Page 1

“Scales for business and industry since 1897”

(800) 238-0152

Set Up Guide

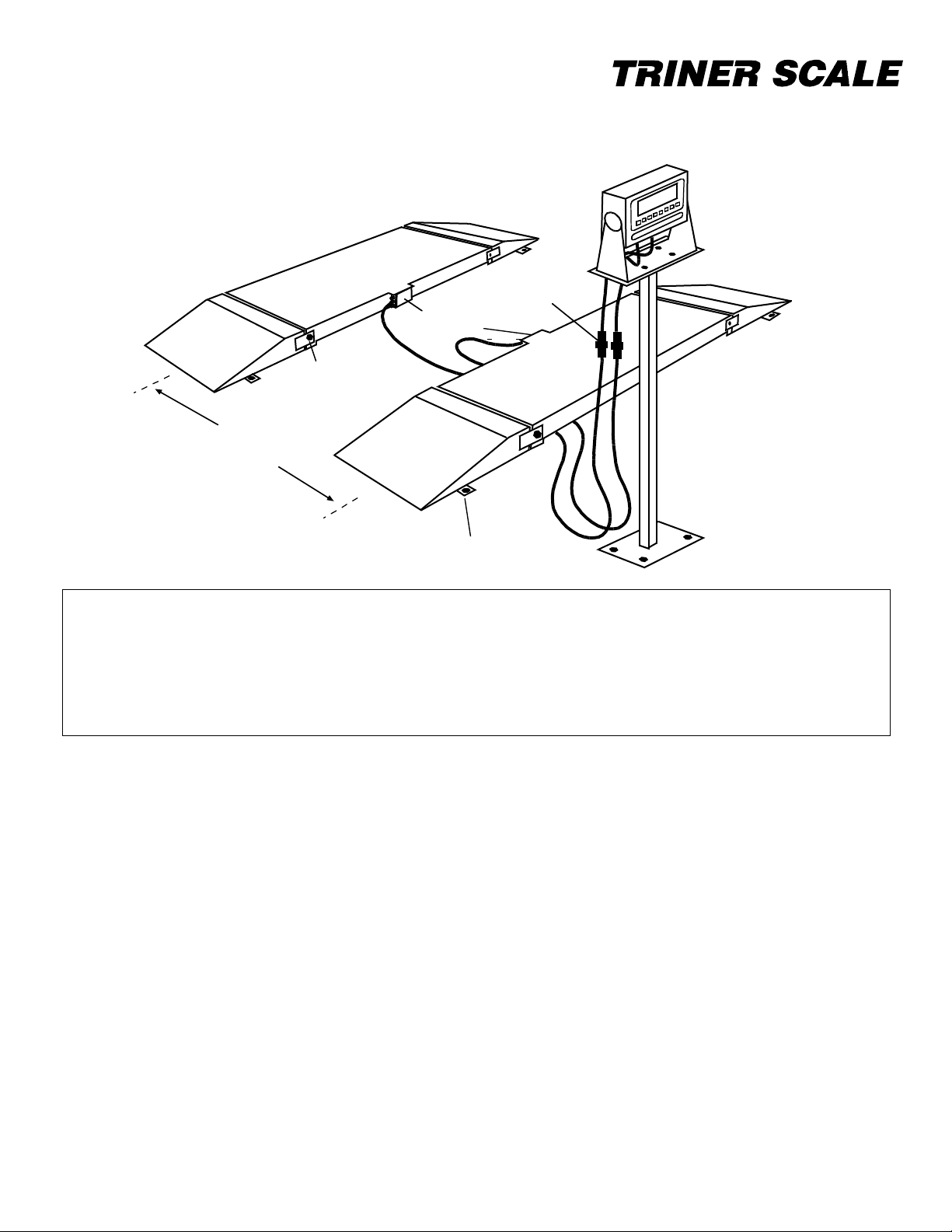

Axle Scale Model TS60-730AW

INSPECT YOUR SHIPMENT

Pallet #1: Two weighing platforms, stand (if included).

Pallet #2: Four ramps.

Box: Digital indicator, manual and instructions, two

cables, misc. hardware.

Confirm all contents and check for any damage

which may have occurred in shipping.

REQUIRED TOOLS

Forklift.

Hammer drill, 3/4” bit (scale anchors), 1/2” bit

(indicator stand anchors).

Socket wrenches, including 30mm socket for ramps,

or adjustable wrenches.

Screwdrivers: small phillips head, small flat blade.

Weighing platform

Ramp

Platform

cables

Indicator stand

(optional)

Digital indicator

Model TS-700 SS

Quick-connectors

Junction boxes

Width of vehicle track

Ramp

connecting

bolt

SET UP THE SCALE

STEP 1: Determine Location of Use

Be sure to select a location that is LEVEL AND

SOLID, such as a thick concrete slab.

Unacceptable surfaces include packed earth,

blacktop, and gravel. Unacceptable surfaces will

give way beneath the weighing platform and result

in inaccurate weighing.

STEP 2: Forklift Platforms Into Position

Unband the platforms pallet. If indicator stand is

included, set aside. With a forklift, pickup one

weighing platform from the shipping pallet. To protect

electronics, be sure to fork from the side of the

platform that does not have the junction box.

Forklift the first platform into position. Refer to the

illustration above: junction boxes should face inward,

and location of digital indicator needs to be taken

into consideration.

Based on the track width of vehicles to be weighed,

place second platform into position. Make sure

platforms DO NOT ROCK from corner to corner.

Remove and set aside the four ramp connecting

bolts from both platforms.

STEP #3: Forklift Ramps Into Position

Place each ramp into position at platform ends.

Securely bolt ramps onto weighing platforms.

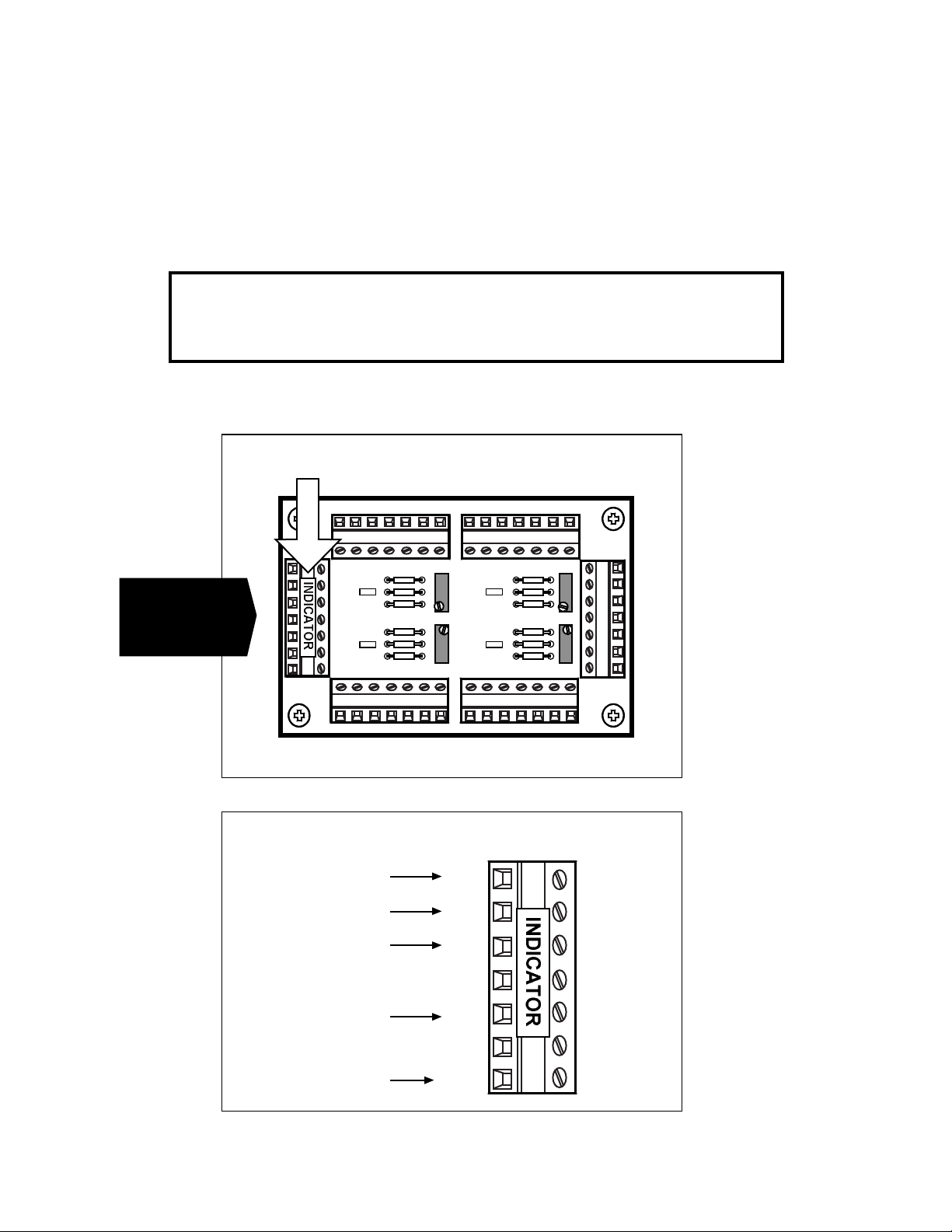

STEP# 4: Connect Cables to Junction Boxes

(wiring diagrams are on the back side of this sheet)

Remove both cables from the shipping box. Remove

the cover from one of the platform’s junction box.

Feed the wire leads of one cable into the box through

the available port on the box. Referring to wiring

diagram, connect the five cable wires to the terminal

block labeled “INDICATOR”. Following the same

procedures, connect the second cable to the second

weighing platform. Replace the covers on the

junction boxes.

STEP#5: Connect Platform Cables to Digital

Indicator

Place digital indicator near platforms and connect

both cables from the platforms to the quick-connect

sockets attached to the digital indicator cables.

Ramp

anchor tab

Page 2

“INDICATOR” label

Terminal block board inside junction box

+IN

-IN

+E

+S

-E

-S

GND

“SHLD” WIRE

Wiring Diagram for Cable Out to Digital Indicator

BLACK WIRE

RED WIRE

WHITE WIRE

GREEN WIRE

STEP 6: Anchor the Ramps and Weighing

Platforms

Using a hammer drill and 3/4” bit, drill anchoring

holes at each ramp anchor tab location. Insert

provided anchor bolts and securely fasten each

anchor.

STEP 7: Anchor the Indicator & Stand (optional)

Using a hammer drill and 1/2” bit, drill anchoring

holes where the stand base is located. Using the

included anchor bolts, securely fasten each anchor.

Using the included bolts, secure the digital indicator

to the stand.

Juncton Box Wiring Diagrams (existing wiring is omitted for clarity))

IMPORTANT NOTE! AVOID DAMAGE TO YOUR SCALE’S CABLES!

To avoid costly damage, be sure to route cables

away from forklift traffic and foot traffic.

Triner Scale & Mfg. Co., Inc. 8411 Hacks Cross Road, Olive Branch MS 381018 (800) 238-0152

For operation of the scale, refer to the digital indicator User’s Guide.

Left Side

Indicator

Connection

Page 3

GND

-S

-E

+S

+E

-IN

+IN

“SHLD” WIRE

BLACK WIRE

RED WIRE

WHITE WIRE

GREEN WIRE

“INDICATOR” label

Terminal block board inside junction box

STEP 6: Anchor the Ramps and Weighing

Platforms

Using a hammer drill and 3/4” bit, drill anchoring

holes at each ramp anchor tab location. Insert

provided anchor bolts and securely fasten each

anchor.

STEP 7: Anchor the Indicator & Stand (optional)

Using a hammer drill and 1/2” bit, drill anchoring

holes where the stand base is located. Using the

included anchor bolts, securely fasten each anchor.

Using the included bolts, secure the digital indicator

to the stand.

Juncton Box Wiring Diagrams (existing wiring is omitted for clarity))

IMPORTANT NOTE! AVOID DAMAGE TO YOUR SCALE’S CABLES!

To avoid costly damage, be sure to route cables

away from forklift traffic and foot traffic.

Triner Scale & Mfg. Co., Inc. 8411 Hacks Cross Road, Olive Branch MS 381018 (800) 238-0152

For operation of the scale, refer to the digital indicator User’s Guide.

Right Side

Indicator

Connection

Loading...

Loading...