(Heating, Cooling and Domestic Hot Water)

MANUAL OF INSTALLATION,

OPERATION AND MAINTENANCE

SPLIT MULTIFUNCTIONAL

AIR TO WATER HEAT PUMP

MQD-14

MQD-17

MQD-20

MQD-8

MQD-23

MQD-11

INDEX

1. INTRODUCTION

2. DESCRIPTION OF UNIT

3. TECHNICAL DATA

4. DIMENSIONS

5. SERVICE AREA

6. INSTALLATION

7.STARTING UP

........................................................................................................................

............................................................................................................

.......................................................................................................................

..................................................................................................................................

...........................................................................................................................

...................................................................................................................

.................................................................................................................................

1

1

4

6

7

8

19

PANE L8.CONTROL

9.UNIT OPERATION

10.TROUBLE SHOOTING

11.SOLAR SYSTEM CONNECTION

12.MAINTENANCE

.......................................................................................................................

.....................................................................................................................

20

21

.....................................................................................

27

28

..........................................................................................................................

29

....................................................................................................

1. INTRODUCTION

The unit purchased by you has been subjected to strict quality control before leaving the factory.

It also me

on it. The repair and maintenance must be con ducted by your service / maintenance

installer.

It is the responsibility of the installation company performing the installation in accordance with the characteristics the project,

subject to the regulations. Before installating the necessary equipment read this manual, and carry out the directions and obserations

in it.

The manufacturer does not responds to any damages

You should check the receiving unit, which is in perfect condition. If otherwise

appropriate to make a written complaint to the carrier.

3

ets the saf ety standar ds

of the CE. Do not tamper with the unit ,or subject to conditions of work not specified in this manual, you may lose any guarantee

and / or indirect, caused by improper installation.

The equipment should be installed only by a duly accredited professional.

2. DESCRIPTION OF UNIT

6-77:@-:*=42,=62<*4457-.4;

Item Part

1 Electric

2 Plate heat exchanger

3 Electric

4 Water control

5 Wire cont roller

6 Water

7 Air discharge

8 Safety

9 Expansion

10 Pressure

11 Electric 3 way

12 Water

13 Needle

1

4

5

10

12

11

9

7

3

3

13

2

box

heater

PCB

tank

valve

valve

tank

Gauge

valve

pump

valve

Name

6

8

2. DESCRIPTION OF UNIT

=<-77:&62<"

1. Electronic board outdoor

2. Compressor Capacitor

3. Compressor Contactor

4. Condenser fan motor

5. Low Pressure switch

6. 4-way valve

7. Injection Valve

8. Injection pressure (high) switch

9. High pressure switch

10. Liquid service valve

11. Gas service valve

12. Compressor

13. Compressor crankcase

14. Outdoor fan

15. Outdoor Fan Motor

16. Suction accumulator

17. Com pres sor soft sta rt capacito r

18. Liquid separator

19. Compressor soft starter

20. Defrost sensor

21. Outside air temperature sensor

22. Discharge tube

23. Thermal expansion valve

24. Transformer

=<-77:&62<"

4

2. DESCRIPTION OF UNIT

=<-77:&62< "

=<-77:&62<"

5

1. Electronic board outside

2. Compressor Contactor

3. Condenser fan motor

4. . Low Pressure switch

5. 4-way valve + coil

6. Injection valve +coil

7. Injection pressure (high) switch

8. High pressure

9. Liquid service valve

10. Gas service valve

11. Compressor

12. Compressor crankcase

13. Outdoor fan

14. Outdoor Fan Motor

15. Suction accumulator

16. Liquid separator

17. Defrost sensor

18. Outside air temperature sensor

19. Discharge tube

20. Thermal expansion valve

21. Transformer

3. TECHNICAL DATA

%$

* Capacities and consumption based on the following conditions:

- Heating: Temperature inlet / outlet water 30/35 ° C. Temperature wet / dry air 6 ° C / 7 ° C.

- Cooling: Temperature inlet / outlet water 23/18 ° C. Dry air temperature 35 º C.

- DHW: Outlet water temperature 45 º C. Temperature wet / dry air 6 ° C / 7 ° C.

* Refrigerant charge is valid for a line length of 5 meters.

* The net weight of the indoor unit does not include the weight of accumulated water in it.

* The sound pressure level is measured at 5 meters from the unit.

6

MQD-8 MQD-14 MQD-17 MQD-20 MQD-23

Capacity Nominal KW 8.42 14.2 16.5 19.5 22.7

Consumption Nominal KW 1.98 3.45 3.92 4.33 5.2

COP W/W 4.25 4.12 4.21 4.5 4.37

Capacity NominalKW KW 7.96 14.5 17.1 19.8 23

Consumption Nominal KW 2.45 4.46 5.21 5.11 6.05

EER W/W 3.25 3.25 3.28 3.87 3.8

Capacity Nominal KW 7.8 12.9 15.8 17.75 21

Consumption Nominal KW 2.2 3.49 4.05 4.57 5.52

COP W/W 3.55 3.7 3.9 3.88 3.8

Power supply V/Ph/Hz

Gas line Inch 5/8”

Liquid line Inch

Compressor type

Refrigerant type

Refrigerant charging volume Kg. 1.9 2.95 4,50 4.6 5.2

Inner water tank Litre

Pressure max climate Bar

Climate expansion tankvolume Litre

Climate output mm

DHW water output mm

Tap water/Climate/DHW water input mm

DHW/Climate safety valve mm

Drain valve mm

Unit Dimension Indoor unit mm

(HeightxWeightxLength) Outdoor unit mm 830x700x300 960x970x345 1260x970x345 1460x970x345 1497x1090x383

PackedDimensions Indoor unit mm

(HeightxWeightxLength) Outdoor unit mm 955x860x395 1080x1085x465 1390x1085x465 1590x1085x465 1630x1210x503

Net weight Indoor unit Kg. 52 55 56 57 59

Outdoor unit Kg. 52 100 120 130

Packedweight Indoor unitr Kg. 58 61 62 63 64

Outdoor unit Kg. 62 112 135 147

Noise level Indoor unit dB(A)

Outdoor unit dB(A) 43 49 51 52 58

Maxpipe length m

Max height difference m

Minwater flow L/S 0.38 0.7 0.8 0.9 1

730*460*322

830*550*425

28

50

30

6

25

25

25

15

15

3/4”

3/8”

Scroll

R-410A

12

7

Heating

Cooling

D.H.W.

TECNICAL CHARACTERS

400/3/50

230/1/50 230/1/50, 400/3/50

Rotary

MQD-11

10.3

2.45

4.2

10.6

3.21

3.3

9.56

2.45

3.9

5/8”

2.4

860x870x325

980x985x415

54

75

60

85

48

0.5

3.ELECTRICS DATA

4.,<:2,*4,76;=58<276

%

7

* Temp. Input / Output water 23/18 ° C. Outdoor air temp. dry bulb 35 ° C.

** Temp. Input / Output water 30/35 ° C. Wet / dry air temp 6 ° C / 7 ° C.

*** Temp. water outlet 45 ° C. Wet / dry airtemp 6 ° C / 7 ° C.

OPERATING LIMITS

8.:*<260252<;

7742607-.

Tª Outdoor Air Temp ºC

Temperatura Salida de Agua ºC

8.:*<260252<;

.*<2607-.

Tª Outdoor Air Temp ºC

Temperatura Salida de Agua ºC

8.:*<260252<;

(7-.

Tª Outdoor Air Temp ºC

Temperatura Salida de Agua ºC

TECNICAL CHARACTERS MQD-8 MQD-14 MQD-17 MQD-20 MQD-23

Operating Voltage V/Ph/Hz 230/1/50 230/1/50 230/1/50 380/3/50 380/3/50

Voltage mín V 205 205 205 360 360

Voltage max V 253 253 253 440 440

Consume

kW 2.45 4.5 4.82 5.2 6.05

A 10.86 19.57 20.96 7.9 9.19

kW 1.98 3.55 3.67 4.15 5.2

A 8.78 15.43 15.96 6.31 7.9

kW 2.2 3.49 4.05 4.57 5.52

A 9.76 15.17 17.61 6.94 8.39

kW 3.3 5.63 6.03 6.5 7.56

A 14.64 24.48 26.22 9.88 11.49

kW 3.06 5.33 5.51 6.23 7.8

A 13.59 23.17 23.96 9.47 11.85

kW 2.51 4.47 5.18 5.85 7.07

A 11.14 19.43 22.52 8.89 10.74

Max D.H.W..

Nominal Cooling *

Nominal Heating **

Nominal Domestic hot water ***

Max Cooling

Max Heating

4.DIMENSIONS

6-77:&62<*4457-.4;

%

Dimensions in mm.

C

8

D

Gasline

Connection

Liquid

Connection

E

B

A

730

460

330

Outdoor unit MQD-8E/MQD-14E

4. DIMENSIONES

=<-77:=62<""

A

C

D

MODEL

Electrical

Connections

GaslineConnection

Liquid Connection

E

B

DIMENSIONS (in mm)

Panel to Access

Electrical Box

MQD-8

MQD-14

MQD-17

MQD-20

A

830

960

1.260

1.460

B

700

970

970

970

C

300

345

345

345

D

350

415

415

415

E

450

640

640

640

9

5.SERVICE AREA

The following is the minimum space needed to carry out the tasks of service and

maintenance of the units.

=<-77:&62<*4457-.4;

%

Dimensions in mm.

200

1.000

300

500

10

6.INSTALLATION

Here are a series of recommendations to follow for proper installation of the unit.

Installation,repair and maintenance of these units must be made with caution because the presence of electrical,

electronic and circuit pressure system refrigerant.Only trained and qualified personnel should perform all

installation,adjustment and maintenance unit.

The manufacturer declines all liability for negligence and breach of safety standards

described below:

- Work in total safety, free from obstacles and clean environment.

- Comply with regulations.

- Before commissioning of the unit, excellent condition confirm the same and its components.

- Wear safety goggles and gloves while working. Use quenching cloth during operations

welding.

- Put in place strong units that can support the weight bearing and allow the right posterior

maintaining it.

- Use the specified cables and make a proper connection at the terminals.

- Make a separate attack unit.

- Check the supply voltage corresponds to the plate.

- Perform the corresponding ground.

- Perform the work safely install hydraulic and drainage pipes as shown

of this manual.

- During operation of the drive circuit part5s refrigerant.(compressor line download) can reach temperatures.

inside the unit.

- The unit can work in environments "normal" residential, commercial or light industry. The unit can not be installed in

explosive atmosphere environment. For applications Special should consult the manufacturer.

Before starting the installation or maintenance operations of the unit disconnect switch general power. Electrical

shock can cause personal injury.

above 70 º C. Take special care when accessing the

6.1 SAFETY CONSIDERATIONS

Very Important!

MOST IMPORTANT!

1. Make sure it is not in cooling mode during first operation or test running, until you make sure

the air conditioning water pump is working properly and water circuit is recycling soothly.

2. Recommand to test the water pump working condition and water circuit directly before switch

on the heat pump.

3. Select a big enough water pump for the air conditioning water circuit.

4. Always keep the electricity connnection with the heat pump to enable inner antifreeze

function wich is valid with electrcity supply.

6.INSTALLATION

Inspect units of receipt to verify any damage or damage during transport. If the unit is damaged you must file a claim

immediately to the company who made the shipment.

6<.:27:7,*<2767/&62<

The indoor unit is designed for installation inside the

housing. For this, the inner cabinet has the same action at its base

that a common household. It also has the possibility of

adjust its height due to small height-adjustable feet.

When installed inside the unit must be left open the door area

access, being necessary to leave the spaces described in paragraph

7 (Service Areas).

7,*<2767/ =<-77:&62<

The outdoor unit must be placed in proper orientation to

climatic characteristics of the region where it is installed.

It should be positioned so that air circulation is free and well

avoid recirculation effects detrimental to performance.

When installing the outdoor unit must be left free the front of the

unit, which is necessary to leave the spaces described in paragraph 7

(Service).

11

All hydraulic connections are labeled as shown in Figures 1 and 2:

1. Refrigerant Liquid valve

2. Refrigerant gas valve

3. Air conditioning water outlet

4.Domestic hot water outlet

5.Water inlet

6.2 Location of units

6.3 Hydraulic connections

6. INSTALLATION

It is necessary to conduct the outlet safety valves of the tank to drain

There is one water pump build inside of our heat pump indoor unit, but the installer need to calculate water flow required and to

overcome the pressure drop during installation machine.

Please check the wiring diagram with the unit for the water pump electricity connection.

A small pump may cause a malfunction or even a fault irreparable.

12

Hydraulic Circuit Connection

Water Pump

Important:

The selection of air conditioning water pump out of the unit should take based on the flow rates

of cooling and heating,internal drop unit (see graph) and the drop of the facility.

Calculation of nominal water flow:

Q water (l / h) = Cooling Capacity

* 0.86

(Kcal / h) / T (º C)

As T = (T first exit water temp - water return Temp) _T = 5 º C

Example: Model MQD-14

Q water = (14,600 W * 0.86) Kcal / h / 5 ° C = 2500 l / h

! #%% The temperature difference in air conditioning heat exchanger should be 5 º C approx. A high temperature

difference can cause a malfunction of the unit and even irreparable damage to it.

Water flow (m3 / h)

1 m.c.a = 10 Kpa

The graph indicates the pressure drop of cooling water circuit of the unit (components inside the unit).

Pressure drop (m.c.a)

MQD-20

MQD-14

MQD-8

MQD-17

There is one built in water pump(C1) for both DHW and air conditioning. But additional water pump for DHW(C2)

and water pump for air conditioning(C3) can be applied according to actual installation.

Tritherma air conditioning Pressure Drop in Hydraulic Circuit

Air Conditioning Water Pump Selection

It is important keep enough water flow to ensure the heat pump optimized COP and

keep the whole system safe.

The water shortage in cooling operation could cause irreparable damage to the unit.

A water flow switch must be installed outside the unit for air conditioning operation to avoid any damage to the unit. The control

The DHW water tank must be with coil heat exchanger inside, so the tank water is clean and seperated with heat pump

After all connection is finished, connect the power supply, NOT SWITCHING ON THE UNIT.

-Open the tap water and let the tap water go into the heat pump hydraulic recycle.

-Open air discharge valve of inner water tank on the top and open air discharge valves of all fan coils. The water pump

-Close air discharge valve when water comes out continuously.

- Open a point of hot water consumption to flush the system.

* A water regulation valve(Normally 1.5-2.5 bar) must be installed before tap water go into the heat pump inlet.

* Check the correct rotation of water pump axis after uncover the maintenance screw with a scew driver.

.Before assure the water pump is working well and water flow is correct, Put the unit in

HEATING mode.

- Check the water pressure gauge installed in the control panel of indoor unit, it must be between 1 and 2.5 bar

(normal 1.5 bar) for properoperation.

- Ensure that all secondary facility is found with water pressure and completely purged of air. The existence of air

in the air conditioning circuit can cause irreparable damage unit.For this reason, air discharge valve should be

installed in the highest part of the hydraulic circuit to remove all air from the system.

Water Flow Switch

Important:

Filling and pressure testing for Hydraulic Circuit

6. INSTALLATION

hydraulic recycle.

maintenance screw

choose air conditioning heating mode to fill the air conditioning side.

-Switch the inner 3 way valve to fill water for both side :

heating temp to 10 centigrade.

maintenance screw can also be loosed to purge air.

should be connect to IN5 of indoor unit control board.

In order to avoid compressor running, firstly set both Domestic hot water target temp and air conditioning

-Set target water temp back after complete installation and check everything ok

Turn on the unit and choose DHW mode, after DHW side air is purged completedly and filled with water,

13

14

6.INSTALLATION

-

It is recommanded to connect the air conditioning water pump directly to the electricity, ie, turn on water pump

only for air conditioning circuit for some time,to eliminate the existence of such air circuit.

Do not connect the unit for operation of the pump. When connectingthe unit and not the water pump

independently, it could cause irreparable damage in the unit.

-

A mesh water filter must be installed outside before the water return to the plate heat exchanger as show Figure 7

whose mission is to retain dust or dirt

which might remain in the cooling circuit of the house.

Figure 7

The dirt from the installation may cause irreparable damage to the unit.

- Once the connections and filling, and prior to starting the unit, it is recommended operating the air conditioning

circuit pump for a while, to retain the mesh filter particles and impurities that could be installed. To this should be

wired air conditioning pump directly to the network.

- Once that is done, and the pump stopped, it should close the stopcocks of input and output on the water circuit

drain water tank through the drain valve and clean the filter. Then fill again the circuit.

- To ensure that no dirt on the circuit, should make this operation as often as necessary.

- Having ensure that the air cooling circuit is clean, insert glycol, if necessary, approximately 20% -30% for cold area.

- Should perform periodic reviews, including cleaning the filter and to ensure that there is no dirt inside the water

circuit. Especially in the first installation.

Attention!

Attention!

During cold climate area, inserting Glycol is necessary to make sure the heat pump won't be damaged during

Attention!

electricity accident. Keep always electricity connection to ensure auto antifreeze.

If the heat pump won't be used for a long time, please drain the system water out.

6.INSTALLATION

- The installer must protect the power line drive disconnecting devices

circuit breaker suitable for installation in accordance with the legislation.-

- The power to the unit must be within a range of voltage (see table consumption

electric page 8).

- It should pay special attention to the connection of ground wire. The ground wire must be of a

larger than the cable phases. .

- Remove the access panel to the control panel located on the front side of the unit.

- Check that the network characteristics match the data on the nameplate of the unit.

- Perform power and interconnection between the interior and exterior units through the 2

presses on the side of

.

Figure 8

Electric power

supply

Signal wires

interconnection

- Ensure that power cords have the correct section for the total consumption

unit. See table below.

support guides, so we have access to the terminals of the unit .

15

automatic magneto-thermal switch and

length slightly

the unit.

6.4 ELECTRICAL CONNECTIONS

Before any electrical installation work to ensure that the main switch is disconnected

General Recommendations

Preliminary operations

In the outdoor unit:

In the indoor unit:

Before commissioning of the unit must perform the following connections:

- Mains supply (outdoor unit), Figure 8.

- Interconnection between the outer and inner drive, figures 8.

Power supply (connection and interconnection between units)

Checking Wiring diagram with the unit before connection

Unscrewing the unit control box, moving outward through

MODEL

Outdoor Power

SUPPLY

Indoor power

SUPPLY COMMINICATION

MQD-8

3 x 4 mm

SIGNAL

2 x 0,5 mm

(no polarity)

MQD-14

MQD-17

MQD-20

3 x 4 mm

5 x 6 mm

3 x 4 mm

2 x 0,5 mm

(no polarity)

2 x 0,5 mm

(no polarity)

*The power to the indoor unit can proceed directly network or coming from the outdoor unit.

3 x 4 mm

3 x 4 mm

6.INSTALLATION

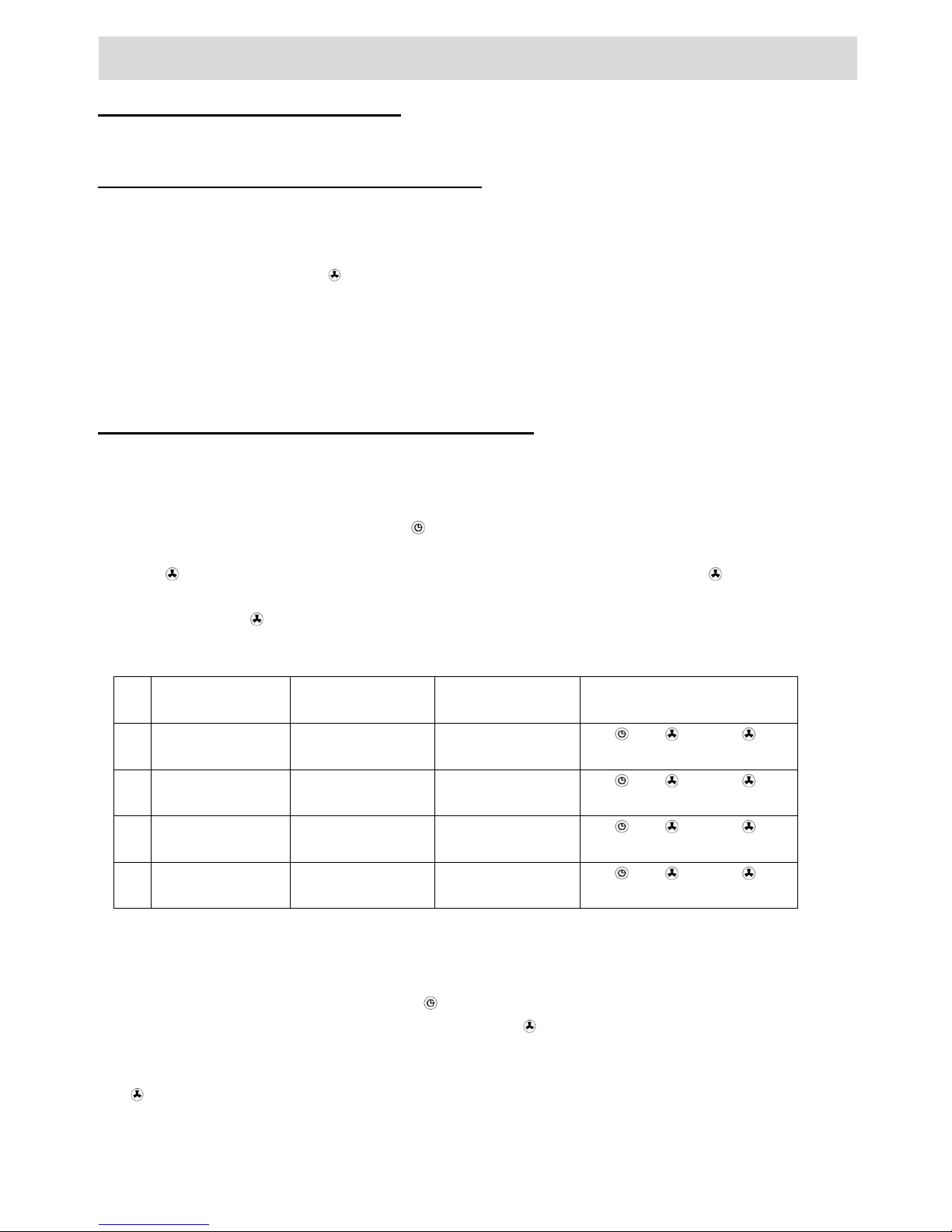

INDOOR UNIT OUTDOOR UNIT INDOOR UNIT OUTDOOR UNIT

16

2 communication cables no polarity

3 x 4 mm cables of SUPPL Y

230/1/50

SUPPLY

ELÉCTRIC

2 communication cablesno polarity

3 x 4 mm cables de SUPPLY

380-425/3/50

SUPPLY

ELÉCTRIC

Model:MQD-8/14 Model:MQD-17/20

Indoor Wiring Diagram

2nd AC Switch Usage (Connect to IN7)

The 2nd switch function enable our heat pump to be controlled by any additional user's thermostat

or remote switches for convenient control.

Function: When 2nd switch is off, the heat pump AC mode will run on standby mode no matter the AC

water temp reach target or not. When 2nd switch is on, the heat pump will run according to set temp.

A Connected to

manual switch

.

B Connected to any user's thermostat.

C Connected to both manual switch

together with any user's thermostat

.

IN7(10)

2nd

6.INSTALLATION

17

Outdoor Unit 1 phase

Outdoor Unit 3 phases

18

6.INSTALLATION

The interconnection lines refrigerant is as follows:

- The indoor unit has identified the taking of gas and liquid, with stickers identifying, the

follows:

Gas line: Gas (coolant) / Gas (refrigera nt )

Liquid line: liquid (coolant) / Liquid (refrigerant)

- All refrigerant connections, as well as water, are threaded.

- You have to isolate the lines to avoid condensation and heat loss.

- Once you have installed the lines, to empty into the circuit refrigerant indoor unit until a

-1 Kg/cm2 pressure for at least 2 hours.

- The discharge circuit refrigerant and refrigerant charge can be made through service valves

side of the outdoor unit.

- Check for leaks in the circuit refrigerant.

6 26-77:=62<

indoor unit (see paragraph 6.Dimensiones scheme) and since the connections are made .

The indoor unit comes with a dry nitrogen load incorporated. The refrigerant lines of the units

interior are a series of adapters and nuts to ensure proper seal until use.

6 &% #&%

The outdoor unit is shipped with a load of R - 410A applies to a line length

maximum equivalent of 5 meters. For lengths over 5 meters is necessary to add load according

located on the right

6.5 REFRIGERANT SYSTEM CONNECTIONS

General considerations

Connection between indoor and outdoor units

to the table in paragraph 6.7

6.INSTALLATION

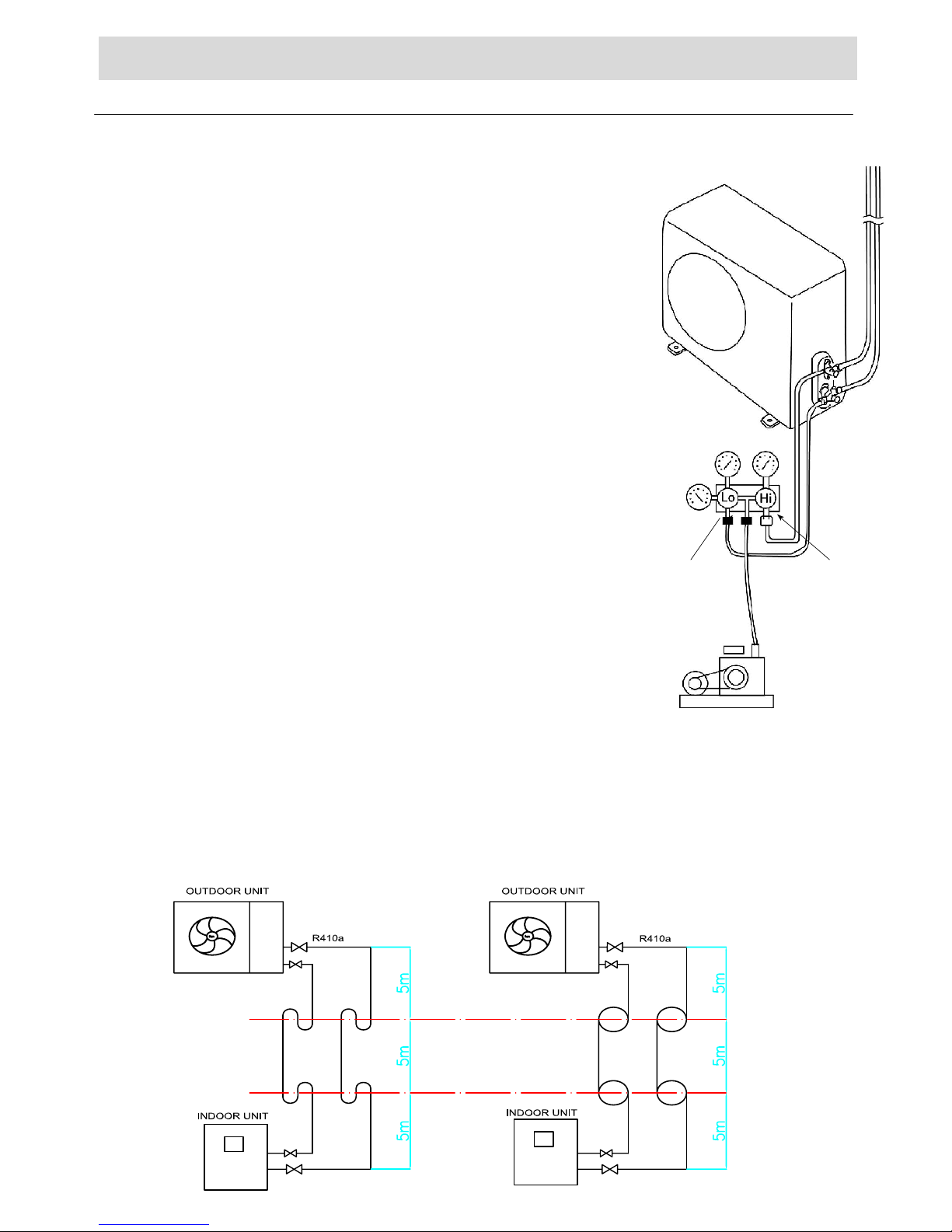

Once the connection refrigerant system between indoor and outdoor, and once it has been found

tightness of this connection, we proceed to the realization of the vacuum in the unit to which it will

the following process:

- With the outdoor unit’s service valves closed (as the unit is delivered from

the factory), remove the plugs of these service valves.

- Connect the pressure gauge connection in the following way:

Make the low pressure gauge connection to the gas service valve.

Make the high pressure gauge connection to the liquid service valve.

Make the centre bridge of the gauge connection to the vaccum pump.

- keep the pump running and open the valves of the bridge of gauges,

so that we ensure the refrigerant circuit system depression by both

refrigerant lines and the indoor unit.

- Perform a vacuum to ensure that the gauge indicates 1 bar.

-

Once the vacuum to turn off the bridge of gauges and off the vacuum pump,

making sure that pressure is maintained vacuum for at least 15 minutes.

-

If pressure is not stable means there is a leak in the circuit, so you need to

locate and remedy it. Once cured repeat the above steps.

-

If vacuum pressure is stable (it may already be done when

necessary refrigerant charge) disconnecting the bridge

Manometer pressure

Low

High

gauge of the vacuum pump first, and keep the bridge

gauge closed ends connected to the valves

or service lines, as appropriate for each model.

Vaccum

Pump

- The outdoor unit is shipped with a charge of refrigerant R-410A is valid for a

length of line maximum equivalent of 5 meters.

- Perform opening the service valves.

- For superior line lengths to 5 meters, recharge the unit as shown in table recharge

refrigerant.

1. -To recover all the refrigerant charge in the outdoor unit for maintenance, just to shut off the liquid valve.

Operate the heat pump in cooling mode. After the pressure is reduced to 0 Pa, shut off the gas valve.

19

6.6 CONDUCT OF VACUUM REFRIGERANT SYSTEM INSTALLATION

NOTE:

2. - If the outdoor unit is more than 5 meter higher than indoor unit, please make a "U" shape or "O" shape

for every 5 meter.

6.INSTALLATION

The outdoor unit incorporates the refrigerant charge (R410A) necessary for the proper functioning of

the unit to a length of interconnecting pipe 5 meters.

If the interconnection line is greater than 5 meters, we should make a refrigerant addiction

according to the following table:

Additional refrigerant charge (g / m)

DIÁMETER

3/8” 5/8”

3/4”

LÍQUID

GAS

60

-

-

8

-

10

20

-

Enter the refrigerant charge in liquid phase

.

In the outdoor unit has two pressure connections (suction and

compressor discharge), through which pressure can be measured

evaporation and condensation of the system in any

three functions (DHW, Heating and Refrigeration).

Indoor unit incorporates two pressure taps, which

DHWand heating mode with high pressure measured,

and cooling mode with low pressure.

High or low pressure, depending

Operating mode

Low pressure

High pressure

6.7 REFRIGERANT CHARGE (R-410A)

6.8 PRESSURE MEASUREMENT LOCATION

NOTE:

OUTDOOR UNIT

INDOOR UNIT

7.STARTING UP

- Confirm that the power is in accordance with the nameplate of the unit and been conducted according to current

regulations.

- Ensure that all electrical connections are well made and according to wiring diagram.

- Check the air conditioning filter is clean water.

- with water and has made the

corresponding vent through the manual traps.

- Check the setting pressure filling group. This pressure must always be less than 2.5 Bar

- Check that all door panels are properly mounted with screws for you.

- Check that all valves of the hydraulic system of air conditioning are open.

- The operation and use of electronic control is explained in Chapter 12. Electronic Controller.

After performing the electrical installation manual for installation and connection electrical, check the following:

- Check the firmness of the attachment of power cables and switching in both the outdoor unit and the inside.

- Activate the differential electric al ci rcu it breaker of th e unit.

- Check that the tension in the outdoor unit is located between the indicated value rang e in the tab le in paragr aph 4

(electrical data). If you were outside these values should not be starting the unit.

- The unit is operated through electronic controller multiprocessor.

- To start the unit press the Start / Stop for 1 second.

- You can select the following modes:

• Water heating and cooling. The priority is to

with the production of cold water for cooling.

the production of hot water for heating.

- Changing temperatures.

• The unit is shipped with a set point temperature selected by default.

• Modify and adapt these temperatures to the installation of side we have: soil heating, fan coil, etc..

• In extreme weather conditions may be appropriate to amend these

21

Check that the deposits of inertia of climate and the accumulation of DHWare filled

• Hot water. The unit produces only

satisfy the demand for DHWwhen such demand is s atisfied, we continued

• Hot water and heating. The priorit y is to sati y the d nd hen such demand is satisfied, we continued withemasf wfor DHW

DHW

- Enable the operation of the unit in DHW, as indicated in paragraph 12 of this manual.

-Once enabled mode, the unit will start to reach set temperature and stop after gain the set temperature.

- Check the pump rotation DHW.

-In the first implementation of the unit, you should consume DHW to the temperature of selected accumulation.

-Enable the operation of the unit heating or cooling mode,as shown in paragraph 12 of this manual.

- After you enable the selected mode, and whenever the unit is not working hal and DHW mode, the unit will start and

send hot or cold water (depending on heating or cooling of the secondary cooling circuit to achieve the set temperature

-Once you have obtained this temperature, the unit will stop, but the cooling water pump continue in operation.

- In operation for heating and cooling, check the water temperature drop

(- T ª return). This jump should be

about 5

the unit will start and send hot or cold water (depending on heating or cooling)

° C.

7.1 CHECK TO BE PERFORMED BEFORE STARTING UP

7.2 POWER CHECK

7.3 TEMPERATURES SELECTION

7.4 OPERATION IN MODE D.H.W.(Domestic hot water)

9.5 OPERATION MODE AIR CONDITIONING

8.CONTROLPANEL

22

8 . 1 Wire controller

Wire controller contains a LCD and 6 operational keys (as show below). It can keep memory when power off

and be a timer.

8. 2. Key functions

(1)Double-colored indicator light: when standby, blue light on; when compressor worked, red light on; when

breakdown happened, red light on. For more details, please check fault code sheet.

(2)Key “on/off” : power on /power off.

(3)Key “time adjusting”: adjust clock or set time.

(4)Key “down”: it’s a combined key to decrease numerical value, continuous press, then continuous decrease;

short press, then decrease by 1.

(5)Key “up”: it’s a combined key also, but opposite to down key. Continuous press, then continuous increase;

short press, then increase by 1.

(6)Key “confirm”: confirm previous operations

(7)Key “mode”: operational mode’s switch. It’s a combined key also.

8. 3. Icon Meaning

NO. Icon meaning NO. Icon meaning NO. Icon meaning

8 Clock display 9 Returned AC Temp. 10 Maintain icon

11 Lock icon 12 Temperature icon (Reserved) 13 Parameter number icon

14 AC Cooling icon 15 Sterilization icon 16 AC heating icon

17 Sanitary hot water icon 18 Water/ground source display 19 Parameter icon

20 Domestic Hot Water

temp

21 Timer on icon 22 Timer off icon

20 Sterilization days dis-

play

21 Sterilization on display 22 Sterilization off display

23 Clock icon

9.

23

UNIT OPERATION

9 . 1 Switch the unit On and off

To start the unit, press and hold the On/Off key for one second

To stop the unit, press and hold the On/Off key for one second

9 . 2 Mode switch(5 modes in total)

A. Under mode standby or On, press the M key repeatly, the following icons will flash by recycling.

AC cooling -> AC heating -> DHW(Domestic hot water)-> AC cooling + DHW ->AC heating +

DHW

When selected a mode, press button to confirm, then the icon will be solid, heat pump will perform as

selected.

B. When in mode AC cooling +DHW or AC heating & DHW, DHW heating will be the priority.

C. When select DHW mode, only hot water system working, no air conditioner working.

D. When select air conditioner mode, only air conditioner system working, no sanitary hot water system working.

E. Sterilization is independent and auto-operated. You can change parameter according to need.

9 .3 Procedures of setting parameter change

A. When in settled mode, the unit will operate in accordance with the factory default temperature or last modified

temperature.

B. Modification method for settled temperature

In the on / standby mode, press key M and for 3 seconds, the current operating mode light will flash;

by press the M key, you can switch modes in the following order: Cooling / heating / hot water / sterilization;

press to confirm the mode and press key ▲ or ▼to setting value, then press key to confirm, then exit

and save current changes;

if didn’t press key

to confirm, it will exit the parameter modification automatically 15 seconds later. Pre-

vious Changes will not be saved.

Detailed settings as follows:

NO. Meaning Settled temperature

range

Default temperature operation for modify settled para-

meters

1 AC cooling returned

water temp

10℃~25℃ 12℃

M+

→M→ →▲or▼→

2 AC Heating returned

water temp

10℃~55℃ 45℃

M+ →M→ →▲or▼→

3 sanitary hot water

heating

(AU)10℃~60℃ 50℃

M+ →M→ →▲or▼→

4 Legionella

Anti-bacteria

60℃~70℃ 65℃

M+

→M→ →▲or▼→

C. Time setting procedure for health sterilization

Only in sanitary hot water mode, health sterilization will work. If sanitary hot water mode off, health sterilization

will fail to work.

In on or standby mode, first, press key M and for 3 seconds, second, press key M ,15 icon appears, then

press the ▲ or ▼ to set sterilization temperature, press key to confirm, the number of days will flash and

show the original or default value 7 (that means 7 days), press key ▲ or ▼ to increase or decrease the number

of days at predetermined intervals, the minimum of 7 days, maximum of no more than 99 days, after that ,press

key to confirm. At this time, "ON" character appears, "hour" appears and flashes, show the original setting

or the default value (default value 01 means it will start at 1:00 am), followed by press key ▲ or ▼ to modify

9.

24

UNIT OPERATION

(0-23) ,after that, press key to confirm, then the new time start running. "ON" character disappears, "OFF"

character appears, "minute" value flashes and shows the original or default value (default value is 10), followed

by press key ▲ or ▼to change (minimum is 10, maximum no more than 99), after that press key to confirm

and exit change mode. If didn’t press key to confirm, machine will exit change mode automatically after 15

seconds. But settings did right now will become invalid.

9.4 Time adjustment

Press key ,time “hour” value will flash, then press key ▲ or ▼,the value will increase or decrease. Press

key and keep, the valve will increase or decrease constantly as you want. After Settle down, please press key

to confirm, then exit from time adjusting mode.

9.5 Time setting

You can set one time to start and one time to off. And select one time working or cyclic working.

A、 settled time on method:

(1) Press for 3 seconds and come to time setting, will flash as show below.

(2) Press key ▲ or ▼ to modify time value, and press to confirm. This setting only valid for one time. If you

want time setting to work cyclic, please press key after time setting, then press key to confirm.

B、 Timing off method are the same as timing on method.

C、 Please press key for 3 seconds and come to timing mode, press to cancel time setting.

9.6 Parameter Checking and setting

Please press key M+▲ for 3 seconds and enter to parameter setting mode as show below.

“01”is parameter code,“78”is parameter values.

Other items’ parameters meaning are the same with above

picture showed.

1.Press for 5 seconds, it will reset all parameter to factory default valve. Indoor unit need power off

and and power on again

when this parameter is 1, when air conditioning heating run, it will compare solar water tank temp with air conditioning returned

water temp, when solar water tank temp is 5 or more degree higher than air conditioning returned temp, the 3-way valve G3

electricity supply will be on; when solar water tank temp - air conditioning returned temp is less than 2 centigrade, G3 electricity

supply will be off. This function is to use solar to preheat for room heating and DHW tank water.

When this parameter is 0, G3 is seasonal switch valve, when the heat pump is working for heating, G3 is on, when heat pump is

working for cooling, G3 is off.

Normally use one 3-way valve with 3 wires. 2 wires are always connected with electricity supply and 1 signal wire is connected

with heat pump G3 terminal port to enable function.

Usage of 14. Function parameter: (As per solar application 1)

Note:

9

. UNIT OPERATION

25

Parameter list:

NO. Name range/meaning default status remark

00 power off auto restart

0:not restart;1:Auto restart

1 check/set

01 hot water temp return differential

2~15℃,minus return differential 2℃

check/set

02 air conditioning return differential

2~15℃,minus return differential 2℃

check/set

03 defrost start temp.

-20~5℃ 0℃

check/set

04 water source anti-freeze temp.

-20~5℃ 2℃

check/set

05 antifreeze exist temp.

-5℃~5℃

5℃

check/set

06 defrost exist temp.

10~35℃ 30℃

check/set

07 Defrost duration time 15~99 mins 30 check/set

08 Interval between 2 defrosts 15~99 mins 35 check/set

09 ambient temp of DHW backup

electrical heater start

-20~20℃ 0℃

check/set

10 ambient temp of AC backup

electrical heater start

-20~20℃ 0℃

check/set

14 3 way valve function parameter

0:G3 is seasonal switch valve;

1:G3 is solar pre-heat valve;

0 check/set

0˖continous running˗

1˖stop when reach target temp

0 check/set

26 AC water pump working mode

2: Run 1 minute for each 15

minutes after reach target temp

3. Usage of Parameter 26: AC water pump working mode

If no AC buffer tank, The Parameter 26 better to be set to 0, then AC water pump will work continously to keep the AC loop water

temp always equivalent.

If with AC buffer tank, the parameter 26 can be set to 1, but the AC inlet water temp must be changed to insert to AC

buffer tank as reference below.

Application with AC water pump stop when reach target temp

1.Set parameter 26 to 1. Must change the AC inlet water temp sensor(6)IN2 into buffer tank.(ref to wiring diagram).

2.Must add AC buffer tank and 2 water pumps at both side of the buffer tank. The room side water pump is contrlled by

room thermostat. Heat pump side water pump is controlled by heat pump C4 or C6.

3.Must use brine not pure water at both side of the buffer tank.

26

9.

UNIT OPERATION

9 .7 Machine operational status Checking

Press both key M and ▼ for 3 seconds, then entered machine status form. Show as below.

“C0”is part or parameter NO. , “28” stands for parameter. Parameter 0 means system on, 1 means system off.

For more detail, please check form below.

Press M+ ▼ for 3 seconds to search and check parameters .

NO. NAME Range/Meaning Default Status Remark

00 external pipe temperature -9~79℃ no Check

01 exhausted air temperature 1(Off); 0(on) no Check

02 Ambient temp. -9~79℃ no Check

03 . -9~79℃ no Check

04 water source inlet temp. -9~79℃ no N/A

05 water source outlet temp. -9~79℃ no N/A

06 power switch status 1(heating and cooling);

0(heating only)

no Check

07 power switch status 0(air source); 1(water source) no Check

08 power switch status 1(DHW invalid); 0(DHW valid) no Check

09 power switch status 0(G1valid); 1(G1 invalid) no Check

10 high pressure switch status 1(off); 0(on) no Check

11 The second high pressure

switch status

0(off); 1(on) no Check

12 Low pressure switch status 1(off); 0(on) no Check

13 Inside water flow controller 1(off); 0(on) no Check

14 outside water flow controller 0(off ); 1(on) no Check

15 defrost no Check

16 AC antifreeze no Check

17 System antifreeze no Check

18 Compressor 1:on;0:off no Check

19 Outside fan 1:on;0:off no Check

20 crankcase heater 1:on;0:off no Check

21 4-way valve 1:on;0:off no Check

22 Bypass valve 1:on;0:off no Check

23 Solenoid valve 1 1:on;0:off no Check

24 Solenoid valve 2 1:on;0:off no Check

25 Solenoid valve 3 1:on;0:off no Check

26 Electric heater 1 1:on;0:off no Check

27 Electric heater 2 1:on;0:off no Check

AC out water temp

9.

UNIT OPERATION

27

28 C4 water pump 1:on;0:off no Check

29 C5 water pump 1:on;0:off no Check

30 C6 water pump 1:on;0:off no Check

31 Function parameter 0-99(total days since last set-

ting)

no Check no

32 settled heating temp. no Check

33 settled cooling temp. no Check

34 settled DHW temp. no Check

35 Settled sterilization temp. no Check

9.8

Displays for different kinds of modes

(1)tritherma water/ground source heat pumps icons (2)air source heat pumps icons:

(3)powered off display

(water source heat pump has water source Icon. If it has timer on/off setting, there is timer icon to indicate. )

(4)AC cooling display (5)heating display

(water source heat pump has water source Icon. If it has timer on/off setting, there is timer icon to indicate. )

9.

UNIT OPERATION

28

(6)sanitary hot water display

(water source heat pump has water source Icon. If it has timer on/off setting, there is timer icon to indicate. )

(7)AC cooling and sanitary hot water display (8)AC heating and sanitary hot water display

(water source heat pump has water source Icon. If it has timer on/off setting, there is timer icon to indicate. )

9.9 way of communication

Non-polarity double wire, maximum running length is 100 meters and point to point connected.

Back view of wired controller showed below.

线控器背面

(after change, need be repowered to enable the change)

SW1-8

OFF:cooling valid; ON: cooling invalid

SW1-7

OFF:heating valid; ON: heating invalid

SW1-6

OFF: :DHW invalid

SW1-5

OFF: :G1 invalid

SW1-4

OFF:inverter outdoor model; ON:on/off outdoor model

SW1-1

OFF:geothermal; ON:air source

SW1-3 reserved

SW1-2 reserved

SW1

SW1

DHW valid; ON

G1 valid; ON

Function Selection Switch:

9.10

29

When Error happened, air conditioner temperature location will display "P" or "E", hot water temperature location

will display fault code, such as "01" ,then press key ▼, you can inquire all Errors at the same time. Meaning for

fault code please check function book.

Display “Ex” or “Px”。For example:E2. P5. Out door LED Light will flash as fill show below.

. Error Meaning Error Code Outdoor unit LED light display Error Display

Compressor over heat E1

Flash 1 time,interval 5seconds

Depend on

outdoor unit

ambient temp. sensor

Error

E2

Flash 2 times,interval 5 seconds

Depend on

outdoor unit

Pipe temp. sensor Error

E3

Flash 3 times,interval 5 seconds

Depend on

outdoor unit

Return water temp.

sensor

E4

Compressor Stop

AC out water temp.

sensor

E5

Compressor Stop

AC Antifreeze protect E9 Compressor Stop

DHW temp. sensor E6

Compressor Stop

DHW antifreeze protect EA Compressor Stop

Solar water temp.

sensor

E7 Compressor Stop

Coil over heating protection

E8

Flash 4 times,interval 5seconds

Depend on

outdoor unit

high pressure protection P1

Flash 6 times,interval 5seconds

Depend on out-

door unit

Low pressure protection P2

Flash 7 times,interval 5seconds

Depend on

outdoor unit

Communication Error

P9 Flash 10 times,interval 5seconds

Over current protection P4 Depend on out-

door unit

indoor unit water circle

Error

P5 Compressor Stop

outdoor unit water circle

Error

P6 Depend on out-

door unit

Outdoor Missing Phase

P7(whole system OFF)

Flash 8 times,interval 5 seconds

Depend on out-

door unit

Outdoor wrong phase

P8(whole system OFF)

Flash 9 times,interval 5seconds

Depend on out-

door unit

10.TROUBLE SHOOTING

11.SOLAR SYSTEM CONNECTION

30

Connected with dual coils solar system. Solar preheating can be used for D.H.W and room heating in the same time.

- Our heat pump inner system can compare the solar tank temp and room heating returned water temp. the returned

- For summer cooling circuit, inner program will always shorten the 'cooling' circuit automatically as it no need heat.

Automatic solar assistant Fuzzy Logic control program built inside to save cost the

water will go through solar tank if it can get extra heat from solar heating. If in cloudy day, the returned water may

- Domestic hot water will always go through solar tank to be preheated.

not go through solar tank to avoid heat loss.

So the heat pump can have a good rest in sunny day to save cost and work more in

cloudy day. Especially excellent for floor heating together with hot water application.

mostly.

Single way valve

Application 2

Application 1(Most Energy Saving Connection)

31

12.MAINTENANCE

Before any maintenance or cleaning of the unit make sure the switch is off and no power to it

This section is intended for end users and is very important to maintain regular operation of the unit over time. A few operations,

carried out regularly can prevent serious intervention by the staff.

Necessary operations do not require particular expertise and are summarized in simple controls of some components of the unit

.

-

Clean outdoor coil, the skin must be able to get through maximum heat exchange. Therefore, it is always necessary to keep

its surface free of dust and dirt that could be deposited by the action of the fans..

• With a brush to remove all foreign objects such as paper, leaves, etc, who are on the surface of the outdoor coil..

• Clean the aluminum surface of the outdoor unit, eg a vacuum cleaner

• Check that all fins are not damaged or bent.

-

Control water flow defrost: During winter operation, occurs from time to time the defrosting of the outdoor coil. You need to

check that the drain is not blocked. If drainage is not correct, with cold temperatures, it could form a layer of ice on the base, which

would compromise the functioning of the whole system

.

We recommend a regular maintenance by qualified personnel

Here are some checks to be performed:

• Check direction of rotation of the DHW pump, and the possible presence of air on the pump.

• Check that the pressure of condensation and evaporation in this mode are accurate at all times, depending on the

temperature of DHW and outdoor air temperature.

• Check the power consumption (Amps) of the unit operating conditions at that time.

• Check that the unit in this mode to achieve the temperature selection.

• Check that when the temperature drops to DHW temperature selection, the unit starts to operate in this mode.

• Check direction of rotation of the pump air conditioning, as well as the possible existence of air in the system.

• Check that the pressure of condensation and evaporation in this mode are accurate at all times, depending on the

temperature of cooling water flow and outside air temperature.

• Check the temperature drop in cooling water, is within the recommended range. If not, check: water pump, air in the

water circuit, dirt in the water system, etc) .

• Check the power consumption (Amps) of the unit operating conditions at that time.

• Check that the unit in this mode to achieve the temperature selection.

• Check that when the temperature drops to air conditioning temperature selection, the unit star ts to opera te in thi s

mode.

• Check and clean air conditioning water filter

• Check and clean tap water inlet water filter

Routine maintenance

Periodic Maintenance

DHW circuit

Air Conditioning Circuit

E-MTI-0001-10

The manufacturer reserves the right to make any changes without notice.

Loading...

Loading...