Page 1

Calibration & Connectivity

TS-700 Series Digital Indicators

This document supplements the User’s Guide

TS-700 MS

Full Function/Advanced Function Digital Indicator

Version 4.0

TS-700 SS

www.trinerscale.com

TS-700 WB

Page 2

Triner Scale & Mfg.Co., Inc.

8411 Hacks Cross Road

Olive Branch, M S 38654

(800) 238- 0152

www.trinerscale.com

© 2013 Triner Scale. Al l rights reserv ed.

Page 3

Calibration & Connectivity | TS-700 Series

Table of Contents

Specifications...................................................2

Load Cell Connections .....................................3

Serial Port Connections ................................... 4

Calibrating a TS-700 Series Indicator...............6

Data Output Formats .....................................12

Error Codes ...................................................15

Factory Defa ult Sett ings.................................16

!!!! CALIBRATION WARNING !!!!

Calibrati on AND inspec t ion of calibration properties

is prohibit ed unless don e s o by

a qualified s c ale technician.

WARNING

The indicator has stat ic s ens it iv e

components.

Do not make any connections without

powering of f t he indicator.

1

Page 4

Calibration & Connectivity | TS-700 Series

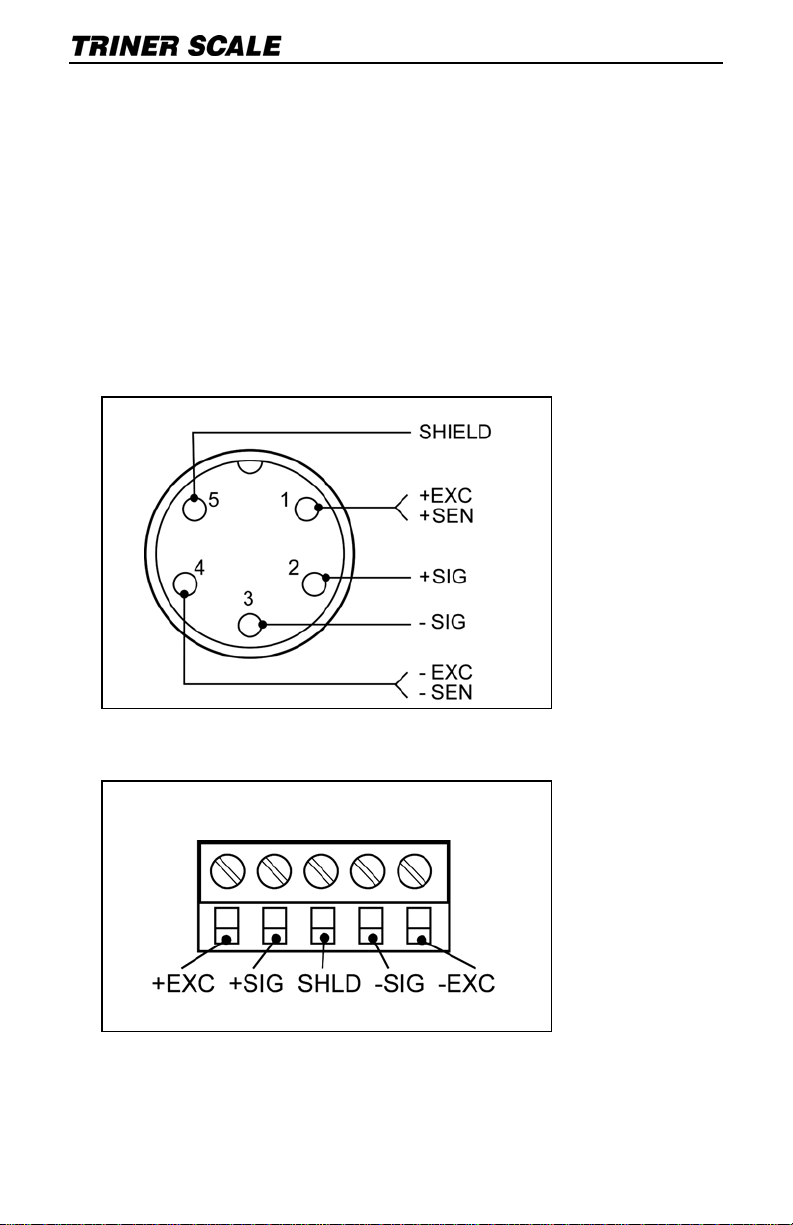

Specifications

TECHNICAL PARAMETERS

Resolution ...................... Display: 30,000

ADC................................ 2,000,000

Zero stability error ........... TK

Span stability error .......... TK

Sensitivity (internal)......... 0. 3 μV /d

Input voltage ................... -30~30mV DC

Excitation circuit.............. 5 VDC

Load Cell Max................. 8, 350Ω

AC power........................ AC100~250V

Operation temp............... - 10 °C ~ + 40 °C

Operation humidity.......... ≤90% RH

Storage temp .................. - 40 °C ~ + 70 °C

NTEP CLASS III............. COC# 09-080

KEYPAD KEYS FUNCTIONS

< 0.1μV//K

0

< ± 6 ppm//K

spn

Hold Hold weight on scale, or Hold peak weight*,

or Hold unstable/animal weight*

Total Total Weight: total of multiple weighings

Kg/lb Display weight in pounds or kilograms

Gross/

Tare

Tare container weight, display gross or net

weight

Zero Returns the indicated weight to “0”

Print Prints receipt (requires optional printer)

PC connectivity (requires PC software)

*requires adjustment of parameter settings

2

Page 5

Calibration & Connectivity | TS-700 Series

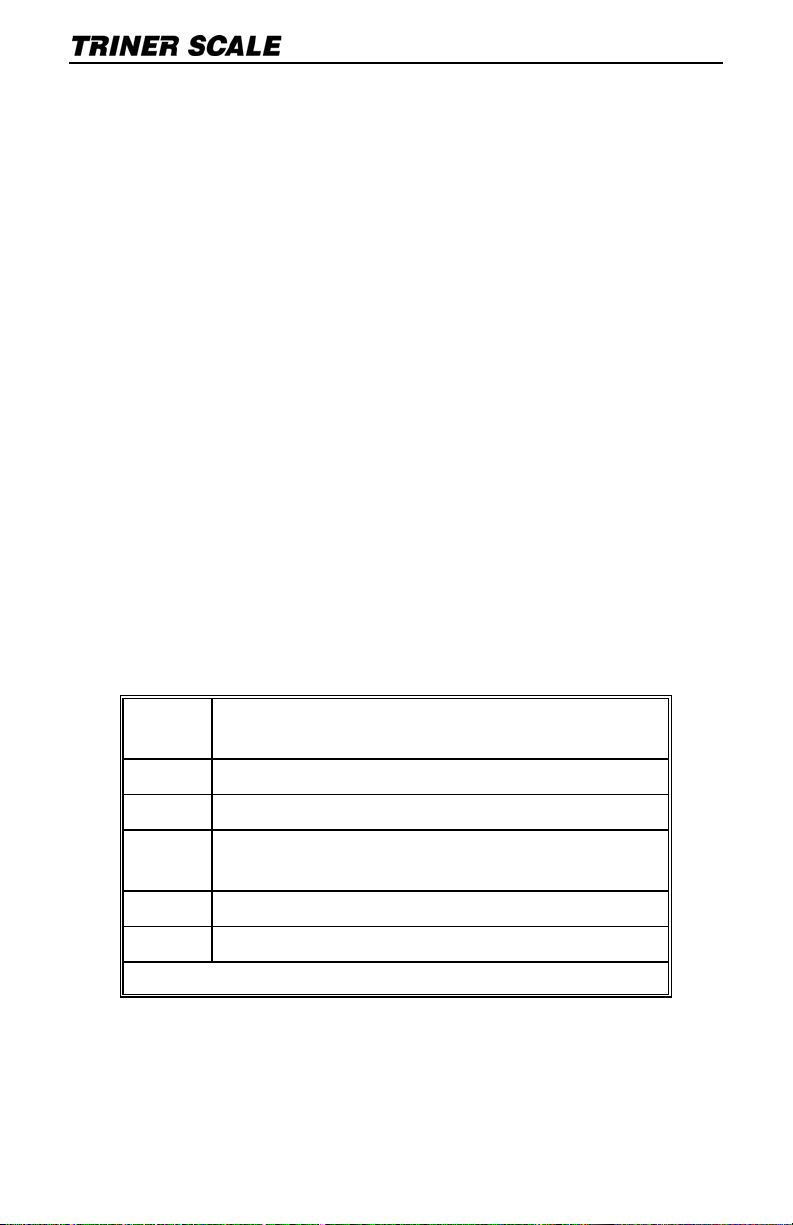

Load Cell Connections

The indicator can con nec t with a maxi mu m of

eight (8) 350Ω load cells, 4 wire or 6 wire

configurations.

Excitation voltage for the load cell is 5VDC, the

maximum output current is 120mA.

TS-700MS/WB Load Quic k- Con nect Pins

TS-700 SS Load C ell Ter minal Block

3

Page 6

Calibration & Connectivity | TS-700 Series

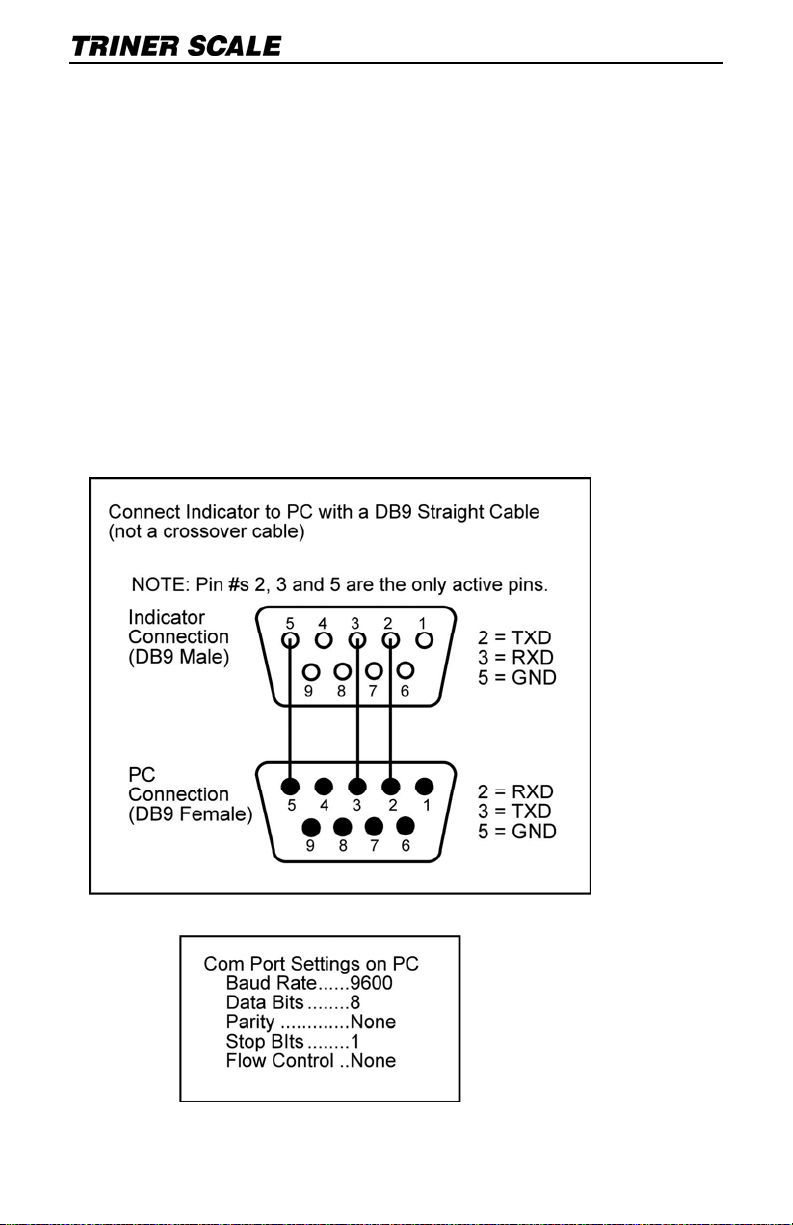

Serial Port Connection

RS232 CONNECTION

TS-700 MS

The RS23 2 DB9 serial p ort c an be utilized to

connect t he indicator to a periphera l dev ice such

as a printer or remote display, or to interface the

indicator with a PC.

NOTE: PC interf ac e requires Tri ner DataLo g

PC™ software to be installed on t he PC.

Indicator t o PC Connect ion

4

Page 7

Calibration & Connectivity | TS-700 Series

TS-700 SS

The 3-wire terminal bloc k located on the main

board can be utilized to connect the indicator to

a peripher al device suc h as a printer or remote

display, or t o int erface the indicator with a PC.

NOTE: PC interf ac e requires Tri ner DataLog

PC™ software to be installed on t he PC.

TS-700 SS RS-2 32 Ter minal Block

TS-700 WB

The RS23 2 3-pin quick-connect serial port can

be utilized to c onnect the indicator to a

peripher al device suc h as a pr inter or remote

display, or to interface the indicator with a PC.

NOTE: PC interf ac e requires Tri ner DataLog

PC™ software to be installed on t he PC.

5

Page 8

Calibration & Connectivity | TS-700 Series

Calibrating a TS-700 Series Indicator

NOTICE: The TS-700 SS/MS/WB are

NTEP Class III Legal for Trade a pproved

and certified. Unlocki ng t he calibrat ion

paramet ers is not allowed by persons

other than qualified scale technicians.

DEFAULT SETTINGS CAUTION

Placing the indicator in calibration mode enables

access to the Default Settings Parameter, CO7.

NEVER activate Parameter C07 unless you are a

qualified scale technician, and:

A) You understand that all custom settings will be

deleted permanently, and

B) You understand how to restore all custom

parameters to the required settings based on the

scale’s specifications and usage.

ALL MO DE L S: Place the Indicator i n

Calibration Mode and Determine if the

Calibration Parameters are Accessible

1) Power on t he indicator.

2) Press the PRINT and H OLD keys. “C ” w ill

display. Release the keys.

3) If the calib rat ion parameters are acces s ible,

“C01” will display, with the 1 flashin g. Proceed

to page 8, “ CA LI BRATION PROCEDUR E”.

NOTE: If C08 Disp lay s ins tead of C01, t he

calibration switch must be adjusted. Disconnect

the AC ada pt er and power of f t he indicator.

6

Page 9

Calibration & Connectivity | TS-700 Series

Calibration Switch, TS-700 MS: Remove the

screws and the back plate of the enc losure. A

white-capped calibrat ion switch is located at the

bottom lef t c orner of the circu it board. Press t he

switch fully in and release. This will place the

switch in the up position, allowing access to the

calibration parameters. Loosely reattach the

rear plate.

Calibration Switch, TS-700 SS: Remove the

screws and the back plate of the enc losure. A

calibration switch is located at the bottom left

corner of the c ircuit boar d. M ov e t he switch to

the “On” pos it ion, allowin g ac c es s t o t he

calibration parameters. Loosely reattach the

rear plate.

Calibration Switch, TS-700 WB: Disconnect all

cables an d c ords. To re m ov e t he back plate of

the enclosure, place the indicator upside dow n

(not face down) on a work s urface. Loc at e t he

two slotted holes near t he c onnection s oc kets.

Insert a flat blade scre wd riv er into each slot

(one at a ti me), pushing th e blade inward while

angled towards the bac k of t he indicator. This

will releas e t he retaining prong and enable

removal of t he back plate. Carefully lift t he rear

plate.

A white-capped calibr at ion switch is loc at ed at

the bottom l ef t c orner of the circ uit board. Pres s

the switch f ully in and release. This will pl ac e

the switch in t he up positio n, allowing access to

the calibration para meters. Loosely reattach t he

rear plate.

ALL MODELS: After enablin g ac c es s t o

7

Page 10

Calibration & Connectivity | TS-700 Series

calibratio n parameters, proceed as f ollows:

CALIBRATION PROCEDURE

1) Power on t he indicator.

2) Press the PRINT and H OLD keys. “C ” w ill

display. Release the keys.

3) “C01” will dis play, with the 1 f lashing. Th e

indicator is now is Parameter Settings mode.

Navigating in Settings Mode

When the indicator is in settings mode, refer to

the graphic printed below the key to det ermine

the keypad key’s function.

The

and arrow keys ar e used to

increase/decrease t he value of the flashing d igit ,

or to navigate up and do w n a lis t of preset

options.

The

and arrow keys ar e used to mov e t he

active digit over to the left or to the right.

The

key and key can be us ed t o move

forward or bac kward through the parameters.

Also, the

key is used to enter/acc ept

changes after they have been made to the

paramet er s et tings.

The

key can be us ed to exit sett ings mode.

With the indicator in set t ings mode and t he

calibratio n weight nea rby , proceed wit h t he

calibration process while referring to the

following chart:

NOTE: After completing and v erif y ing the

calibration, set the calibration switch to the “Off”

position a nd s ecurely fas t en t he rear plate.

8

Page 11

Calibration & Connectivity | TS-700 Series

PARAMETER FUNCTION OPTIONS

C01

C02

Default weighing

unit

1 = kg

2 = lb

Description:

With C01 flashing, press the

key, then use the up or

down arrow keys to change

the parameter setting as

needed.

Press the

the setting and continue on

to the next parameter.

Decimal location 0 = none

1 = one decimal place

2 = two decimal places

3 = three decimal places

Description:

With C02 flashing, press the

key, then use the up or

down arrow keys to change

the parameter setting as

needed.

Press the

the setting and continue on

to the next parameter.

key to accept

key to accept

9

Page 12

Calibration & Connectivity | TS-700 Series

C03

Graduations 1 = one unit

2 = two units

5 = five units

10 = ten units

20 = twenty units

50 = fifty units

Description:

With C03 flashing, press the

key, then use the up or

down arrow keys to change

the parameter setting as

needed.

Press the

the setting a nd continue on

to the next parameter.

C04

Capacity Description:

With C04 flashing, press the

key, then use the left

and right arrow keys to

select the ac tive digit, then

use the up and down keys to

adjust the digits to the

desired capacity, i.e.,

5,000.

Press the

the setting and continue on

to the next parameter.

C05

Zero Calibration 0 = skip zero calibration

1 = proceed with zero

calibration

Description:

With C05 flashing, press the

key, then use the up

arrow key to change the

parameter setting to 1.

Press the

proceed. The zero cal will

count down from 10.

Press the

proceed to the next

parameter.

key to accept

key to accept

key to

key to

10

Page 13

Calibration & Connectivity | TS-700 Series

C06 Calibration 0 = skip calibration

1 = proceed with calibration

Description:

With C06 flashing, press the

key, then use the up

arrow key to change the

parameter setting to 1.

Press the

key to

proceed. “Span” will briefly

display, then all digits will

display.

Load the weighing platfo rm,

then adjust t he displayed

digits to match the weight on

the platform, i.e, 4,000.

Press the

key to

proceed. The indicator will

calibrate, then display

“CalEnd”.

PRESS THE

ACCEP T TH E

CALIBRATION AND EXIT

SETTINGS MODE.

KEY TO

CAUTION -- IMPORTANT NOTICE!!

After ca li br a ti ng , be sur e t o e xit s e tti n gs m o de

without activati ng parameter C07!

Parameter C07 is the parameter that can DELETE all

custom settings and reset the indicator to factory

settings.

C07

CAUTION!!

FACTORY

RESET…

Erases all

custom

settings!

0 = skip reset to factory

defaults

1 = proceed with reset to

defaults

Description:

To reset to factory defaults,

change the 0 setting to 1 and

press the key.

11

Page 14

Calibration & Connectivity | TS-700 Series

Data Output For mats

REM O TE DI S P L AY F O RM AT

State A

Bits: 0,1,2

0 1 2

1 0 0 XXXXXX0

0 1 0 XXXXXXX

1 1 0 XXXXX-X

0 0 1 XXXX-XX

1 0 1 XXX-XXX

Bits: 3,4 Division

0 1 X1

1 0 X2

State B

BITS FUNCTION

Bits0 Gross = 0, net=1

Bits1 Symbol: posit ive = 0,negative =1

Bits2 Overload (or under zero)=1

Bits3 Dynamic = 1

Decimal point

position

Bits4 Unit: lb=0, kg=1

Bits5 Constant 1

Bits6 Constant 0

12

Page 15

Calibration & Connectivity | TS-700 Series

State C

Bit2 Bit1 Bit0 unit

0 0 0 Kg or lb

0 0 1 g

0 1 0 t

Bit 3 printing=1

Bit 4

Bit 5

Bit 6

Extend

display=1

Constant

1

Constant

0

PC COMPUTER CONTINUOUS SENDING FORMAT

, ,

CR L

S 1 S 2 S 3 Data S 4

S1: Weight status :

ST = standst ill

US = not st ands t ill

OL = overload

F

S2: Weight mode:

GS = gross mode

NT = net mode

S3: Weight of positive and negat ive,

“+” or ” –“

S4: “kg” or “lb”

Data: Weight value, includi ng decimal p oint

CR: C arriag e return

LF: Line feed

13

Page 16

Calibration & Connectivity | TS-700 Series

SERIAL INTERFACE RECEPTION COMMAND

RS232C OM serial interf ace can receive simple

ASCII command.

Command word and role as follo ws:

Command Name Function

T TARE Save and clear tare

Z ZERO Zero gross weight

P PRINT Print the weight

R G. W /N.W Read gross weight or net weight

C Kg/lb Kg/lb conversion

G G.W Check gross weight at net weight mode

Data Format

Print Format

ID.NO...................004 (Serial No. )

Date:....................XX.XX. XX (yy.mm.dd)

Time:....................XX.XX.XX (hh.mm.ss)

GROSS................NNNNNN lb/kg

TARE...................NNNNNN lb/kg

NET.....................NNNNNN lb/kg

14

Page 17

Calibration & Connectivity | TS-700 Series

Error Codes

ERROR CAUSE SOLUTION

uuuuuu

nnnnnn

ERR1

ERR2

1. Overloaded conditi on.

2. Wrong connection at

load cell.

3. Load cell has quality

problem.

1. Calibration is incorrect.

2. Bad connections.

3. Load cell has quality

problem

Overweight calibration

error.

Incorrect weight input or

incorrect weight on

weighing platform.

Underweight calibration

error.

Incorrect weight input or

incorrect weight on

weighing platform.

.

1. Reduce the weight.

2. Check load cell

connection

3. Inspect load cell.

Check the input and

output.

1. Check scale is resisted

or not, foot is kept

level or not.

2. Check load cell

connection.

3. Check input and

output resistance of

load cell

1. Input weight correctly

during calibration.

2. Place correct weight

on weighing platform.

The calibration weights

Minimum is 10% of

Max. cap.

Recommend 60 %80% of Max. Cap.

.

During calibration, the

input signal is negative.

ERR3

During calibration, the

ERR4

ERR5 Circuitry error Replace the PCB.

signal is unstable.

15

Check all connections.

Check load cell.

If connections and

load cell are okay,

PCB needs replacing.

After the platform is

stable, start

calibration.

Page 18

Calibration & Connectivity | TS-700 Series

Factory Default Settings

PARAMETER INSTRUCTION DEFAULT

C01

Calibration

1

C02

C03

C04

C05

C06

C07

C08

C09

C10

C11

Decimal digits

Resolution

Max. capacity

Empty calibration

Capacity calibration

Restore default

Warning tone

Power-off automatically

Power saving mode

Hold function

0

1

10000

0

0

0

1

0

0

0

C12 Disable kg/lb conversion 1

C13 Upper limit alarm 000000

C14 Under limit alarm 000000

C15 Inner code ---C16 Date setting ---C17 Time setting ---C18 Serial interface data

0

output

C19 Serial interface Baud rate 3(9600)

C20 Zero manually 10

C21 Initial zero 10

C22 Zero tracking range 0

16

Page 19

Calibration & Connectivity | TS-700 Series

C23 Zero tracking time 1

C24 Overload range 9

C25 Negative range 10

C26 Standstill time 1

C27 Standstill range 2

C28 Dynamic filter 0

C29 Noise filter 2

C30 Print format 0

C31 Analog signal options 1

C32 4~20mA testing 4

C33 Relay output setting 1

C34 Reserved 0

C35 Reserved 6

C36 Calibration location gravity

C37 Destination gravity 9.7936

C38 Version No. check ---C39 Reserved menu ----

9.7936

17

Page 20

Triner Scale & Manufacturing Co. Inc.

8411 Hacks Cross Road

Olive Branch, MS 38654

(800) 238-0152

www.trinerscale.com

Loading...

Loading...