Page 1

EVALUATION FOR ICs EVALUATION BOARDS

V 1.00

EVAL BOARD MANUAL

+ +

Evaluation kit

for TMC429 and TMC24x

TMC429+TMC24x-EVAL

+ +

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

www.trinamic.com

Page 2

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 2

Table of Contents

1 Introduction ................................................................................................................................................................... 3

2 Quick start ....................................................................................................................................................................... 5

3 Hardware ......................................................................................................................................................................... 7

3.1 Connectors ............................................................................................................................................................. 7

3.2 Pin assignments of connectors ....................................................................................................................... 8

3.3 Motor drivers ......................................................................................................................................................... 8

3.4 Communication with PC .................................................................................................................................... 8

4 The PC software ............................................................................................................................................................ 9

4.1 The Main Window ............................................................................................................................................... 9

4.1.1 Example .......................................................................................................................................................... 10

4.2 The graphic display window .......................................................................................................................... 11

4.3 The register window ........................................................................................................................................ 12

4.3.1 Motor 1, motor 2, and motor 3 ............................................................................................................... 12

4.3.2 Global parameters ....................................................................................................................................... 12

4.3.3 RAM Table ...................................................................................................................................................... 13

4.4 The stallGuard™ window................................................................................................................................ 14

4.5 Calc429 program ................................................................................................................................................ 15

4.6 Eval429EEP program .......................................................................................................................................... 15

5 The stallGuard™ profiler .......................................................................................................................................... 16

5.1 Installation .......................................................................................................................................................... 16

5.2 Usage ..................................................................................................................................................................... 16

5.3 The result ............................................................................................................................................................. 17

5.4 Interpreting the result ..................................................................................................................................... 17

6 Revision history .......................................................................................................................................................... 18

6.1 Document revision ............................................................................................................................................ 18

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 3

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 3

1 Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent of

TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support or

sustain life, and whose failure to perform, when properly

used in accordance with instructions provided, can be

reasonably expected to result in personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2011

Information given in this data sheet is believed to be

accurate and reliable. However neither responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties,

which may result from its use.

Specifications are subject to change without notice.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 4

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 4

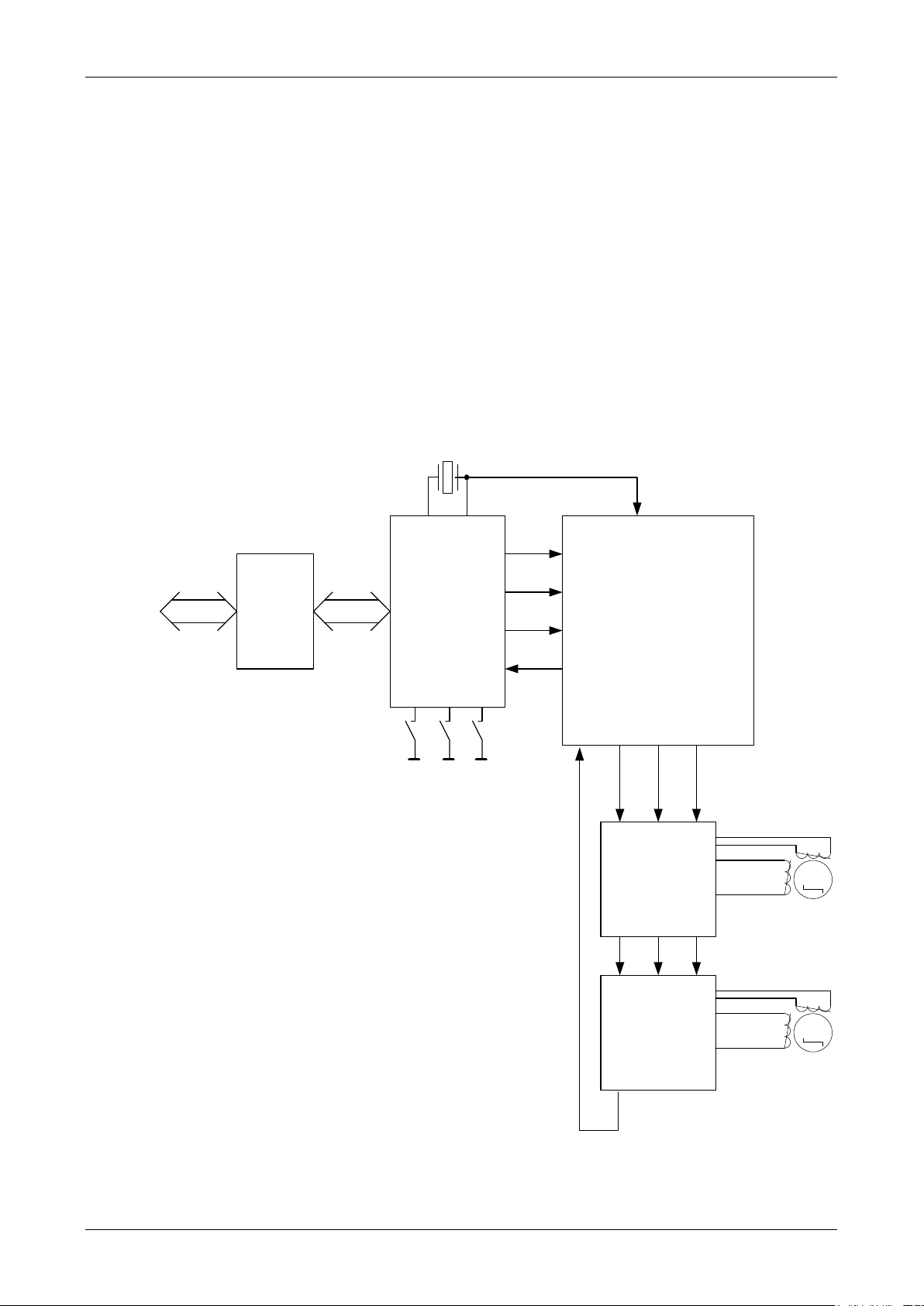

RS 232

(e.g . PC)

TMC 429

Microcontroller

ATmega8

RS 232

driver

( MAX 232)

8 MHz

Driver Motor 2

TMC 246

Driver Motor 1

TMC 249

( with external

FETs)

M

M

C L K

SCK _C

nSCS

_

C

SDI_ C

SDO_ C

S DI

_

S

S D O _ S

S C K _

S

nS C S _ S

2 Introduction

The TMC429+TMC24x evaluation kit makes it possible to evaluate and to test all functions of the TMC429.

It contains the following components:

The evaluation board is equipped with the TMC429 and three stepper motor drivers

A null-modem-cable for connecting the evaluation board to the PC

On the evaluation board the Atmel ATmega8 microprocessor is used to control the TMC429. The

microprocessor’s FLASH ROM contains a program which configures the TMC429 after a reset and controls the

communication with the PC via the RS232 interface. A software running under Windows enables access to

all the registers and functions of the TMC429 from a PC. Furthermore, some simple functions can be

controlled by keys on the evaluation board.

Up to two bipolar two-phase stepper motors can be connected.

Figure 2.1: The structure of the evaluation board

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 5

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 5

Order code

Description

Size of unit [mm3]

TMC429+TMC24x-EVAL

Evaluation board for TMC429, TMC246 and TMC249.

Null-modem-cable included

3 Order codes

Table 3.1: Order codes

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 6

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 6

RS232

ATmega8

µC

TMC-429

Power

Connector

Function Keys

Stepper Motor Connectors

Power

LED

MAX-202

GND

+U

STOP_L STOP_R MOVE1 STOPMOVE2

uC-DIS

EXTERN

428_SPI_IN

Stop Switch

Connector

TMC246

MOTOR2

TMC249

MOTOR1

RA

RB

428_SPI_OUT

INTERN

DRIVERS

4 Quick start

For a first quick start, connect at least one stepper motor to the connectors MOTOR1 or MOTOR2 (as shown

in Figure 5.1). Please note that the stepper motors may only be connected to or disconnected from the

evaluation board while the board is disconnected from power, as otherwise the motor drivers could

get damaged!

Now, connect a power supply of 10... 28V DC and at least 1A to the power connector. The positive pole is

marked +U. When the power supply is working, the power LED will light up. Also the other two LEDs near

the buttons will flash once after powering on.

Now the following functions can be used:

The MOVE1 key: After pressing the MOVE1 key, all motors start rotating using different

accelerations and velocities and the LED near this button lights up.

The STOP key: When the STOP key is pressed once, all motors will be decelerated using different

decelerations. If this key is pressed again while the motors are being decelerated all motors will

be stopped immediately.

The MOVE2 key: The functionality of this key is similar to that of the MOVE1 key, but the motors

rotate in the opposite directions and the LED near this button lights up.

The functions MOVE1 and MOVE2 are indicated by LEDs. It is also possible to press the other MOVE key

while the motors are running. The motors will be decelerated and then accelerated in the opposite

directions.

Figure 4.1: TMC429 evaluation board overview

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 7

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 7

Pin

Function

Pin

Function

1

SDO_C (TMC429)

2

uC-DISABLE

3

SDI_C (TMC429)

4

GND

5

SCS_C (TMC429)

6

GND

7

SCK_C (TMC429)

8

GND

9

+U (Motor Power)

10

+5V/+3.3V

Pin

Function

Pin

Function

1

SDO_S (TMC429)

2

uC-DISABLE

3

SDI_S (TMC429)

4

GND

5

SCS_S (TMC429)

6

GND

7

SCK_S (TMC429)

8

GND

9

+U (Motor Power)

10

+5V/+3.3V

5 Hardware

Please see also the schematics of the evaluation board (supplied as PDF files on www.trinamic.com) for a

better understanding of this description.

5.1 Connectors

The evaluation board is equipped with the following connectors:

RS232 (9-pin Sub-D plug): This is the RS232 interface for connection to a PC. The interface uses

19200 Baud, 8 data bits, no parity and one stop bit. Only the pins 2, 3 and 5 (RxD, TxD, GND) are

connected.

+U/GND: socket for power supply. The positive pole is marked +U. A diode protects the board

against wrong polarity. The voltage connected to it must not exceed 28 volts DC.

Reference switch connector: Every reference switch pin is pulled to ground by a 1k resistor. The

pin assignment of the connector is printed on the board.

MOTOR1 and MOTOR2: Stepper motor connectors. Motor #1 is driven by the TMC249 driver with

external power transistors and the other motor is driven by the TMC246 stepper motor driver.

ISP-PROG: Atmel ISP connector. This permits changing the microprocessor’s firmware using an

Atmel ISP.

Microcontroller disable jumper (uC-DIS): If this jumper is closed all functions of the

microcontroller are disabled and its SPI interface enters a high impedance state. This allows

connecting different microcontrollers to be connected to the board so that the TMC429 can also

be controlled with a different microcontroller. So for normal operation this jumper must be

open.

EXTERN/INTERN jumpers (pls. refer schematic J401, J402): Normally, these jumpers must be in the

INTERN setting (connecting the middle and the right pin). The other setting is needed to use the

428_SPI_OUT connector.

428_SPI_IN: Here, an external microcontroller can be connected to the TMC429. To use this

connector, close the microcontroller disable jumper. The pin assignment of this connector is as

follows:

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

428_SPI_OUT: The motor driver SPI interface of the TMC429 is connected here. So, other drivers

can be connected to the TMC429 using this connector. To make use of this feature, set the

EXTERN/INTERN jumpers to the EXTERn setting. The pin assignment of the 428_SPI_OUT

connector is as follows:

3V3: This jumper selects between 5V and 3.3V power for the microcontroller, the TMC429, the

TMC246 and the TMC249. If the jumper is open 5V will be used and if the jumper is closed 3.3V

will be used.

Page 8

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 8

M

OB2

OB1

OA2

OA1

5.2 Pin assignments of connectors

The pin assignment of each connector is marked on the board. Please connect the stepper motors to the

MOTOR1 and MOTOR2 connectors as shown in the drawing below (Figure 5.1).

Figure 5.1: How to connect a stepper motor

5.3 Motor drivers

The TMC429 evaluation board comes with two motor drivers: The Trinamic TMC246 and the Trinamic TMC249.

Both support 4-bit microstepping and stall detection. The difference is that the TMC249 uses external power

transistors and thus can drive motors with a coil current of more than 1.5A (on this board transistor for max

3A coil current are used).

The maximum coil current of the TMC249 can be selected using the jumpers RA and RB. It is 1.5A when they

are open and 3.0A when they are closed.

5.4 Communication with PC

The RS232 interface uses the following communication parameters: 19200 Baud, 8 data bits, no parity bit,

one stop bit. The evaluation board expects data telegrams which contain at least one command byte and,

depending on the command byte, some data bytes. Depending on the command byte, some data bytes will

be sent back as a response. There are the following command bytes (noted in hexadecimal):

$23: Send an SPI telegram to the TMC429. The evaluation board expects four data bytes which form the SPI

telegram that will be sent to the TMC429. The response from the evaluation board consists of four bytes

which contain the SPI telegram that has been sent back from the TMC429.

$45<address><data><checksum>(one byte each):Change the contents of the microprocessor’s EEPROM. The

EEPROM of the microprocessor contains 128 bytes which are copied to the configuration RAM of the TMC429

after each reset.

<Address> may be a value between 0 and 127. The following formula is used to calculate the checksum:

<Checksum>=(<Address>+<Data>) modulo 255

On success ACK ($06) will be sent back, otherwise NAK ($15) will be sent back.

$FF: The evaluation board will send a ten byte identification string, containing the firmware version number.

Data bytes are not expected by this command.

Examples:

Reading Motor #0 position register

Command from PC: $23 $03 $00 $00 $00

Response from evaluation board: $15 $00 $00 $00

Querying the identification string:

Command form PC: $FF

Response from evaluation board: EV428 V2.0

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 9

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 9

6 The PC software

The PC software supplied with the TMC429 evaluation kit is a program running under Windows

95/98/NT/2000 and allows access to all the registers of the TMC429. You can install the program simply by

downloading the file EVAL429.EXE from the TRINAMIC website www.trinamic.com. After that, the software

can be run simply by double clicking the file EVAL428.EXE.

Before starting the software, the evaluation board should be connected to an RS232 interface of your PC

using the null modem cable supplied with the evaluation kit.

6.1 The Main Window

After starting the software the main window will open up (Figure 6.1). First, select the interface to which

your evaluation board is connected and click the Open button. If the connection to the evaluation board

could be established successfully, the message The board is active will be displayed. If a message like The

board does not respond is displayed, please check the power supply and the connection to your PC again

.

Now, the TMC429 status register is displayed in the TMC429 status bits section. Using the controls in the

Motor 1, Motor 2 and Motor 3 sections, the motors can be run. Just enter all necessary parameters and click

the appropriate Go! button. You can stop a motor by clicking the appropriate Stop! button. Use the buttons

All Go! and All Stop to run or stop all motors simultaneously.

Figure 6.1: The main window

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 10

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 10

As the evaluation board is equipped with only two motor drivers, the Motor 3 section will have no effect

(but a third motor driver can be added to the board externally). Motor 1 is driven by the TMC249 and Motor

2 is driven by the TMC246.

First select the Ramp Mode first then fill in the other necessary parameters and last start the motor or all

motors. You will find an explanation of all parameters in the TMC429 data sheet and also in an example in

Chapter Fehler! Verweisquelle konnte nicht gefunden werden..

By clicking the TMC429 Registers button the register window opens and gives you access to every TMC429

register (Chapter 0). Click on the Graphics button to open the graphics window which displays the driving

ramps of all motors (Chapter 6.2).

6.1.1 Example

In this example it is assumed that a motor is connected to the MOTOR1 connector.

First, set the ramp mode of motor #1 to RAMP. Then enter the following parameters:

Target Position: 100000

Vmin: 1

Vmax: 500

Max Accel.: 150

Now click the appropriate Go! button. The motor will now be running until position

100000 is reached. After that, enter zero as Target Position and click the Go! button

again. The motor will run back to position zero. You can also try to change the

position on the fly, whilst the motor is running. Just enter a different position, click

the Go! button and see how the motor reacts. Also open the graphics window

(Chapter 6.2) and watch the ramps.

Now try also the other modes: The SOFTMODE is nearly similar to the RAMP mode, except that the motor

starts and stops softer. Please note, that in the RAMP and SOFTMODE modes the Vmin parameter must not

be zero because otherwise the target position sometimes cannot be reached. Hint: Some other parameters

which are not displayed in the main window are calculated and set up automatically according to the

acceleration parameter.

When using the VELOCITY mode, you can enter the acceleration and the Vmax parameter. The motor is then

accelerated to that velocity and keeps running constantly until you change the velocity and click the Go!

button again. The motor will then be accelerated or decelerated to the new velocity using the acceleration

parameter you have entered.

If you set the ramp mode to HOLD, you can only enter the Actual velocity parameter, click the Go! button

and control the velocity directly.

Please see also the files TMC429_rhz.xls and tmc429_rhzva.xls in the TMC429_Examples directory

(www.trinamic.com) for calculating the TMC429 parameters and converting them to or from physical units.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 11

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 11

6.2 The graphic display window

The graphic display window (Figure 6.2) shows the driving ramps of all the stepper motors. The following

values are displayed:

Green: the actual position of the motor

Red: the actual velocity of the motor. The value is shown as an absolute value, so negative

velocities will also be shown as positive values

Blue: the actual acceleration, also shown as an absolute value

Yellow: the actual target velocity of the motor, also displayed as an absolute value

Please note that this is only a rough and not an exact diagram.

Figure 6.2: The graphic display window

The value Time Interval shows the time between two pixels on the X axis. This value mainly depends on the

performance of the PC and will be slower when the register window is open (the display then gets slower

because more values are queried from the evaluation board). The scales of the Y axis are automatically

adapted to fit the entire curves. The curves are also displaced one pixel against each other for a better view.

If Stop when velocity = 0 is activated the display will be stopped when the velocities of all motors are zero.

All curves are cleared by clicking the Clear display button.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 12

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 12

6.3 The register window

The register window makes the direct access to all TMC429 registers possible. It contains five pages on

which all registers are displayed sorted by functional blocks. You can read more about the registers in the

TMC429 data sheet.

Figure 6.3: The register window showing the Motor 1 page

6.3.1 Motor 1, motor 2, and motor 3

On the motor pages, all registers belonging to the motors #1, #2, and #3 are displayed (Figure 6.3). In

the Actual Values and Read Only Values sections, the contents of all readable registers are displayed.

These values are updated permanently.

To change the contents of a register, first click on its name in the Registers section. Then change the

value in the appropriate edit field in the New Value section. You can also copy the actual values into

the edit fields by clicking the Copy button.

In the SPI Telegram section, the necessary SPI telegram to set the selected register to the desired

value is shown. Click the Send SPI Telegram button to send it to the evaluation board, and the value

will be set.

6.3.2 Global parameters

This page (Figure 6.4) contains all the TMC429 global parameter registers. It is made up just like the

motor register pages. The contents of the read only registers (including the reference switch flags) are

shown in the Read Only section. In the Read/Write section all writable registers are displayed. In the

Actual Values section the actual contents of the registers are shown and updated permanently. To

change a register, select it in the Registers section and fill in the new value in the New Value section.

Using the Copy button, you can copy the actual contents into the edit fields.

In the SPI Telegram section, the necessary SPI telegram to set the selected register to the desired

value is shown. Click the Send SPI Telegram button to send it to the evaluation board, and the value

will be set.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 13

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 13

Figure 6.4: The register window showing the Global Parameters page

6.3.3 RAM Table

On this page (Figure 6.5), the internal configuration RAM of the TMC429 chip (which contains the driver

configuration and the microstepping table) can be viewed and modified. Furthermore, any SPI data telegram

can be entered and sent to the evaluation board and the response can be viewed.

Figure 6.5: The register window showing the RAM Table page

Click the Read from RAM button to read the contents of the TMC429 RAM into the RAM editor. The progress

bar below the RAM editor shows the reading progress. After that, the values can be modified. By clicking the

Write to RAM button, the values will be written back to the TMC429 RAM, which is also shown by the

progress bar. Use the Save to file function to save the contents of the RAM editor to a file and the Load

from file function to read the file back into the RAM editor.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 14

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 14

The Microstep Shape function is used to calculate enhanced microstepping tables. To do this, first set the

Sigma value to the desired value (any floating point number between –1 and +1). By clicking the Calculate

button the new microstepping table will be written to the RAM editor only, and by clicking the Calculate &

Write to RAM button, the values are not only written to the RAM editor, but also to the TMC429

microstepping RAM. The driver configuration bytes will not be modified by this process.

In the SPI direct section, any SPI telegram can be entered and sent to the TMC429 by clicking the Send

button. The response sent from the TMC429 is then displayed below the Send button.

6.4 The stallGuard™ window

Clicking the TMC24x StallGuard button opens the StallGuard window (Figure 6.6). Here the StallGuard

features of the TMC246 and the TMC249 can be explored.

Figure 6.6: The StallGuard window

For each of the motor driver chips the evaluation board is equipped with the error flags are shown

by the blue LEDs and the load value is shown by the red bar in the Stall Detection. A stall detection

threshold can be set with the slider beside the red bar. If the load value shown by the bar reaches

the stall detection theshold the motor will be stopped immediately (this is done by the

microcontroller firmware of the evaluation board that gets is parameters via the RS232 interface).

The abbreviations at the error flag LEDs have the following meanings:

OC-A: Overcurrent on phase A.

OC-A: Overcurrent on phase B.

OL-A: Open load on phase A.

OL-B: Open load on phase B.

OC-HS: Overcurrent on high side.

UV: Undervoltage.

OT-PW: Overtemperature pre-warning.

OT: Overtemperature.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 15

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 15

6.5 Calc429 program

The software CD also contains the program Calc428. This program serves as a help to calculate the PMul and

PDiv parameters (see the TMC429 datasheet for an exact explanation of these parameters). It can be run

simply by double clicking the file CALC429.EXE.

Figure 6.7: Calc429 program

First, enter the parameters on the left side. After that, click the Calculate button and the values will be

calculated and displayed on the right side of the window.

6.6 Eval429EEP program

Using the program Eval429EEP, you can modify the contents of the EEPROM of the microprocessor on the

evaluation board via the RS232 interface. The contents of the EEPROM are copied to the TMC429 RAM after

each reset. So, for example, a modified microstepping table could be stored in the EEPROM and will be

present immediately after powering on the evaluation board. To do this, you will first have to edit the RAM

contents using the RAM editor (see Chapter 6.3.3) and store it in a file. The contents of such a file can then

be stored in the EEPROM using the Eval429EEP program.

Start the program by double clicking the EVAL428EEP.EXE file.

Figure 6.8: Eval428EEP program

Then select the interface your evaluation board is connected to and make sure that it is connected and

powered on. Now select your RAM file either by entering its path directly or by clicking the Browse button

and selecting a file in the file selection dialogue. Last, click the Start button. After a confirmation, the

programming process starts. This is also shown by the progress bar. At the end of the programming

process, a message dialogue shows if the programming process has been successful.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 16

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 16

7 The stallGuard™ profiler

The stallGuard™ profiler is a utility that helps you to find the best parameters for using stall detection. It

can be used together with the TMC429 evaluation board.

7.1 Installation

The file StallProfiler429.exe is available on www.trinamic.com. To start it, just double click the file. There is

no special installation procedure needed. The program can only be used together with the TMC429+TMC24xEVAL V1.0 or higher.

7.2 Usage

After starting the program its window appears. First make sure that your evaluation board is connected to

the PC and supplied with power. It is not possible to change parameters of the TMC429 using this program.

Do this by using the Eval429 program before using this one (do not power off the evaluation board after

that). Then select the COM port to which the evaluation is connected and click the Open button. Now the

connection to the evaluation board will be established.

Figure 7.1: The StallGuard profiler window

To record a stallGuard™ profile, first fill in the necessary parameters:

Motor driver: Select the motor driver on the evaluation board which you would like to use. As the

evaluation board is equipped with a TMC246 and a TMC249, it can either be TMC246 or TMC249. Make

sure that your motor is connected to the driver you would like to use.

Start velocity: This is the velocity value that is used at the beginning of the profile recording.

End velocity: The profile recording stops when this velocity value has been reached. Start velocity and

end velocity must not be equal. The range for each of the values is -2047… +2047.

Pulse_Div: This is the pulse divisor of the TMC429 that is a pre-divider that selects the velocity range

(see the TMC429 data sheet for explanation). It is set to 5 when the evaluation board is switched on, but

it can be set to meet your needs here.

Microsteps: The number of microsteps to be used can also be set here. The default value on the

evaluation board is 16.

After all these parameters have been set, click on the start button to start the stallGuard™ profile recording.

Depending on the range between start and end velocity this can take several minutes, as the load value for

every velocity value is measured ten times. The Actual velocity value shows the velocity that is currently

being tested and so tells you the progress of the profile recording. You can also abort a profile recording by

clicking the Abort button.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 17

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 17

7.3 The result

The result is shown as a graphic at the right side of the program window. After the profile recording has

finished you can scroll through the profile graphic using the scroll bar below it. The scale on the vertical

axis shows the load value: a higher value means a higher load. The scale on the horizontal axis is the

velocity scale. The color of each line shows the standard deviation of the ten load values that have been

measured for the velocity at that point. This is an indicator for the vibration of the motor at the given

velocity.

There are three colors used:

Green: The standard deviation is very low or zero. This means that there is effectively no vibration at

this velocity.

Yellow: This color means that there might be some low vibration at this velocity.

Red: The red color means that there is high vibration at that velocity.

Figure 7.2: A stallGuard™ profile

The data can also be exported as a text file or to Microsoft Excel. To do this, click the Export button and a

pop-up menu with the following choices appears:

Text file: This function lets you choose a text file to which the data will be saved.

Excel: This function exports the data to Microsoft Excel. It must be installed on your PC to make use of

this function, as Excel is now started (if not already running) and the data is directly sent to Excel and

not written into a file. Of course you can then save the data by using the Save function in Excel. Please

note that it takes some time to transfer the data to Excel.

A profile that has been saved to a text file can be reloaded: just click the Load button and you can select a

file. The contents of the file will be shown as a graphical profile.

7.4 Interpreting the result

In order to make effective use of the stallGuard™ feature you should choose a velocity where the load

value is as low as possible and where the color is green. The very best velocity values are those where the

load value is zero (areas that do not show any green, yellow or red line). Velocities shown in yellow can

also be used, but with care as they might cause problems (maybe the motor stops even if it is not stalled).

Velocities shown in red should not be chosen. Because of vibration the load value is often unpredictable

and so not usable to produce good results when using stall detection.

As it is very seldom that exactly the same result is produced when recording a profile with the same

parameters a second time, always two or more profiles should be recorded and compared against each

other.

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Page 18

TMC429+TMC24x-EVAL Manual (V1.00 / 2011-NOV-11) 18

Version

Date

LL – Lars Larsson

OK- Olav Kahlbaum

SD – Sonja Dwersteg

Author

Description

1.00

2011-NOV-11

SD

Initial version, based on TMC428 Eval Kit 3.0 Manual

(writers: LL, OK)

8 Revision history

8.1 Document revision

Copyright © 2011, TRINAMIC Motion Control GmbH & Co. KG

Loading...

Loading...