4

4

8

0

0

S

E

R

I

E

S

8

0

0

S

E

R

i

N

S

T

A

L

L

A

T

i

O

N

i

N

S

T

R

U

C

TRINE 4800 SERIES SURFACE MOUNT

ELECTRIC STRIKE

Congratulations on the purchase of this quality

TRINE security product. This product has been

designed to install easily, perform reliably, and

provide years of trouble free security.

BEFORE PROCEEDING

review the following list of features. If you have any

questions after reading this document please call TRINE's

TECHNICAL SUPPORT (718) 829-2332 EXT. 447, or visit

the TRINE Web site at www.TrineOnline.com

SURFACE MOUNTING:

Unit only requires the drilling of (3) holes*

*ANCHORING SYSTEM: (Included)

Uniquely designed optional (4) four pin anchoring system

provides additional support beyond the standard

two tapped mounting holes.

ONE PIECE LOCKING MECHANISM:

Our patent pending locking mechanism only has

one mechanism providing incredible strength,

durability and reliability due to fewer moving parts.

STAINLESS STEEL CONSTRUCTION

FAIL SECURE/FAIL SAFE FIELD SELECTABLE:

Unit is supplied with fail safe spring that is

changed in the field when desired.

1,500,000+ LIFE CYCLE TESTED

3,000+ LBS. HOLDING FORCE

STEEL SPACER:

We supply a 1/8" thick spacer for those installations that

require mounting the strike closer to the panic bar.

In addition, the spacer is used as a template during

installation.

4800 & 4801 - 12 THRU 24 AC/DC OPERATING VOLTAGE:

Expanding the use of our popular LC unit in the 3000

series, the 4800/4801 has this unit built in providing

the flexibility along with surge and kickback protection.

with your installation, please

T

I

i

O

E

S

N

1440 Ferris Place Bronx New York 10461

VOLTAGE

12DC

24DC

12AC

16AC

24AC

AVAILABLE FINISHES

US3 - Bright Brass

US4 - Satin Brass

US10 - Satin Bronze

PULL IN / HOLD AMPS

.566/.217

.253/.099

.509/.181

.402/.149

.215/.087

US10B - Dark Bronze

US26 - Bright Chrome

US32D - Satin Stainless Steel

DUTY

Intm./Cont.

Intm./Cont.

Intm./Cont.

Intm./Cont.

Intm./Cont

SOUND

Silent

Silent

Silent

Silent

Silent

.

1

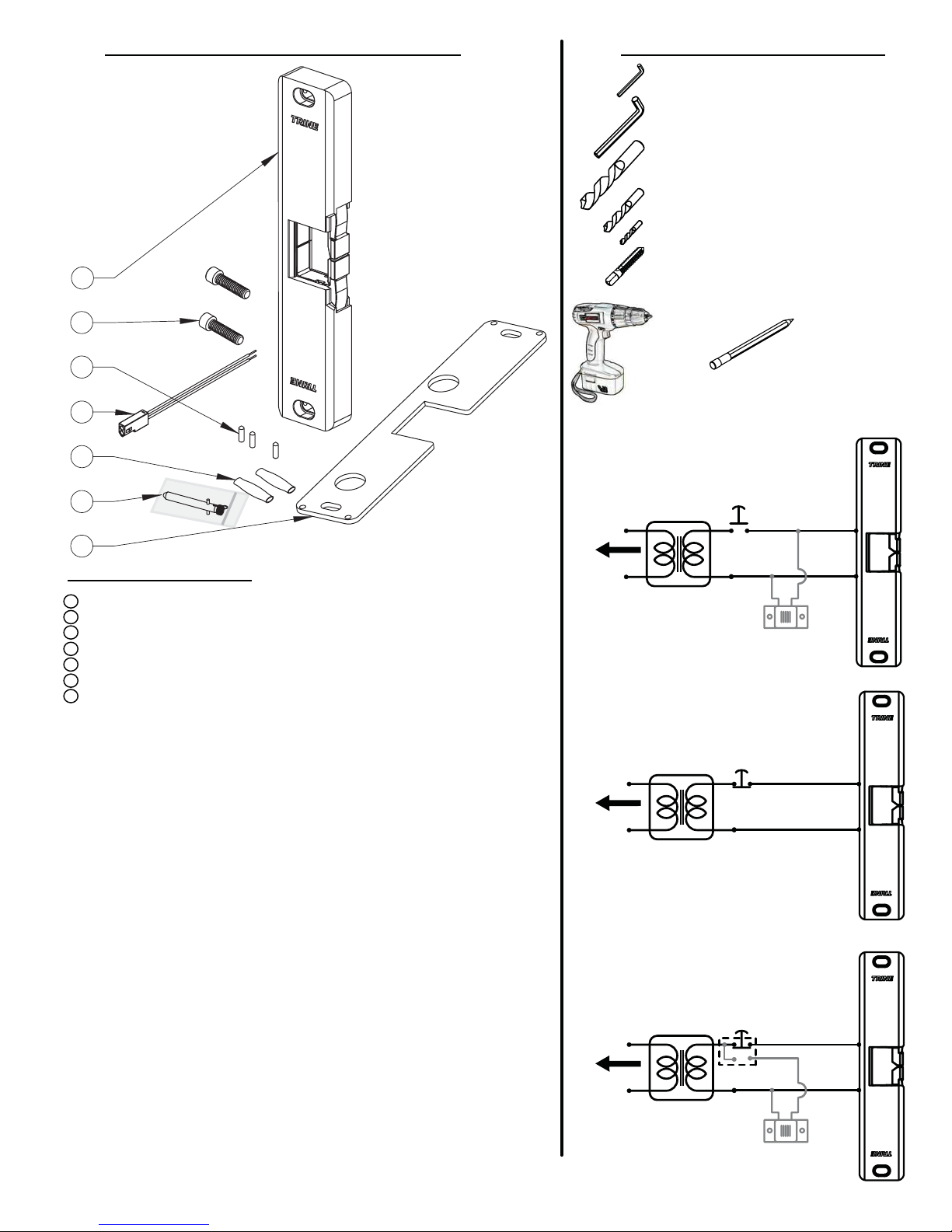

RECOMMENDED TOOLS:

WHAT IS INCLUDED IN THE BOX:

WHAT IS INCLUDED IN THE BOX:

RECOMMENDED PREINSTALLATION CHECK

FOR 4800 SERIES SURFACE MOUNT STRIKE

WIRING FOR

FAIL-SECURE MODE

WIRING FOR

FAIL-SAFE MODE

WIRING FOR

FAIL-SAFE MODE

WITH OPTIONAL BUZZER

RECOMMENDED TOOLS:

- 3/32 inch Allen Wrench

- 3/16 inch Allen Wrench

- 3/4 inch diameter Drill Bit

- #7 (0.201 inch diameter) Drill Bit

- #30 (0.128 inch diameter) Drill Bit

(for the optional Anchor Pins)

1

2

3

4

5

6

7

INCLUDED IN THE BOX ARE:

1 - (1) Surface Mounted Strike

2 - (2) 1/4-20 x 1 inch UH Cap Socket Mounting Screws

3 - (4) Anchor System Pins

4 - (1) Quick Connect Socket and Wire Assembly

5 - (2) Sealed Crimp Connectors

6 - (1) Fail Safe Spring (RED colored) & Solenoid Plunger

7 - (1) 1/8 inch Thick Spacer Plate/Frame Mounting Template

RECOMMENDED PREINSTALLATION CHECK

FOR 4800 SERIES SURFACE MOUNT STRIKE

1. Determine that door is properly adjusted; Door must operate

properly in order for system to provide best results.

2. Door must swing properly, without interfering with jamb or sill

3. The door should be equipped with a door closer and the door

closer "latch mode" must hold door in a completely closed

position in order to avoid the lock latch from applying pressure

against the releasing latch portion of the electric strike.

4. Electrical wire connections must be completed and ready to

be terminated inside the frame.

5. Confirm that the power line in the frame is the correct voltage

and that the switch works properly.

6. Confirm proper clearance exists between the end of the lock

latch and jamb.

7. The electric door strike must be aligned properly with lock

latch when it is installed on the doorjamb.

8. For best installation results, the door frame must be

reasonably flat and straight.

2

- 1/4-20 Tap

- Drill - Marker

WIRING FOR

FAIL-SECURE MODE

SWITCH

TO 120V

AC LINE

USE 12V THRU 24V

AC OR DC

TRANSFORMER

WIRING FOR

FAIL-SAFE MODE

TO 120V

AC LINE

USE 12V THRU 24V

AC OR DC

TRANSFORMER

WIRING FOR

FAIL-SAFE MODE

WITH OPTIONAL BUZZER

TO 120V

AC LINE

USE 12V THRU 24V

AC OR DC

TRANSFORMER

NORMALLY

OPEN

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

SWITCH

NORMALLY

CLOSED

SWITCH

SINGLE POLE

DOUBLE THROW

NOTE: MATCH THE VOLTAGE

OF THE TRANSFORMER

FAIL-SECURE

CONFIGURED

OPTIONAL BUZZER

AND IF REQUIRED,

OBSERVE POLARITY

FAIL-SAFE

CONFIGURED

FAIL-SAFE

CONFIGURED

OPTIONAL BUZZER

AND IF REQUIRED,

OBSERVE POLARITY

STRIKE

STRIKE

STRIKE

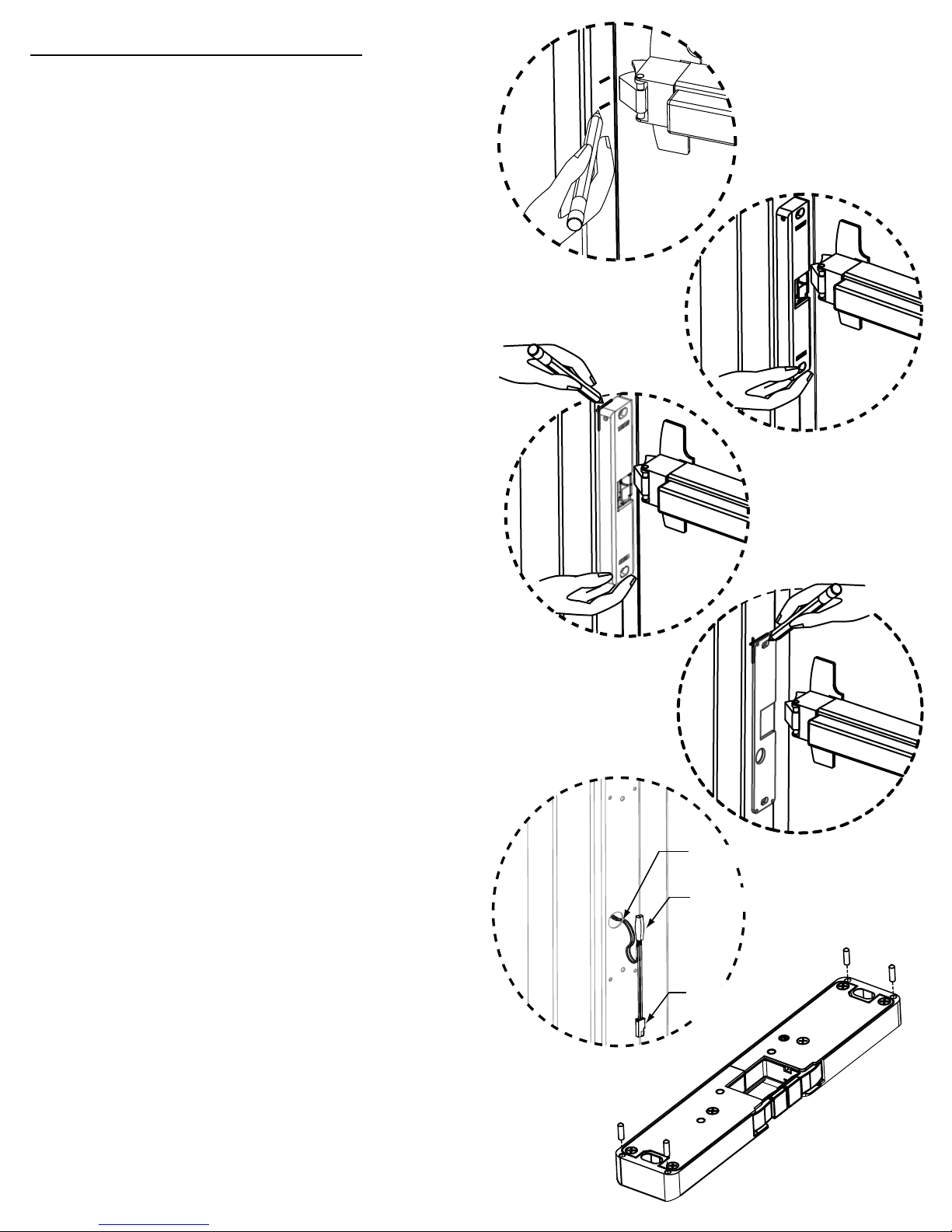

INSTALLATION PROCEDURE:

CAUTION: TO AVOID ELECTRICAL SHOCK AND

INJURIES, BEFORE DOING YOUR WIRING, TURN OFF

THE POWER FROM THE CIRCUIT BREAKER.

1. Mark the end position of the exit devices latchbolt on the

doorframe. (Take off the original strike if present). See

Figure 1.

2. Using the marks you just made as your guide, position

the 4800 over the mark on the frame. Make sure that the

Auxiliary latch rides up properly over the 4800's edge, and

is engaged, and that the door is in the fully closed position.

See Figure 2

3. When you are confident with the position of the 4800,

mark two perpendicular edges of the 4800 on the frame.

See Figure 3

4. Put the 4800 aside for a moment and place the spacer

supplied with the 4800 inside the marks you just made on

the frame.

5. Using the spacer as a template; mark the two mounting

holes and the wire exit hole. If you are using the optional

anchor pins, mark the anchor pin positions using the

spacer as a template. See Figure 4

Figure 1

With the door closed,

mark the position of

the bolt on the frame.

Figure 2

Position the 4800 on

the frame and mark

the desire position.

6. Using a #7 bit, drill the two mounting holes and tap them

¼-20.

7. Using a ¾ inch diameter bit, drill the power wire exit

hole.

8. If you are utilizing the anchor pin system, use a #30 bit,

drill the four anchor pin holes.

9. Deburr any sharp edges around the holes after drilling,

so that the 4800 will rest on a smooth clean surface and

the wires will not be accidentally cut or damaged while

installing.

10. Pull the power wiring down the door frame and through

the ¾ inch diameter power wire hole.

11. Using the provided sealed crimp connectors, terminate

the quick connect socket assembly to the power wires.

See Figure 5 (NOTE: The 4800 is none polarized)

12. If you intend to use the anchor pins system, insert

them into the four holes on the back side of the 4800. See

Figure 6. If you also intend to use the 1/8" thick spacer

plate, you can now slip the plate over the pins.

13. Snap together the power supply side connector coming

off the frame to the 4800 connector. Carefully push the

wires and connectors back into the frame.

14. Using the 2 mounting screws, mount the 4800 strike to

the frame.

Use the spacer as

Figure 4

template to mark the

holes you desire to use.

Figure 3

Power Wire

Crimp Connectors

Quick Connect

Socket Assembly

Figure 5

Crimp the quick

connect socket

assembly to the

power wires.

15. Adjust the strike to the desired position and tighten the

mounting screws using the 3/16 inch Allen wrench.

16. Using the 3/32 inch Allen wrench turn the two

setscrews on the side of the 4800 until they support the

strike. DO NOT over tighten the setscrews.

17. Turn the power ON and test your installation.

18. Installation is now complete.

Figure 6

Push the anchor pins in

the back of any 4800

series strike if you

desire to use this

3

4

4

8

5

0

H

A

L

F

I

N

C

H

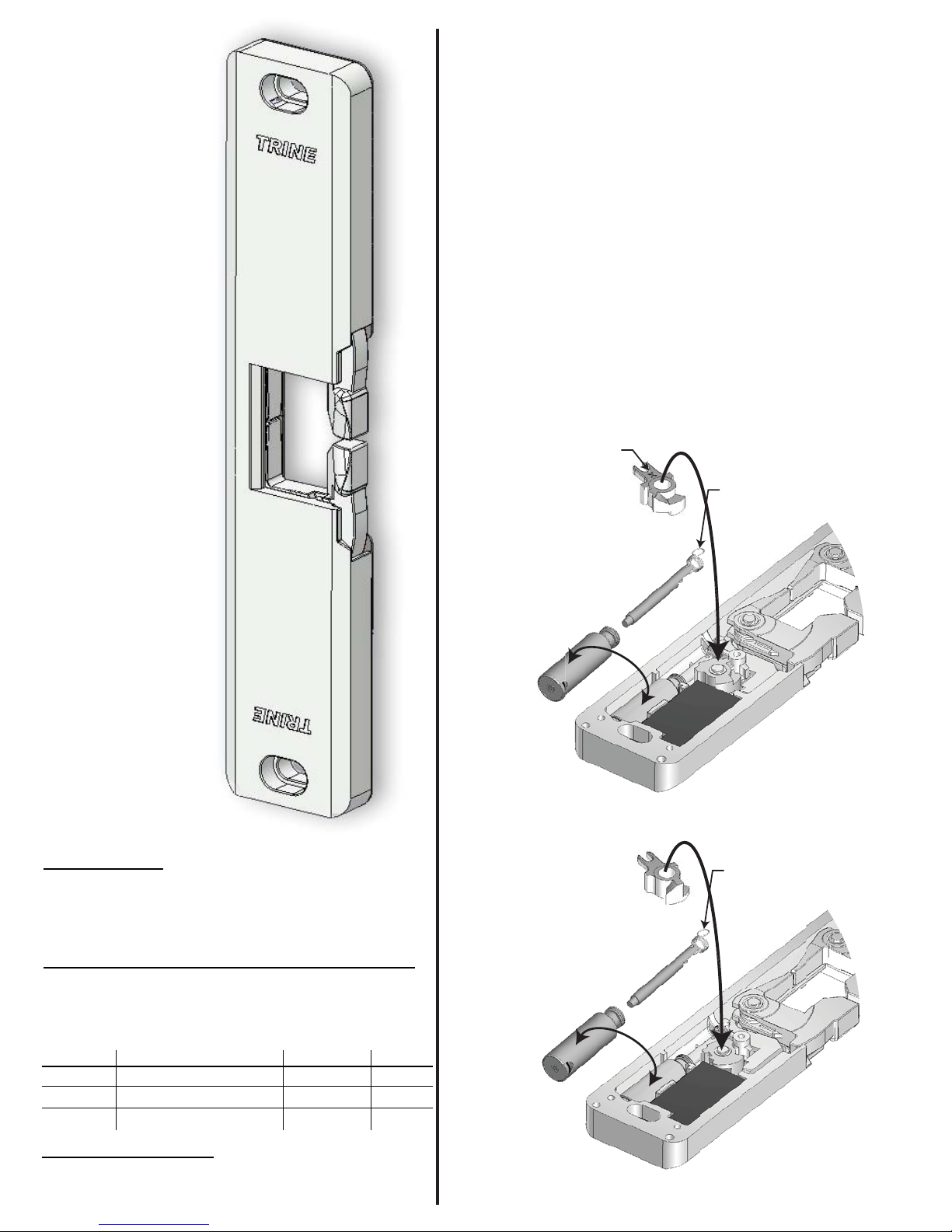

INSTRUCTIONS FOR CHANGING

THE 4850 SURFACE MOUNT FROM

FAIL SECURE TO FAIL SAFE

AND VICE VERSA:

8

5

0

H

A

L

F

I

S

U

R

F

A

C

E

M

O

U

N

T

To change the Fail Secure 4850 into a Fail Safe 4850, open

the mechanism side of the 4850 (as shown below) by

removing the mechanism cover screws (3 places) and the

cover (the side with wire lead). Lift the solenoid and gently

pull off the Fail Secure solenoid plunger and BLUE spring

assembly and replace it with the Fail Safe plunger and RED

spring assembly. Pull off the Fail Secure actuator cam, and

slip in the Fail Safe cam (this cam is marked with an "X" as

shown on the picture below). Before closing the unit, make

sure that the wires are properly seated on the wire channel.

Save the Fail Secure plunger and BLUE colored spring for

future use.

For changing from Fail Safe to Fail Secure, just reverse the

above procedure.

Fail-Safe Cam

has a "X" mark.

This spring loop

must be on the top.

Replace the solenoid

plunger & spring. The

Fail-Safe has a "RED"

colored spring.

N

C

H

STEEL SPACER:

Use the 1/8" thick spacer for those installations that

require mounting the strike closer to the panic bar.

In addition, the spacer is used as a template during

installation.

12 THRU 24 VDC (ONLY) OPERATING VOLTAGE:

Expanding the use of our popular LC unit in the 3000

series, the 4850 has this unit built-in electronic that

will provide the flexibility along with surge and

kickback protection.

VOLTAGE

12DC

16DC

24DC

AVAILABLE FINISHES

US32D/BHMA 630 - Satin Stainless Steel

US10B/BHMA 640 - Dark Bronze

E

D

PULL IN / HOLD AMPS

.500/.178

.385/.131

.255/.084

DUTY

Intm./Cont.

Intm./Cont.

Intm./Cont.

SOUND

Silent

Silent

Silent

Carefully lift

the Solenoid

assembly off

the strike body.

Replace the solenoid

plunger & spring. The

Fail-Secure has a "BLUE"

colored spring.

Carefully lift

the Solenoid

assembly off

the strike body.

FAIL-SAFE ASSEMBLY

This spring loop

must be on the top.

FAIL-SECURE ASSEMBLY

4

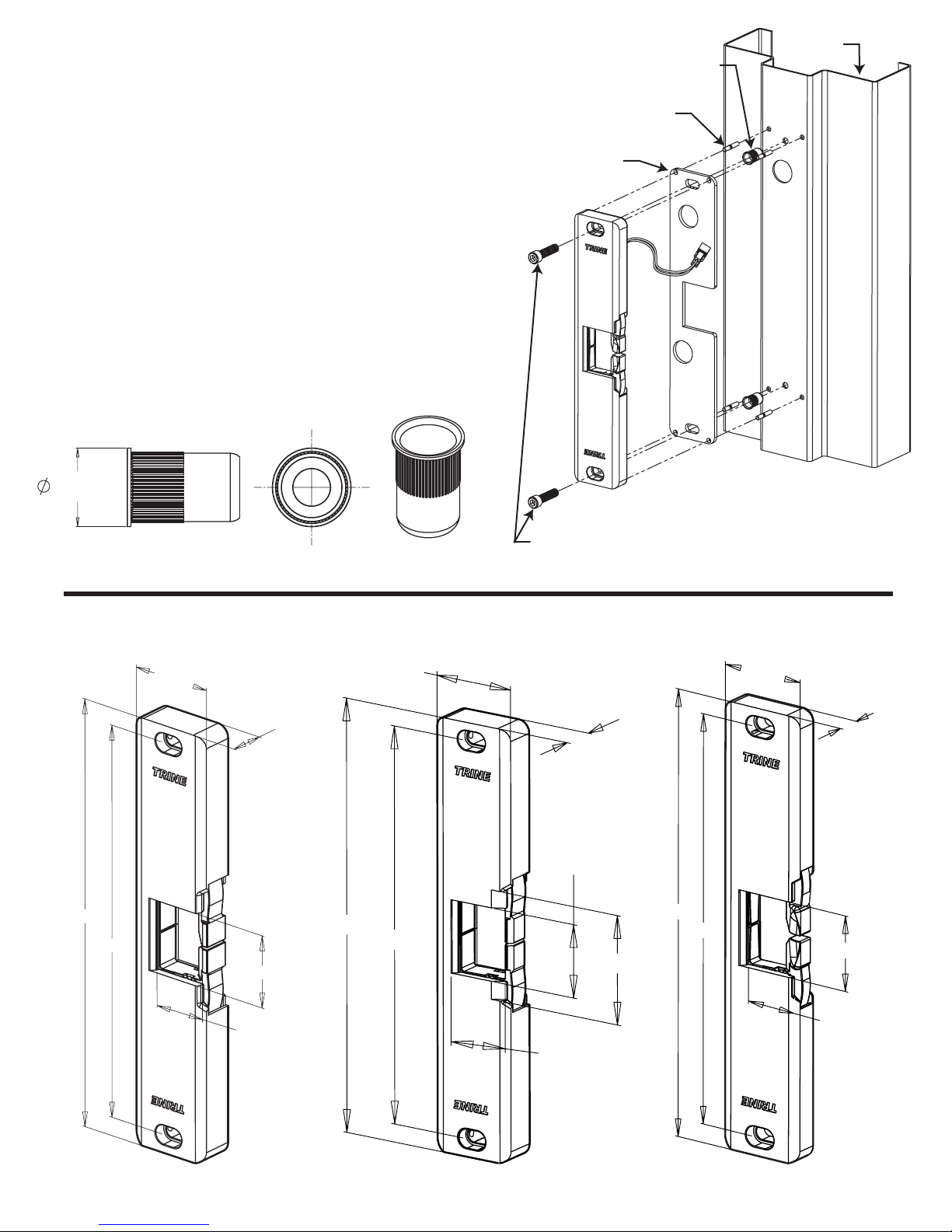

4850 INSTALLATION:

The installation of the 4850 surface mounted strike is

similar the 4800 and 4801. Please follow the instructions

on page 3 of this instruction sheet. If needed, please

refer to page 6 for troubleshooting the installation.

If the 4850 is to be installed in aluminum frames, it is

recommended that the installer use a nut insert for the

#1/4-20 mounting screws. The 4850 provides clearance for

the head of the nut insert but for only the ones that have a

small flange on them. See the recommended dimension

for the flange below.

There are many companies that make the nut insert, for

example, PEM® fasteners, ENFASCO Inc.®, ... etc.,

please refer to their catalogs for the proper part number.

PREFERRED NUT INSERT

1/8" SPACER/

TEMPLATE

INSERT

ANCHOR

PINS

NUT

FRAME

13/32"

9"

8 1/4"

1 3/4"

4850 STRIKE

#1/4-20 MNT. SCREWS

4800 SERIES STRIKE DIMENSIONS:

1 3/4"

3/4"

1 17/32"

9"

8 1/4"

1 1/2"

2 9/32"

3/4"

1 3/4"1 3/4"

1/2"1/2"

9"9"

8 1/4"8 1/4"

1 1/2"1 1/2"

1 1/8"

4800 4801 4850

1 5/32"

USE WITH THE SECUREBOLT®

OR SQUAREBOLT PANIC BARS®

1 1/8"1 1/8"

5

INSTRUCTIONS FOR CHANGING

THE 4800/4801 FROM FAIL SECURE

TO FAIL SAFE AND VICE VERSA:

To change the Fail Secure 4800/4801 into a Fail Safe , open the

mechanism side of the strike (as shown on the right) by removing the

mechanism cover screws (3 places) and the cover. Lift the solenoid and

gently pull off the solenoid plunger and BLUE spring assembly and

replace it with the solenoid plunger and RED colored spring assembly.

Pull off the actuator cam, and flip it to use the cam profile for Fail Safe (the

side without an "X" mark). Before closing the unit, make sure that the

wires are properly seated on the wire channel (see figure on right). Save

the plunger and BLUE colored spring assembly for future use.

For changing from Fail Safe to Fail Secure, just reverse the above

procedure.

Use the plunger and

BLUE colored solenoid

spring assembly.

Turn the actuator cam over

to utilize the Fail Safe

side of the cam profile.

Use the plunger and

RED colored solenoid

spring assembly.

DO NOT OPEN

THIS SIDE.

Seat wires properly in

the housing channel so

the cover will seat flat.

Fail Secure

You should have

the "X" mark

on top of the

actuator cam.

Configuration

(Standard)

TROUBLESHOOTING THE COMPLETED INSTALLATION

SYMPTOM: Electric release is not actuating:

1. Verify proper voltage is present AT STRIKE. If voltage

is present: the strike may have been affected during

the installation, or dirt or debris may be preventing

proper operation. Inspect electric release and clean.

DO NOT LUBRICATE SOLENOID.

2. If voltage IS NOT present:

Verify Circuit breaker is on

Verify voltage at the transformer/power supply output.

Verify that there are no additional, external switches or

devices which may be interrupting your circuit.

Check for damaged wiring or bad wire splices.

SYMPTOM: Door will not open but strike is working

• Check for other locks on door

Fail Safe

You should NOT

see the "X"

on top of the

actuator cam.

• Check for proper lock-latch engagement

• Check for excessive back pressure on door release

latch by following these steps:

Push the door from the outside to try and relieve

the bolt to latch pressure and actuate the 4800.

While the 4800 is unlatched swing the door open. If

the door opens, then the bolt maybe applying

pressure to the latch. Adjust the position of the

4800 to relieve the pressure.

Possible remedies include:

• Re-adjust (or install) a door closer

• Remove door silencers

• Correct excessive door warpage

• Re-center electric release in jamb

• Remove or trim weather stripping around the door

Configuration

PHONE: (718) 829-2332 FAX: (718) 829-6405

1440 FERRIS PLACE

BRONX, NY 10461

email: CustomerService@TrineOnline.com

website: www.TrineOnline.com

6

Loading...

Loading...