Page 1

Model 9065

True RMS Data Logging MultiMeter

Instruction Manual

84-910

12/15

Page 2

Contents

I. Introduction----------------------------------------------------------1

II.Included Items------------------------------------------------------1

Ill. Rules for Safe Operation---------------------------------------2

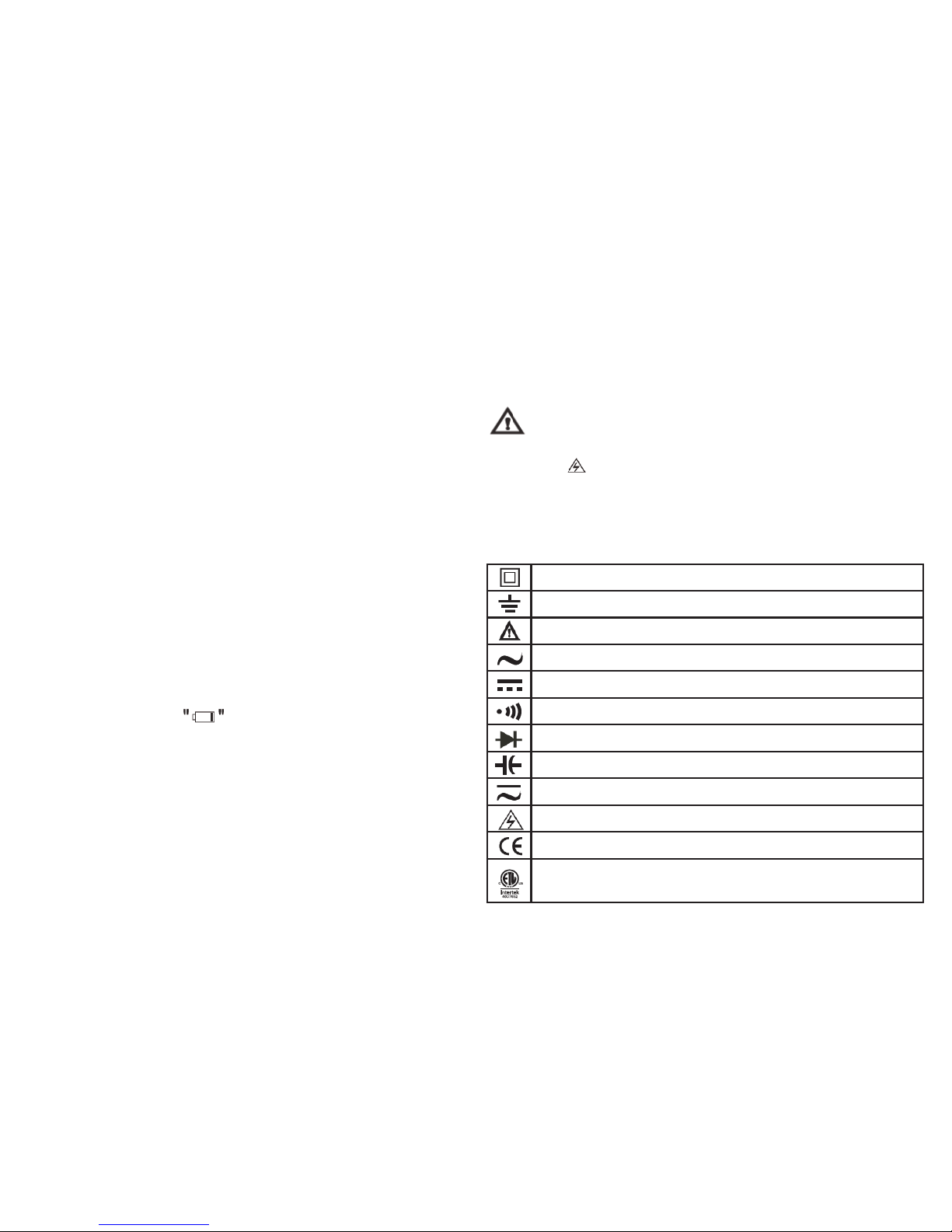

IV. Electrical Symbols-----------------------------------------------3

V. Meter Structure----------------------------------------------------4

VI. LCD Display-------------------------------------------------------5

VII. Keys, Rotary Switch and Input Terminals-----------------6

VIII. Technical lndex--------------------------------------------------8

1. General Specications---------------------------------------8

2. Electrical Specications-------------------------------------9

IX. Measurement Operation--------------------------------------17

1. Meter Power Control----------------------------------------17

2. Meter Settings------------------------------------------------18

3. AC Voltage----------------------------------------------------20

4. DC Voltage----------------------------------------------------20

5. AC and DC Current-----------------------------------------21

6. Resistance----------------------------------------------------22

7. Conductance-------------------------------------------------24

8. Capacitance--------------------------------------------------24

9. Continuity------------------------------------------------------25

10. Diode Test----------------------------------------------------25

11. Frequency/Duty Cycle Measurement/Pulse Width-27

12. Temperature------------------------------------------------27

13. LPF-----------------------------------------------------------28

14. dBV-----------------------------------------------------------29

15. dBm----------------------------------------------------------29

16. Maximum Value and Minimum Value----------------29

17. Relative Value Mode-------------------------------------30

18. Peak Detection Mode------------------------------------30

19. Compare Mode--------------------------------------------30

20. Recording Measurement Data------------------------31

21. Communication-------------------------------------------33

X. Maintenance and Repair-------------------------------------34

1. General Maintenance and Repair---------------------34

2. Testing Fuses-----------------------------------------------34

3. Replacing Fuses-------------------------------------------35

4. Battery Charge---------------------------------------------35

X. Warranty-----------------------------------------------------------36

X. Notes---------------------------------------------------------------37

Page 3

I. Introduction

The Model 9065 is a 60000 count, or 4 5/6 digit,

handheld auto-ranging true RMS Digital Multimeter

(hereinafter referred to as “the meter’’). The meter can be

used to accurately measure AC and DC voltage, AC and

DC current, resistance, conductance, capacitance, temperature, frequency and pulse width. It can also perform

diode testing, continuity testing, and it provides useful test

functions such as data hold, maximum/minimum/average

measurements, comparison measurement, relative measurement, peak detection, trend capture and data record/

readback of as many as 20,000 measurements.

This Operating Manual provides information on safe and

recommended uses of this product. Please read the relevant information carefully and observe all the Warnings

and Notes.

Warning:

Please read the “Rules for Safe Operation” before using

the meter.

II. Included Items

Open the package and the carrying case and inspect the

contents. Please check that all of the following items are

included:

1. One operating manual

2. A pair of test leads

3. Two K type temperature probes

4. One temperature connector

5. One charging adapter

6. One charging connector

7. One USB cable

8. One CD

9. One cloth bag

If you discover any missing or damaged pieces, please

contact Triplett at 1-800 Triplett or support@triplett.com.

1

Page 4

III. Rules for Safe Operation

Please note the Warning symbol. Warnings indicate

the conditions and actions which pose hazards to users or

may damage the meter or equipment under test.

This Meter is designed to comply with several

safety standards, This meter conforms to UL STD. 61010-1,

61010-2-030, 61010-2-032, 61010-2-033, Certied to CSA

SID. C22.2 NO. 61010-1,61010-2-030, IEC STD 610102-032, 61010-2-033 in pollution degree 2, measurement

category (CAT III 1000V, CAT IV 600V), double insulation

as well as with IP65 standards for water resistance and

dustproong. Use of the meter without following the operating instructions can reduce or circumvent the protection

provided by the meter.

Measurement Category Ill (CAT Ill) is intended for

measurements performed in building installation. Examples

may include measurements on distribution boards, circuitbreakers, wiring, including cables, bus-bars, junction boxes,

switches, socket-outlets in xed installations, and equipment

for industrial use and some other equipment, for example,

stationary motors with permanent connection to the xed

installation.

Measurement Category IV (CAT IV) is intended for

measurements performed at the source of the low-voltage

installation. Examples include electricity meters and measurements on primary overcurrent protection devices and

ripple control units.

1. Never use a damaged meter. Before using the meter,

check the meter case for visible cracks or any missing plastic

parts. Pay special attention to the insulation areas around the

connectors.

2. Before using the meter, ensure the battery cover is closed

and secured. Before opening the battery cover, remove the

test leads from the meter.

3. Inspect the test leads for damaged insulation or exposed

metal. Check the test leads for continuity. If any test lead is

damaged, replace it before using the meter.

4. Do not apply more than the rated voltage, as marked on

the meter, between the terminals or between any terminal

and ground.

5. Do not have the meter turned on when removing the cover

or opening the case.

6. When working with a voltage >30V AC (RMS), >42VAC

(peak), or over 60V DC, special care should be taken to avoid

electric shock.

7. Replacement fuses must comply with the specications in

this Operating Manual.

8. Use the proper terminals, function and range for your measurement.

9. When measuring current, shut off the power to the circuit,

then connect the meter to the circuit. Remember: the meter

and the circuit must be connected in series.

10. When making electrical connections, connect the common test lead before connecting the main test lead; when

disconnecting, disconnect the main test lead before disconnecting the common test lead.

2

Page 5

11. If the meter works improperly, do not use it. The protection

measures of the meter may have failed. If in doubt, contact

your distributor or Triplett Customer Service.

12. Do not store or use the meter in an environment with high

temperature, humidity, strong magnetic elds, or with inammable or explosive materials.

13. When using the probes, keep your ngers behind the

nger guards.

14. Do not use the low-pass lter to verify hazardous voltage,

as there may be an AC voltage over the indicated value. First,

measure the voltage without a lter to check whether it is

hazardous, then select low-pass ltering.

15. Before testing resistance, continuity, conductance, diode

or capacitance, shut off the power to the circuit and discharge

all high-voltage capacitors.

17. Do not measure a voltage or current higher than the

allowed input values. When the range of measured values

cannot be determined, set the functional range switch at the

maximum-range position.

18. When the symbol shows on the LCD display, the

battery should be promptly charged to ensure measurement

accuracy.

19. Do not change the wiring within the meter to avoid injury

and damaging the meter.

20. A soft cloth and mild detergent should be used to clean

the surface of the meter when servicing. No abrasive cleaners or solvents should be used on the product.

21.Test a known voltage before use to conrm the meter is

functioning correctly.

22. If you want to replace the test lead, you need to replace

it with a test lead of the same or higher grade of CAT Ill

1000V/CAT IV 600V.

Dangerous Voltage

When the meter detects voltage ≥ 30V or overload (OL),

the symbol will display as a warning for potential hazardous voltage.

Double Insulated

Grounding

Warning

AC (Alternating Current)

DC (Direct Current)

Continuity Buzzer

Diode

Capacitance

AC or DC (Alternating Current or Direct Current)

Danger High Voltage

Conforms to Standards of European Union.

This symbol signies the product complies with both

USA and Canadian electrical requirements.

IV. Electrical Symbols

3

Page 6

V. Meter Structure (see Figure 1)

1

Case

2

LCD

3

Function Keys

4

Rotary Switch

5

Input Terminals

4

Page 7

V. LCD Display (see Figure 2)

No. Function Description

1

Label of Function

Keys

Indicates auxiliary functions under current

measuring interface

2

Simulation Bar Analog display of input signals

3

Minus Sign Indicates negative reading

4

Lightning Symbol Danger- High Voltage

5

Time and Date Indicates the time and date set in internal

clock

6

Small

Measurements

Real-time input values are displayed when

the primary and secondary displays are

covered by menus or pop-up messages.

7

Communications Indicates the USB communication is

enabled.

8

Sound Setting Indicates the button sound is enabled

(beeps when a button is pressed)

9

Battery Level Indicates the charge level of rechargeable

battery

10

Range Indicator Indicates the current range and range

mode for the meter (auto or manual)

11

Unit Indicates the measurement unit

12

Assisted Function

Mode

Indicates the active assisted measuring

function, such as Low Pass Filter

13

Assisted Function

Display

Shows additional measuring information

from the assisted function mode that is

active.

5

Page 8

VII. Keys, Rotary Switch and Input Terminals

(1) Keys

The 14 keys on the meter are used to activate the alternate functions of the rotary switch, browse menus or control the meter power.

The keys shown in Figure 3 are described in the following table.

Key Function

Turn on or turn off the power to the meter

F1 F2 F3 F4 Select the sub-functions and modes indicated by the labels on the LCD screen.

Cursor keys are used to select menu items, scroll through text and input data

HOLD Keep the current reading held on the display

RANGE Switch the range mode of the meter to Manual mode, then switch between all the available ranges. Long

press the button to return to Automatic range mode.

MAX MIN Starts to record Minimum & Maximum values.

SELECT Press to select the alternate function. Long press to enter Help Menu.

Press the key to switch the backlight brightness. Long press it to turn off backlight.

Knob Function

Measurement of AC Voltage

Measurement of mV in AC and mV in AC+DC

Measurement of voltage in DC and AC+DC

Measurement of mV in DC and temperature

Measurement of resistance, continuity and specic conductance

Diode test and capacitance measurement

(2) Rotary Switch (see Figure 4)

6

Page 9

Knob Function

Hz% mS-Pulse Measurement of frequency, duty cycle and pulse width

µA Measurement of A in AC, DC and AC+DC

mA Measurement of mA in AC, DC and AC+DC

A Measurement of ampere in AC, DC and AC+DC

Battery is charging

Terminal Description

A Measurement of frequency, duty cycle and pulse width

mA µA Measurement of A in AC, DC and AC+DC

COM Measurement of mA in AC, DC and AC+DC

VΩ °C Hz Measurement of ampere in AC, DC and AC+DC

(3) Input Terminals

In addition to the above, all four terminals are used for charging and temperature measurement through corresponding

adapters .”Lead Error!” will show on the display to warn if the probes are inserted improperly.

7

Figure 3 & 4

Page 10

VIII. Technical Index

1. General Specications

The maximum voltage between any terminal and ground: 1000 V

The fuse protection of mA or µA input terminals: 0. 8A H 1000V Fuse Type 6X32mm

The fuse protection of the A input terminal: 10A H1000V Fuse Type 10X38mm

Max. display: 60000

Range: Auto/Manual

Polarity: Auto

Operating temperature: -20°~50°C Storage temperature: -30°C~60°C

Relative humidity: ≤80% (0°C~30°C), ≤75% (30°C~40°C), ≤45% (40°C~50°C)

Electromagnetic compatibility: In an RF E-eld of 1V/m: Overall accuracy= specied accuracy+ 5% of range. No specied accuracy guarantee for RF E-eld strength > 1V/m.

Operating altitude: 0~2000m

Temperature coefcient: 0.1X (specied accuracy)/ °C (<18°C or >28°C) Internal battery: Lithium battery of 7.4V 2200mAh

Power adapter: Input of 100V~240V,50/60Hz 0.2A max, Output of DC10V 500mA(short-circuit protection for output). External

diameter of 5.5 mm and internal diameter of 2.5mm.

Low battery: The symbol shows on the LCD.

Dimension: About (225 X100 X 60) mm

Weight: About 608g (including battery)

Safety standards: IEC/EN61010-1, EN61010-2-030, EN 61010-2-033 in pollution degree 2, CAT III 1000V,CAT IV 600V IP65

standards for waterproof and dustrproof rating

8

Page 11

2. Electrical Specications

Accuracy: ±(% Reading + Digits), one-year calibration period.

Ambient temperature: 23°C± 5°C;

Ambient humidity: 75%RH;

Temperature coefcient: 0.1x (Accuracy)/ °C (<18 °C or >28°C)

2. Electrical Specications

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

60mV 0.001mV

45~1kHz 1k~10kHz 10k~20kHz 20k~100kHz

±(0.6%+60) ±(1.2%+60) ±(3%+60) ±(4%+60)

600mV 0.01V

45~1kHz 1k~10kHz 10k~20kHz 20k~100kHz

±(0.3%+30) ±(1.2%+40) ±(3%+40) ±(4%+40)

6V 0.0001V

45~1kHz 1k~10kHz 10k~20kHz 20k~100kHz

±(0.3%+30) ±(1.2%+40) ±(3%+40) ±(4%+40)

60V 0.001V

45~1kHz 1k~10kHz 10k~20kHz 20k~100kHz

±(0.3%+30) ±(1.2%+40) ±(3%+40) ±(4%+40)

600V 0.01V

45~1kHz 1k~10kHz 10k~20kHz 20k~100kHz

±(0.3%+30) ±(1.2%+40) ±(3%+40) Only for reference

1000V 0.1V

45~1kHz 1k~5kHz 5k~10kHz 10k~100kHz

±(0.6%+30) ±(3%+40) ±(6%+40) Only for reference

• Input impedance: About 10MΩ

• Overload protection: 1000V

• Display: True RMS value for 10% to 100% of the range.

9

Page 12

(2) DC Voltage

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

60mV 0.001mV ± (0.025%+20)

600mV 0.01mV

± (0.025%+5)6V 0.0001V

60V 0.001V

600V 0.01V

± (0.03%+5)

1000V 0.1V

(3) AC Voltage + DC Voltage

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

60mV 0.001mV

50~1kHz 1k~10kHz 10k~35kHz

+(1%+80) +(3%+40) +(6%+40)

600mV 0.01V

50~1kHz 1k~10kHz 10k~35kHz

+(1%+80) +(3%+40) +(6%+40)

6V 0.0001V

50~1kHz 1k~10kHz 10k~35kHz

+(1%+80) +(3%+40) +(6%+40)

60V 0.001V

50~1kHz 1k~10kHz 10k~35kHz

+(1%+80) +(3%+40) +(6%+40)

600V 0.01V

50~1kHz 1k~10kHz 10k~35kHz

+(1%+80) Only for reference Only for reference

1000V 0.1V

50~1kHz 1k~10kHz 10k~35kHz

+(1.2%+80) Only for reference Only for reference

• Input impedance: About 10MΩ

• Overload protection: 1000V

• Display: True RMS value for 10% to 100% of the range.

10

Page 13

• Input impedance: About 10MΩ

• Overload protection: 1000V

• Display: True RMS value for 10% to 100% of the range.

(4) AC Current

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

600µA 0.01µA

45~1kHz 1k~10kHz

+(0.6%+40) +(1.2%+40)

6000µA 0.1µA

45~1kHz 1k~10kHz

+(0.6%+20) +(1.2%+40)

60mA 0.001mA

45~1kHz 1k~10kHz

+(0.6%+40) +(1.2%+40)

600mA 0.01mA

45~1kHz 1k~10kHz

+(0.6%+20) +(1.2%+40)

10A 0.001A

45~1kHz 1k~10kHz

+(1%+20) +(3%+40)

• Display: True RMS value for 10% to 100% of the range.

• Overload protection: µAmA range: 0.8A H 1000V Fuse Type ɸ 6x32 mm

10 A range: 10A H 1000V Fuse Type ɸ 10x38mm

• Switch on for 30 seconds and suspend measurement for 10 minutes for 20A. Not specied for over 10A.

11

Page 14

(5) DC Current

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

600µA 0.01 µA +(0.08%+20)

6000µA 0.1 µA + (0.08%+10)

60mA 0.001 mA + (0.08%+20)

600mA 0.01 mA +(0.15%+10)

10A 0.001A +(0.5%+10)

• Overload protection: µAmA range: 0.8A H 1000V Fuse Type ɸ 6x32 mm

10 A range: 10A H 1000V Fuse Type ɸ 10x38mm

• Switch on for 30 seconds and suspend measurement for 10 minutes for 20A. Not specied for over 10A.

(6) AC Current + DC Current

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

600µA 0.01µA

50~1kHz 1k~10kHz

+(0.8%+40) +(2.0%+40)

6000µA 0.1µA

50~1kHz 1k~10kHz

+(0.8%+20) +(2.0%+40)

60mA 0.001mA

50~1kHz 1k~10kHz

+(0.8%+40) +(2.0%+40)

600mA 0.01mA

50~1kHz 1k~10kHz

+(0.8%+20) +(2.0%+40)

10A 0.001A

50~1kHz 1k~10kHz

+(1.2%+20) +(3%+40)

12

Page 15

• Display: True RMS value for 10% to 100% of the range.

• Overload protection: µAmA range: 0.8A H 1000V Fuse Type ɸ 6x32 mm

10 A range: 10A H 1000V Fuse Type ɸ 10x38mm

• Switch on for 30 seconds and suspend measurement for 10 minutes for 20A. Not specied for over 10A.

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

600Ω 0.01Ω In REL state: ±(0.05%+10)

6kΩ 0.0001kΩ

+(0.05%+2)60kΩ 0.001kΩ

600kΩ 0.01kΩ

6MΩ 0.0001MΩ +(0.3%+10)

60MΩ 0.001MΩ +(0.3%+10)

(7) Resistance

• Overload protection: 1000V

• Humidity for 60 MΩ: <50%

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

60ns 0.01nS +(2%+10)

(8) Conductance

• Overload protection: 1000V

• Humidity: <50%

13

Page 16

(9) Capacitance

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

6nF 0.001nF +(3%+10)

60nF 0.01nF +(2.5%+5)

600nF 0.1nF

+(2%+5)

6µF 0.001µF

60µF 0.01µF

600µF 0.1µF

6mF 1µF +(5%+5)

60mF 10µF Not specied

• Overload protection: 1000V

• Display digits: 6000

(10) Temperature

Range Resolution Accuracy

-40°C~40°C

0.1°C

+(2.0%+30)

40°C~400°C +(1.0%+30)

400°C ~1000°C +2.5%

-40°F~104°F

0.2°F

±(2.5%+50)

104°F~752°F +(1.5%+50)

752°F~1832°F +2.5%

Overload protection: 1000V

• Two-channel temperature measurement can be performed via temperature connectors.

• Temperature sensor: Applicable to K type(chromel-silicel) thermocouple. Spare parts are point contact

Ktype (chromel-silicel) thermocouple (only applicable to the measurement when temperature is below 800°C)

14

Page 17

(11) Frequency

Range Resolution Accuracy

60Hz 0.001 Hz +(0.02%+8)

600Hz 0.01 Hz

+(0.01%+5)

6kHz 0.0001kHz

60kHz 0.001kHz

600kHz 0.01kHz

6MHz 0.0001MHz

60MHz 0.001MHz

• Overload protection: 1000V

• Display digits: 6000

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

10%~90%(10Hz~2kHz) 0.01% +(1.2%+30)

(12) Duty Cycle

• Overload protection: 1000V

• Humidity: <50%

Range Resolution Accuracy Tolerance: ± (% Reading + Digits)

250mS 0.001mS~0.01mS +(1.2%+30)

(13) Pulse Width

• Overload protection: 1000V

• When the rise time is less than 1 µs, the signals center on trigger level.

• The pulse width is greater than 2 µs for 10Hz to 200kHz. The pulse width depends on signal frequency.

15

Page 18

Range Resolution Remark

0.01Ω

Open circuit voltage is around 3V.

When the buzzer is set for Short Circuit warning; If the impedance tested is

less than 10Ω, the buzzer continuously sounds. If the impedance tested is

greater than 50Ω, the buzzer does not sound.

When the buzzer is set for Open Circuit warning; If the impedance tested is

greater than 50Ω, the buzzer continuously sounds. If the impedance tested is

less than 10Ω, the buzzer does not sound.

(14) Continuity Test

• Overload protection: 1000V

Range Resolution Remark

0.0001V

Open circuit voltage is around 3V. The forward voltage drop value of the mea-

sured PN junction is approximately ≤ 3V.

When the buzzer is selected in Diode Test Mode; it will beep briefly for the

normal semiconductor junction. If the semiconductor junction shorts out (im-

pedance <10Ω), the alarm will continuously sound. Typical silicon PN junction

voltage drops vary between 0.5~0.8V.

(15) Diode Test

• Overload protection: 1000V

16

Page 19

IX. Measurement Operation

1. Meter Power Control

1) To manually power up and power down the meter:

When the meter is off, long press to start the meter. When the meter is on, long press to shut it off.

The meter cannot be powered off when charging.

2) Indicators for Battery Level:

The meter is powered by a rechargeable lithium battery. The indicators for battery level are in the upper right corner of the

When the battery capacity is lower than 3% of full capacity, the meter will automatically shut down.

3) Backlight Control

If the display is not visible in low-light situations, press the backlight button to switch the backlight brightness. Long

press the button to turn off the backlight and enter power saving mode. When the backlight is off, the green light

ashes to indicate that the meter is still collecting data. Press any key or turn the rotary switch to turn on the backlight again.

4) Auto Power-off

When the Auto Power Off is set, the meter will turn off if no button is pressed or the dial selector is not turned within the time

set. To disable Auto Power Off, set the Power Off mode to “OFF” under the SETUP – Auto Power Save Menu.

5) Power Saving Mode

Set the control time for dimming the brightness and turning off the display, found in the SETUP – Auto Power Save Menu

17

Page 20

2. Meter Settings

Press the function key labelled, SETUP to access the general settings for the meter. Press the cursor keys to

navigate through the settings menu.

1) Keypad Tone

This function enables or disables sound when a button is pressed. The beeper symbol in the upper right corner

indicates that sound is enabled.

2) Lead Alarm Buzzer

This function enables or disables the alarm sound for improper probe lead connection.

3) Communication

Set as ON to enable USB communication. A symbol will appear in the upper right corner when active. When

Communication Mode is OFF, the symbol will disappear.

4) Date & Time

With “Date & Time” highlighted in the SETUP Menu, press the function key labelled, “SET” to set the date and time.

Press (LEFT) or (RIGHT) to select the eld to edit, and press (UP) or (DOWN) to enter different numbers, then press the

function key “OK” to conrm. To cancel the settings, press the function key labelled, “CANCEL”.

5) Auto Power Save Options

With “Auto Power Save” highlighted in the SETUP Menu, press the function key labelled, “SET” to edit the time of inactivity

to dim the brightness, turn off the display, and power down the meter. Press (UP) or (DOWN) to move the cursors to select

different items. Press (LEFT) or (RIGHT) to enter the time, in minutes, to activate the power saving feature.

Menu Item Description Set Value

Brightness Down

Dim the display brightness after the elapsed

time of inactivity.

ON: 1-60 Min OFF: This function is disabled

Display Off Turn off the display after the elapsed time. ON: 1-60 Min OFF: This function is disabled

Power Off Turn off the power after the elapsed time. ON: 1-60 Min OFF: This function is disabled

Press the function key “OK” to conrm the above settings. To cancel the settings, press the function key “CANCEL”.

18

Page 21

6) More Settings

With “More Settings” highlighted in the SETUP Menu, press the function key “ENTER” to: Set the language of the Help

Menu, Format Memory, Reset the meter settings, or check the model number, serial number and available memory space.

Press the cursor keys to select between the following menu items.

- Help Menu Language

Press the function key labelled, “SET” to set the Help Menu language. Press (UP) or (DOWN) to select a different lan

guage. Then press the function key “OK” to conrm. To cancel the settings, press the function key “CANCEL”.

- Memory Format

With “Memory Format” highlighted, press the function key labelled, “FORMAT” to enter the memory format menu, then

press the function key labelled “YES” to conrm. To cancel the format, press the function key labelled, “NO”.

- Reset All Setting

With “Reset All Setting highlighted, Press the function key “RESET” to reset the meter to default settings, then press the

function key “YES” to conrm. To cancel the reset, press the function key “NO”.

- About

Press the function key “ABOUT” to check product model, serial number and available memory space.

19

Page 22

3. AC Voltage

1) Insert the red test lead into the V terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to V or mV as shown in Figure 5.

Connect the test leads to the power or load under test in

parallel.

3) Directly read the measured voltage values on the display.

True virtual values are displayed for AC measurement.

4) Press the function key labelled, “MENU” to access

additional features for measuring AC voltage. Press

the cursor keys to select menu items. The red

highlighting indicates the selected item. Press F1

to enter the corresponding measuring mode, press F2 to

enter Relative value mode when available, and press F3

to set dBm impedance (AC V only), and press F4 to close

the measurement features menu.

Attention:

After completing all the measuring operations, disconnect the test leads and the circuit under test Do not input a

voltage higher than 1000V. Higher voltage may be

measured but it may damage the meter.

• When measuring high voltage, special care should be

taken to avoid electric shock.

• After completing all the measuring operations, disconnect

the connection between the test leads and the circuit under

test.

• The meter’s True RMS response is calibrated to an AC sinusoidal input signal. Measuring non-sinusoidal AC signals

will have decreased accuracy.

4. DC Voltage

1) Insert the red test lead into the V terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to DC V or DC mV as shown in

Figure 6. Connect the test leads to the power

or load under test in parallel.

3) Directly read the measured voltage values on the display.

4) Press the function key labelled, “MENU” to access

additional features for measuring DC voltage. Press

the cursor keys to select menu items. The red

highlighting indicates the selected item. Press F1 to

enter the corresponding measuring mode, press F2 to

enter Relative value mode when available, and press F4

to close the measurement features menu.

20

Page 23

Attention:

• Do not input a voltage higher than 1000V. Higher voltage

may be measured but it may damage the meter.

• When measuring high voltage, special care should be

taken to avoid electric shock.

• After completing all the measuring operations, disconnect

the connection between the test leads and the circuit under

test.

5. AC and DC Current

1) Insert the red test lead into the µAmA or A terminal and

the black test lead into the COM terminal.

2) Set the rotary switch to the position as shown in Figure 7.

Press the key “SELECT” to measure either AC or DC.

Connect the test leads to the test circuit in series.

3) Directly read the measured current values on the display.

4) Press the function key labelled, “MENU” to access

additional features for measuring AC or DC current.

Press the cursor keys to select menu items.

The red highlighting indicates the selected item. Press F1

to enter the corresponding measuring mode, press F2 to

enter Relative value mode when available, and press F4

to close the measurement features menu.

Warning:

• Before connecting to the test circuit, turn off the power to

the circuit rst and discharge all the high-voltage

capacitors.

• Use proper input terminals and functions for measurement.

If the current amperage cannot be estimated, rst measure

using the largest range.

• When the test lead is inserted in a current terminal, do not

connect its test probe to any circuit in parallel, it could

blow the fuses within the meter and damage the meter.

• After completing all the measuring operations, disconnect

the connection between the test leads and the circuit under

test.

21

Page 24

22

Page 25

6. Resistance

1) Insert the red test lead into the Ω terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to the Ω nS position. The

meter will default to resistance measurement. Connect

the test leads to both ends of the measured resistance as

shown in Figure 8.

3) Directly read the measured resistance values on the

display.

Attention:

• If measuring an open circuit or resistance value exceeds

the maximum range of the meter, “OL” will show on the

display.

• When measuring the in-circuit resistance, all the power

within the measured circuit must be shut off before

measurement and all the capacitors must be discharged to

ensure a correct measurement, and to avoid damaging the

meter.

• When measuring low resistance, the test leads may

add additional resistance between 0.10 Ω to 0.20Ω. To

obtain accurate readings, Relative measurement can be

used. First short the input test leads, then press the

function key labelled, “MENU” and press F2 to enter

Relative measurement mode. Perform the low resistance

measurement and the meter will automatically subtract the

resistance of the shorted test leads.

• If the resistance value is greater than 0. 50Ω with shorted

test leads, the test leads should be checked for loose

connections or other factors.

• When measuring a resistance >1MΩ, the readings require

a few seconds to stabilize. This is normal for high resis

tance measurements. In order to obtain stable readings,

short test lines can be used for the measurement.

• Do not input a voltage in resistance measurement mode to

avoid possible product damage or personal injury.

• After completing all the measuring operations, disconnect

the connection between the test leads and the circuit under

test

23

Page 26

7. Conductance

1) Insert the red test lead into the Ω terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to the measurement Ω nS .

Press the SELECT key twice to select Conductance

measurement. Connect the test leads to both ends of the

measured resistance as shown in Figure 8.

3) Directly read the measured conductance value on the

display.

Attention:

• When measuring the in-circuit resistance, all the power

within the measured circuit must be shut off before

measurement and all the capacitors must be discharged to

ensure a correct measurement, and to avoid damaging the

meter.

• Do not input a voltage when in conductance measurement

mode to avoid possible product damage or personal injury.

• After completing all the measuring operations, disconnect

the connection between the test leads and the circuit under

test.

8. Capacitance

1) Insert the red test lead into the terminal and the

black test lead into the COM terminal.

2) Set the rotary switch to the measurement

press the SELECT key to select Capacitance

measurement. Connect the test leads to both ends of the

measured capacitance as shown in Figure 9.

3) Directly read the measured capacitance value on the

display.

Attention:

• If the measured capacitance shorts or capacitance value

exceeds the maximum range of the meter, “OL” will show

on the display.

• For the measurement of small capacitance within range,

relative measurement REL should be used to avoid the

inuence of test lead capacitance for correct readings.

• For capacitance measurements > 600 µF,

the readings require a few seconds to be stable.

• To ensure the measuring accuracy, the capacitor should

be discharged completely then put onto the meter to

measure, especially for a capacitor with high voltage to

avoid damage to the meter and personal injury.

• Do not input a voltage when in capacitance measurement

mode to avoid possible product damage or personal injury.

• After completing all the measuring operations, disconnect

the connection between the test leads and the capacitor

under test.

24

Page 27

9. Continuity Test

1) Insert the red test lead into the Ω terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to the measurement Ω nS ,

press the SELECT key to select the Continuity test

. Connect the test leads to both ends of

the measured resistance as shown in Figure 8. Press

the function key labelled, “MENU” to select measurement

options. Pressing the function key labelled, “SHORT”

will put the meter in Short Circuit Alarm mode. Pressing

the function key labelled, “OPEN” will put the meter in

Open Circuit Alarm mode.

When the buzzer is set for Short Circuit warning; If the

impedance tested is less than 10Ω, the buzzer continuously

sounds. If the impedance tested is greater than 50Ω, the

buzzer does not sound.

When the buzzer is set for Open Circuit warning; If the

impedance tested is greater than 50Ω, the buzzer continuously sounds. If the impedance tested is less than 10Ω, the

buzzer does not sound.

3) Directly read the measured resistance value on the

display.

Warning

• When measuring the in-circuit resistance, all the power

within the measured circuit must be shut off before

measurement and all the capacitors must be discharged to

ensure a correct measurement.

• Do not input a voltage when in continuity test mode to

avoid possible product damage or personal injury.

• After completing all the measurements, disconnect the

connection between the test leads and the circuit under

test.

10. Diode

1) Insert the red test lead into the terminal and the

black test lead into the COM terminal. The polarity of red

test lead is “+” and “-” for black test lead.

25

Page 28

2) Set the rotary switch to the position.

The meter will default to Diode measurement. Connect

the test leads to both ends of the diode as shown in

Figure 10. Directly read the approximate forward

PN junction voltage of the measured diode on the

display.

3) Press the function key labelled, “MENU” to choose

measurement options. Pressing the function key

labelled,“ALARM” will enable the beeper. It will beep

briey when connected to a normal semiconductor

junction; If the measurement shorts out, it will beep

continuously. Typical Silicon PN junction drops vary

between 0.5V ~ 0.8V. Pressing the function key labelled,

“NORMAL” will run the diode test without the beeper

function.

Attention:

• If the measurement is an open circuit, or the diode polarity

is reversed, “OL” will be displayed.

• When measuring an in-circuit diode, all the power within

the measured circuit must be shut off before measurement

and all the capacitors must be discharged.

• Open-circuit voltage of diode test is around 3V.

• Do not input a voltage when in diode test mode to avoid

possible product damage or personal injury.

• After completing all measurements, disconnect the

connection between the test leads and the circuit under

test.

26

Page 29

11. Frequency/Duty Cycle Measurement /Pulse

Width

1) Insert the red test lead into the V terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to the measurement Hz%

ms-Pulse position. Press the SELECT key to select Hz,

Duty Cycle (%), or ms-Pulse. Connect the test leads to

the signal source under test in parallel as shown in

Figure 11.

3) Directly read the measured values of frequency, duty

cycle or pulse width on the display.

Attention:

• Simulation bar displays the frequency of the measured

signal for duty cycle and pulse width.

• After completing all measurements, disconnect the

connection between the test leads and the circuit

under test.

12. Temperature

1) Set the rotary switch to the measurement mV °C °F then

press the SELECT key to choose Celsius °C or

Fahrenheit °F. Insert the temperature connector into the

four input terminals and connect two temperature probes

to the temperature connector as shown in Figure 12. The

temperature probes detect the surface temperature of the

object under test.

2) Directly read the temperature values of the two sensors

on the display.

3) Press the function key labelled, “MENU” to choose

measurement options. Scroll through the menu with

keys and press F1 to choose the highlighted

option. Press F2 while in the Menu to enter Relative

Mode. Press F4 to close the Menu.

27

Page 30

Attention:

• If the ambient temperature for the meter is outside the

range of 18 °C to 28 °C, it may cause measurement errors.

The measurement effects are more obvious at low

temperatures.

• Remove the temperature probes after completing all the

measurements.

• Point contact K type (chromel-silicel) thermocouple

accuracy specication is for temperature measurements

below 230 °C.

13. LPF Measurement

1) Insert the red test lead into the V terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to v. Connect the test leads to the

power or load to be tested in parallel as shown in

Figure 5.

3) Press the function key labelled, “MENU” to choose

measurement options. Press the cursor keys

to highlight “Low Pass”, then press the function key

labelled, “Low Pass” to enter LPF measuring mode.

4) The meter performs the measurement in AC mode.

The AC signals go through a lter which lters out

voltage signals with frequencies higher than 1KHz. As

shown in the following gure, the low-pass lter can

measure the composite signals of sinusoidal waves

generated by inverter and variable-frequency motor.

Attention:

• To avoid electric shock or personal injury, do not use the

low-pass lter to verify hazardous voltage, there may be

a voltage over the indicated value. First, measure the

voltage without a lter to check whether it is hazardous,

then select low-pass ltering.

28

Page 31

• In the LPF measuring mode, the meter will turn to manual

mode. Press the RANGE key to select a range. When the

low-pass lter is enabled, automatic range is unavailable.

• Do not input a voltage above 1000V. Higher voltage may

be measured but it poses the risk of damaging the meter.

• After completing all measurements, disconnect the

connection between the test leads and the circuit under

test.

14. dBV

1) Insert the red test lead into the V terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to v. Connect the test leads to the

power or load to be tested in parallel as shown in

Figure 5.

3) Press the function key labelled, “MENU” to choose

measuring options. Press the cursor keys to

highlight “dBV”, then press the function key labelled,

“dBV” to enter dBV measurement mode.

4) dBV is the primary measurement shown and AC voltage

value is the secondary value shown on the display. AC

voltage of the measured signal is also displayed on the

15. dBm

1) Insert the red test lead into the V terminal and the black

test lead into the COM terminal.

2) Set the rotary switch to V. Connect the test leads to the

power or load to be tested in parallel as shown in

Figure 5.

3) Press the function key labelled, “MENU” to choose

measurement options. Press the cursor keys

to highlight “dBm”. A reference impedance must be

used to calculate the dBm measurement. Press the

function key labelled, “RES” to select a reference

impedance value. Press (UP) or (DOWN) to scroll

between ten dened reference values: 4, 8, 16, 25, 32,

50, 75, 600, 1000Ω, and User Dened. While selecting

a User dened reference impedance, press the function

key labelled, “EDIT” and use the cursor keys to

input a reference impedance value between

4-1,200Ω. Press the function key labelled, “OK” to set

reference values. Press the function key labelled, “dBm”

to enter dBm measurement.

4) dBm is the primary measurement shown and AC voltage

value is the secondary value shown on the display. AC

voltage of the measured signal is also displayed on the

simulation bar.

16. Maximum and Minimum Value

Press the “MAX MIN” key to activate Max Min Mode.

Real-time measurements are the primary value displayed.

Maximum, minimum, and average values, as well as

elapsed time, start date and times corresponding to the

three values are secondarily displayed.

29

Page 32

Press the function key labelled, “EXIT” to exit Max Min Mode.

17. Relative Value Mode

Press the function key labelled, “MENU” to enter the

measurement option menu. While in the menu, press the

function key labelled, “REL” to enter Relative Value Mode*.

The meter will store the value shown at the time that “REL” is

pressed as the “Reference” measurement. Press the

function key labelled, “REL” to store the present value as the

“Reference”. The real-time measurement will be displayed as

“Measurement”. The primary value displayed will be the Relative value (Measurement – Reference). Press the “MENU”

function key to select other modes and exit Relative Value

Mode. *NOTE: When applicable. Relative Value Mode is not

available for all measurement types.

18. Peak Detection Mode

While in a Voltage or Current measuring mode, press the

“MENU” function key to choose measurement options. While

in the menu, press the function key labelled, “PEAK” to activate Peak Detection Mode. Response time is 1ms. Transient

values can be more accurately measured by using Peak

Mode while using the Record function.

19. Compare Mode

Press the F3 function key labelled, “COMP” to begin Compare Mode. Press (UP) or (DOWN) to scroll between the

settings of Compare Mode. Press the “EDIT” function key to

edit the highlighted Compare Mode setting.

1) Pass Mode

• INNER(Low Value ≤ Input Value ≤ High Value)

• OUTER (Input Value < Low Value OR Input Value >High

Value)

• <Value

• >Value

Press the “OK” function key to conrm the above settings.

To cancel the settings, press the “CANCEL” function key.

2) Beep Mode

While highlighting the “Beep Mode” setting, press the “EDIT”

function key to edit the Beep settings. Press the keys

to select one of the three following options:

• PASS ON

The meter will beep when the Pass Mode criteria are met,

and the meter displays, “PASS”.

• FAIL ON

The meter will beep when the Pass Mode criteria are NOT

met, and the meter displays, “FAIL”.

• OFF

The meter will not beep in Compare Mode.

Press the function key OK to conrm the above

settings. To cancel the settings, press the “CANCEL”

function key.

3) Low Value or High Value or Value

This setting controls the value(s) for the Pass Mode criteria.

After completing the settings, press the “START” function

key to start the measurement in Compare Mode. Press the

“EXIT” function key to exit Compare Mode.

30

Page 33

20. Recording Measurement Data

Press the function key labelled, “SAVE” to enter the menu

for saving, recording or viewing data. Press the cursor keys

to select the following options.

1) Save

While in the Save menu, press the “SAVE” function key to

store the measurement currently displayed. Up to 20,000

measurements can be saved on the meter.

2) View Save

In the Save menu with “View Save” highlighted, press the

“VIEW” function key to view stored save les. Press or

hold the function keys labelled, “PREV” or “NEXT” to scroll

through the saved data. Press the “DELETE” function key to

delete the selected saved data. Press the “RETURN” function key to return to the last menu. In addition to displaying

the saved data, the le save # and total number of saved

les are displayed in the lower left corner. The date and time

of the saved data are displayed in the lower right corner.

3) Delete All Save

In the Save menu with “Delete All Save” highlighted, press

the function key labelled, “DELETE” to delete all saved data

les. Press the function key labelled, “YES” to conrm. To

cancel the operation, press the function key labelled, “NO”.

4) Record

In the Save menu with “Record” highlighted, press the function key labelled, “ENTER” to enter the continuous

recording mode with a maximum of 10000 data points.

Press (UP) or (DOWN) to edit the three following settings.

• Edit Name

In the Record Menu with “Edit Name” highlighted, press the

“EDIT” function key to edit the name of the recording. Press

(LEFT) or (RIGHT) to move the cursor and select where

to edit. Press the F1 key to switch the input to Uppercase

mode, then press (UP) or (DOWN) to input uppercase

letters. Press the F2 key to switch the input to Lowercase

mode, then press (UP) or (DOWN) to input lowercase letters. Press the F3 key to switch the input to Digit mode, then

press (UP) or (DOWN) to enter numbers or symbols. Press

the F4 key to save the Record name and exit edit mode.

• Set Interval

With “Set Interval” highlighted, press the “EDIT” function key

to set the time interval between recorded data points. Press

or hold (LEFT) or (RIGHT) to move the cursors to select

where to edit. Press or hold (UP) or (DOWN) to enter different numbers. The interval time can be set from 1 sec to 60

min between data points.

• Set Duration

With “Set Duration” highlighted, press the “EDIT” function key to set the duration of the recording. Press or hold

(LEFT) or (RIGHT) to move the cursors to select where

to edit. Press or hold (UP) or (DOWN) to enter different

numbers. The duration time can be set in days, hours and

minutes.

• Max Duration

Displays the maximum time for continuous recording with

the current settings. When ready to Record, press the

“START” function key to start a recording with the current

settings.

31

Page 34

When Recording, the characters “REC” show on the display

with a ashing red dot, as shown in Figure 13. The relevant

display information is shown in the following table.

To manually stop recording, press the “STOP” function

key. After stopping the recording, the record data will be

displayed. See the viewing options in the following “view

Record” section.

5) View Record

In the Save Menu with “View Record” highlighted, press the

“View” function key to view the information on recordings.

The data will be displayed as shown in Figure 14. The basic

display information is in the following table.

Information Description

Name Name of recording

Interval Time between data points

Duration Duration of recording from start to stop

Samples Total number of data points recorded

Maximum Maximum recorded value

Average Average value of the recorded data

Minimum Minimum recorded value

REC Record le number and total number of

recordings

Start Time and date at beginning of recording

Information Description

Elapsed Time Run time displayed in hours: minutes

Remaining

Time

Time left displayed in hours: minutes:

seconds

Samples Total number of recorded data points for

the active recording

Start Time and date of the start of the

recording.

32

Page 35

While viewing a Record, press the “PREV” function key to

display the previous record. Press the “NEXT” function key

to display the next record. Press the “RETURN” function key

to return to the previous menu. Press the function key labelled, “TREND” to view the recording graphically, as shown

in Figure 15. The display information of trend data is in the

following table:

No. Description

1 Measured value corresponding to cursor

2 Date and time of measurement at the cursor

3 Cursor

4 Trend line

5 Elapsed time labels on X-axis

6 Name of recording

7 Time and date at the start of the recording.

Viewing the trend chart: Press or hold the F2 key to move

the cursor left. Press or hold the F3 key to move the cursor right. The cursor moves one data point for each press.

Holding, or long pressing the keys will scroll through data

points more quickly. Press (UP) or (DOWN) to scale the

graph vertically. Press (LEFT) or (RIGHT) to scale the graph

horizontally.

Press the F1 key to delete this record. Press the function

key labelled, “YES” to conrm the deletion. To cancel the

deletion, press the “NO” function key.

6) Delete All Record

In the Save menu with “Delete All Record” highlighted, press

the function key labelled, “DELETE” to delete all record-

ings. Press the “YES” function key to conrm. To cancel the

operation, press the “NO” function key.

21. Communication

33

Page 36

USB Communication

Turn on communication via settings (see detailed operations

in the section 2. Meter Settings). The symbol will

appear in the upper right corner on the display as shown in

Figure 15.

The meter performs USB communication with the supplied

USB cable (standard accessory) connecting to the PC.

X. Maintenance and Repair

1. General Maintenance and Repair

Regularly clean the meter case with damp cloth and mild detergent. Do not use abrasives, isopropyl alcohol or solvents.

Dirt or moisture on the terminals can affect readings but can

also enable the “Lead Error” warning. Clean the terminals

according to the following steps:

1) Turn off the meter and remove all test leads.

2) Clean up the dirt on the terminals.

3) Soak a clean cotton swab in mild detergent and water.

Clean each terminal with the cotton swab. Dry each terminal

with canned compressed air to force water and detergent to

ow out of the terminals.

4) In the case of abnormal meter function, stop using it and

send it for repair.

5) When the meter needs to be veried or repaired, qualied

service personnel or a designated maintenance department

are required to repair it.

2. Testing Fuses

As shown in Figure 17, put the meter in resistance mode.

Insert a test lead into the terminal as shown in Figure 17

and contact the probe tip of the test lead with the metal in

the of a current input terminal. If the message, “Lead Error!”

(connection error for test leads) appears, it shows that the

probe tip is inserted too deeply in the input current terminal.

Draw out the test lead a little until the error message disappears and OL (overload) or resistance reading appears on

the display. If the resistance reading for A terminal is less

than 0.50Ω, it shows that the fuse F2 is normal. If the

reading is “OL”, you need to replace F2; If the resistance

reading of the µAmA terminal is less than 1.2MΩ, it shows

that the fuse F1 is normal. If the reading is OL, F1 needs to

be replaced;

34

Page 37

3. Replacing Fuses

Inspect or replace the meter fuse as shown in Figure 18

according to the following steps:

1) Turn off the meter and remove the test leads from the

terminals.

2) Use a at-head screwdriver to turn the screw on the bat-

tery cover counterclockwise, then remove the battery cover.

3) Gently pry one end of the fuse and then remove the fuse

from the clip.

4) The required fuse installed for mA or µA input terminal:

0.8A H 1000V Fuse Type 6X32mm (F1) The required fuse

installed for A input terminal: 10A H 1000V Fuse Type

10X38 mm (F2)

5) Reinstall the battery cover and then turn the screw

clockwise to tighten the battery cover.

4. Battery Charge

When the indicator of battery level in upper right corner is

less than 5% of full capacity, the meter should be immediately charged, otherwise it will affect the measurement

accuracy. As shown in Figure 19, set the rotary switch to

. The message, “Please plug in AC adapter!” will prompt

you to insert a power adapter for charging. Connect the

power connector to the four terminals in the meter, then

insert the power adapter into the power connector, as shown

in Figure 19. The message, “Charging” on the display indicates it is in charging with a progress bar displaying battery

charge to the nearest 5%. The power button will light red.

When the battery is fully charged, the red light will turn off

and the charging process stops. A “Charge

complete” message will display when fully charged.

Attention:

You must use the power adapter specied by Triplett.

35

Page 38

XI. Warranty

Triplett extends the following warranty to the original

purchaser of these goods for use. Triplett warrants to the

original purchaser for use that the products sold by it will be

free from defects in workmanship and material for a period

of (3) three years from the date of purchase.

This warranty does not apply to any of our products which

have been repaired or altered by unauthorized persons in

any way or purchased from unauthorized distributors so as,

in our sole judgment, to injure their stability or reliability, or

which have been subject to misuse, abuse, misapplication,

negligence, accident or which have had the serial numbers

altered, defaced, or removed. Accessories, including batteries and fuses, are not covered by this warranty.

To register a claim under the provisions of this warranty,

please contact the distributor from which you purchased the

product from for warranty

consideration.

ALL WARRANTIES IMPLIED BY LAW ARE HEREBY

LIMITED TO A PERIOD OF THREE YEARS FROM DATE

OF PURCHASE, AND THE PROVISIONS OF THE WARRANTY ARE EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES EXPRESSED OR IMPLIED.

The purchaser agrees to assume all liability for any damages and bodily injury which may result from the use or misuse

of the product by the purchaser, his employees, or others,

and the remedies provided for in this warranty are expressly

in lieu of any other liability Triplett may have, including incidental or consequential damages.

Some states (USA ONLY) do not allow the exclusion or

limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you No representative of Triplett or any other person is authorized to

extend the liability of Triplett in connection with the sale of its

products beyond the terms hereof.

Triplett reserves the right to discontinue models at any time,

or change specications, price or design, without notice and

without incurring any obligation.

This warranty gives you specic legal rights, and you may

have other rights which vary from state to state.

36

Page 39

XII. Notes

37

Page 40

Model 9065

Part Number: 9065

Made in China

84-910

10/15

Loading...

Loading...