Page 1

21

6.7 Error messages

Display

Meaning

Out of error mode

Err01

Load cell signal is unstable

Automatic

Err02

Overload on full scale

Automatic after removing weight

Err03

Gross negative. This action is not allowed

Automatic

Err04

Out of zero range

Press any key

Err05

Sampling accuracy too low

Press any key

Err06

Input signal too high

Automatic after correcting input

Err08

Calibration out of range (negative)

Automatic

Err09

Calibration out of range (signal too low)

Automatic

Err10

Calibration count 2nd(3rd) point lower than count

1st(2nd) point

Automatic

Err14

Setpoint value 2 < setpoint value 1. This is not allowed

Automatic

Err98

Calibration point must be higher than previous one

Automatic

Err99

ErrF1

ErrF2

---L - _

ErrCS

Action only allowed in start-up units

Problem with fork 1 (no communication)

Problem with fork 2 (no communication)

Loadcell signal negative

Forks are out of level (only legal-for-trade version)

Problem with correction sensor

Automatic

Restart indicator. Restart forks & indicator

Restart indicator. Restart forks & indicator

Lift up the forks from the ground

Put the forks into horizontal position

Contact the RAVAS Service department

Display

Meaning

BltF1

BltF2

Successful Bluetooth link with fork 1

Successful Bluetooth link with fork 2

No error

No error

ERROR MESSAGES

DISPLAY MESSAGES

OWNERS MANUAL – iForks

Page 2

22

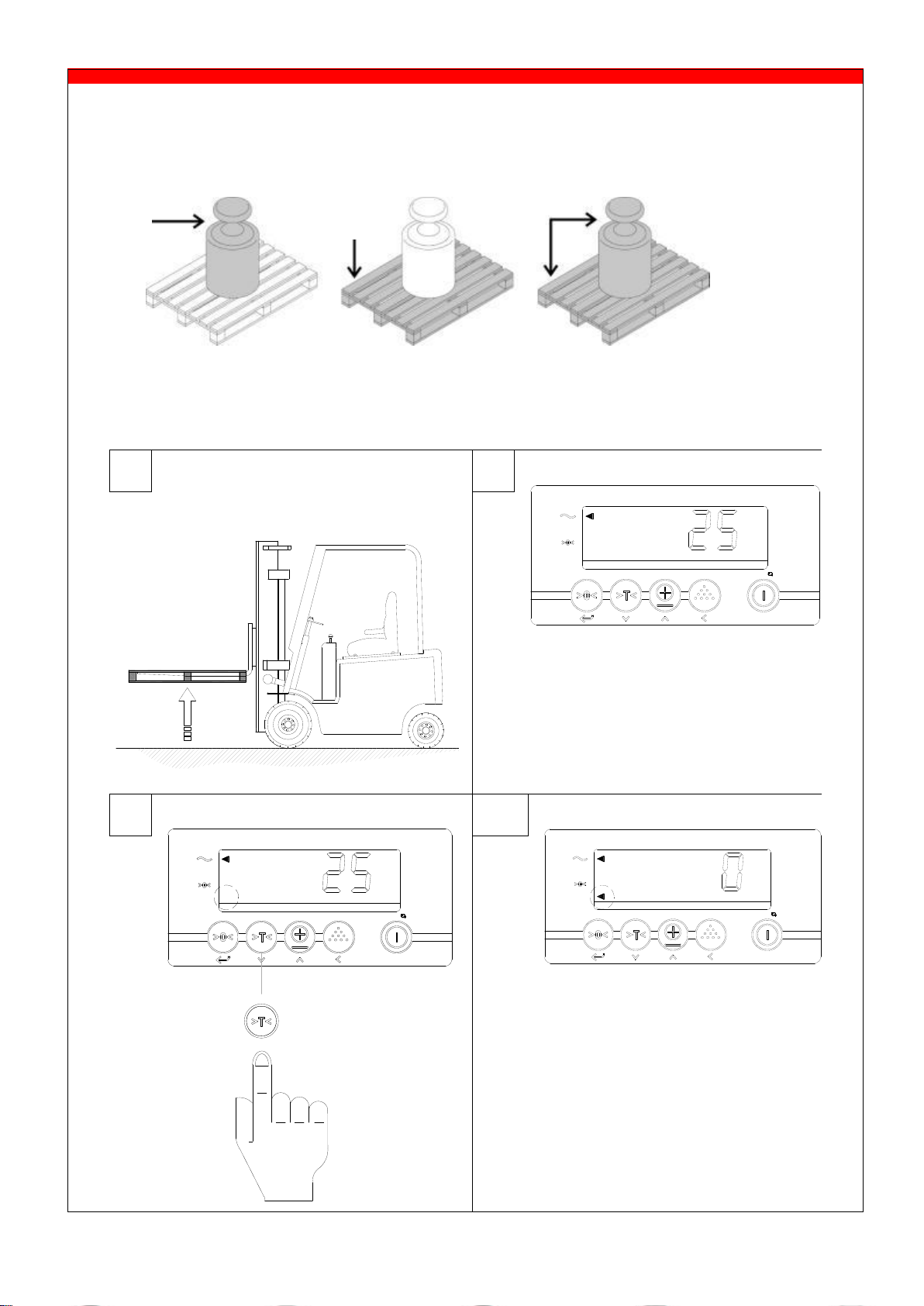

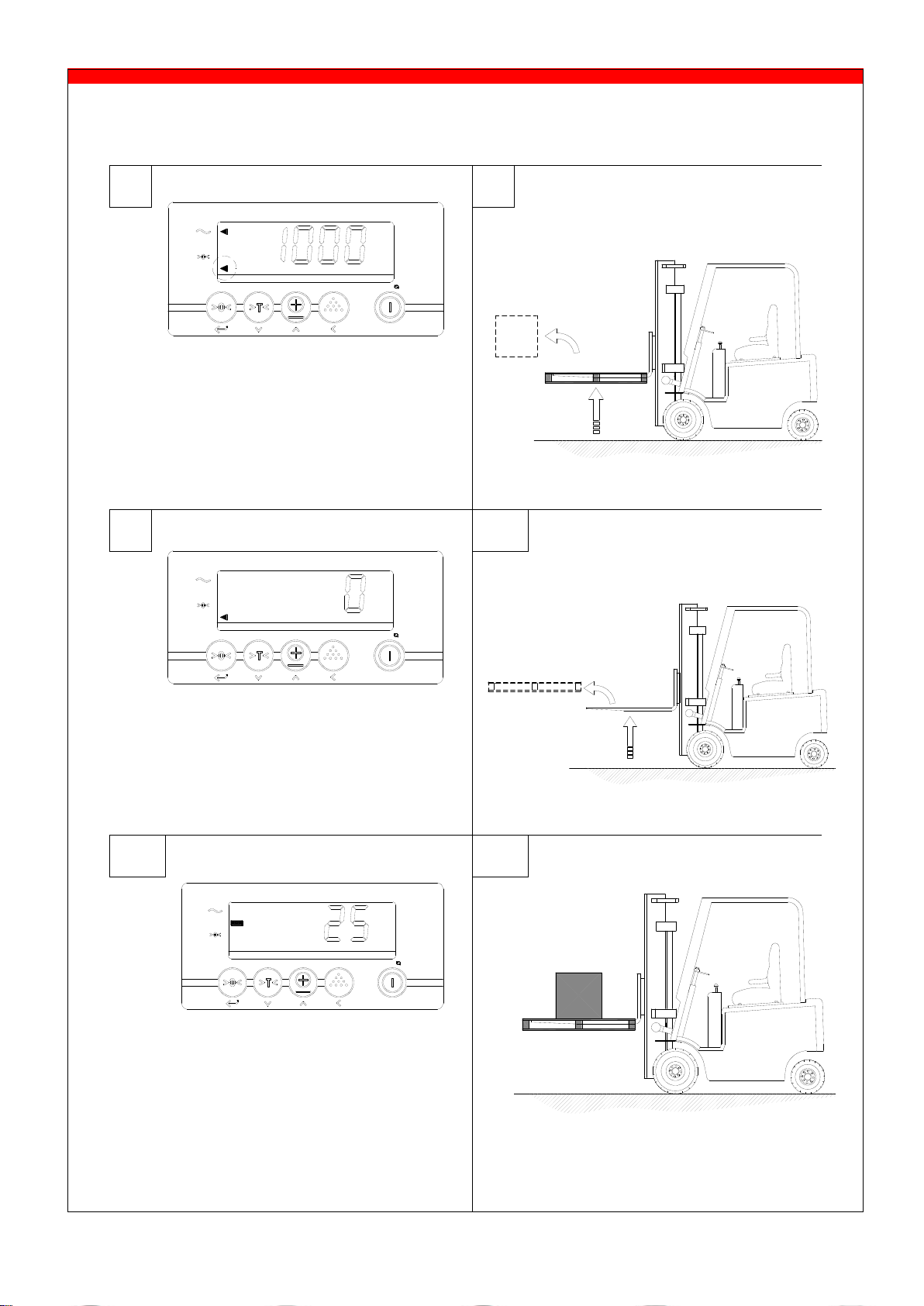

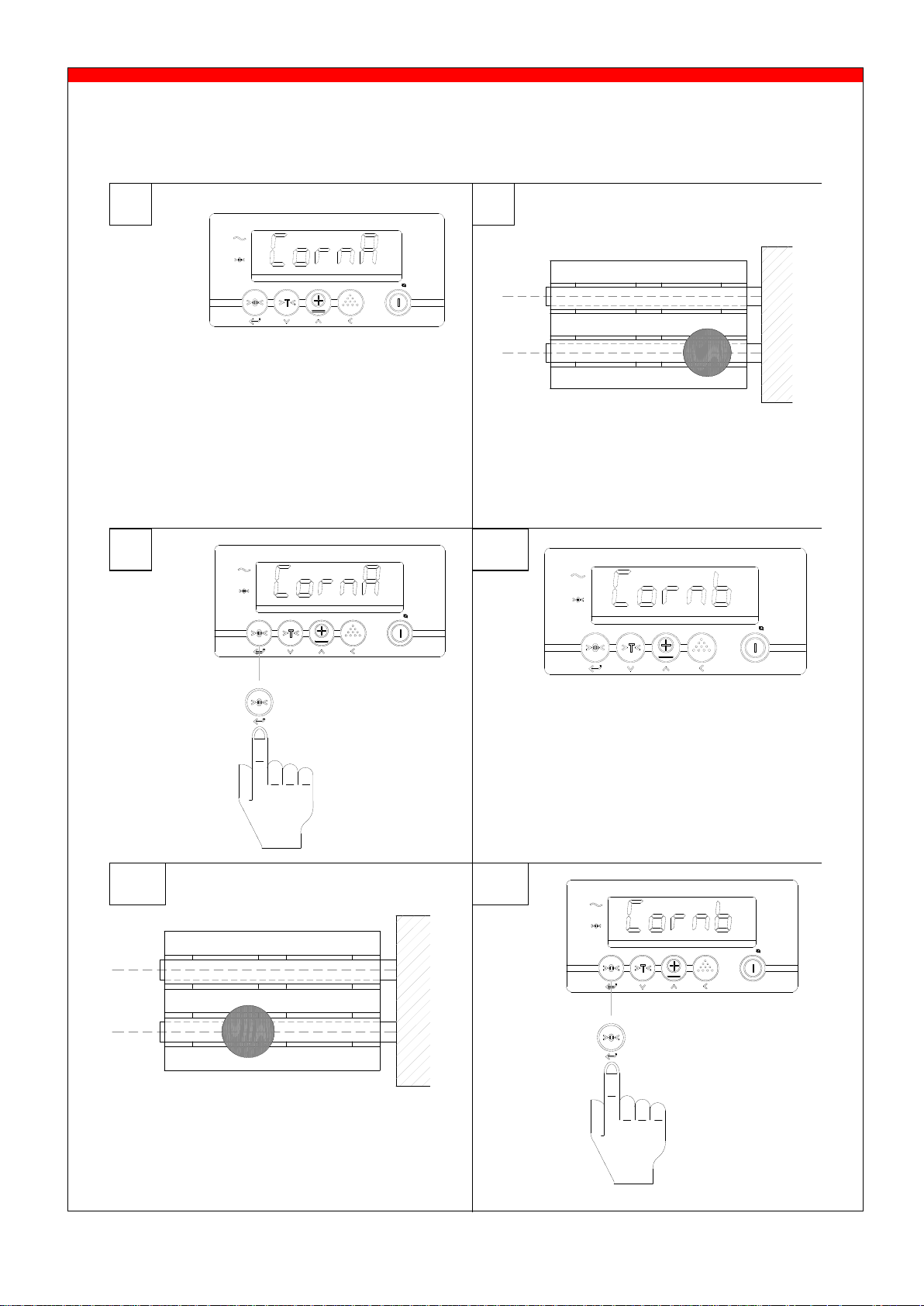

6.8 Net / Tare / Gross weight

2 1 3

4

The indicator is set to zero.

The “NET” pointer shows that

the tare weight is activated

1 2 3

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

EXPLANATION: Net(1) + Tare(2) = Gross(3)

6.8.1 Net weighing: automatic tare

OWNERS MANUAL – iForks

Page 3

23

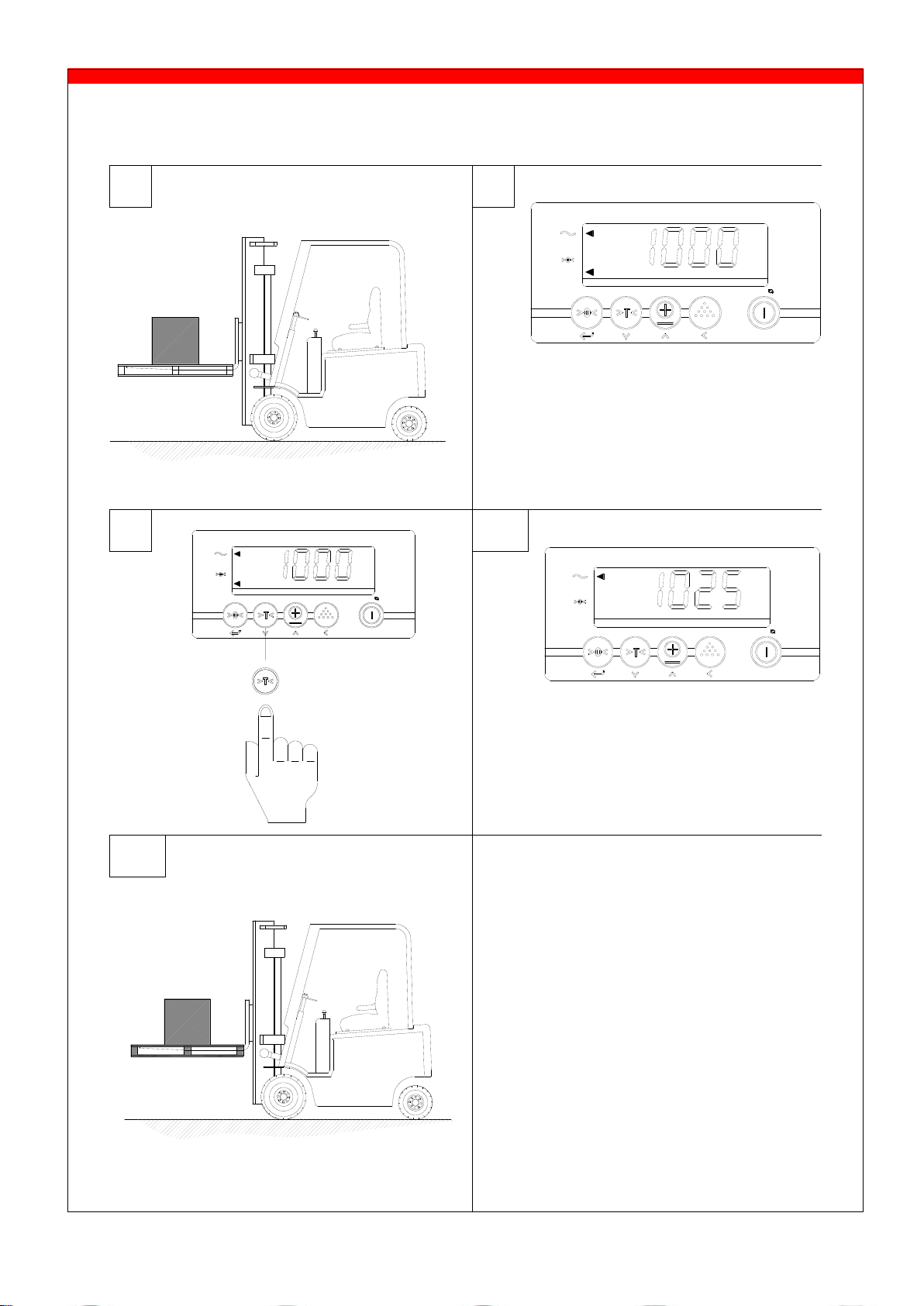

5 7 8

9

The display shows the net value

of the weighed load.

The gross weight is displayed

again.

1000

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

6

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

1000

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL

PCS KG/LB

CLR

OWNERS MANUAL – iForks

Page 4

24

3 sec.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL

PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

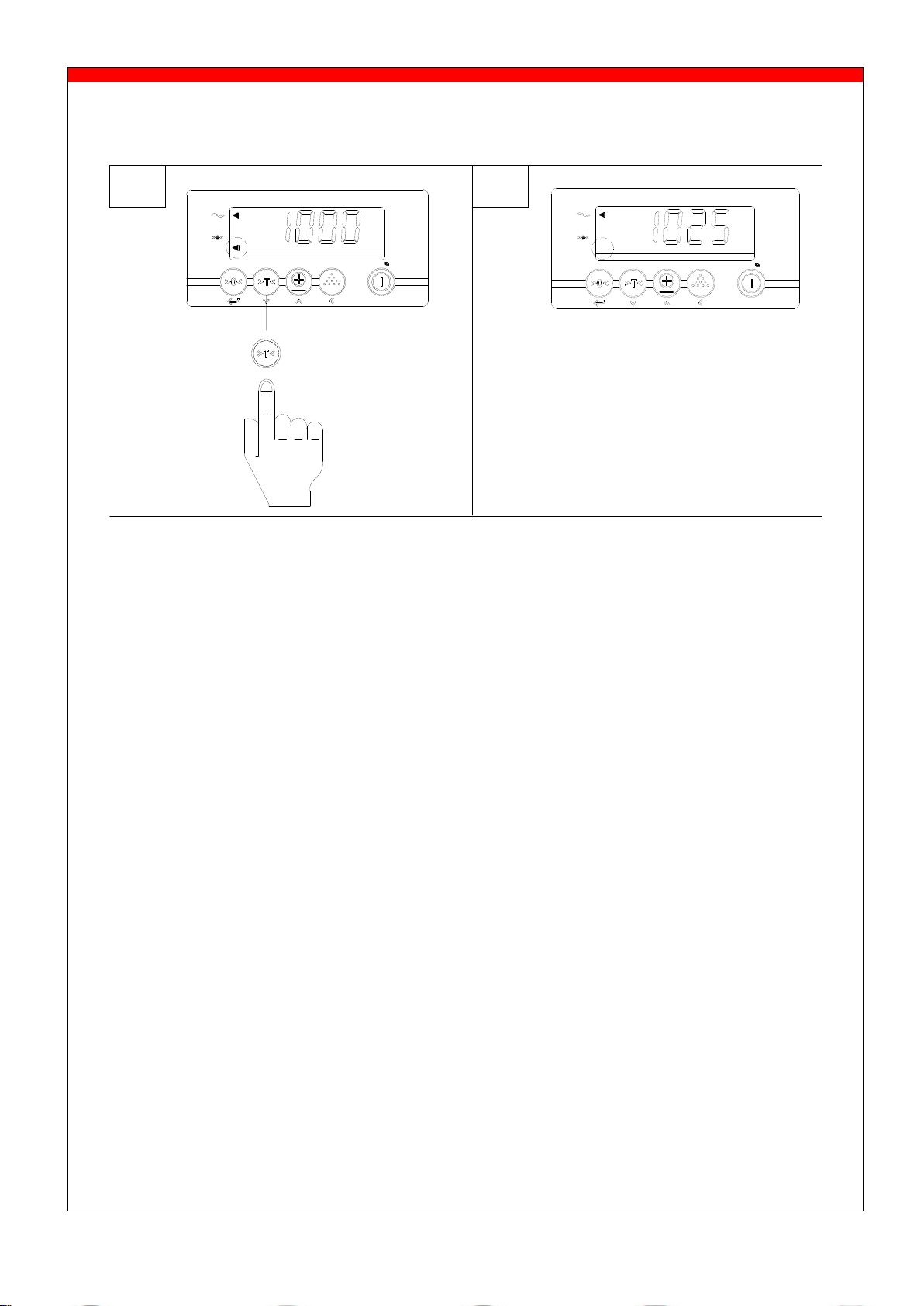

6.8.2 Net weighing: manual tare (PT)

2 1 6 3 4

5

Press the

PT key for 3

sec.

Press the up

or down key

until the

desired

value is

reached.

5x

Press the up

or down key

until the

desired

value is

reached.

1x

1000

25

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

Press ENTER

to activate the

tare weight

2x

OWNERS MANUAL – iForks

Page 5

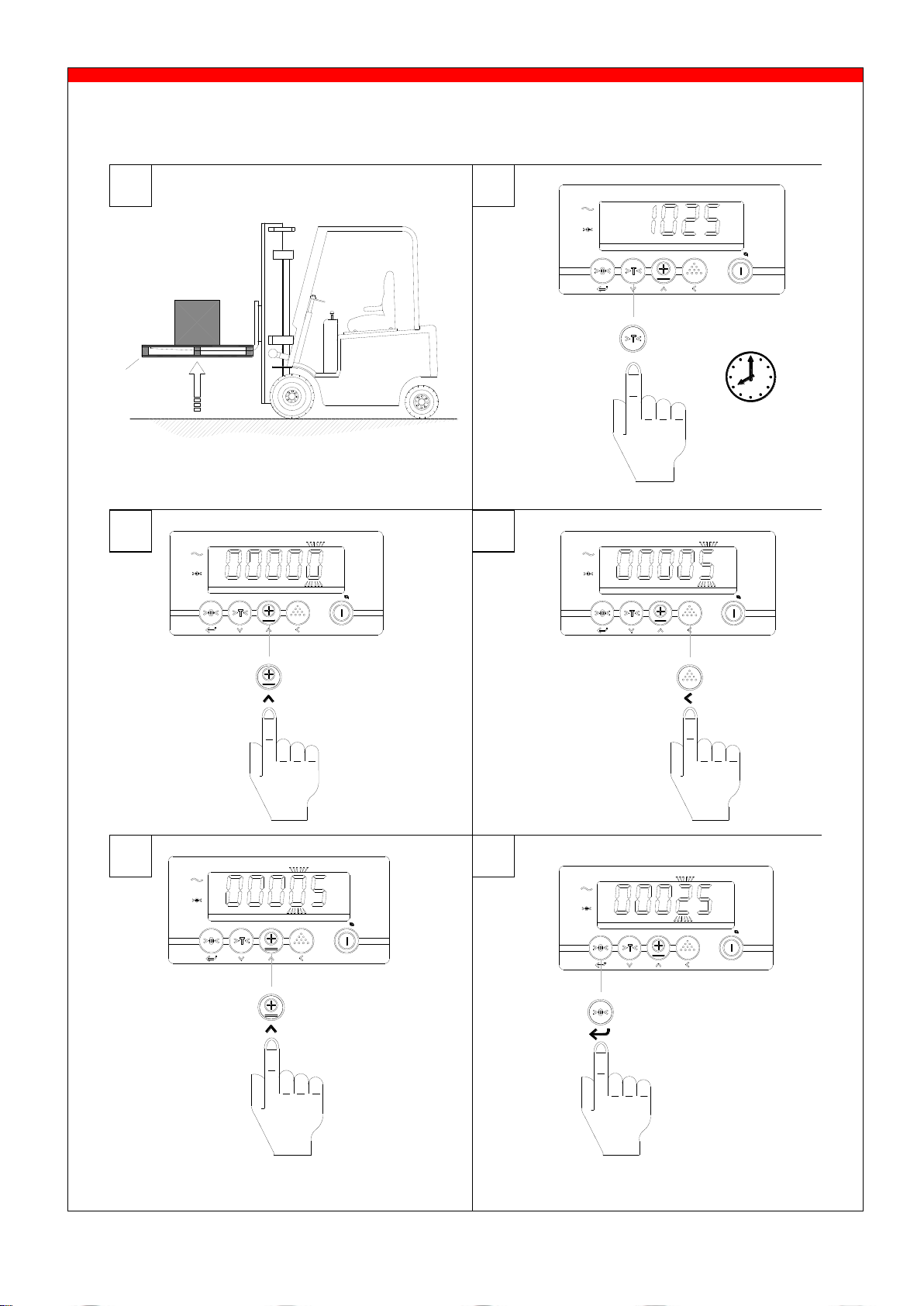

25

8 7 12 9 10

11

The “NET”pointer lights up

When the iForks are

completely unloaded, the

tare value is displayed

negatively.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

1000

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

1000

OWNERS MANUAL – iForks

Page 6

26

14

13

The gross weight is displayed

again.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL

PCS KG/LB

CLR

OWNERS MANUAL – iForks

Page 7

27

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

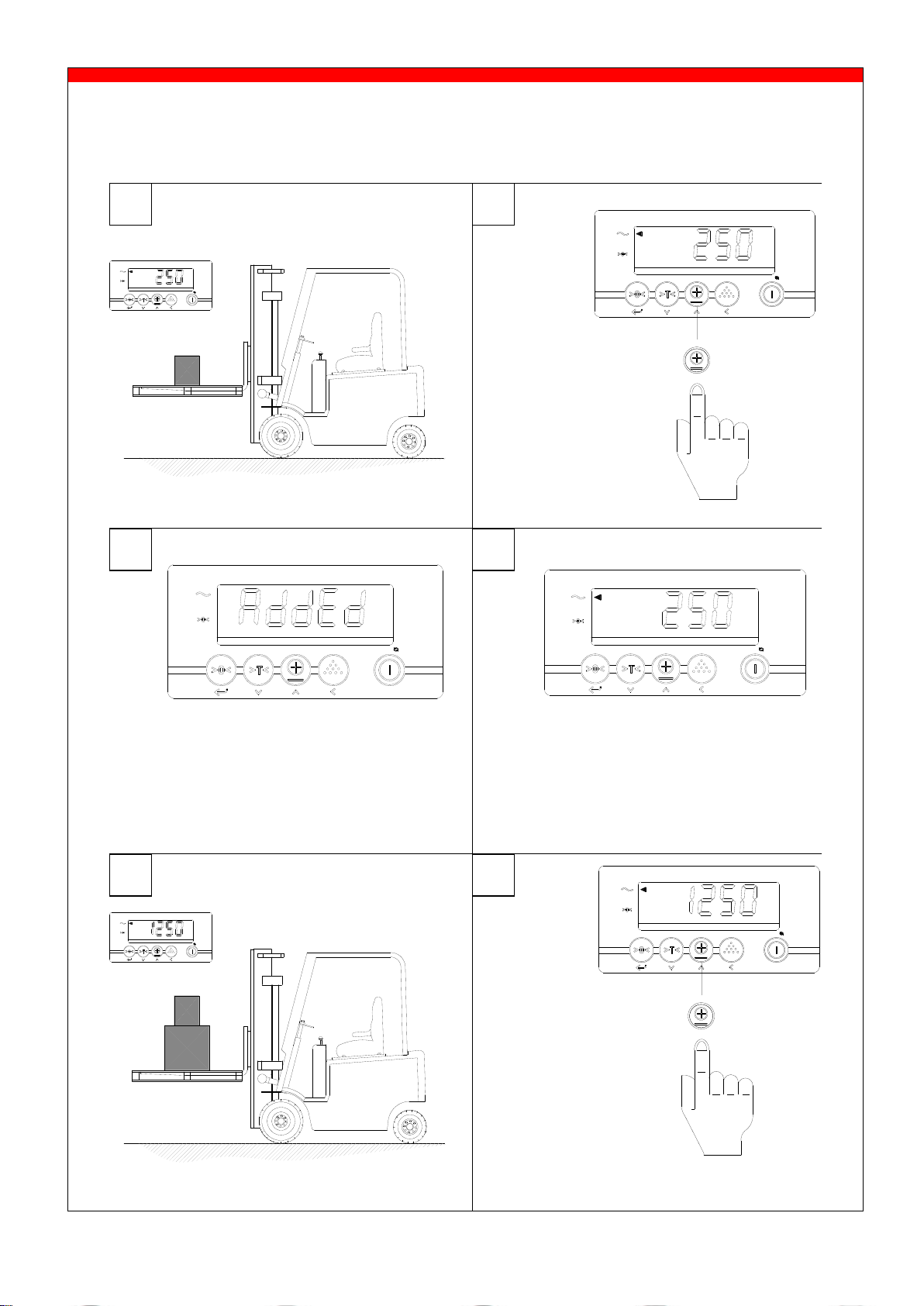

6.9 Adding & reset

Press the TOTAL key

to add the weight load

to the total weight.

2 1 6 3 4

5

The display returns to the

weighing mode automatically.

If a printer is

installed, a printout

will be made. The

gross, net and tare

weights are printed.

250

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

250

1000

e1 e2 e3 F1 F2

NET

ID CODEPTTOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODEPTTOTAL PCS KG/LB

CLR

Press the TOTAL

key to add the

weight load to the

total weight.

If a printer is

installed, a printout

will be made. The

gross, net and tare

weights are printed.

OWNERS MANUAL – iForks

Page 8

28

3 sec.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

3 sec.

CLR

8 7 9

The subtotal

can be checked

by pressing the

TOTAL key for

3 sec.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

TOTAL

KG/LB

CLR

= RESET TOTAL & PRINT

= RESET TOTAL

OWNERS MANUAL – iForks

Page 9

29

6.10 KG- LB switch

2

1

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

kg

KG/LB

5 sec.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

lb

OWNERS MANUAL – iForks

Page 10

30

6.11 User settings

2 1 3

CLR

3 sec.

EXIT without SAVING

EXIT & SAVE

Back to

weigh mode

Back to

weigh mode

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

10 sec.

??

The user menu

can be entered

by pressing the

TOTAL key for

10 sec.

These user settings can be changed if

desired. See next pages.

OWNERS MANUAL – iForks

Page 11

OWNERS MANUAL – iForks

31

Set the auto shut-off time indicator (delay time in minutes)

Set backlight (intensity in %)

0 min = indicator always on

0 % = backlight off

Page 12

OWNERS MANUAL – iForks

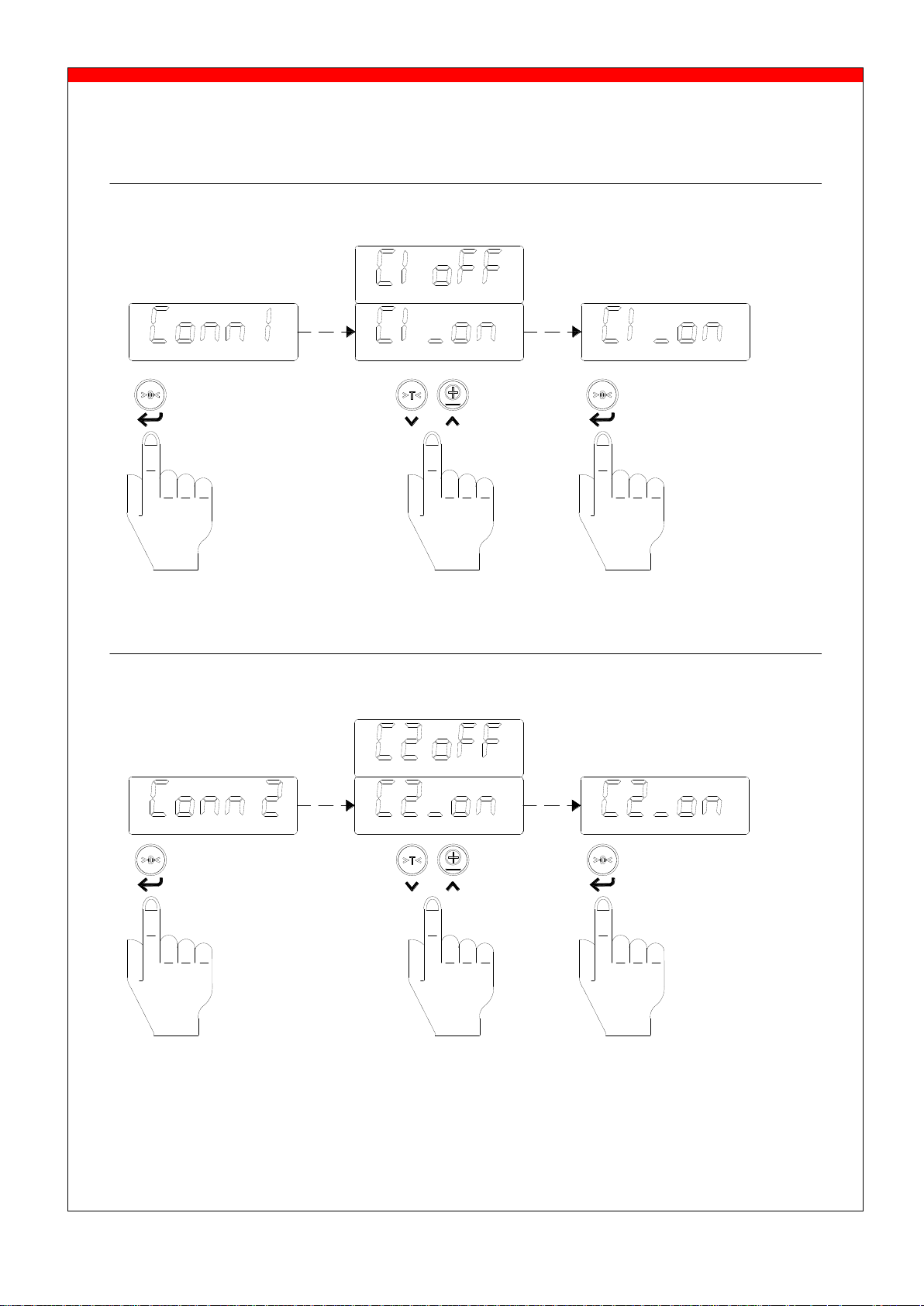

32

(De-) activate Com Port 2

(De-) activate Com Port 1

It is not possible to de-activate Com Port 1 for iForks

Page 13

33

7. Calibration

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

2 sec.

????

2 1 6 3 4

5

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

Start up the indicator.

Press the on/off key.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

Put an empty pallet on

the iForks.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

10 sec.

??

7.1 Corner calibration

OWNERS MANUAL – iForks

Page 14

34

8 7 12 9 10

11

B A

C

D

Put load M (100–500kg) on

position A of the pallet.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL

PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

AB

C

D

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

Put load M (100–500kg) on

position B of the pallet.

OWNERS MANUAL – iForks

Page 15

35

14

13

18

15

16

17

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

AB

C

D

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

AB

C

D

Put load M (100–500kg) on

position C of the pallet.

Put load M (100–500kg) on

position D of the pallet.

OWNERS MANUAL – iForks

Page 16

36

7.2 Zero calibration

2 1 3

4

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL

PCS KG/LB

CLR

Start up the indicator.

Press the on/off key.

Empty forks !

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

10 sec.

??

OWNERS MANUAL – iForks

Page 17

37

7.3 Weight calibration

2 1 6 3 4

5

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL

PCS KG/LB

CLR

Start up the indicator.

Press the on/off key.

EXAMPLE:

M1 = 500

M2 = 1500

M3 = 2500

M = total calibration

weight loaded onto the

iForks (incl. pallet if used)

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

1x

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

10 sec.

??

OWNERS MANUAL – iForks

Page 18

38

8 7 12 9 10

11

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

Change if needed !

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

5x

3x

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

1x

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

M1

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

3 sec.

OWNERS MANUAL – iForks

Page 19

39

e1 e2 e3 F1 F2

14

13

18

15

16

17

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

M2

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

Change the value if

needed, by pressing

the >0< key shortly.

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL

PCS KG/LB

CLR

3 sec.

e1 e2 e3 F1 F2

Afterwards, repeat this

cycle for load M3 -> move

the pointer to e3

Move the

pointer to e2

1x

OWNERS MANUAL – iForks

Page 20

40

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

20

19

21

1x

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

Change gravitation

value if needed (enter

value of destination)

Or confirm with enter

(back to weigh mode)

22

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

??

e1 e2 e3 F1 F2

NET

ID CODE

PT

TOTAL PCS KG/LB

CLR

OWNERS MANUAL – iForks

Page 21

41

2. Parameter settings

Par.

Function

Default

settings

EU US

Settings

01

Calibration and start-up units (and print units)

kg

lb

kg;lb

02

Smallest graduation step for multirange

1 2 0.1/0.2/0.5/1/2/5/10/20/50

03

Biggest graduation step for multirange

2 5 0.1/0.2/0.5/1/2/5/10/20/50

04

Number of divisions for every range

1000

1000

0000 - 9999 divisions

05

Weighing capacity system (full scale)

2500

5000

0-99999

06

Motion tolerance for stable

2 2 off/0.5/1/2/4/8/16/32 grad./sec

07

Filter size

8 8 off; 1-12 (1 light filtering, 12 high filtering)

08

Auto zero range (zero track)

0.5

0.5

off/0.5/1/3 grad./sec

09

Zero range positive (+)

10

10

0-100 % of span

10

Zero range negative (-)

10

10

0-100 % of span

11

Test function (display service mode)

basic

basic

basic/count/res10

12

Power on – automatic zero

no

no

Yes/no

13

Approved / non-approved version

no

no

No/ntep/oiml

14

Sampling quantity

10

10

1/2/5/10/20/50/95

15

Units switch mode active

yes

yes

no/yes

16

Setpoint function

0 0 0 (not used); 1 (gross overload); 2 (net overload); 3

(fill manual tare); 4 (fill auto tare); 5 (gross overload

not authorize to change gross setting); 6 (net overload

not authorize to change net setting); 7(gross overload

delayed); 8 (net overload delayed); 9 (gross overload

delay not authorize to change gross setting); 10 (net

overload delay not authorize to change net setting)

17

Number of wires per loadcell (sence active)

4 4 4/6

18

Gravity value working area

9.812

9.797

9.750-9.850

19

Print format date/time

EU

US

EU (dd/mm/yy);US (mm/dd/yy)

20

Baudrate com1

9600

9600

600/1200/2400/4800/9600/19200

21

Setting com1

8_n_1

8_n_1

8_n_1; 8_n_2; 7_n_1; 7_n_2

24

End character com1

cr

cr

cr;lf;crlf

25

Protocol com1

5 5 0(PC bi-directional NU); 1(PC Excel format on print

command); 2 (remote display); 3 (printer protocol with

power control); 4 (printer protocol without power

control); 5 (Bluetooth master)

26

Number of linefeeds com1

4 4 0-9

27

Handshake com1

soft

soft

soft (Xon/Xoff)/hard (CTS)

28

Printout format for com1 and com2

stnd

stnd

stnd;total;confi

29

Header lines added

0 0 0 - 3

30

Baudrate com2

9600

9600

600/1200/2400/4800/9600/19200

31

Setting com2

8_n_1

8_n_1

8_n_1; 8_n_2; 7_n_1; 7_n_2

34

End character com2

cr

cr

cr/lf/crlf

35

Protocol com2

0 0 0(PC bi-directional NU); 1(PC Excel format on print

command); 2 (remote display); 3 (printer protocol with

power control); 4 (printer protocol without power

control); 5 (Bluetooth master)

36

Number of linefeeds com2

4 4 0-9

37

Handshake com2

soft

soft

soft (Xon/Xoff)/hard (CTS)

40

Level sensor

no

no

no/ls nc/ls no/cs fa/cs ra

41

Delay trigger time level sensor

3 3 0 -1 0 sec

43

Compensation factor correction factor

1 1 0.1-10.0

44

Compensation factor X-direction

1 1 0.1-10.0

45

Compensation factor Y-direction

1 1 0.1-10.0

60

Battery used

6 6 6V /12V

61

Low Bat switch-off time

2 2 0 = never off; 1-99 min

62

Auto shut-off time indicator

2 2 0 = never off; 1-99 min

63

Auto shut-off time forks

3 3 0 = never off; 1 = 30min; 2 = 1h; 3 = 2h

64

Sleep time indicator if used

0 0 0 = not used; 1 to 99 min

65

Auto shut-off time backlight

20

20

off/20/40/80/160/320 sec

66

Backlight brightness

100

100

100%/ 75%/ 50%/ 25%/ 0% (off)

67

Low bat switch off time forks

10

10

0 = never off; 1-99 min

68

Buzzer function active

off

off

off/ on (direct); on (2 sec. delay)

80

Digital corner calibration active

0 0 0 (enabled); 1 (disabled)

81

Compensation factor digital corner A

1.000

1.000

Do not change value after digital corner calibration

82

Compensation factor digital corner B

1.000

1.000

Do not change value after digital corner calibration

83

Compensation factor digital corner C

1.000

1.000

Do not change value after digital corner calibration

84

Compensation factor digital corner D

1.000

1.000

Do not change value after digital corner calibration

85

Matching Bluetooth forks

Only enter this parameter to establish a complete new

OWNERS MANUAL – iForks

Page 22

42

Bluetooth connection! Enter last 6 characters of MACaddress of fork1 and 2 or cancel by pressing CLR

90

Default settings without changing calibration

91

Default settings with changing calibration

96

Printout parameter setup

Pr-C1

Pr-C1

Pr-C1; Pr-C2

97

Key test function (buzzer and nr)

98

Scale id number

0 0 0 - 9999

99

Software version

OWNERS MANUAL – iForks

Loading...

Loading...