Page 1

Safety 2

Feature Identification 3

Operation 4

Application Guide 5

Mounting 6

Battery Connection 7

AC Output Connection 8 (back page)

Troubleshooting/Service/

Maintenance/Warranty 8 (back page)

Warranty Registration 8 (back page)

Owner’s Manual

PowerVerter®Plus

DC-to-AC Inverters

Input Output

12 VDC 120V, 60 Hz. AC

1111 W. 35th Street, Chicago, IL 60609 USA

Customer Support: (773) 869-1234

www.tripplite.com

Copyright © 2005. PowerVerter®is a registered trademark of Tripp Lite. All rights reserved.

* Inverters are moisture-resistant, not waterproof.

Contents

Reliable AC Power Wherever You Need It!

Congratulations! You’ve purchased the most advanced, feature-rich

Inverter designed as a mobile energy source for your vehicle.

PowerVerter Inverters efficiently convert DC (battery) power into

120V AC (household) power, allowing you to use equipment you

commonly use at home—appliances, entertainment systems, computers,

power tools and more—while cruising the open road. PowerVerter

Inverters, through a high-efficiency conversion process and a charge

conservation setting, draw the highest level of performance from your

batteries without overtaxing them, lengthening their service life. An

automatic low battery shutdown feature ensures you'll always have

plenty of power for starting purposes.

• Automatic Overload Protection

• Automatic “Battery-Saver” Low Voltage Shutdown

• High Efficiency DC-to-AC Inversion

• Multi-Function Lights & Switches

• Optional Remote Control Capability

• Frequency-Controlled Output

• Moisture-Resistant Construction*

• Battery Charge Conserver (Load Sense)

Warranty

Registration

Register online today for a

chance to win a FREE

Tripp Lite product!

www.tripplite.com/warranty

Regulatory Compliance Identification Numbers

For the purpose of regulatory compliance certifications and identification, your Tripp Lite product has been assigned a unique series number. The series number can be found on

the product nameplate label, along with all required approval markings and information. When requesting compliance information for this product, always refer to the series number.

The series number should not be confused with the marking name or model number of the product.

* Applies to models with "UL" in their model numbers.

Page 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS!

This manual contains important instructions and warnings that should be followed during the installation, operation and storage of all Tripp Lite Inverters.

Location Warnings

• Install your Inverter in a location or compartment in your vehicle that minimizes exposure to heat, dust, direct sunlight and moisture.

Flooding the unit with water will cause it to short circuit and could cause personal injury due to electric shock.

• Leave a minimum of 2" clearance at front and back of the Inverter for proper ventilation. To avoid overheating the Inverter, any

compartment that contains the Inverter must be properly ventilated with adequate outside air flow. The heavier the load of connected

equipment, the more heat will be generated by the unit.

• Do not install the Inverter directly near magnetic storage media, as this may result in data corruption.

• Do not install near flammable materials, fuel or chemicals.

Battery Connection Warnings

• Multiple battery systems must be comprised of batteries of identical voltage, age, amp-hour capacity and type.

• Because explosive hydrogen gas can accumulate near batteries if they are not kept well ventilated, your batteries should not be

installed in a “dead air” compartment. Ideally, any compartment would have some ventilation to outside air.

• Sparks may result during final battery connection. Always observe proper polarity as batteries are connected.

• Do not allow objects to contact the DC input terminals. Do not short or bridge these terminals together. Serious personal injury

or property damage could result.

Ground Connection Warnings

• Safe operation requires connecting the Inverter's Main Ground Lug directly to the frame of the vehicle or earth ground.

Equipment Connection Warnings

• Do not use a Tripp Lite Inverter in life support or healthcare applications where a malfunction or failure of a Tripp Lite

Inverter could cause failure of, or significantly alter the performance of, a life support device or medical equipment.

• You may experience uneven performance results if you connect a surge suppressor, line conditioner or UPS system to the output of

the Inverter.

Operation Warnings

• Your Inverter does not require routine maintenance.

• Potentially lethal voltages exist within the Inverter as long as the battery supply is connected. During any service work, the battery

supply should therefore be disconnected.

• Do not connect or disconnect batteries while the Inverter is operating from the battery supply. Dangerous arcing may result.

2PV

Page 3

3PV

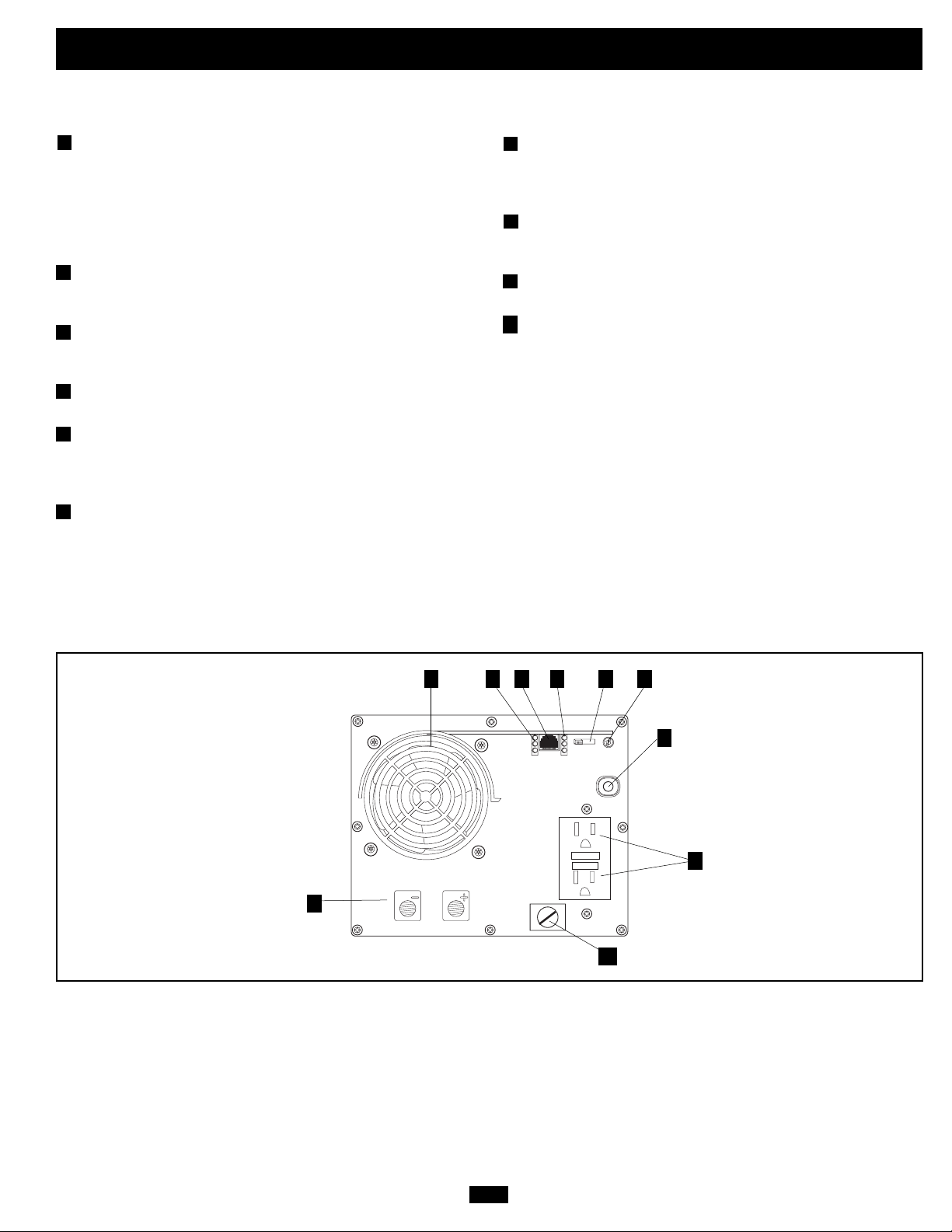

Feature Identification

Identify the premium features on your specific model and quickly locate instructions on how to maximize their use.

Operating Mode Switch: controls Inverter operation. Set this

2-position slide switch to “ON/REMOTE” to have your Inverter

provide connected equipment with AC power by converting DC

power from an attached battery or remotely monitor and control

the Inverter with the use of an optional remote module. Set

switch to “OFF” when not using connected equipment to prevent battery drain.

“LOAD” Indicator Lights: intuitive “traffic light” signals show

approximate equipment load level. See page 4 for instructions

on reading indicator lights.

“BATTERY” Indicator Lights: intuitive “traffic light” signals

show approximate charge level of your battery. See page 4 for

instructions on reading indicator lights.

DC Power Terminals: connect to your battery terminals. See

page 7 for connection instructions.

Ground Fault Interrupter (GFI) AC Receptacles: allow you

to connect equipment that would normally be plugged into a

utility outlet. They feature ground fault interrupter switches that

trip if there is excessive current on the ground safety wire.

Resettable Circuit Breaker: protects your Inverter against

damage due to overload. See page 4 for resetting instructions.

Remote Control Module Connector: allows remote monitoring

and control with an optional module (Tripp Lite model

APSRM4, sold separately). See remote module owner’s manual for connection instructions.

Battery Charge Conserver (Load Sense) Dial: conserves battery

power by setting the low-load level at which the Inverter automatically shuts off. See page 4 for setting instructions.

Multi-Speed Cooling Fan(s): quiet, efficient fans prolong

equipment service life.

Main Ground Lug: properly grounds the Inverter to vehicle

grounding system or earth ground. See page 7 for connection

instructions.

Low Battery Alarm/Shutdown (internal, not shown): automatically detects low voltage and shuts down Inverter to preserve

vehicle battery.

Overload Alarm/Shutdown (internal, not shown): automatically

detects wattage overload on Inverter outlets and shuts down

Inverter as a protective measure.

Ignition Switch Control Jack (rear panel, not shown): use to

connect the Inverter to your vehicle’s ignition switch (with usersupplied cable) in order to automatically control the Inverter

with the vehicle's ignition switch. See Operation section.

1

2

3

4

5

6

7

8

9

10

Front View (750 & 1250 Models)

13 2

4

5

6

79

10

8

Page 4

4PV

Operation

Switch Modes

Switch between the following operating modes as appropriate to

your situation:

“ON/REMOTE”: Switch to this setting to provide connected equipment with AC power. Also,

switch to this setting to remotely monitor and

control the Inverter with the use of an optional

remote module. See remote module’s owner’s manual for operating

instructions.

“OFF”: Switch to this setting to shut down the

Inverter completely, preventing it from drawing

power from the batteries. Use this switch to automatically reset the unit if it shuts down due to low

battery or overload. Use an optional remote control module (Tripp Lite

model APSRM4, sold separately) to reset unit due to overload only.

Indicator Lights

Your Inverter is equipped with a simple, intuitive, user-friendly set of

indicator lights. These easily-remembered “traffic light” signals will

allow you, shortly after first use, to tell at a glance the charge condition

of your batteries, as well as ascertain approximate equipment load level.

“BATTERY” Indicator Lights: These three lights will illuminate in

several sequences to show the approximate charge level of your connected battery:

Approximate Battery Charge Level

†

Indicator Illuminated Battery Capacity

Green 91%–Full

Green & Yellow 81%–90%

Yellow 61%–80%

Yellow & Red 41%–60%

Red 21%–40%

Flashing Red (slowly)* 1%–20%

Flashing Red (quickly)** 0% (Inverter

has shutdown)

“LOAD” Indicator Lights: These three lights will illuminate in

several sequences to show the approximate equipment load level on

the Inverter’s AC receptacles.

Approximate Equipment Load Level

Indicator Illuminated Load Level

Green 0%-50%

Green & Yellow 51%-75%

Yellow 76%-90%

Red >

90%

Flashing Red (quickly)** OVERLOAD

(Inverter has

shutdown)

† Charge levels listed are approximate. Actual conditions vary depending on battery condition

and load. * Approximately ½ second on, ½ second off. ** Approximately ¼ second on, ¼ second

off. See “Resetting Your Inverter to Restore AC Power” to reset after Inverter shut down.

Resetting Your Inverter to Restore

AC Power

Your Inverter may cease supplying AC power in order to protect

itself from overload or to protect your electrical system. To restore

normal functioning:

Low Battery Shutdown Reset: Set operating mode switch to

“OFF” and run vehicle engine to recharge battery. When battery is

adequately charged, switch operating mode switch back to

“ON/REMOTE.”

Overload Shutdown Reset: Set operating mode switch to “OFF”

and remove some of the connected electrical load (ie: turn off some

of the AC devices drawing power which may have caused the overload of the unit). Wait one minute, then switch operating mode

switch back to “ON/REMOTE.”

Output Circuit Breaker Reset (Select Models): Alternatively,

check output circuit breaker on the unit’s front panel. If tripped,

remove some of the electrical load, then wait one minute to allow

components to cool before resetting the circuit breaker. See

Troubleshooting for other possible reasons AC output may be absent.

Set Battery Charge Conserver (Load Sense) Dial

In order to save battery power, the Inverter automatically shuts off in the absence of any power demand from

connected equipment or appliances (the electrical

load). When the unit detects a load, it automatically

turns on. Users may choose the minimum load the

Inverter will detect by adjusting the Battery Charge Conserver Dial

(see diagram). Using a small tool, turn the dial clockwise to lower

the minimum load that will be detected, causing the Inverter to turn

on for smaller loads. When the dial is turned fully clockwise, the

Inverter will operate even when there is no load. Turn the dial counterclockwise to set a higher minimum load, causing the Inverter to stay

off until the new minimum load is reached. When the dial is turned

fully counterclockwise, the Inverter will turn on when it detects any

load greater than approximately 150 Watts.

Note: The factory setting for the dial is fully clockwise. However, based on the threshold load to which

you’d like the Inverter to respond, you should adjust the dial counterclockwise to reduce its sensitivity

until the Inverter is active only when connected equipment or appliances are actually in use.

Connect Remote Control—OPTIONAL

All models feature an 8-conductor telephone style receptacle on the

front panel for use with an optional remote control module (Tripp Lite

model APSRM4, sold separately.) The remote module allows the

Inverter to be mounted in a compartment or cabinet out of sight, while

operated conveniently from your vehicle’s dashboard. See instructions

packed with the remote control module.

Connect Ignition Switch Control Jack—OPTIONAL

All models feature a jack which can be used to connect the Inverter to

your vehicle's ignition switch in order to automatically control the

Inverter. This connection is optional; the Inverter will function without

this connection.

WARNING! THE IGNITION SWITCH CONTROL

FUNCTION IS ONLY FOR USE WITH 12V NEGATIVE GROUND SYSTEMS.

Wiring the Ignition Switch Control Cable to your

vehicle’s ignition requires a qualified technician,

who must determine the proper wiring procedure.

When connected to the vehicle’s ignition switch, this function automatically disables (turns OFF) the AC power output from the Inverter when

the vehicle’s ignition switch is placed in the “Engine Run” position.

This function will satisfy local codes and requirements concerning

video monitors (or TVs) that are located within a driver’s view by automatically turning them off when the engine is started. Tripp Lite makes

a current-limited cable assembly (part # 73-0977) for this purpose.

Connect the current-limited cable's red wire to the ignition switch's

"Engine Run" terminal. The cable's black wire can be left unterminated.

Then, connect the current-limited cable's mini-plug to the Ignition

Switch Control Jack located on the Inverter's rear panel. After connecting the interface cable, set the Inverter's switch to "ON/REMOTE". The

current-limited cable's mini-plug should remain in the Inverter's

Ignition Switch Control Jack whenever the ignition is on to avoid shorting the battery.

1

2 3

4

5

6

7

1

2

3

4

5

6

7

1

2

3

4

5

1

2 3

4

5

LOAD

SENSE

GREATER

LOAD

ON

LESSER

LOAD

ON

Page 5

5PV

Application Guide

540 watts ÷ 12V = 45 DC Amps

45 DC Amps × 5 Hrs. Runtime

× 1.2 = 270 Amp-Hours

Match Battery Amp-Hour Capacity to Your Application

Select a battery or system of batteries that will provide your Inverter with proper DC voltage and an adequate amp-hour capacity to power

your application. Even though Tripp Lite Inverters are highly efficient at DC-to-AC inversion, their rated output capacities are limited by

the total amp-hour capacity of connected batteries and the support of your vehicle’s alternator if the engine is kept running.

• STEP 1: Determine Total Wattage Required

Add the wattage ratings of all equipment you will connect to your Inverter.

Wattage ratings are usually listed in equipment manuals or on nameplates. If

your equipment is rated in amps, multiply that number times AC utility voltage

to determine watts. (Example: a ¼ in. drill requires 2½ amps. 2½ amps × 120

volts = 300 watts.)

Note: Your Inverter will operate at higher efficiencies at about 75% - 80% of nameplate rating.

• STEP 2: Determine DC Battery Amps Required

Divide the total wattage required (from step 1, above) by the battery voltage (12)

to determine the DC amps required.

• STEP 3: Estimate Battery Amp-Hours Required (for operation

unsupported by the alternator)

Multiply the DC amps required (from step 2, above) by the number of hours

you estimate you will operate your equipment exclusively from battery power

before you have to recharge your batteries. Compensate for inefficiency and

wiring losses by multiplying this number by 1.2. This will give you a rough

estimate of how many amp-hours of battery power (from one or several batteries)

you should connect to your Inverter.

NOTE: Battery amp-hour ratings are usually given for a 20-hour discharge rate. Actual amp-hour capacities are less when

batteries are discharged at faster rates. For example, batteries discharged in 55 minutes provide only 50% of their

listed amp-hour ratings, while batteries discharged in 9 minutes provide as little as 30% of their amp-hour ratings.

You must allow your batteries to recharge long enough to replace the charge lost during Inverter operation or else you will eventually run down your batteries.

NOTE: For Tripp Lite Inverters over 1000 watts used in mobile applications, Tripp Lite recommends you use at least two batteries, if possible, fed by a heavy-duty alternator anytime the vehicle is

running. Tripp Lite Inverters will provide adequate power for ordinary usage within limited times without the assistance of your vehicle’s alternator. However, when operating extremely heavy electrical

loads at their peak, you may wish to “assist your batteries” by running your vehicle engine faster than normal idling.

Example

Tools

300W + 220W + 20W = 540W

¼" Drill Orbital Sander Cordless Tool Charger

Appliances

300W + 140W + 100W = 540W

Blender Color TV Laptop Computer

Page 6

Vehicular and Non-Vehicular Horizontal Mount

Using the measurements from the diagram, install two user-supplied ¼" (6 mm) fasteners into a rigid horizontal surface, leaving

the heads slightly raised. Slide the Inverter/Charger back over

the fasteners to engage the mounting slots molded on the bottom of

the Inverter/Charger cabinet. Install and tighten two user-supplied ¼" (6 mm) fasteners into the mounting feet molded on the

front of the Inverter/Charger cabinet.

6PV

Mounting

optional

WARNING! If you choose to mount your Inverter, mount it and wire its DC input

BEFORE DC battery connection. Failure to follow these instructions may lead to

personal injury and/or damage to the Inverter and connected systems.

Tripp Lite Inverters are designed for horizontal mounting in a variety of vehicular or non-vehicular applications. User must supply mounting

hardware and is responsible for determining if the hardware and mounting surface are suitable to support the weight of the Inverter. Contact

Tripp Lite if you require further assistance in mounting your Inverter.

A

B

C

C

B

M

7.87 in (20 cm)

6.75 in (17.1 cm)

M

M

M

M

M

M

4.5 in (11.4 cm)

A

Page 7

7PV

• Connect DC Wiring:

You must run positive

cable(s) through user-sup-

plied UL-listed fuse(s)

and fuse block(s) of the

proper size.

See Specifications page for Minimum Recommended Cable Sizing

Chart. An excellent source of cables is battery jumper cables. Output

performance will decrease if you use only one jumper cable.

Although your Inverter is a high-efficiency

converter of electricity, its rated output

capacity is limited by the length and gauge

of the cabling running from the battery to

the unit. Use the shortest length and largest

diameter cabling (maximum 00 gauge) to fit

your Inverter’s DC Input terminals. Shorter

and heavier gauge cabling reduces DC volt-

age drop and allows for maximum transfer

of current. Your Inverter is capable of delivering peak wattage at up to 200% of its rated

continuous wattage output instantaneously.

See Specifications page for details. Heavier

gauge cabling should be used when continuously operating heavy draw equipment under

these conditions. Tighten your Inverter and

battery terminals to approximately 3.5

Newton-meters (2.58 foot lbs.) of torque to

create an efficient connection and to prevent

excessive heating at this connection.

Insufficient tightening of the terminals could

void your warranty.

• Connect Ground: Using a #8 AWG wire

or larger, directly connect the Main Ground

Lug to the vehicle's chassis ground or earth

ground. See Feature Identification section to

locate Main Ground Lug. All installations

must comply with national and local codes

and ordinances.

• Connect Fuse: In addition to the

protection provided by the Inverter’s

internal fuses, NEC article 551 requires that

you connect your Inverter’s positive DC

Terminal(s) directly to a UL-listed fuse(s)

and fuse block(s) within 18 inches of the

battery. See diagrams below for proper fuse

placement.

Battery Connection

Vehicular

Your Inverter’s Nominal DC Input Voltage must match the voltage of your battery or batteries—12 Volts in most vehicular applications. It is possible

to connect your Inverter to the main battery within your vehicle’s electrical system. In many vehicular contexts, the Inverter will be connected

to one or more dedicated auxiliary (house) batteries which are isolated from the drive system to prevent possible draining of the main battery.

12 Volt Main Battery Connection—two DC terminals

12 Volt Alternator

Vehicle Battery Ground

12 Volt Main Battery

12 Volt Auxiliary (House)

Battery

UL-Listed Fuses & Fuse

Blocks (mounted within 18

inches of the battery)

Battery Isolator

Large Diameter Cabling,

Maximum 00 Gauge to Fit

Terminals

8 AWG (minimum) Ground

Wire to Vehicle Frame or

Earth Ground

8

7

6

5

4

3

2

1

12 Volt Main and Auxiliary (House) Battery Connection (Isolated Parallel)—two DC terminals

Connect your Inverter to your batteries using the following procedures—always loosely twist each pair of cables together before

connecting them separately to the appropriate DC terminal on the Inverter (positive or negative).

WARNING! Never attempt to operate your Inverter by connecting it directly to output from an alternator rather than

a battery or battery bank.

CAUTION! Observe proper polarity with all DC connections.

1

2

3

5

7

8

1

2

2

6

4

3

5

7

8

12 Volts

12 Volts

12 Volts

12 Volts

12 Volts

12 Volt Inverter

12 Volt Inverter

Page 8

8PV

Try these remedies for common Inverter problems before calling for assistance. Call Tripp Lite Customer Service at (773) 869-1234 before

returning your unit for service.

Troubleshooting

SYMPTOM PROBLEMS CORRECTIONS

No AC Output Operating Mode Switch is set to “OFF.” Set Operating Mode Switch to “ON/REMOTE.”

(All Indicator Lights Are OFF)

User-supplied UL-listed external DC input fuses have blown. Replace fuses.

Red Battery Indicator Light Unit has shut down due to excessive battery discharge. Run your engine to raise battery voltage. Check external battery

Is Rapidly Flashing connections and fuse. Reset by moving Operating Mode Switch

(¼ Second Flashes) to “OFF.” Wait one minute and switch to “ON/REMOTE.”

If unit remains in shutdown mode after several attempts to reset

contact Tripp Lite Customer Service for assistance.

Red Load Indicator Light Unit has shut down due to overload. Reduce load. Reset by moving Operating Mode Switch to “OFF.”

Is Rapidly Flashing Wait one minute and switch to “ON/REMOTE.” If unit remains in

(¼ Second Flashes) shutdown mode after several attempts to reset contact Tripp Lite

Customer Service for assistance.

Connected Equipment Experiences Audio/Video interference. Reposition equipment antennas and Inverter.

Buzzing Sound Or Picture Distortion

Inverter Output Seems Intermittent Loose cable connections. Check and secure all connections.

Operating Mode Switch

Battery Indicator Lights

Load Indicator Lights

200501058 93-2425

Limited Warranty

Tripp Lite warrants its Inverters to be free from defects in materials and workmanship for a period of one year (domestic) or 120 days (export) from the date of retail

purchase by end user.

Tripp Lite’s obligation under this warranty is limited to repairing or replacing (at its

sole option) any such defective products.To obtain service under this warranty you

must obtain a Returned Material Authorization (RMA) number from Tripp Lite or an

authorized Tripp Lite ser vice center. Products must be returned to Tripp Lite or an

authorized Tripp Lite ser vice center with transportation charges prepaid and must

be accompanied by a brief description of the problem encountered and proof of

date and place of purchase. This warranty does not apply to equipment which has

been damaged by accident, negligence or misapplication or has been altered or

modified in any way, including opening of the unit’s casing for any reason. This

warranty applies only to the original purchaser who must have properly registered the product within 10 days of retail purchase.

EXCEPT AS PROVIDED HEREIN, TRIPP LITE MAKES NO WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. Some states do not permit limitation or exclusion of implied warranties; therefore, the aforesaid limitation(s) or

exclusion(s) may not apply to the purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL TRIPP LITE BE LIABLE

FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF THIS PRODUCT, EVEN IF ADVISED OF

THE POSSIBILITY OF SUCH DAMAGE. Specifically, Tr ipp Lite is not liable for

any costs, such as lost profits or revenue, loss of equipment, loss of use of equipment, loss of software, loss of data, costs of substitutes, claims by third parties,

or otherwise.

Tripp Lite has a policy of continuous improvement. Specifications are subject to

change without notice.

Service

If you are returning your Inverter to Tripp Lite, please pack it carefully, using the ORIGINAL PACKING MATERIAL that came with the

unit. Enclose a letter describing the symptoms of the problem. If the Inverter is within the warranty period, enclose a copy of your sales

receipt. To obtain service you must obtain a Returned Material Authorization (RMA) number from Tripp Lite or an authorized Tripp Lite

service center.

Your Inverter requires no maintenance and contains no user-serviceable or replaceable parts, but should be kept dry at all times. Periodically

check, clean and tighten all cable connections, as necessary, both at the unit and at the battery.

Maintenance

Warranty Registration

Visit www.tripplite.com/warranty to register the

warranty of your new Tripp Lite product.You'll be

automatically entered into a drawing for a chance

to win a FREE Tripp Lite product!*

* No purchase necessary. Void where prohibited. Some restrictions

apply. See website for details.

This product designed and engineered in the USA.

AC Output Connection

To avoid overloading your Inverter, be sure to match the power requirements of the equipment you plan to run at any one time (add their total

watts) with the output wattage capacity of your Inverter model (see Specifications). When figuring the power requirements of your equipment, do not confuse “continuous” wattage with “peak” wattage ratings. Most electric motors require extra power at start-up (“peak”

wattage) than required to run continuously after start-up, sometimes over 100% more. Some motors, such as in refrigerators and pumps,

start and stop intermittently according to demand, requiring “peak” wattage at multiple, unpredictable times during operation.

• DoubleBoost™Feature

Tripp Lite Inverters deliver up to twice their nameplate rated

wattage for up to 10 seconds,* providing the extra power

needed to cold start heavy-duty tools and equipment.

• OverPower™Feature

Tripp Lite Inverters deliver up to 150% of their name

plate rated wattage for up to 1 hour,* providing plenty of reserve

power to reliably support tools and equipment longer.

* Actual duration depends on battery age, battery charge level and ambient temperature.

Loading...

Loading...