Page 1

Engineered Solutions For Clean Air

Trion’s AIR BOSS media units are industrial air

cleaners designed for both general ventilation

(removal of airborne pollutants from plant

atmospheres) or source capture (ductwork or arms

positioned at the origin of pollutants). These units help

solve welding smoke, oil mist, rubber dust, diesel

smoke, grinding dust, numerous gases/odors and

many other indoor air pollution problems.

M6000

Features/Benefits

• Straight through or side discharge —

ability to better control airflow

(M3000 & M6000)

• Odor and High Efficiency Filters —

from HEPA and adsorber modules to

mini-pleat filters (194/388 sq. ft.) for

maximum efficiency and effectiveness

(M3000 & M6000)

• Belt driven blower with variable pitch

sheave — providing adjustment for precise

CFM operating range (M3000 & M6000)

• Collects wet or dry particulates —

providing versatility in a wide range of

applications (M3000 & M6000)

• High static blower packages — capacity

for additional external static offers more

contaminant pickup points

(optional for M3000)

Principle of Operation

Dirty Air Clean AirPre-Filter Main Filter

Media Air Cleaning

How It Works

Trion’s Air Boss Media Series uses the Interception

Filtration Principle. Dirty, polluted air is drawn

through the pre-filter to remove larger dust

particles. The second stage, micro-glass deep

pocket media filter removes submicron particles

from the air stream by interception. The small

diameter fibers in the filter intercept and retain

these small particles while the large surface area

of the filter gives long life and low pressure drop.

The blower is designed specifically to handle

the filtration system at rated CFM over the useful

life of the filter.

Page 2

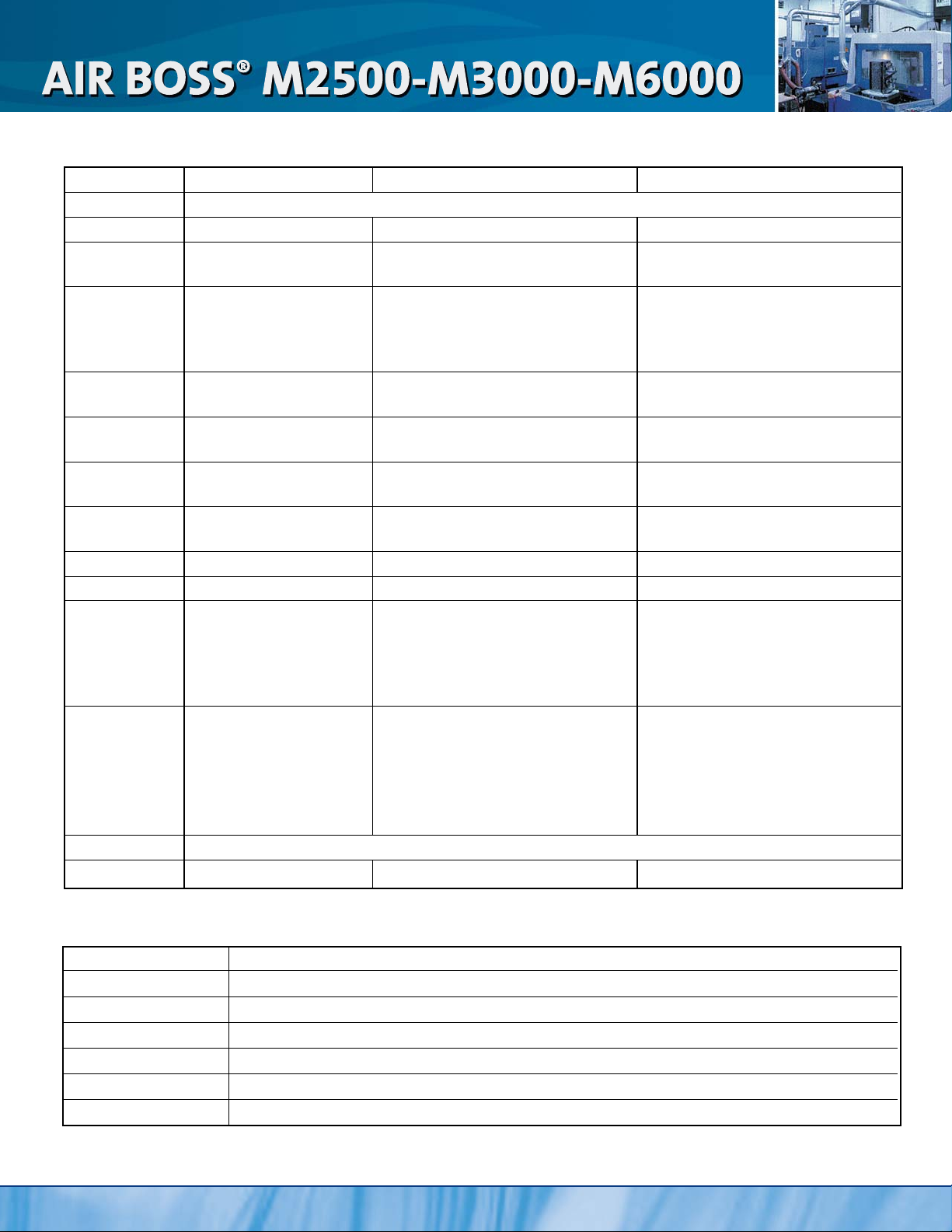

Specifications M2500 M3000 M6000

Dimensions 47" L x 25" W x 25" H 68" L x 25" W x 26.25" H 73.5" L x 49" W x 30" H

Installation Suspended, Wall or Frame Mounted

Weight 180 lbs./Shipping 250 lbs. 260 Lbs./Shipping 330 lbs. 610 Lbs./700 lbs.

Electrical: .75HP: 120VAC/60/1ph 2 HP: 208-240/480/60/3ph 7.5 HP: 208-240/480/60/3ph

Standard 10.5 Amps 5.8/2.9 Amps 19.8/9.9 Amps

Optional N/A 2 HP: 575/60/3ph 5HP: 208-230/460/60/3ph

3 HP: 208-240/480/60/3ph-9.1/4.6 Amps

3 HP: 575/60/3ph 5 HP: 575/60/3ph

Motors: Thermally protected TEFC, Ball Bearings TEFC, Ball bearings

Standard

Blowers: Direct drive, forward curved Belt drive, forward curved Belt drive, forward curved

Standard

Optional N/A Belt drive, backward inclined, N/A

Air Volume 1240-2010 1300-3300 (factory set 3000) 3500-7100 (factory set 6000)

(CFM) Throw distance: 70 ft. Throw distance: 80 ft.

Controls 3-speed selector switch Motor starter (optional) Motor starter (optional)

Sound Rating 50-70 dB @ 5 ft. 74 dB @ 5 ft. 80 dB @ 5 ft.

Filters:

Pre 4 inch 35% pleated (standard) 4 inch 35% pleated (standard) 2 ea. 4 inch 35% pleated (standard)

Polyester pad (optional) 2 inch aluminum mesh (optional) 2 ea. 2 inch aluminum mesh (optional)

3-way wrap around (optional) 2 inch impinger (optional) 2 ea. 2 inch impinger (optional)

Primary 95% Bag filter (standard) 95% bag filter (standard) 2 ea. 95% bag filter (standard)

65% Bag filter (optional) 65-95% extended surface (optional) 2 ea. 65-95% extended surface (optional)

Secondary N/A 95% short bag (optional)* 2 ea. 95% short bag (optional)*

Gauge Kit (Optional)

Silencer (Optional)

NA Reduces sound to 72.5 dB. Reduces sound to 78 dB.

1740 RPM (standard); 3450 RPM (optional)

airfoil, 3HP high static

3 way wrap around (optional)

99.97% HEPA (optional)* 2 ea.99.97% HEPA (optional)*

2 ea. Adsorber Modules (optional)* 4 ea. Adsorber Modules (optional)*

(25 lbs. carbon each) (25 lbs. carbon each)

Manometer or Magnehelic to indicate when filters need changing

13.4/6.7 Amps

7.5 HP: 575/60/3ph

1740 RPM

(standard)

; 3450 RPM

(optional)

*secondary filter typically used with HEPA and Adsorber Modules

Standard Specifications for Each Unit

Cabinet 16 and 18 gauge galvanized steel

Finish Pearl white epoxy, baked on, oil resistant

Air Flow Horizontal — right to left or left to right, optional side discharge (M3000 & M6000)

Filter Access Hinged doors — M3000 & M6000. End loading — M2500.

Drain Prefilter & main filter drain (M2500 - no drain)

Plenum Source capture with inlet collar (14" or 20" dia.), with no hole, dual arm (M3000 & M6000 only)

Agency Approvals UL Listed Components

Page 3

Dimensions M2500

CFM Delivery for Various Filter Combinations

Primary Filter

Pre-filter Speed 65% 95%

2" Polyester High 2010 CFM 1800 CFM

Wraparound Med 1710 CFM 1630 CFM

(10 sq. ft.) Low 1240 CFM 1265 CFM

4" Pleated High 1875 CFM 1690 CFM

(28 sq. ft.) Med 1760 CFM 1600 CFM

Low 1250 CFM 1265 CFM

2" polyester High 1950 CFM 1720 CFM

(4 sq. ft.) Med 1650 CFM 1620 CFM

Low 1250 CFM 1265 CFM

(66 sq. ft.) (66 sq. ft.)

Dimensions M3000

Page 4

Dimensions M6000

Air Delivery

M3000 M6000

4" pleated /32" bag

Air Delivery in Cubic Feet Per Minute

Air Delivery in Cubic Feet Per Minute

Trion Inc.

101 McNeill Road

Sanford, NC 27330, USA

Phone: 800-884-0002

Fax: 800-458-2379

www.trioninc.com

email: sales@trioninc.com

Trion, Ltd.

The Cavendish Centre

Winnall Close

Winchester, Hampshire,

SO23 0LB, UK

Phone: +44 (0) 1962 840465

Fax: +44 (0) 1962 828619

www.trion.co.uk

email: info@trion.co.uk

Trion Deutschland GmbH

Boschstr. 60

D - 50171 Kerpen

Phone: +49 (0) 2237 922-103

Fax: +49 (0) 2237 922-104

email: info@trion-deutschland.de

Fedders International Air Conditioning

A-30, Chintels House,

Kailash Colony

New Delhi

India 110048

Phone: 91 11 5173 0730

Fax: 91 11 5173 0743

Fedders International, Inc.

128 Joo Seng Road

#05-01

DP Computers Building

Singapore 368 356

Phone: (65) 6286 0995

Fax: (65) 6286 0859

Fedders International

No. 728 Fuzhou Road

Rm. 3002-3005

Raffles City Office Tower

Shanghai, P.R. China 200001

Phone: (86-21) 6340 3232

Fax: (86-21) 6340 3867/ 6340 3868

Form No. 02-001-2M

©2004 Trion Inc. 3/04

Loading...

Loading...