Page 1

TMCM-160

Hardware

BLDC motor controller/driver module 5A/36V

with RS232 / RS485 and analog interface

V1.11

August 8

th

, 2007

Trinamic Motion Control GmbH & Co. KG

Sternstraße 67

D – 20357 Hamburg, Germany

www.trinamic.com

Page 2

TMCM-160 Manual (V1.11 / August 8th, 2007) 2

Contents

1

Features........................................................................................................................................................................... 3

2 Life support policy....................................................................................................................................................... 4

3 Outer Description......................................................................................................................................................... 5

3.1 Pinning................................................................................................................................................................... 5

3.2 Dimensions........................................................................................................................................................... 7

3.3 Connectors............................................................................................................................................................ 7

3.4 Application Environment.................................................................................................................................. 7

4 Operational / Limiting Ratings................................................................................................................................. 8

4.1 Power supply requirements ............................................................................................................................ 8

5 Functional description................................................................................................................................................ 9

5.1 General Functions (explore using the Windows based demo software)........................................... 9

5.2 Options for stand alone operation................................................................................................................ 9

5.3 Evaluation Version – Additional Features.................................................................................................... 9

5.4 LEDs - Temperature, Current and Voltage monitoring ............................................................................ 9

5.5 Under voltage behavior .................................................................................................................................. 10

5.6 Demonstration Application ............................................................................................................................ 10

5.7 Programmable motor current limit ............................................................................................................. 10

5.8 Parameterizing the PID velocity regulator................................................................................................ 11

5.9 Parameterizing the positioning algorithm................................................................................................ 12

5.10 Restoring factory default settings................................................................................................................ 12

6 Revision History.......................................................................................................................................................... 13

6.1 Documentation Revision................................................................................................................................. 13

6.2 Firmware Revision............................................................................................................................................ 13

7 References .................................................................................................................................................................... 13

List of Figures

Figure 3.1: Pinning................................................................................................................................................................ 5

Figure 3.2: Dimensions........................................................................................................................................................ 7

Figure 3.3: Application Environment............................................................................................................................... 7

Figure 5.1: PID velocity regulator parameters............................................................................................................ 11

Figure 5.2: Parameterizing the positioning algorithm............................................................................................. 12

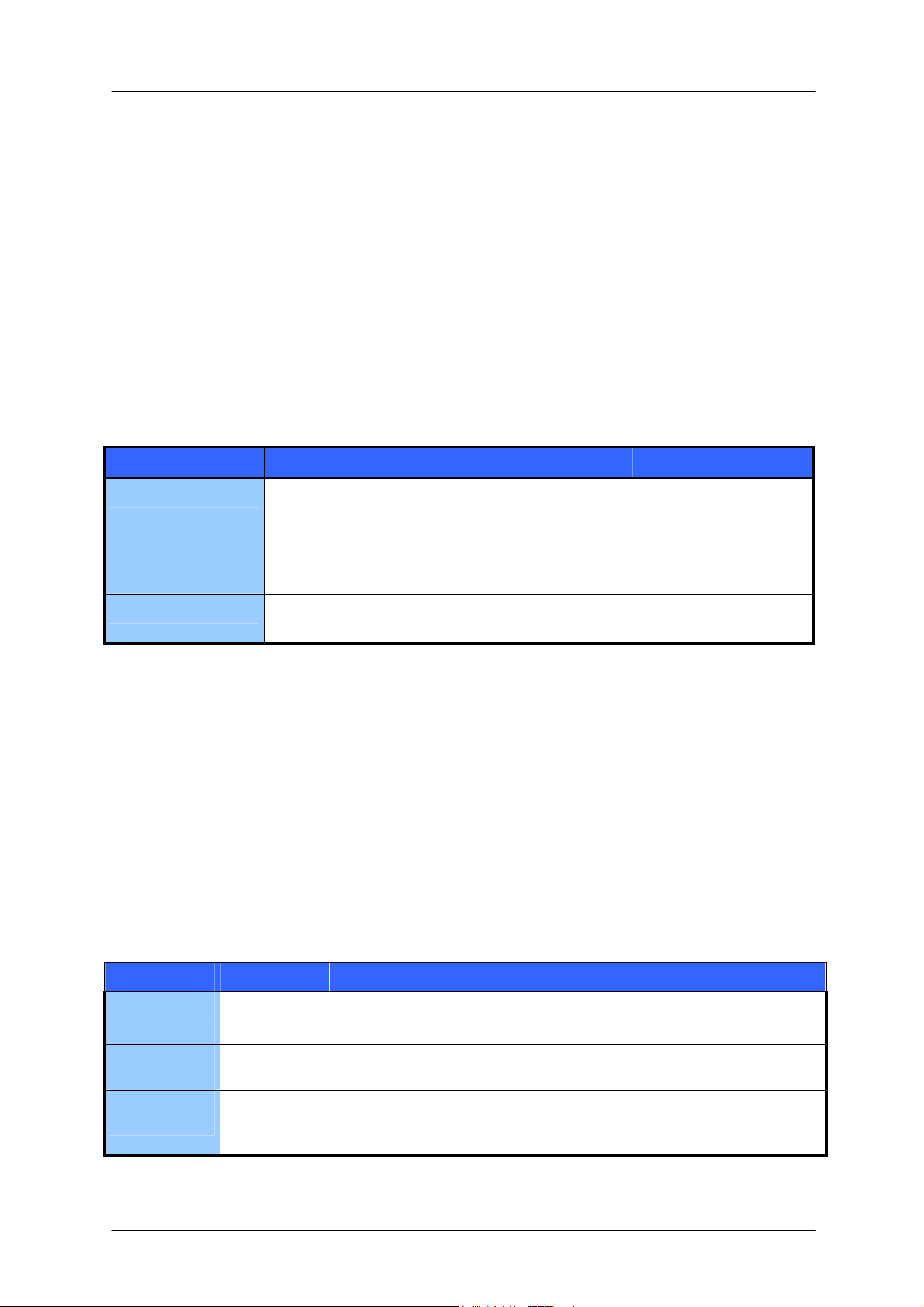

List of Tables

Table 1.1: Order codes......................................................................................................................................................... 3

Table 3.1: Pinning of supply, motor and hall connector .......................................................................................... 5

Table 3.2: Pinning of I/O connector ................................................................................................................................ 6

Table 4.1: Operational / Limiting Ratings ...................................................................................................................... 8

Table 5.1: Options for stand alone operation.............................................................................................................. 9

Table 5.2: LEDs - Temperature, Current and Voltage monitoring function..........................................................9

Table 6.1: Documentation Revision............................................................................................................................... 13

Table 6.2: Firmware Revision .......................................................................................................................................... 13

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 3

TMCM-160 Manual (V1.11 / August 8th, 2007) 3

1 Features

The TMCM-160 is a controller / driver module for general Brushless DC motor applications. It

integrates velocity and torque control as well as a hall sensor based positioning mode. The position

resolution depends on the motor, i.e. a standard 8 pole motor gives a motor axis resolution of 15

degrees. The module can be used in stand alone operation or remote controlled via a RS232 or RS485

interface (ordering option). Its small form factor (50 x 92 mm

board as a plug-on module or for panel mounting, by connecting flat ribbon cables to the two 2x13

2.54mm standard header connectors. A version with screw terminal connectors is available (TMCM-160EvalBoard).

Its integration into the TRINAMIC family of stepper motor controllers makes it easy to choose either a

stepper motor or a BLDC motor or any combination for an application.

Applications

• Constant velocity and torque limited drives

• Positioning applications with automatic ramp generation

• Remote controlled (RS232 or RS485) or stand-alone operation (0 – 10V signal)

• Plug-On module or panel mount operation

• Very compact multi-axis drives (integrate several modules on a single base board)

Motor type

• Block commutated 3 phase BLDC motors with hall sensors

• Motor power from a few Watts to 180W

• Motor velocity up to 100,000 RPM (electrical field)

• 12, 24 or 36V nominal motor voltage (or any value in between) (ask for 48V option)

• Coil current up to 3A nominal, 5A with forced cooling (up to 8.5A current for short time)

Highlights

• High-efficiency operation, low power-dissipation

• Typical Supply voltage 14V – 36V (ask for 48V option)

• Integrated Protection: Overload and overtemperature, reverse polarity on EVAL board.

• Supports the TRINAMIC TMCL protocol and the TMCL software environment for parameterizing

• On the fly alteration of motion parameters (e.g. position, velocity, acceleration)

Other

• Two 2-row 2.54mm connectors

• ROHS compliant

• Size: 50x92mm²

Order code Description

TMCM-160 (-option) BLDC module

TMCM-160 Evalboard BLDC evaluation module with screw terminals

TMCM-160 EvalKit BLDC evaluation module + motor + cables

Option Host interface

232 RS232 interface (standard version)

485 RS485 interface

Table 1.1: Order codes

2

) allows for integration onto a user

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 4

TMCM-160 Manual (V1.11 / August 8th, 2007) 4

2 Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent

of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to

support or sustain life, and whose failure to perform,

when properly used in accordance with instructions

provided, can be reasonably expected to result in

personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2005

Information given in this data sheet is believed to be

accurate and reliable. However no responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third

parties, which may result form its use.

Specifications subject to change without notice.

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 5

TMCM-160 Manual (V1.11 / August 8th, 2007) 5

3 Outer Description

3.1 Pinning

direction

5V_AREF

AIN1

DIRIN

/MOTOR_OFF

LED_CURLIM

GND

MCLR

GND

PGC

1

2

6

10

14

18

22

26

AIN0 / VIN

GND

GPIO1

LED_TEMP

+5V

GND

+5V

PGD

RXD / RS485INV

TXD / RS485NI

-

354

798

111312

151716

192120

-

232524

-

-GND

Connectors shown as top view

0-10V for

velocity

Do not use these

pins

Pins 18 to 26 for

RS232 via DSUB

male and

nullmodem cable

Standard connector for

Supply and Motor / Hall Sensors

26

H1

GND

22

User I/O

GND

GND

18

VS

VS

14

W

W

10

V

V

6

U

U

H3H2

+5V

232524

GND

GND

192120

GND

VS

151716

VS

W

111312

W

V

798

V

U

354

U

12

Optional connectors on

Evaluation board

5

H3

4

1.5mm

Connector

H2

3

H1

2

GND

1

+5V

5

4

3

2

1

Connectors each shown

as top view

U

V

W

VS

GND

Figure 3.1: Pinning

CAUTION:

Since the two connectors of the TMCM-160 are similar be careful not to connect the module

turned around. When powered up this would damage the module. Figure 3.1 depicts the connectors

and their position on the board. The supply, motor and hall connector is next to the three capacitors.

Be sure to place the connectors exactly to their opponents. A deviation of only one pin row can

damage the module also.

Pin

Name Function

1 to 12 U, V, W BLDC motor driver outputs

13 to 16 VS Positive power supply voltage

17 to 22 GND Power Ground

23 +5V 5V supply for motor hall sensors

24 to 26 H1, H2, H3 Hall sensor signals (5V TTL input with integrated 10K pull-up resistor

to 5V)

Table 3.1: Pinning of supply, motor and hall connector

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 6

TMCM-160 Manual (V1.11 / August 8th, 2007) 6

g

Pin

Name Function

1 5V_AREF 5V analog reference as used by the internal DAC. Max. load 0.5mA

2 AIN0 / VIN Analog input: Used for velocity control in stand alone operation by

supplying external 0 - 10V signal

3 AIN1 Additional analog input. Currently unused – leave open

5 DIRIN 5V TTL input. Tie to GND to inverse motor direction, leave open or

tie to 5V otherwise.

6 GPIO1 Starting from Version 1.02: This pin outputs a tacho impulse, i.e.

toggles on each hall sensor change

7 /MOTOR_OFF Emergency stop. Tie this pin to GND to stop the motor (same as

Motor Off switch on PCB). The motor can be restarted via the

interface, or by cycling the power supply.

8 LED_TEMP 5V TTL output: Toggling with 3Hz when temperature pre-warnin

threshold is exceeded, high when module shut down due to

overtemperature.

9 LED_CURLIM High, when module goes into current limiting mode

10, 14 +5V 5V supply as reference for external purpose

11, 12, 26 GND GND reference

20 RXD /

RS485INV

22 TXD /

RS485NI

RXD signal of module for RS232 communication (RS232 version)

Inverting RS485 signal (RS485 version)

TXD signal of module for RS232 communication (RS232 version)

Non-inverting RS485 signal (RS485 version)

All other pins Leave all other pins unconnected!

Table 3.2: Pinning of I/O connector

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 7

TMCM-160 Manual (V1.11 / August 8th, 2007) 7

3.2 Dimensions

92mm*50mm*8.3mm (height measured from PCB to highest part on PCB connector side, parts on top

side not included, since these are just for evaluation purpose)

Figure 3.2: Dimensions

3.3 Connectors

Hall sensor: JST1.5mm type: S5B-ZR-SM2-TF (only on EvalBoard)

Board-Plug on connectors: 2.54 mm two-row Header

3.4 Application Environment

TMCM-160

„classic“ analog

control

programmable

Motion

Controller

14..36V DC

RS-232

or

RS-485

5V Power Supply

3-ph

MOSFET

Driver

Stage

HALL sensors

BLDC

Motor

Figure 3.3: Application Environment

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 8

TMCM-160 Manual (V1.11 / August 8th, 2007) 8

4 Operational / Limiting Ratings

The operational ratings show the intended / the characteristic range for the values and should be

used as design values. An operation within the limiting values is possible, but shall not be used for

extended periods, because the unit life time may be shortened. In no case shall the limiting values be

exceeded.

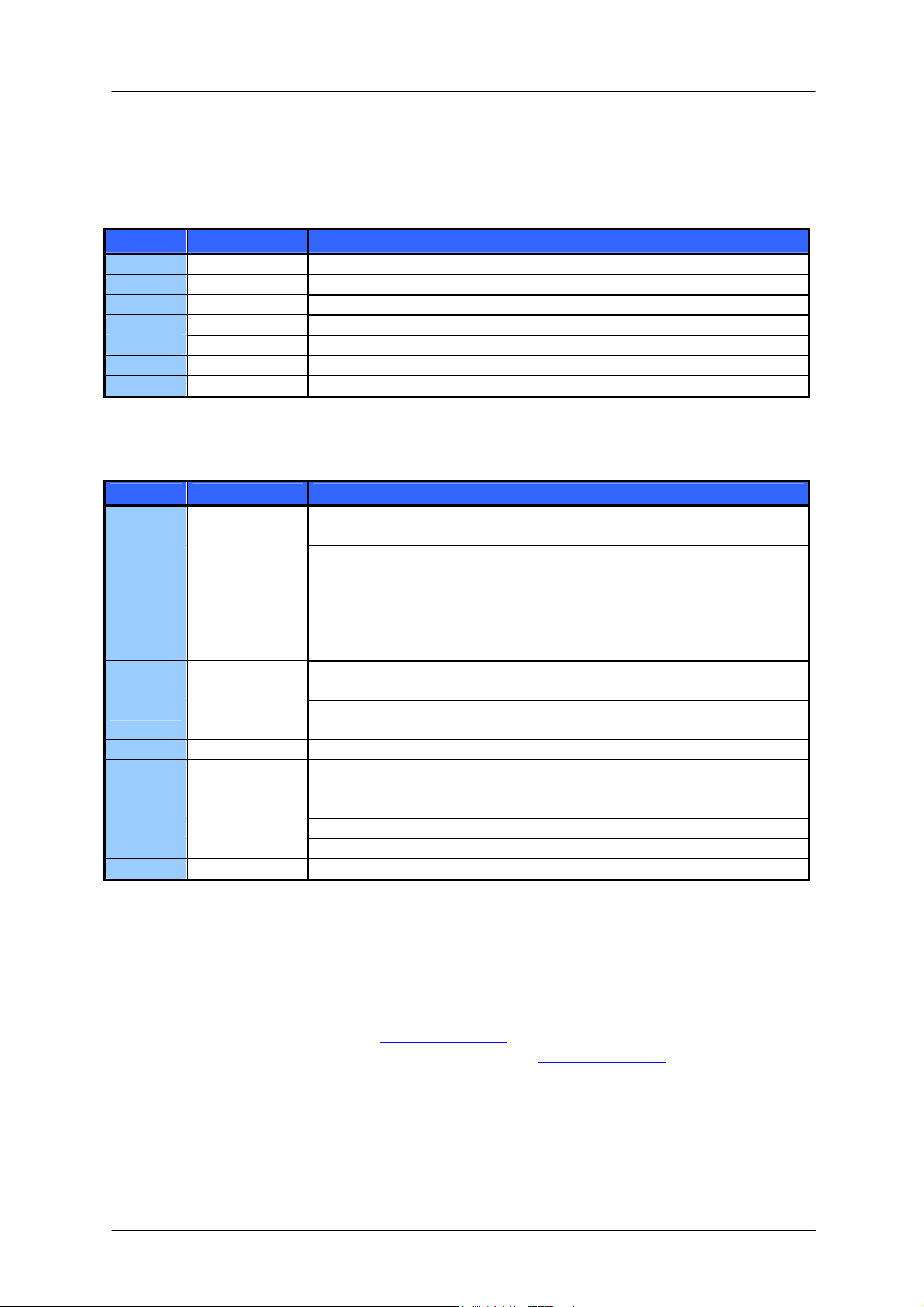

Symbol Parameter Min Typ Max Unit

VS Power supply voltage for operation 9.0*) 14 - 36 40.0 V

IS Power supply current 0.04 I

A

MOT

PID Module idle power consumption 1.2 W

V5 5 Volt (+-8%) output external load (hall sensors plus

30 mA

other load)

V5A 5 Volt (+-8%) analog reference output external load 0.5 mA

IMC Continuous Motor current at VMF 0 – 3 5 A

IMP Short time Motor current in acceleration periods

0 – 6 8.5 A

It is not recommended to set motor current above 6A!

I

Peak coil output current for 100ms 20 A

MPP

VI Logic input voltage on digital / hall sensor inputs -0.3 VCC+

V

0.3

VO Logic output current on digital outputs (5V CMOS output) 10 mA

VIA Analog input voltage -24 0 – 10 24 V

f

Chopper frequency 20 kHz

CHOP

Ex Exactness of voltage and current measurement -8 +8 %

T

Motor output slope (U, V, W) 100 ns

SL

TO Environment temperature operating -25 +70 °C

TOF Environment temperature for operation at full specified

-25 +60 °C

current (air flow might required, depending upon motor

/ voltage)

T

Temperature of the module, as measured by the

board

<100 125 °C

integrated sensor.

Table 4.1: Operational / Limiting Ratings

*) At supply voltages below 12V, maximum motor current linearly decreases down to about 0.5A at

9V. To be sure to be outside this area when using the EVALboard, use at least 13V supply voltage,

due to voltage drop in the reverse polarity protection.

4.1 Power supply requirements

The power supply should be designed in a way, that it supplies the nominal motor voltage at the

desired maximum motor current. In no case shall the supply value exceed the upper / lower voltage

limit. To be able to cope with voltage which might be fed back by the motor, the supply should

provide a sufficient output capacitor, additionally a 39V suppressor (zener-)diode may be used.

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 9

TMCM-160 Manual (V1.11 / August 8th, 2007) 9

5 Functional description

5.1 General Functions (explore using the Windows based

demo software)

The TMCM-160 module can either be remote controlled via the PC demonstration software or a user

specific program, or it can be controlled by an analog voltage (stand alone mode). The function of the

stand alone mode can be modified by the user by writing initialization values to the on-board

EEPROM, e.g. a maximum rotation velocity, motor current limit and rotation direction. For more

detailed software information refer to the TMCM BLDC Module – Reference and Programming

Manual (7).

5.2 Options for stand alone operation

Mode Functionality Software settings

PWM control Motor PWM controlled by the analog input VIN.

Motor direction controlled by DIR in pin.

PID enforced velocity Maximum motor velocity v

velocity is scaled by VIN pin voltage and enforced

by the PID velocity regulator.

Constant velocity Desired motor velocity v set via software Remote control flag = 1

Table 5.1: Options for stand alone operation

In all modes, the motor torque is limit by the maximum current setting. The polarity of the DIR pin

can be inversed by the direction input reverse flag setting.

set via software. This

max

Remote control flag = 0

Power on velocity = 0

Remote control flag = 0

Power on velocity = v

Power on velocity = v

max

5.3 Evaluation Version – Additional Features

The evaluation version comes equipped with a screw terminal connector for the motor and for the

supply. The hall sensor connector is a 5 pin 1.5mm JST type, which directly fits to a NMB motors. An

emergency stop switch as well as indicator LEDs are included on the board. An integrated

potentiometer allows velocity setting in the stand-alone mode. To use the external 0-10V input, turn

this potentiometer to zero velocity (right turn).

5.4 LEDs - Temperature, Current and Voltage monitoring

LED / Output Action Meaning

Current Limit Blink The current limit LED blinks upon under voltage switch off

Current Limit On / Flicker Motor PWM is reduced due to exceeding the set motor current limit

Temperature

Warning

Temperature

Warning

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Blink The power stage on the module has exceeded a critical temperature

of 100°C. (Pre-warning)

On The power stage on the module has exceeded a critical temperature

of 125°C. The motor becomes switched off, until temperature falls

below 115°C. The measurement is correct to about +/-10°C

Table 5.2: LEDs - Temperature, Current and Voltage monitoring function

Page 10

TMCM-160 Manual (V1.11 / August 8th, 2007) 10

5.5 Under voltage behavior

• The motor is switched on, if the supply voltage exceeds 9.0V

• The motor is switched off, if the supply voltage falls below 8.5V

• The current reduction due to low supply voltage may inhibit starting-up of the motor

• EVALboard: Motor current is reduced to a lower value, if the voltage is below 12V. If motor load

is too high, the module goes into under voltage switch off again. This is due to the voltage drop

in the reverse polarity protection. Motor current is additionally limited at low supply voltages:

0.5A at 9V and linear increasing to 4A at 12V. To be sure to be outside this area, use at least 13V

supply voltage, due to voltage drop in the reverse polarity protection.

5.6 Demonstration Application

You can use the Demonstration application for the TMCM-160 to set the module into operation. Please

remark, that you first should as a first step switch the module to remote controlled mode. You can

use the TRINAMIC TMCL IDE to update the modules firmware and to test / set all of the modules

parameters. If your motor shows instable behavior, you have to tune the PID regulator values. In

order to do this, you need to use the TMCL IDE.

5.7 Programmable motor current limit

The motor current limiting function is meant as a function for torque limiting, and for protection of

motor, power supply and mechanics.

Whenever the pre-programmed motor current is exceeded in a chopper cycle, the TMCM-160 calculates

a reduced PWM value for the next chopper cycle. New values are calculated 100 times a second. The

response time of the current regulation can be set using the parameter “current regulation loop

delay”:

A value of zero means, that in every 100Hz period, the current correction calculation is directly

executed and the resulting PWM value is taken. A higher current loop delay acts like a filter for the

current. The higher the delay value, the slower the current loop response time. A value of 5 (default)

leads to a current regulation response time of about 60 ms. On the mechanical side, a higher value

simulates a higher dynamic mass of the motor.

t

= 1 / (1 / 3s + 1 / (10ms * (1+x

LIM

x

is the current regulation loop delay parameter, t

CRLD

The actual current regulation time may be faster, depending on the PID settings.

Attention:

Please be careful, when programming a high value into the current regulation loop

delay register or if you want to work above the modules’ rated motor current: The

motor current could reach a very high peak value upon mechanical blocking of the

motor. If the short time current is not limited to a maximum of about 20A, this could

destroy the unit.

• The current measurement can not detect currents below about 200-300mA. If the current limit is

set to a too low value, the motor may become continuously switched off.

• The current limiting function is not meant as a protection against a hard short circuit.

• The maximum motor current should never be set above the rated short time motor current,

because the current regulator can not operate correctly, if the current limit is set too close to the

measurement range limits.

CRLD

)))

the resulting time for an 1/e response.

LIM

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 11

TMCM-160 Manual (V1.11 / August 8th, 2007) 11

5.8 Parameterizing the PID velocity regulator

The motion control commands (TMCL_ROL, TMCM_ROR, TMCL_MVP) use a PID regulator for velocity

control. The PID regulator has to be parameterized with respect to a given motor in a given

application. The default parameter set of the PID regulator covers a range of motors suitable for the

TMCM-160 module, and typically works stable up to 15000 rpm maximum motor velocity. However, for

slower motors, the response time with this parameter set may become quite slow.

The PID regulator uses four basic parameters: The P, I and D values, as well as a timing control value.

The timing control value (PID regulation loop delay) determines, how often the PID regulator is

evoked. It is given in multiple of 10ms:

t

PIDDELAY

x

calculations

The PID parameters are divisors, e.g. use a higher value, to get less influence from the parameter. To

parameterize for a given motor, first modify the P parameter, starting from a high value and going to

a lower value, until fastest response with minimum oscillation is given.

After that, do the same for the I parameter. Now, modify the D parameter in the same way. It will

damp part of the oscillations of the other parameters, too.

As a thumb-rule, you can set the P-parameter to a starting value, such that:

P-param = (Maximum actual RPM of the motor at 100% PWM) * 0.15

The module uses the internally calculated velocity value (1/4 of electrical RPM value) as input into the

PID regulator (see schematic).

= x

is the PID regulation loop delay parameter, t

PIDRLD

PIDRLD

* 10ms

PIDDELAY

is the resulting delay between two PID

actual RPM

(1/4 electrical

RPM)

target RPM

(1/4 electrical

RPM)

Default values:

P-param = 2400

I-Param = 150

D-Param = 600

x

= 2

PIDRLD

Clip

4095

32 / I-param

Clip

32767

32 / P-param

32 / D-param

last

sum

CLK: 100Hz /

PIDloopdelay

Figure 5.1: PID velocity regulator parameters

CLK: 100Hz /

PIDloopdelay

actual PWM

0-1023

new PWM

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 12

TMCM-160 Manual (V1.11 / August 8th, 2007) 12

5.9 Parameterizing the positioning algorithm

The module supports a positioning based on the motor’s hall sensor information. Please refer to the

schematic for the required set of parameters.

You can optimize the parameter set in your application to get a good positioning accuracy and a fast

positioning speed:

1. Select the maximum positioning speed as desired

2. Choose a minimum positioning speed, that allows a fast stop of the motor

3. Set the MVP_slow_down_distance in a way, that the motor slows down to the min_pos_speed in

this area (dotted line)

4. Choose the active brake velocity as allowable for your application

5. Set MVP_target_reached_distance to the value, which gives a stop as near as possible to the

target position

MVP_target_reached_distance

MVP_slow_down_distance

|velocity|

velocity enforced by

PID regulator

actual motor velocity

Velocity enforced by

max_pos_speed

min_pos_speed

active_brake_velocity

PID regulator

Motor off in this area

Motor braked in this

area if hard_stop_flag

set

position

target position

(set via MVP)

Figure 5.2: Parameterizing the positioning algorithm

5.10 Restoring factory default settings

The module stores user settings in an on-board EEPROM. You can restore the factory values, by setting

and storing a 255 to the current limit parameter. Upon next power on, all EEPROM values are loaded

with the default settings. However, this also clears the temperature measurement calibration, which

should be recalibrated before operating the device near its temperature limits.

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Page 13

TMCM-160 Manual (V1.11 / August 8th, 2007) 13

6 Revision History

6.1 Documentation Revision

Version Comment Description

1.07 New Version Revised Version

1.08

1.09 Appl. Env. Added application environment and optical changes

1.10 HW change Reverse protection on EVALboard only

1.11 Pinning Clarification of pinning to avoid module damage

Table 6.1: Documentation Revision

6.2 Firmware Revision

Version Comment Description

1.01 Initial Version Bug in current regulation algorithm: Instable operation with settings

above 4.6A

1.02 Added RS485,

Tacho output

1.03 Invert Hall Added possibility for inversion for hall sensor signals

1.04 Disable Stop

switch

1.05 RS485 Corrected sent back address

1.06 Corrected

position

counter

Added baud rate switching

Added RS485 interface

Fixed current regulation bug

GPIO1 provides for a hall sensor derived tacho signal

Analog control input now uses 10 bit resolution for PWM / velocity

control

Corrected velocity readout when motor is turned by external force

Added disable stop switch function

In older firmware versions, the position counter sometimes looses a

step, which may add up during longer motions to 1/1000 of total

count.

Table 6.2: Firmware Revision

7 References

[TMCL] TMCL Manual, www.trinamic.com

TMCM BLDC Module Reference and Programming Manual, www.trinamic.com

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

Loading...

Loading...