Page 1

Owner’s Manual

APS PowerVerter

Alternative Power Sources (120V, 60 Hz)

• Voltage- and Frequency-Controlled • Peak Power • High Efficiency

Introduction

Important Safety Instructions

Configuration & Connection

Features

Maintenance and Service

Warranty

®

2

4

5

11

14

14

Troubleshooting

Specifications

Español

1111 W. 35th Street Chicago, IL 60609 USA

Customer Support: (773) 869-1234 • www.tripplite.com

PowerVerter ®is a registered trademark of Tripp Lite. All rights reserved.

15

16

18

Page 2

Introduction

Congratulations! You’ve purchased the most advanced, feature-rich integrated inverter/battery

charger on the market. Your APS provides your equipment with utility-supplied AC power when

it is available, and during blackouts, overvoltages and brownouts, your APS automatically

switches over to an external battery source to power connected equipment with voltage and

frequency-controlled AC power. In addition to reliable APS performance, your model features:

High Efficiency Output

Your APS’s advanced circuitry produces a more efficient DC-to-AC conversion, minimizing

energy loss. This allows you to run connected equipment longer between battery charges. The

APS will maintain this highly-efficient output even as the battery charge decreases.

Automatic Overload Protection

If you overload your APS, it will automatically protect itself and your valuable batteries from

damage.

Fast Load Switching

Your APS provides an uninterruptible power supply. If AC power goes down, your APS will

switch over to providing battery backup power in 6 milliseconds or less so that your equipment

will operate with no interruption.

Multi-Function Indicator Lights

Several sets of multifunction indicator lights keep you constantly informed of battery charge

levels, fault conditions and APS operation.

Multi-Operation Switches

An array of user-configurable switches gives you convenient options when operating your

APS. You can select the voltage level at which your APS’s inverter will turn on to maximize

equipment protection and minimize battery drain; set your APS for maximum charging

efficiency with your battery type; even set up your APS for remote control operation.

2

Page 3

Introduction

15

14

13

12

Stage 2

Absorption

Stage 3

Float

Stage 1

Bulk

continued

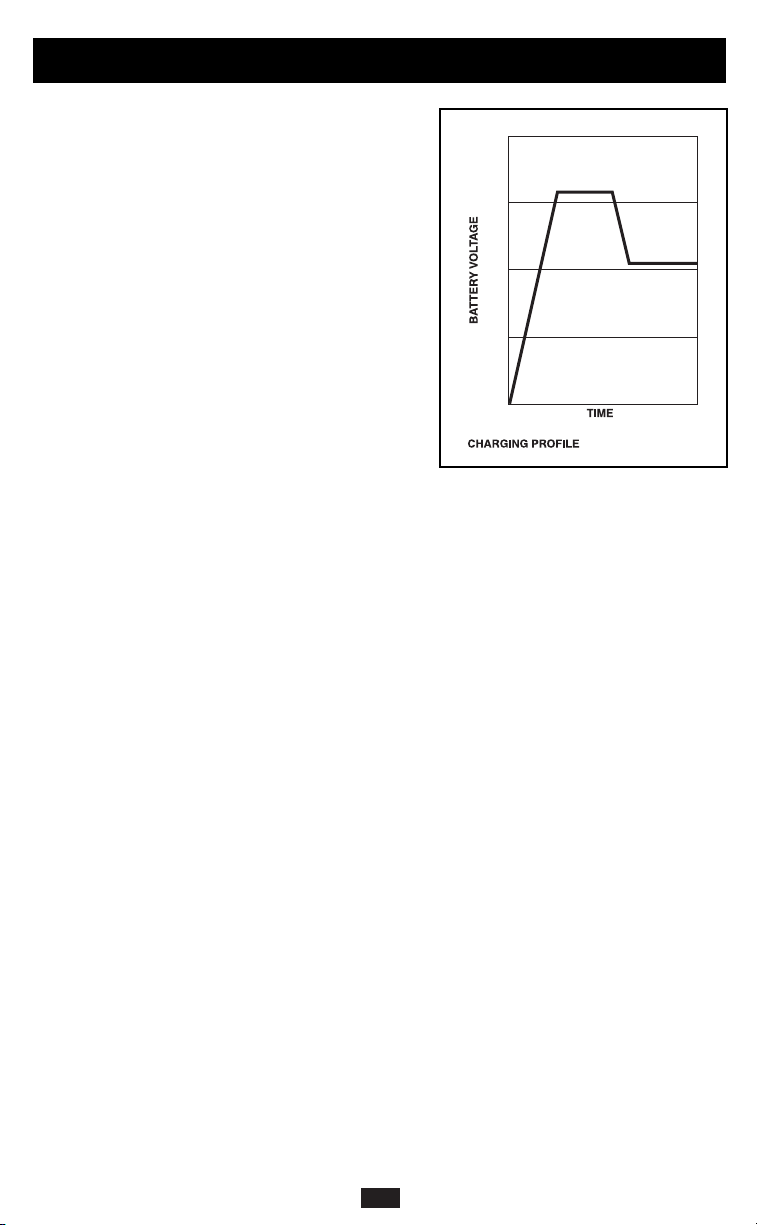

3-Stage Battery Charger

Your APS recharges your battery faster than

conventional chargers because its three-stage

charger profile (Bulk, Absorption and Float) are

optimized, regardless of the type of battery you

use (Wet or Gel).* In addition, the advanced

charging system protects against over-charge

and over-discharge to ensure a longer service

life from your battery.

* The Absorption and Float levels vary according to battery

type, which can be set to either “Wet” or “Gel”cell.

Voltage Regulation (Select models only)

“VR” APS models regulate incoming AC power

by automatically “boosting” or “cutting” the

voltage to keep your equipment running through

brownouts and overvoltages without draining

battery power.

Load Sharing (Select models only)

Select APS models can be set to limit their own

charging functions so they can charge their

batteries at the quickest rate possible without

overloading their power input circuits.

Frequency-Controlled

Inverter Output

All APS models feature Frequency-Controlled

Inverter Output which allows devices dependent

on AC line frequency (such as computers,

VCRs, CD players, tape recorders, clocks and

turntables) to operate properly.

Circuit Board Protection

A silicone conformal coating safeguards the circuit boards against moisture.

3

Page 4

Important Safety Instruction

SAVE THESE INSTRUCTIONS

This manual contains important instructions and warnings that should be followed during

the installation, operation and storage of all Tripp Lite APS Systems.

APS Location Warnings

• Install your APS indoors, away from excess moisture or heat, dust or direct sunlight.

• Your APS is NOT waterproof. Contact with water can cause the unit to short circuit and

could cause personal injury due to electric shock. Never immerse your APS. Mount it in

the driest location available.

• Leave adequate space around all sides of the APS for proper ventilation. The heavier the

load of connected equipment, the more heat will be generated by the APS.

• When mounting unit on a vertical surface, mount it with the control panel facing to the

side to reduce the risk of foreign objects entering the APS enclosure.

• Do not install the APS near magnetic storage media, as this may result in data corruption.

Battery Connection Warnings

• Your APS will not operate with or without utility power until batteries are connected.

• Multiple battery systems must be made up of batteries of the same voltage, age, amp hour

capacity and type.

• Keep battery location well ventilated. Explosive hydrogen gas can accumulate near

batteries if they are not kept well ventilated.

• Sparks may result during final battery connection. Always observe proper polarity as

batteries are connected.

• Do not allow objects to contact the two DC input terminals. Do not short or bridge these

terminals together. Serious injury to property or person could result.

Equipment Connection Warnings

• Do not use Tripp Lite APS Systems in life support applications where a malfunction or

failure of a Tripp Lite APS System could cause failure or significantly alter the performance of a life support device.

• Do not connect a surge suppressor, line conditioner or UPS to the output of the APS.

• Corded models: Do not modify the APS’s plug in a way that eliminates its ground

connection. Do not use power adaptors that will eliminate the plug's ground connection.

Connect your APS only to a properly grounded AC power outlet. Do not plug your APS

into itself; this will damage the APS and void your warranty.

Operation Warnings

• Your APS does not require routine maintenance. Do not open your APS for any reason.

There are no user-serviceable parts inside.

• Potentially lethal voltages exist within this unit as long as the battery supply and/or AC

input are connected. During any service work, the battery supply and AC input connection

(if any) should therefore be disconnected.

• Do not connect or disconnect batteries while the APS is operating from the battery supply.

Dangerous arcing may result.

4

Page 5

Configuration

4321

Gel Cell

Wet Cell*

4321

145V

135V*

4321

105V

4321

95V

4321

85V

4321

75V*

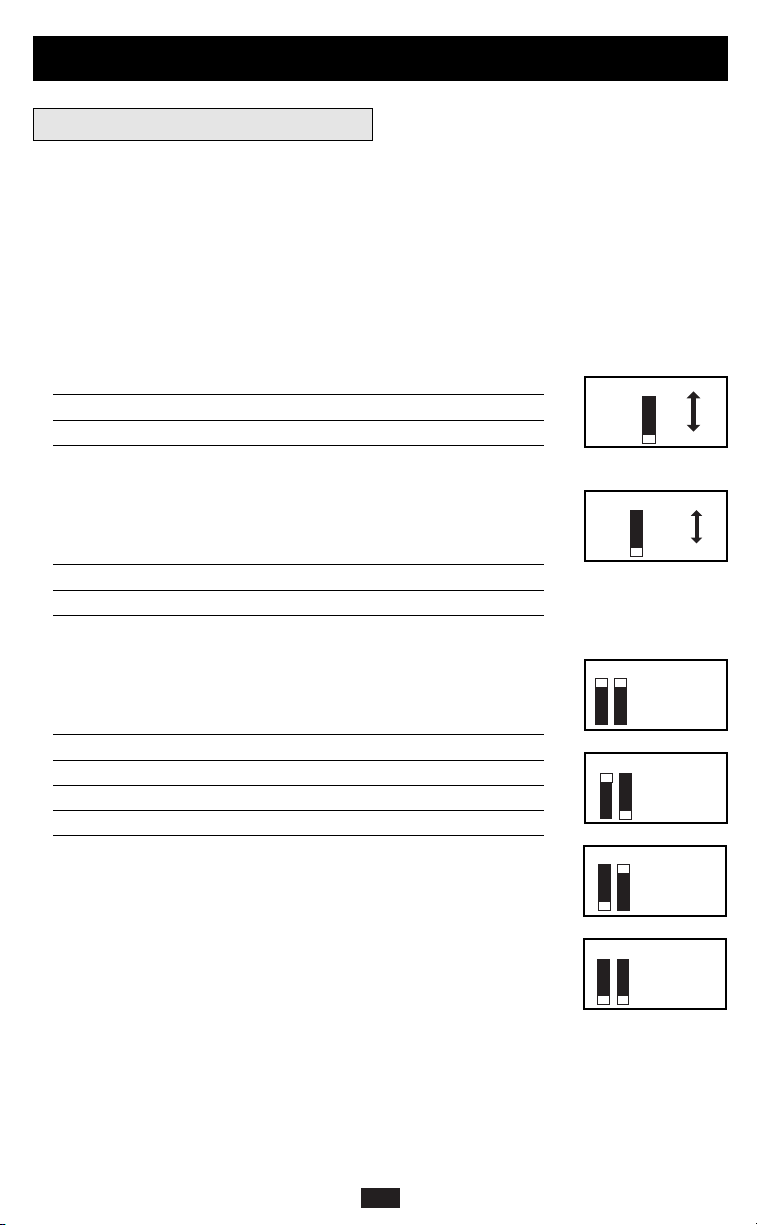

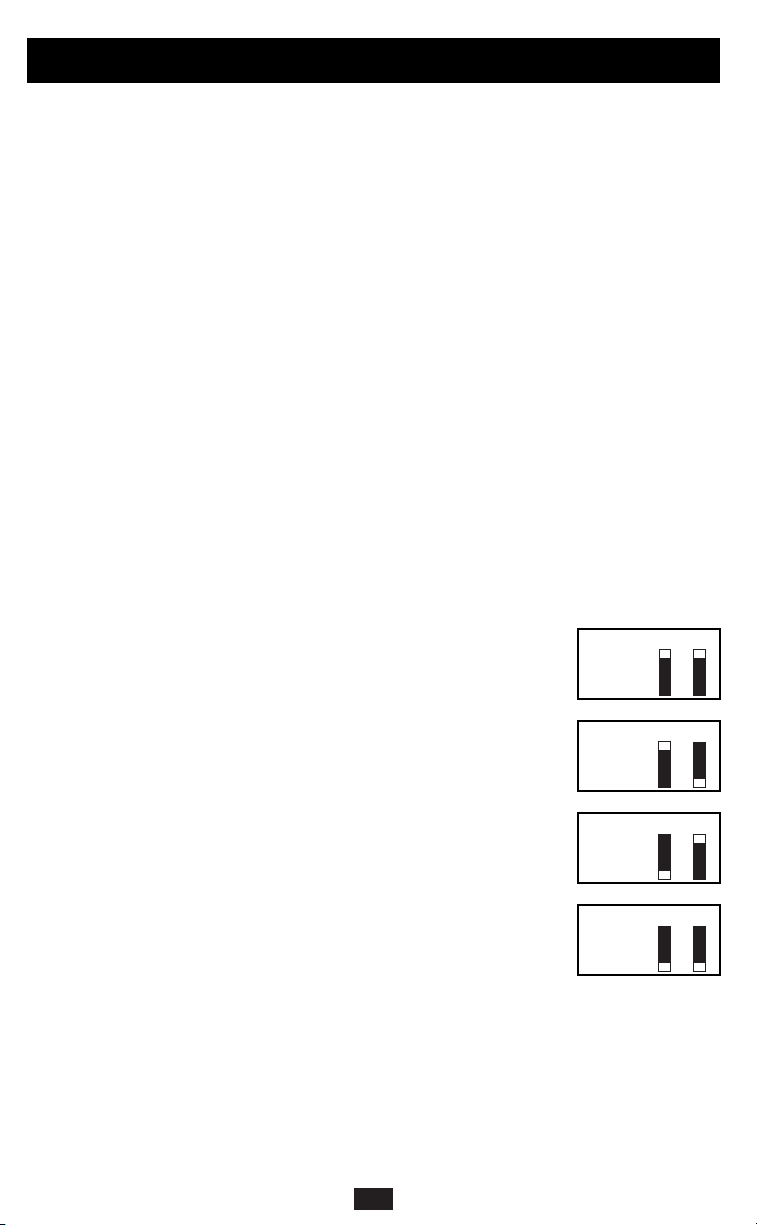

Configuration Dip Switch Settings

DIP SWITCH GROUP A

(All models)

BATTERY TYPE / VOLTAGE POINT

Using a small tool, set the 4 “Battery Type / Voltage Point” Configuration DIP Switches, Group

A (located on the front panel of your APS; see Diagram 1, p. 36) to select battery type and set

the voltage range outside of which your APS will switch to battery power.

• Select Battery Type

CAUTION: The Battery Type DIP Switch setting must match the type of batteries you connect or your batteries may be

degraded or damaged over an extended period of time. See “Battery Selection,” page 8 for more information.

(DIP Switch #1, Group A)

Battery Type Switch Position

Gel Cell (Sealed) Battery Up

Wet Cell (Vented) Battery Down*

• Select High AC Voltage Switch To

Battery Point

Voltage Switch Position

145V Up

135V Down*

(DIP Switch #2, Group A)

• Select Low AC Voltage Switch To

Battery Point

Voltage Switch Postion

105V #4 Up & #3 Up

95V #4 Up & #3 Down

85V #4 Down & #3 Up

75V #4 Down & #3 Down*

(DIP Switches #4, Group A & #3, Group A)

Most loads will perform adequately when your APS’s High AC Voltage

Point DIP Switch #2 is set to 135V and its Low AC Voltage Point DIP

Switches #3 and #4 are set to 95V. However, if your APS frequently

switches to battery power due to momentary high/low line voltage

swings that would have little effect on equipment operation, you may

wish to adjust these settings. By raising the High AC Voltage Switch to

Battery point and/or lowering the Low AC Voltage Switch to Battery

Point, you may reduce the number of times your APS switches to

battery due to voltage swings.

* Factory default settings.

5

Page 6

Configuration

4321

4321

4321

4321

continued

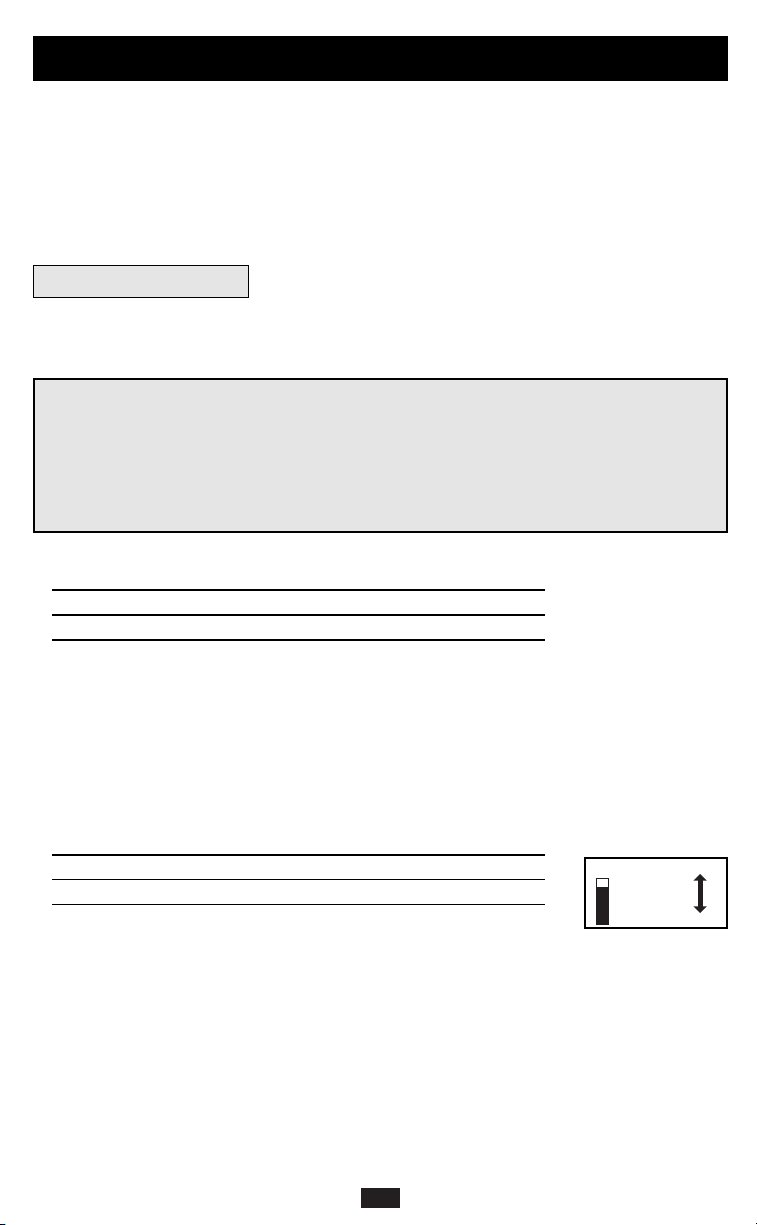

DIP SWITCH GROUP B (Available on Select Models)

LOAD SHARING/EQUALIZE BATTERY CHARGE

The “Load Sharing” Configuration DIP Switches, #1 and #2 of Group B (located on the front

panel of your APS; see Diagram 1, p. 36), should be set with a small tool according to the guidelines below. DIP Switch #3, Group B should be kept in the “UP” position when you are not equalizing your batteries' charges. DIP Switch #4, Group B has different functions, or no function,

depending on your APS model.

• Load Sharing

Your APS features a high-output battery charger that can draw a significant amount of power

from your line power source when charging at its maximum rate. If an APS is supplying its

full AC power rating to its connected load at the same time as it is charging, it could trip its

line source circuit breaker. Tripping this breaker will cut off AC power to your load and stop

battery charging.

To reduce the chance of tripping this breaker, select APS models may be set to automatically

limit their charger output to keep the sum of their AC load and charger power within their

circuit breakers’ rating.

This charger limiting function has four settings, allowing you to choose less charger limiting

for APS configurations with higher rated breakers. The figures below show how to set your DIP

Switches to select how heavy a load can be placed on your APS before charger limiting begins.

(DIP Switches #1, Group B & #2, Group B)

Battery Charger Limiting Points

Most Limiting (#1 & #2 Up*): Charger limiting takes effect the

moment any load is applied; charger output falls gradually from full

output at no load to no output at full load.

Less Limiting (#1 Down & #2 Up): Charger limiting begins when the

APS's load reaches 33% of the APS’s load rating. Charger output falls

gradually from full output at 33% of the APS's load rating to about 40%

of full output at full load.

Least Limiting (#1 Up & #2 Down): Charger limiting begins at when

the APS’s load reaches 66% of the APS’s load rating. Charger output

falls gradually from full output at 66% of the APS's load rating to about

40% of full output at full load.

No Limiting (#1 & #2 Down): No charger limiting occurs at any load size.

* Factory default settings.

6

Page 7

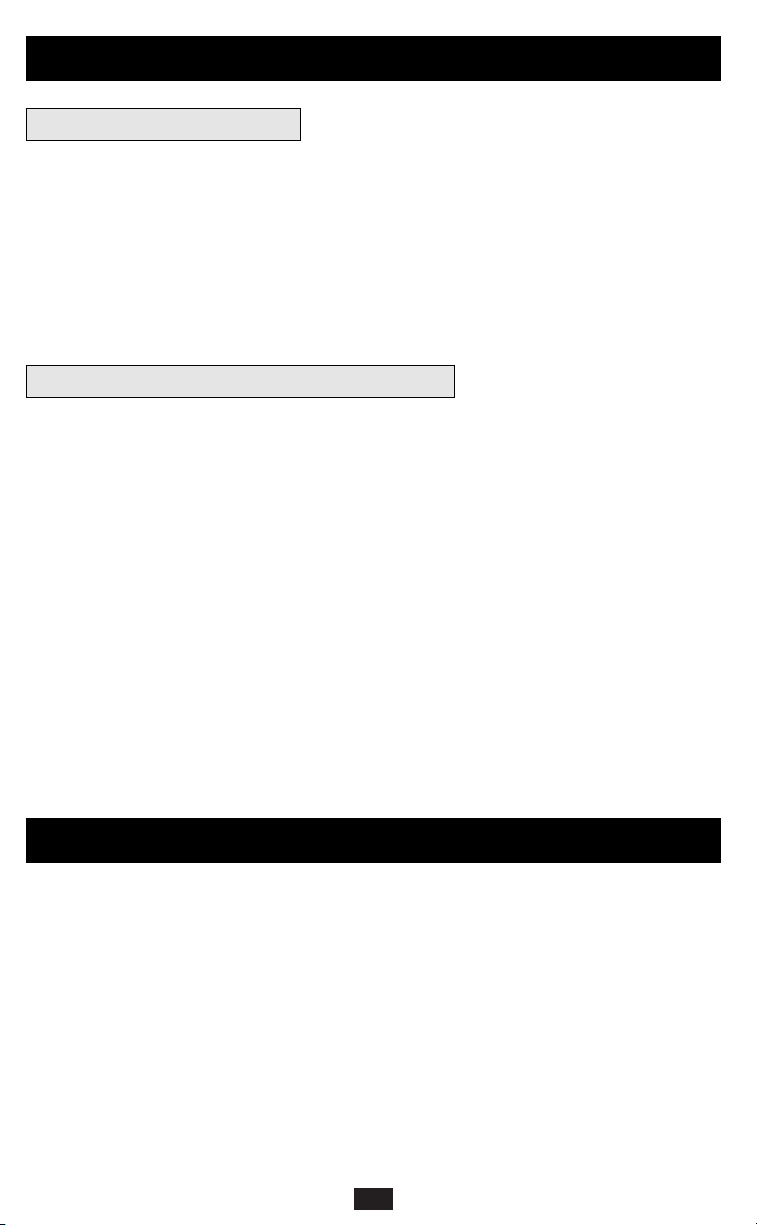

Configuration

4321

Partial*

Full

continued

• Equalize Battery Charge

This DIP Switch is momentarily engaged to begin the process of equalizing the internal resistance

of your battery's cells. This can extend the useful life of certain types of batteries; consult with

your battery's manufacturer to determine if your batteries could benefit from this process. The

charge equalization process is automatic and once started can only be stopped by removing the

input power.

(DIP Switch #3, Group B)

Setting Procedure:

• Move to “Equalize” (DOWN) position for three seconds.

• Move to “Reset” (UP) position and leave it there.

CAUTION: Battery charge equalization should only be performed in

strict accordance with the battery manufacturer’s instructions and

specifications.

CAUTION: Do not leave DIP switch #3 in the down position after

beginning process.

Battery Charge Switch Position

Reset Up*

Equalize Down

* Factory default setting.

• Limit Battery Charger

To prevent overheating smaller batteries, the charger on these UPS systems is initially set to

deliver only a fraction of its maximum power rating to connected batteries. If you are using either

of these APS systems with a larger battery or battery system (over 100 amp-hours), you may

switch your charger to full power without overheating your batteries.

Battery Charger Switch Position

Partial (1/3) Charging Power Up*

Full Charging Power Down

* Factory default setting.

(APS1012, APS1524 & APS2012 only)

7

(DIP Switch #4, Group B)

Page 8

Battery Selection

Selecting Battery Type

Select a battery or system of batteries that will provide your APS with proper DC voltage and an

adequate amp hour capacity.* Select ‘Deep-Cycle’batteries to enjoy optimum performance from

your APS. Batteries of either Wet-Cell (vented) or Gel-Cell/Absorbed Glass Mat (sealed)

construction are ideal. 6 Volt “golf-cart,” Marine Deep-Cycle or 8D Deep-Cycle batteries are also

acceptable.**

* Even though APS models are high-efficiency converters of electricity, their rated output capacities are limited by the

amp-hour size of the external batteries. ** You must set Configuration DIP Switch #1, Group A (Battery Type) to match the

type of batteries you connect or your batteries may be degraded or damaged over an extended period of time. See “APS

Configuration,” page 5 for more information.)

Selecting Battery Amp Hour Capacity

1. Add the Wattage Ratings of your connected equipment to determine the Total Wattage Required.*

2. Divide the Total Wattage Required (from Step 1) by the battery voltage to determine the DC

Amperes Required.

3. Multiply the DC Amperes Required (from Step 2) by the number of hours you estimate will

pass without AC power before your battery can recharge to determine a Battery Amp-Hours

Required Rough Estimate.**

4. Compensate for inefficiency by multiplying your Battery Amp-Hour Required Rough Estimate

(from Step 3) by 1.2 to determine how many amp-hours of battery backup (from one or several

batteries) you should connect to your APS. Note that the Amp-Hour ratings of

batteries are usually given for a 20 hour discharge rate. Actual Amp-Hour capacities are less

when batteries are discharged at faster rates: batteries discharged in 55 minutes provide only

about 50% of their listed Amp-Hour ratings, while batteries discharged in 9 minutes provide

as little as 30% of their Amp-Hour ratings.

* The wattage rating is usually stated in the equipment’s manuals or on their nameplates. If your equipment is rated in amperes, convert

to watts by multiplying the ampere rating by your nominal AC line voltage (120). ** Your charging amps multiplied by the charging

hours must exceed the discharge amp-hours taken from the batteries between charges or you will eventually run down your battery bank.

Mounting

(Optional)

(See Diagram 2, p. 36)

Horizontal mounting should be used for all vehicular applications. Due to their size and weight,

all APS PowerVerter systems in vehicles should be mounted on a rigid horizontal (not vertical)

surface, mounting plate or bracket before battery connection. User must supply all fasteners and

brackets and verify their suitability for use with the intended mounting surface. Turn your APS

PowerVerter and connected equipment OFF before mounting.

• Install two 8 mm (1/4 in.) fasteners (A) into a rigid horizontal surface using the

measurements in the diagram. Leave the heads of fasteners raised slightly above

the surface in order to engage the slots in the APS’s feet.

• Slide PowerVerter forward to fully engage the fasteners in the APS’s feet. Install two

8 mm (1/4 in.) fasteners (B) into the surface, through the slots in the APS’s two

unsecured feet. Tighten the screws to secure the APS in position.

8

Page 9

Battery Connection

Standard

1. Connect your APS’s positive DC Terminal directly to a fuse.

UL recommends that you install a recognized UL component fuse block and fuse within 18

inches of the battery. The fuse’s rating must equal or exceed the Minimum DC Fuse Rating

listed in your APS model’s specifications on pages 16 or 17.

2. Choose a battery configuration appropriate to your batteries.

• Single Battery Connection: Refer to Diagram 4, page 37. When using a single battery, its

voltage must be equal to the voltage of your APS's Inverter Nominal Input Voltage (see

specs).

• Parallel Battery Connection: Refer to Diagram 5, page 37. When using multiple batteries

in parallel, each battery's voltage must be equal to the voltage of your APS’s Inverter

Nominal Input Voltage (see specs).

• Series Battery Connection: Refer to Diagram 6, page 37. When using multiple batteries

in series, all batteries must be equal in voltage and amp hour capacity, and the sum of their

voltages must be equal to the voltage of your APS's Inverter Nominal Input Voltage (see specs).

3. Use 2/0 gauge wire ONLY to make battery connections. Tighten terminals to a torque of 4 N-m.

Battery connection cable lengths should be short as possible, and must not exceed the Maximum

Cable Length listed under Specifications, page 16 or 17. Shorter and heavier gauge cabling limits

DC voltage drop and allows for maximum transfer of current.* You must tighten your battery

terminals to approximately 4 Newton-meters of torque to create an efficient connection and prevent

excessive heating. Insufficiently tightening terminals could void your PowerVerter’s warranty.

* APS models are capable of delivering a much higher wattage output for brief periods of time. Wiring should be

configured to handle this brief high-current draw. Though your APS is a high-efficiency converter of electricity, its

rated output capacity is limited by the length and gauge of the wires running from the battery to the APS.

DC Vehicular

APS systems may be permanently mounted in a car, truck or boat and connected to draw power

from the vehicle's battery. Note: An APS can ONLY be connected to vehicle batteries with

voltage that matches the APS’s Nominal DC Input—12V vehicle batteries to 12V Nominal

DC Input APS systems, etc. (See Specifications). There are two main ways to make this sort of

vehicular battery connection. Choose the Basic Connection if you are running light hand tools or

other small appliances for a brief period of time (see Diagram 7, p. 38). Choose the Advanced

Connection if you are using your APS to power heavy loads for extended periods of time (see

Diagram 8, p. 38). The Advanced Connection incorporates a battery isolator and separate

battery system to provide battery power to your APS while preventing it from draining your vehicle’s

battery. Note: Depending on your application, you may require more than one Deep Cycle Battery.

Note: The main ground stud on the rear panel must be connected to the vehicle chassis. A non-grounded unit could

cause an electrical shock hazard.

Caution: Never operate your APS from an alternator without a battery connected as shown in Diagrams 7 or 8, p. 38.

DC Ground Connection

APS systems must be connected to a grounded, permanent wiring system. For most installations,

the negative battery conductor must be bonded to the grounding system at one (and only one)

point in the system. All installations must comply with national and local codes and ordinances.

9

Page 10

AC Connection

Before AC connection, match the power requirements of your

equipment with the power output of your APS to avoid overload.

When figuring the power requirements of your equipment, do not confuse “continuous” power

ratings with “peak” power ratings. Electric motors require more power to turn on (“peak power”)

than they require to run continuously. “Peak” power ratings are usually 2 to 5 times “Continuous”

ratings. Most electric motors require “peak power” only when they are first turned on. The electric

motors in equipment such as refrigerators and sump pumps, however, constantly turn on and off

according to demand. These motors require “peak power” at multiple, unpredictable times during

their operation.

Hardwired Electrical Connections (All hardwire models)

Consult a qualified electrician and follow all applicable electrical codes and requirements.

HARDWIRE PROCEDURE

1. Remove screws and cover plate from your APS’s Hardwire AC electrical box. Remove the

knockout covers closest to the desired electrical source and to your equipment.

2. Thread your wires through the knockouts, adding strain reliefs if desired.

3. Connect both input and output ground wires to the ground (green) terminal.

4. Connect the incoming hot wire to the input hot (brown) terminal.

5. Connect the incoming neutral wire to the input neutral (blue) terminal.

6. Connect the outgoing hot wire to the output hot (black) terminal.

7. Connect the outgoing neutral wire to the output neutral (white) terminal.

8. Tighten and affix strain reliefs. Replace cover plate and tighten screws.

(See Diagram 3, p. 36)

AC Input Electrical Connection (All corded models)

Plug the line cord into an outlet providing 120V AC, 60 Hz. power. Make sure that the circuit you

connect your APS to has adequate overload protection, such as a circuit breaker or a fuse.

AC Output Electrical Connection (All corded models)

Simply plug your equipment into the unit’s AC receptacles.

10

Page 11

AC Connection

continued

Set Operating Mode Switch

• Switch to “AUTO/REMOTE” when you are using connected equipment. ADVANTAGE:

Uninterruptible power supply. Provides battery backup power during blackouts or

brownouts.

Note: When the switch is in the “AUTO/REMOTE” position, you can operate a user-supplied switch to transfer

between battery-backup and charge-only modes. (See Remote Connector manual for more information.)

• Switch to “CHARGE ONLY” when you are not using connected equipment. (WARNING!

APS will not provide battery backup!) ADVANTAGES: A) Continues to charge battery

when power is present, and B) Turns OFF the APS’s inverter, preventing battery drain

during blackouts or brownouts.

• Switch to “OFF” to completely turn off the APS and connected equipment or to reset the

APS after it has shut down due to overload or overheating.

Switches, Indicator Lights & Other Features

(See Diagrams 9a and 9b, p. 39-40, to locate the following switches, indicator lights and other features.)

Switches

1. Operating Mode Switch (All models): This switch selects the APS operating mode (either

“AUTO/REMOTE”, “OFF” or “CHARGE ONLY”). See “Set Operating Mode Switch”, pg. 11

to select the optimum setting for this switch.

2. “CONFIGURATION SWITCHES”—DIP Switch Group A (All models): These four

switches must be set for the type of battery your APS will be connected to and the voltage

points at which your APS will switch to battery power. See “Configuration”, pg. 5 to select

the optimum settings for these switches.

3. “CONFIGURATION SWITCHES”—DIP Switch Group B (Select models only): These

DIP Switches allow you to equalize the internal resistance of your battery’s cells and set the

percentage of your model's maximum load at which the APS will limit battery charging. See

“Configuration”, pg. 6 to select the optimum settings for these switches.

11

Page 12

Switches, Indicator Lights & Other Features

continued

Indicator Lights

4. “LINE” (All models): This green light will turn continuously ON whenever connected equipment

is receiving utility-supplied AC power and your APS is set to “AUTO/REMOTE”, meaning

that it will provide battery backup if utility power fails. It will flash intermittently when

connected equipment is receiving utility power and your APS’s Operating Mode Switch is set

to “CHARGE ONLY” to warn you that the APS’s inverter is OFF and that the APS WILL

NOT provide battery backup during blackouts, brownouts or overvoltages.

5. “INV” (Inverting—all models): This yellow light will turn continuously ON whenever

connected equipment is receiving battery-supplied AC power (during a blackout, brownout or

overvoltage while connected to utility power or when connected to batteries during vehicular

operation).

6. “LOAD” (All models): This red light will turn continuously ON when the APS’s load is

between 80% and 110% of capacity. The light will flash intermittently when the APS’s inverter

shuts down due to a severe overload or overheating. If this happens, turn Operating Mode

Switch OFF. Remove the overload and let the unit cool. You may then turn the APS ON after

it cools.

7. “CUT/BOOST” (VR models only): These lights will turn ON whenever your APS is

automatically correcting high (CUT) or low (BOOST) AC line voltage. This is a normal, automatic

operation of your APS that does not drain battery power, and no action is required on your part.

8. “BATTERY HI/MED/LO” (All models): These three lights will turn ON in several

sequences to show the approximate charge level and voltage of your connected battery bank

and alert you to several fault conditions:

BATTERY CHARGE INDICATION (Approximate)

Indicator Capacity

Green 91% - Full

Green & yellow 81% - 90%

Yellow 61% - 80%

Yellow & red 41% - 60%

Red 21% - 40%

All three lights off 1% - 20%

Flashing red 0% (Inverter shutdown)

All three lights flash slowly* Excessive discharge

All three lights flash quickly** Overcharge

* Approximately 1/2 second on, 1/2 second off. See Troubleshooting section.

** Approximately 1/4 second on, 1/4 second off. May also indicate a battery charger fault exists. See Troubleshooting section.

12

Page 13

Switches, Indicator Lights & Other Features

continued

Other Features

9. DC Input Terminals (All models): The terminals’ lug screws secure the wires leading from

your external battery or battery system. Your battery or battery system must provide your

APS with proper DC voltage and your equipment with an adequate amp hour capacity. See

Battery Selection section, pg. 8 for more information.

10. AC Receptacles: NEMA 5-15R (Corded models only): These receptacles allow you to

connect equipment that would normally be plugged into a utility outlet. They feature ground

fault indicator switches that trip when the receptacles are in danger of short circuiting. If the

switches trip, press to reset them when the short circuit situation is remedied.

11. AC Input Line Cord: NEMA 5-15P fixed (Corded models only): This cord should be

plugged into a 120V, 60 Hz, dedicated 15 Amp AC utility outlet. DO NOT plug the cord into

the APS’s AC receptacles.

12. Hardwire AC Input/Output Terminal Strip (Hardwire models only): Use the lug screws

on these terminals to secure hardwire connections for AC input and output. See pages 10 &

36 for wiring instructions.

13. Resettable Circuit Breakers (All models): These circuit breakers protect your APS against

damage due to input or output overload. If a breaker trips, remove some of the load on the

APS to prevent overload, then wait 1 minute to allow components to cool before resetting

the circuit breaker.

14. Remote Module Connector (All models): The front panel of all models has an RJ 45

receptacle for use with the optional remote module. (Module is included with all VR models.)

See the installation instructions packed with the remote module.

15. Load Sense Potentiometer (All models): In order to save battery power, the APS’s inverter

automatically shuts off when no load is connected. When the unit detects a load, it

automatically turns the inverter on. Users may choose the minimum load the APS will detect

by adjusting the Load Sense Potentiometer. Using a small tool, turn the potentiometer clockwise

to lower the minimum load that will be detected, causing the inverter to turn on for smaller

loads. When the potentiometer is turned fully clockwise, the inverter will operate even when

there is no load. Turn the potentiometer counterclockwise to increase the minimum load that

will be detected, causing the inverter to stay off until the new minimum load is reached.

The factory setting for the potentiometer is fully clockwise, but in areas with frequent power

interruptions, the potentiometer should be adjusted counterclockwise until the inverter is

only in operation when the APS’s load is in use.

13

Page 14

Maintenance & Service

Maintenance

Your APS model requires no maintenance but should be kept dry at all times. Periodically check

all cable connections both at the unit and at the battery. Clean and tighten connections as necessary.

Service

If returning your APS to Tripp Lite, please pack the APS carefully, using the ORIGINAL PACKING

MATERIAL that came with the unit. Enclose a letter describing the symptoms of the problem. If

the APS is within the warranty period, enclose a copy of your sales receipt.

Limited Warranty

Tripp Lite warrants its products to be free from defects in materials and workmanship for a period of one year

(domestic) or 120 days (export) from the date of initial purchase. Tripp Lite’s obligation under this warranty is

limited to repairing or replacing (at its sole option) any such defective products.To obtain service under this warranty

you must obtain a Returned Material Authorization (RMA) number from Tripp Lite or an authorized Tripp Lite

service center. Products must be returned to Tripp Lite or an authorized Tripp Lite service center with transportation

charges prepaid and must be accompanied by a brief description of the problem encountered and proof of date

and place of purchase. This warranty does not apply to equipment which has been damaged by accident, negligence

or misapplication or has been altered or modified in any way. This warranty applies only to the original purchaser

who must have properly registered the product within 10 days of purchase.

EXCEPT AS PROVIDED HEREIN, TRIPP LITE MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Some states do not

permit limitation or exclusion of implied warranties; therefore, the aforesaid limitation(s) or exclusion(s) may not

apply to the purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL TRIPP LITE BE LIABLE FOR DIRECT, INDIRECT, SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF THIS PRODUCT, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. Specifically, Tripp Lite is not liable for any costs, such as

lost profits or revenue, loss of equipment, loss of use of equipment, loss of software, loss of data, costs of

substitutes, claims by third parties, or otherwise.

14

Page 15

Troubleshooting

Try these remedies for common APS problems before calling for help. Call Tripp Lite Customer Service at

(773) 869-1234 before returning your APS for service.

SYMPTOM PROBLEMS CORRECTIONS

APS does not provide APS not properly connected to Connect APS to utility power.

AC output (AC input present) utility power.

Circuit breaker is tripped. Reset circuit breaker.

APS shutdown due to excessive Turn APS “OFF”.Wait 1 minute and

battery voltage, indicating possible switch to “AUTO/REMOTE”.

charger failure. Line disconnected

to prevent permanent battery

damage.

APS is set to “OFF” Set APS to “AUTO/REMOTE” or

APS does not provide Circuit breaker is tripped. Reset circuit breaker.

AC output (AC input absent)

Operating Mode Switch is set Set Operating Mode Switch to “AUTO/

to “CHARGE ONLY”. REMOTE.”

Load or High Temperature fault. Turn APS “OFF”. Wait 1 minute.

Excessive battery discharge. Check battery condition.

APS will not charge the Connected batteries are dead. Check and replace old batteries.

battery (AC input present)

Battery fuse* is blown. Check and replace fuse.

Battery cabling* is loose or degraded. Check and tighten or replace cabling.

APS charger failure. Turn APS “OFF”.Wait 1 minute and

All APS Indicator Lights are This is normal if the APS is set —

OFF (AC input absent) to “CHARGE-ONLY”

All APS Indicator Lights are Excessive battery discharge. Use an auxiliary charger* to raise

OFF (AC input is present or battery voltage. Check external battery

absent) connections and fuse. Automatically

All APS Battery Indicator Excessive battery discharge. Use an auxiliary charger* to raise

Lights are slowly flashing. battery voltage. Automatically resets

APS “LOAD” Battery Light Inverter shutdown because battery Reset by cycling control switch to

flashing voltage dropped too low for more “OFF” position then to “AUTO/

than 5 seconds. Protects battery REMOTE”.

from permanent damage.

All APS Battery Lights are High battery voltage shutdown Check all charging sources. Reset by

rapidly flashing during Charge mode. cycling control switch to "OFF" then to

APS “LOAD” Indicator Light Inverter overload caused by Reset by reducing load and cycling

is rapidly flashing excessive load or short circuit. control switch to “OFF” position then

If sustained for more then 5 to “AUTO/REMOTE”.

seconds the Inverter is shutdown.

*User supplied

“CHARGE-ONLY”.

Remove overload. Switch to

“AUTO/REMOTE”.

switch to “AUTO/REMOTE”. If

automatic shutdown occurs, call

Tripp Lite Customer Service.

resets when condition is cleared.

when condition is cleared.

“AUTO/REMOTE” or “CHARGE-ONLY”.

15

Page 16

Specifications

CORDED MODELS: APS 1012

Weight: 26.4 lbs.

INVERTER

Continuous power (@ 20° C): 1000 W

Surge power (5 seconds): 2000 W

Efficiency (Full Load): 88%

Minimum DC Fuse Rating: 225A

DC Input Current @ Nominal V DC

Full Load 95 A

No Load 2.2 A*

Nominal Input Volts: 12 VDC

DC Input Voltage Range: 10-15 VDC

Nominal Output Volts: 120 VAC ±5%

Nominal Output Frequency: 60 Hz ±.3%

BATTERY CHARGER

Charging Capacity DC: 10 A**

Maximum Cable Length 2 ft.

Acceptance Volts VDC: Selectable 14.4 V**/14.2 V Wet**/Gel

Float Volts VDC (w/gel): 13.3 V (13.6 V)

Input Voltage AC: 120 V

Input Current AC: 1.4 A**

LINE VAC OPERATION

Minimum Input AC Volts: Selectable 75**,85, 95, or 105 VAC

Maximum Input AC Volts

(Continuous, Charger at Maximum): Selectable 135** or 145 VAC

Maximum Input Current

(Continuous, Charger at Maximum): 12 A

Input Frequency: 60 Hz ±10%

Maximum Output AC (Continuous): 8.3 A

Automatic Transfer Time: 4-6 ms

(Corded Models)

* Load sense can reduce this to 1/30 of the listed current. **Factory default setting.

16

Page 17

Specifications

HARDWIRED MODELS: APS 1524 APS 2012

Weight: 26.4 lbs. 38.0 lbs.

INVERTER

Continuous power (@ 20° C): 1500 W 2000 W

Surge power (5 seconds): 3000 W 4000 W

Efficiency (Full Load): 89% 87%

Minimum DC Fuse Rating: 125A 500A

DC Input Current @ Nominal V DC

Full Load 70 A 192 A

No Load 1.3 A* 2.5 A*

Nominal Input Volts: 24 VDC 12 VDC

DC Input Voltage Range: 20-30 VDC 10-15 VDC

Nominal Output Volts: 120 VAC ±5% 120 VAC ±5%

Nominal Output Frequency: 60 Hz ±.3% 60 Hz ±.3%

BATTERY CHARGER

Charging Capacity DC: 10 A** 20 A**

Maximum Cable Length 7 ft. 1 ft.

Acceptance Volts VDC: Selectable Selectable

Float Volts VDC (w/gel): 26.6 V (27.2 V) 13.3 V (13.6 V)

Input Voltage AC: 120 V 120 V

Input Current AC: 4.2 A** 4.2 A**

LINE VAC OPERATION

Minimum Input AC Volts: Selectable 75**,85, 95, or 105 VAC Selectable 75**,85, 95, or 105 VAC

Maximum Input AC Volts

(Continuous, Charger at Maximum): Selectable 135* *or 145 VAC Selectable 135** or 145 VAC

Maximum Input Current

(Continuous, Charger at Maximum): 26 A 29 A

Input Frequency: 60 Hz ±10% 60 Hz ±10%

Maximum Output AC (Continuous) 12.5 A 16.7 A

Automatic Transfer Time: 4-6 ms 4-6 ms

HARDWIRED MODELS (Cont.): APS2424 APSVR3636

Weight: 41.0 lbs. 56.9 lbs.

INVERTER

Continuous power (@ 20° C): 2400 W 3600 W

Surge power (5 seconds): 4800 W 7200 W

Efficiency (Full Load): 89% 88%

Minimum DC Fuse Rating: 300A 300A

DC Input Current @ Nominal V DC

Full Load 112 A 114 A

No Load 1.5 A* 1.7 A*

Nominal Input Volts: 24 VDC 36 VDC

DC Input Voltage Range: 20-30 VDC 30-45 VDC

Nominal Output Volts: 120 VAC ±5% 120 VAC ±5%

Nominal Output Frequency: 60 Hz ±.3% 60 Hz ±.3%

BATTERY CHARGER

Charging Capacity DC: 30 A 30 A

Maximum Cable Length 3 ft. 4.5 ft.

Acceptance Volts VDC: Selectable Selectable

Float Volts VDC (w/gel): 26.6 V (27.2 V) 39.9 V (40.8 V)

Input Voltage AC: 120 V 120 V

Input Current AC: 13.3 A 20 A

LINE VAC OPERATION

Minimum Input AC Volts: Selectable 75**,85, 95, or 105 VAC Selectable 75**,85, 95, or 105 VAC

Maximum Input AC Volts

(Continuous, Charger at Maximum): Selectable 135** or 145 VAC Selectable 135** or 145 VAC

Maximum Input Current

(Continuous, Charger at Maximum): 33 A 54 A***

Input Frequency: 60 Hz ±10% 60 Hz ±10%

Maximum Output AC (Continuous) 20 A 30 A

Automatic Transfer Time: 4-6 ms 4-6 ms

(Hardwired Models)

28.8 V**/28.4 V Wet**/Gel 14.4 V**/14.2 V Wet**/Gel

28.8 V**/28.4 V Wet**/Gel 43.2 V**/42.6 V Wet**/Gel

* Load sense can reduce this to 1/30 of the listed current. ** Factory default setting. *** When AVR is boosting incoming current.

17

Page 18

Manual de Operación

APS PowerVerter

Fuentes Alternativas de Energía (120V, 60 Hz)

• Con Voltaje y Frecuencia Controlada • Energía de Cresta • Alta Eficiencia

Introducción

Seguridad

Configuración y Conexión

Características

Mantenimiento y Servicio

Garantía

®

19

21

22

29

32

32

Resolución de Problemas

Especificaciones

1111 W. 35th Street Chicago, IL 60609 USA

Servicios a Clientes: (773) 869-1234 • www.tripplite.com

Copyright © 2001 Tripp Lite. Propiedad Literaria de Tripp Lite 2001. Reservados todos los derechos.

18

33

34

Page 19

Introducción

Introducción

¡Felicitaciones! Usted ha adquirido el inversor / cargador de batería integrado más avanzado y

con más características en el mercado. Este modelo APS suministrará a sus equipos energía de

CA mientras ésta esté presente. Durante un apagón, caída o subida de voltaje, esta unidad cambia

automáticamente a la batería externa para suministrar energía de CA de voltaje y frecuencia

controlada.

Salida de Alta Eficiencia

La circuitería avanzada de este sistema APS produce una conversión de alta eficiencia de CD a

CA, minimizando así la pérdida de energía. Esto le permite a usted operar los equipos conectados por

períodos prolongados entre carga y carga de las baterías. Este sistema mantendrá la salida de alta

eficiencia aún mientras disminuye la carga de las baterías.

Protección Automática contra Sobrecargas

Si usted sobrecarga este APS, la unidad protegerá automáticamente sus baterías y a sí misma contra daños.

Cambio Rápido de Carga

El sistema APS brinda alimentación eléctrica ininterrumpida. Si se pierde el suministro de corriente

alterna de la red, el APS conmutará en 6 milisegundos o menos a la alimentación por pilas de

reserva, de modo que sus equipos funcionarán sin interrupción.

Luces Indicadoras de Funciones Múltiples

Varios juegos de luces indicadoras de funciones múltiples le mantienen constantemente informado

acerca de los niveles de carga de la batería, fallas y operación del sistema APS.

Interruptores de Operaciones Múltiples

Una variedad de interruptores ajustables por el usuario le ofrecen convenientes opciones para

operar el sistema APS. Usted puede seleccionar el nivel de voltaje de activación del inversor del

APS para maximizar la protección de sus equipos y minimizar el desgaste de las baterías; regular el APS para incrementar la eficiencia de recarga de acuerdo al tipo de baterías

utilizadas; y hasta activar la operación de su APS por control remoto.

19

Page 20

Introducción

15

14

13

12

Stage 2

Absorption

Stage 3

Float

Stage 1

Bulk

continua

Cargador Avanzado

de 3 Etapas para Baterías

Este sistema APS recargará sus baterías más

rápido que otros cargadores convencionales

debido a que su perfil de recarga de 3 etapas

(Alimentación en Masa, Absorción y

Alimentación por Flotador) provee óptimo

rendimiento independientemente del tipo de

baterías que usted utilice (Húmeda o de Gel).*

Además, el sistema avanzado de recarga

protege contra exceso de carga y descarga para

prolongar la vida útil de sus baterías.

* Los niveles de Absorción y Alimentación por Flotador

varían de acuerdo al tipo de baterías conectadas. Esta

unidad puede ser regulada para operar con Baterías

Húmedas o de Gel.

Regulación Automática de Voltaje

(Modelos Selectos Solamente)

Los modelos “VR” regulan el voltaje de entrada

de CA, elevando o disminuyendo dicho voltaje

para mantener sus equipos en operación durante

caídas y subidas de voltaje sin desgastar las baterías.

Compartición de Carga

(Modelos selectos solamente)

Algunos modelos APS pueden ser regulados para

limitar sus propias funciones de carga y así recargar

sus baterías lo más rápido posible sin sobrecargar

sus circuitos de entrada de energía.

Inversor con Salida de

Frecuencia Controlada

Todos los modelos APS incluyen Inversores con

Salida de Frecuencia Controlada para permitir

que los equipos que dependen de la frecuencia de

la línea de CA (como computadoras, grabadoras

de video, lectores de CD, grabadoras de audio,

relojes eléctricos y tocadiscos) operen correctamente.

Tarjetas de Circuitos Protegidas

Tarjetas de circuitos son protegidas por revestimiento

de conformación de silicona transparente.

20

Page 21

Seguridad

Este manual contiene advertencias e instrucciones importantes que deben seguirse durante

la instalación, operación y almacenaje de todos los Sistemas APS de Tripp Lite.

Precauciones Sobre la Ubicación del APS

• Instale este sistema bajo techo, lejos de calor o humedad excesivos, polvo o luz solar directa.

• Deje suficiente espacio alrededor del APS para permitir ventilación adecuada.

• No instale este sistema APS cerca de dispositivos magnéticos de memoria ya que esto

puede producir la corrupción de los datos grabados.

• Los modelos APS no son impermeables o resistentes al agua. El contacto con agua puede

causar cortocircuitos y lesiones corporales debido a choques eléctricos. No sumerja este

APS. Instálelo en el lugar más seco posible.

Precauciones Sobre la Conexión de Baterías

• El APS no funcionará, con alimentación de la red o sin ella, hasta que se conecten las pilas.

• Los sistemas múltiples de baterías deben estar formados por baterías del mismo tipo,

voltaje, edad y capacidad en amperios/hora.

• Mantenga ventilación adecuada. Gases hidrógenos explosivos pueden acumularse cerca de

las baterías si el área no está bien ventilada.

• Durante la conexión final de las baterias pueden producirse chispas.

• No permita que ningún objeto foráneo entre en contacto con las terminales de entrada de

CD. No conecte estas terminales entre sí con ningún objeto. Esto puede producir serias

lesiones corporales o daños a objetos.

Precauciones Sobre la Conexión de Equipos

• No utilice los Sistemas APS de Tripp Lite en aplicaciones para el soporte de la vida

humana donde una falla del APS pueda causar anomalías o alterar significativamente

el rendimiento del dispositivo de soporte de vida.

• No conecte supresores de sobretensiones transitorias, reguladores de voltaje, acondicionadores

de línea o no-breaks / sistemas UPS a los receptáculos de salida de esta unidad.

• Modelos con cables: no modifique el enchufe del APS de forma tal que se elimine la

conexión a tierra. No use adaptadores de potencia que eliminen la conexión a tierra del

enchufe. Conecte el APS exclusivamente a tomas de corriente alterna debidamente

conectadas a tierra. No conecte el APS a sí mismo; con ello se dañaría el APS y quedaría

sin efecto la garantía.

Precauciones de Operación

• Este sistema APS no requiere mantenimiento rutinario alguno. No abra este sistema APS

por ninguna razón. No existen partes interiores que puedan ser reparadas por el usuario.

• Existen voltajes potencialmente letales dentro de esta unidad mientras las baterías estén

conectadas. Durante cualquier procedimiento de servicio, siempre deben desconectarse las

baterías y la entrada de CA (cuando sea necesario).

• No conecte o desconecte baterías mientras el sistema APS esté operando con la energía

de las baterías.

21

Page 22

Configuración

4321

Bateria

de Gel

Bateria*

Húmeda

4321

145V

135V*

4321

105V

4321

95V

4321

85V

4321

75V*

Regulación de los Interruptores DIP de Configuración

GRUPO A DE INTERRUPTORES DIP (Todos los modelos)

TIPO DE BATERÍAS / PUNTOS DE VOLTAJA

Usando una herramienta pequeña, ajuste los 4 Interruptores DIP de Configuración, Grupo A:

“Battery Type / Voltage Point” (tipo de baterías / punto de voltaje) ubicados en el panel frontal

del sistema APS (vea el Diagrama 1, página 36) para seleccionar el tipo de baterías que desea

utilizar y programar el rango de voltaje para el cambio automático del sistema APS a energía de batería.

• Seleccione el Tipo de Baterías (Interruptor DIP No. 1, Grupo A)

PRECAUCION: El Interruptor DIP “Battery Type” (tipo de baterías), para seleccionar el tipo de baterías, debe ser

colocado en la posición correcta y de acuerdo al tipo de baterías utilizadas para evitar daños o desgaste durante un

período extendido de tiempo. Refiérase a la sección “Selección de Baterías” en la página 25 para obtener más información.

Tipo de Batería Posición del Interruptor

Batería de Gel (Sellada) Arriba

Batería Húmeda (Ventilada) Abajo*

• Seleccione el Punto Alto de Voltaje de CA

para el Cambio a Batería

Voltaje Posición del Interruptor

145V Arriba

135V Abajo*

(

Interruptor DIP No. 2, Grupo A)

• Seleccione el Punto Bajo de Voltaje de CA

para el Cambio a Batería

Grupo A y No. 3, Grupo A)

Voltaje Posición del Interruptor

105V #4 Arriba & #3 Arriba

95V #4 Arriba & #3 Abajo

85V #4 Abajo & #3 Arriba

75V #4 Abajo & #3 Abajo*

La mayoría de las cargas funcionarán correctamente cuando el

Interruptor DIP No. 2 para el ajuste del Punto Alto de Voltaje de CA

está regulado a 135 V y los Interruptores DIP No. 3 y No. 4 para el

ajuste del Punto Bajo de Voltaje de CA están regulados a 95 V. No

obstante, si su sistema APS cambia frecuentemente a batería debido a

las fluctuaciones de alto / bajo voltaje que no interfieren con la

operación de sus equipos, usted pude cambiar estos ajustes.

Incrementando el Punto Alto de Voltaje de CA para el Cambio a Batería

y/o disminuyendo el Punto Bajo de Voltaje de CA para el Cambio a

Batería, usted puede reducir el número de veces que su sistema APS

cambia a batería debido a fluctuaciones de voltaje.

* Regulación de fábrica

(Interruptores DIP No. 4,

22

Page 23

Configuración

4321

4321

4321

4321

continua

GRUPO B DE INTERRUPTORES DIP

COMPARTICION DE CARGA / IGUALAR CARGA DE BATERIAS

Usando una herramienta pequeña, ajuste los Interruptores DIP de Configuración “Load Sharing”

(compartición de carga) del Grupo B (ubicados en el panel frontal del sistema APS; vea el

Diagrama 1, página 36). El Interruptor DIP No.3 del Grupo B debe estar en la posición “UP”

(hacia arriba) cuando usted no desee igualar la carga de las baterías. El interruptor DIP No. 4,

Grupo B tiene diferentes funciones, o no función alguna, de acuerdo con el sistema APS.

• Compartición de Carga

Este sistema APS incluye un cargador de alta salida para baterías que puede demandar una cantidad

considerable de energía de su fuente de CA mientras está recargando a su índice máximo. Si

el APS está suministrando su índice completo de energía de CA a la carga conectada al mismo

tiempo que está recargando las baterías, podría saltar el interruptor de circuitos correspondiente a

la fuente de línea. Al saltar este interruptor de circuitos se cortará la energía de CA suministrada

a sus equipos y se suspenderá la función de recarga de las baterías.

Para reducir la posibilidad de tal evento, algunos sistemas APS pueden ser regulados para limitar

automáticamente la salida del cargador y mantener la suma de la carga conectada de CA y de

la energía del cargador dentro de los límites del interruptor de circuitos.

Esta función de limitación del cargador tiene cuatro posiciones para permitirle escoger una

menor limitación del cargador para configuraciones de sistemas APS con fusibles de mayor

capacidad. Los diagramas en esta página representan las instrucciones para regular los

Interruptores DIP y seleccionar la cantidad de carga que puede conectarse al sistema APS

antes de que se active la limitación automática del cargador.

(Interruptores DIP No. 1 y No. 2, Grupo B)

(Modelos Selectos)

Puntos Limites del Cargador de Baterias

Limitación Superior (#1 & #2 Arriba*): La limitación del cargador

se activa al momento de la conexión de equipos; la salida del cargador

disminuye gradualmente desde salida completa sin carga conectada, a

cero salida con carga completa conectada.

Limitación Medio (#1 Abajo, #2 Arriba): La limitación del cargador se

activa cuando la carga conectada al APS llega a 33% de la capacidad

máxima del APS. La salida del cargador disminuye gradualmente desde

salida completa a 33% de la capacidad máxima del APS, a 40% de

salida con carga completa conectada.

Limitación Inferior (#1 Arriba, #2 Abajo): La limitación del cargador

se activa cuando la carga conectada al sistema APS llega a 66% de la

capacidad máxima del APS. La salida del cargador disminuye gradualmente

desde salida completa a 66% de la capacidad máxima del APS, a 40% de

salida con carga completa conectada.

Limitación Desactivada (#1 & #2 Abajo): La limitación del cargador

estará desactivada independientemente del tamaño de la carga conectada.

* Regulación de fábrica

23

Page 24

Configuración

4321

Restablecer*

Igualar

4321

Parcíal*

Total

continua

• Igualar la Carga de Baterías

(Interruptores DIP No. 3, Grupo B)

Este interruptor DIP se acciona momentáneamente para iniciar el proceso de igualar la resistencia

interna de las pilas. Con ello se prolonga la vida útil de algunos tipos de pilas; consulte con el

fabricante de sus pilas para conocer si éstas se beneficiarían con dicho proceso. El proceso de

igualación de carga es automático y una vez iniciado sólo se puede detener si se interrumpe la

alimentación de electricidad.

Procedimiento de Regulacion:

• Mueva el interruptor hacia abajo hasta la posición “Equalize” (igualar) por tres segundos.

• Mueva el interruptor hacia arriba hasta la posición “Reset” (restablecer) y manténgalo

permanentemente en esta posición.

PRECAUCION: El procedimiento para igualar la carga de las baterías debe

ejecutarse como lo indican las instrucciones y especificaciones del fabricante

de las baterías.

PRECAUCION: no deje el interruptor DIP # 3 de abajo después de iniciar el proceso.

Carga de Baterías Posición del Interruptor

Restablecer Arriba*

Igualar Abajo

* Regulación de fábrica

• Límites del Cargador de Baterías

(Interruptor DIP #4, Grupo B)

Para evitar el calentamiento excesivo de baterías de menor tamaño, el cargador incluido con estos

No-breaks/Sistemas UPS viene limitado de fábrica para suministrar una fracción de su capacidad

máxima a las baterías conectadas. Si usted desea utilizar los sistemas APS mencionados con

baterías de mayor capacidad o con bancos de baterías (más de 100 amperios-hora), puede ajustar

el cargador para que éste suministre su capacidad total sin calentar excesivamente las baterías.

(APS1012, APS1524 y APS2012 únicamente)

Cargador de Baterías Posición del Interruptor

Capacidad Parcial (1/3) de Carga Arriba*

Capacidad Total de Carga Abajo

* Posición de fábrica.

·

24

Page 25

Selección de Baterías

Seleccione el Tipo de Batería(s)

Seleccione una batería o sistema de baterías que suministre voltaje apropiado de CD y capacidad

adecuada en amperios / hora al sistema APS.* Seleccione baterías de ciclo profundo para obtener

el máximo rendimiento de su sistema APS. Las baterías húmedas (ventiladas) o de gel / fibra de

vidrio absorbido (selladas) son ideales. Las baterías de 6 voltios (“golf-cart”), ciclo profundo

marino o ciclo profundo 8D también son aceptables.**

* Aún cuando los sistemas APS son inversores de energía de alta eficiencia, su capacidad de salida será limitada por el

tamaño en amperios/hora de sus baterías externas. ** Usted debe ajustar el Interruptor DIP No. 1, Grupo A (tipo de

batería) de acuerdo con el tipo de baterías que desea conectar. De lo contrario, las baterías pueden sufrir daños o

desgaste excesivo durante un prolongado periodo de tiempo. Refiérase a la sección “Configuarción” en la página 22

para obtener más información.

Seleccione la Capacidad en Amperios/Hora de las Baterías

1. Sume los índices de demanda eléctrica de los equipos que desea conectar para determinar el

Total Requerido en Vatios.*

2. Divida el Total Requerido en Vatios (obtenido en el paso 1) entre el voltaje de entrada del

sistema APS para determinar el Indice de Amperios de CD Requerido.

3. Multiplique el Indice de Amperios de CD Requerido (obtenido en el paso 2) por el número de

horas (estimado) que pasará sin energía de CA antes de que las baterías puedan recargarse,

para determinar un Estimado Aproximado de Capacidad en Amperios-Hora.**

4. La capacidad de baterías en Amperios/Hora se indica usualmente para una intensidad de

descarga de 20 horas. La capacidad actual en Amperios/Hora es menor cuando la batería se

descarga a mayor intensidad. Compense por la ineficacia multiplicando el Estimado

Aproximado en Amperios-Hora de su Batería (obtenido en el Paso 3) por 1.2 para determinar

cuantos amperios-hora de respaldo de batería (suministrados por una o varias baterías) debe

conectar al APS. Tenga en cuenta que las capacidades en Amperios-Hora de las baterías usualmente

se expresan para un índice de descarga de 20 horas. Las capacidades verdaderas en Amperios-Hora

disminuyen cuando las baterías se descargan a mayor velocidad: las baterías que se descargan

en 55 minutos proporcionan solamente un 50% de la capacidad nominal, mientras que las

baterías que se descargan en 9 minutos proporcionan solamente 30% de su capacidad nominal

en Amperios-Hora.

* La demanda eléctrica de los equipos electrónicos normalmente se encuentra en el manual de operación o en la placa

de identificación. Si este índice está expresado en amperios, conviértalos a vatios multiplicando los amperios por el

voltaje nominal de línea (120). ** El resultado de la multiplicación de los amperios de carga y las horas de carga debe

exceder los amperios/hora de descarga tomados de las baterías entre carga y carga. De lo contrario, eventualmente se

desgastará totalmente su banco de baterías.

25

Page 26

Montaje (Opcional*)

El usuario debe suministrar todos los sujetadores y piezas de fijación necesarias y verificar que

éstas sean adecuadas para la superficie de montaje que desea utilizar. Apague el PowerVerter y

todos lo equipos conectados antes de comenzar el proceso de montaje.

• Instale dos fijadores de 8 mm (1/4 pulgada) (A) en una superficie rígida horizontal

utilizando las medidas especificadas en el diagrama. Permita que las cabezas de los

fijadores permanezcan ligeramente por encima de la superficie de montaje para

asegurarlas en las ranuras de las patas del Sistema APS.

• Deslice el PowerVerter hacia delante hasta que los fijadores entren firmemente en las

patas del Sistema APS. Instale dos fijadores de 8 mm (1/4 pulgada) (B) en la superficie

y a través de las ranuras de las dos patas del Sistema APS. Apriete los tornillos para

asegurar el Sistema APS en esta posición.

* Utilice montaje horizontal en todas las aplicaciones de vehículos. Debido a su tamaño y peso, todos los sistemas APS

en vehículos deben montarse en superficies rígidas horizontales (no verticales) y la placa o sujetadores de montaje deben

in stalarse antes de conectar la batería.

(Refiérase al diagrama 2, página 36)

Conexión de Baterías

Estándar

1. Conecte la terminal positiva de CD del sistema APS directamente a un fusible

UL recomienda que usted instale una caja de fusibles y un fusible aceptado por UL a una

distancia no mayor de 18 pulgadas (46 centímetros) de la batería. El índice de capacidad del

fusible debe ser igual o mayor al índice Mínimo de Capacidad del Fusible indicado en las

especificaciones de su modelo APS en las páginas 34 ó 35.

2. Escoja la configuración apropiada a sus baterías

• Conexión de Una Batería: Refiérase al Diagrama 4, página 37. Si desea utilizar una

sola batería, el voltaje de la misma debe ser igual al Voltaje Nominal de Entrada

del Inversor del APS (vea las especificaciones).

• Conexión Paralela de Baterías: Refiérase al Diagrama 5, página 37. Si desea

utilizar baterías múltiples en forma paralela, el voltaje de cada batería debe ser

igual al Voltaje Nominal de Entrada del Inversor del APS (vea las especificaciones).

• Conexión en Serie de Baterías: Refiérase al Diagrama 6, página 37. Si desea

utilizar baterías múltiples en serie, el voltaje de cada batería debe ser igual al

Voltaje Nominal de Entrada del Inversor del APS (vea las especificaciones).

3. SOLAMENTE cables de calibre 2/0 para la conexión de baterías externas. Apriete las terminales

o bornes de las baterías a una torsión de 4 Newton – metro.

¡Advertencia! El no atenerse a estas instrucciones puede causar daños

al producto debido a sobrecalentamiento excesivo.

26

Page 27

Conexión de Baterías

Los cables de conexión de las baterías deben ser de longitud mínima posible y en ninguna

circunstancia deben exceder 10 pies de longitud. Los cables cortos y de calibres espesos limitan

la pérdida de voltaje de CD y permite transferencia máxima de corriente.* Debe apretar las

terminales o bornes de las baterías a una torsión de aproximadamente 4 Newton-metro para crear

una conexión eficiente y prevenir sobrecalentamiento excesivo. El no apretar suficientemente las

terminales o bornes de las baterías puede anular la garantía del PowerVerter.

* Los modelos APS incluyen capacidad para entregar una salida más alta en vatios durante breves períodos de tiempo.

Por esta razón, el cableado debe ser configurado para soportar adecuadamente la posible demanda de alta corriente. Aún

cuando los sistemas APS son inversores de energía de alta eficiencia, su capacidad de salida será limitada por el tamaño

en amperios/hora de sus baterías externas.

continua

Conexión de Baterías (DC Vehículos)

Los sistemas APS pueden montarse permanentemente en coches (automóviles), camiones o

embarcaciones y obtener la energía de las baterías del vehículo. Nota: el APS SÓLO se puede

conectar a las baterías del vehículo si éstas coinciden con la entrada nominal de corriente

directa del APS – baterías del vehículo a 12 V para los sistemas APS de 12 V de entrada

nominal de corriente directa, etc. (Ver especificaciones). Hay dos maneras principales de efectuar

la conexión a las baterías del vehículo. Utilice la conexión básica si es para alimentar a pequeñas

herramientas manuales u otros dispositivos pequeños durante un período breve de tiempo (ver

Diagrama 7, p. 38). Utilice la conexión avanzada si emplea el sistema APS para alimentar

equipos pesados durante largos períodos de tiempo (ver Diagrama 8, p. 38). La conexión avanzada

incorpora un aislante de la batería y un sistema propio de batería para permitir que ésta alimente

al APS sin descargar la batería del vehículo. Nota: En dependencia de la aplicación en cuestión,

puede que necesite más de una batería de ciclo profundo.

Preacución: Nunca opere su APS desde un alternador sin baterías conectadas como se indica en los Diagramas 7 y 8 en

la página 38.

Conexión de CA

Conexión de CD a Tierra

Los sistemas APS deben conectarse a una instalación eléctrica permanente y con conexión a tierra.

En la mayoría de las instalaciones, el conductor negro de la batería debe estar soldado al sistema

de conexión a tierra en un punto (y solamente uno) del sistema. Todas las instalaciones deben

cumplir con los códigos y regulaciones nacionales y locales.

27

Page 28

Conexión de CA

Antes de la conexión de CA, cerciórese de que la demanda

de energía de sus equipos coincida con la capacidad de salida

del APS para evitar sobrecargas.

Cuando calcule la demanda de energía de sus equipos, no confunda el índice de energía

“continua” con el índice de energía “de cresta”. Ciertos motores eléctricos necesitan más energía

para arrancar (“energía de cresta”) de lo que requieren para su operación continua. Los índices

de energía “de cresta” son normalmente de 2 a 5 veces mayores que los índices de energía

“continua”. La mayoría de los motores eléctricos demandan “energía de cresta” solamente para

su arranque. No obstante, otros motores eléctricos, como los incluidos con refrigeradores y bombas

de agua, se encienden y se apagan continuamente de acuerdo con la demanda impuesta. Estos

motores pueden requerir “energía de cresta” a intervalos múltiples e imprevisibles durante su

operación.

Conexiones Eléctricas Directas al Circuito

(Todos los modelos con toma directa al circuito – “hardwire”)

Consulte a un electricista capacitado y aténgase a los códigos y requisitos eléctricos de su zona

de residencia.

PROCEDIMIENTO DE CONEXION DE MODELOS CON TOMA DIRECTA AL CIRCUITO

1. Remueva los tornillos y la cubierta de la Terminal de CA del sistema APS con toma directa al

circuito (hardwire). Remueva la cubierta más cercana a la fuente de energía que desea utilizar

y a sus equipos.

(Refiérase a los esquemáticos eléctricos, Diagrama 3, página 36.)

2) Enhebre sus alambres a través de los sujetacables y a través de la perforación para este propósito

3) Conecte los alambres de conexión a tierra de la entrada y la salida a la terminal de conexión a

tierra (verde).

4) Conecte el alambre positivo de entrada a la terminal positiva de entrada (café).

5) Conecte el alambre neutro de entrada a la terminal neutra de entrada (azul).

6) Conecte el alambre positivo de salida a la terminal positiva de salida (negra).

7) Conecte el alambre neutro de salida a la terminal neutra de salida (blanca).

8) Apriete y fije los sujetacables. Instale nuevamente la cubierta y los tornillos.

Conexión de la Entrada Eléctrica de CA

Enchufe el cable a una toma que suministre energía de 120V de CA y 60 Hz. Cerciórese de que

el circuito al cual desea conectar el sistema APS posea protección adecuada contra sobrecargas,

como un interruptor de circuitos o un fusible.

28

(Todos los modelos con cable)

Page 29

Conexión de CA

continua

Conexión de la Salida Eléctrica de CA

Simplemente conecte sus equipos a los receptáculos de CA de la unidad.

Regule el Interruptor “Operating Mode”

• Colóquelo en la posición “AUTO/REMOTE” (automático / remoto) cuando usted desee

utilizar los equipos conectados. VENTAJA: Suministra energía de respaldo durante caídas

de voltaje y apagones.

Importante: Cuando el interruptor está en la posición “AUTO/REMOTE” (automático / remoto), usted puede utilizar

un interruptor (suministrado por el usuario) para conmutar entre los modos “battery-backup” (respaldo a batería) y

“charge-only” (recarga solamente). (Vea el Manual del Conector Remoto).

• Colóquelo en la posición “CHARGE ONLY” (recarga solamente) cuando usted no necesite

utilizar los equipos conectados. (¡ADVERTENCIA! el sistema APS no suministrará energía

de respaldo) VENTAJAS: A) Continúa recargando las baterías cuando la energía eléctrica

está presente, y B) Apaga el Inversor del sistema APS para prevenir el desgaste de las

baterías durante apagones y caídas de voltaje.

• Colóquelo en la posición “OFF” (apagado) para apagar completamente el APS y los equipos

conectados o para restablecer el sistema APS después de que éste se haya apagado debido a

una sobrecarga o calor excesivo.

(Todos los modelos con cable)

(Modo de Operación)

Interruptores, Luces Indicadoras y

Otras Características

(Vea los Díagramas 9a y 9b en las páginas 39-40 para localizar los siguientes interruptores, luces

indicadoras y otras características.)

Interruptores

1. Interruptor “Operating Mode” (Modo de operación): Este interruptor selecciona el modo

de operación del sistema APS: “AUTO/REMOTE” (automático/remoto); “OFF” (apagado);

“CHARGE ONLY” (recarga solamente). Vea la sección “Conexión de CA” en p. 28 para

seleccionar la regulación más favorable de este interruptor.

2. Interruptores de Configuración (“Configuration Switches”) – Grupo A de Interruptores

DIP (Todos los modelos): Estos cuatro interruptores deben ser regulados de acuerdo al tipo

de baterías conectadas al sistema APS y los puntos de voltaje en que el sistema APS suministrará

energía de batería. Refiérase a la sección “Configuración” en la página 22 para seleccionar la

regulación más favorable de estos interruptores.

3. Interruptores de Configuración (“Configuration Switches”) – Grupo B de Interruptores

DIP (Modelos selectos únicamente): Estos Interruptores DIP le permiten igualar la resistencia

interna de las celdas de las baterías y ajustar el porcentaje de la capacidad máxima del APS y

la limitación de recarga de baterías. Refiérase a la sección “Configuración” en la página 23

para seleccionar la regulación más favorable de estos interruptores.

29

Page 30

Interruptores, Luces Indicadoras y

Otras Características

Luces Indicadoras

4. “LINE” (Línea – Todos los modelos): Esta luz verde se iluminará continuamente para indicar

que los equipos conectados están recibiendo energía de CA suministrada por la compañía local

de electricidad y el sistema APS está en el modo “AUTO/REMOTE” (automático / remoto), lo

que significa que el APS suministrará energía de respaldo si se produce una falla de la energía

eléctrica. También parpadeará para indicar que sus equipos están recibiendo energía de línea y

que el Interruptor “Operating Mode” (modo de operación) del sistema APS está en la posición

“Charge Only” (recarga solamente) para advertirle que el inversor está apagado (OFF) y que

el sistema APS NO suministrará energía de respaldo durante apagones, caídas o subidas de voltaje.

5. “INV” (Inversor – Todos los modelos): Esta luz amarilla se iluminará continuamente para

indicar que los equipos conectados están recibiendo energía suministrada por de las baterías

(durante un apagón, caída o subida de voltaje mientras la unidad esté conectada a una línea de

CA o mientras esté conectada a baterías externas durante la operación en un vehículo).

6. “LOAD” (Carga Conectada – Todos los modelos): Esta luz roja se iluminará continuamente

para indicar que la carga conectada al sistema APS está entre 80% y 110% de su capacidad.

También parpadeará cuando se haya desactivado el inversor del sistema APS debido a

condiciones severas de sobrecarga o sobrecalentamiento. Si esto sucediera, apague (OFF) el

Interruptor “Operating Mode” (modo de operación). Disminuya la carga conectada. Permita

que se enfríe la unidad y encienda (ON) nuevamente el sistema APS.

7. “CUT/BOOST” (disminuyendo / elevando – Modelos VR solamente): Estas luces se

iluminarán cuando el sistema APS esté regulando automáticamente el voltaje alto (“CUT” –

disminuyendo) o bajo (“BOOST” – elevando) de línea de CA. Esta es una función automática

y normal del sistema APS que no desgasta las baterías y no requiere acción o interferencia del usuario.

continua

8. “BATTERY HI/MED/LO” (Carga de Baterías Alta/Media/Baja – Todos los modelos):

Estas tres luces se iluminarán en combinaciones diferentes para indicar el nivel aproximado de

carga y el voltaje del banco conectado de baterías, y para alertarle acerca de varias condiciones o fallas

CARGA DE LAS BATERIAS (Aproximada)

Luz Indicadora Capacidad

Verde 91% - Completa

Verde y Amarilla 81% - 90%

Amarilla 61% - 80%

Amarilla y Roja 41% - 60%

Roja 21% - 40%

Las tres luces apagadas 1% - 20%

Roja Parpadeando 0% (Apagado del Inversor)

Las tres luces parpadean lentamente* Descarga Excesiva

Las tres luces parpadean rápidamente** Sobrecarga

* Parpadean aproximadamente cada 1/2 segundo. Vea la sección “Guía de Resolución de Problemas”. ** Parpadean

aproximadamente cada 1/4 segundo. También puede indicar la existencia de una falla en el cargador de baterías. Vea la

sección “Guía de Resolución de Problemas”.

30

Page 31

Interruptores, Luces Indicadoras y

Otras Características

Otras Características

9. Terminales de Entrada de CD (Todos los modelos): Las tuercas aseguran los cables

provenientes de la batería externa o sistema externo de baterías. Sus baterías o sistema de

baterías deben proporcionar voltaje adecuado de CD al sistema APS y a sus equipos, y

también capacidad adecuada en amperios/hora. Refiérase a la sección “Selección de

Baterías” en la página 25 para obtener más información.

10. Receptáculos de CA: NEMA 5-15R (Solamente en los modelos con cable de CA): Estos

receptáculos permiten la conexión de equipos diseñados para operar a 120V de CA y 60 Hz.

11. Cable de Línea de CA: NEMA 5-15P fijo (Solamente en los modelos con cable de CA):

Este cable debe conectarse a un enchufe de CA dedicado de 15 amperios y 120V, 60 Hz. NO

CONECTE este cable a los receptáculos de CA del sistema APS.

12. Barra de Terminales de Toma Directa a Entrada/Salida de CA (Modelos “hardwire”

solamente): Utilice las tuercas mariposa en estas terminales para asegurar las tomas directas

de entrada y salida de CA. Refiérase a las páginas 28 y 36 para obtener instrucciones

de conexión.

13. Interruptores de Circuito con Restablecimiento (Todos los modelos): Los interruptor de

circuitos protege el sistema APS contra daños causados por sobrecargas. Si saltara un interruptor,

disminuya la carga conectada al sistema APS para prevenir sobrecargas, después espere

1 minuto para permitir que se enfríen los componentes antes de restablecer el interruptor

de circuitos.

14. Conector para el Módulo de Control Remoto (Todos los modelos): El panel frontal de

todos los modelos incluye un conector tipo RJ45 para utilizarlo con el módulo opcional de

control remoto. (Este módulo se incluye con los modelos “VR”). Refiérase a las instrucciones

incluidas con el módulo de control remoto.

continua

15. Potenciómetro Sensor de Carga Conectada (Todos los modelos): Con el fin de ahorrar

corriente de la pila, el inversor del APS se apaga automáticamente cuando no haya carga

onectada. La unidad enciende automáticamente el inversor cuando detecte la presencia de

carga. El usuario puede ajustar el potenciómetro de detección de carga (Load Sense

Potentiometer) para seleccionar la carga mínima que detectará el APS. Use una herramienta

pequeña para girar el potenciómetro en el sentido del reloj si desea reducir la carga mínima

a detectar, lo que hará que el inversor se encienda con pequeñas cargas. Cuando el

potenciómetro se gire por completo en el sentido del reloj, el inversor funcionará incluso

cuando no haya carga. Gire el potenciómetro en sentido contrario al reloj para aumentar la

carga mínima a detectar, lo que hará que el inversor se mantenga apagado hasta que se

alcance la nueva carga mínima. El potenciómetro viene de fábrica en la posición de giro

completo en el sentido del reloj, pero en aquellas zonas donde haya frecuentes interrupciones

de la alimentación eléctrica de la red, el potenciómetro debe ajustarse en sentido contrario

al reloj hasta que el inversor sólo funcione cuando haya carga conectada al APS.

31

Page 32

Mantenimiento y Servicio

Mantenimiento

Este sistema APS no requiere mantenimiento alguno. No obstante, debe mantenerse seco en todo

momento. Verifique periódicamente todas las conexiones y cables en la unidad y sus baterías.

Apriete y limpie estas conexiones como sea necesario.

Servicio

Si necesita enviar el sistema APS a Tripp Lite, por favor empáquelo cuidadosamente usando el

MATERIAL ORIGINAL DE EMPAQUE. Adjunte una carta con la descripción de los síntomas

del problema. Si la unidad está dentro del período de garantía, adjunte una copia de su factura o

recibo original de compra.

Servicio en México

Compusupport México provee 36 centros autorizados de servicio ubicados en diferentes partes

del país para reparar los APS sistemas de Tripp Lite. Si usted está en México D.F., lleve las

unidades que necesiten ser reparadas en la oficina central de Compusupport México, localizada

en Roberto Gayol 29; Col. del Valle; México D.F. Tel / Fax: 5 559-3022. Si usted no está

en México D.F., por favor visite nuestra página PowerZone en español en el Internet:

www.tripplite.com para obtener una lista completa de los centros autorizados de servicio,

incluyendo direcciones y números telefónicos, de Compusupport.

Si usted necesita soporte técnico, por favor comuníquese a la oficina de Tripp Lite de México,

localizada en Av. San Antonio 256, Piso 6; Col. Ampliación Nápoles, 03849 México D.F.

Tel: 5 615-0252; Fax: 5 615-0255; Hotline (línea de soporte técnico): 5 575-0929

Garantía Limitada

Tripp Lite garantiza que sus productos estarán libres de defectos en materiales y mano de obra por un período

de un año (unidades utilizadas en EE.UU.) ó 120 días (unidades utilizadas fuera de EE.UU) a partir de la fecha

inicial de compra. La obligación de Tripp Lite bajo esta garantía está limitada a reparar o reemplazar (a sola

discreción de Tripp Lite) los productos defectuosos. Para obtener servicio bajo esta garantía usted debe obtener un

número de Autorización de Devolución de Material (RMA) de Tripp Lite o de uno de sus centros autorizados de

servicio. Los productos defectuosos deben ser enviados, con los cargos de transporte pagados, a Tripp Lite o a

uno de sus centros autorizados de servicio y deben estar acompañados por una breve descripción del problema

que ha experimentado el usuario y comprobación de fecha y lugar de compra. Esta garantía no cubre equipos

que hayan sido dañados por accidente, negligencia o uso incorrecto, o que hayan sido alterados o modificados