Page 1

User’s Guide

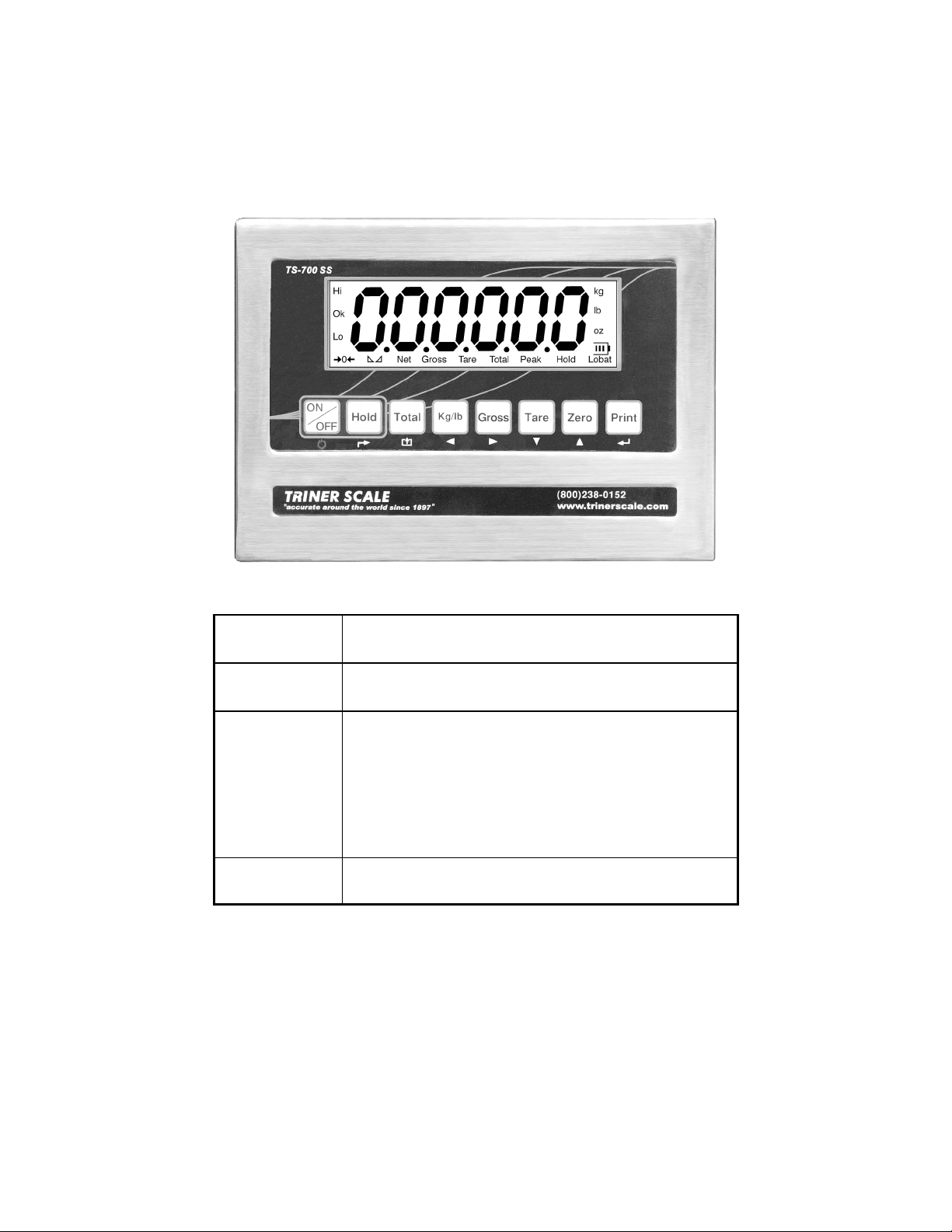

TS 700-SS Digital Indicator

Series 3

Version 3.0 11/15/10

Triner Scale & Mfg. Co., Inc

(800) 238-0152

Page 2

!!!! CALIBRATION WARNING !!!!

Calibration AND Inspection of calibration properties is prohibited

unless done so by a qualified scale technician.

WARNING

The indicator is the static and sensitive equipment,

cut off the power during electrical connections,

internal components touched by hand is prohibited,

and please take the measure of anti-static.

© 2010 Triner Scale. All rights reserved.

Page 3

1

Table of Contents

Specifications __________________________________ 2

Load Cell Connections ___________________________ 3

Serial Port Connections __________________________ 4

Operation ______________________________________ 5

Parameters and Settings _________________________ 7

Data Output Formats ___________________________ 15

Error Codes ___________________________________ 19

Factory Default Settings _________________________ 20

Page 4

2

Specifications

Technical parameters

Accuracy class 6000 e

Resolution Display: 30, 000 ADC: 2,000,000

Zero stability error TK

0

< 0.1µV//K

Span stability error TK

spn

< ± 6 ppm//K

Sensitivity (internal) 0. 3 µV /d

Input voltage -30~30mV DC

Excitation circuit 5 VDC, 4 wire connection,

Load Cell Max 8 load cell of 350Ω

AC power AC100~250V

Operation temperature - 10 °C ~ + 40 °C

Operation humidity ≤90%RH

Storage temperature - 40 °C ~ + 70 °C

Battery Operation

- Before operating with the internal battery, charge the battery fully, for

18+ hours.

- The battery icon in the lower right area of the display indicates battery

status:

3 bars = fully charged

2 bars = half discharged

1 bar = 2/3rds discharged

No bars = discharged/must be recharged. .

- In order to keep the battery in its best condition, it is recommended the

battery be fully discharged and recharged once a month.

Page 5

3

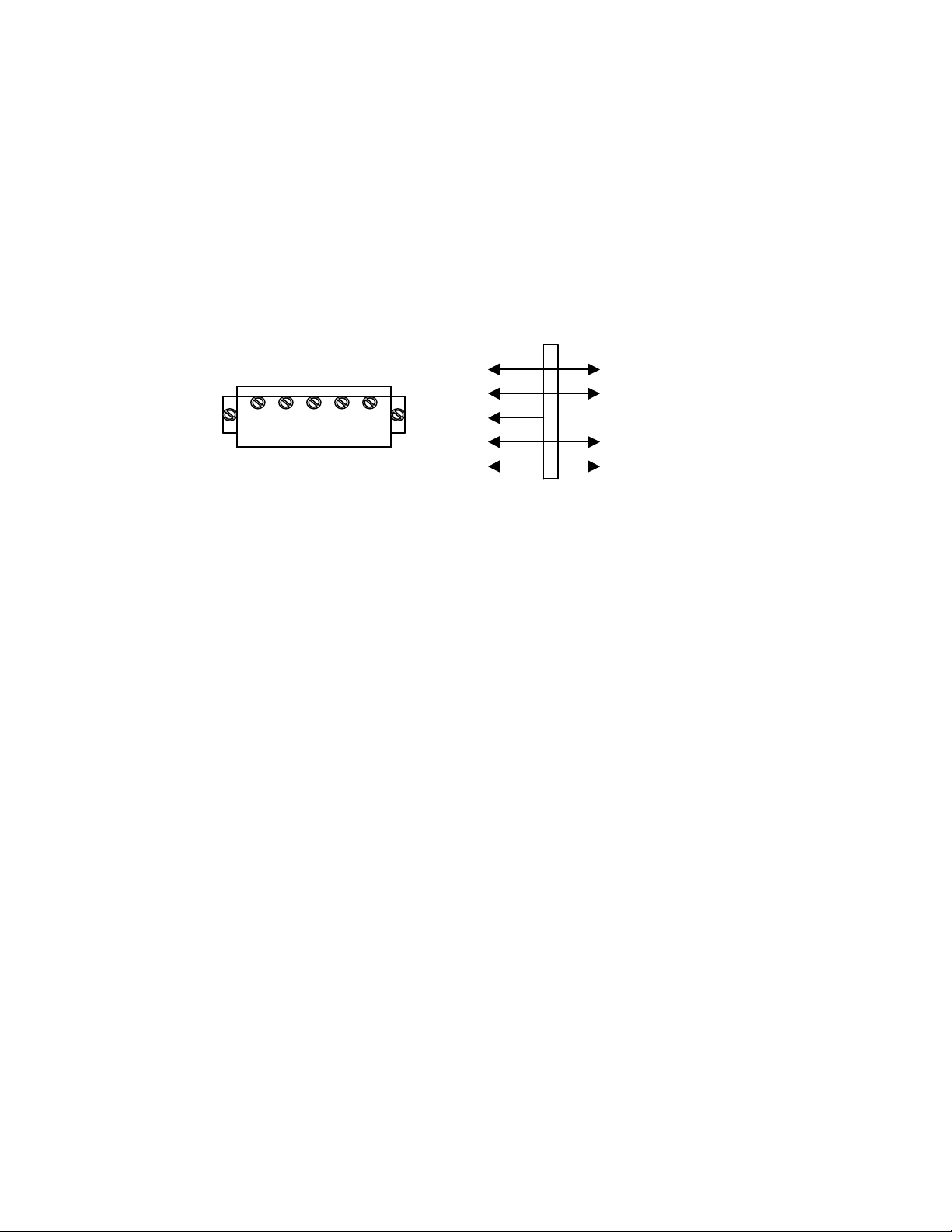

Load Cell Connections

The indicator can connect with a maximum of eight of 350Ω load cells, 4

wire or 6 wire configurations.

Excitation voltage for the load cell is 5VDC, the largest output current

120mA.

Terminal Block on Circuit Board:

Circuit Board Terminals Load cell

+EXC + voltage

+SIG + output signal

HD --------- Shielded wire

- SIG - output signal

-EXC -SIG HD +SIG +EXC - EXC - voltage

Page 6

4

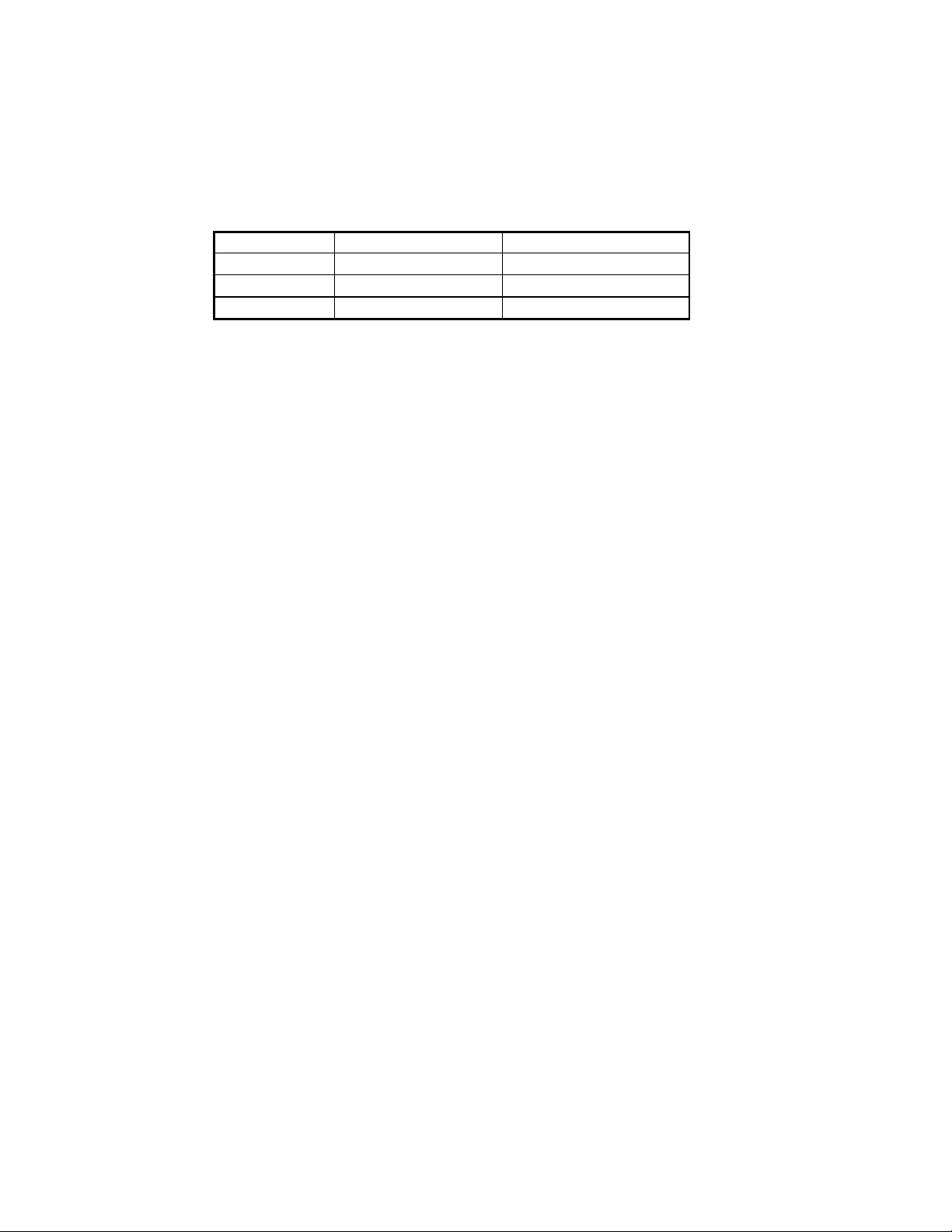

Serial Port Connection

RS232 Terminal on Circuit Board

DB9

Definition

Function

2

TXD

Sending data

3

RXD

Receiving data

5

GND

Ground interface

Note: if RS485, The connection pin is 2 and 5 pin.

Page 7

5

Operation

Keys and Their Functions

KEY

OPERATION / FUNCTION

On/Off

Press and hold for 2+ seconds to operate.

Hold

To Hold Weight on Scale

- With weight on scale, press key to hold weight.

To Hold Peak Weight of Multiple Weighings

- Without weight on scale, press key to put indicator

in peak hold mode.

To Remove Hold Function

- Press key again to return to normal operation.

Total

- With weight on scale, press key to place weight

and count in memory. Remove weight, place next

Page 8

6

item on scale, press Total to add weight to total

weight and total count.

- To view totals, press Total and Print key at the

same time. The total weight will flash continuously.

- To go out of view totals mode, press and hold the

Total key. “Clr n” will display.

- If you wish to continue adding to the totals, press

the Print to accept the “Clear-No” prompt. Continue

weighing and adding items as required.

- If you wish to clear the totals memory, press the

Zerro/Up Arrow key to change the “Clr n” display

to “Clr y”. Press the Print key to accept the

kg/lb

Change pounds/kilograms

Gross

For use after a TARE weight has been stored in the

indicator. Press key to toggle view between gross

and net weight.

PLEASE NOTE that there may be a momentary

pause in the display when going from gross to tare

weight.

Tare

- With weight on the scale, press to Tare the weight.

- Press again to remove Tare weight.

Zero

Press key to zero the scale.

Print

Press key to print a ticket (requires optional printer).

Page 9

7

Parameters and Settings

CAUTION: Use care when accessing and adjusting your indicator’s

parameters. Several parameters can be accessed that, if altered, will

change your indicator’s operations.

To access and adjust the TS-700 SS parameters:

Press the PRINT and HOLD keys. “C” will display. Release the keys.

“C08” will display, with the 8 flashing. The digit flashing is the active

digit, and can be adjusted up or down by using the ZERO/UP

ARROW or TARE/DOWN ARROW key. Use the KG-LB/LEFT

ARROW key and the TARE/RIGHT ARROW KEY to change which

units digit is active (flashing).

TIP: You can move forward through all parameters and view

the settings by pressing the PRINT/ENTER key repeatedly.

Navigate to the setting parameter you wish to adjust and use the

arrow keys to change the settings values. Press the PRINT/ENTER

key to accept your settings, then press the TOTAL/EXIT key.

EXAMPLE: To adjust the date setting in parameter C16:

- With “C08” flashing, use the down arrow key to reduce the

flashing 8 to 6. Use the left arrow key to make 0 the active digit.

- Use the up arrow key to increase the 0 to 1.

- “C16” will display. Press the PRINT/ENTER key.

- The display will show digits for month, day and year. Use the

arrow keys as discussed above to navigate to and change the

digits.

- Press the PRINT/ENTER key to accept your settings.

- Press the TOTAL/EXIT key to exit.

Page 10

8

Function

Setting Parameter

Parameters Settings

Warning tone

C08

Options:

0 = no warning tone

1 = warning tone on

Automatic

power off

C09

Options:

0 = no auto power off

10 = power off automatically if no

change within 10 minutes.

30 = power off automatically if no

change within 30 minutes.

60 = power off automatically if no

change within 60 minutes.

Power saving

setting

C10

Options:

0 = close power saving setting

3 = close display if no change

within 3min.

5 = close display if no change

within 5 min.

Hold function

C11

Options:

0 = no hold function

1 = Peak hold

2 = Data Hold

- Peak-hold shows the max. load

of multiple weighings.

- Data hold locks the current

weight value.

Kg/lb

conversion

C12

C12 = 0 disable kg/lb conversion

C12 = 1 kg/lb conversion is ok

Upper/lower

limit alarm

C13

Upper limit alarm

value

Enter numeric values for upper

and lower checkweighing limits.

Page 11

9

C14

Lower limit alarm

value

Inner Code

display

C15

Enter C15 to check the inner

code.

C16

Date

Enter C16, set the date, from left

to right: year/month/day

Date and time

C17

Time

Enter C17, set the time from left

to right: hour/min./sec.

C18

Serial interface data

output method

Options:

0 = Close serial interface data

output

1 = Continuous sending, connect

big display

2 = Print method, connect printer.

3 = Command request method ,

connect computer.

4 = PC continues sending format,

connect computer.

5 = PC/ big display continuous

sending format.

Communication

setting

C19

Baud rate

Options:

0=1200/1=2400/2=4800/3=9600

C20

Manually zero range

Options:

0 = disable manual zero setting

1 = ±1% max capacity

2 = ±2% max capacity

4 = ±4% max capacity

10 = ±10% max capacity

20 = ±20% max capacity

100 = ±100% max capacity

Zero range

CAUTION;

Changing these

parameters will

effect the indicator’s

performance.

C21

Initial zero range

Options:

0 = no initial zero setting

Page 12

10

1 = ±1% max capacity

2 = ±1% max capacity

5 = ±1% max capacity

10 = ±1% max capacity

20 = ±1% max capacity

C22

Automatically zero

tracking range

Options:

0 = disable zero tracking

0.5 = ±0.5d

1.0 = ±1.0d

2.0 = ±2.0d

3.0 = ±3.0d

4.0 = ±4.0d

5.0 = ±5.0d

Note:

1. d = division

2. the zero tracking range can not

more than manual zero range.

Zero tracking

CAUTION;

Changing these

parameters will

effect the

indicator’s

performance.

C23

Automatically zero

tracking time

Options:

0 = disable zero tracking time

1 = 1 second

2 = 2 seconds

3 = 3 seconds

Overload

range

C24

CAUTION;

Changing these

parameters will effect the

indicator’s performance.

option:00= close overload range

01d~99d

remark:d =division

Negative

display

C25

Options

:0 = -9d

10 = 10% max. capacity

20 = 20% max. capacity

50 = 50% max. capacity

100 = 100% max. capacity

Page 13

11

C26

Standstill time

Options:

0 = quick

1 = medium

2 = slow

Standstill time

CAUTION;

Changing these

parameters will

effect the indicator’s

performance.

C27

Standstill range

Options:

1 = 1d 2 = 2d

5 = 5d 10 = 0d

(d = division)

Digital filter

CAUTION;

Changing these

parameters will

effect the indicator’s

performance.

C28

To compensate for

unstable loads on

the weighing

platform (for

example, animal

weighing).

Options:

0 = close dynamic filter

1 = 1 digital filter strength

2 = 2 digital filter strength

3 = 3 digital filter strength

4 = 4 digital filter strength

5 = 5 digital filter strength

6 = 6 digital filter strength

CAUTION;

Changing these

parameters will

effect the indicator’s

performance.

C29

Noise filter

0 = disable noise filter

1 = 1 digital filter strength

2 = 2 digital filter strength

3 = 3 digital filter strength

C30

Print time and date

C30 = 0 yy.mm.dd

C30 = 1 mm.dd.yy

C30 = 2 dd.mm.yy

C30 = 3 yy.mm.dd

Analog output

setting

C31 output type

C31 = 0 0~5Vouput

C31 = 1 4~20mA output

4~20mA

current

calibrate

C32

(RESERVED)

Page 14

12

Relay output

setting

C33 Relay output

C33 = 0 close relay output

C33 = 1 Open relay output

function 1

C3 = 2 Open relay output

function2

C33 = 3 Preserved menu

Mutli

communication

add.

C34 Communication

add.

C34 = 0~99 Add. Code

(RESERVED)

Wireless

communication

C35

C35 = 0~99 signal (RESERVED)

Gravity of

calibration

location

C36

CAUTION;

Changing these

parameters will effect the

indicator’s performance.

C36 = 9.7000~9.9999

Gravity of

destination

C37

CAUTION;

Changing these

parameters will effect the

indicator’s performance.

C37 = 9.7000~9.9999

Version No.

C38

Preserved

menu

C39

Page 15

13

Data Output Formats

Remote Display Format

Output continuous format

S

T

X

S

W

A

S

W

B

S

W C X X X X X X X X X X X

X

C

R

C

K

S

1

2 3 4

5

6

State A

Bits0,1,2

0 1 2

Decimal point position

1 0 0

XXXXXX0

0 1 0

XXXXXXX

1 1 0

XXXXX.X

0 0 1

XXXX.XX

1 0 1

XXX.XXX

Bits3,4

Division

0 1 X1

1 0 X2

State B

BitsS

function

Bits0

gross=0, net=1

Bits1

Symbol: positive =0,negative =1

Bits2

Overload(or under zero)=1

Bits3

dynamic=1

Bits4

unit:lb=0, kg=1

Bits5

Constant 1

Bits6

Constant 0

State C

Page 16

14

Bit2

Bit1

Bit0

unit

0 0 0

Kg or lb

0 0 1

g

0 1 0

t

Bit 3

printing=1

Bit 4

Extend

display=1

Bit 5

Constant 1

Bit 6

Constant 0

PC Computer Continuous Sending Format

, ,

CR

LF

S 1 S 2 S 3 Data S 4

S1: weight status, ST= standstill, US= not standstill, OL= overload

S2: weight mode, GS=gross mode, NT=net mode

S3: weight of positive and negative, “+” or ” –“

S4: “kg” or “lb”

Data: weight value, including decimal point

CR: carriage return

LF: line feed

Serial Interface Reception Command

RS232COM serial interface can receive simple ASCII command.

Command word and role as follows:

Command

NAME

Function

T

TARE

Save and clear tare

Z

ZERO

Zero gross weight

P

PRINT

Print the weight

R

G.W/N.W

Read gross weight or net weight

C

Kg/lb

Kg/lb conversion

G

G.W

Check gross weight at net weight mode

Page 17

15

R command receive data format

5.4 Print format

ID.NO. 004 (Serial No.)

Date: XX.XX. XX (yy.mm.dd)

Time: XX.XX.XX (hh.mm.ss)

GROSS 8.88kg (gross weight)

TARE 2.88kg (tare)

NET 6.00kg (net weight)

5.5 PC or Big display continuous sending format

Page 18

Page 19

17

Error Codes

ERROR

REASON

SOLUTION

UUUUUU

1. Overload

2. wrong connection

with load cell

3. load cell has quality

problem.

1. reduce the weight

2. check load cell connection

3. inspection load cell. Check

the input and output

nnnnnnn

1. calibration is no

good

2. wrong connection

3. load cell has quality

problem

1. check scale is resisted or

not, foot is kept level or not.

2. check load cell connection.

3. checking load cell: check

input and output resistance to

judge it is good or not.

ERR1

During calibration, not

input the weights or

the weight is overload

Input the correct weights

ERR2

During calibration , the

weights is below than

Min. required weights

The calibration weights

Minimum is 10% of Max. cap.

Recommend 60%-80% of Max.

Cap.

ERR3

During calibration, the

input signal is

negative

1. check the connection is

correct

2. check load cell is no

problem

3. recalibration if still wrong

change the PCB

ERR4

During calibration, the

signal is unstable

After the platform is stable,

start calibration

ERR5

Change PCB

Page 20

18

Factory Default Settings

Parameter

instruction

Default

C01

Calibration

1

C02

Decimal digits

0

C03

Resolution

1

C04

Max. capacity

10000

C05

Empty calibration

0

C06

Capacity calibration

0

C07

Restore default

0

C08

Warning tone

1

C09

Power-off automatically

0

C10

Power saving mode

0

C11

Hold function

0

C12

Prohibit kg/lb conversion

1

C13

Upper limit alarm

000000

C14

Under limit alarm

000000

C15

Inner code

C16

Date setting

C17

Time setting

C18

Serial interface data output

0

C19

Serial interface Baud rate

3(9600)

C20

Zero manually

10

Page 21

19

C21

Initial zero

10

C22

Zero tracking range

0.5

C23

Zero tracking time

1

C24

Overload range

9

C25

Negative range

10

C26

Standstill time

1

C27

Standstill range

2

C28

Dynamic filter

0

C29

Noisy filter

2

C30

Print format

0

C31

Analog signal options

1

C32

4~20mA testing

4

C33

Relay output setting

1

C34

Muti PC communication

add.

0

C35

Wireless communication channel

6

C36

Calibration location gravity

9.7936

C37

Destination gravity

9.7936

C38

Version No. check

C39

Reserved menu

Loading...

Loading...