Page 1

1-Axis Stepper

Controller / Driver

2 A / 24 V

sensOstep™ Encoder

USB, RS485, and CAN

MODULE FOR STEPPER MOTORS MODULE

Firmware Version V1.19

TMCL™ FIRMWARE MANUAL

+

+ +

+

TMCM-1140

UNIQUE FEATURES:

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

www.trinamic.com

Page 2

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 2

Table of Contents

1 Features ........................................................................................................................................................................... 4

2 Putting the Module into Operation ........................................................................................................................ 6

2.1 Basic Set-Up .......................................................................................................................................................... 6

2.1.1 Start the TMCL-IDE Software Development Environment ................................................................. 8

2.2 Using TMCL Direct Mode .................................................................................................................................... 9

2.2.1 Important Motor Settings ......................................................................................................................... 10

2.3 Testing with a Simple TMCL Program ......................................................................................................... 11

3 TMCL and the TMCL-IDE: Introduction ................................................................................................................. 12

3.1 Binary Command Format ................................................................................................................................ 12

3.1.1 Checksum Calculation ................................................................................................................................ 13

3.2 Reply Format ....................................................................................................................................................... 13

3.2.1 Status Codes ................................................................................................................................................. 14

3.3 Standalone Applications .................................................................................................................................. 14

3.4 TMCL Command Overview .............................................................................................................................. 15

3.4.1 TMCL Commands ......................................................................................................................................... 15

3.4.2 Commands Listed According to Subject Area .................................................................................... 16

3.5 The ASCII Interface ........................................................................................................................................... 20

3.5.1 Format of the Command Line ................................................................................................................. 20

3.5.2 Format of a Reply ....................................................................................................................................... 20

3.5.3 Configuring the ASCII Interface ............................................................................................................. 21

3.6 Commands ........................................................................................................................................................... 22

3.6.1 ROR (rotate right) ....................................................................................................................................... 22

3.6.2 ROL (rotate left) ........................................................................................................................................... 23

3.6.3 MST (motor stop)......................................................................................................................................... 24

3.6.4 MVP (move to position) ............................................................................................................................ 25

3.6.5 SAP (set axis parameter) ........................................................................................................................... 27

3.6.6 GAP (get axis parameter) .......................................................................................................................... 28

3.6.7 STAP (store axis parameter) ..................................................................................................................... 29

3.6.8 RSAP (restore axis parameter) ................................................................................................................. 30

3.6.9 SGP (set global parameter) ...................................................................................................................... 31

3.6.10 GGP (get global parameter)...................................................................................................................... 32

3.6.11 STGP (store global parameter) ................................................................................................................ 33

3.6.12 RSGP (restore global parameter) ............................................................................................................ 34

3.6.13 RFS (reference search) ................................................................................................................................ 35

3.6.14 SIO (set output) ........................................................................................................................................... 36

3.6.15 GIO (get input/output) ............................................................................................................................... 38

3.6.16 CALC (calculate) ............................................................................................................................................ 40

3.6.17 COMP (compare)........................................................................................................................................... 41

3.6.18 JC (jump conditional) ................................................................................................................................. 42

3.6.19 JA (jump always) ......................................................................................................................................... 43

3.6.20 CSUB (call subroutine) ............................................................................................................................... 44

3.6.21 RSUB (return from subroutine) ................................................................................................................ 45

3.6.22 WAIT (wait for an event to occur) ......................................................................................................... 46

3.6.23 STOP (stop TMCL program execution) ................................................................................................... 47

3.6.24 SCO (set coordinate) ................................................................................................................................... 48

3.6.25 GCO (get coordinate) .................................................................................................................................. 49

3.6.26 CCO (capture coordinate) .......................................................................................................................... 50

3.6.27 ACO (accu to coordinate) .......................................................................................................................... 51

3.6.28 CALCX (calculate using the X register) .................................................................................................. 52

3.6.29 AAP (accumulator to axis parameter) .................................................................................................... 53

3.6.30 AGP (accumulator to global parameter) ............................................................................................... 54

3.6.31 CLE (clear error flags) ................................................................................................................................. 55

3.6.32 VECT (set interrupt vector) ........................................................................................................................ 56

3.6.33 EI (enable interrupt) ................................................................................................................................... 57

3.6.34 DI (disable interrupt) .................................................................................................................................. 58

3.6.35 RETI (return from interrupt) ..................................................................................................................... 59

www.trinamic.com

Page 3

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 3

3.6.36 Customer Specific TMCL Command Extension (UF0… UF7 / User Function) ............................... 60

3.6.37 Request Target Position Reached Event ............................................................................................... 60

3.6.38 TMCL Control Functions ............................................................................................................................. 61

4 Axis Parameters .......................................................................................................................................................... 63

4.1 stallGuard2 ........................................................................................................................................................... 70

4.2 coolStep Related Axis Parameters ................................................................................................................ 70

5 Global Parameters ...................................................................................................................................................... 72

5.1 Bank 0 ................................................................................................................................................................... 72

5.2 Bank 1 ................................................................................................................................................................... 74

5.3 Bank 2 ................................................................................................................................................................... 74

5.4 Bank 3 ................................................................................................................................................................... 75

6 Hints and Tips ............................................................................................................................................................. 76

6.1 Reference Search ............................................................................................................................................... 76

6.2 Changing the Prescaler Value of an Encoder ............................................................................................ 79

6.3 Using the RS485 Interface .............................................................................................................................. 80

7 TMCL Programming Techniques and Structure ................................................................................................. 81

7.1 Initialization ........................................................................................................................................................ 81

7.2 Main Loop ............................................................................................................................................................ 81

7.3 Using Symbolic Constants .............................................................................................................................. 81

7.4 Using Variables .................................................................................................................................................. 82

7.5 Using Subroutines ............................................................................................................................................. 82

7.6 Mixing Direct Mode and Standalone Mode ................................................................................................ 83

8 Life Support Policy ..................................................................................................................................................... 84

9 Revision History .......................................................................................................................................................... 85

9.1 Firmware Revision ............................................................................................................................................ 85

9.2 Document Revision ........................................................................................................................................... 85

10 References .................................................................................................................................................................... 85

www.trinamic.com

Page 4

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 4

1 Features

The TMCM-1140 is a single axis controller/driver module for 2-phase bipolar stepper motors with state of

the art feature set. It is highly integrated, offers a convenient handling and can be used in many

decentralized applications. The module can be mounted on the back of NEMA 17 (42mm flange size)

stepper motors and has been designed for coil currents up to 2 A RMS and 24 V DC supply voltage. With its

high energy efficiency from TRINAMIC’s coolStep™ technology cost for power consumption is kept down. The

TMCL™ firmware allows for both, standalone operation and direct mode.

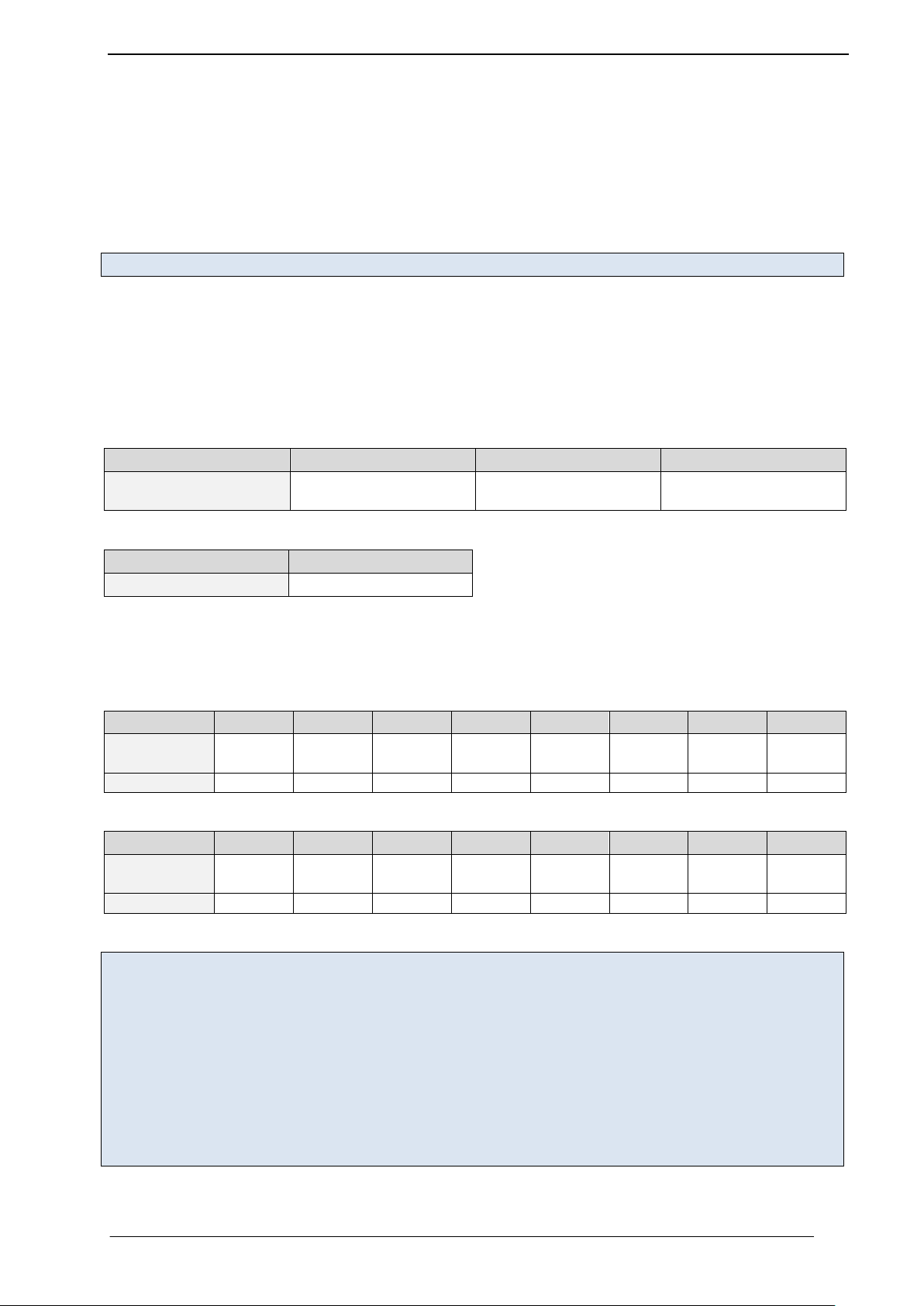

MAIN CHARACTERISTICS

Motion controller

- Motion profile calculation in real-time

- On the fly alteration of motor parameters (e.g. position, velocity, acceleration)

- High performance microcontroller for overall system control and serial communication protocol

handling

Bipolar stepper motor driver

- Up to 256 microsteps per full step

- High-efficient operation, low power dissipation

- Dynamic current control

- Integrated protection

- stallGuard2 feature for stall detection

- coolStep feature for reduced power consumption and heat dissipation

Encoder

- sensOstep magnetic encoder (1024 increments per rotation) e.g. for step-loss detection under all

operating conditions and positioning supervision

Interfaces

- RS485 2-wire communication interface

- CAN 2.0B communication interface

- USB full speed (12Mbit/s) device interface

- 4 multipurpose inputs:

- 3x general-purpose digital inputs

(Alternate functions: STOP_L / STOP_R / HOME switch inputs or A/B/N encoder input)

- 1x dedicated analog input

- 2 general purpose outputs

- 1x open-drain 1A max.

- 1x +5V supply output (can be switched on/off in software)

Software

- TMCL: standalone operation or remote controlled operation,

program memory (non volatile) for up to 2048 TMCL commands, and

PC-based application development software TMCL-IDE available for free.

Electrical and mechanical data

- Supply voltage: +24 V DC nominal (9… 28 V DC)

- Motor current: up to 2 A RMS / 2.8 A peak (programmable)

Refer to separate Hardware Manual, too.

www.trinamic.com

Page 5

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 5

Load

[Nm]

stallGuard2

Initial stallGuard2

(SG) value: 100%

Max. load

stallGuard2 (SG) value: 0

Maximum load reached.

Motor close to stall.

Motor stalls

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

0 50 100 150 200 250 300 350

Efficiency

Velocity [RPM]

Efficiency with coolStep

Efficiency with 50% torque reserve

TRINAMICS UNIQUE FEATURES – EASY TO USE WITH TMCL

stallGuard2™ stallGuard2 is a high-precision sensorless load measurement using the back EMF on the

coils. It can be used for stall detection as well as other uses at loads below those which

stall the motor. The stallGuard2 measurement value changes linearly over a wide range of

load, velocity, and current settings. At maximum motor load, the value goes to zero or

near to zero. This is the most energy-efficient point of operation for the motor.

Figure 1.1 stallGuard2 load measurement SG as a function of load

coolStep™ coolStep is a load-adaptive automatic current scaling based on the load measurement via

stallGuard2 adapting the required current to the load. Energy consumption can be reduced

by as much as 75%. coolStep allows substantial energy savings, especially for motors

which see varying loads or operate at a high duty cycle. Because a stepper motor

application needs to work with a torque reserve of 30% to 50%, even a constant-load

application allows significant energy savings because coolStep automatically enables

torque reserve when required. Reducing power consumption keeps the system cooler,

increases motor life, and allows reducing cost.

www.trinamic.com

Figure 1.2 Energy efficiency example with coolStep

Page 6

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 6

In/Out

Interface

USB

Motor

1

Motor

1

USB

Serial USB

interface

Converter

e.g. USB-2-485

USB

RS

485

CAN

Converter

e.g. USB-2-X

CAN

Pin 6 CAN_L

Pin 5 CAN_H

Pin 1 GND

RS485

Pin 4 RS485Pin 3 RS485+

Pin 1 GND

Power supply

Pin 2 9… 28V DC

Pin 1 GND

Note, that the

GND pin has to

be used for

power supply

and for the

interfaces also.

PRECAUTIONS

Do not connect or disconnect the TMCM-1140 while powered!

Do not connect or disconnect the motor while powered!

Do not exceed the maximum power supply voltage of 28 V DC!

Note, that the module is not protected against reverse polarity!

START WITH POWER SUPPLY OFF!

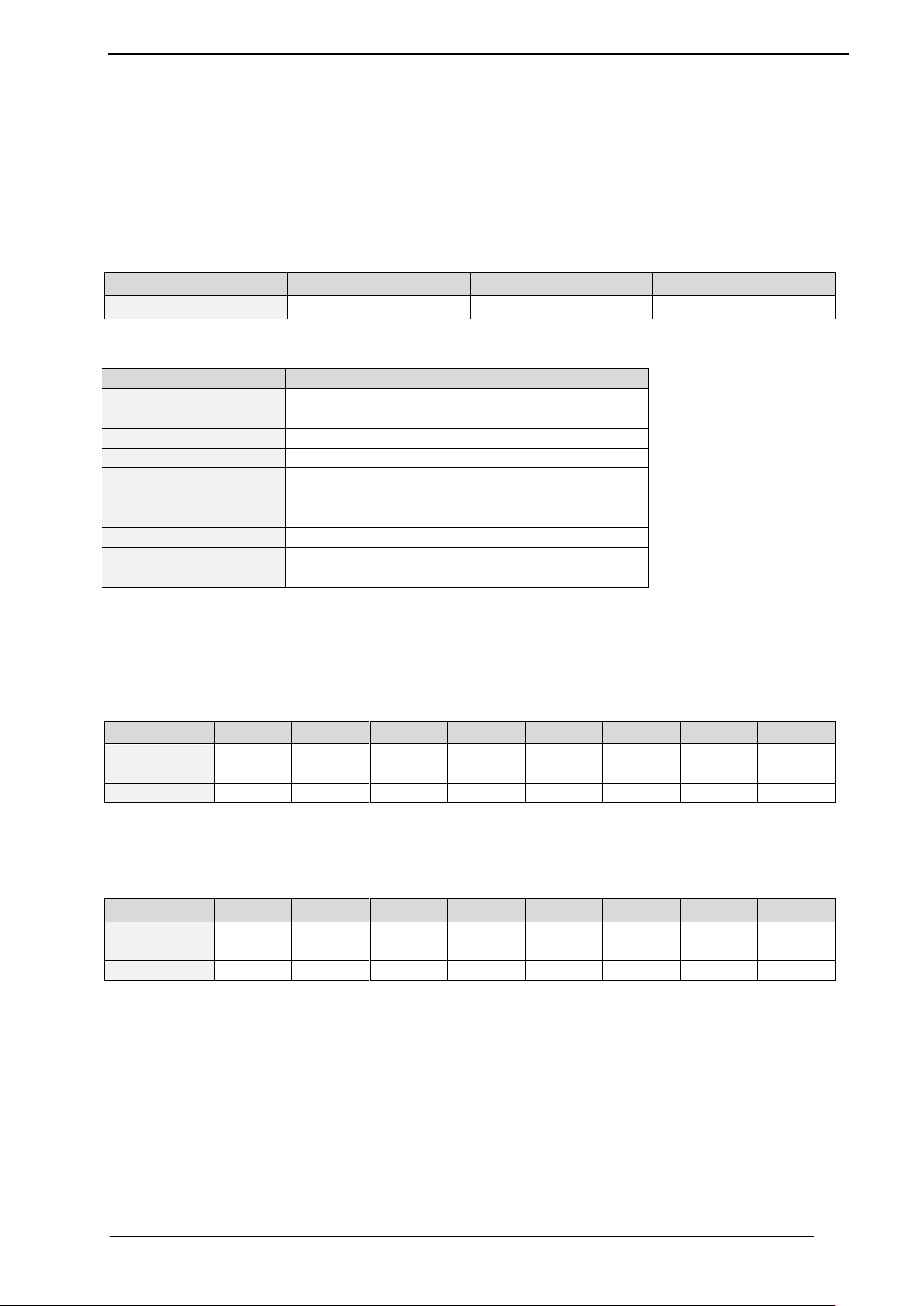

2 Putting the Module into Operation

Here you can find basic information for putting your TMCM-1140 into operation. If you are already common

with TRINAMICs modules you may skip this chapter.

The things you need:

- TMCM-1140

- Interface (RS485/CAN/USB) suitable to your module with cables

- Nominal supply voltage +24V DC for your module

- TMCL-IDE program and PC

- Stepper motor

2.1 Basic Set-Up

The following paragraph will guide you through the steps of connecting the unit and making first

movements with the motor.

CONNECTING THE MODULE

Figure 2.1: Starting up

www.trinamic.com

Page 7

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 7

Pin

Label

Description

1

GND

System and signal ground

2

VDD

VDD (+9V…+28V)

3

RS485+

RS485 interface, diff. signal (non-inverting)

4

RS485-

RS485 interface, diff. signal (inverting)

5

CAN_H

CAN interface, diff. signal (non-inverting)

6

CAN_L

CAN interface, diff. signal (inverting)

Pin

Label

Description

1

VBUS

+5V power

2

D-

Data –

3

D+

Data +

4

ID

ground

5

GND

ground

Pin

Label

Description

1

GND

System and signal ground

2

VDD

VDD, connected to VDD pin of the power and communication connector

3

OUT_1

Open-drain output (max. 1A)

Integrated freewheeling diode to VDD

4

OUT_0

+5V supply output (max. 100mA)

Can be switched on/off in software

5

AIN_0

Dedicated analog input,

Input voltage range: 0..+10V

Resolution: 12bit (0..4095)

6

IN_0,

STOP_L,

ENC_A

General purpose digital input (+24V compatible)

Alternate function 1: left stop switch input

Alternate function 2: external incremental encoder channel A input

7

IN_1,

STOP_R,

ENC_B

General purpose digital input (+24V compatible)

Alternate function 1: right stop switch input

Alternate function 2: external incremental encoder channel B input

8

IN_2,

HOME,

ENC_N

General purpose digital input (+24V compatible)

Alternate function 1: home switch input

Alternate function 2: external incremental encoder index / zero channel input

Pin

Label

Description

1

OB2

Pin 2 of motor coil B

2

OB1

Pin 1 of motor coil B

3

OA2

Pin 2 of motor coil A

4

OA1

Pin 1 of motor coil A

1. Connect power supply and choose your interface

a) Connect CAN or RS485 and power supply

CAN interface will be de-activated in case USB is connected due to internal sharing of hardware

resources.

b) Connect USB interface (as alternative to CAN and RS485; use a normal USB cable)

Download and install the file TMCM-1140.inf (www.trinamic.com).

2. Connect In/Out connector

If you like to work with the GPIOs or switches, use the In/Out connector.

3. Connect the motor

www.trinamic.com

Page 8

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 8

4. Switch ON the power supply

Turn power ON. The green LED for power lights up and the motor is powered but in standstill

now.

If this does not occur, switch power OFF and check your connections as well as the power

supply.

2.1.1 Start the TMCL-IDE Software Development Environment

The TMCL-IDE is available on www.trinamic.com.

Installing the TMCL-IDE:

Make sure the COM port you intend to use is not blocked by another program.

Open TMCL-IDE by clicking TMCL.exe.

Choose Setup and Options and thereafter the Connection tab.

Choose COM port and type with the parameters shown in Figure 2.2 (baud rate 9600). Click OK.

USB interface

If the file TMCM-1140.inf is installed correctly, the module will be identified automatically.

Figure 2.2 Setup dialogue and connection tab of the TMCL-IDE.

Please refer to the TMCL-IDE User Manual for more information (see www.TRINAMIC.com).

www.trinamic.com

Page 9

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 9

Direct Mode

2.2 Using TMCL Direct Mode

1. Start TMCL Direct Mode.

2. If the communication is established the TMCM-1140 is automatically detected. If the module is not

detected, please check all points above (cables, interface, power supply, COM port, baud rate).

3. Issue a command by choosing Instruction, Type (if necessary), Motor, and Value and click

Execute to send it to the module.

Examples:

- ROR rotate right, motor 0, value 500 -> Click Execute. The motor is rotating now.

- MST motor stop, motor 0 -> Click Execute. The motor stops now.

Top right of the TMCL Direct Mode window is the button Copy to editor. Click here to copy the chosen

command and create your own TMCL program. The command will be shown immediately on the editor.

Note:

Chapter 4 of this manual (axis parameters) includes a diagram which points out the coolStep related axis

parameters and their functions.

www.trinamic.com

Page 10

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 10

Number

Axis Parameter

Description

Range [Unit]

4

Maximum

positioning

speed

Should not exceed the physically highest possible

value. Adjust the pulse divisor (axis parameter 154), if

the speed value is very low (<50) or above the upper

limit.

0… 2047

5

Maximum

acceleration

The limit for acceleration (and deceleration). Changing

this parameter requires re-calculation of the

acceleration factor (no. 146) and the acceleration

divisor (no. 137), which is done automatically. See

TMC 429 datasheet for calculation of physical units.

0… 2047*1

6

Absolute max.

current

(CS / Current

Scale)

The maximum value is 255. This value means 100% of

the maximum current of the module. The current

adjustment is within the range 0… 255 and can be

adjusted in 32 steps.

The most important motor setting, since too high

values might cause motor damage!

0… 7

79…87

160… 167

240… 247

8… 15

88… 95

168… 175

248… 255

16… 23

96… 103

176… 183

24… 31

104… 111

184… 191

32… 39

112… 119

192… 199

40… 47

120… 127

200… 207

48… 55

128… 135

208… 215

56… 63

136… 143

216… 223

64… 71

144… 151

224… 231

72… 79

152… 159

232… 239

0… 255

7

Standby current

The current limit two seconds after the motor has

stopped.

0… 255

140

Microstep

resolution

0

full step

1

half step

2

4 microsteps

3

8 microsteps

4

16 microsteps

5

32 microsteps

6

64 microsteps

7

128 microsteps

8

256 microsteps

0… 8

Attention:

The most important motor setting is the absolute maximum motor current setting, since too high values

might cause motor damage!

2.2.1 Important Motor Settings

There are some axis parameters which have to be adjusted right in the beginning after installing your

module. Please set the upper limiting values for the speed (axis parameter 4), the acceleration (axis

parameter 5), and the current (axis parameter 6). Further set the standby current (axis parameter 7) and

choose your microstep resolution with axis parameter 140. Please use the SAP (Set Axis Parameter)

command for adjusting these values. The SAP command is described in paragraph 3.6.5. You can use the

TMCL-IDE direct mode for easily configuring your module.

IMPORTANT AXIS PARAMETERS FOR MOTOR SETTING

*1 Unit of acceleration:

www.trinamic.com

Page 11

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 11

Assemble

Download Run

Stop

ROL 0, 500 //Rotate motor 0 with speed 10000

WAIT TICKS, 0, 500

MST 0

ROR 0, 500 //Rotate motor 0 with 50000

WAIT TICKS, 0, 500

MST 0

SAP 4, 0, 500 //Set max. Velocity

SAP 5, 0, 50 //Set max. Acceleration

Loop: MVP ABS, 0, 10000 //Move to Position 10000

WAIT POS, 0, 0 //Wait until position reached

MVP ABS, 0, -10000 //Move to Position -10000

WAIT POS, 0, 0 //Wait until position reached

JA Loop //Infinite Loop

2.3 Testing with a Simple TMCL Program

Type in the following program:

1. Click the Assemble icon to convert the TMCL program into binary code.

2. Then download the program to the TMCM-1140 module by clicking the Download icon.

3. Click the Run icon. The desired program will be executed.

4. Click the Stop button to stop the program.

www.trinamic.com

Page 12

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 12

Bytes

Meaning

1

Module address

1

Command number

1

Type number

1

Motor or Bank number

4

Value (MSB first!)

1

Checksum

3 TMCL and the TMCL-IDE: Introduction

As with most TRINAMIC modules the software running on the microprocessor of the TMCM-1140 consists

of two parts, a boot loader and the firmware itself. Whereas the boot loader is installed during production

and testing at TRINAMIC and remains untouched throughout the whole lifetime, the firmware can be

updated by the user. New versions can be downloaded free of charge from the TRINAMIC website

(http://www.trinamic.com).

The TMCM-1140 supports TMCL direct mode (binary commands) and standalone TMCL program execution.

You can store up to 2048 TMCL instructions on it. In direct mode and most cases the TMCL communication

over RS485, CAN, or USB follows a strict master/slave relationship. That is, a host computer (e.g. PC/PLC)

acting as the interface bus master will send a command to the TMCM-1140. The TMCL interpreter on the

module will then interpret this command, do the initialization of the motion controller, read inputs and

write outputs or whatever is necessary according to the specified command. As soon as this step has been

done, the module will send a reply back over RS485/CAN/USB to the bus master. Only then should the

master transfer the next command. Normally, the module will just switch to transmission and occupy the

bus for a reply, otherwise it will stay in receive mode. It will not send any data over the interface without

receiving a command first. This way, any collision on the bus will be avoided when there are more than

two nodes connected to a single bus.

The Trinamic Motion Control Language [TMCL] provides a set of structured motion control commands.

Every motion control command can be given by a host computer or can be stored in an EEPROM on the

TMCM module to form programs that run standalone on the module. For this purpose there are not only

motion control commands but also commands to control the program structure (like conditional jumps,

compare and calculating).

Every command has a binary representation and a mnemonic. The binary format is used to send

commands from the host to a module in direct mode, whereas the mnemonic format is used for easy

usage of the commands when developing standalone TMCL applications using the TMCL-IDE (IDE means

Integrated Development Environment).

There is also a set of configuration variables for the axis and for global parameters which allow individual

configuration of nearly every function of a module. This manual gives a detailed description of all TMCL

commands and their usage.

3.1 Binary Command Format

Every command has a mnemonic and a binary representation. When commands are sent from a host to a

module, the binary format has to be used. Every command consists of a one-byte command field, a onebyte type field, a one-byte motor/bank field and a four-byte value field. So the binary representation of a

command always has seven bytes. When a command is to be sent via RS485 or USB interface, it has to be

enclosed by an address byte at the beginning and a checksum byte at the end. In this case it consists of

nine bytes.

This is different when communicating is via the CAN bus. Address and checksum are included in the CAN

standard and do not have to be supplied by the user.

The binary command format for R485/USB is as follows:

- The checksum is calculated by adding up all the other bytes using an 8-bit addition.

- When using CAN bus, just leave out the first byte (module address) and the last byte (checksum).

www.trinamic.com

Page 13

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 13

Bytes

Meaning

1

Reply address

1

Module address

1

Status (e.g. 100 means no error)

1

Command number

4

Value (MSB first!)

1

Checksum

3.1.1 Checksum Calculation

As mentioned above, the checksum is calculated by adding up all bytes (including the module address

byte) using 8-bit addition. Here are two examples to show how to do this:

- in C:

unsigned char i, Checksum;

unsigned char Command[9];

//Set the “Command” array to the desired command

Checksum = Command[0];

for(i=1; i<8; i++)

Checksum+=Command[i];

Command[8]=Checksum; //insert checksum as last byte of the command

//Now, send it to the module

- in Delphi:

var

i, Checksum: byte;

Command: array[0..8] of byte;

//Set the “Command” array to the desired command

//Calculate the Checksum:

Checksum:=Command[0];

for i:=1 to 7 do Checksum:=Checksum+Command[i];

Command[8]:=Checksum;

//Now, send the “Command” array (9 bytes) to the module

3.2 Reply Format

Every time a command has been sent to a module, the module sends a reply.

The reply format for RS485/ /USB is as follows:

- The checksum is also calculated by adding up all the other bytes using an 8-bit addition.

- When using CAN bus, just leave out the first byte (module address) and the last byte (checksum).

- Do not send the next command before you have received the reply!

www.trinamic.com

Page 14

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 14

Code

Meaning

100

Successfully executed, no error

101

Command loaded into TMCL

program EEPROM

1

Wrong checksum

2

Invalid command

3

Wrong type

4

Invalid value

5

Configuration EEPROM locked

6

Command not available

3.2.1 Status Codes

The reply contains a status code. The status code can have one of the following values:

3.3 Standalone Applications

The module is equipped with a TMCL memory for storing TMCL applications. You can use TMCL-IDE for

developing standalone TMCL applications. You can download a program into the EEPROM and afterwards it

will run on the module. The TMCL-IDE contains an editor and the TMCL assembler where the commands

can be entered using their mnemonic format. They will be assembled automatically into their binary

representations. Afterwards this code can be downloaded into the module to be executed there.

www.trinamic.com

Page 15

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 15

Command

Number

Parameter

Description

ROR

1

<motor number>, <velocity>

Rotate right with specified velocity

ROL

2

<motor number>, <velocity>

Rotate left with specified velocity

MST

3

<motor number>

Stop motor movement

MVP

4

ABS|REL|COORD, <motor number>,

<position|offset>

Move to position (absolute or relative)

SAP

5

<parameter>, <motor number>, <value>

Set axis parameter (motion control

specific settings)

GAP

6

<parameter>, <motor number>

Get axis parameter (read out motion

control specific settings)

STAP

7

<parameter>, <motor number>

Store axis parameter permanently (non

volatile)

RSAP

8

<parameter>, <motor number>

Restore axis parameter

SGP

9

<parameter>, <bank number>, value

Set global parameter (module specific

settings e.g. communication settings

or TMCL™ user variables)

GGP

10

<parameter>, <bank number>

Get global parameter (read out module

specific settings e.g. communication

settings or TMCL™ user variables)

STGP

11

<parameter>, <bank number>

Store global parameter (TMCL™ user

variables only)

RSGP

12

<parameter>, <bank number>

Restore global parameter (TMCL™ user

variable only)

RFS

13

START|STOP|STATUS, <motor number>

Reference search

SIO

14

<port number>, <bank number>, <value>

Set digital output to specified value

GIO

15

<port number>, <bank number>

Get value of analogue/digital input

CALC

19

<operation>, <value>

Process accumulator & value

COMP

20

<value>

Compare accumulator <-> value

JC

21

<condition>, <jump address>

Jump conditional

JA

22

<jump address>

Jump absolute

CSUB

23

<subroutine address>

Call subroutine

RSUB

24 Return from subroutine

EI

25

<interrupt number>

Enable interrupt

DI

26

<interrupt number>

Disable interrupt

WAIT

27

<condition>, <motor number>, <ticks>

Wait with further program execution

STOP

28 Stop program execution

SCO

30

<coordinate number>, <motor number>,

<position>

Set coordinate

GCO

31

<coordinate number>, <motor number>

Get coordinate

CCO

32

<coordinate number>, <motor number>

Capture coordinate

CALCX

33

<operation>

Process accumulator & X-register

AAP

34

<parameter>, <motor number>

Accumulator to axis parameter

AGP

35

<parameter>, <bank number>

Accumulator to global parameter

VECT

37

<interrupt number>, <label>

Set interrupt vector

RETI

38 Return from interrupt

ACO

39

<coordinate number>, <motor number>

Accu to coordinate

3.4 TMCL Command Overview

In this section a short overview of the TMCL commands is given.

3.4.1 TMCL Commands

www.trinamic.com

Page 16

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 16

Mnemonic

Command number

Meaning

ROL

2

Rotate left

ROR

1

Rotate right

MVP

4

Move to position

MST

3

Motor stop

RFS

13

Reference search

SCO

30

Store coordinate

CCO

32

Capture coordinate

GCO

31

Get coordinate

Mnemonic

Command number

Meaning

JA

22

Jump always

JC

21

Jump conditional

COMP

20

Compare accumulator with constant value

CSUB

23

Call subroutine

RSUB

24

Return from subroutine

WAIT

27

Wait for a specified event

STOP

28

End of a TMCL™ program

Mnemonic

Command number

Meaning

SIO

14

Set output

GIO

15

Get input

Mnemonic

Command number

Meaning

SAP

5

Set axis parameter

GAP

6

Get axis parameter

STAP

7

Store axis parameter into EEPROM

RSAP

8

Restore axis parameter from EEPROM

SGP

9

Set global parameter

GGP

10

Get global parameter

STGP

11

Store global parameter into EEPROM

RSGP

12

Restore global parameter from EEPROM

3.4.2 Commands Listed According to Subject Area

3.4.2.1 Motion Commands

These commands control the motion of the motor. They are the most important commands and can be

used in direct mode or in standalone mode.

3.4.2.2 Parameter Commands

These commands are used to set, read and store axis parameters or global parameters. Axis parameters

can be set independently for each axis, whereas global parameters control the behavior of the module

itself. These commands can also be used in direct mode and in standalone mode.

3.4.2.3 Control Commands

These commands are used to control the program flow (loops, conditions, jumps etc.). It does not make

sense to use them in direct mode. They are intended for standalone mode only.

3.4.2.4 I/O Port Commands

These commands control the external I/O ports and can be used in direct mode and in standalone mode.

www.trinamic.com

Page 17

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 17

Mnemonic

Command number

Meaning

CALC

19

Calculate using the accumulator and a constant value

CALCX

33

Calculate using the accumulator and the X register

AAP

34

Copy accumulator to an axis parameter

AGP

35

Copy accumulator to a global parameter

ACO

39

Copy accu to coordinate

Mnemonic

Command number

Meaning

EI

25

Enable interrupt

DI

26

Disable interrupt

VECT

37

Set interrupt vector

RETI

38

Return from interrupt

3.4.2.5 Calculation Commands

These commands are intended to be used for calculations within TMCL applications. Although they could

also be used in direct mode it does not make much sense to do so.

For calculating purposes there is an accumulator (or accu or A register) and an X register. When executed

in a TMCL program (in standalone mode), all TMCL commands that read a value store the result in the

accumulator. The X register can be used as an additional memory when doing calculations. It can be

loaded from the accumulator.

When a command that reads a value is executed in direct mode the accumulator will not be affected. This

means that while a TMCL program is running on the module (standalone mode), a host can still send

commands like GAP and GGP to the module (e.g. to query the actual position of the motor) without

affecting the flow of the TMCL™ program running on the module.

3.4.2.6 Interrupt Commands

Due to some customer requests, interrupt processing has been introduced in the TMCL firmware for ARM

based modules.

3.4.2.6.1 Interrupt Types

There are many different interrupts in TMCL, like timer interrupts, stop switch interrupts, position reached

interrupts, and input pin change interrupts. Each of these interrupts has its own interrupt vector. Each

interrupt vector is identified by its interrupt number. Please use the TMCL included file Interrupts.inc for

symbolic constants of the interrupt numbers.

3.4.2.6.2 Interrupt Processing

When an interrupt occurs and this interrupt is enabled and a valid interrupt vector has been defined for

that interrupt, the normal TMCL program flow will be interrupted and the interrupt handling routine will

be called. Before an interrupt handling routine gets called, the context of the normal program will be

saved automatically (i.e. accumulator register, X register, TMCL flags).

There is no interrupt nesting, i.e. all other interrupts are disabled while an interrupt handling routine is

being executed.

On return from an interrupt handling routine, the context of the normal program will automatically be

restored and the execution of the normal program will be continued.

www.trinamic.com

Page 18

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 18

Interrupt number

Interrupt type

0

Timer 0

1

Timer 1

2

Timer 2

3

(Target) position reached

15

Stall (stallGuard2)

21

Deviation

27

Stop left

28

Stop right

39

IN_0 change

40

IN_1 change

255

Global interrupts

3.4.2.6.3 Interrupt Vectors

The following table shows all interrupt vectors that can be used.

3.4.2.6.4 Further Configuration of Interrupts

Some interrupts need further configuration (e.g. the timer interval of a timer interrupt). This can be done

using SGP commands with parameter bank 3 (SGP <type>, 3, <value>). Please refer to the SGP command

(paragraph 3.6.9) for further information about that.

3.4.2.6.5 Using Interrupts in TMCL

For using an interrupt proceed as follows:

- Define an interrupt handling routine using the VECT command.

- If necessary, configure the interrupt using an SGP <type>, 3, <value> command.

- Enable the interrupt using an EI <interrupt> command.

- Globally enable interrupts using an EI 255 command.

- An interrupt handling routine must always end with a RETI command

EXAMPLE FOR THE USE OF A TIMER INTERRUPT:

VECT 0, Timer0Irq //define the interrupt vector

SGP 0, 3, 1000 //configure the interrupt: set its period to 1000ms

EI 0 //enable this interrupt

EI 255 //globally switch on interrupt processing

//Main program: toggles output 3, using a WAIT command for the delay

Loop:

SIO 3, 2, 1

WAIT TICKS, 0, 50

SIO 3, 2, 0

WAIT TICKS, 0, 50

JA Loop

//Here is the interrupt handling routine

Timer0Irq:

GIO 0, 2 //check if OUT0 is high

JC NZ, Out0Off //jump if not

SIO 0, 2, 1 //switch OUT0 high

RETI //end of interrupt

Out0Off:

SIO 0, 2, 0 //switch OUT0 low

RETI //end of interrupt

www.trinamic.com

Page 19

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 19

In the example above, the interrupt numbers are used directly. To make the program better readable use

the provided include file Interrupts.inc. This file defines symbolic constants for all interrupt numbers which

can be used in all interrupt commands. The beginning of the program above then looks like the following:

#include Interrupts.inc

VECT TI_TIMER0, Timer0Irq

SGP TI_TIMER0, 3, 1000

EI TI_TIMER0

EI TI_GLOBAL

Please also take a look at the other example programs.

www.trinamic.com

Page 20

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 20

3.5 The ASCII Interface

There is also an ASCII interface that can be used to communicate with the module and to send some

commands as text strings.

THE FOLLOWING COMMANDS CAN BE USED IN ASCII MODE:

ROL, ROR, MST, MVP, SAP, GAP, STAP, RSAP, SGP, GGP, STGP, RSGP, RFS, SIO, GIO, SCO, GCO, CCO, UF0, UF1,

UF2, UF3, UF4, UF5, UF6, and UF7.

Note:

Only direct mode commands can be entered in ASCII mode!

SPECIAL COMMANDS WHICH ARE ONLY AVAILABLE IN ASCII MODE:

- BIN: This command quits ASCII mode and returns to binary TMCL™ mode.

- RUN: This command can be used to start a TMCL™ program in memory.

- STOP: Stops a running TMCL™ application.

ENTERING AND LEAVING ASCII MODE:

1. The ASCII command line interface is entered by sending the binary command 139 (enter ASCII mode).

2. Afterwards the commands are entered as in the TMCL-IDE.

3. For leaving the ASCII mode and re-enter the binary mode enter the command BIN.

3.5.1 Format of the Command Line

As the first character, the address character has to be sent. The address character is A when the module

address is 1, B for modules with address 2 and so on. After the address character there may be spaces

(but this is not necessary). Then, send the command with its parameters. At the end of a command line a

<CR> character has to be sent.

EXAMPLES FOR VALID COMMAND LINES:

AMVP ABS, 1, 50000

A MVP ABS, 1, 50000

AROL 2, 500

A MST 1

ABIN

The command lines above address the module with address 1. To address e.g. module 3, use address

character C instead of A. The last command line shown above will make the module return to binary

mode.

3.5.2 Format of a Reply

After executing the command the module sends back a reply in ASCII format.

The reply consists of:

- the address character of the host (host address that can be set in the module)

- the address character of the module

- the status code as a decimal number

- the return value of the command as a decimal number

- a <CR> character

So, after sending AGAP 0, 1 the reply would be BA 100 –5000 if the actual position of axis 1 is –5000, the

host address is set to 2 and the module address is 1. The value 100 is the status code 100 that means

command successfully executed.

www.trinamic.com

Page 21

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 21

3.5.3 Configuring the ASCII Interface

The module can be configured so that it starts up either in binary mode or in ASCII mode. Global

parameter 67 is used for this purpose (please see also chapter 5.1).

Bit 0 determines the startup mode: if this bit is set, the module starts up in ASCII mode, else it will start

up in binary mode (default).

Bit 4 and Bit 5 determine how the characters that are entered are echoed back. Normally, both bits are set

to zero. In this case every character that is entered is echoed back when the module is addressed.

Character can also be erased using the backspace character (press the backspace key in a terminal

program).

When bit 4 is set and bit 5 is clear the characters that are entered are not echoed back immediately but

the entire line will be echoed back after the <CR> character has been sent.

When bit 5 is set and bit 4 is clear there will be no echo, only the reply will be sent. This may be useful in

RS485 systems.

www.trinamic.com

Page 22

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 22

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

1

(don't care)

0*

<velocity>

0… 2047

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$01

$00

$00

$00

$00

$01

$5e

3.6 Commands

The module specific commands are explained in more detail on the following pages. They are listed

according to their command number.

3.6.1 ROR (rotate right)

With this command the motor will be instructed to rotate with a specified velocity in right direction

(increasing the position counter).

Internal function: First, velocity mode is selected. Then, the velocity value is transferred to axis parameter

#0 (target velocity).

The module is based on the TMC429 stepper motor controller and the TMC262 power driver. This makes

possible choosing a velocity between 0 and 2047.

Related commands: ROL, MST, SAP, GAP

Mnemonic: ROR 0, <velocity>

Binary representation:

*motor number is always O as only one motor is involved

Reply in direct mode:

Example:

Rotate right, velocity = 350

Mnemonic: ROR 0, 350

Binary:

www.trinamic.com

Page 23

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 23

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

2

(don't care)

0*

<velocity>

0… 2047

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$02

$00

$00

$00

$00

$04

$b0

3.6.2 ROL (rotate left)

With this command the motor will be instructed to rotate with a specified velocity (opposite direction

compared to ROR, decreasing the position counter).

Internal function: First, velocity mode is selected. Then, the velocity value is transferred to axis parameter

#0 (target velocity).

The module is based on the TMC429 stepper motor controller and the TMC262 power driver. This makes

possible choosing a velocity between 0 and 2047.

Related commands: ROR, MST, SAP, GAP

Mnemonic: ROL 0, <velocity>

Binary representation:

*motor number is always O as only one motor is involved

Reply in direct mode:

Example:

Rotate left, velocity = 1200

Mnemonic: ROL 0, 1200

Binary:

www.trinamic.com

Page 24

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 24

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

3

(don't care)

0*

(don't care)

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$03

$00

$00

$00

$00

$00

$00

3.6.3 MST (motor stop)

With this command the motor will be instructed to stop with a soft stop.

Internal function: The axis parameter target velocity is set to zero.

Related commands: ROL, ROR, SAP, GAP

Mnemonic: MST 0

Binary representation:

*motor number is always O as only one motor is involved

Reply in direct mode:

Example:

Stop motor

Mnemonic: MST 0

Binary:

www.trinamic.com

Page 25

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 25

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

4

0 ABS – absolute

0*

<position>

1 REL – relative

0

<offset>

2 COORD – coordinate

0

<coordinate number>

(0… 20)

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$04

$00

$00

$00

$01

$5f

$90

3.6.4 MVP (move to position)

With this command the motor will be instructed to move to a specified relative or absolute position. It

will use the acceleration/deceleration ramp and the positioning speed programmed into the unit. This

command is non-blocking – that is, a reply will be sent immediately after command interpretation and

initialization of the motion controller. Further commands may follow without waiting for the motor

reaching its end position. The maximum velocity and acceleration are defined by axis parameters #4 and

#5.

The range of the MVP command is 32 bit signed (−2.147.483.648… +2.147.483.647). Positioning can be

interrupted using MST, ROL or ROR commands.

THREE OPERATION TYPES ARE AVAILABLE:

- Moving to an absolute position in the range from −2.147.483.648… +2.147.483.647 (-2

- Starting a relative movement by means of an offset to the actual position. In this case, the new

resulting position value must not exceed the above mentioned limits, too.

- Moving the motor to a (previously stored) coordinate (refer to SCO for details).

Please note, that the distance between the actual position and the new one should not be more than

2.147.483.647 (231-1) microsteps. Otherwise the motor will run in the opposite direction in order to take the

shorter distance.

Internal function: A new position value is transferred to the axis parameter #2 target position”.

Related commands: SAP, GAP, SCO, CCO, GCO, MST

Mnemonic: MVP <ABS|REL|COORD>, 0, <position|offset|coordinate number>

Binary representation:

31

… 231-1).

*motor number is always O as only one motor is involved

Reply in direct mode:

Example:

Move motor to (absolute) position 90000

Mnemonic: MVP ABS, 0, 9000

Binary:

www.trinamic.com

Page 26

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 26

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instructio

n

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$04

$01

$00

$ff

$ff

$fc

$18

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$04

$02

$00

$00

$00

$00

$08

Example:

Move motor from current position 1000 steps backward (move relative –1000)

Mnemonic: MVP REL, 0, -1000

Binary:

Example:

Move motor to previously stored coordinate #8

Mnemonic: MVP COORD, 0, 8

Binary:

When moving to a coordinate, the coordinate has to be set properly in advance with the help of the

SCO, CCO or ACO command.

www.trinamic.com

Page 27

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 27

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

5

<parameter number>

0*

<value>

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$05

$06

$00

$00

$00

$00

$c8

3.6.5 SAP (set axis parameter)

With this command most of the motion control parameters of the module can be specified. The settings

will be stored in SRAM and therefore are volatile. That is, information will be lost after power off.

Please use command STAP (store axis parameter) in order to store any setting permanently.

For a table with parameters and values which can be used together with this command please refer to

chapter 4.

Internal function: The parameter format is converted ignoring leading zeros (or ones for negative values).

The parameter is transferred to the correct position in the appropriate device.

Related commands: GAP, STAP, RSAP, AAP

Mnemonic: SAP <parameter number>, 0, <value>

Binary representation:

*motor number is always O as only one motor is involved

Reply in direct mode:

Example:

Set the absolute maximum current of motor to 200mA

Mnemonic: SAP 6, 0, 200

Binary:

www.trinamic.com

Page 28

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 28

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

6

<parameter number>

0*

(don't care)

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$06

$01

$00

$00

$00

$00

$00

Byte Index

0 1 2 3 4 5 6

7

Function

Host-

address

Target-

address

Status

Instructio

n

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$02

$01

$64

$06

$00

$00

$02

$c7

3.6.6 GAP (get axis parameter)

Most parameters of the TMCM-1140 can be adjusted individually for the axis. With this parameter they can

be read out. In standalone mode the requested value is also transferred to the accumulator register for

further processing purposes (such as conditioned jumps). In direct mode the value read is only output in

the value field of the reply (without affecting the accumulator).

For a table with parameters and values which can be used together with this command please refer to

chapter 4.

Internal function: The parameter is read out of the correct position in the appropriate device. The

parameter format is converted adding leading zeros (or ones for negative values).

Related commands: SAP, STAP, AAP, RSAP

Mnemonic: GAP <parameter number>, 0

Binary representation:

*motor number is always O as only one motor is involved

Reply in direct mode:

Example:

Get the actual position of motor

Mnemonic: GAP 0, 1

Binary:

Reply:

status=no error, position=711

www.trinamic.com

Page 29

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 29

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

7

<parameter number>

0*1

(don't care)*2

STATUS

VALUE

100 – OK

(don't care)

Parameter number

Motor number

Value

s. chapter 4

0

s. chapter 4

Byte Index

0 1 2 3 4 5 6

7

Function

Targetaddress

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$07

$04

$00

$00

$00

$00

$00

3.6.7 STAP (store axis parameter)

An axis parameter previously set with a Set Axis Parameter command (SAP) will be stored permanent. Most

parameters are automatically restored after power up (refer to axis parameter list in chapter 4).

For a table with parameters and values which can be used together with this command please refer to

chapter 4.

Internal function: An axis parameter value stored in SRAM will be transferred to EEPROM and loaded from

EEPORM after next power up.

Related commands: SAP, RSAP, GAP, AAP

Mnemonic: STAP <parameter number>, 0

Binary representation:

*1motor number is always O as only one motor is involved

*2the value operand of this function has no effect. Instead, the currently used value (e.g. selected by SAP) is saved.

Reply in direct mode:

Parameter ranges:

Example:

Store the maximum speed of motor

Mnemonic: STAP 4, 0

Binary:

Note:

The STAP command will not have any effect when the configuration EEPROM is locked (refer to 5.1). In

direct mode, the error code 5 (configuration EEPROM locked, see also section 3.2.1) will be returned in this

case.

www.trinamic.com

Page 30

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 30

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

8

<parameter number>

0*

(don't care)

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Targetaddress

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$08

$06

$00

$00

$00

$00

$00

3.6.8 RSAP (restore axis parameter)

For all configuration-related axis parameters non-volatile memory locations are provided. By default, most

parameters are automatically restored after power up (refer to axis parameter list in chapter 4). A single

parameter that has been changed before can be reset by this instruction also.

For a table with parameters and values which can be used together with this command please refer to

chapter 4.

Internal function: The specified parameter is copied from the configuration EEPROM memory to its RAM

location.

Relate commands: SAP, STAP, GAP, and AAP

Mnemonic: RSAP <parameter number>, 0

Binary representation:

*motor number is always O as only one motor is involved

Reply structure in direct mode:

Example:

Restore the maximum current of motor

Mnemonic: RSAP 6, 0

Binary:

www.trinamic.com

Page 31

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 31

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

9

<parameter number>

<bank number>

<value>

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Targetaddress

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$09

$42

$00

$00

$00

$00

$03

3.6.9 SGP (set global parameter)

With this command most of the module specific parameters not directly related to motion control can be

specified and the TMCL user variables can be changed. Global parameters are related to the host interface,

peripherals or application specific variables. The different groups of these parameters are organized in

banks to allow a larger total number for future products. Currently, only bank 0 and 1 are used for global

parameters, and bank 2 is used for user variables. Bank 3 is used for interrupt configuration.

All module settings will automatically be stored non-volatile (internal EEPROM of the processor). The

TMCL user variables will not be stored in the EEPROM automatically, but this can be done by using

STGP commands.

For a table with parameters and bank numbers which can be used together with this command please

refer to chapter 5.

Internal function: the parameter format is converted ignoring leading zeros (or ones for negative values).

The parameter is transferred to the correct position in the appropriate (on board) device.

Related commands: GGP, STGP, RSGP, AGP

Mnemonic: SGP <parameter number>, <bank number>, <value>

Binary representation:

Reply in direct mode:

Example:

Set the serial address of the target device to 3

Mnemonic: SGP 66, 0, 3

Binary:

www.trinamic.com

Page 32

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 32

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

10

(see chapter 6)

<bank number>

(don't care)

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$0a

$42

$00

$00

$00

$00

$00

Byte Index

0 1 2 3 4 5 6

7

Function

Host-

address

Target-

address

Status

Instructio

n

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$02

$01

$64

$0a

$00

$00

$00

$01

3.6.10 GGP (get global parameter)

All global parameters can be read with this function. Global parameters are related to the host interface,

peripherals or application specific variables. The different groups of these parameters are organized in

banks to allow a larger total number for future products. Currently, only bank 0 and 1 are used for global

parameters, and bank 2 is used for user variables. Bank 3 is used for interrupt configuration.

For a table with parameters and bank numbers which can be used together with this command please

refer to chapter 5.

Internal function: The parameter is read out of the correct position in the appropriate device. The

parameter format is converted adding leading zeros (or ones for negative values).

Related commands: SGP, STGP, RSGP, AGP

Mnemonic: GGP <parameter number>, <bank number>

Binary representation:

Reply in direct mode:

Example:

Get the serial address of the target device

Mnemonic: GGP 66, 0

Binary:

Reply:

Status=no error, Value=1

www.trinamic.com

Page 33

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 33

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

11

(see chapter 8)

<bank number>

(see chapter 5)

(don't care)

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$0b

$2a

$02

$00

$00

$00

$00

3.6.11 STGP (store global parameter)

This command is used to store TMCL user variables permanently in the EEPROM of the module. Some

global parameters are located in RAM memory, so without storing modifications are lost at power down.

This instruction enables enduring storing. Most parameters are automatically restored after power up.

For a table with parameters and bank numbers which can be used together with this command please

refer to chapter 5.

Internal function: The specified parameter is copied from its RAM location to the configuration EEPROM.

Related commands: SGP, GGP, RSGP, AGP

Mnemonic: STGP <parameter number>, <bank number>

Binary representation:

Reply in direct mode:

Example:

Store the user variable #42

Mnemonic: STGP 42, 2

Binary:

www.trinamic.com

Page 34

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 34

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

12

<parameter number>

<bank number>

(don't care)

STATUS

VALUE

100 – OK

(don't care)

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$0c

$2a

$02

$00

$00

$00

$00

3.6.12 RSGP (restore global parameter)

With this command the contents of a TMCL user variable can be restored from the EEPROM. By default,

most parameters are automatically restored after power up. A single parameter that has been changed

before can be reset by this instruction.

Internal function: the specified parameter is copied from the configuration EEPROM memory to its RAM

location.

Relate commands: SGP, STGP, GGP, and AGP

Mnemonic: RSAP <parameter number>, <bank number>

Binary representation:

Reply structure in direct mode:

For a table with parameters and bank numbers which can be used together with this command please

refer to chapter 5.

Example:

Restore user variable #42

Mnemonic: RSGP 42, 2

Binary:

www.trinamic.com

Page 35

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 35

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

13

0 START – start ref. search

1 STOP – abort ref. search

2 STATUS – get status

0

see below

STATUS

VALUE

100 – OK

don’t care

STATUS

VALUE

100 – OK

0

ref. search active

other values

no ref. search

active

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$0d

$00

$00

$00

$00

$00

$00

3.6.13 RFS (reference search)

The TMCM-1140 has a built-in reference search algorithm which can be used. The reference search

algorithm provides switching point calibration and three switch modes. The status of the reference search

can also be queried to see if it has already finished. (In a TMCL program it is better to use the WAIT

command to wait for the end of a reference search.) Please see the appropriate parameters in the axis

parameter table to configure the reference search algorithm to meet your needs (chapter 4). The reference

search can be started, stopped, and the actual status of the reference search can be checked.

Internal function: the reference search is implemented as a state machine, so interaction is possible

during execution.

Related commands: WAIT

Mnemonic: RFS <START|STOP|STATUS>, <motor>

Binary representation:

REPLY IN DIRECT MODE:

When using type 0 (START) or 1 (STOP):

When using type 2 (STATUS):

Example:

Start reference search of motor 0

Mnemonic: RFS START, 0

Binary:

With this module it is possible to use stall detection instead of a reference search.

www.trinamic.com

Page 36

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 36

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

14

<port number>

<bank number>

2

<value>

0/1

STATUS

VALUE

100 – OK

don’t care

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$0e

$07

$02

$00

$00

$00

$01

Multipurpose I/O

1

8

Pin

I/O port

Command

Range

4

OUT_0

SIO 0, 2, <n>

1/0

3

OUT_1

SIO 1, 2, <n>

1/0

3.6.14 SIO (set input / output)

- SIO sets the status of the general digital output either to low (0) or to high (1). Bank 2 is used for

this purpose.

- SIO is used to switch the pull-up resistors for all digital inputs ON (1) and OFF (0). Bank 0 is used

for this purpose.

Internal function: the passed value is transferred to the specified output line.

Related commands: GIO, WAIT

Mnemonic: SIO <port number>, <bank number>, <value>

Binary representation:

Bank 2 is used for setting the status of the general digital output either to low (0) or to high (1).

Reply structure:

Example:

Set OUT_7 to high (bank 2, output 7)

Mnemonic: SIO 7, 2, 1

Binary:

Figure 3.1 I/O connector

I/O PORTS USED FOR SIO AND COMMAND

www.trinamic.com

Page 37

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 37

Pin

I/O port

Command

Range

6

7

8

IN_0

IN_1

IN_2

SIO 0, 0, <n>

1/0

1: ON

0: OFF

ADDRESSING BOTH OUTPUT LINES WITH ONE SIO COMMAND:

- Set the type parameter to 255 and the bank parameter to 2.

- The value parameter must then be set to a value between 0… 255, where every bit represents one

output line.

- Furthermore, the value can also be set to -1. In this special case, the contents of the lower 8 bits

of the accumulator are copied to the output pins.

Example:

Set all output pins high.

Mnemonic: SIO 255, 2, 3

THE FOLLOWING PROGRAM WILL SHOW THE STATES OF THE INPUT LINES ON THE OUTPUT LINES:

Loop: GIO 255, 0

SIO 255, 2,-1

JA Loop

SPECIAL COMMAND FOR SWITCHING THE PULL-UP RESISTORS FOR ALL THREE DIGITAL INPUTS ON / OFF

www.trinamic.com

Page 38

TMCM-1140 TMCL Firmware V1.19 Manual (Rev. 1.01 / 2012-JUL-27) 38

INSTRUCTION NO.

TYPE

MOT/BANK

VALUE

15

<port number>

<bank number>

don’t care

STATUS

VALUE

100 – OK

<status of the port>

Byte Index

0 1 2 3 4 5 6

7

Function

Target-

address

Instruction

Number

Type

Motor/

Bank

Operand

Byte3

Operand

Byte2

Operand

Byte1

Operand

Byte0

Value (hex)

$01

$0f

$00

$01

$00

$00

$00

$00

Byte Index

0 1 2 3 4 5 6