Page 1

RAVAS-310

OWNERS MANUAL

1

Page 2

OPERATORS MANUAL

RAVAS-310

INDEX PAGE

1. Safety Instructions 3

2. System Setup 4

3. Operation Manual 6

3.1 Using the Weighing Hand Pallet Truck

3.2 Touch Panel Indicator

3.3 Indicator Functions

3.4 Printer (Option)

4. Trouble Shooting 18

5. Spare Parts 21

6. Calibration 23

7. Parameter Settings 25

Contact Us:

RAVAS USA, LLC

975Deerfield Parkway

Buffalo Grove, IL 60089

(224) 676-2238 phone

(224) 676-2136 fax

www.ravasusa.com

info.usa@ravas.com

2

Page 3

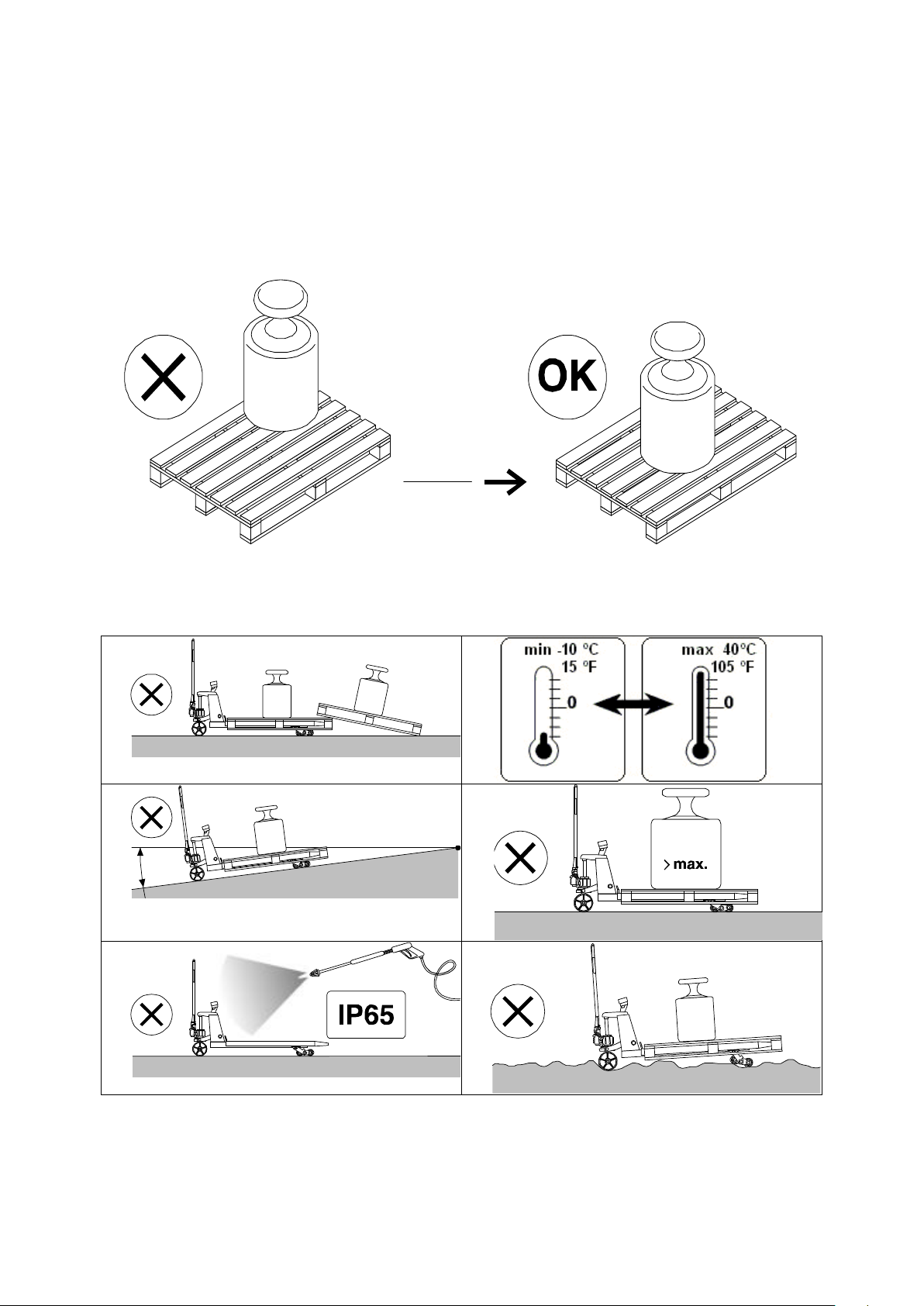

1 SAFETY INSTRUCTIONS

1. NEVER lift a heavy load with just the points of the forks. This could damage the electronic

weighing elements permanently.

2. NEVER weigh without a pallet. This could affect the accuracy of the weighing result.

3. The unit may be loaded with weights up to 5000 lb. However we advise you not to move any

weights above 1650 lb. (750 kg) with the unit. RAVAS is not responsible for injury that may

result when moving heavy loads.

4. Use caution in the vicinity of moving parts - these parts can cut and/or crush hands, arms, feet

and legs.

5. Always center the load you are lifting on both the forks.

6. Do not operate the weighing system on ramps, inclines or declines, without the addition of our

optional parking brake.

7. Do not operate the weighing system while others are on or near the unit. No riding!

8. All modifications must be approved in writing from the supplier, prior to any work being

completed.

9. It is the sole responsibility of the purchaser to train their own employees in the proper use and

maintenance of this equipment.

10. Do not operate this unit unless you have been fully trained of its capabilities.

11. Do not use the weighing system in potentially explosive areas.

12. Do not carry passengers with the truck.

13. Do not weld or make changes to the weighing system without consulting the supplier.

14. Do not lift unstable loads.

15. Check the accuracy of the scale on a regular basis to prevent faulty readings.

16. Only trained and authorized personnel are allowed to operate the truck.

17. Always follow the operating, maintenance and repair instructions of this truck and ask the

supplier when in doubt.

18. Never lower loads if you are unsure you can place the goods on a stable surface. Personal

injury may result from placement on an unstable environment.

19. Always remain with the scale during dosing applications. Incorrect lifting of the pallet can

cause overflowing.

20. RAVAS is not responsible for errors that occur due to incorrect weightings or inaccurate

scales.

3

Page 4

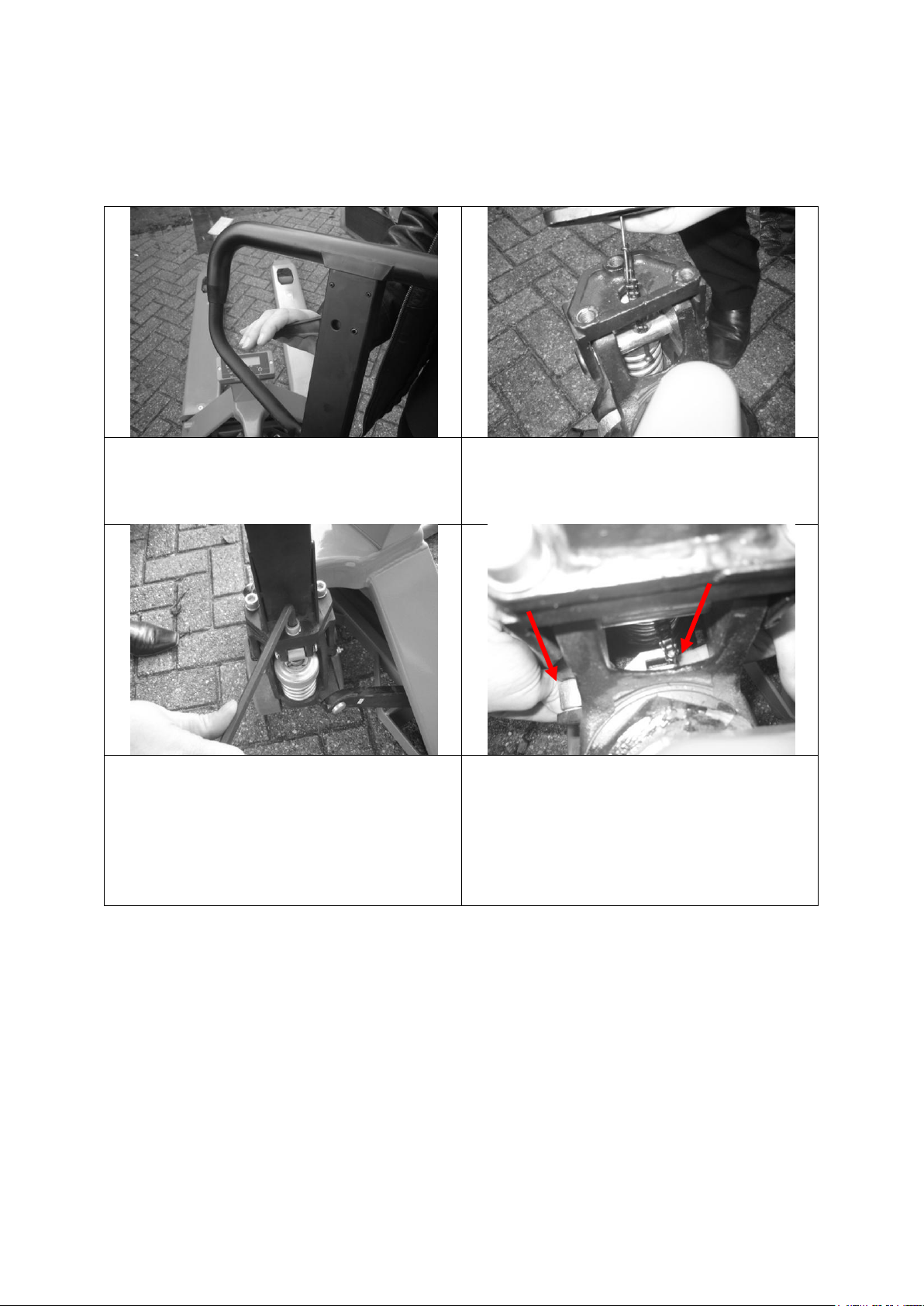

2 SYSTEM SETUP

Make sure the lever is pushed down to

the “pump” position.

Thread the chain through the hole in the

triangle and through the hole in the axle.

Place the handle bar onto the triangle and

insert the bolts.

Tighten the bolts firmly.

Push the silver part “A” on the outside of

the pump downwards.

At the same time; insert the chain into the

open side of the slot “B” on the inside of

the pump.

A

B

MOUNTING THE PUMP HANDLE

4

Page 5

THE BATTERY

The power supply to the system takes place through an exchangeable battery pack.

A completely charged battery should operate for a total weighing time of about 35

hours (on a system without a printer).

When the voltage level of the battery is running low, the display

will show “LO-BA”. When the battery is completely empty, the

weighing system shuts off.

It is necessary to charge the battery for at least 6 hours before the first use.

Recharge battery when the LO-BA indicator comes on.

If you use the system in shift work or if the system has a built-in printer, it is

recommended to purchase a supplementary battery pack.

The battery should be charged on the adapter supplied with the charger. When the

battery is charging, the LED on the charger is lit. When the LED turns off, the battery

is fully charged.

It is not possible to overload the battery because the charger shuts off automatically.

5

Page 6

3 OPERATION MANUAL

INDEX PAGE

3.1 Using the Weighing Hand Pallet Truck 7

Accurate Weighing

Taking the System into Operation

Maintenance

3.2 Touch Panel Indicator 9

The Display

The Touch Panel

Error Messages

3.3 Indicator Functions 12

Graduation

Before Weighing: Check Zero Point

Gross Weighing

Net Weighing: Automatic Tare

Net Weighing: Pre-set Tare

Piece Count: Sampling

Piece Count: Enter a Piece Weight

Summing

Change Units

3.4 Printer (Option) 15

The Print Out

Changing the Thermal Roll Paper

Changing the Date and Time on the Print Out

6

Page 7

3.1 USING THE WEIGHING HAND PALLET TRUCK

-2

Accurate Weighing

The weight must be centered over the forks of the pallet truck and lift freely: without

touching the housing of the indicator or other pallets

Fast temperature changes should be avoided because condensation may form

in the electronics. During acclimatization the indicator must be turned off.

7

Page 8

TAKING THE SYSTEM INTO OPERATION

To activate the scale turn it on using the on/off () button on the terminal.

After 3 to 5 minutes the electronics and load cells have reached the operational

temperature. Before this, inaccuracies of up to 0.3% may occur.

It is recommended not to lift loads before the zero-point correction has been

executed. (See Chapter 5)

MAINTENANCE

The maintenance guidelines for normal pallet trucks apply to the chassis of the

mobile scale. The integrated scale will still function even though the chassis has

been damaged by overloading.

Main guidelines:

- Because the steering wheels are mounted in the front, pulling of the pallet truck is

preferred above pushing it.

- When the lifting mechanism is not used, the handle should be kept in the neutral

(middle) position. This prolongs the life-span of the sealings.

- The scale meets up to the protection class NEMA 4/IP65. This means that dust or

moisture (rain or water beam from all sides), will not influence the operation of the

electronics. However, high-pressure cleansing in combination with warm water or

chemical cleansers will lead to the entry of moisture and have a negative influence

on the operation of the system.

- To avoid damage to load cells and electronics only specialists may undertake any

welding.

- The bearings of the wheels (non-polyurethane) and the pivoting points of the

levelling bar of the loading wheels must be cleansed and greased regularly.

8

Page 9

3.2 TOUCH PANEL INDICATOR

Indicator Front

◄

the scale (including load) is stable

▬ the weight shown is negative

ZERO

◄

the weight shown is within the zero range

NET

◄

the display is showing the net weight

e1 ▼ displayed weight shown is in range 1

e2 ▼ displayed weight shown is in range 2

e3 ▼ displayed weight shown is in range 3

stp1

▼

Set-point 1 is activated

stp2

▼

Set-point 2 is activated

There are 3 display-modes: lbs, kg or the number of pieces.

Also the battery sign is integrated in the display in order to show a low battery status.

THE DISPLAY

By means of eight pointer bars the display shows:

9

Page 10

THE TOUCH PANEL

Key

Function level 1

(short key press)

Function level 2

(long key press)

Function level 3

(entry mode)

zero setting

code entry

enter

automatic tare

pre-set tare

decrease the value of

the digit flashing

print weight and add

to the total

check subtotal and

print total

increase the value of

the digit flashing

sampling a piece

weight

enter a piece weight

shift to the next digit

on the left

on/off switch

Change units mode

clear entry

Each key has 2 operational and one entry function

IMPORTANT

Operation of a key is not accepted unless the scale is stable (and the “load stable”

pointer lights up). This means that the indicator only executes commands with a

stable load.

WARNING

When the weighed load surpasses the pre-set maximum the display shows:

“ERR02”. In order to prevent damage to the indicator or load cells, the scale must be

unloaded immediately.

10

Page 11

ERROR MESSAGES

Displayed error

Meaning

Out of error mode

Err01

Load cell signal is unstable

Automatic

Err02

Overload on full scale

Automatic after

removing weight

Err03

Gross negative. This action is not allowed

Automatic

Err04

Out of zero range

Press any key

Err05

Sampling accuracy too low

Press any key

Err06

Input signal too high

Automatic after

correcting input

Err07

Input signal too low

Automatic after

correcting input

Err08

Calibration out of range (negative)

Automatic

Err09

Calibration out of range (signal too low)

Automatic

Err10

Calibration count 2nd(3rd) point lower than

count 1st(2nd) point

Automatic

Err14

Set-point value 2 < set-point value 1. This is

not allowed

Automatic

Err98

Calibration point must be higher than

previous one

Automatic

Err99

Action only allowed in start-up units

Automatic

11

Page 12

3.3 INDICATOR FUNCTIONS

GRADUATION

From 0 to 5000 lbs the weight is shown in 2 lb increments.

BEFORE WEIGHING: CHECK ZERO POINT

Before each weighing it is necessary to check whether the system is unloaded and

free. The indicator is fitted with an automatic zero correction. This means that small

deviations of the zero point will be corrected automatically. If the indicator does not

determine the zero point automatically, it must be done manually by pressing the >0<

key.

GROSS WEIGHING

After lifting a load, the display shows the gross value of the weighed load.

NET WEIGHING: AUTOMATIC TARE

The indicator offers the possibility to reset tare weights to zero automatically. This

way added or subtracted weights can be determined.

Lift load.

Press key T.

The indicator is set to zero.

The "NET" pointer shows that a tare weight is activated.

Place or remove the net load.

The display shows the net value of the weighed load.

When load is removed, a negative weight is displayed.

By pressing the T key again, the gross weight is displayed.

NET WEIGHING: MANUAL TARE ENTRY

A tare weight can be entered at any time, either in a loaded or unloaded situation.

Press the

seconds).

The display shows the current tare value.

The right digit is blinking.

Press ENTER () if the current tare value is correct.

Or

PT key until the display changes and the last digit is blinking (approx 3

12

Page 13

Press the

PT key until the display changes and the last digit is blinking (approx 3

seconds).

The display shows the current tare value.

The right digit is blinking.

Press the

key to go up a value or press the key to go down a value until the

required value is reached for that place.

Press to change to the next digit.

Repeat this procedure until the required tare value is displayed.

Press ENTER () to activate the tare weight.

The tare weight is activated.

The “NET” pointer lights up.

When the system is loaded, the net value appears in the display

When the system is unloaded, the read-out displays the negative value of the

given tare.

The entered value remains active until a new tare weight is entered (display

shows the new net weight).

Press the T key to return to gross weighing mode.

PIECE COUNT: SAMPLING

If an unknown piece weight is to be determined you may do this by sampling a

certain number of pieces. The number of pieces taken from or placed on the scale

determines the accuracy of the sampling. The total weight of the pieces taken from or

placed on the scale for the sampling should be no less than 9-10 lb. The greater the

weight difference, the greater accuracy. The standard sampling amount is 10 pieces,

but this number can be increased up to 95 pieces. (wordy)

Press the key.

The display shows “add10”. The “lb” pointer changes to “pcs”.

Take or place 10 pieces from/on the scale and press the ENTER () key.

The sampling is done and the display will show the total number of pieces on

the scale.

Or

Press the key or the key to change the number of pieces to add.

The display will show the new value to add. (for example “add50”)

Take or place 50 pieces from/on the scale and press the ENTER () key.

The sampling is done and the display will show the total number of pieces on

the scale.

To return to the normal weighing mode press the key for 3 seconds.

PIECE COUNT: ENTER A PIECE WEIGHT

Press the key for 3 seconds.

The last used piece weight will be displayed with the right digit flashing.

To accept the old value press ENTER ().

The display shows the number of pieces currently on the scale.

13

Page 14

Or

Change the piece weight value by using the or and keys.

The display shows the new piece weight.

To accept the new value press ENTER ().

The display shows the number of pieces currently on the scale.

To return to the normal weigh mode press the key.

SUMMING

The indicator offers the possibility to add weighings and show the total weight. When

a tare weight is active, the net weight is added automatically.

Load the system with the weight that should be added.

Press the key to add the weighed load to the total weight.

The display shows the message “ADDED” and after a short delay returns to

the weighing mode.

Note that no weight can be recorded twice. The system needs to be returned to the

net zero-range before another weight can be added up.

To check the subtotal can be checked by pressing the key for 3 seconds.

The display shows the net total weight and the number of weightings totaled

so far repeatedly for 3 seconds.

If the key is pressed during this period, the total is printed out (if option

is installed) and reset to 0.

If the “CE” key is pressed during this period, the total is reset but not

printed out.

If no key is pressed during this period, the subtotal stays in memory and

the system returns to the weighing mode after 60 seconds.

CHANGE UNITS

The system is set to start up in „lbs‟ or in „kg‟. However you may, at any time in the

weighing mode, change to the second unit (lbkg or kglb).

Press the key for 3 seconds.

❏ The display will show the current weight in the new units for 5 seconds and

then automatically change back to the start up units.

Note: The same key is used to change from the piece counting mode back to the

weighing mode.

14

Page 15

3.4 PRINTER (Option)

The RAVAS 310 comes equipped with a thermal printer. Obtained and entered

weighing data can be printed.

THE PRINT OUT

In the printout a gross weight is indicated with the letters “B/G” and a net weight with

the letter “N”. A manually entered tare weight will also be printed and is indicated with

the letters “PT”. The total weight is shown with the letters “TOT”.

Standard print-out Standard print-out

without code with code

B/G 1234.5 lb. CODE 12345

T 34.5 lb. B/G 1234.5 lb.

N 1200.0 lb. T 34.5 lb.

N 1200.0 lb.

Nr. 1

10/07/03 17:45 Nr. 1

10/07/03 17:45

Piece count print-out Piece count print-out

without code with code

B/G 1234.5 lb. CODE 12345

T 34.5 lb. B/G 1234.5 lb.

N 1200.0 lb. T 34.5 lb.

N 1200.0 lb.

PcWt 1.234 lb.

Qty 12345 PCs PcWt 1.234 lb.

Qty 12345 PCs

Nr. 1

10/07/03 17:45 Nr. 1

10/07/03 17:45

Total print-out (always without code)

Tot. B/G 1234.5 lb.

Tot. T 34.5 lb.

Tot. N 1200.0 lb.

Tot. Nr. 999

10/07/03 17:45

15

Page 16

CHANGING THE THERMAL PAPER ROLL

Open the printer cover by pressing down

the 2 levers and pulling the cover towards

you.

Remove the existing paper roll. Position

the new paper roll, making sure it unrolls

in the correct direction, as shown above.

Unroll the paper slightly. Re-close the

cover, holding the edge of the paper.

The printer is now ready for use.

16

Page 17

CHANGING THE TIME AND DATE ON THE PRINT-OUT

The date and time can be printed together with the weight information.

Press the key for 6 seconds.

The display will show “ho_00” or the previous hour time setting, with the right

digit flashing.

To accept the old value press ENTER ().

Or

Press the key to go up a value or press the key to go down a value until the

required value is reached.

Press to change to the next digit and use the or key to change the value until

the required value is reached.

To accept the new value press ENTER ().

The display will show “m_00” or the previous minute time setting, with the right

digit flashing.

Repeat the above procedure to accept or change the minute setting.

The display will show “dA_00” or the previous date of the month setting, with

the right digit flashing.

Repeat the above procedure to accept or change the date of the month setting.

The display will show “m_00” or the previous month setting, with the right digit

flashing.

Repeat the above procedure to accept or change the month setting.

The display will show “YE_00” or the previous year setting, with the right digit

flashing.

Repeat the above procedure to accept or change the year setting.

The indicator will return to normal weighing mode.

17

Page 18

No power

Change

batteries

Replace battery pack

Use a fully charged battery pack. (see page 5)

12Vdc on the

board

Check the board for

burned components

Picture of component most likely to blow when

batteries have been entered the wrong way.

Accuracy

No

repeatability

Check if there is a

mechanical problem.

Load left and right fork with for example body weight

and see if weight changes when you are in different

positions on the scale.

There should not be a difference larger than 2 lb.

If there is a bigger difference then 5 lb you have a

load cell or a mechanical problem.

To make sure it is a mechanical problem, repeat test

with a heavy load on the scale, Lift a pallet with 2000

or 3000 lb.

Reset Indicator for 0 lb using the tare function.

Load corners with body weight by standing on or on

the sides of the pallet. If readings change more than 5

lb you have a mechanical problem.

The push rods in the forks may not interfere with the

load cells. Take of the fork shoe by unscrewing the

nuts on the bottom side of the pallet truck.

Push the pushrods sideways towards the load cells to

see if they come in contact with the load cells: see if

they can interfere with the load cells.

With the forks lifted half way up, the brackets for the

loading wheels may touch the fork shoe. By taking off

the fork shoe, Scratches will show if it does and where

it does.

Check if bolts are loose.

Check the load cells. If

one is broken or gives

more or less signal

than the others, the

scale will give different

reading depending

how it is loaded.

To be sure that it is not a mechanical problem, load

the load cells directly. Take off the fork cover. Try to

apply weight 25 to 50 kg / lb, direct onto each load

cell. If the indicator shows the same reading, the load

cells are OK.

Tap with a hammer onto the load cells. Do not be

afraid to break it. Repeat the test for each load cell.

Measure resistance with ohm meter between wires

and load cell body. Do this with the other load cells

disconnected from indicator. No resistance is allowed.

The load cells should have +/- 350 ohm between the

signal wires: yellow and green, and excitation wires,

black and red.

Check cables

Bad connections will cause changes when moving the

scale.

Bend and move the cable briskly especially where the

cable is moving continuously while lifting. While doing

so, look at the display to see if it reacts to the

movements.

4 TROUBLE SHOOTING

18

Page 19

The potentiometers

with which we

calibrate the output of

the load cells, are

mechanical parts

therefore, higher risk

components

Move the board and but pressure with fingers on the

potentiometers while looking at the display to see if it

reacts. Do not touch the contact itself.

Not linear

Check if it is load cells

or indicator

Load cells or indicator are very rarely the cause of this

problem. Easiest way to check is by changing the

indicator temporarily. If problem is not solved when

changing the indicator, the problem is the load cell,

cable or mechanics

Check cable

Very rarely the cause. Maybe in a lift truck.

Instability

With no load it

is most of the

time humidity,

bad connection

or component r

bad shield.

Check for humidity

Check for water marks on the indicator board or load

cell connections (potentiometers).

Check the indicator.

Sometimes the indicator will show a weight when the

load cells are disconnected. If you do this and the

indicator becomes more stable, it is most likely

elsewhere in the system.

Check visually for traces of oxidation. If found, heating

the solder contacts can solve the problem.

Check cables. In

warehouse and lift

truck the cable is

working all the time

when following the

lifting movement. It

may be worn or

damaged. Changing

temperatures and

chemicals have an

effect on the lifetime of

a cable.

Bad connections will cause changes when moving the

scale.

Bend and move the cable briskly especially where the

cable is moving continuously when lifting. While doing

so, look at the display to see if it reacts to the

movements.

The potentiometers

with which we

calibrate the output of

the load cells are

mechanical parts and

are sensitive to

humidity, shocks and

vibration.

Move the board and but pressure with fingers on the

potentiometers while looking at the display to see if it

reacts. Do not touch the contact itself.

Check the load cells.

If connected independently to the indicator, it can be

checked which one is unstable and which one is not.

With load

Check mechanics.

Function

error

No reaction

when pushing

keys

Check the touch panel

Test can be done by making short cut on connection

of the touch panel to simulate a key being pressed.

Check for wear of broken contacts in the flat cable

going to the indicator board

Lock up

Take out the battery pack and replace to see if it

starts up afterwards.

19

Page 20

Not summing

Operator error

.

Load is not stable.

Scale needs to be unloaded before accepting new

print.

System will not print weights that are smaller than the

graduation.

HELP

messages

HELP 2

Scale is overloaded

Take load from scale. If there is no load do the same

checks as you do with HELP 3 and 7.

Help 3 or 7

Load cell signal too

high or too low.

Check cables for damage. Move the cable while

looking at display to see if indicator reacts.

Measure load cells to see if they are fine.

Check the excitation signal of the indicator

Help 4

Out of zero range

Zero calibration needed.

20

Page 21

5 SPARE PARTS

21

Page 22

SPARE PARTS LIST

Weighing Hand Pallet Truck RAVAS 310

Nr

Article Number

Description

Quantity

1

899193001.3

set fork shoes

1

2

895200708

chassis

1

3

891112256 or

load cell

4

891112255

4

899172200

mounting plate load cell 6 mm

4

5

894141903

load cell mounting bolt (M12 x 35)

8

6

894141922

forkshoe mounting bolt (M12 x 60)

4

7

894142331

forkshoe mounting nut self tightening (M12)

4

8

895201705

handle (black)

1

9

895200780

pump (black)

1

10

895201799

pump repair set

1

11

895201701

steering wheel (polyurethane)

2

12

895201702

loading wheel (polyurethane tandem)

2

13

894141664

indicator support mounting bolt (M8 x 20)

3

30

892131291

touch panel with support plate

1

31

892142545.2

LCD display

1

32

892142545

indicator print board

1

33

892203003

RS232 board indicator

1

34

892203001.1

indicator adaptor bracket

1

35

892203002

indicator mounting support

1

36

894142400

butterfly nut

2

37

899193027.03

steel housing indicator

1

38

893142060

level switch 2° (approved version)

1

39

894207008

enclosure bolt (M5 x 8)

4

40

894203000

screw (KB40 x 8)

6

41

893203004

battery fixation clip

1

42

898202000

charger 230V - 12 V

1

43

893161500

load cell calibration board

1

44

893201006

plastic housing battery module

1

45

983209002

battery connection pins

2

46

893201003

fuse cover

1

47

893143606

fuse 5 x 20mm 2A

1

48

898201000

battery module 12V - 1.2Ah with handle

1

49

892132601

cable for thermal printer

1

50

892132600

thermal printer

1

51

892132604

paper roll for thermal printer

1

52

899193027.33

cover plate

1

22

Page 23

6 CALIBRATION

CALIBRATION INSTRUCTIONS INDICATOR 310

The calibration mode can only be reached from the standard weighing mode. You cannot get into the

calibration mode when you are in piece count mode.

DEFINING ZERO

Unload the system.

Switch the system on.

To enter the zero calibration mode press the >0< key for 10 seconds.

After 3 seconds the display will show the last entered code.

After 7 seconds the display will go into the zero calibration mode and start adjusting.

The display will show “Adj08” and run down until “Adj00”. The adjustment has been

completed.

The indicator shows the percentage of the total capacity that was adjusted. For a normal scale

this would be between 5 and 8 percent. A larger percentage could mean one or more load

cells are broken. A lower percentage could mean the fork cover is not mounted.

The zero point has been defined, the system automatically returns to the standard weighing

mode.

SINGLE POINT CALIBRATION

Press the T key for about 10 seconds.

After 3 seconds the display will show the last entered pre-set tare value.

After 7 seconds the display will go into calibration mode.

The display will show the first calibration point with the pointer “e1” flashing.

Using the and keys you can see the three earlier programmed values on the display.

The pointer will move through e1-3. “e1” is the first calibration point, “e2” the second and “e3”

the third.

When calibrating only one point the second and third values should be set to zero.

Use the and keys to move to the second calibration point.

The display will show the pointer “e2” flashing.

Press the key.

The display will show the previously entered calibration value, with the last segment flashing.

Use the , and keys to return all the segments to zero.

Press the key.

Use the and keys to move to the third calibration point.

Repeat the above to set all the segments to zero.

Press the key.

Calibrating the single point

Use the and keys to return to the first point.

The indicator shows the value of the first calibration point, with the “e1”pointer flashing.

Load the scale with a known weight.

Press the key to enter this weight onto the indicator, the first segment starts flashing.

Use the and keys to change all the segments until the proper weight has been entered.

Press the key to return to calibration mode. The “e1” pointer will start flashing.

Press the key for 3 seconds to confirm the entered weight.

This calibration number counts down from Adj 08 to Adj 00, the first calibration point has now

been set.

Leave the calibration mode by pressing the or key until AP XX appears. This number indicates

the calibration sensitivity percentage, eg AP 07.

Press the key.

The display now shows the value of the gravitation constant. Use the , and keys to

correct this for your position.

Press the key to return to the standard weighing mode.

23

Page 24

MULTI-POINT CALIBRATION

Push the T key for about 10 seconds.

After 3 seconds the display will show the last entered pre-set tare value.

After 7 seconds the display will go into the calibration mode.

The display will show the first calibration point with the pointer “e1” flashing.

Using the and keys you can see the three earlier programmed values on the display. The

pointer will move through e1-3. “e1” is the first calibration point, “e2” the second and “e3” the third.

Use the and keys to return to the first point.

The indicator shows the value of the first calibration point, with the “e1” pointer flashing.

Load the weighing system with a known weight.

Press the key to enter this weight onto the indicator.

The first segment will start flashing.

Use the , and keys to change all segments until the proper weight has been entered.

Press the key to return to calibration mode.

The “e1” pointer will start flashing.

Press the key for 3 to confirm the entered weight.

This calibration number counts down from Adj 08 to Adj 00, the first calibration point has now

been set.

Move to the second calibration point.

The display will show the pointer “e2” flashing.

Repeat the procedure for a second known weight. Be aware that the value of this weight has to be

higher than that of the first weight. If not, the display will show ERR98 and return to the entry

mode for the calibration point.

Repeat the procedure for the third known weight. Leave calibration mode by pressing the or

key until AP XX appears.

This number indicates the calibration sensitivity percentage, eg AP 07.

Press the key.

The display now shows the value of the gravitation constant. Use the , and keys to

correct this for your position.

Press the key to return to the standard weighing mode.

24

Page 25

7 PARAMETER SETTINGS

ATTENTION: Before entering the setup mode make sure that the battery

supply is sufficient. A low battery may cause the micro-processor to block. If

this happens remove the empty battery and replace it with a fully charged

battery. You should be able to start the indicator in the normal way.

To enter the setup mode, turn on the indicator and keep the key pressed for 20

seconds. You will go through the normal start-up routine (all segments on; software

version; calibration number and weight) and end up in the “P_01” with the right digit

flashing.

At this stage you may proceed as follows:

To enter parameter 01 press the key quickly.

o The display will show the setting for this parameter at this moment.

You may change the setting by using the or the key.

OR

You can accept the setting by pressing .

OR

To move to the next parameter you press the key.

OR

To move to the previous parameter you press the key.

To leave the set-up mode you do the following:

With P_XX in the display press the key quickly.

o The display will show “P_00”

Press the key again quickly.

o If a change was made to the settings the display will show “SET__”

briefly and then return to the normal weighing mode. The calibration

number will be increased by every time a change was made in the set

up and also after a new calibration.

o If no change was made, the display will return into the normal weighing

mode.

In the following pages the different parameters are explained and the standard

settings are given. Parameters that are not used yet will not be accessible or

displayed with underscores.

25

Page 26

PARAMETERS:

Parameter

Function

Settings

Default

US

01

Start-up unit (and print units)

1=kg / 2=lb

2

02

Smallest graduation step for

multi-range

0.1/0.2/0.5…………10/20/50

0.5

03

Largest graduation step for

multi-range

0.1/0.2/0.5 ……….. 10/20/50

2

04

Number of graduations for

every range

0000-9900 divisions

1000

05

Weighing capacity system (full

scale)

0000-99999 units

5000

06

Motion tolerance for stable

0-32

1

off 0.5 grad./sec

1 grad./sec 2 grad./sec

4 grad./sec 8 grad./sec

16 grad./sec 32 grad./sec

07

Filter size

0-12

8

0=off

1=light filtering, 12=heavy filtering

08

Auto zero range

0=off 0.5 division

0.5

1=division 3 divisions

09

Zero range positive (+)

0-100% (approved 2%) of span

10

10

Zero range negative (-)

0-100% (approved 2%) of span

10

11

Test Function

BASIC ADC Counts

bASIC

10x Resolution

12-13

Not used

14

Start-up number to add in

sampling mode

1-2-5-10-20-50-95

10

15

Units switch mode active

Yes / No

Yes

16

Setpoint function

0-4

0

0=not used

1=overload gross (only 1 setpoint used)

2=overload gross (only 1 setpoint used)

3=Printer (without date/time/switched supply)

4=not used

17

Application

Basic (standard) or Peakhold (Phold)

bASIC

18

Gravity value working area

9.750-9.850

9.797

19

Key function

Remote - Local - Both

Local

20

Baudrate comport 1

600-1200-2400-4800-9600-19200

9600

21

Databits comport 1

7-8 8 22

Parity comport 1

none/odd/even

none

23

Stopbits comport 1

1-2

1

24 Not used

26

Page 27

25

Dataprotocol comport 1

0-4

0

0=PC bi-directional command structure

1=not used

2=Remote display continuously

3=Printer (without date/time/switched supply)

4=not used

26

Number of linefeeds comport

1

0-9 0 27-29

Not used

30

Baudrate comport 2

600-1200-2400-4800-9600-19200

9600

31

Databits comport 2

7-8 8 32

Parity comport 2

none/odd/even

none

33

Stopbits comport 2

1-2 1 34

Not used

35

Dataprotocol comport 2

0-4 3 0=PC bi-directional command structure

1=not used

2=Remote display continuously

3=Printer (without date/time/switched supply)

4=not used

36

Number of linefeeds comport

2

0-9 5 37

Printout form

0-1

0

0=standard 1=total

38

Printout format time/date

European format dd/mm/yy hh:mm

USA

USA format mm/dd/yy hh:mm

39

Not used

40

Level switch

0=not used 1=N.C. 2=N.O.

0

41

Delay trigger time level switch

0-10 sec.

3

42

Not used

43-49

Not used

50

Battery used

12VDC 6 VDC

12v

51

Low Bat switch off time

0-99 mins

2

0=not switched off

52

Auto shut off time if not used

0-99 mins

15

0= always on

53

Not used

54

Peak hold time

0-7 4 55

threshold value

9999kg/lb

200

56-89

Not used

90

Reset to default parameter

If parameter 01 was on 1 it will default to the

setting without altering

EU settings. If P_01 =2 the US settings will be

calibration parameters

defaulted. New delivered boards will have

EU settings.

27

Page 28

91

Reset to default parameter

If parameter 01 was on 1 it will default to the

settings including calibration

EU settings. If P_01 =2 the US settings will be

parameters

defaulted. New delivered boards will have

EU settings.

92-99

Not used

RAVAS USA, LLC

975 Deerfield Parkway

Buffalo Grove, IL, USA 60089

(224) 676-2238

www.ravasusa.com

Rev. 05.10.10

28

Loading...

Loading...