low res. Internet brochurelow res. Internet brochure

PSxxx-90 Laser Scanner

low res. Internet brochure

User’s Manual

PS300-90

PS250-90

PS100-90

PS250-90 HT

PS100-90 HT

Triple-In GmbH | Poppenbütteler Bogen 64, D-22339 Hamburg, Germany

Content

Triple-IN

GmbH

1 INTRODUCTION ................................................................................................................ 3

1.1

A

BOUT PS LASER SCANNERS

1.2

A

BOUT THIS DOCUMENT

low res. Internet brochure

low res. Internet brochure

1.3

W

EBSERVER WITH LATEST DOCUMENTS AND FIRMWARE UPDATES

2 SAFETY INSTRUCTIONS ..................................................................................................... 5

3 ABOUT THE PSXXX-90 LASER SCANNER ............................................................................. 6

3.1

N

AMES AND FUNCTIONS OF COMPONENTS

3.2

S

YSTEM PARTS

3.3

T

RIPLE

3.4

S

ENSOR ORIGIN AND SCAN AREA

3.5

PS100-90-HT

4 TRANSPORT AND INSTALLATION ...................................................................................... 11

4.1

G

ENERAL HANDLING INSTRUCTIONS

4.2

P

ACKAGE AND TRANSPORT

4.3

M

ECHANICAL MOUNTING

5 CONNECTORS .................................................................................................................. 13

5.1

P

HOENIX

5.2

D

ATA AND POE CONNECTOR

5.3

S

ERIAL INTERFACE CONNECTOR

................................................................................................................... 7

-IN’S KEM T

FOR HIGH SURFACE TEMPERATURES

SPEEDCON

................................................................................................. 3

...................................................................................................... 3

............................................... 4

.............................................................................. 6

IME-OF-FLIGHT TECHNOLOGY

........................................................................................... 9

..................................................................................... 11

................................................................................................. 11

.................................................................................................. 12

®

QUICK LOCKING SYSTEM

.............................................................................................. 14

........................................................................................... 16

..................................................................... 7

.................................................................. 9

..................................................................... 13

6 SETTING INTO OPERATION ............................................................................................... 21

6.1

W

INDOWS® SOFTWARE TOOLS

6.2

P

OWER-UP

6.3

S

ERIAL

6.4

E

THERNET CONNECTION

6.5

PS L

6.6

T

AKING SCANS

6.7

F

ILTERS AND MASTER ECHO SELECTION

6.8

S

ETTING UP THE DIGITAL SWITCHING OUTPUTS

6.9

C

ONTROLLING THE HEATER (OPTIONAL

6.10 R

7 MAINTENANCE ................................................................................................................ 48

7.1

7.2

8 TROUBLE SHOOTING ........................................................................................................ 52

8.1

8.2

9 TECHNICAL SPECIFICATIONS............................................................................................. 55

9.1

EADING THE EXTERNAL INCREMENTAL ENCODER (OPTIONAL

C

LEANING

U

PDATING THE FIRMWARE

LED I

S

ELF-TEST MESSAGES AND SYSTEM HEALTH STATUS

T

ECHNICAL DATA

..................................................................................................................... 24

RS232

COMMUNICATION

ASER SCANNER CONFIGURATION

................................................................................................................. 36

....................................................................................................................... 48

NDICATORS

.............................................................................................................. 52

............................................................................................................. 55

............................................................................................ 21

........................................................................................ 24

.................................................................................................... 28

................................................................................... 31

................................................................................. 40

...................................................................... 43

) ................................................................................ 46

) ................................................... 46

................................................................................................. 48

................................................................. 53

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

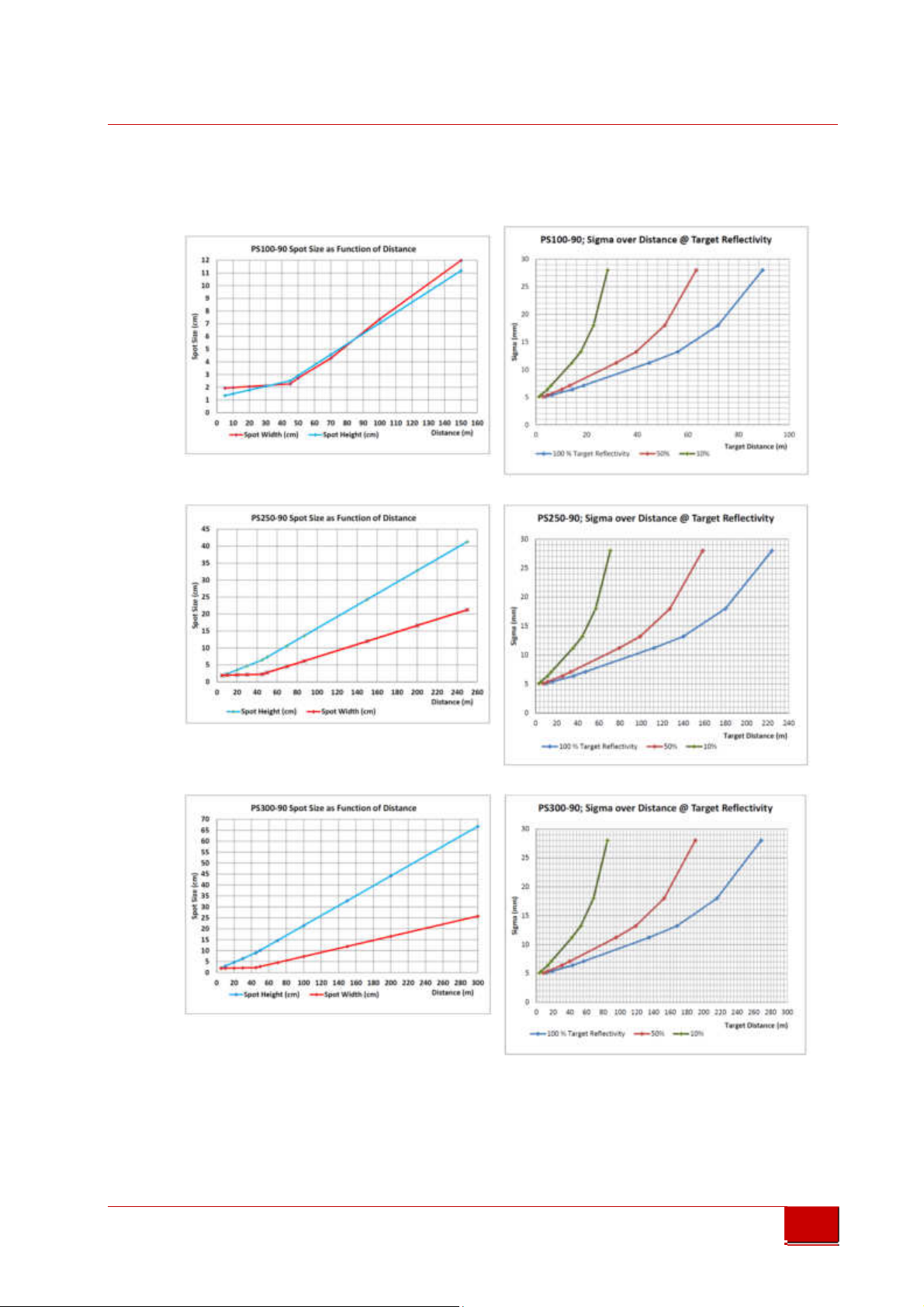

PS

XXX

.90 HT V

L

ASER SPOT SIZE AND SIGMA DIAGRAMS

L

ASER SPOT PATTERN

3D CAD M

PS

XXX

-90 L

S

ERIAL MULTIFUNCTION CABLE LAY OUT

E

THERNET AND POE CABLE LAYOUT

ERSIONS

........................................................................................................ 59

ODEL

.............................................................................................................. 61

ASER SCANNER OUTLINES

Triple-IN

GmbH

.................................................................................................... 57

............................................................................... 58

.................................................................................. 62

................................................................................ 63

...................................................................................... 64

low res. Internet brochure

low res. Internet brochure

10 INDEX .............................................................................................................................. 65

10.1 T

10.2 D

ABLE OF FIGURES

OCUMENT VERSIONS

............................................................................................................ 65

....................................................................................................... 66

Copyright © 2017 by Triple-IN GmbH

All rights reserved, including the right to reproduce this book or portions

thereof in any form whatsoever.

All trademarks, product names and logos are the property of their respective

owners.

Text, photographs, and illustration by C. Bruelle-Drews/Triple-IN GmbH

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

2

Triple-IN

GmbH

1 Introduction

1.1 About PS Laser Scanners

Triple-Ins PS Laser Scanners are 2D Laser Scanners for outdoor automation,

low res. Internet brochure

low res. Internet brochure

industrial applications, security and surveying.

• long range

• large scan angle

• small spot size

• accurate in range and angle

• fast scan rate

• robust, IP67

• real time Ethernet

PSxxx-90 is the backbone of the whole Triple-IN sensors portfolio, providing

rapidly and efficiently accurate and detailed 3D data. PSxxx-90 is suitable for both

indoor and outdoor applications, ensuring also goals achievement for existing

systems integration.

1.2 About this document

This document describes the PSxxx-90 Laser Scanner family. It is related to the

PS Firmware Version 3.03.16

If you or your colleagues have any comments on this manual, we would be

grateful to hear from you. Please write to:

Triple-IN GmbH

Poppenbütteler Bogen 64

D-22399 Hamburg

Germany

Telefon +49(0)40 50091998

Mail

info@triple-in.de

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

3

Triple-IN

GmbH

1.3 Webserver with latest Documents and Firmware

Updates

The latest version of this document and the latest firmware updates can be

obtained from Triple-IN’s webserver:

low res. Internet brochure

low res. Internet brochure

Picture 1 Triple-IN webserver login

Please contact Triple-IN to get access to the reserved area of the webserver:

info@triple-in.de

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

4

2 Safety Instructions

Triple-IN

GmbH

ATTENTION

low res. Internet brochure

low res. Internet brochure

• Before using the PS Laser Sensor, the user manual must be read and all

instructions must carefully be observed.

• The PS Laser Scanner must be installed, configured, and serviced only by

qualified personnel.

• National and international rules and regulations must be applied according

to the field of application and usage.

• PS Laser Sensor cannot be used as a safety device.

ATTENTION

• Measurement Laser is a laser class 1 product. Emits invisible light (905 nm).

Do not look into the laser beam!

• Red laser marker is a laser class 2 product. Emits visible light (660 nm). Do

not look into the laser beam!

ATTENTION

Only authorized personnel are allowed to perform the electrical installation

work.

To reduce the risk of electric shock, do not remove the cover. Device contains

high voltage components!

Connect and disconnect electrical linkages only under de-energized conditions.

WARNING

Do not open the PS Laser Scanner.

If opened, the mechanical adjustment will be damaged and warranty will get

void!

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

5

Triple-IN

Front

window

GmbH

3 About the PSxxx-90 Laser Scanner

3.1 Names and Functions of Components

low res. Internet brochure

low res. Internet brochure

4 x M4 x 6mm

Protection tube thread holes

Operating LEDs

Picture 2: PS Laser Scanner front view

5 x M6 Mounting thread holes

WARNING

Never remove these two plastic caps!.

Serial interface connector

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

Data and PoE connector

Picture 3: PS Laser Scanner rear side.

6

Triple-IN

GmbH

3.2 System Parts

• Red Laser Marker

is a visible class-2 laser. The red laser beam is aligned with the beam of the

measurement laser.

• Measurement Laser

low res. Internet brochure

low res. Internet brochure

emits a 905 nm invisible laser beam.

• Receiver

contains a receiver diode and is connected with the KEM-IC.

• Micro Processor Unit (MPU)

contains a microcontroller and a Triple-IN KEM-IC chip to record time-offlight events.

• Angle Encoder

is an encoder with a resolution of 32000 coder counts.

• Motor Unit

drives the mirror cube motor with a constant frequency. The motor

frequency is adjusted in the factory and cannot be changed. The motor can

be switched off for calibration purposes.

• Communication Board (“Olimex”)

is a separate board with a microcontroller and an Ethernet interface. This

board is responsible for the TCP/IP communication.

• Heater (optional)

The heater extends the temperature working range to -30 Celsius.

• Discrete switch outputs SW1and SW2

are configurable 5 Volt DC collector switch outputs. The function of the

digital switching output can be programmed.

• External incremental encoder interface

is the 3.3 - 5 Volt input for a 32 bit counter used to provide a horizontal

position from an external encoder.

3.3 Triple-IN’s KEM Time-of-Flight Technology

The technological basis for the Triple-IN PS Laser Scanners is “Time-of-Flight”

(ToF): the travel time of light emitted by a laser diode to natural surface.

Triple-IN’ KEM method (“kontinuierliche Event Messung”) improves this wellknown technology:

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

7

Triple-IN

GmbH

low res. Internet brochure

low res. Internet brochure

Picture 4 Principle of operation

1. An angle encoder triggers a laser diode in regular angle steps. The laser

diode emits an infrared laser beam. This “start pulse“marks the beginning

of the time-of-flight measurement.

2. A mirror cube, which is connected to the angle encoder, reflects the laser

beam in certain directions. Each rotation of the mirror provides four scans.

3. The laser beam is reflected by natural surfaces. Several echoes can be the

result of window panes, rain drops, snowflakes and similar objects which

reflect parts of the laser pulse’s energy. This effect is called “multi-echo”.

4. PS Laser sensors can record the results of up to 4 echoes for each laser

beam. One echo signal is used as “Master Echo” to build the final

measurement result

5. The echo signal varies by the surface reflectivity and the distance to the

object. The echo signal will be detected as soon as it passes a receiver

threshold. The sensor measures the time-of-flight and the pulse width

(PW) of the echo signal.

6. The KEM technology applies various corrections to compensate deviations

of the echo signal strength. The result is accurate time-of-flight

measurement, independently of the temperature, reflectivity, and target

distance. The distance to the target is calculated by

d = ToF * c / 2 - corr

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

8

Triple-IN

GmbH

d distance

ToF measured time-of-flight

c speed of light in ambient atmosphere

corr echo signal corrections

low res. Internet brochure

low res. Internet brochure

3.4 Sensor Origin and Scan Area

PSxxx-90 Laser Scanners trigger 1000 laser beams on a 90° scan field:

• The angle encoder zero-direction is to vertical axis of the sensor.

• The scan field starts at angle encoder position 45° and ends after 90° at

encoder position 135°.

The zero point (origin of the measurements) is marked on the casing.

The laser source is located with a parallaxes of 17 mm beside the vertical axis.

Picture 5: Scan area and Sensor origin

3.5 PS100-90-HT for high Surface temperatures

Standard PSxxx-90 Laser Scanners measures on natural target surfaces with

temperatures up to 500° Celsius.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

9

Triple-IN

GmbH

PSxxx-90-HT is a special version dedicated to high temperature operating

conditions. Technical data are based on standard PSxxx-90 sensors, with essential

improvements to stand hard working conditions where temperature is extremely

high, such as in steel industry.

PS100-90-HT Types extend this temperature range up to 1200° Celsius and allow

measurement on hot and glowing surfaces.

low res. Internet brochure

low res. Internet brochure

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

10

Triple-IN

GmbH

4 Transport and Installation

4.1 General Handling Instructions

• Ensure during the installation that the entire system is disconnected from

low res. Internet brochure

low res. Internet brochure

power supply.

• Mount the sensor at a location where the device is protected from damages,

pollution and high humidity.

• Mount the PS laser sensors in a way that it is not exposed to direct sunlight!

• Route cables such that danger is excluded for persons and all cables are

protected from damages.

• Do not remove the label or the two gray plastic caps from the rear side.

• Follow the safety instructions in the chapter 2.

4.2 Package and Transport

Use original Triple-IN packing material to transport the sensor.

Two deepings at the top side indicate the upper foam inlet.

Picture 6 Storage packaging

ATTENTION

Your warranty may be voided if returned sensor is received as a result of

inadequate packaging.

At the time of delivery, the user should examine the shipment for loss or damage.

If there is evidence of loss or damage, note it on the delivery receipt; this will be

used as evidence to back up the claim. Do not use or install a defective device.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

11

Triple-IN

GmbH

4.3 Mechanical Mounting

PSxxx-90 Laser Sensors can be fitted at the rear side with five socket head screws

with washers.

• Maximum Screw-in depth is max. 10 mm.

• Minimum screw-in depth is 4 mm.

low res. Internet brochure

low res. Internet brochure

• Maximum tightening torque is 12 Nm.

5x M6 thread holes

Max. screw-in depth 10 mm

Picture 7: Mounting thread holes

ATTENTION

• Use correct M6 screws only.

• Apply washers. The sensor must be fixed with at least four mounting screws.

• Observe the maximum screw-in depth for the screw holes. The device will be

mechanically destroyed if the maximum screw-in depth is exceeded!

• Do not extend the maximum tightening torque of 12 Nm.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

12

Triple-IN

CLICK

GmbH

5 Connectors

5.1 Phoenix SPEEDCON® quick locking System

low res. Internet brochure

low res. Internet brochure

ATTENTION

Before attaching the connectors, make sure the sealing rubber rings in the

sockets are all in place.

Always fit sealing connector caps onto plugs which are not used.

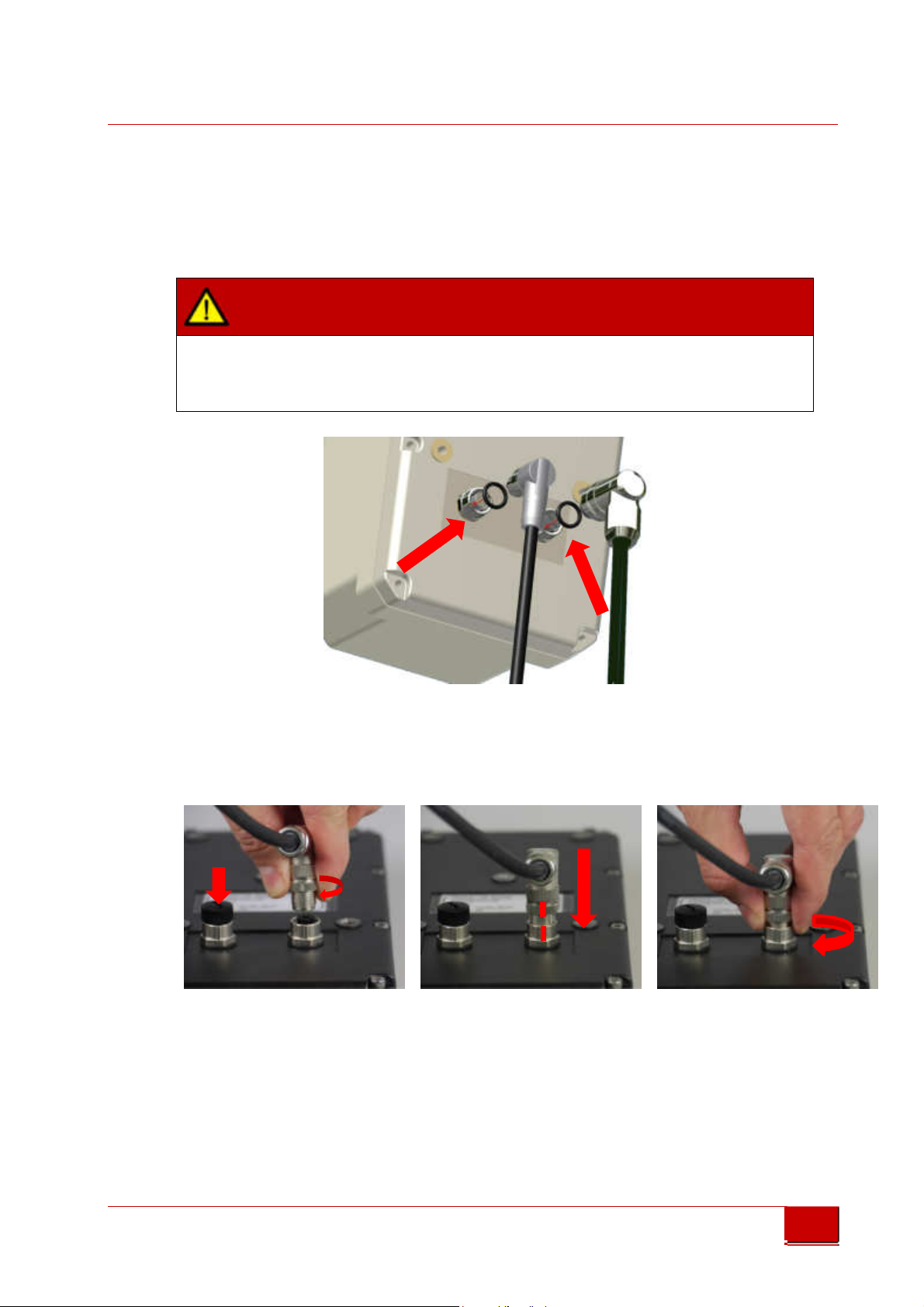

Picture 8: Connector rubber gaskets

PS Laser sensors are equipped with Pheonix SPEEDCON® M12 quick locking

connectors.

cap

Picture 9: Using the quick locking connectors

1. Make sure the rubber gaskets in the sockets are in place.

2. Turn the retainer ring until you notice a distinct „click“.

3. Align marks at the retainer ring and the socket.

4. Push the connector into the socket.

5. Turn the retainer ring to secure the connection.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

13

Triple-IN

GmbH

5.2 Data and PoE Connector

5.2.1 Layout of the Data and PoE Connector

The Data and PoE Connector connects the sensor with the local network and

includes Power over Ethernet.

low res. Internet brochure

low res. Internet brochure

The Data and PoE Connector connects the sensor with the local network and

includes Power over Ethernet.

• M12 connector/ IP67/CAT6 connector

• Type Phoenix Contact

" Flush-type socket - SACC-CI-M12FS-8CON-L180-10G - 1402457"

• Adapter type reference is Phoenix Contact

" Bus system plug connector - VS-08-M12MR-10G-P SCO - 1417443".

• The pin/pair assignments conforms with the T568B standard

Picture 10: M12 Data and PoE scheme (plug side view)

Pin Signal Purpose

1. Tx+ Transmit

2. Tx- Transmit

3. Rx+ Receive

4. DC+ Positive supply voltage

5. DC+ Positive supply voltage

6. Rx- Receive

7. DC- Negative supply voltage

8. DC- Negative supply voltage

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

14

Triple-IN

GmbH

5.2.2 Power over Ethernet (PoE)

PS Laser Sensor uses the Power over Ethernet (PoE) technology. PoE systems pass

electrical power along with data on Ethernet cabling. This allows a single cable to

provide both data connection and electrical power.

The power lines on the serial interface become outputs if PoE is used. These

low res. Internet brochure

low res. Internet brochure

input/output lines are designed to provide power to an external turn table.

Picture 11 Scheme of the cross-linked power connectors

DANGER

Power supply

• Without heater: 24 Volt, 0.30 Ampere, 8 Watt

• With optional internal heater: 24 Volt, 1.25 Ampere, 30 Watt

To reduce the risk of electric shock and damages, only suitable PoE devices and

Ethernet cables specified for 30 Watt must be used. Note that IEEE

802.3af/Power over Ethernet Standards limit power to 12.95 Watt and PS Laser

Scanners will not meet this standard.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

15

Triple-IN

GmbH

DANGER

Danger of a short circuit:

PoE and Serial interface connector are cross-linked.

The power lines on the serial interface become outputs if PoE is used.

low res. Internet brochure

low res. Internet brochure

The Ethernet interface of the control computer shall be protected by an

Ethernet Splitter to prevent short circuits if power is connected to the serial

interface connector.

Suitable PoE injectors and power supplies are offered by:

PHIHONG® USA

Model: POE31U-240 for 24 Volt/30 Watt

Available on www.digikey.com

Digikey part number: 993-1083-ND

5.3 Serial Interface Connector

5.3.1 Layout of the Serial Interface Connector

The PS Interface cable connects the control computer with the RS232 interfaces of

the Ethernet board and the measurement board.

The connector is type M12 connector/IEC 61076-2-101.

Picture 12: M12 Serial interface connector scheme (plug side view)

Pin

1 brown DC- Negative supply voltage Input

2 blue 24V DC+ Positive supply voltage Input

3 white GND 5 Volt Ground (RS232)

Color Signal Comment Direction

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

16

Triple-IN

GmbH

Pin

4 green 5V_IB 5 Volt DC output Do not connect

5 pink ORX RS 232 RxD Ethernet Board Input

6 yellow OTX RS 232 TxD Ethernet Board Output

7 black SWI4 Reserved for future use Output

8 gray SWI3 Reserved for future use Output

9 red 485A Reserved for future use Do not connect

low res. Internet brochure

low res. Internet brochure

10 purpur 485B Reserved for future use Do not connect

11 gray pink CH_A External incremental encoder input A Input

12 red blue CH_B External incremental encoder input B Input

13 white green CH_I Reserved for future use Do not connect

14 brown green SWI2 Digital switching output SW2 Output

15 white yellow SWI1 Digital switching output SW1 Output

16 yellow brown STD_RXD RS 232 RxD Measurement Board Input

17 white gray STD_TXD RS232 TxD Measurement Board Output

The color column refers to the layout of the optional “Serial interface cable”.

If Pin 1 and 2 are used for power supply, the Power-over-Ethernet connection

must be disconnected by use of a PoE splitter. Otherwise there can be a short

circuit in the Ethernet connector to the gateway.

Color Signal Comment Direction

ATTENTION

ATTENTION

In the table, any grey field is there for an expansion to a standard sensor. These

signals are required for special scanner versions

5.3.2 Power over the serial interface connector

The Serial interface connector includes 24 Volt power lines cross linked with the

PoE adapter. These input lines are designed to supply power over the serial

interface connector.

WARNING

Power supply

• Without heater: 24 Volt, 0.30 Ampere, 8 Watt

• With optional internal heater: 24 Volt, 1.25 Ampere, 30 Watt

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

17

Triple-IN

GmbH

5.3.3 Wiring the Measurement Board (MPU) RS232 Serial

Interface

The Serial Interface Connector includes RS232 to the the Measurement Board

(MPU).

The RS232 interface to the Measurement board (MPU) is used for system

low res. Internet brochure

low res. Internet brochure

configuration, e.g. to setup the network parameter.

PS Laser Sensors are classified as Data Terminal Equipment (DTE). According to the

standard, PS Laser Sensors shall be equipped with male connectors. A “null

modem cable” consisting only of “Transmit Data”, “Receive Data”, and “Ground”,

is commonly used since the full facilities of RS-232 are not required.

A DSUB9 connector must connect the following leads:

Picture 13 Measurement Board (MPU) DSUB9 male DTE pin layout (socket view)

Pin Color Signal Comment Direction

3 white GND 5 Volt Ground

16 yellow brown STD_RXD RS 232 RxD Measurement Board Input

17 white gray STD_TXD RS232 TxD Measurement Board Output

The color column refers to the layout of the optional “Serial interface cable”.

5.3.4 Wiring the Communication Board RS232 Serial Interface

The Serial Interface Connector includes the RS232 to the the Communication

Board (“Olimex”).

The Communication board provides the Ethernet interface. The RS232 interface is

only used for network status messages and for firmware updates of the

Communication board.

PS Laser Sensors are classified as Data Terminal Equipment (DTE). According to the

standard, PS Laser Sensors shall be equipped with male connectors. A “null

modem cable” consisting only of “Transmit Data”, “Receive Data”, and “Ground”,

is commonly used since the full facilities of RS-232 are not required.

Picture 14 Communication Board DSUB9 male DTE pin layout (socket view)

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

18

Triple-IN

GmbH

Pin Color Signal Comment

3 white GND 5 Volt Ground

5 pink ORX RS 232 RxD Communication Board Input

6 yellow OTX RS 232 TxD Communication Board Output

The color column refers to the layout of the optional “Serial interface cable”.

low res. Internet brochure

low res. Internet brochure

5.3.5 Wiring Digital Switching Outputs

The PS Laser scanner has two 5 Volt digital open-collector outputs, called SW1 and

SW2. These outputs can be programmed for different purposes:

• To give a scan synchronization signal

• As switch output, controlled by the connected computer

• As a preset counter, providing a programmable number of output signals.

Direction

Pin

1 brown DC- Ground

14 brown green SWI2 Digital switching output SW2 Output

15 white yellow SWI1 Digital switching output SW1 Output

The color column refers to the layout of the optional “Serial interface cable”.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

Color Signal Comment

Picture 15 Digital output wiring scheme

Direction

19

Triple-IN

GmbH

5.3.6 Wiring an External Incremental Encoder

The PS Laser Scanner provides one 3.3 to 5.0 Volt incremental encoder input.

Purpose of the external incremental encoder is to report changes in the horizontal

position of the sensor.

The incremental encoder must provide two pulses A and B. The PS Sensor

low res. Internet brochure

low res. Internet brochure

firmware counts these pulses in both directions by use of a 32 bit register.

Input is limited to 128.000 counts/second.

Reset of the counter is done at startup or by software.

Picture 16 Incremental encoder wiring scheme

Pin

1 brown DC- Ground

3 white GND 5 Volt Ground (RS232)

11 gray pink CH_A External incremental encoder input A Input

12 red blue CH_B External incremental encoder input B Input

The color column refers to the layout of the optional “Serial interface cable”.

Color Signal Comment

Direction

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

20

6 Setting into Operation

6.1 Windows® Software Tools

Triple-IN

GmbH

low res. Internet brochure

low res. Internet brochure

6.1.1 Windows Program TeraTerm for the RS232 Serial Interface

TeraTerm, written by T. Teranishi, is a very suitable program for the so-called

Terminal Mode of the PS Laser Scanner. TeraTerm is a free software terminal

emulator (serial communication program) for Windows. The program is available

on Triple-IN’s webserver. Any other terminal program will be suitable as well.

1. Download TeraTerm from Triple-IN’s webserver.

2. Run the TeraTerm program installer.

3. Connect the EDM via a RS232 connection, using either a generic COM port or

an USB-to-serial adapter.

4. Open TeraTerm and navigate to "Setup > Serial port..."

5. Choose the correct COM port.

6. Set the baud rate to 115200, 8 data bits, no parity, 1 stop bit, no flow control.

7. Close the setup dialog.

8. If you want to store these settings for future use, go to "Setup > Save setup…"

9. Navigate to the TeraTerm installation directory and store the setup in

TERATERM.INI.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

21

Triple-IN

GmbH

6.1.2 Windows® Program “TCP/IP Manager” to manage

Network Configurations

Triple-IN recommends the open-source Freeware “TCP/IP Manager” (author: A. C.

Tundrea) to prepare the computer’s network settings for PS Laser Sensors. With

the tool, you may simply save and restore network settings for PS Laser Scanners

low res. Internet brochure

low res. Internet brochure

and standard Windows applications in different profiles.

1. Download TCP/IP Manager from Triple-IN’s webserver.

2. Run the installer resp. unpack the ZIP file.

3. Start TCP/IP Manager.

4. Select in “TCP/IP Settings > Network connection name” the network

adapter connected with the PS Laser Sensor.

5. Check if “IP address” matches the Gateway IP address as stored in the PS

Laser Sensor. The default Gateway address is 10.0.10.0.

6. Check if “Subnet mask” matches the subnet mask as stored in the PS Laser

Sensor. The default network mask is 255.255.0.0.

7. For later use, consider “Network profile > Create a new profile” to save the

setup.

8. Choose “Apply Settings”.

9. To connect a PS Laser Sensor with the default settings:

Picture 17 Network configuration for PS Laser Sensors with TCP/IP Manager

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

22

Triple-IN

GmbH

After disconnecting the sensor, you may use TCP/IP Manager to restore the

Windows standards:

low res. Internet brochure

low res. Internet brochure

Picture 18 Restore the Network configuration with TCP/IP Manager

1. Start TCP/IP Manager.

2. Select in “TCP/IP Settings > Network connection name” the network

adapter connected with the PS Laser Sensor.

3. “Obtain an IP address automatically” should be checked.

4. For later use, consider “Network profile > Create a new profile” to save the

setup.

5. Choose “Apply Settings”.

6.1.3 Triple-IN’s PSControlProgram

Triple-IN’s PSControlProgram is a PC application for controlling the functionality of

Triple-In Laser sensors via Ethernet connection. It makes the user able to set the

user parameters of the sensor, start measurements, record the scans to files or

show it on the chart or in the table.

The program is available on Triple-IN’s webserver.

To install the application please follow the instructions:

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

23

Triple-IN

GmbH

1. Start Windows installation program “Install_PSControlProgram.exe”.

2. Confirm that you have administrator permissions to install the program.

3. The installer inspects the version information in order to use it during the

installation process.

4. The product information (company, product name and version) is displayed

on the screen if it's found during the analysis process.

low res. Internet brochure

low res. Internet brochure

5. Confirm installation.

A full description of the program can be found in the “of PSControlProgram User’s

manual”. The manual is part of the program distribution.

6.2 Power-up

To start the system:

• Connect the control computer to the same network of the PS Laser Scanner.

• Connect the power supply to the PS Laser Scanner

• After switching on the supply voltage the scanner runs through a self-test. All

LEDs are flashing. The firmware of the device checks important hardware

components and parameters. Commands will respond to the control computer

with a "device not ready" error.

• The red LED is switched off after the self-test has passed successfully.

ATTENTION

After disconnecting the sensor from power supply, you have to wait 30 seconds

before turning it on. Otherwise capacitors not being discharged could leave the

sensor peripheral not fully reset

6.3 Serial RS232 communication

6.3.1 Setting up the serial Communication

PS Laser Scanners have serial RS232 interfaces to connect a control computer with

the measurement board. A second RS232 can be connected to the Ethernet board

to allow firmware updates. The standard communication settings are:

• RS232 Serial input/output

• Baud rate 115.200 Baud,

• Data 8 data bit,

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

24

Triple-IN

GmbH

• no parity, 1 stop bit,

• no flow control, no handshake

The first serial interface, internally connected with the Measurement board

(MPU), is used to program the TCP/IP connection parameters and to update the

Measurement board firmware. This interface supports the so-called Terminal

Mode (see chapter "Terminal Mode"). After startup displays the terminal the

low res. Internet brochure

low res. Internet brochure

sensor's serial number, IP address and self-test results.

Picture 19: TeraTerm with Measurement Board startup message

The second serial interface is connected with the communication board and is

used for Ethernet firmware updates only (see chapter "Firmware updates"). It

displays the current Ethernet board firmware version and a connection status.

Picture 20: TeraTerm with Communication board startup message

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

25

Triple-IN

GmbH

6.3.2 Entering the Terminal Mode

The PS Laser Scanner provides a Terminal Mode as an additional user interface.

This is an ASCII oriented, human-readable menu structure and user interface

available on the RS232 serial interface.

The Terminal mode is entered after the user sends 4 successive carriage return

low res. Internet brochure

low res. Internet brochure

characters from a RS232 terminal console.

Note

The Ethernet interface is not available while the sensor operates in the Terminal

Mode.

________________________________________________________________________

Terminal Mode

________________________________________________________________________

1 - Show user parameter

2 - Show system health status

3 - Network configuration...

4 - Restore to factory settings

5 - Show reference tables...

E - Edit parameter

S - Take a scan

L - Switch laser marker

0 - Exit to Run Mode

>

Show user parameter

Lists the parameters set by the user. With the function "Edit parameter" these

values can be edited.

Show system health status

List the results of the self-test.

Network configuration

Change the IP settings to standard configurations.

Restore to factory settings

This function is used to set parameters to their default values.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

26

Triple-IN

GmbH

IMPORTANT

All changed user parameters will get lost.

Show reference tables

Display the firmware versions and parameter code reference tables.

low res. Internet brochure

low res. Internet brochure

Edit parameters

This function is used to change any parameter. The parameter codes are needed

for this. After entering the parameter code the firmware shows the current value,

the measurement unit and the valid range of values. The program then asks

whether the changed parameters should be stored in the flash.

> E

> Enter parameter ID:

3_

> Enter parameter "Scan mode: 0=off, 1=normal, 2=fast, 3=fine":

2_

Take a scan

Starts the motor and carries out a single scan. The result is presented as CVS table.

This function shall be used to check the basic functionality of the sensor.

Switch laser marker

Switch the red laser marker on and off.

6.3.3 Binary Command/Control Interface

Control computer programs, such as PSControlProgram, communicate with PS

Laser Scanners over Ethernet or serial RS232 by use of binary commands. A full

reference of the binary command/control interface can be found in the “PS Laser

Scanner Programmer’s Manual”.

IMPORTANT

Avoid communicating with the PS Laser Sensor via Ethernet and RS232 at the

same time. The commands can influence each other and may lead to

unpredictable system states.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

27

Triple-IN

GmbH

6.4 Ethernet Connection

6.4.1 PS Laser Scanner Network Settings

PS Laser scanners use the Internet Socket Interface for communications over

Ethernet.

low res. Internet brochure

low res. Internet brochure

The sensor socket address is the combination of an IP address (the location of the

sensor) and a port (which is mapped to the application program process) into a

single identity.

The transport protocol UDP assumes that error checking and correction is

performed in the application by checking the CRC that comes with the sensor

command structure. This avoids the overhead of such processing at the network

interface level. As a time-sensitive application use the firmware UDP because

dropping packets is preferable to waiting for delayed packets.

• Type: 100 MBit/s Local area network

• Network layer Ethernet IPv4

• Transport Protocol UDP

• Application Protocol Binary Command Interface

• Sensor IP address 10.0.xx.xx

where x is formed by the sensor serial number

• Server socket port 1024 (factory pre-setting)

• Gateway IP address 10.0.10.0 (factory pre-setting)

• Gateway socket port 1025 (factory pre-setting)

IMPORTANT

The sensor replies to any computer in the same IP address space.

The Gateway IP address is used as default.

The MAC address of the scanner is locally administered by setting the secondleast-significant bit of the most significant byte (the so-called U/L bit, short for

Universal/Local). That address bit is 1, the address is locally administered and

the sensor might be used in local networks only.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

28

Triple-IN

GmbH

6.4.2 Changing the Sensor’s Network Settings using the RS232

Terminal Mode

The sensor IP address and the Gateway IP address can be set in the RS232

Terminal Mode with the parameters “Sensor IP address”, “Gateway IP address”,

and “IP Subnet Mask”.

low res. Internet brochure

low res. Internet brochure

The Terminal Mode includes a function “3 - Network configuration ...” for a simple

IP setup. The following configurations are available and can be changed

individually:

______________________________________________________________________________

Network configuration menu

Sensor IP address is 10.0.8.01

Gateway IP address is 10.0.10.0

______________________________________________________________________________

1 - Set default sensor IP address

2 - Set static sensor IP address

3 - Set private sensor address (APIPA)

4 - Edit sensor IP address

5 - Edit Gateway IP address

6 - Edit network mask

0 - Exit

• Default sensor IP address which is created in address space 10.0.x.x

according to the sensor serial number.

• A static sensor IP address which is 192.168.0.10 by default.

• Private sensor IP address (APIPA) which is 169.254.0.10 by default.

APIPA addresses are by standalone Windows computers.

These IP settings can be changed individually after the default has been set:

> Enter Parameter “Sensor IP Address AAA.xxx.xxx.xxx”:

192

> Enter parameter “Gateway IP Address xxx.BBB.xxx.xxx”:

168

[…]

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

29

Triple-IN

GmbH

IMPORTANT

• The sensor need to be restarted after IP addresses has been changed.

• The Ethernet interface is disabled while the Terminal mode is active.

low res. Internet brochure

low res. Internet brochure

6.4.3 Changing the Sensor’s Network Settings using

PSControlProgram

PSControlProgram is useful to change the sensors’s default network settings over

Ethernet:

1. Start PSControlProgram.

2. Choose button “Connect” to connect the application with a sensor. The IP

and port dialog appears on the beginning of the connection progress.

3. Enter the sensor’s standard IP address and the computer’s IP address. Note

that both addresses must be part of the same network.

Picture 21 PSControlProgram network connection dialog

4. Once the connection has been made, all parameters including the network

settings can be changed on the “Parameters” view.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

30

Triple-IN

GmbH

low res. Internet brochure

low res. Internet brochure

Picture 22 PSControlProgram Parameter view

5. Switch-off and restart the sensor to apply the changed network settings.

6.5 PS Laser Scanner Configuration

6.5.1 Ways of Configuration

You can configure the PS Laser Scanner in two ways:

• Using the commands “GPRM get parameter” and “SPRM set parameter” of

the binary command/control interface. This way is most suitable for

computer programs, such as PSControlProgram

• interactively using the RS232 Terminal Mode

6.5.2 About User Parameters

The entire sensor configuration is stored in a table of user parameters. Every

parameter has a number as unique parameter identification code. The user can

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

31

Triple-IN

GmbH

edit the parameter either by use of the Terminal Mode, or over RS232 and

Ethernet by use of binary commands.

ATTENTION

Parameter identifiers always refer to a certain firmware version. Therefore an

low res. Internet brochure

low res. Internet brochure

individual parameter reference table exists for every firmware version.

You find the description of the binary commands for the processing of the user

parameters in the “PS Laser Scanner Programmer’s Manual”.

There are different types of parameter:

• Usual parameters can be set by the user for sensor configuration. Those

parameters are stored in the non-volatile memory of the sensor.

•

Constant parameters

user.

•

Temporary parameters

a device status has been changed. Note that temporary parameters are

typically updated by a self-test during the startup phase. It is

recommended to set temporary parameters only after the self-test has

been finished.

(e.g. the serial number) cannot be changed by the

(e.g. the system temperature) will be overwritten if

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

32

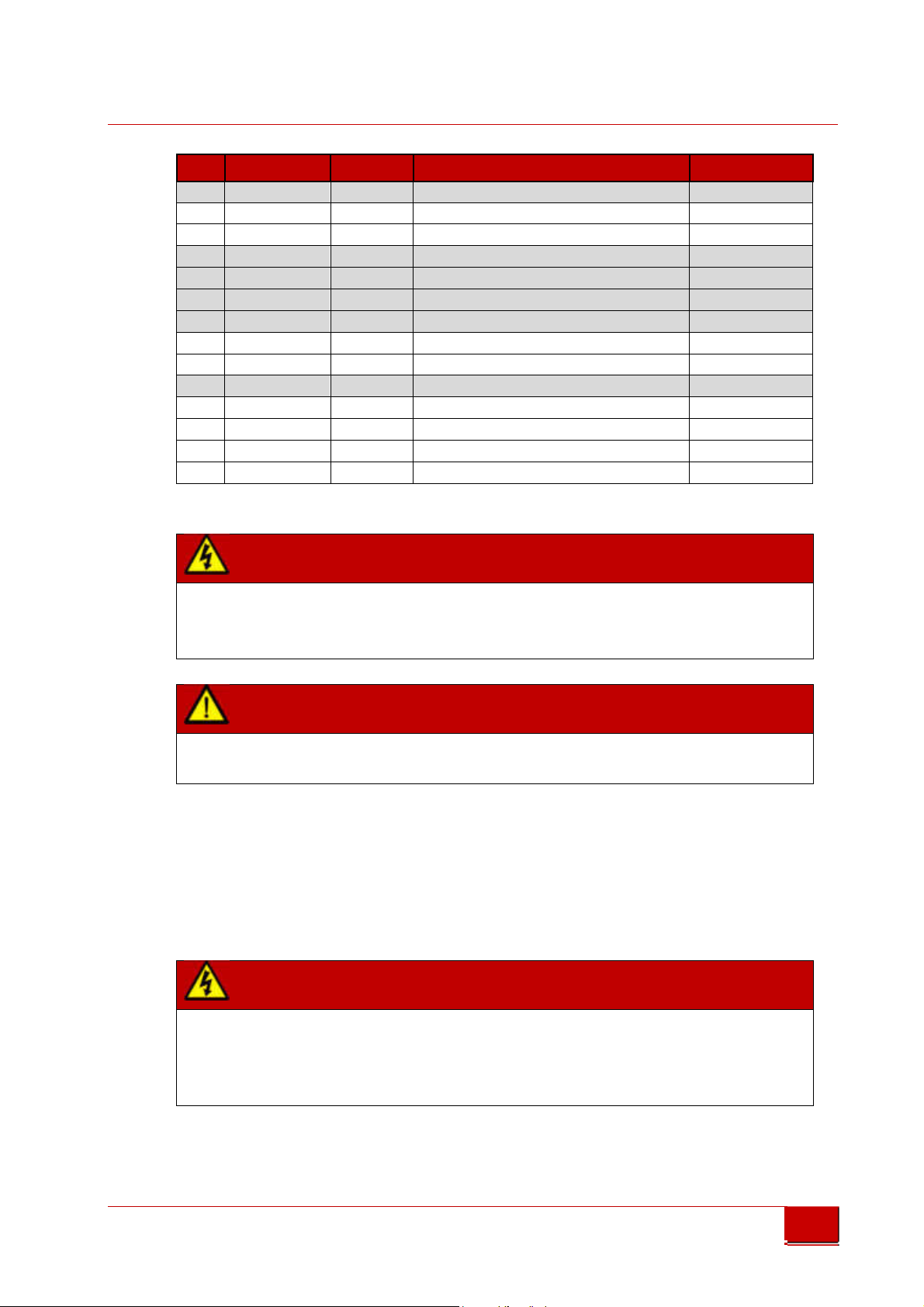

6.5.3 Table of User Parameters

ID Default

Name Description

A version number of the parameter set

The terminal mode can be protected by a password

This parameter defines

the operating scan mode:

If this parameter is 1, the scanner provides a continuous

If this parameter

was set to 1, the scanner enters the

If this parameter was set to 1, the startup messages like

If this parameter was set to 1, the red laser marker is

Temporary parameter

indicating the current status of the

A constant that defines the angle unit.

Defines the size of the scan angle and the scan area.

Defines the start direction of the scans.

Defines the angle between two measurements in a scan.

Each of four subsequent scans is shifted by

this angle. Only

Contains the local IP address of the sensor

Contains the local IP address of the sensor

Contains the local IP address of the sensor

Contains the local IP address of the sensor

IP Socket number of the sensor

Contains the Gateway IP

address of the control computer

Contains the Gateway IP address of the control computer

Contains the Gateway IP address of the control computer

Contains the Gateway IP address of the control computer

Contains the socket number at the control computer

Triple-IN

GmbH

1 20160112 Const: User

2 0 User parameter

low res. Internet brochure

low res. Internet brochure

3 0 Scan mode:

4 0 Auto-start without

5 0 Start mode,

6 1 Startup message on

7 1 Red Laser Marker at

8 1 Temp: Red Laser

9 360000 Const: Angle units

10 90000 Scan angle size

11 45000 Profile scan start

12 90 Const: Scan a ngle

13 0 Const: Sc an angle

14 10 Sensor IP Add ress

15 0 Sensor IP Address

16 1 Sensor IP Address

17 23 Sensor IP Add ress

18 1024 Sensor socket port

19 10 Gateway IP Ad dress

20 0 Gateway I P Address

21 10 Gateway IP Ad dress

22 0 Gateway I P Address

23 1025 Gateway socket port

settings

password,

0=disabled

off=0,

normal=1,

fast=2,

fine=3

SCAN/GSCN command,

enabled=1,

disabled=0

0=Standard,

1=Terminal Mode

serial interface,

enabled=1

startup:

off=0,

on=1,

auto=2

Marker status:

off=0, on=1

on a full circle

[0.001 deg]

direction

[0.001 deg]

step [0.001 deg]

shift [0.001 deg]

AAA.xxx.xxx.xxx

xxx.BBB.xxx.xxx

xxx.xxx.CCC.xxx

xxx.xxx.xxx.DDD

AAA.xxx.xxx.xxx

xxx.BBB.xxx.xxx

xxx.xxx.CCC.xxx

xxx.xxx.xxx.DDD

number.

Enter "0" to disable the password

fine/normal/fast.

output stream of profiles

Terminal mode after startup.

the firmware version are not displayed on the serial

interface.

switched after startup.

Set to 0 if you wish the red laser marker to be off after

startup.

red laser marker.

used by the “Fine Mode”.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

33

Triple-IN

ID Default

Name Description

Defines the IP sub

-

net mask of the local sensor network.

Defines the IP sub

-

net mask of the local sensor network.

Defines the IP sub

-

net mask of the local sensor network.

Defines the IP sub

-

net mask of th

e local sensor network.

The number of different echoes the sensor is able to

Defines the

master echo.

Defines how many scans shall be buffered. This parameter

Defines the data transmitted with the GSCN command.

Number of scans to be

stored in the internal buffer

This offset is added to all distances.

This parts

-

per-million correction is applied to all distances.

The heater is switched on if the internal temperature is

The heater is switched off i f the internal temperature is

Temporary parameter containing the curre

nt status of the

If set to “0”, the motor is stopped after the sensor has

Temporary

parameter containing the current status of the

The optional incremental encoder input is enabled if this

This param

eter contains the offset of the external

GmbH

24 255 IP Sub-net mask

25 255 IP Sub-net mask

26 0 IP Sub-ne t mask

27 0 IP Sub-ne t mask

28 1 Const: Nu mber of

low res. Internet brochure

low res. Internet brochure

29 1 Master ec ho:

30 4 Temp: Num ber of

31 8 Scan data content:

32 14 Scan buffer size;

33 0 User defi ned

34 0 Const: Us er defined

35 150 Air condition

36 200 Air condition

37 0 Temp: Air condition

38 1 Vertical motor at

39 1 Temp: Ver tical

40 0 External

42 0 External

AAA.xxx.xxx.xxx

xxx.BBB.xxx.xxx

xxx.xxx.CCC.xxx

xxx.xxx.xxx.DDD

multi-echos

1=first, 0=last

profiles to be

measured with SCAN

4=distances,

7=distance+Echo+PW

8=distances+PW

distance offset

[0.1 mm]

ppm correction

[mm/km]

heater ON threshold

[0.1 celsius]

heater OFF

threshold [0.1

celsius]

heater status,

off=0, on=1

startup, off=0,

on=1

motor status,

1=running

incremental

encoder: enabled=1,

disabled=0

incremental

encoder: offset

output. Constantly 1, because either the first echo or

alternately the last echo is provided.

If the parameter is set to “1” the closest target is

measured.

If the parameter is set to “0”, the fu rthest target is

measured.

is set by the SCAN command.

The parameter is equal with the number of bytes

transferred for each echo:

4: only distances are transmitted (4 bytes)

7: distance (4 bytes), echo number (1 byte), and pulse

widths are transmitted.

8: distances (4 bytes) and pulse widths (4 bytes) are

transmitted

Other values may lead to unexpected results.

below this threshold.

Note that the internal temperature is about 15° Celsius

above ambient temperature.

above this threshold.

The heater is always switched on if the temperature is

below the operating range.

heater.

passed the self-test.

The motor is restarted by the first SCAN command.

vertical motor.

parameter was set to 1.

incremental encoder.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

34

Triple-IN

ID Default

Name Description

This parameter contains the current reading from the

Bit map that reflects the system health. Invalid if bit 0 is

Reserved for future use.

If this parameter was set on 0, the front LEDs flash only at

Current reading of the temperature sensor in 0.1 Celsius

Constant parameter, containing the pulse width in

Constant parameter, containing the pulse width in

Sensor model number to identify the type of sensor

Sensor seria

l number

Gives information about the actual near field dimension.

Defines the near field suppression zone. Each zone extends

Programs the function of the digital switching output 1:

Current logical status of the discrete output switch 1

Number of signals to be output if digital output switch 1

"Holds" digital switching output 1 for the given

Requires a sensing event to last for at least the given

Defines the physical logic of digital switching output 1:

Programs the function of the digital switching output 2:

Current logical status of digital switching output 2

Number of signals to be output if digital switching output 2

"Holds" digital switching output 2 for the given

Requires a sensing event to last for at least the given

GmbH

42 0 Temp: Ext ernal

43 0 System he alth

44 0 (reserved )

45 1 Front sid e LEDs

low res. Internet brochure

low res. Internet brochure

46 368 Const: Temperature

47 12000 Const: Pulse width

48 4096 Const: Pulse width

49 2025 Const: Sensor

50 1234 Const: Sensor

51 21000 Const: Near field

52 0 Near fiel d

53 1 SW1 funct ion:

54 0 Temp: SW1 status:

55 0 Temp: SW1 preset

56 20 SW1 hold time [ms]

57 20 SW1 delay [ms ]

58 0 SW1 logic :

59 0 SW2 funct ion:

60 0 Temp: SW2 status:

61 0 Temp: SW2 preset

62 20 SW2 hold time [ms]

63 20 SW2 delay [ms ]

incremental

encoder: counts

status

enabled=1,

disabled=0

sensor reading [0.1

celsius]

at 100% signal [ps]

at 3% signal [ps]

model;

serial number

suppression range

[0.1 mm]

suppression zone:

0=min

0=off, 1=scan sync,

2=switch, 3=counter

0=open 1=closed

counter: setup

0=normal, 1=low

active

0=off, 1=scan sync,

2=switch, 3=counter

0=open 1=closed

counter: setup

external incremental encoder.

set.

the start and be turned off then.

picoseconds related to a signal of 100%.

picoseconds related to a signal of 3%.

the near field for about 0.8 m.

1=SW is closed while a scan is active

2=SW is closed if parameter "SW status" is set to 1

3=SW is used as a preset counter

was configured as preset counter.

milliseconds after the input signal is removed.

Allows the control device to igno re intermittent signal

losses.

milliseconds before digital switching output 1 is switched.

Allows the control device to igno re short sensing events.

0=SW is high active, 1=SW is low active.

1=SW is closed while a scan is active

2=SW is closed if parameter "SW status" is set to 1

3=SW is used as a preset counter

was configured as preset counter.

milliseconds after the input signal is removed.

Allows the control device to igno re intermittent signal

losses.

milliseconds before digital switching output 2 is switched.

Allows the control device to igno re short sensing events.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

35

Triple-IN

ID Default

Name Description

Defines the physical logic of digital switching output 2:

If the laser spot is only partly reflected by object edges,

If the laser spot is

reflected by several surfaces, incorrect

Parameter without function.

User parameters

are stored the volatile memory.

GmbH

64 0 SW2 logic :

65 0 Low echo filter:

66 1 High echo filter:

low res. Internet brochure

low res. Internet brochure

67 0 User para meter ID

68 0 Temp: Mem ory write

0=normal, 1=low

active

0=disabled,

1=enabled

0=disabled,

1=enabled

used for testing

protection,

1=locked

0=SW is high active, 1=SW is low active.

incorrect measuring arises. This filter removes

measurements with very low echo signals.

measurements arise. This filter removes measurements

with very strong echo signals.

Setting this parameter to “0” prevents the firmware to

write parameters to the flash.

6.6 Taking Scans

6.6.1 Setting up the Scan mode

PS Laser Scanners can operate in “normal scan mode”, “fast scan mode”, or “fine

scan mode”. Scan modes are set by binary commands or by use of the Terminal

mode. The scan mod can be set with the user parameter:

Scan mode: 0=off, 1=normal, 2=fast, 3=fine

With each of the scan modes, the following measurement parameters are set:

• Scan rate: Number of scans per second.

• Scan start direction: direction of the first measurement point of a scan.

• Scan angle: size of the scan area in degree.

• Scan angle step: small angle between two subsequent measurement points.

Defined by the scan angle size and the number of measurement points.

• Scan Angle Shift: small angle between the start directions of subsequent scans.

Normal scan mode

The „Normal Scan Mode” is defined by the following parameters:

• Scan rate: 20 scans per second.

• Scan start direction: min. 45°

• Scan angle: max. 90° with 1000 points.

• Scan angle step: 90°/1000 points = 0.090°

• Scan Angle Shift: Normal-Mode scans are not shifted.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

36

Triple-IN

GmbH

Fast scan mode

For increasing the scan rate the point density has to be reduced. In „Fast Scan

Mode” the point density is halved, the scan rate is doubled and the “profile rate”

reduced accordingly.

• Scan rate: 40 scans per second.

• Scan start direction: min. 45°

low res. Internet brochure

low res. Internet brochure

• Scan angle: max. 90° with 500 points.

• Scan angle step: 90°/500 points = 0.180°

• Scan Angle Shift: Fast-Mode scans are not shifted.

Fine scan mode

If the scan rate is not important but the lateral resolution is the important

parameter, the shift of the scans may be reduced. This leads to more

“scans/profile” and consequently to a better lateral resolution with overlapping

spots and a reduced profile rate. This measurement mode is called “Fine Scan

Mode”.

• Scan rate: 20 scans per second

• Profile rate: 5 profiles per second

• Scan start direction: min. 45°

• Scan angle: max. 90° with 1000 points.

• Profile angle: max. 90° with 3000 points interlaced.

• Scan angle step: 90°/1000 points = 0.090°

• Profile angle step: 90°/3000 points interlaced = 0.0225°

Scan Angle Shift: Each scan is shifted by 0.0225°. Subsequent scans are interlaced

to a single profile.

Reserved scan mode

Option for customized scanners. Do not use this scan mode with standard PSxxx90 Laser scanners.

6.6.2 Taking Scans with the Terminal Mode

The Terminal Mode function “Take a scan” creates a table with the latest profile

scan. The ASCII format is "comma separated" and can easily use Excel or Open

Office.

1. Enter the Terminal Mode

2. Open in TeraTerm "File > Log...". Check "Plain text" and disable "Append"

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

37

Triple-IN

GmbH

3. Choose a log file name and close the dialog. Teraterm will now record all

sensor outputs.

4. Choose "S – Take a Scan"

5. Close TeraTerm

6. The log file can be opened directly with a common spread sheet program

low res. Internet brochure

low res. Internet brochure

like Excel or OpenOffice Calc.

Scan;

______________________________________________________________________________

375.877; Time Stamp [s] ;

0; Incremental encoder position [counts];

45.000; Profile start direction [deg];

90.000; Scan angle [deg];

0.090; Angle step [deg];

1000; Points in profile ;

0; Master echo (0=last echo);

1; Number of echoes;

31.7; Temperature [Celsius];

______________________________________________________________________________

Point ; Echo ; Direction ; Distance ; Pulse width ;

; ; [deg] ; [m] ; [ps] ;

______________________________________________________________________________

1 ; 1 ; 45.000 ; 2.4388 ; 9907 ;

2 ; 1 ; 45.090 ; 2.4305 ; 9895 ;

3 ; 1 ; 45.180 ; 2.4340 ; 9871 ;

4 ; 1 ; 45.270 ; 2.4437 ; 9772 ;

[…]

1000 ; 1 ; 314.910 ; 1.6629 ; 6465 ;

The header of the table contains

• Time stamp [s]: is the time in seconds since the sensor was started

• Incremental encoder position [count]: is the count of the external

incremental encoder.

• Profile start direction: is the start direction of the profile, where 0 is

upwards to the zenith.

• Scan angle: is the scanned area in degrees.

• Angle steps: give the scan resolution in degrees.

• Points in profile: give the length of the following table.

• Master echo: 1 for the first echo or 0 for the last echo.

• Number of echoes: the number of echoes processed.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

38

Triple-IN

• Temperature: is the reading from the internal temperature sensor in

Celsius.

The measurement table contains

• Point: the number of the current point in the scan

GmbH

low res. Internet brochure

low res. Internet brochure

• Echo: the number of the evaluated echo. This value is always 1 if the

Master Echo parameter has been set to “1=first echo”. The echo number

varies from 1 to 4 if the Master Echo has been set to “0=last echo”.

• Direction: direction to the target in degree.

• Distance: distance in meters to the target surface.

• Pulse width : echo signal pulse width in pico-seconds

6.6.3 Taking Scans with Triple-IN’s PSControlProgram

Triple-IN’s PSControlProgram is a Windows application with user menu, toolbar,

status line, workspace explorer bar and the data output widgets ordered in the

tabs. User menu and main toolbar are providing the basic functionality for the

system actions like connecting the program with a sensor, performing the scans,

recording, loading or, exporting the data to “*.csv” files.

1. Connect to the PS Laser Sensor

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

39

Triple-IN

GmbH

2.

Once online the record button allows the user to write the scans to the

binary files for later evaluation.

3. If the recording starts successfully the application starts to write the binary

data to files. Every minute the new file for recorded files is created.

4. To find the easily files easily press “Open output directory” button on the

toolbar and windows

low res. Internet brochure

low res. Internet brochure

6.7 Filters and Master Echo selection

6.7.1 Near-field suppression

The near-field suppression is used to suppress measurements to targets close to

the sensor. This prevents the sensor to detect contamination of the optics.

PS Laser Scanners have optional, adjustable near-field suppression. This is divided

up in zones, each with a width of 760 millimeter. Zone 0 defines the closest

distance. The closest distance depends on the PS Senor type.

The near field suppression zone can be configured with the user parameter:

Near-field suppression zone, min=0

The current near field range can be obtained by the parameter

Const: Near field suppression range [0.1 mm]

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

40

Triple-IN

GmbH

low res. Internet brochure

low res. Internet brochure

Picture 23 Near-field configuration, example with zone 3

Example:

1) Echoes of targets in Zone 0 are always ignored and not detected by the

laser receiver.

2) In this example was zone 3 has set as near field zone. The target in this

range is ignored. The near-field range is calculated as

Near_field_range = zone0 + zone1 + zone2 + zone3

Any echo in this range will be ignored.

3) Echoes of targets beyond the near-field range give valid echoes.

6.7.2 Low echo filter

If the laser spot is only partly reflected by object edges, incorrect measurements

may arise. A “low echo filter” removes measurements with echo signals less than

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

41

Triple-IN

GmbH

3%. To use the full range of sensitivity, the low echo filter can be disabled. The

user parameter must be set to 0:

Low echo filter; 0=disabled, 1=enabled

low res. Internet brochure

low res. Internet brochure

6.7.3 High echo filter

If the laser spot is reflected by several surfaces, incorrect measurements may arise

due to deformations of the echo signal. The “high echo filter” removes

measurements which appear with very wide echo signal amplitudes.

The high echo filter can be disabled to allow measurements on reflectors and

reflecting foil. The user parameter must be set to 0:

High echo filter: 0=disabled, 1=enabled

6.7.4 Master Echo selection

At measuring through rain, through protection windows, or in dusty surroundings

several objects may reflect the laser beam. The echo of the actual measuring

target is called “Master Echo”.

Picture 24 Multi-Echo with Master Echo selection

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

42

Triple-IN

GmbH

PS Laser scanners can handle the first or the last one of up to 4 echoes as "Master

Echo". For configuration the user parameter “Master echo” is used:

Master echo: 1=first, 0=last

• Scans contain the first echo (closest object) if the parameter has been set to

low res. Internet brochure

low res. Internet brochure

“1”.

• If the parameter is set to “0”, the furthest measuring is evaluated.

6.7.5 Alternating Master Echo

Some applications require measurements to the first and the last echo. The

master echo configuration can be set to alternate with each scan. With every new

Scan the master echo changes between "first echo" and "last echo" to support this

requirement.

For alternating master echo configuration the following user parameters are used:

Number of registered echoes: 2

Master echo: 0=last

• The “Number of registered echoes” defines the echoes to be captured.

Always the same echo (first or last) is taken if the parameter was set to 1. If

set to 2 allows to capture alternating echoes.

• The parameter “Master echo” must always be set to “0=last echo” for

alternating master echoes.

6.8 Setting up the Digital Switching Outputs

PSxxx-90 Laser Scanners have two digital outputs. These outputs can be

programmed for different purposes:

• To give a scan synchronization signal

• As switch output, controlled by the connected computer

• As a preset counter, providing a programmable number of output signals.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

43

Triple-IN

GmbH

6.8.1 Using a digital output for scan synchronization signals

One digital output can be configured to provide a scan synchronization signal. The

signal is set high while the measuring laser is active during a scan. The signal is

cleared during the idle period between two scans.

Only one of the digital outputs can be used for the synchronization signal.

low res. Internet brochure

low res. Internet brochure

Changing the synchronization output port will leave the previous synchronization

output port inactive.

The feature is set active by setting the parameter “SW function” to “1=scan sync”:

SWn function: 1=scan

6.8.2 Setting the status of a digital switching output

The state of the digital switching outputs can be set by software. This allows a

control computer to signal application depending status information to another

system.

The feature is set active by setting the parameter “SW function” to “2=switch”.

The open/closed status of the output is set by the user parameter:

SWn function: 2=switch

SWn status: 0=open, 1=closed

6.8.3 Using a digital switching output as preset counter

User applications can set a counter value in advance to produce output signals of

a specific count. This function permits a control computer to transmit a counting

stand or volume information as digital signals to another system. All digital

switching outputs can be used independently. The preset counter feature is set

active by setting user parameter “SW function” to “3=counter”.

The counter value must be written to the parameter

SWn function: 3=counter

SWn preset counter: setup

The sensor firmware copies this value, sets the parameter register back to 0, and

starts the countdown. After this, new counts can be added to current output by

writing another counter value. Make sure that the parameter “SW preset counter

setup” has reached 0 before adding new counts.

The hold time can be defined by the user parameter

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

44

Triple-IN

GmbH

SWn hold time [ms]

The delay between counter signals can be defined by the user parameter

SWn delay [ms]

low res. Internet brochure

low res. Internet brochure

The resolution of both timing parameters is about 10 ms.

Example

The parameter setup

53; 3; SW1 function: 0=off, 1=scan sync, 2=switch, 3=counter;

56; 10; SW1 hold time [ms];

57; 20; SW1 delay [ms];

58; 0; SW1 logic: 0=normal, 1=low active;

59; 3; SW2 function: 0=off, 1=scan sync, 2=switch, 3=counter;

62; 30; SW2 hold time [ms];

63; 40; SW2 delay [ms];

64; 1; SW2 logic: 0=normal, 1=low active;

In conjunction with the counter parameters

55; 4; Temp: SW1 preset counter: setup;

61; 2; Temp: SW2 preset counter: setup;

Results in the following signal pattern:

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

45

Triple-IN

GmbH

Picture 25 Digital switching output example signal pattern

6.9 Controlling the Heater (optional)

PS Laser Scanners for outdoor applications can optionally be equipped with an

th

internal heater. Temperature parameters are handled in 10

low res. Internet brochure

low res. Internet brochure

“312” are 3.12°C.

The switching points of the heater can be configured by the user parameters

Air condition heater ON threshold [0.1 celsius]

Air condition heater OFF threshold [0.1 celsius]

The heater is switched on if the internal temperature is below the ON threshold

and is switched off if the internal temperature is above the OFF threshold.

Note that the internal temperature during operation is about 15° Celsius above

ambient temperature. Allow a hysteresis difference between the on and the off

temperature of >5° Celsius.

The current heater status and the actual system temperature can be read from

the user parameters

Celsius. Example:

Temp: Air condition heater status, off=0, on=1

Const: Temperature sensor reading [0.1 celsius]

6.10 Reading the external Incremental Encoder

(optional)

The PS Range Module provides one 3.3 to 5.0 Volt incremental encoder input.

Purpose of the external incremental encoder is to report changes in the horizontal

position of the sensor.

The incremental encoder must provide two pulses A and B. The PS Sensor

firmware counts these pulses in both directions by use of a 32 bit register.

Input is limited to 128.000 counts/second.

The external incremental encoder must be enabled by setting the parameter

External incremental encoder: 0=disabled, 1=enabled=1;

An offset can be added to every encoder value:

External incremental encoder: offset;

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

46

Triple-IN

GmbH

The current reading plus offset can be read from parameter:

Temp: External incremental encoder: counts;

Reset of the counter is done at startup or with software by disabling and reenabling the external incremental encoder.

low res. Internet brochure

low res. Internet brochure

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

47

Triple-IN

GmbH

7 Maintenance

7.1 Cleaning

PS Laser Scanners are mainly free of maintenance. The front window must be

low res. Internet brochure

low res. Internet brochure

checked regularly and must be cleaned from dust and dirt.

• Use a clean and moistened cloth to clean the body.

• Use a microfiber cloth to clean the front window. Don’t put pressure on the

cloth while cleaning the front window.

WARNING

Don't use abrasives, household cleaners, or other aggressive liquids.

7.2 Updating the Firmware

The PS Laser Scanner contains two different computer boards:

• The MPU board is responsible for the measurement process

• The Communication Board (“Olimex”) is used for the Ethernet communication.

Both boards can be updated over the serial RS232 interfaces by use of the

XMODEM protocol. The sensor supports XMODEM-CRC and XMODEM-1K variants

to improve performance and transfer safety.

ATTENTION

Carefully read the entire instructions before you start updating your sensor.

Do not power off the sensor until the firmware is updated!

Do not try to downgrade to previous versions! Contact Triple-IN if there is a

reason to do so.

7.2.1 Updating the Measurement Board (MPU)

1. Download the new firmware image from the internet.

2. Make sure that the "MPU RS232" lines of the serial interface connector are

connected with the serial interface of your computer.

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

48

3. Start Teraterm.

Triple-IN

GmbH

4. Switch the sensor

- Running self-test ...

- Selftest OK!

low res. Internet brochure

low res. Internet brochure

Type 4 x ENTER to switch to Terminal Mode

Check the serial connection if that message does not appear.

5. Switch the sensor off.

6. Choose Teratrem File > Transfer > XModem > Send...

Locate and single click on the required firmware binary file.

7.

Select

8.

from the options at the foot of the dialogue and click "Open

1K

. Make sure the following message appears:

on

":

Picture 26 Teraterm Firmware file selection

9. When the XMODEM Send dialogue is displayed in TeraTerm, power the sensor

on

10. Data will start transferring to the sensor. TeraTerm Pro will display progress:

Picture 27 Teraterm XMODEM upload

© Triple-In GmbH • 11/01/2017 14:31:00

PSxxx-90 Laser Scanner User's Manual

49

Triple-IN

GmbH

11.

Once the firmware has been transferred, the sensor will update the firmware

in the flash memory. This process needs about 30 seconds.

- new firmware; size: 328704

- unlock and erase 20 blocks from 1 to 20

- Programming from RAM 0x04001000 to ROM 0x00008000 = 164352 words

low res. Internet brochure

low res. Internet brochure

12. The sensor will now reboot the new firmware.

PS Laser Scanner

[PS Firmware; 03.xx.xx; 2016-01-20; (c) Triple-IN GmbH 2016]

SN: 1234

Local IP: 10.0.12.34:1024

Gateway IP: 10.0.10.0:1025