TRIUMPH 1050 Service Manual

iiu e

Motorcycle anual

1

Part Number T3856080 issue 1, 03.2005

This document is protected by copyright and may not, in whole or part be stored in a retrieval system, or

transmitted in any form or by any means, copied, photocopied, translated or reduced to any machine-readable

form without prior consent in writing from Triumph Motorcycles Limited.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care

has been taken to make it as complete and accurate as possible.

Triumph Motorcycles Limited reserves the right to make changes and alter specifications without prior notice and

without incurring an obligation to make such changes to products manufactured previously. See your authorised

Triumph Dealer for the latest information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of

publication. Illustrations in this publication are intended for reference use only and may not depict actual model

component parts.

@

Triumph Motorcycles Ltd 2005

* From VIN 21 0445 onwards.

I

--

Service Manual - Speed Triple

i

Table of Contents

Introduction

General Information

Scheduled Maintenance

Cylinder Head

Clutch

Crankshaft, Connecting Rods and Pistons

Balancer

Transmissiow

Lubrication

ngine RemovallRefit

Fuel SystemlEngine Management

Cooling

Rear Suspension

Front Suspension

Brakes

WheelsKyres

Frame and Bodywork

Electrical

Service

Manual

-

Speed Triple

This page intentionally left blank

Service

Manual - Speed Triple

Service Manual - Speed Triple

iii

This manual is designed primarily for use by trained

technicians in a properly equipped workshop.

However, it contains enough detail and basic

information to make it useful to the owner who desires

perform his own basic maintenance and repair

to

work. The work can only be carried out if the owner

has the necessary hand and special service tools to

complete the job.

A basic knowledge of mechanics, including the proper

use of tools and workshop procedures is necessary in

order to carry out maintenance and repair work

satisfactorily. Whenever the owner has insufficient

experience or doubts his ability to do the work, an

authorised Triumph dealer must undertake all

adjustments, maintenance, and repair work.

In order to perform the work efficiently and to avoid

costly mistakes, read the text and thoroughly

familiarise yourself with procedures before starting

work.

All work should be performed with great care and in a

clean working area with adequate lighting.

Always use the correct special service tools or

equipment specified. Under no circumstances use

makeshift tools or equipment since the use of

substitutes may adversely affect safe operation.

Where accurate measurements are required, they

can only be made using calibrated, precision

instruments.

For the duration of the warranty period, an authorised

Triumph Dealer must perform all repairs and

scheduled maintenance.

To maximise the life of your Motorcycle:

Accurately follow the maintenance requirements

of the periodic maintenance chart in the service

manual.

Do not allow problems to develop. Investigate

unusual noises and changes in the riding

characteristics of the motorcycle. Rectify all

problems as soon as possible (immediately if

safety related).

How to use this manual

To assist in the use of this manual, the section title is

given at the top.

Each major section starts with a contents page, listing

the information contained in the section.

The individual steps comprising repair operations are

to be followed in the sequence in which they appear.

Adjustment and repair operations include reference to

service tool numbers and the associated illustration

depicts the tool.

Where usage is not obvious, the tool is shown in use.

Adjustment and repair operations also include

reference to wear limits, relevant data, torque figures,

specialist information and useful assembly details.

Warning, Caution and Note

Particularly important information is presented in the

following form:

I

This warning symbol identifies special instructions

or procedures which, if not correctly followed, could

result in personal injury, or loss of life.

A

This caution symbol identifies special instructions or

I

procedures which, if not strictly observed, could

I

result in damage to or destruction of equipment.

Note:

This note symbol indicates points of

particular interest for more efficient and

convenient operation.

Caution

/

/

I

c

f'

(,

,

Use only genuine Triumph parts as listed in the

cataloguelparts microfiche.

parts

Follow the procedures in this manual carefully

and completely. Do not take short cuts.

Keep complete records of all maintenance and

repairs with dates and any new parts installed.

Use only approved lubricants, as specified in the

owner's handbook, in the maintenance of the

motorcycle.

Service Manual - Speed Triple

Introduction

I

Tampering with Noise Control

System Prohibited

Owners are warned that the law may prohibit:

a) The removal or rendering inoperative by any

person other than for purposes of maintenance,

repair or replacement, of any device or element

of design incorporated into any new vehicle for

the purpose of noise control prior to its sale or

delivery to the ultimate purchaser or while it is in

use; and

b) the use of the vehicle after such device or

element of design has been removed or rendered

inoperative by any person.

Whenever tapping to aid removal of an item is

necessary, tap lightly using a hide or plastic faced

mallet.

Edges

Watch for sharp edges, especially during engine

disassembly and assembly. Protect the hands with

industrial quality gloves.

When replacement parts are required, it is essential

that only genuine Triumph parts are used.

Safety features and corrosion prevention treatments

embodied in the motorcycle may be impaired if other

than genuine Triumph parts are fitted. In certain

territories, legislation prohibits the fitting of parts not

to the manufacturer's specification.

References

1

References to the left-hand or right-hand side given in

this manual are made when viewing the motorcycle

from the rear.

Operations covered in this manual do not always

include reference to testing the motorcycle after

repair. It is essential that work is inspected and tested

after completion and if necessary a road test of the

motorcycle is carried out particularly where safety

related items are concerned.

Tightening procedure

Generally, when installing a part with several bolts,

nuts or screws, they should all be started in their

holes and tightened to a snug fit, evenly and in a

cross pattern. This is to avoid distortion of the part

andlor causing gas or oil leakage. Conversely, bolts,

nuts, or screws, should all be loosened (in sequence if

specified) by about a quarter of a turn and then

removed.

Where there is a tightening sequence specified in this

Dimensions

The dimensions quoted are to design engineering

specification with service limits where applicable.

During the period of running-in from new, certain

adjustments may vary from the specification figures

given in this manual. These will be reset by the dealer

at the 500

be maintained at the figures specified in this manual.

J

mile1800 km service, and thereafter should

Repairs and Replacements

Before removal and disassembly, thoroughly clean the

motorcycle. Any dirt entering the engine or other parts

will work as an abrasive and shorten the life of the

motorcycle. Particular attention should be paid when

installing a new part, that any dust or metal filings are

cleared from the immediate area.

Service Manual, the bolts, nuts, or screws must be

tightened in the order and by the method indicated.

Torque wrench setting figures given in this Manual

must be observed. The torque tools used must be of

accurate calibration.

Locking devices, where specified, must be fitted. If the

efficiency of a locking device is impaired during

removal it must be renewed. This applies particularly

to micro-encapsulated fixings which must always be

replaced if disturbed. Where necessary, the text in

this manual will indicate where such a fixing is used.

Force

Common sense should dictate how much force is

necessary in assembly and disassembly. If a part

seems especially difficult to remove or install, stop

and examine what may be causing the problem.

Never lever a component as this will cause damage

both to the component itself and to the surface being

levered against.

Service Manual - Speed Triple

This page intentionally left blank

Sewice Manual - Speed Triple

Table of Contents

Ignition System Safety Precautions

DangerousSusbstances

Fluoroelastomers

Oils

............................................................................

(

i

I

,

Health Protection Precautions 1-3

Environmental Protection Precautions

Brakes

Safetylnstructions 1-5

FuelHandlingPrecautions 1-7

..........................................................................

Jackingandlifting 1-5

Precautionsagainstdamage 1-5

Coolant 1-5

Cleaningcomponents

Lubrication 1-6

Jointsandjointfaces 1-6

Gaskets, O-rings

Liquid gasket, non-permanent locking agent

ScrewThreads

Locking Devices 1-7

Fitting a split pin 1-7

Circlips, retaining rings

Selflockingnuts 1-7

Encapsulatedbolt 1-7

Oilandgreaseseals 1-7

Press 1-7

Ballbearing 1-7

General

Petrol-Gasoline

Fueltankremoval

Chassisrepairs

ElectricalPrecautions 1-9

Batterydisconnecting 1-9

Disciplines 1-9

Electrical wires

Inspection

Replacementparts

Servicedata

Specification 1-10

....................................................................

.....................................................................

....................................................................

..................................................................

.................................................................

............................................................

............................................................

................................................................

............................................................

.........................................................

.................................................................

.........................................................

.............................................................

..............................................................

.............................................................

.............................................................

.............................................................

............................................................

..........................................................

.................................................................

..........................................................

.............................................................

............................................................

..............................................................

..............................................................

.........................................................

.............................................................

..........................................................

...............................................................

...............................................................

...................................................

.

.

..................................................

.................................................

...................................................

.......................................

........................................................

1-3

1-3

1-3

1-3

1-4

1-4

1-6

1-6

1-6

1-6

1-7

1-7

1-8

1-8

1-8

1-10

1-10

1-10

1-10

Service Manual . Speed Triple

Service Tools and Garage Equipment

Special Service Tools 1-11

Engine

CylinderHeadValves

Camshafts

Clutch / Primary Drive 1-17

Balancer

Pistons

Connecting Rods

Crankshaft

Transmission 1-19

FinalDrive 1-19

Lubrication

Ignitionsystem

Fuelsystem

FuellnjectionSystem

Emissions Controls* 1-20

Coolantsystem

Suspension 1-21

Brakes

WheelsandTyres

Frame

Electrical Equipment 1-22

TorqueWrenchSettings

CylinderHeadArea

Clutch

Balancer, Crankshaft and Crankcase 1-23

Enginecovers

Transmission

Lubrication System 1-24

CoolingSystem

Fuel System, Exhaust System and Airbox

Rearsuspension

Frontsuspension

Wheels

FrontBrakes 1-27

RearBrakes

Frame, Footrests, Control Plates and Engine Mountings

Electrical

Bodywork

Clutchcablerouting 1-29

Throttlecablerouting

Main wiring harness routing 1-31

Frontbrakehoserouting 1-32

Rearbrakehoserouting

Fueltankbreath'erhoserouting 1-34

....................................................................

.................................................................

...................................................................

....................................................................

.................................................................

...............................................................

..................................................................

.................................................................

................................................................

.................................................................

.....................................................................

.....................................................................

.....................................................................

...............................................................

alDrive,.

..................................................................

....................................................................

...............................................................

................................................................

..................................................................

..................................................................

..............................................................

.........................................................

.........................................................

........................................................

............................................................

.............................................................

........................................................

..........................................................

.............................................................

...........................................................

.........................................................

..........................................................

..........................................................

..............................................................

..........................................................

--

.............................................................

............................................................

............................................................

.............................................................

........................................................

..........................................................

..........................................................

................................................

............................................

...

-

-

...

-

.

..

-

~

....

..-

-...

~~

.

.-

.

.

.........................................

.............................

.....................................................

...--.

...

1-1 1

1-16

1-16

1-17

1-17

1-18

1-18

1-18

1-19

1-20

1-20

1-20

1-20

1-21

1-21

1-22

1-23

1-23

1-23

1-24

1-24

3-25,

1-25

1-25

1-26

1-26

1-26

1-27

1-27

1-28

1-28

1-30

1-33

(

.

Service Manual . Speed Triple

General Information

I

I

Ignition System Safety Precautions

The ignition system produces extremely high

voltages. Do not touch any part of the ignition

system or any cables while the engine is running.

An electric shock caused by contact with the ignition

system may lead to illness, injury or death.

Wearers of surgically implanted heart pacemaker

devices should not be in close proximity to ignition

circuits and or diagnostic equipment.

The ignition system and any diagnostic equipment

may interrupt the normal operation of such devices

causing illness or death.

Dangerous Susbstances

Manv liauids and other substances used in motor

.

vehicles are poisonous and should under no

circumstances be consumed and should, as far as

possible, be kept from contact with the skin. These

substances among others include acid, anti-freeze,

asbestos, brake fluid, fuel, lubricants, and various

adhesives. Always pay close attention to the

instructions printed on labels and obey the

instructions contained within. These instructions

are included for your safety and well-being.

NEVER DISREGARD THESE INSTRUCTIONS!

.

Fluoroelastomer material is used in the manufacture

of various seals in Triumph motorcycles.

In fire conditions involving temperatures greater

315OC

than

then be potentially hazardous. Highly toxic and

corrosive decomposition products, including

hydrogen fluoride, carbonyl fluoride, fluorinated

olefins and carbon monoxide can be generated and

will be present in fumes from fires.

In the presence of any water or humidity hydrogen

fluoride may dissolve to form extremely corrosive

liquid hydrofluoric acid.

If such conditions exist, do not touch the material

and avoid all skin contact. Skin contact with liquid or

decomposition residues can cause painful and

penetrating burns leading to permanent, irreversible

skin and tissue damage.

this material will decompose and can

Oils

I

The ennine and bevel box oils mav be hot to the

touch. Contact with hot oil may cause the skin to be

scalded or burned.

I

Prolonged or repeated contact with engine oil can

lead to skin dryness, irritation and dermatitis. In

addition used engine oil contains potentially harmful

contaminants which can cause cancer. Wear

suitable clothing and avoid skin contact.

I

I

Sewice

Manual

Health Protection Precautions

*

Avoid prolonged and repeated contact with oils,

particularly used engine oils.

Wear protective clothing, including impervious

gloves where practicable.

*

Do not put oily rags in pockets.

*

Overalls must be cleaned regularly. Discard

heavily soiled clothing and oil impregnated

footwear.

*

First aid treatment should be obtained

immediately for open cuts and wounds. Always

-

Speed Triple

1.3

be aware of who your nearest first-aider is and

where the medical facilities are kept.

Use barrier creams, applying before each work

period to protect the skin from the effects of oil

and grease and to aid removal of the same after

completing work.

Wash with soap and water to ensure all oil is

removed (skin cleansers and nail brushes will

help). Preparations containing lanolin replace the

natural skin oils which have been removed.

Do not use petrol, kerosene, diesel fuel, gas oil,

thinners or solvents for cleaning skin.

If skin disorders develop, obtain medical advice

without delay.

Where practicable, de-grease components prior

to handling.

Any risk of eye injury must be avoided. Always wear

eye protection when using a hammer, air line,

cleaning agent or where there is ANY risk of flying

debris or chemical splashing.

rakes

Brake fluid is hygroscopic which means it will absorb

moisture from ;he air: Any absorbed moisture will

greatly reduce the boiling point of the brake fluid

causing a reduction in braking efficiency.

Replace brake fluid in line with the routine

maintenance schedule. A dangerous riding

condition could result if this important maintenance

item is neglected!

Do not spill brake fluid onto any area of the

bodywork as this will damage any painted or plastic

surface.

Always use new brake fluid from a sealed container

and never use fluid from an unsealed container or

from one that has been previously opened.

Do not mix different brands of fluid. Check for fluid

leakage around brake fittings, seals and joints.

Check regularly for brake hose damage.

FAILURE TO OBSERVE ANY OF THE ABOVE

WARNINGS MAY REDUCE BRAKING

EFFICIENCY LEADING TO AN ACCIDENT.

recautions

drains, or into water courses. To prevent pollution of

water-courses etc., dispose of used oil sensibly. If in

doubt contact your local authority.

Burning of used engine oil in small space heaters or

boilers can be recommended only for units of

approved design. If in doubt, check with the

appropriate local authority

approved appliance.

Dispose. of used oil and used filters through

authorised waste disposal contractors, to licensed

waste disposal sites, or to the waste oil reclamation

trade. If in doubt, contact your local authority for

advice on disposal facilities.

andlor manufacturer of the

If there has been an appreciable drop in the level of

the fluid in either brake fluid reservoir, consult your

1

applied, or if the leverlpedal travel becomes

excessive, there may be air in the brake lines or the

brake may be defective.

It is dangerous to operate the motorcycle under

such conditions and remedial action must be taken

by your authorised Triumph dealer before riding the

motorcycle.

Failure to take remedial action may reduce braking

efficiency leading to an accident.

in the

The use of brake fluids other than those

fluids listed in the general information section may

reduce the efficiency of the braking system leading

to an accident.

I

Failure to change the brake fluid at the interval

specified in the routine maintenance schedule may

reduce braking efficiency resulting in an accident.

general information section of this manual.

0.0.7.

1

4

Service Manual - Speed Triple

Never use mineral based grease in any part of the

braking system or in any area where contact with

the braking system is possible. Mineral based

grease will damage the hydraulic seals in the

calipers and master cylinders.

Damage caused by contact with mineral based

grease may reduce braking efficiency resulting in an

accident.

Safety Instructions

Jacking and lifting

General Information

Coolant

"

c

'

--

,.

A-warning

-

"

Coolant mixture, which is blended with anti-freeze

and corrosion inhibitors contains toxic chemicals

which are harmful to the human body. Never

swallow anti-freeze, corrosion inhibitors or any of the

I

motorcycle coolant.

Do not remove the radiator cap when the engine is

hot. When the engine is hot, the coolant inside the

radiator is hot and also under pressure. Contact

with the pressurised coolant will cause scalds and

skin damage.

'

3

,

I

?-

-.

'

I)

s-

,

Always ensure that any lifting apparatus has

adequate load and safety capacity for the weight to

be lifted. Ensure the motorcycle is well supported to

prevent any possibility of the machine falling prior

during lifting or jacking or while repairs and servicing

are carried out.

Never rely on a single means of support when

workin'g with the motorcycle. Use additional safety

supports and straps to prevent toppling.

Do not leave tools, lifting equipment, spilt oil, etc. in

a place where they could become a hazard to

health. Always work in a clean, tidy area and put all

tools away when the work is finished.

The coolant anti-freeze contains a corrosion

inhibitor which helps prevent damage to the metal

surfaces inside the cooling system. Without this

inhibitor, the coolant would 'attack' the metals and

the resulting corrosion would cause blockages in the

cooling system leading to engine overheating and

damage. Always use the correct anti-freeze as

specified in the Owner's Handbook. Never use a

methanol based anti-freeze as this does not contain

the required corrosion inhibition properties.

A

Caution

Precautions against damage

1

I

Avoid spilling brake fluid or battery acid on any part of

the bodywork. Wash spillages off with water

immediately.

Disconnect the battery earth lead before starting

work, see

Always use the recommended service tool where

specified.

Protect exposed bearing and sealing surfaces, and

screw threads from damage.

ELECTRICAL PRECAUTIONS.

(see specification for anti-freeze) in the cooling

system.

If hard water is used in the system, it causes scale

accumulation in the water passages, and

considerably reduces the efficiency of the cooling

system. Reduced cooling system efficiency may

lead to the engine overheating and engine damage.

Service

Manual

-

Speed Triple

Cleaning components

A high flash-point solvent is recommended to reduce

fire hazard.

Always follow container directions regarding the use

of any solvent.

Always use the recommended cleaning agent or

equivalent.

Do not use degreasing equipment for components

containing items which could be damaged by the use

of this process. Whenever possible, clean

components and the area surrounding them before

removal. Always observe scrupulous cleanliness

when cleaning dismantled components.

Lubrication

Liquid gasket, non-permanent locking agent

Follow manufacturer's directions for cleaning and

preparing surfaces where these compounds will be

used. Apply sparingly as excessive amounts of sealer

may block'engine oil passages and cause serious

damage.

Prior to reassembly, blow through any pipes, channels

or crevices with compressed air.

To prevent injury, always use eye, face and ear

protection when using compressed air. Always wear

protective gloves if the compressed air is to be

directed in

proximity.to the skin.

(

\

The majority of engine wear occurs while the engine

is warming up and before all the rubbing surfaces

have an adequate lubrication film. During assembly,

oil or grease (whichever is more suitable) should be

applied to any rubbing surface, which has lost its

lubrication film. Old grease and dirty oil should be

cleaned off. This is because used lubricants will have

lost some lubrication qualities and may contain

abrasive foreign particles.

Use recommended lubricants. Some oils and greases

in particular should be used only in certain

applications and may be harmful if used in an

application for which they are not intended. This

manual makes reference to molybdenum disulphide

grease in the assembly of certain engine and chassis

AlwaJiS

parts.

before using such special lubricants.

chFck-m~fZt~-Ec3mmeTdati~s

Joints and joint faces

Assemble joints dry unless otherwise specified in this

Manual.

If gaskets

for use; remove all traces of old jointing material prior

to reassembly. Do not use a tool which will damage

the joint faces and smooth out any scratches or burrs

on the joint faces using an oil stone. Do not allow dirt

or jointing material to enter any tapped holes.

andlor jointing compound is recommended

Gaskets, O-rings

Screw Threads

Metric threads to IS0 standard are used.

Damaged nuts, bolts and screws must always be

discarded.

Castellated nuts must not be slackened back to

accept a split-pin, except in those recommended

cases when this forms part of an adjustment.

Do not allow oil or grease to enter blind threaded

holes. The hydraulic action on screwing in the bolt or

stud could split the housing.

Always tighten a nut or bolt to the recommended

torque figure. Damaged or corroded threads can

affectthe-&xqu

Unless specified, threaded fixings must always be

fitted dry (no lubrication).

I

Never lubricate a thread unless instructed to do so.

When a thread of a fixing is lubricated, the thread

friction is reduced. When the fixing is tightened,

reduced friction will cause overtightening and

possible fixing failure.

IA fixing which fails in service could cause1

component detachment leading to loss of control

and an accident.

f

\

I

Do not re-use a gasket or O-ring once it has been in

service. The mating surfaces around the gasket

should be free of foreign matter and perfectly smooth

to avoid oil or compression leaks.

Service Manual - Speed Triple

General Information

11

Locking Devices

Always release locking tabs and fit new locking

washers, do not re-use locking tabs.

Fitting a split pin

Always fit new split-pins of the correct size for the hole

in the bolt or stud. Do not slacken back castle nuts

when fitting split pin, except in those recommended

cases when this forms part of an adjustment.

Always fit new roll pins of an interference fit in the

hole.

Circlips, retaining rings

Replace any circlips and retaining rings that are

removed. Removal weakens and deforms circlips

causing looseness in the circlip groove. When

(

i

installing circlips and retaining rings, take care to

compress or expand them only enough to install

them.

Always use the correct replacement circlip as

recommended in the Triumph parts catalogue.

the original sealing surface cannot be completely

restored.

Protect the seal from any surface which could cause

damage over which it has to pass when being fitted.

Use a protective sleeve or tape to cover the relevant

surface and avoid touching the sealing lip.

Lubricate the sealing lips with a recommended

lubricant. This will help to prevent damage in initial

use. On dual lipped seals, smear the area between

the lips with appropriate grease.

When pressing in a seal which has manufacturer's

marks, press in with the marks facing out.

Seals must be pressed into place using a suitable

driver. Use of improper tools will damage the seal.

Press

A part installed using a press or driver, such as a

wheel bearing, should first be coated with oil or

grease on its outer or inner circumference so that it

will locate smoothly.

Ball bearing

Self locking nuts

Self-locking nuts can be re-used, providing resistance

can be felt when the locking portion passes over the

thread of the bolt or stud.

DO NOT re-use self-locking nuts in critical locations,

e.g. suspension components. Always use the correct

replacement self-locking nut.

When installing a ball bearing, the bearing race which

is an interference fit should be pushed by a suitable

driver. This prevents severe stress or damage to the

load carrying components. Press a ball bearing until it

touches the shoulder in the bore or on the shaft.

Press or drift seals to the depth of its housing, with the

sealing lip facing the lubricant to be retained if the

housing is shouldered, or flush with the face of the

housing where no shoulder is provided.

Encapsulated bolt

An encapsulated bolt can be identified by a coloured

I

section of thread which is treated with a locking agent.

Unless a specified repair procedure states otherwise,

encapsulated bolts cannot be reused and MUST be

replaced if disturbed or removed.

I

Failure to replace an encapsulated bolt could lead to

a dangerous riding condition. Always replace

encapsulated bolts.

Fuel Handling Precautions

General

The following information provides basic precautions

which must be observed if petrol (gasoline) is to be

handled safely. It also outlines other areas of risk

which must not be ignored. This information is issued

for basic guidance only and, if in doubt, appropriate

enquiries should be made of your local Fire Officer.

I

Oil and grease seals

Replace any oil or grease seals that are removed.

Removal will cause damage to an oil seal which, if reused, would cause an oil leak.

Ensure the surface on which the new seal is to run is

I

J

free of burrs or scratches. Renew the component if

Service Manual - Speed Triple

Petrol - Gasoline

When petrol (gasoline) evaporates it produces

150

times its own volume in vapour which when diluted

with air becomes a readily ignitable mixture. The

vapour is heavier than air and will always fall to the

lowest level. It can readily be distributed throughout

any indoor environment by air currents, consequently,

even a small spillage of petrol (gasoline) is potentially

very dangerous.

Petrol (gasoline) is highly flammable and can be

explosive under certain conditions. When opening

the fuel tank cap always observe all the following

items;

Turn the motorcycle ignition switch OFF.

Do not smoke.

Always have a fire extinguisher containing FOAM,

C02, HALON or POWDER close at hand when

handling or draining fuel or fuel systems. Fire

extinguishers must also be present in areas where

fuel is stored.

Always disconnect the vehicle battery, negative

(black) lead first, before carrying out dismantling or

draining work on a fuel system.

Whenever petrol (gasoline) is being handled,

drained, stored or when fuel systems are being

dismantled, make sure the area is well ventilated. All

potential forms of ignition must be extinguished or

.(this

removed

--

--

--

-

includes any ap_plLance witha- pilot

-

--

--

-

--

-- - -

light). Any leadJIamis mu3 be flame-proof and kept

clear of any fuel spillage.

Warning notices must be posted at a safe distance

from the site of the work to warn others that petrol is

being openly handled. The notice must instruct the

reader of the precautions which must be taken.

Failure to observe any of the above warnings may

lead to a fire hazard which could result in personal

injury.

Draining or extraction of petrollgasoline from a

vehicle fuel tank must be carried out in a well

ventilated area.

The receptacle used to contain the

petrol1 gasoline

must be more than adequate for the full amount of

fuel to be extracted or drained. The receptacle

should be clearly marked with its contents, and

placed in a safe storage area which meets the

requirements of local authority regulations.

petrollgasoline has been extracted or drained

When

from a fuel tank, the precautions governing naked

lights and ignition sources should be maintained.

Failure to observe any of the above warnings could

bring about a safety hazard leading to a risk of

personal injury.

Fuel tank removal

Fuel tanks should have a 'PETROL (GASOLINE)

VAPOUR' warning label attached to them as soon as

they are removed from the vehicle. In all cases, they

must be stored in a secured, marked area.

Chassis repairs

If-the-motorcycle-is=involved-in-anraccident=or

collision it must be taken to an authorised Triumph

dealer for repair or inspection. Any accident can

cause damage to the motorcycle, which if not

correctly repaired, may cause a second accident

which may result in injury or death.

The frame must not be modified as any modification

to the frame such as welding or drilling may weaken

the frame resulting in an accident.

No one should be permitted to repair components

associated with

petroilgasoline without first having

specialist training on the fire hazards which may be

created by incorrect installation and repair of items

associated with petrollgasoline.

Repairs carried out by untrained personnel could

bring about a safety hazard leading to a risk of

personal injury.

Service Manual - Speed Triple

General Information

I

Electrical Precautions

The following guidelines are intended to ensure the

safety of the operator whilst preventing damage to the

electrical and electronic components fitted to the

motorcycle. Where necessary, specific precautions

are detailed in the relevant sections of this manual

which should be referred to prior to commencing

repair operations.

-

Equipment

on the motorcycle ensure that the relevant test

equipment is working correctly and any harness or

connectors are in good condition, in particular mains

leads and plugs.

Prior to commencing any test procedure

connectors apart either by using tools

the wiring itself. Always ensure locking mechanisms

are disengaged before removal and note the

orientation to enable correct reconnection. Ensure

that any protective covers and substances are

replaced if disturbed.

Having confirmed a component to be faulty, switch off

the ignition and disconnect the battery negative

(black) lead first. Remove the component and support

the disconnected harness. When replacing the

component keep oily hands away from electrical

connection areas and push connectors home until any

locking mechanism becomes fully engaged.

or<by pulling on

Battery disconnecting

Before disconnecting the battery, switch off all

electrical equipment.

The ignition system produces extremely high

voltages. Do not touch any part of the ignition

system or any cables while the engine is running.

An electric shock caused by contact with the ignition

system may lead to illness, injury or death.

Wearers of surgically implanted heart pacemaker

devices should not be in close proximity to ignition

circuits and or diagnostic equipment.

The ignition system and any diagnostic equipment

may interrupt the normal operation of such devices

causing illness or death.

To prevent the risk of a battery exploding and to

prevent damage to electrical components ALWAYS

disconnect the battery negative (black) lead first.

When reconnecting the battery, always connect the

positive (red) lead first, then the negative (black)

lead. Always disconnect the battery when working

on any part of the electrical system.

Failure to observe the above warnings may lead to

electrical damage and a fire hazard which could

cause personal injury.

Always ensure that battery leads are routed correctly

and are not close to any potential chafing points.

The battery contains harmful materials.

keep children away from the battery whether or not it

is fitted in the motorcycle.

Do not jump start the battery, touch the battery

cables together or reverse the polarity of the cables

as any of these actions may cause a spark which

would ignite battery gasses causing a risk of

personal injury.

-

High Voltage Circuits

H.T. circuits always use insulated pliers. Exercise

caution when measuring the voltage on the coil

terminals while the engine is running, high voltage

spikes can occur on these terminals.

Connectors and Harness

motorcycle is a particularly hostile environment for

electrical components and connectors. Always ensure

these items are dry and oil free before disconnecting

and connecting test equipment. Never force

Whenever disconnecting live

-

The engine of a

Always

Sewice Manual - Speed Triple

Disciplines

Switch off the ignition prior to making any connection

or disconnection in the system. An electrical surge

can be caused by disconnecting 'live' connections

which can damage electronic components.

Ensure hands and work surfaces are clean and free of

grease, swarf, etc. as grease collects dirt which can

cause tracking or high-resistance contacts.

Prior to commencing any test, and periodically during

any test, touch a good earth to discharge body static.

This is because some electronic components are

vulnerable to static electricity.

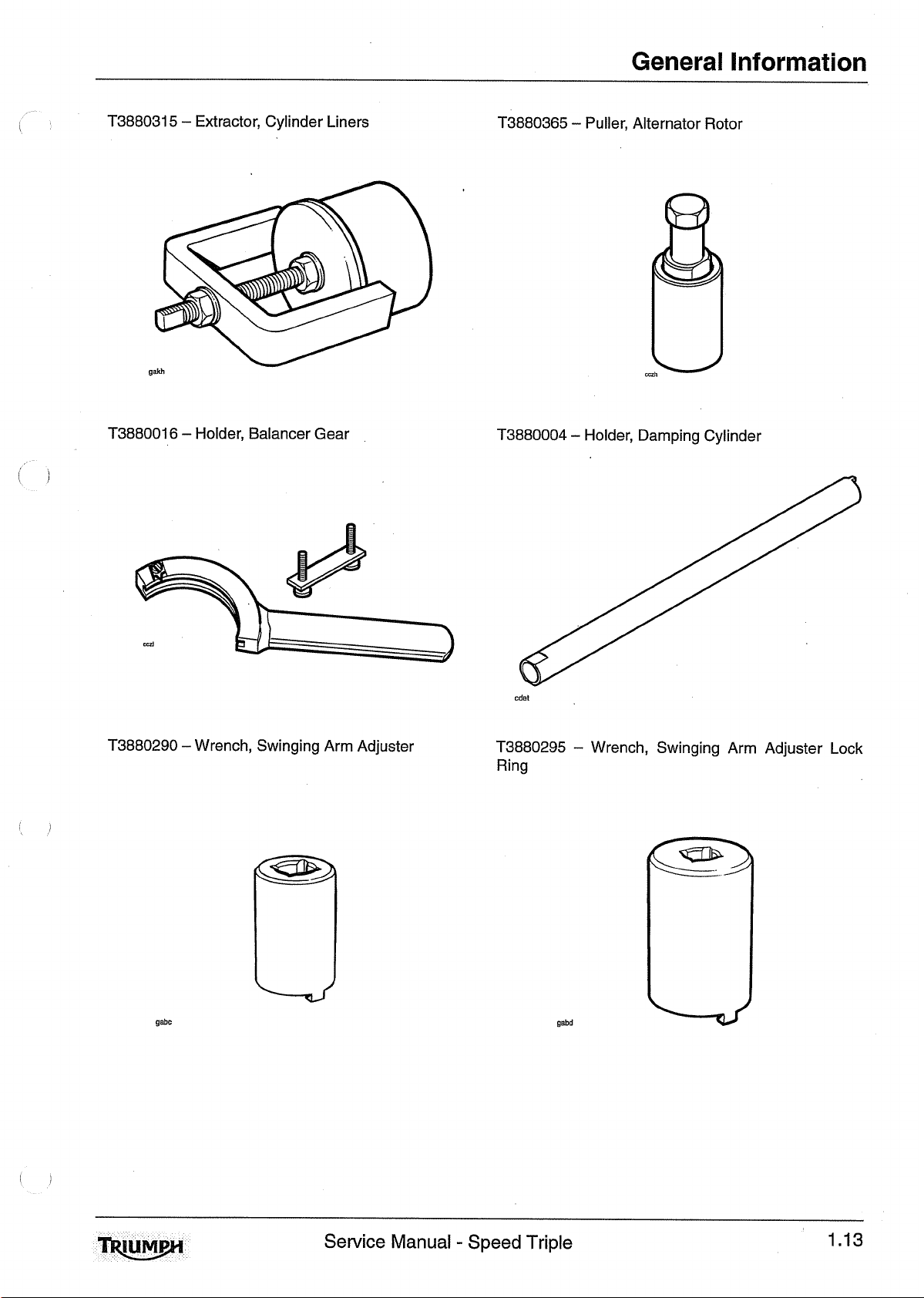

Electrical wires

All the electrical wires are either single-colour or twocolour and, with only a few exceptions, must be

connected to wires of the same colour. On any of the

two-colour wires there is a greater amount of one

colour and a lesser amount of a second colour. A

two-colour wire is identified by first the primary colour

and then the secondary colour. For example, a yellow

wire with thin red stripes is referred to as a

red' wire; it would be a 'redlyellow' wire if the colours

were reversed to make red the main colour.

'yellow1

Inspection

I

Always have Triumph approved parts, accessories

and conversions fitted by a trained technician. To

ensure that a trained technician is used, have an

authorised Triumph dealer fit the parts. The fitment

of parts, accessories and conversions by personnel

other than a trained technician at an authorised

Triumph dealer may affect the handling, stability or

other aspects of the motorcycle operation which

may result in an accident causing serious injury or

death.

Disassembled parts should be visually inspected and

replaced with new ones if there are any signs of the

following:

Abrasions, cracks, hardening, warping, bending,

dents, scratches, colour changes, deterioration,

seizure or damage of any nature.

Replacement Parts

Only Triuniph genuine parts should be used to

service, repair or convert Triumph motorcycles. To

ensure that Triumph genuine parts are used, always

order parts, accessories and conversions from an

authorised Triumph dealer. The fitting of

approved parts, accessories or-conversions-may

adversely affect the handling, stability or other

aspects of the

result in an accident causing serious injury or death:

Always have Triumph genuine parts, accessories

and conversions fitted by an &uthorised Triumph

dealer. The fitment of parts, accessories and

conversions by a dealer who is not an authorised

Triumph dealer may affect the handling, stability or

other aspects of the motorcycle operation which

may result in an accident causing serious injury or

death.

motorcycle operation which may

non-

Service data

The service data listed in this manual gives

dimensions and specifications for brand new, original

parts. Where it is permissible to allow a part to exceed

these figures, then the service limit is given.

The terms of the motorcycle warranty will be

invalidated by the fitting of other than genuine Triumph

parts.

All genuine Triumph parts have the full backing of the

motorcycle warranty. Triumph dealers are obliged to

supply only genuine Triumph recommended parts.

1

Specification

Triumph are constantly seeking to improve the

specification, design and production of their

While every effort has been made to ensure the

accuracy of this Manual, it should not be regarded as

an infallible guide to current specifications of any

particular motorcycle.

Authorised Triumph Dealers are not agents of

Triumph and have no authority to bind the

manufacturer by any expressed or implied

undertaking or representation.

.

ly .---_

-

-

,-

f

(

Sewice Manual - Speed Triple

General Information

Service

Special service tools have been developed to facilitate removal, dismantling and assembly of certain mechanical

components in a practical manner without causing damage. Some operations in this Service Manual cannot be

carried out without the aid of the relevant service tools. Where this is the case, the tools required will be

described during the procedure.

Special

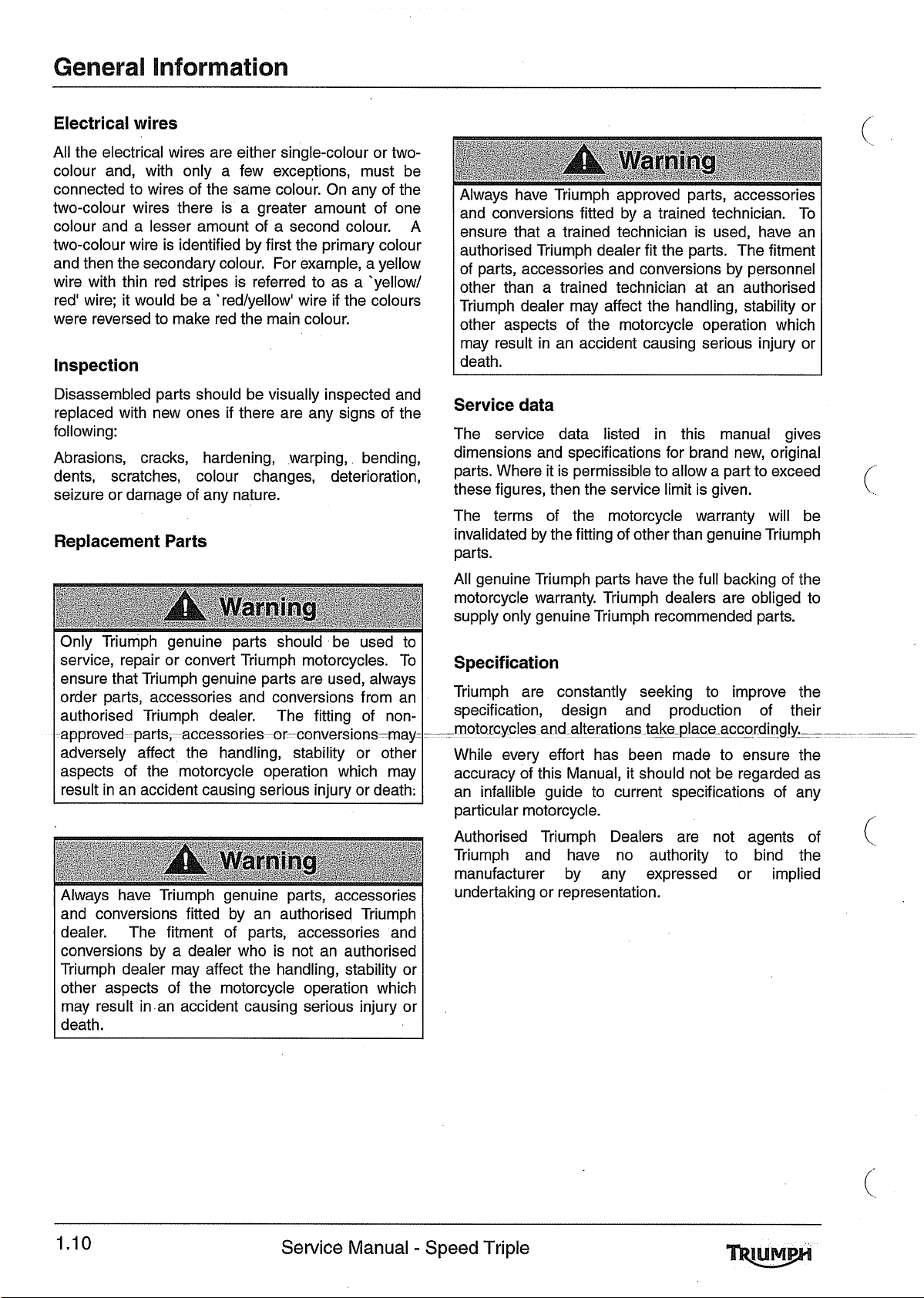

T3880105 - Angular Torque Gauge

Tools

Service

and Garage Equipment

Tools

T3880371

-

Holder, Oil Pump Drive Gear

cbxt

T3880250 - Engine Management Diagnostics

A993801 7

-

Chain Link Took Kit

Service

Manual - Speed Triple

1.1

1

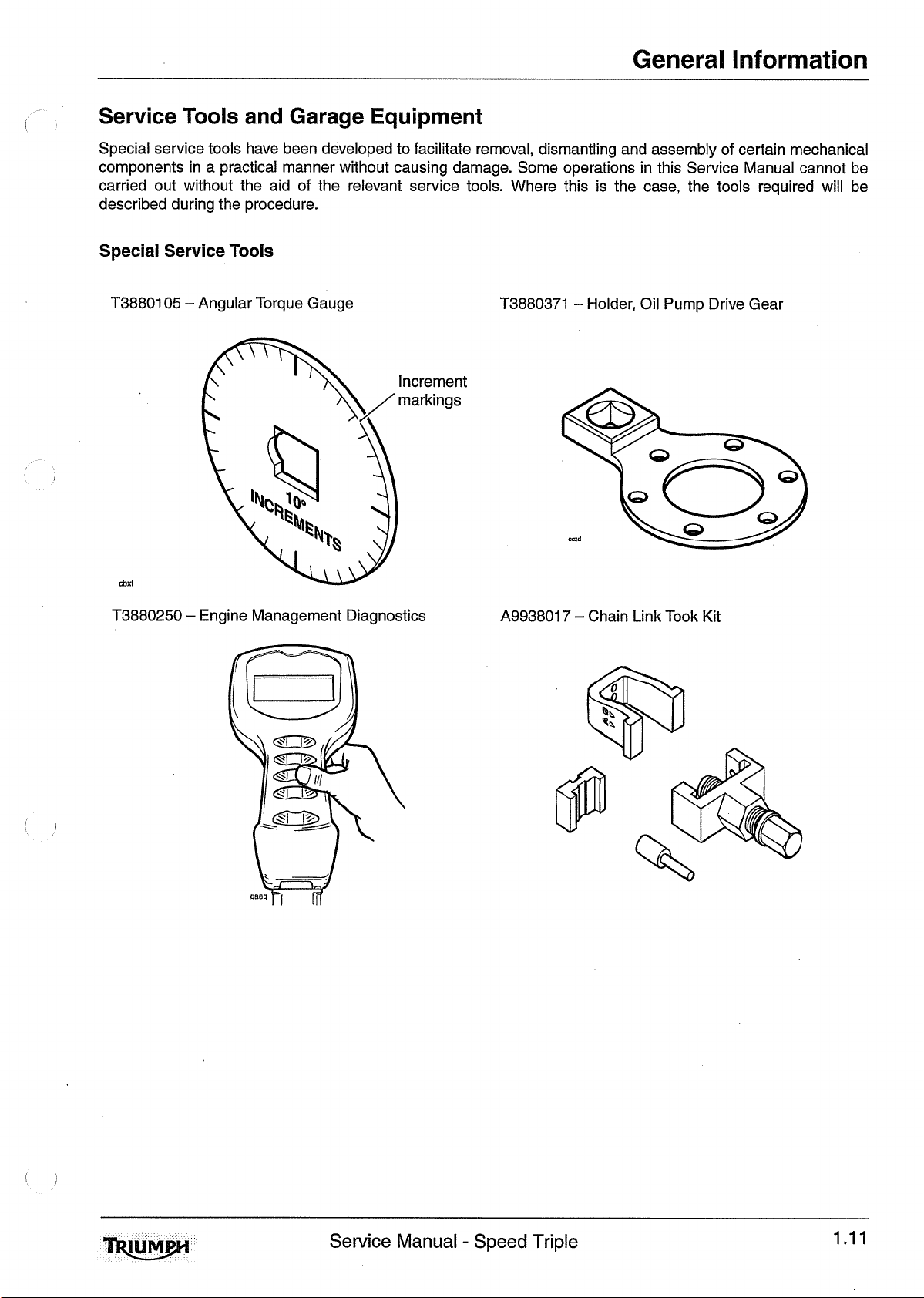

3880085-TO301 - Fork Piston Holder T3880017 - Holder, Sprag Clutch

38801 60-TO301

ccha

T3880375 - Alternator Rotor Holder

-

Fork Filler / Evacuator 13880305 - Clutch Anti-rotation Tool

1.12

Service

Manual

-

Speed Triple

General Information

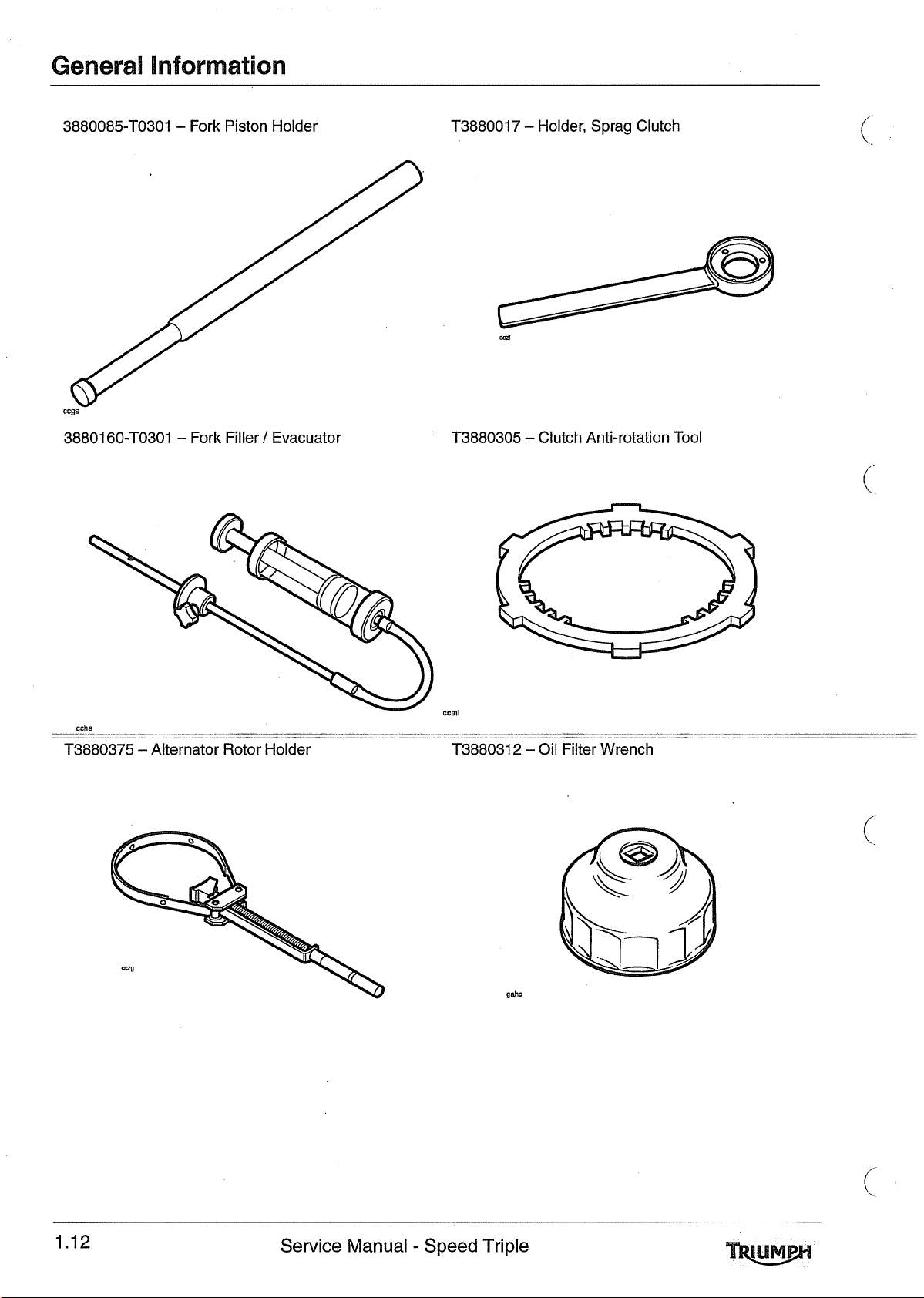

T3880315 - Extractor, Cylinder Liners T3880365 - Puller, Alternator Rotor

-

7-388001 6

Holder, Balancer Gear

-

Holder,

Damping Cylinder

T3880290 - Wrench, Swinging Arm Adjuster

cdet

T3880295

Ring

-

Wrench, Swinging Arm Adjuster Lock

Sewice

Manual

-

Speed Triple

1.13

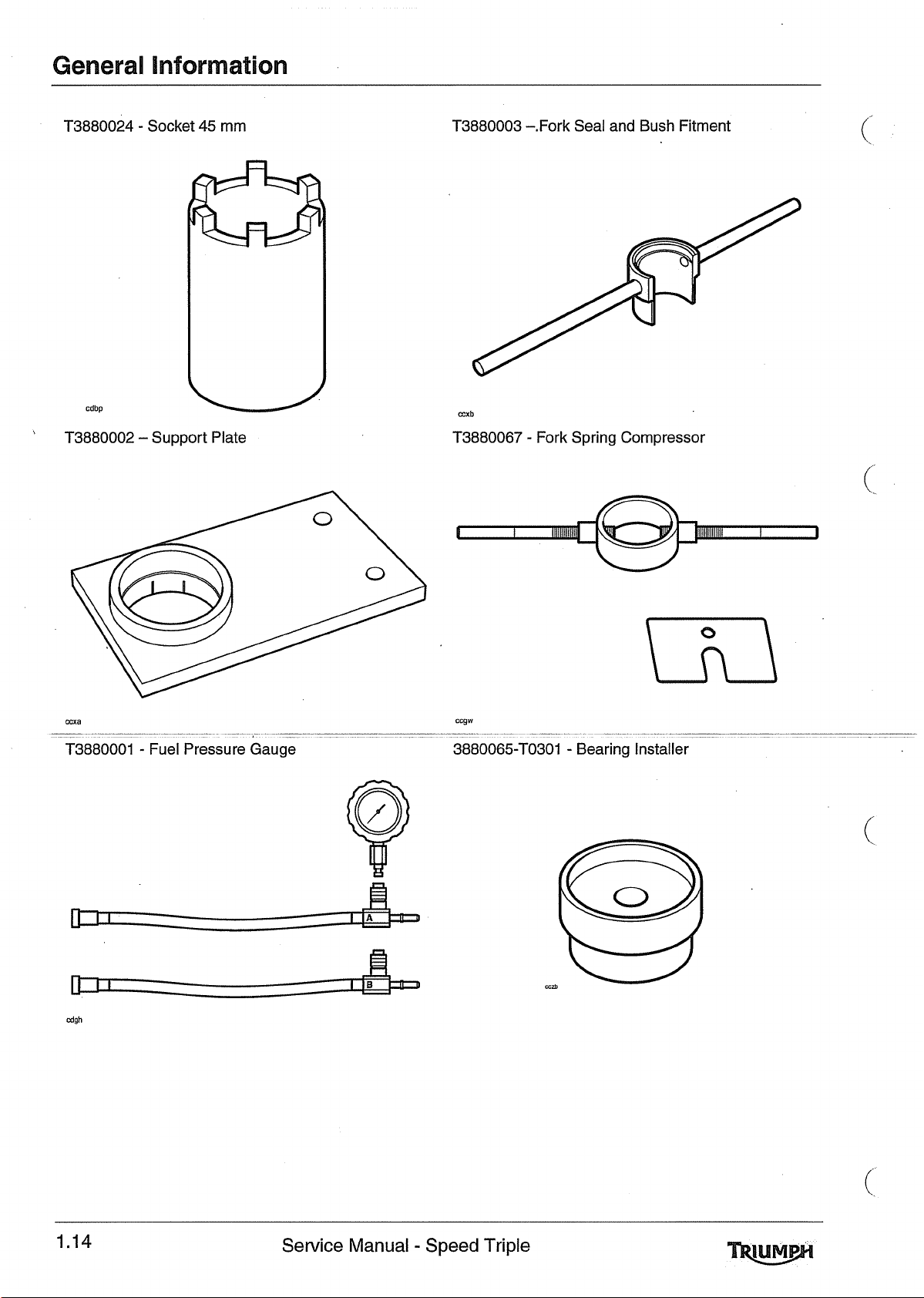

T3880024 - Socket 45 mm

13880003 -.Fork Seal and Bush Fitment

cdbp

'

T3880002 - Support Plate

ffixa

T3880001 - Fuel Pressure Gauge

ffixb

13880067 - Fork Spring Compressor

CqlW

-

3880065-TO301

Bearing Installer

Sewice

Manual

-

Speed Triple

General Information

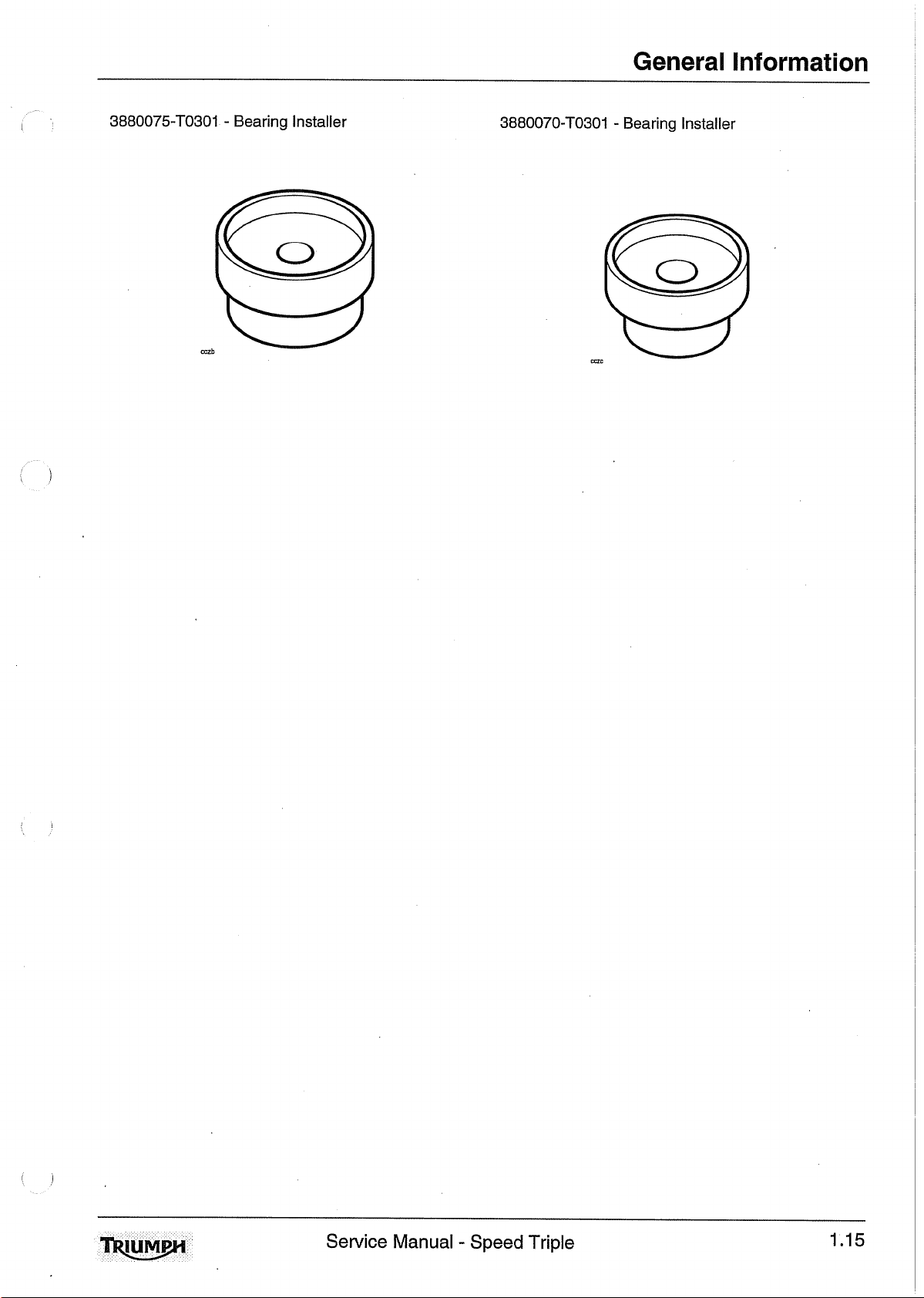

3880075-TO301 - Bearing Installer

3880070-TO301 - Bearing Installer

Service

Manual

-

Speed Triple

1.15

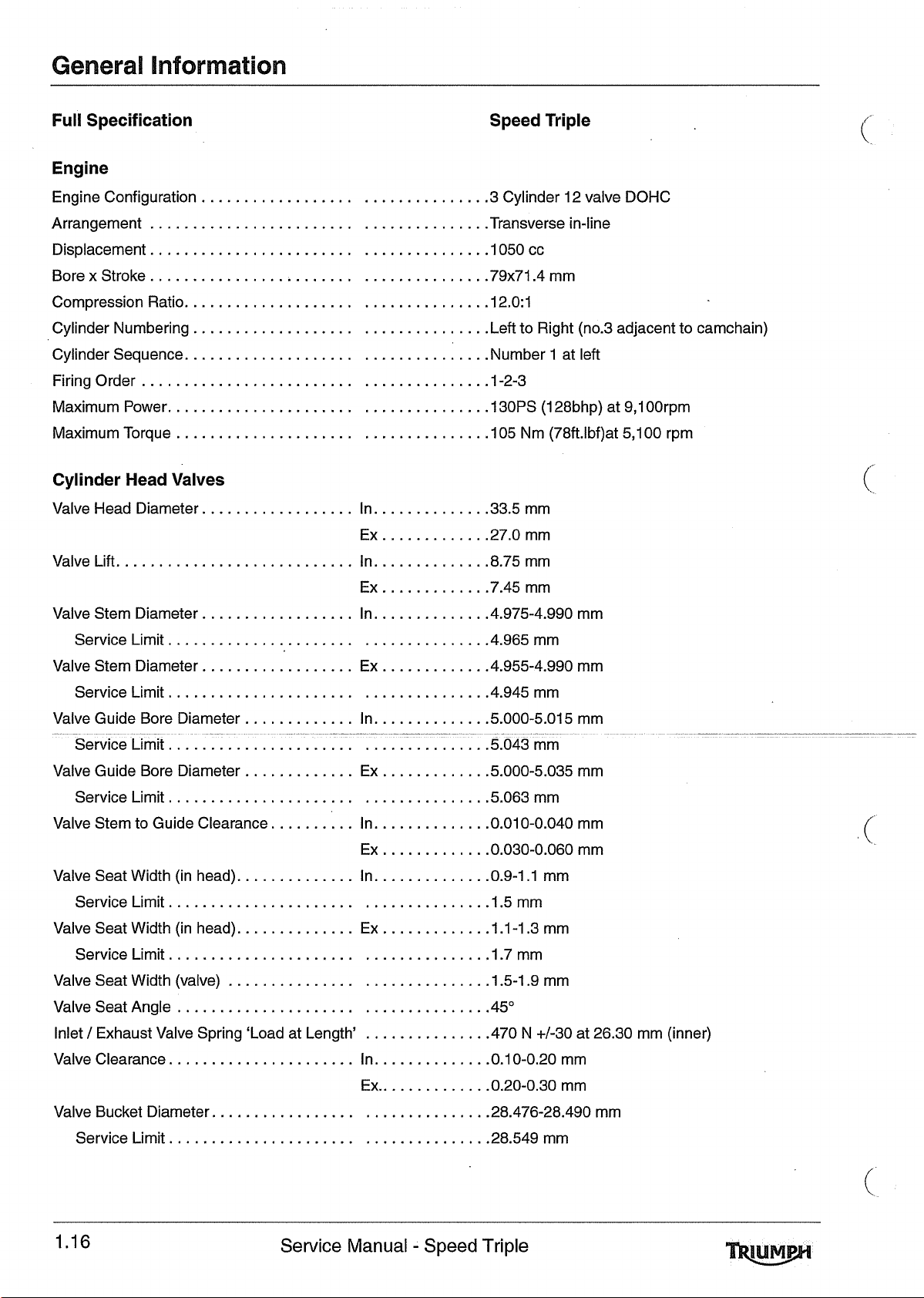

Full Specification Speed Triple

Engine

Engine Configuration

Arrangement

Displacement

Bore x Stroke.

Compression Ratio.

Cylinder Numbering ................................. .Left to Right (110.3 adjacent to camchain)

Cylinder Sequence.

Firing Order

Maximum Power.

Maximum Torque

Cylinder Head Valves

Valve Head Diameter.

Valve Lift.

Valve Stem Diameter

Service Limit

Valve Stem Diameter

......................................

......................................

.......................................

...........................

................................

.....................................

.................................

.3 Cylinder 12 valve DOHC

.Transverse in-line

.I050 cc

.79x71.4 mm

.12.0:1

................................. .Number 1 at left

.I-2-3

....................................

...................................

.................

In.

............

...........

Ex.

In.

............

...........

Ex.

130PS (1 28bhp) at 9,100rpm

.I05 Nm (78ft.lbf)at 5,100 rpm

.33.5 mm

.27.0 mm

.8.75 mm

.7.45 mm

.................. In. ............ .4.975-4.990 mm

....................................

.................. Ex

............

.4.965 mm

.4.955-4.990 mm

Service Limit.

Valve Guide Bore Diameter

Valve Guide Bore Diameter

Service Limit.

Valve Stem to Guide Clearance.

Valve Seat Width (in head).

Service Limit.

Valve Seat Width (in head).

Service Limit.

Valve Seat Width (valve)

Valve Seat Angle

/

Exhaust Valve Spring 'Load at Length'

Inlet

Valve Clearance. ..................... In. ............ .0.10-0.20 mm

Valve Bucket Diameter.

Service Limit.

................................... .4.945 mm

.............

.............

...................................

In.

............

Ex

............

.5.000-5.015 mm

.5.000-5.035 mm

,5063 mm

......... In. ............ .0.010-0.040 mm

............. In. ............ .0.9-1.1 mm

...................................

.............

Ex

............

...................................

.............................

.I

.5 mm

.I .I

-1.3 mm

.I

.7 mm

.I

51.9 mm

................................... .45"

..............

........... .0.20-0.30 mm

EX..

.470 N +/-30 at 26.30 mm (inner)

.............................. .28.476-28.490 mm

...................................

.28.549 mm

Service

Manual

-

Speed Triple

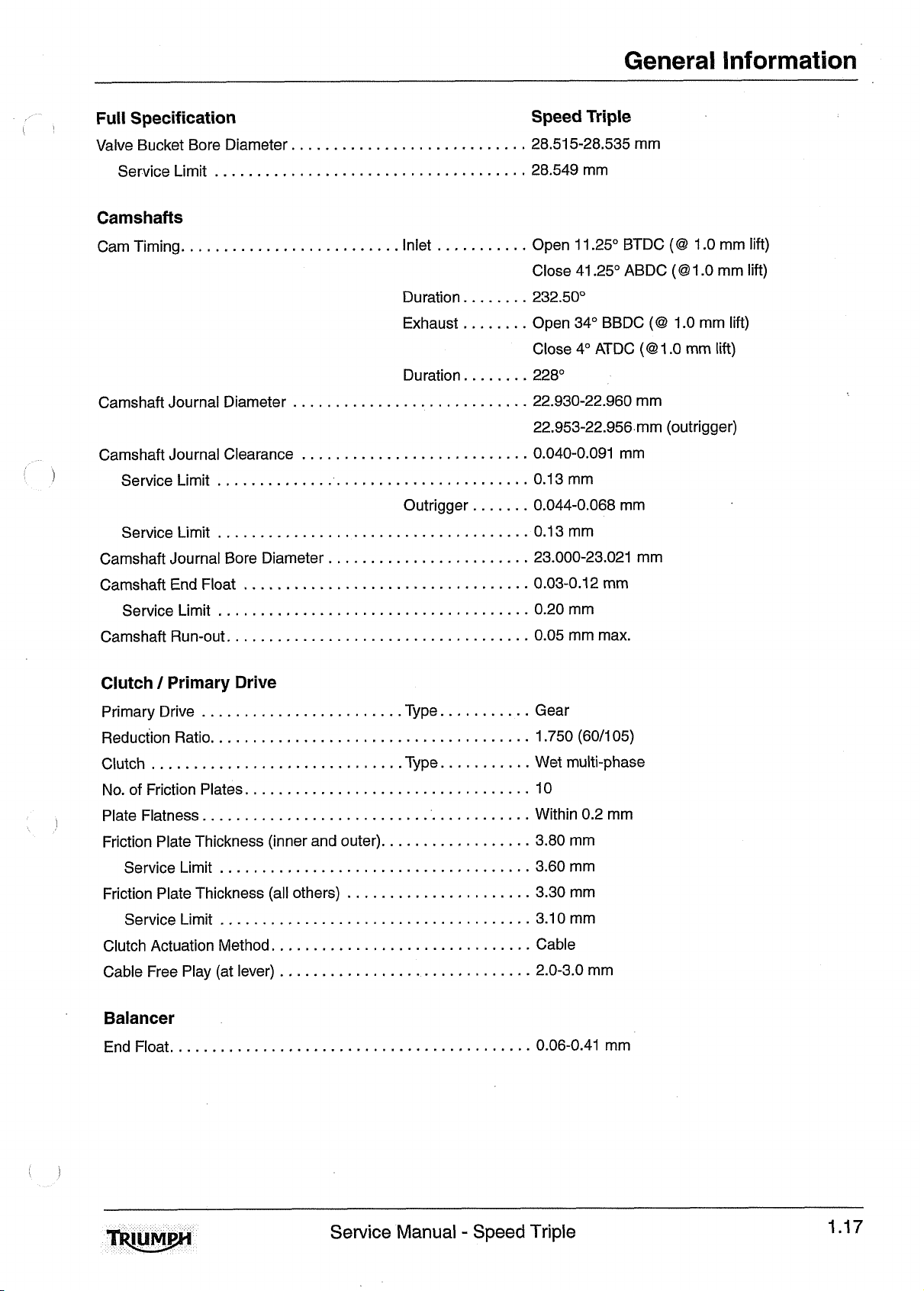

Full

1'

Specification Speed Triple

Valve Bucket Bore Diameter.

Service Limit 28.549 mm

Camshafts

...........................

28.51 5-28.535 mm

.....................................

General Information

Cam Timing.

Camshaft Journal Diameter 22.930-22.960 mm

Camshaft Journal Clearance 0.040-0.091 mm

i

Service Limit 0.1 3 mm

Service Limit 0.1 3 mm

Camshaft Journal Bore Diameter

Camshaft End Float

Service Limit 0.20 mm

Camshaft Run-out. 0.05 mm max.

Clutch / Primary Drive

.........................

............................

...........................

.....................................

.....................................

........................

..................................

.....................................

...................................

...........

Inlet

Duration

Exhaust

Duration

Outrigger

Open 11 .25" BTDC (8 1.0 mm lift)

Close 41.25" ABDC (81 .0 mm lift)

........

........

232.50"

Open 34" BBDC

Close 4" ATDC

........

.......

(@

1.0 mm lift)

(@

1.0 mm lift)

228"

22.953-22.956 mm (outrigger)

0.044-0.068 mm

23.000-23.021 mm

0.03-0.1 2 mm

Primary Drive

Reduction Ratio. 1.750 (6011 05)

Clutch

No, of Friction Plates.

Plate Flatness. Within 0.2 mm

Friction Plate Thickness (inner and outer).

Friction Plate Thickness (all others)

Clutch Actuation Method. Cable

Cable Free Play (at lever)

Balancer

End Float. 0.06-0.41 rnm

..............................

Service Limit 3.60 mm

Service Limit 3.1 0 mm

........................

Type..

.........

.....................................

Type.

..........

.................................

.......................................

.................

.....................................

......................

.....................................

..............................

..............................

..........................................

Gear

Wet multi-phase

10

3.80 mm

3.30 mm

2.0-3.0 mm

Service

Manual

-

Speed Triple

Full Specification Speed Triple

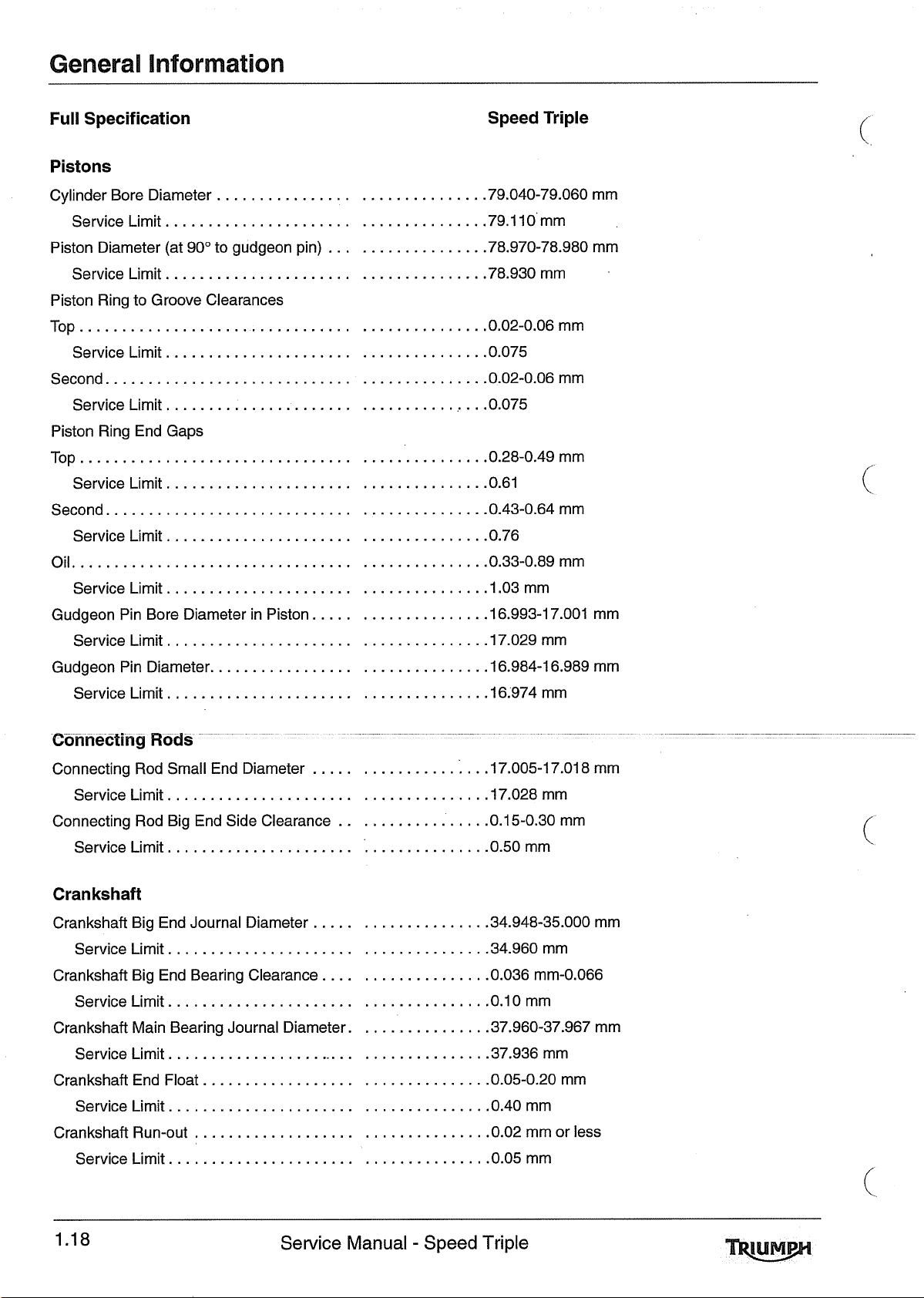

Pistons

Cylinder Bore Diameter .79.040-79.060 mm

Service Limit. .79.110'mm

Piston Diameter (at 90" to gudgeon pin)

Service Limit

Piston Ring to Groove Clearances

...............................................

Top 0.02-0.06mm

Service Limit. .0.075

Second 0.02-0.06mm

Piston Ring End Gaps

Top 0.28-0.49mm

Second 0.43-0.64mm

Oil 0.33-0.89mm

Gudgeon Pin Bore Diameter in Piston.

............................................

Service Limit .0.075

...............................................

Service Limit .0.61

............................................

Service Limit .0.76

................................................

Service Limit.

Service Limit .17.029 mm

....................................

.....................................

....................................

....................................

....................................

..............................

...................................

.................

.78.970-78.980 mm

.78.930 mm

...................................

...................................

..................

.I

.16.993-17.001 mm

.03 mm

Gudgeon Pin Diameter. .16.984-16.989 mm

Service Limit .16.974 mm

C0s;lneetimg

Connecting Rod Small End Diameter

Service Limit. .17.028 mm

Connecting Rod Big End Side Clearance

Service Limit .0.50 mm

Crankshaft

Crankshaft Big End Journal Diameter

Service Limit .34.960 mm

Crankshaft Big End Bearing Clearance.

Service Limit. .0.10 mm

Crankshaft Main Bearing Journal Diameter.

Service Limit .37.936 mm

Crankshaft End Float. .0.05-0.20 mm

Service Limit. .0.40 mm

Crankshaft Run-out

Service Limit. .0.05 mm

....................................

....................................

....................................

.....................................

..............................

...................

.17.005-17.018 mm

...................................

................

...................

.................

.0.15-0.30 mm

.34.948-35.000 mm

.0.036 mm-0.066

...................................

..............

.37.960-37.967 mm

...............................

...................................

.................................

.0.02 mm or less

...................................

Service Manual - Speed Triple

General Information

i

1)

Full Specification

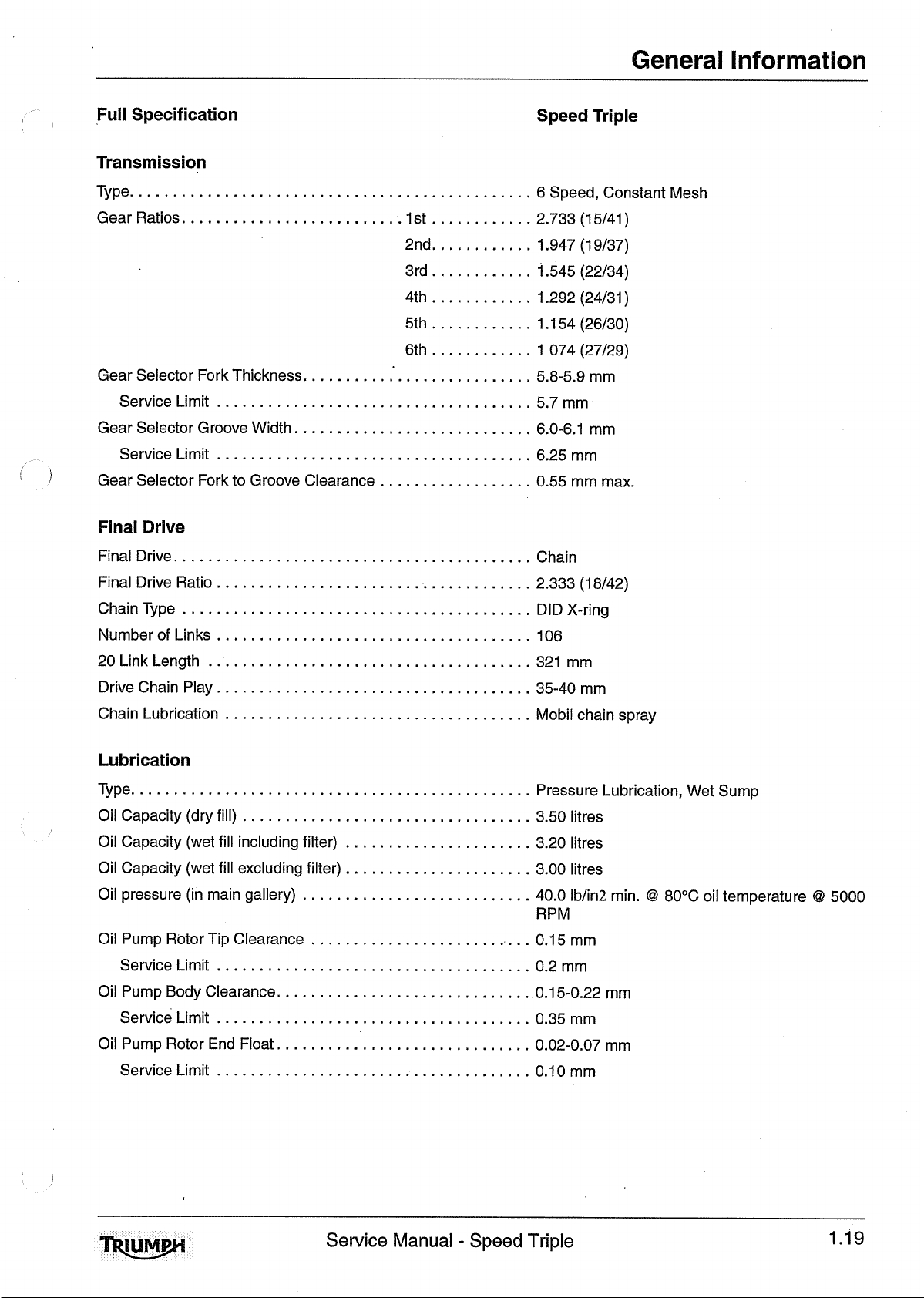

Transmission

...............................................

Type 6Speed,ConstantMesh

Gear Ratios.

Gear Selector Fork Thickness.

Service Limit

Gear Selector Groove Width.

Service Limit

Gear Selector Fork to Groove Clearance

Final Drive

Final Drive.

........................

.....................................

.....................................

.........................................

Speed Triple

............

.I

st 2.733 (1 5/41

2nd. 1.947 (1 9/37)

...........

3rd 1.545 (22134)

............

4th

............

5th

............

6th

............

..........................

...........................

..................

1.292 (24131)

1

1 074 (27129)

5.8-5.9 mm

5.7 mrn

6.0-6.1 mm

6.25 mm

0.55 mm max.

Chain

.I

54 (26130)

)

Final Drive Ratio

Chain Type

Number of Links

20LinkLength

Drive Chain Play.

Chain Lubrication

Lubrication

Type.

..............................................

Oil Capacity (dry fill)

Oil Capacity (wet fill including filter)

Oil Capacity (wet fill excluding filter)

Oil pressure (in main gallery)

Oil Pump Rotor Tip Clearance

Service Limit

Oil Pump Body Clearance.

service Limit

......................................

.........................................

.....................................

......................................

....................................

....................................

..................................

......................

......................

........................... 40.0 Iblin2 min.

...........................

..................................... 0.2 mm

.............................

.....................................

2.333 (1 8/42)

DID X-ring

106

321mm

35-40 mm

Mobil chain spray

Pressure Lubrication, Wet Sump

3.50 litres

3.20 litres

3.00 litres

Q

80°C oil temperature 8 5000

RPM

0.1 5 mm

0.1 5-0.22 mm

0.35 mm

Oil Pump Rotor End Float.

Service Limit

.....................................

.............................

Service Manual - Speed Triple

0.02-0.07 mm

0.1 0 mm

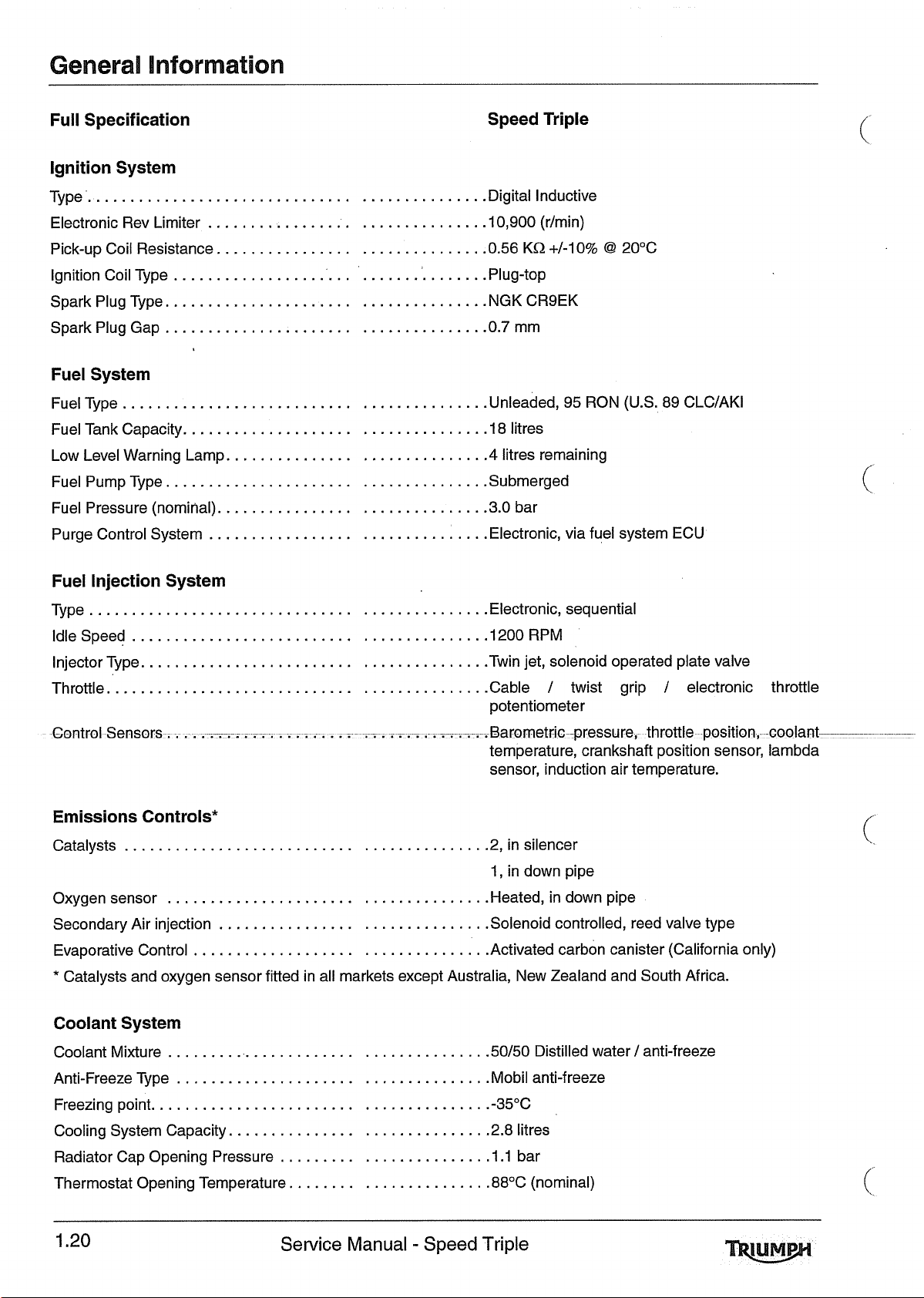

Full Specification Speed Triple

Ignition System

..............................................

Type .Digital Inductive

Electronic Rev Limiter 10,900 (rlmin)

Pick-up Coil Resistance. .0.56

Ignition Coil Type Plug-top

Spark Plug Type. .NGK CR9EK

Spark Plug Gap

Fuel System

Fuel Type

Fuel Tank Capacity.

Low Level Warning Lamp.

Fuel Pump Type. .Submerged

Fuel Pressure (nominal).

Purge Control System

Fuel Injection System

Type .Electronic, sequential

Idle Speed .I200 RPM

Injector Type.

Throttle. .Cable

Gontrol Sensors

.........................................

.............................................

........................................

......................................

..........................................

................................

.............................

......................................

...................................

....................................

.................................

............................

.0.7 mm

.unleaded, 95 RON (U.S. 89 CLCIAKI

.I8 litres

.4

...................................

.............................

...............................

--

.......................

-

..

r.

..

.3.0 bar

.Electronic, via fuel system ECU

.Twin jet, solenoid operated plate valve

-;-.

.,

.

KC2

+/-I 0% Q 20°C

litres remaining

/

twist grip

potentiometer

.Barometric -pressure, throttle position, cool

temperature, crankshaft position sensor, lambda

sensor, induction air temperature.

I

electronic throttle

Emissions Controls*

Catalysts .2, in silencer

Oxygen sensor

Secondary Air injection

Evaporative Control

*

Catalysts and oxygen sensor fitted in all markets except Australia, New Zealand and South Africa.

Coolant System

Coolant Mixture

Anti-Freeze Type .Mobil anti-freeze

Freezing point.

Cooling System Capacity.

Radiator Cap Opening Pressure

Thermostat Opening Temperature.

.........................................

1, in down pipe

....................................

..............................

.................................

.....................................

.Heated, in down pipe

.Solenoid controlled, reed valve type

.Activated carbon canister (California only)

.50/50 Distilled water

...................................

.....................................

............................

.......................

.....................

.-35°C

.2.8 litres

.I .I

.88"C (nominal)

bar

/

anti-freeze

Service Manual - Speed Triple

General Information

I

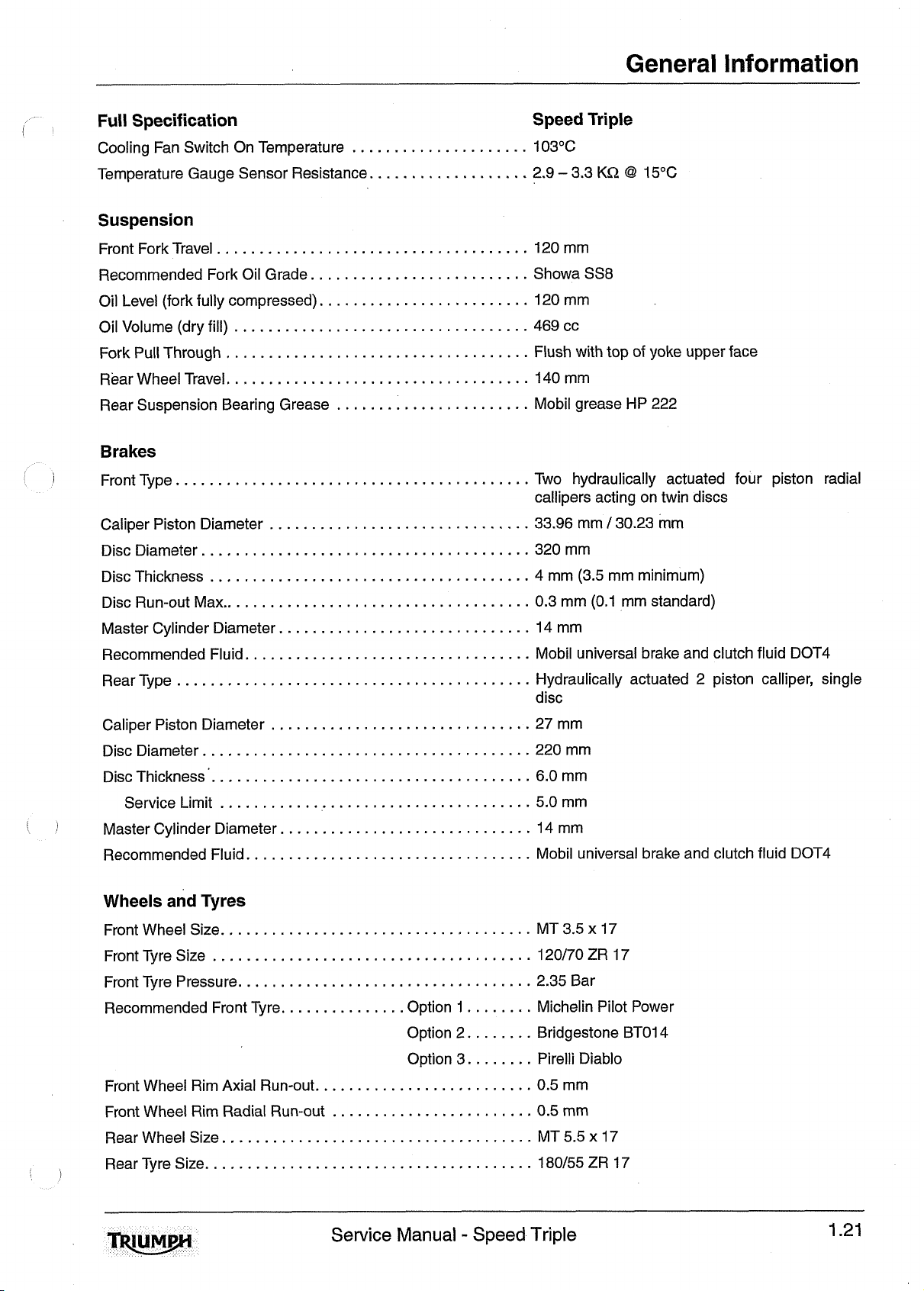

Full

Specification Speed Triple

Cooling Fan Switch On Temperature

Temperature Gauge Sensor Resistance.

Suspension

Front Fork Travel 120 mm

Recommended Fork Oil Grade.

Oil Level (fork fully compressed).

Oil Volume (dry fill)

Fork Pull Through

Rear Wheel Travel. 140 mm

Rear Suspension Bearing Grease

Brakes

i

Front Type.

Caliper Piston Diameter

Disc Diameter. 320 mm

Disc Thickness

Disc Run-out Max..

Master Cylinder Diameter. 14 mm

Recommended Fluid.

Rear Type Hydraulically actuated 2 piston calliper, single

Caliper Piston Diameter 27 mm

Disc Diameter. 220 mm

~isc Thickness 6.0 mm

Service Limit 5.0 mm

.....................................

...................................

....................................

...................................

.........................................

...............................

......................................

......................................

...................................

.................................

..........................................

...............................

......................................

.......................................

.....................................

.....................

..................

2.9 - 3.3

.........................

........................

469 cc

.......................

Two hydraulically actuated four piston radial

.............................

103°C

KC? Q 15°C

Showa SS8

120 mm

Flush with top of yoke upper face

Mobil grease HP 222

callipers acting on twin discs

/

33.96 mm

4 mm (3.5 mm minimum)

0.3 mm (0.1 mm standard)

Mobil universal brake and clutch fluid DOT4

disc

30.23 mm

Master Cylinder Diameter. 14 mm

Recommended Fluid.

Wheels and Tyres

Front Wheel Size.

Front Tyre Size

Front Tyre Pressure.

Recommended Front Tyre.

Front Wheel Rim Axial Run-out.

Front Wheel Rim Radial Run-out

Rear Wheel Size.

Rear Tyre Size.

....................................

......................................

....................................

......................................

.............................

.................................

..................................

..............

Option 1

Option 2.

Option 3.

........

.......

.......

.........................

........................

Mobil universal brake and clutch fluid DOT4

MT 3.5 x 17

120/70 ZR 17

2.35 Bar

Michelin Pilot Power

Bridgestone BT014

Pirelii Diablo

0.5 mm

0.5 mm

MT 5.5 x 17

180155 ZR 17

Service Manual - Speed Triple

Full Specification Speed Triple

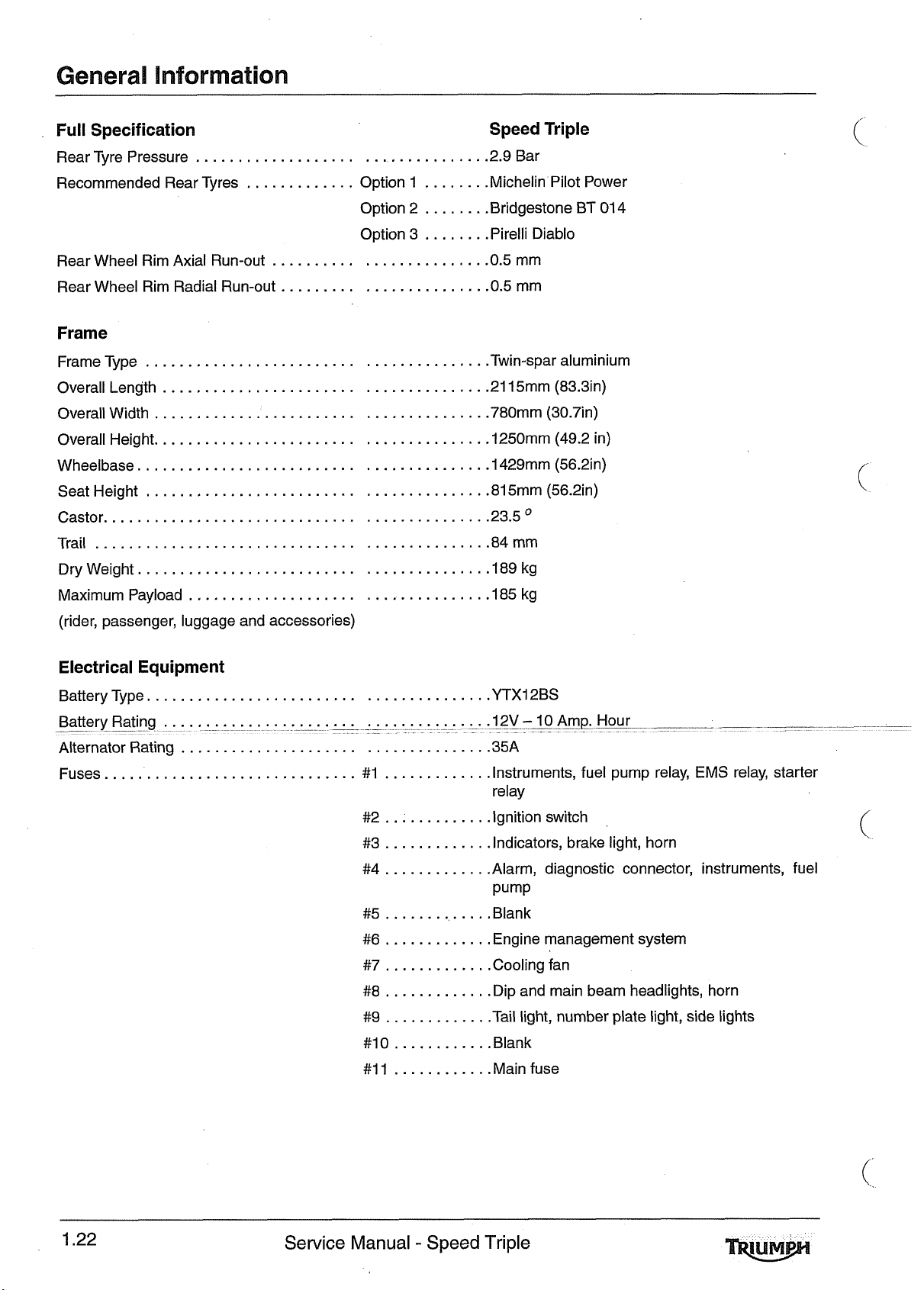

Rear Tyre Pressure .2.9 Bar

.................................

Recommended Rear Tyres

Rear Wheel Rim Axial Run-out

Rear Wheel Rim Radial Run-out

Frame

Frame Type

Overall Length

Overall Width

Overall Height.

Wheelbase

Seat Height

Castor

Trail

...............................

Dry Weight.

Maximum Payload

(rider, passenger, luggage and accessories)

.........................

.......................

........................

.......................

..........................

.........................

..............................

.........................

....................

.............

........................

.......................

Option 1

Option 2

Option 3

........

........

........

..............

..............

..............

...............

...............

..............

..............

...............

...............

..............

Michelin Pilot Power

Bridgestone BT 01 4

Pirelli Diablo

.0.5 mm

.0.5 mm

.Twin-spar aluminium

.2115mm (83.3in)

.780mm (30.7in)

1250mm (49.2 in)

1429mm (56.2in)

.815mm (56.2in)

.23.5

84mm

189kg

.A85 kg

Electrical Equipment

Alternator Rating .35A

Fuses.

.............................

...................................

............

#I

............

#2 .Ignition switch

............

#3 .Indicators, brake light, horn

............

#4

#5

.............

............

#6 .Engine management system

#7

............

............

#8

#9

............

............

#I0 Blank

...........

#I 1 .Main fuse

.Instruments, fuel pump relay, EMS relay, starter

.Alarm, diagnostic connector, instruments, fuel

.Blank

.Cooling fan

.Dip and main beam headlights, horn

relay

Pump

.Tail light, number plate light, side lights

Service Manual - Speed Triple

Loading...

Loading...