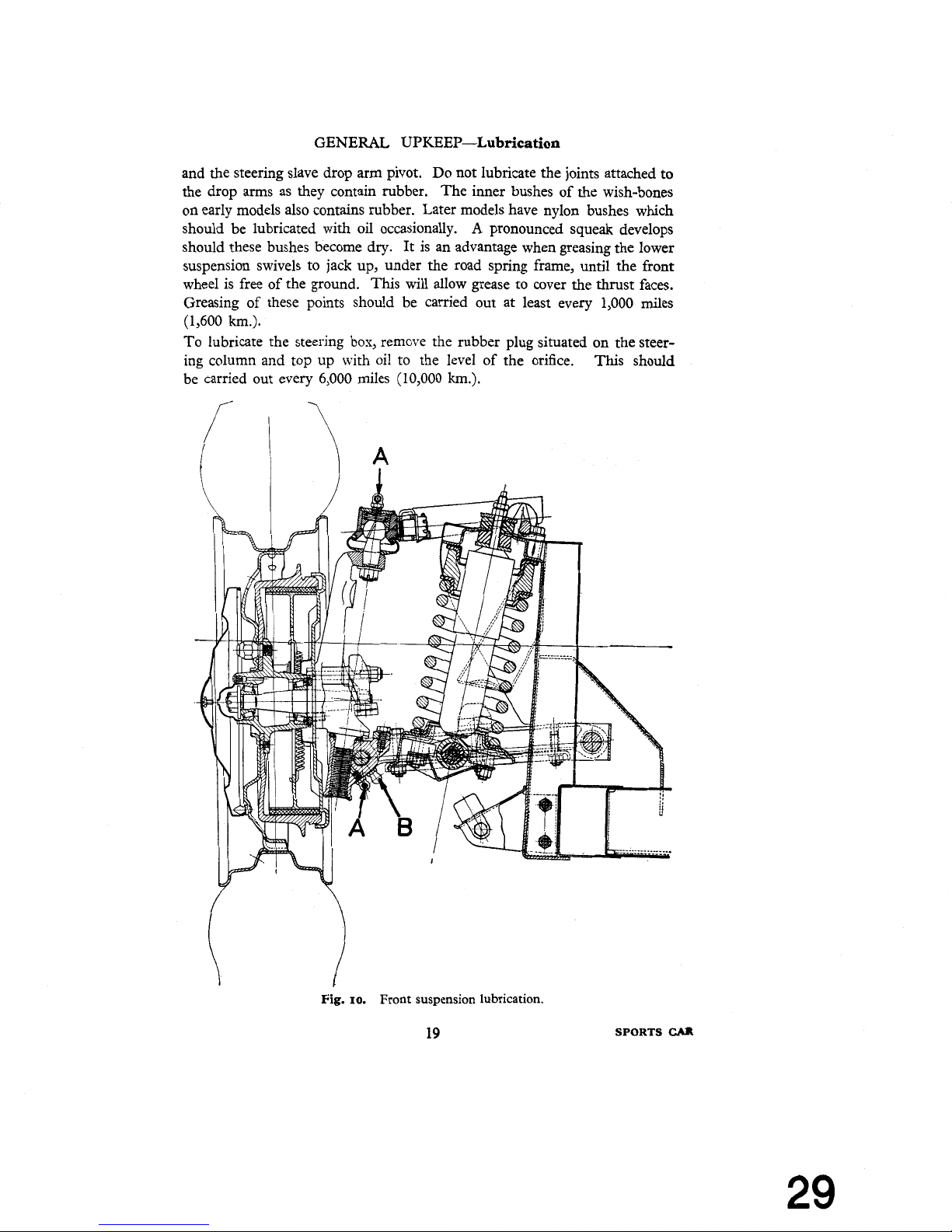

FRONT SUSPENSION

AND

STEERING

Nipples are provided for the lubrication of the steering swivels (A), outer

tie rod, ball joints, outer bushes of the lower wish-bones (see

B

Fig. 10),

GENERAL UPKEEP-Lubrication

and the steering slave drop arm pivot. Do not lubricate the joints attached to

the drop arms as they contain rubber. The inner bushes of the wish-bones

on early models also contains rubber. Later models have nylon bushes which

should be lubricated with oil occasionally.

A

pronounced squeak develops

should these bushes become dry. It is an advantage when greasing the lower

suspension swivels to jack up, under the road spring frame, until the front

wheel is free of the ground. This will allow grease to cover the thrust faces.

Greasing of these points should be carried out at least every 1,000 miles

(1,600 km.).

To lubricate the steering box, remove the rubber plug situated on the steering column and top up with oil to the level of the orifice. This should

be carried out every 6,000 miles (10,000

km.).

Fig.

1

10.

Front suspension

lubrication.

SPORTS

CAR

GENERAL UPKEEP-Lubrication

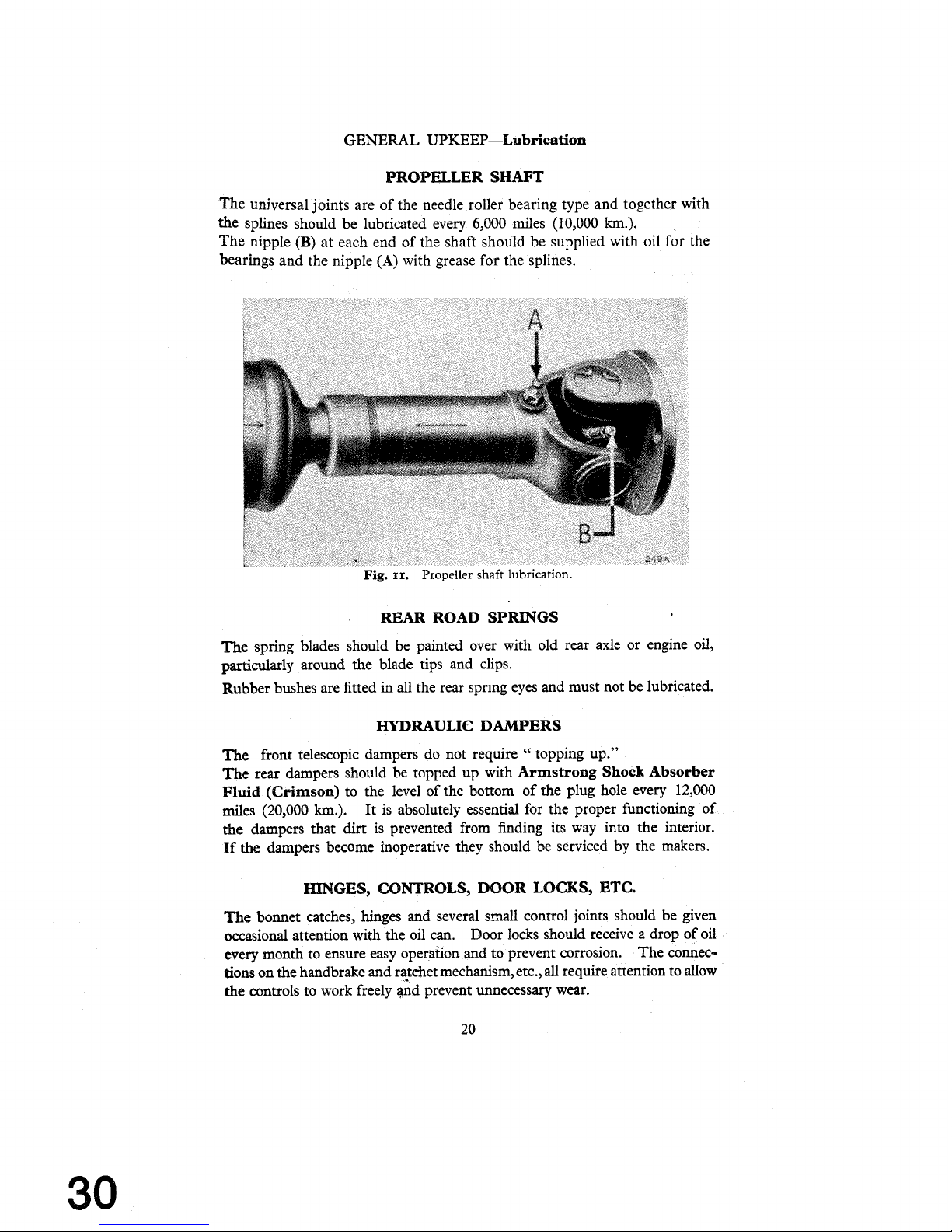

PROPELLER SHAFT

The universal joints are of the needle roller bearing type and together with

splines should be

the

The nipple

bearings and the nipple

(B)

at each end of the shaft should be supplied with oil for the

lubricated every 6,000 miles (10,000

(A)

with grease for the splines.

km.).

REAR

The spring blades should be painted over with old rear axle or engine oil,

particularly around the blade tips and clips.

Rubber bushes are fitted in all the rear spring eyes and must not be lubricated.

ROAD SPRINGS

HYDRAULIC DAMPERS

The

front telescopic dampers do not require " topping up."

The rear dampers should be topped up with

Fluid

(Crimson)

miles (20,000

the dampers that

If

the dampers become inoperative they should be serviced by the makers.

to the level of the bottom of the plug hole every

km.).

It is absolutely essential for the proper functioning of

dirt

is prevented from finding its way into the interior.

Armstrong Shock Absorber

12,000

HINGES, CONTROLS, DOOR LOCKS, ETC.

The bonnet catches, hinges and several S-all control joints should be given

occasional attention with the oil

every month to ensure easy operation and to prevent corrosion. The connections on the handbrake and

the controls to work freely

can.

Door locks should receive a drop of oil

r+&et mechanism, etc., all require

pd prevent unnecessary wear.

attention to allow

Loading...

Loading...