Page 1

Air Boss MP 600M

Vertical Air Flow Mist Precipitator

Installation

Operation

Service

Please read these instructions carefully for

trouble free operation and to get the most out of

your purchase. For further information

concerning this project, contact your local Trion

representative.

Phone: 800-884-0002 • Fax: 800-458-2379 • Email: sales@trioninc.com

101 McNeill Road • Sanford, NC 27330

www.trioninc.com

Manual Part No. 153632-001 • June 2002

Page 2

DESCRIPTION

The Trion MP 600M air cleaner is designed to capture

machine tool fluids, metal dust and smoke for clean air

filtration. It can be mounted to a wall, frame, platform, or

directly on the machine tool. Mist, dust, and smoke are

drawn from each machine through an external duct into

the air cleaner. A self-draining Impinger removes the

heavy mist and droplets (including water soluble fluids),

and the remaining contaminates are captured by the prefilter and the primary filter. Clean air is returned to the

plant through the vertical discharge. The air cleaner

operates at 95-99.97% efficiency at the rated 600 CFM

airflow.

NEW UNIT INSPECTION

At the time the unit is received, all shipping containers

and their contents should be examined for damage. Any

damage occurring in shipment must be immediately

reported to the carrier, an inspection report completed

and a claim filed at the receiving point. The unit cabinet

is shipped completely assembled

POSITION AIR CLEANER CABINET

To reduce weight for ease in handling, remove the prefilters, main filters and place them safely aside. Position

the cabinet in the designated location giving

consideration to following points:

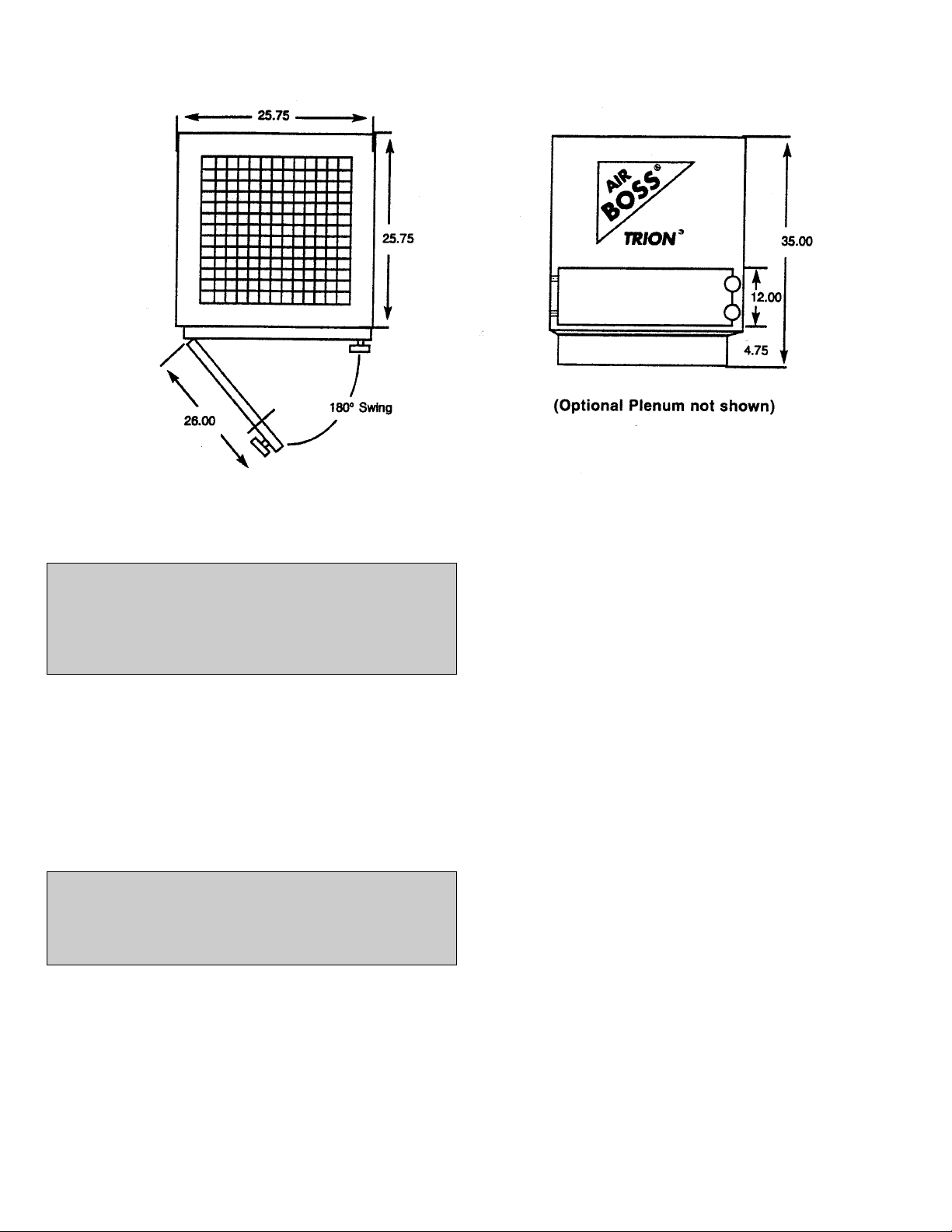

(a) Provide sufficient clearance in front of the

access doors for mechanical filter replacement.

A minimum of 26” is required (see figure 2).

(b) Level the cabinet to assure proper drainage from

the drain pan.

(c) Unless specific design features have been

prearranged, the direction of air flow through th

e cabinet may be from any side or upward

through the bottom. When the filters are

reinstalled, the directional arrows on the filters

must concur with airflow through the cabinet. If

mist suppressors have been specified, they are

to be installed on the air entering side of the unit.

After the cabinet has been properly located, it may be

secured into place at the mounting pads either by bolting

or welding.

2

Page 3

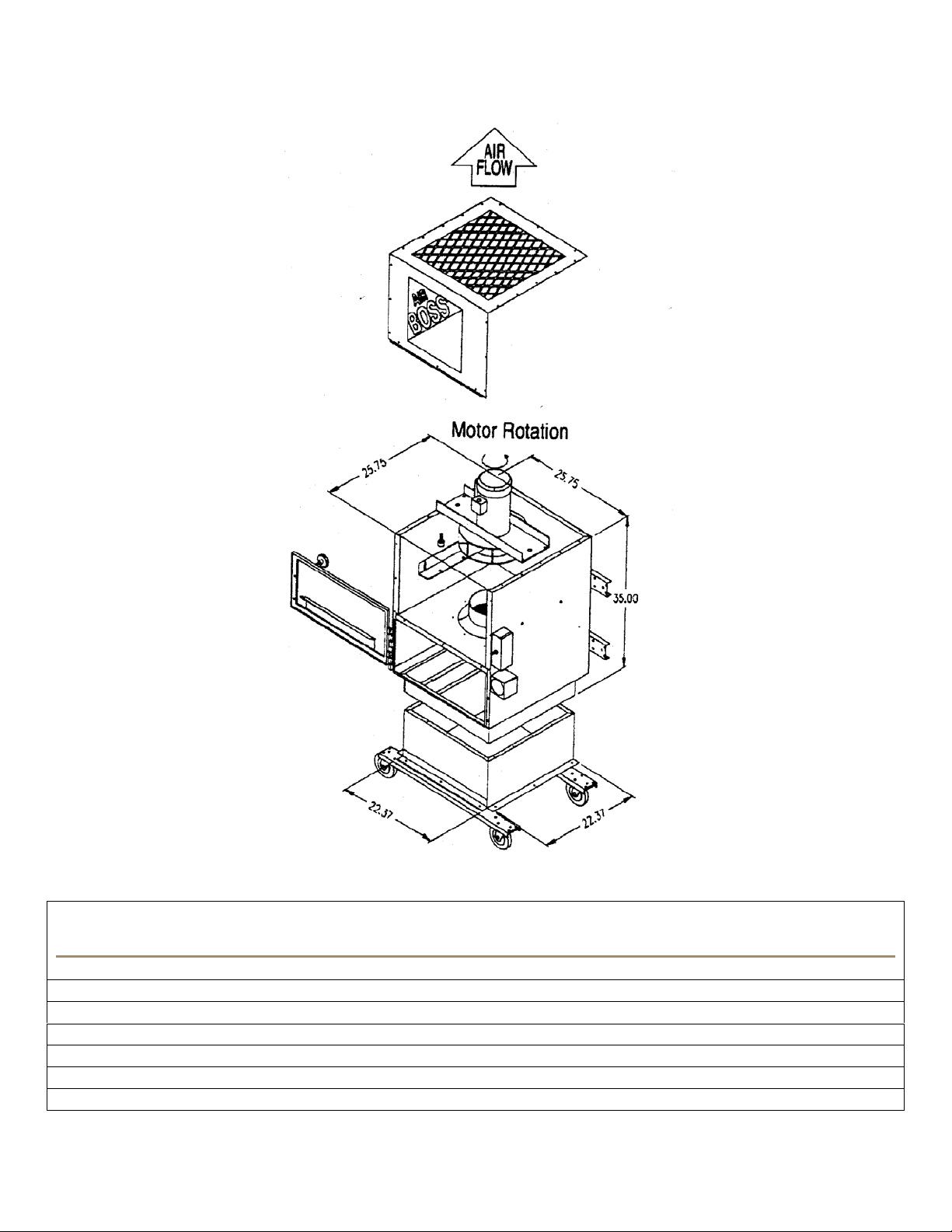

Figure 1 - MP 600M High Static

SPECIFICATIONS STANDARD OPTIONAL MP600M and High Static

MP 600M

Voltage 115 208-230 208-230/460 575 115/230

Phase 1 1 3 3 1

HZ 60 60 60 60 60

AMPS 17 9.4-8.5 4.9-4.6/2.3 1.9 8.0-4.0

Motor ½ hp 1 ½ hp 1 ½ hp 1 ½ hp ½ hp

CFM 600 600 600 600 600

Shipping Weight 175 lbs 225 lbs. 225 lbs. 225 lbs. 225 lbs.

3

Page 4

Figure 2 – Dimension and Access Data

GENERAL SAFETY INFORMATION

WARNING: RISK OF ELECTRIC SHOCK

These serving instructions are for use by qualified

personnel only, To reduce the risk of electric shock, do

not perform any servicing other than that contained in

the operating instructions unless you are qualified to do

so.

1. Read this manual thoroughly before beginning

the installation of this unit.

2. Conference to all local ordinances associated

with building codes and electrical codes is

required prior to beginning installation of this

unit. Authorities having jurisdiction should be

consulted before installation is made. If there are

no local codes, the installation should conform to

the National Electrical Code.

CAUTION:

The weight of the air cleaner is 150 lbs. Any mounting

arrangement must be able to support this weight. Failure

to determine if mounting is sufficient may result in

damage or injury within the area.

INSTALLATION

Prior to beginning installation, select the location for the

air cleaner. The air cleaner should be located as close to

the contaminant source as possible. The air enters the

air cleaner from the bottom (or specified side with inlet

plenum as viewed from the access door side) and

discharges vertically through the grille in the cabinet top

panel. Do not obstruct the air flow from the unit. Maintain

at least 18 inches (45 cm) clearance above the unit.

MOUNTING

WALL OR VERTICAL SUPPORT MOUNTED

1. Four (4) tapped holes are provided in the

cabinet back. Bars may be mounted to the

cabinet with existing hard ware. The MP600M

can then be mounted to the wall or vertical

support stand (not provided) with 3/8” hardware

(not provided).

2. The inlet plenum is equipped with a ½” half

coupling to connect drain piping. Plumbing

should be routed to the collection point to

facilitate drainage.

3. Affix duct(s) or elbow fitting(s) or flex hose(s) to

the inlet plenum flange collar using hose clamps

or other similar connection method. (Clamps,

elbows and/or duct are not provided).

4

Page 5

CAUTION:

When using flex duct connections with other than

straight runs of duct, 45 degree elbows should be used

to connect ducting to flanged collars to maximize air

flow.

ENCLOSED MACHINING CENTER DIRECT MOUNT

1. When mounting directly to an enclosed

machining center ensure there is 53” (135 cm)

clearance above the enclosure and structure

integrity is sufficient to support the MP 600M.

2. Open the filter access door and remove all the

filtering elements. Set these components aside

until the installation is complete.

3. Prepare an outlet opening on the top of he

enclosed machining center (8” minimum to 20”

maximum diameter opening).

4. Center the MP600M over opening and secure to

the enclosure with self-drilling/self-tapping

screws or other similar method in accordance

with local codes. No additional duct connections

or drain plumbing is required on this type of

installation.

ARM ASSEMBLY (OPTIONAL) MOUNTING

Mount the arm assembly(s) to the arm connection collar

on the inlet plenum in accordance with the mounting

instructions provided in the arm assembly kit.

TRAPEZE MOUNT

1. Four (4) through holes are provided in the inlet

plenum bottom flange to which two (2) mounting

channels are affixed with 3/8” hardware (not

provided).

2. The MP600M can be suspended from overhead

with chains or 3/8” diameter (minimum) rods (not

provided).

3. The inlet plenum is equipped with a ½” half

coupler to connect drain piping. Plumbing should

be routed to the collection point to facilitate

drainage (P – trap not Required).

4. Affix duct(s) or elbow fitting(s) or flex hose(s) to

the inlet plenum flange collar using hose clamps

or other similar connection method (not

provided).

MINI-HELIC GAUGE (Optional Mounting)

1. Gauge may be mounted directly on MP600M

unit or may be remotely mounted for improved

visibility.

2. Gauge may be connected to measure entire

system static pressure or only pressure drop

across filter section.

3. All hardware, components and detailed

installation instructions are included in gauge kit

option.

Figure 3 - MP 600M Wall Mounted with 8” Arm Assembly and Drain Pipe

5

Page 6

Figure 4 - MP 600M Inlet Plenum and Stand Options

6

Page 7

Figure 5 – Wiring Diagrams for Model MP 600M

7

Page 8

Figure 6 – Wiring Diagram

8

Page 9

Figure 6A – Motor Wiring Diagram

9

Page 10

The MP600M is wired directly from the power source

with 20 amps minimum, service utilizing 3 wire grounded

cable, (115-208-230-460-575/60/3) for single 208230/60/1, phase service and 4 wire grounded cable for 3

phase service, routed through appropriate conduit (See

figure 5 wiring diagram). All wiring must be connected in

accordance with local electrical codes.

The conduit is connected to the cabinet junction box, or

motor starter enclosure on the top-right front corner of

unit.

OPERATION

To start the air cleaner, close the access door and

activate the ON-OFF control switch to ON. The blower

motor should start.

the pressure reading when the pre-filter is replaced. At

that point, the unit would be allowed to run until 3.1” w.c.

and both filters replaced.

NOTE:

The unit can continue to run beyond the 3.1” w.c.

pressure reading; however, airflow will be reduced

further.

CAUTION:

To check internal components, disconnect power source

to unit to prevent accidental shock.

MAINTENANCE

Blower Rotation (3 phase power only)

By looking down through the MP600M discharge grille

confirm blower rotation agrees with rotation label on

motor mount. If rotation is incorrect reverse two (2) input

power leads connections in the junction box, switch box

or motor starter enclosure. Again verify correct blower

rotation.

FILTER CHANGE (MINI-HELIC GAUGE)

INDICATOR (OPTIONAL) OPERATION

Change filter according to the pressure drop across the

filter. A minihelic gauge with a range from 0-5” water

column is optional for reading filter pressure.

Estimated Filter Change Pressure

Main Filter Both Filters Change Pre-filter Recommended Final

95% 1.8”w.c. 3.1”w.c.

HEPA 1.8”w.c. 3.1”w.c.

These readings will vary slightly due to altitude and

temperature.

Upon installation of the unit, note the initial pressure

reading and record in the table above. Check daily and

replace pre-filter at the reading shown in the table.

Pressure should return to near the initial pressure

reading. When the pressure reading, with new pre-filter,

shows little improvement (less than 0.1”) allow unit to run

until recommended final pressure is reached. At that

point, both pre-filter and main filter should be replaced.

Impinger models will have greater pressure initially than

standard models.

Estimated Estimated

NOTE:

Precision equipment will require a minimum amount of

maintenance to keep it in operating condition. You can

perform all normal preventative maintenance. If you are

unfamiliar with the terminology used in the in the

following sections, refer to the Parts List (Figure 7-A).

CLEANING AND INSPECTION

Cleaning of Impinger, and inspection and replacement of

pre-filter and main filter.

CAUTION:

Always disconnect the power source before working on

or near any electrical component. If the disconnect point

is out of sight, lock it in the proper position and tag to

prevent unexpected application of power.

1. Turn unit off.

2. Open access door by turning door latches

counter clockwise.

3. Remove filter element, pre-filter and impinger

assembly or pre-filter support.

4. Clean impinger by first rinsing with warm to hot

water, then immerse in a commercial grade

detergent. Trion recommends our specially

formulated Tridex detergent to provide maximum

cleaning efficiency on air cleaning equipment.

For best results, the cleaning solution should be

140ºF to 160ºF. The impinger should be soaked

in the solution for 1½ to 2 hours (longer if

extremely dirty).

NOTE:

Using non-factory approved detergents can cause

damage to the metal surface.

Once a pattern is established, the pre-filters can be

replaced on a calendar basis with the main filter being

replaced when the gauge reads “Recommended Final”

in the Table. For example, if the unit takes 6 weeks to go

from initial reading to 1.8” w.c., the pre-filter would then

be replaced every 6 weeks until no change occurred in

5. While impinger is soaking, make the following

inspections:

10

Page 11

A.

Thoroughly inspect the main and prefilter for holes, tears or any other

condition that might allow air to leak

through or around the filter. Replace the

filters if any damage is found.

B. Inspect the cabinet. Remove all foreign

debris and dirt accumulation inside the

cabinet.

C. Check for dirt accumulation on the

blower wheel blades and clean if there

is a buildup.

D. Bearings of blower motor should be

checked for signs of unusual wear.

E. If liquids are being collected, check the

drain fittings for proper drainage.

6. When soaking of impinger is complete, rinse

7. Reinstall impinger and filters into the unit.

8. Switch unit on at the control switch. The blower

9. If the air flow is now adequate to draw the

F. Check rubber gasketing and adhesion of

gasketing to cabinet surfaces.

with clean water and allow to dry.

should start.

contaminant being collected off the process, it

will not be necessary to replace the main filter.

If, however, the air flow remains unsatisfactory,

replace the main and pre-filter.

TROUBLESHOOTING CHART

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Failure to start

(motor does not start when unit is

turned on

Motor / Blower operates with little or

no air volume

Blow Through / Bypass

1. Proper power not reaching unit

2. Loose electrical connections

3. Defective control switch

4. Defective Motor

1. Dirty or dogged filters

2. Discharge grille obstructed

3. Blower wheel blades loaded with

dirt

4. Blower wheel loose on motor shaft

5. Incorrect voltage

6. Dirty or dogged impinger

7. Motor rotation incorrect

1. Filter ruptured or torn

2. Gasket missing or damaged

3. Filter saturated or damaged

1. Check that unit is connected to live

power line with good fuses, and

that the voltage at the unit is

correct

2. Check; tighten if necessary

3. Replace control switch

4. Replace motor/ blower assembly

1. Replace filters

2. Clean or remove obstruction

3. Clean blower wheel blades

4. Tighten blower wheel on shaft

5. Supply correct line voltage

6. Clean impinger

7. Reverse 2 of the 3 input power

leads (3 Phase only)

1. Replace filter

2. Install or repair

3. Replace filter

11

Page 12

Figure 7 – MP 600M Unit Assembly

12

Page 13

Figure 7A – Unit Assembly Parts List

MP 600M MP 600M HS

Qty Qty Item Part No. Description Remarks

1 1 1 353613-001 Cabinet Assembly

1 1 2 354477-001 Access Door

1 1 3 253619-001 Blower Housing Cover

2 2 5 248956-002 Clamping Knob

2 2 6 321449-002 Nut Retainer

2 2 7 146442-002 Hinge

6’ 6’ 8 224779-015 Gasket ¼” x 1”

1 - 9 247350-101 Blower Motor Assembly 120/240/50-60/1 Feature & Option

1 - 10 253631-001 Adapter Plate Feature & Option

- 1 11A 150825-001 Motor 115/208/-230/60/1 Feature & Option

- 1 11B 150825-003 Motor 208-230/460/60/3 Feature & Option

- 1 11C 150825-004 Motor 575/60/3 Feature & Option

- 1 11D 150825-005 Motor 110/220/50/1 Feature & Option

- 1 11E 150825-006 Motor 220/380-440/50/3 Feature & Option

- 1 12 250819-007 Inlet Cone Feature & Option

- 1 13 250837-102 Blower Wheel Feature & Option

- 1 14 253617-001 Motor Mount Feature & Option

- 2 15 253621-001 Motor Adjusting Angle Feature & Option

1 1 16A 353622-001 Plenum 1 – 8” Hose Feature & Option

1 1 16B 353622-002 Plenum 2 – 6” Hose @ 90º Feature & Option

1 1 16C 353622-003 Plenum 2 – 6” Hose @ 180º Feature & Option

1 1 16D 353622-004 Plenum 2 – 6” Hose @ 0º Feature & Option

1 1 16E 353622-005 Plenum 1 – 8” Arm @ Bottom Feature & Option

1 1 16F 353622-006 Plenum 1 – 8” Hose @ Bottom Feature & Option

1 1 16G 354988-001 Plenum 1 – 8” Arm @ Side Feature & Option

1 1 17A 246901-011 Impinger Feature & Option

1 1 17B 248533-001 Pre-Filter Support Feature & Option

1 1 18A 148534-001 Synthetic Filter - 22¼ x 22¼ x 2 Feature & Option

1 1 18B 224451-022 Aluminum Mesh Feature & Option

1 1 19A 248535-008 Filter 55%, 30 SF – Special Order Feature & Option

1 1 19B 248535-007 Filter 65%, 30 SF – Special Order Feature & Option

1 1 19C 248535-006 Filter 85%, 30 SF – Special Order Feature & Option

1 1 19D 248535-005 Filter 95%, 30 SF – Special Order Feature & Option

1 1 19E 248535-004 Filter 65%, 54 SF – Special Order Feature & Option

1 1 19F 248535-003 Filter 85%, 54 SF – Special Order Feature & Option

1 1 19G 248535-002 Filter 95%, 70 SF – Stock Feature & Option

1 1 19H 248535-001 Filter 99.97% DOP, 90 SF – Stock Feature & Option

1 1 19J 248535-009 Filter 95% DOP – Stock Feature & Option

- 1 20A 253625-002 Switch Box Assembly 1Ø Feature & Option

- 1 20B 253625-003 Switch Box Assembly 1Ø w/ Cord Feature & Option

- 1 20C 253625-004 Switch Box Assembly 3Ø Feature & Option

- 1 20D 355032-006 Compact Starter 110-120/50-60/1 Feature & Option

- 1 20E 355032-007 Compact Starter 220-240/50-60/1 Feature & Option

- 1 20F 355032-008 Compact Starter 208/60/1 Feature & Option

- 1 20G 355032-009 Compact Starter 208/60/3 Feature & Option

- 1 20H 355032-010 Compact Starter 220-230/50-60/3 Feature & Option

- 1 20I 355032-011 Compact Starter 380/50/3 Feature & Option

- 1 20J 355032-012 Compact Starter 440-460/50-60/3 Feature & Option

- 1 20K 355032-013 Compact Starter 575/60/3 Feature & Option

1 - 21A 253625-002 Switch Box Assembly 1Ø Feature & Option

1 - 21B 253625-003 Switch Box Assembly 1Ø w/ Cord Feature & Option

REF REF 22 253625-001 Junction Box Assembly Feature & Option

1 1 23A 253763-001 Gauge Kit System Feature & Option

1 1 23B 253763-002 Gauge Kit Filter Feature & Option

1 1 23C 253763-003 Gauge Kit System – Remote Feature & Option

1 1 23D 253763-004 Gauge Kit Filter – Remote Feature & Option

1 1 24A 354970-001 Arm Assembly 8” x 10” Feature & Option

1 1 25 253761-001 Mounting Bar Feature & Option

1 1 26 60000-0003-01-00 Swivel Caster Feature & Option

REF REF 27A 238001-002 Toggle Switch 1Ø Feature & Option

REF REF 27B 238001-003 Toggle Switch 3Ø Feature & Option

1 1 28 254643-001 Stand Not Shown

- 4 29 145541-003 Vibration Isolator

13

Page 14

Figure 8 – Filter Locking Mechanism

- Access opening increased 3.5” height

- 16 GA tapered filter retainer welded in door and cabinet rear

- As door closes, filter gasket is compressed and seal is made

14

Page 15

Figure 9 – System Performance Curves (without Filters)

Flow – CFM @ 60 Hz

Added Static @ Filter 600 CFM 1000 m3/hr

Filter Inches W.C. Pascals

99.97% DOP HEPA 1.00 250

95% DOP 0.35 87

90-95% ASHRAE 0.20 50

80-85% ASHRAE 0.15 37

60-65% ASHRAE 0.10 25

45-55% ASHRAE 0.05 13

Impinger 0.15 37

Aluminum Mesh Pre-Filter 0.05 13

Glass Pre-Filter 0.00 1

** To determine performance with various filter combinations, add total static of filters (from table)

15

Page 16

WARRANTY

All Trion air cleaners are warranted for component failure and workmanship for a

period of three years after purchase. Do not return defective parts without prior

permission from the factory. Contact your local Trion Distributor or Trion Customer

Service Department at 1-800-884-002 of Fax 1-800-458-2379 to obtain

material return authorizations and service information.

Form No. 153632-001

June 2002

Corporate Office: 101 McNeill Road • Sanford, NC 27330

Phone: 800-884-0002 • Fax: 800-458-2379 • Email: sales@trioninc.com

www.trioninc.com

Loading...

Loading...