Page 1

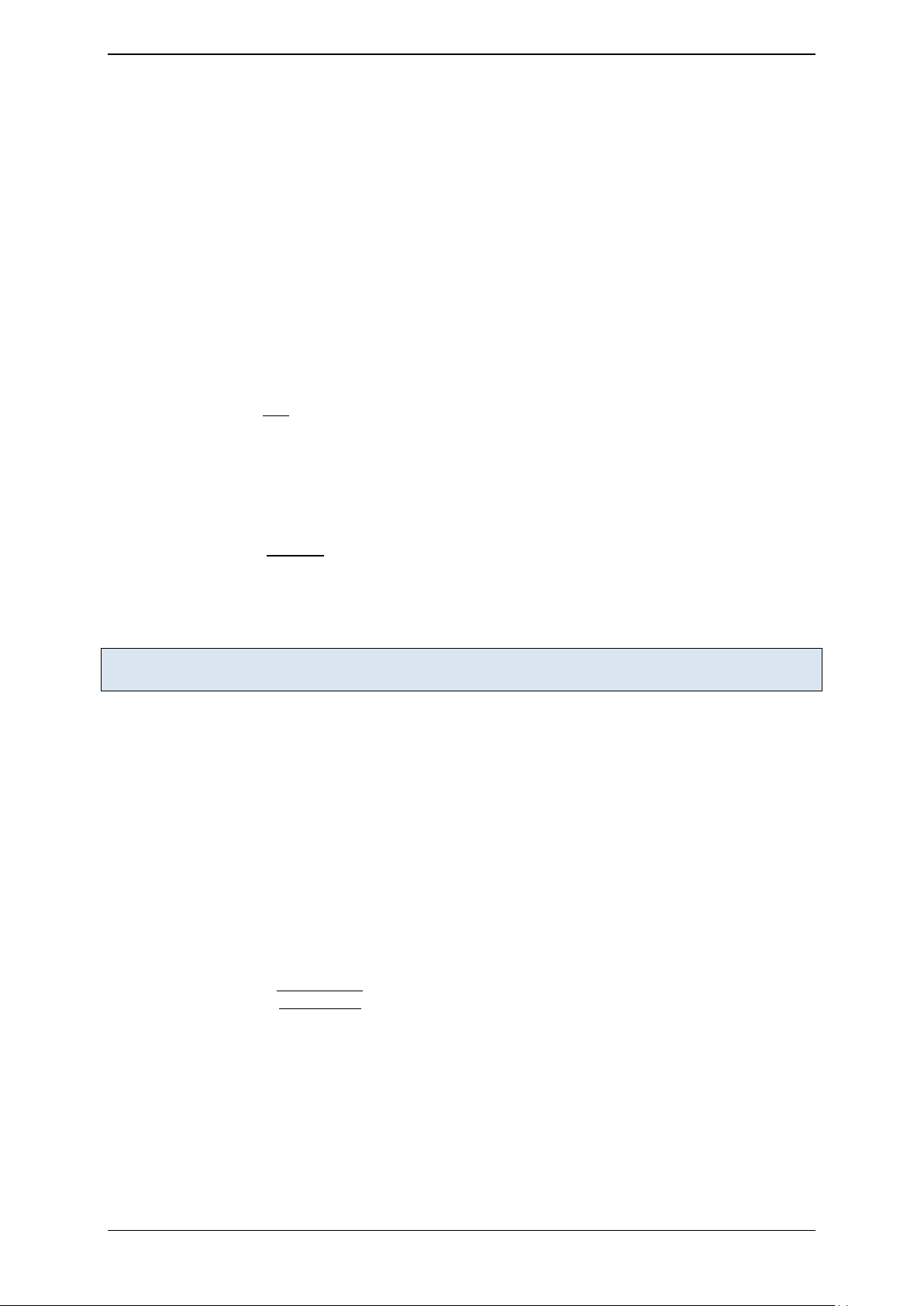

BLOCK DIAGRAM

Step/Direction interface. The SPI interface

programmable 6 bit microstep

table (64 µsteps / fullstep) for best step

serial peripheral interfaces allow for

forms a complete motion control system.

TMC429

SPI to

Master

CLK

Position

Comparator

Interrupt

Controller

Ref. Switch

Processing

Step/Dir

Pulse

Generation

OUTPUT SELECT

- SPI

or

-

Step/Dir

Microstep

Table

Serial Driver

Interface

3x Ref. Switches

3x Linear

RAMP Generator

SPI to Stepper

Motor Driver 0/1/2

Step/Dir OUT 0/1/2

SPI to µC

SDO to µC

Muliplexed

Output

Position Compare OUT

MOTION CONTROLLER FOR STEPPER MOTORS INTEGRATED CIRCUITS

TMC429 DATASHEET

Intelligent Triple Stepper Motor Controller with Serial Peripheral Interfaces and Step/Direction

Full Compatible Successor of the TMC428

APPLICATIONS

CCTV, Security

Antenna Positioning

Heliostat Controller

Battery powered applications

Office Automation

ATM, Cash recycler, POS

Lab Automation

Liquid Handling

Medical

Printer and Scanner

Pumps and Valves

FEATURES AND BENEFITS

Controls up to three stepper motors

3.3 V or 5 V operation with CMOS / TTL compatible IOs

Serial 4-wire interface for µC with easy-to-use protocol

Interface for SPI™ motor drivers with data rates up to 1 Mbit/s

Step/Direction interface

Clock frequency: up to 32 MHz (can use CPU clock)

Internal position counters 24 bit wide

Microstep frequency up to 1 MHz

Read-out option for all motion parameters

Programmable 6 bit microstep table, up to 64 entries for a

quarter sine wave period

DESCRIPTION

The TMC429 is a miniaturized stepper motor

controller with an industry leading feature

set. It controls up to three motors via SPI or

provides a

accuracy with 2-phase stepper motors. Based

on target positions and velocities - which can

be altered on the fly - it performs all real

time critical tasks autonomously. The TMC429

offers high level control functions for robust

and reliable operation. Two separate 4 wire

Ramp generators for autonomous positioning / speed control

On-the-fly change of target motion parameters

Power boost automatic acceleration dependent current control

Low power operation: 1.25 mA at 4 MHz (typ.)

communication with the microcontroller and

with up to three daisy chained stepper motor

drivers.

Together with a microcontroller the TMC429

Compact Size: ultra small 16 pin SSOP package, small 24 pin SOP

package, and 32 pin QFN 5x5 mm package

Directly controls TMC23x, TMC24x, TMC26x, and TMC389

High integration and small form factor allow

for miniaturized designs for cost-effective and

highly competitive solutions.

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

Page 2

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 2

Layout for Evaluation of TMC429 with

Controller/Driver Chain

TMC429

TMC429-LI

3-axis controller QFN32-package (5x5mm2), full functionality

5 x 5 mm2

package (TMC428 replacement

TMC429+26x-EVAL

Evaluation board for S/D chipset (TMC429with TMC260,

TMC261, TMC262 and TMC424)

16 x 10 cm2

TMC429+TMC24x-EVAL

Evaluation board for SPI chipset (TMC429, TMC246, and

TMC249)

13.5 x 8,2 cm2

is a single axis

It features the

This evaluation board is a development

in combination with TMC260, TMC261, and

The board

and RS232 interfaces. The control software

parameters and visualizing the dynamic

APPLICATION EXAMPLES: RELIABLE CONTROL FOR UP TO 3 MOTORS

The TMC429 scores with its autonomous handling of all real time critical tasks. By offloading the

motion-control function to the TMC429, up to three motors can be operated reliably with very little

demand for service from the microcontroller. Software only needs to send target positions, and the

TMC429 generates precisely timed step pulses by hardware for up to three stepper motor driver chips.

Parameters for each motor can be changed on the fly while software retains full control using an SPI

bus. This way, high precision and reliable operation is achieved while costs are kept down.

STEPROCKER™

The TMCM-1110 stepRocker

motor controller and driver board for 2-phase

bipolar stepper motors.

TRINAMIC controller/driver chain consisting of

TMC429 and TMC262. The Module is intended to

be a fully functional development platform with

6A MOSFETs. Because of the TMC429s ability to

control up to three motors the stepRocker can

be extended to a full 3-axes system.

Development platform with TMC262

TMC262, TMC261, and TMC260

ORDER CODES

Order code Description Size

TMC429-PI24 3-axis controller SOP24-

possible)

TMC429-I 3-axis controller SSOP16-package (SPI only, for TMC428

replacement)

TMC429+TMC26X-EVAL

platform for applications based on the TMC429

TMC262. Common supply voltages are +12V DC /

+24V DC / +48V DC (TMC261 only).

features an embedded microcontroller with USB

provides a user-friendly GUI for setting control

responses of the motors.

Motor movements can be controlled via the

step and direction interface using inputs from

an external source or signals generated by the

microcontroller acting as a step generator.

15.5 x 10.5 mm

6 x 5 mm2

2

www.trinamic.com

Page 3

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 3

TABLE OF CONTENTS

1 PRINCIPLES OF OPERATION 4

1.1 KEY CONCEPTS 4

1.2 CONTROL INTERFACES 5

1.3 SOFTWARE VISIBILITY 6

1.4 STEP FREQUENCIES 6

1.5 MOVING THE MOTOR 7

2 GENERAL DEFINITIONS, UNITS, AND

NOTATIONS 9

2.1 NOTATIONS 9

2.2 SIGNAL POLARITIES 9

2.3 UNITS OF MOTION PARAMETERS 9

2.4 REPRESENTATION OF SIGNED VALUES BY TWO’S

COMPLEMENT 9

3 PACKAGE VARIANTS 10

4 PIN ASSIGNMENTS 10

4.1 PACKAGE OUTLINES 11

4.2 SIGNAL DESCRIPTIONS 12

10 STEP/DIR DRIVERS 53

10.1 TIMING 53

11 SPI MODE DRIVER INTERFACE 54

11.1 BUS SIGNALS 54

11.2 TIMING 54

11.3 RAM ADDRESS PARTITIONING AND DATA

11.4 STEPPER DRIVER SPI DATAGRAM CONFIGURATION

11.5 INITIALIZATION OF MICROSTEP LOOK-UP TABLE62

12 RUNNING A MOTOR 67

12.1 GETTING STARTED 67

12.2 RUNNING A MOTOR WITH START-STOP-SPEED IN

13 ON-CHIP VOLTAGE REGULATOR 68

14 POWER-ON RESET 69

ORGANIZATION 55

57

RAMP

_MODE 67

5 SAMPLE CIRCUITS 13

5.1 APPLICATION EXAMPLE: TMC429 IN QFN32

PACKAGE 13

5.2 APPLICATION EXAMPLE: TMC429 IN SSOP16

PACKAGE 14

5.3 APPLICATION EXAMPLE: TMC429 WITH DRIVERS

WITHOUT

6 CONTROL INTERFACE 15

6.1 BUS SIGNALS 15

6.2 SERIAL PERIPHERAL INTERFACE FOR µC 15

7 ADDRESS SPACE PARTITIONS 20

7.1 READ AND WRITE 20

7.2 REGISTER SET 20

7.3 REGISTER MAPPING 21

8 REGISTER DESCRIPTION 22

8.1 AXIS PARAMETER REGISTERS 22

8.2 GLOBAL PARAMETER REGISTERS 39

9 REFERENCE SWITCH INPUTS 49

9.1 REFERENCE SWITCH CONFIGURATION, MOT1R,

AND REFMUX

9.2 TRIPLE SWITCH CONFIGURATION 51

9.3 HOMING PROCEDURE 52

9.4 SIMULTANEOUS START OF UP TO THREE STEPPER

MOTORS 52

SERIAL DATA OUTPUT (SDO) 14

49

15 ABSOLUTE MAXIMUM RATINGS 70

16 ELECTRICAL CHARACTERISTICS 70

16.1 POWER DISSIPATION 70

16.2 DC CHARACTERISTICS 71

16.3 TIMING CHARACTERISTICS 72

18 PACKAGE MACHANICAL DATA 73

18.1 TMC429-LI / QFN32 73

18.2 TMC429-PI24 / SOP24 74

18.4 TMC429-I / SSOP16 75

19 MARKING 76

20 COMPATIBILITY INFORMATION: TMC429

AND TMC428 77

20.1 SIGNAL DESCRIPTIONS: TMC428 VS. TMC42977

20.2 TMC428 SDO_C OUTPUT 78

20.3 UNUSED ADDRESSES 78

20.4 GENERAL TIMING PARAMETERS 79

21 DISCLAIMER 80

22 ESD SENSITIVE DEVICE 80

23 TABLE OF FIGURES 81

24 REVISION HISTORY 82

25 REFERENCES 83

www.trinamic.com

Page 4

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 4

Serial

µC

Inte

rface

3 x RAMP

Generator

3 x STEPPULS

Generator

3x Step/Dir

Microstep

Unit

(incl. Sequencer)

Serial Driver

Interface

Multiple Ported RAM

M

U

X

SPI Mode

6

Voltage

Regulator

GND

Power-on

Reset

POSCOMP

Interrupt Controller

REF1

REF2

REF

3

REF1R*

REF2R*

REF3R*

nSCS_C

SCK_C

SDI_C

nINT_SDO_C

TEST

SDOZ_C*

nSCS_S / Step 2

SCK_S / Dir 1

SDO_S / Step 1

SDI_S / Dir 2

nSCS3 / Dir 3*

nSCS2 / Step 3*

470nF

POSCMP*

CLK

4-32MHz

GND

DIE PAD

GND

GND

100nF

TMC429

GND

V5 /+5V supply or

+3V supply

* Not available with all IC packages. Please refer to the package outlines.

SPI

SPI / Step/Dir

to driver

SPI to

µC

Connect for

+3.3V operation

V33

V5

1 Principles of Operation

Figure 1.1 TMC429 functional block diagram

The TMC429 is a miniaturized high performance stepper motor controller with an outstanding costperformance ratio. It is designed for high volume automotive as well as for demanding industrial

motion control applications. Once initialized the TMC429 controls up to three 2-phase stepper motors

simultaneously. A programmable sequencer for 2-phase motors is integrated. The TMC429 motion

controller is equipped with an SPI™ host interface with easy-to-use protocol and two driver interfaces

(SPI and STEP/DIR) for addressing various stepper motor driver types.

1.1 Key Concepts

The TMC429 realizes real time critical tasks autonomously and guarantees for a robust and reliable

drive. These following features contribute toward greater precision, greater efficiency, higher

reliability, and smoother motion in many stepper motor applications.

Initialization Adapt the TMC429 to the driver type and configuration and send initial configuration

data to SPI drivers. Configure microstep resolution and waveform for SPI drivers.

Interfacing The TMC429 offers application specific interfacing via Step/Dir or SPI.

Positioning The TMC429 operates the motors based on user specified target positions and

Programming Every parameter can be changed at any time. The uniform access to any TMC429

Microstepping Based on internal position counters the TMC429 performs up to ±2

The range goes from full stepping (1 microstep = 1 full step) and half stepping (2

www.trinamic.com

velocities. Modify all motion target parameters on-the-fly during motion.

register simplifies application programming. A read-back option for all internal

registers is available.

23

(micro)steps

completely independent from the microcontroller. Microstep resolutions are

individually programmable for each stepper motor.

microsteps per full step) up to 6 bit micro stepping (64 microsteps per full step) for

precise positioning and noiseless stepper motor rotation. With STEP/DIR drivers any

microstep resolution is possible as supported by the driver.

The internal microstep table can be adapted to specific motor characteristics to

further reduce torque ripple, if desired.

Page 5

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 5

µC

High Level

Interface

Stepper Motor

Driver

e.g. TMC260/TMC261

M

Motor 3

Stepper Motor

Driver

e.g. TMC260/TMC261

M

Motor 2

Stepper Motor

Driver

e.g. TMC260/TMC261

M

Motor 1

TMC429

Motion Controller

SPI

Step/Dir 1 Step/Dir 3Step/Dir 2

SPI

µC

High Level

Interface

Stepper Motor

Driver

e.g. TMC236/TMC246

M

Motor 3

Stepper Motor

Driver

e.g. TMC236/TMC246

M

Motor 2

Stepper Motor

Driver

e.g. TMC236/TMC246

M

Motor 1

TMC429

Motion Controller

SPI

SPI

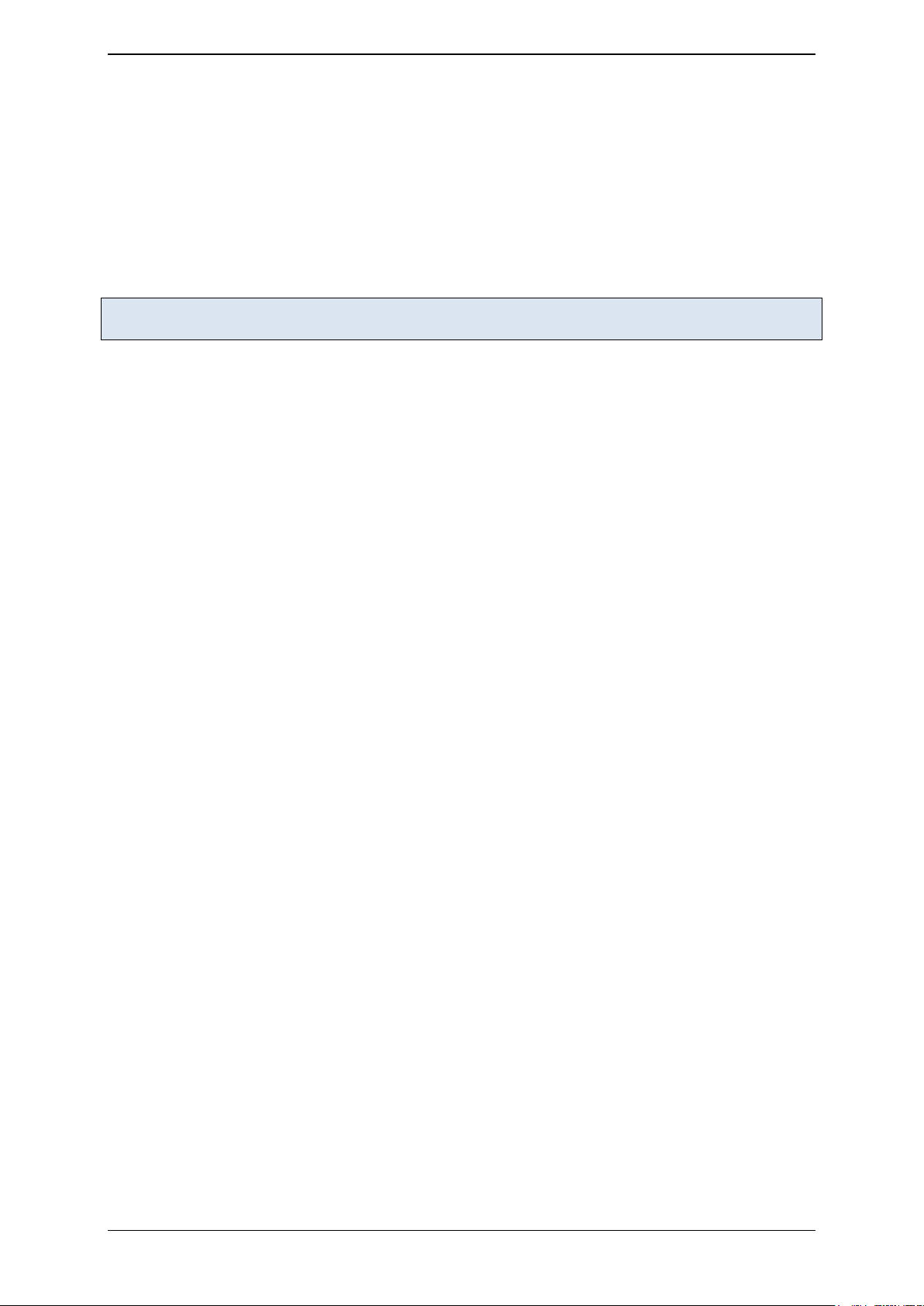

1.2 Control Interfaces

1.2.1 Serial µC Interface

From the software point of view, the TMC429 provides a set of registers, accessed by a

microcontroller via a serial interface in a uniform way. Each datagram contains address bits, a readwrite selection bit, and data bits to access the registers and the on-chip memory. Each time the

microcontroller sends a datagram to the TMC429 it simultaneously receives a datagram from the

TMC429. This simplifies the communication with the TMC429 and makes programming easy. Most

microcontrollers have an SPI hardware interface, which directly connects to the serial four wire

microcontroller interface of the TMC429. For microcontrollers without SPI

serial communication is sufficient and can easily be implemented.

1.2.2 Step/Dir Driver Interface

The TMC429-LI controls the motor position by sending pulses on the STEP signal while indicating the

direction on the DIR signal. A programmable step pulse length and step frequencies up to 1MHz allow

operation at high speed and high microstep resolution. The driver chip converts these signals into the

coil currents which control the position of the motor. The TMC429-LI perfectly fits to the TMC26x smart

power Step/Dir driver family.

hardware software doing the

Figure 1.2 Application example using Step/Dir driver interface

1.2.3 Serial Driver Interface

The TMC429 automatically generates the required data-stream for SPI drivers and provides user

configurable microstep waves and motor ramps for up to three motors. The serial interface to the

motor drivers is flexibly configurable for different types (from different vendors) with up to 64 bit

length for the SPI daisy chain. The TMC429-I perfectly fits to the TMC24x driver family.

Figure 1.3 Application example using SPI driver interface

www.trinamic.com

Page 6

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 6

1.3 Software Visibility

From the software point of view the TMC429 provides a set of registers and on-chip RAM (see Figure

1.1), accessed via the serial µC interface in a uniform way. The serial interface uses a simple protocol

with fixed datagram length for the read- and write-access. These registers are used for initializing the

chip as required by the hardware configuration. Afterwards the motor can be moved by writing target

positions or velocity and acceleration values.

1.4 Step Frequencies

The desired motor velocity is an important design parameter of an application. Therefore it is

important to understand the limiting factors.

1.4.1 Step Frequencies using the Step/Dir driver interface

The step pulses can directly be fed to a Step/Dir driver. The maximum full step rate (fsf

the microstep resolution of the external driver chip.

The TMC429 microstep rate (µsf) is up to 1/32 of the clock frequency:

f

=

f

32

EXAMPLE FOR FULL STEP FREQUENCY CALCULATION

f

= 16 MHz

CLK

= 500 kHz

µsf

max

µstep resolution of external driver: 16

) depends on

max

=

16

= 31.25

500

With a standard motor with 1.8° per full step this results in up to 31.25kHz/200= 156 rotations per

second, which is far above realistic motor velocities for this kind of motor and thus imposes no real

limit on the application.

A 16 microsteps resolution can be extrapolated to 256 microsteps within the driver when using the

TMC26x driver family.

1.4.2 Step frequencies using the SPI driver interface

The microstep unit with included sequencer processes step pulses from the pulse generator, which

represent microsteps, half steps, or full steps (depending on the selected step resolution). The serial

driver interface sends datagrams to the stepper motor driver chain whenever a step pulse comes.

The theoretical microstep frequency is identical to Step/Dir mode, but the achievable step frequency

may be limited by the SPI data rate. Maximum SPI frequency (bit rate) is clock frequency divided by 16

(when CLK2DIV=7). An overhead of 1.5 bits is required per datagram. The maximum microstep

transmission frequency depends on the total length of the datagrams sent to the SPI stepper motor

driver chain.

EXAMPLE FOR SPI DATA RATE CALCULATION

At a clock frequency of 16 MHz, with a daisy chain of three SPI stepper motor drivers of 12 bit

datagram length each (e.g. TMC246), the theoretical maximum SPI transmission frequency (fSPI

=

16

16

3 × 12 + 1.5

max

) is:

This is approximately 27 kHz. It is the theoretical upper limit for the fullstep frequency. In an

application, the maximum desired fullstep frequency should be a factor 4 to 8 lower in order to avoid

a beat between the step frequency and the SPI transmission rate.

The microstep rate may be higher than the SPI transmission frequency, even if the stepper motor

driver does not note all microsteps due to the SPI data rate limit. At high step rates (respectively

pulse rates) the differences between microstepping and full step excitation vanish.

www.trinamic.com

Page 7

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 7

1.5 Moving the Motor

Moving the motor is simple:

- To move a motor to a new target position, write the target position into the associated register

by sending a datagram to the TMC429.

- To move a motor with a new target velocity, write the velocity into the register assigned to the

stepper motor.

1.5.1 Motion Controller Functionality

The ramp generator monitors the motion parameters stored in its registers and calculates velocity

profiles. Based on the actual ramp generator velocity a pulse generator supplies step pulses to the

motor driver.

1.5.2 Modes of Motion – Individually Programmable for Each Axis

ramp_mode For positioning applications the ramp_mode is most suitable. The user sets the

position and the TMC429 calculates a trapezoidal velocity profile and drives

autonomously to the target position. During motion, the position may be altered

arbitrarily.

velocity_mode For constant velocity applications the velocity_mode is most suitable. In

velocity_mode, a target velocity is set by the user and the TMC429 takes into account

user defined limits of velocity and acceleration.

hold_mode In hold_mode, the user sets target velocities, but the TMC429 ignores any limits of

velocity and acceleration, to realize arbitrary velocity profiles, controlled completely

by the user.

soft_mode The soft_mode is similar to the ramp_mode, but the decrease of the velocity during

deceleration is done with a soft, exponentially shaped velocity profile.

1.5.3 Interrupts

The TMC429 has capabilities to generate interrupts. Interrupts are based on ramp generator conditions

which can be set using an interrupt mask. The interrupt controller (which continuously monitors

reference switches and ramp generator conditions) generates an interrupt if required.

SPECIAL HANDLING: TMC429-I / 16-PIN PACKAGE

- On 16-pin package the SDO_C signal becomes a low active interrupt signal called nINT_SDO_C

while nSCS_C is high. Set SDO_INT=1 to access the non-multiplexed interrupt signal output

nINT_SDO_C for the other packages.

- If the microcontroller disables the interrupt during access to the TMC429 and enables the

interrupt otherwise, the multiplexed interrupt output of the TMC429 behaves like a dedicated

interrupt output.

- For polling, the TMC429 sends the status of the interrupt signal to the microcontroller with each

datagram.

1.5.4 Reference Switch Handling

The TMC429 has a left and a right reference switch input for each motor. Note, that these inputs are

not available with all packages.

SPECIAL HANDLING: TMC429-I / 16-PIN PACKAGE

Because of its 16-pin package the TMC429-I has only three reference switch inputs: REF1, REF2, and

REF3. Therefore the TMC429-I provides two different modes for reference switch handling:

- In the Default Reference Switch Mode the three reference switch inputs are defined as left side

reference switches, one for each stepper motor.

- The Second Reference Switch Mode defines the first reference input REF1 as left reference switch

input of motor one, the second reference input REF2 as left reference switch input of motor two,

and the 3rd reference input REF3 as right reference switch input of motor one. In the second

reference switch mode there is no reference switch input available for stepper motor three.

- With an external multiplexer 74HC157 any stepper motor may have a left and a right reference

switch.

www.trinamic.com

Page 8

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 8

1.5.5 Integrated Programmable µstep Sequencer

The serial SPI interface to the stepper motor driver chain has to be configured by an initialization

sequence which writes the configuration into the on-chip RAM. Once configured the serial driver

interface works autonomously. The internal multiple port RAM controller of the TMC429 takes care of

access scheduling. So, the user may read and write registers and on-chip RAM at any time. The

registers hold global configuration parameters and motion parameters. The on-chip RAM stores the

configuration of the serial driver interface and the microstep table.

The sequencer internally generates a number of control signals available for transmission to SPI

driver ICs. These sequencer output signals are selected as configured by the internal stepper motor

driver datagram configuration table.

During power-on reset, the TMC429 initializes a default configuration within the on-chip RAM for an

SPI driver chain for TMC23x and TMC24x stepper motor drivers.

1.5.6 Access to Status and Error Bits

STEP/DIR

The microcontroller directly controls and monitors the stepper drivers. It also needs to take care for

advanced current control, e.g. power down in stand still.

SPI

Many serial stepper motor drivers provide status bits (driver active, inactive…) and error bits (short to

ground, wire open…), which are sent back from the stepper motor driver chain to the motion

controller. To have access to error bits and datagrams with a total length up to 48 bits the TMC429

buffers the information by means of two 24 bit wide registers. The microcontroller has direct access

to these registers.

Although, the TMC429 provides datagrams with up to 64 bits to the driver chain, only the last 48 bits

sent back from the driver chain are buffered for read out by the microcontroller. Buffering of up to 48

bits is sufficient for a chain of three stepper motor drivers. For a chain of three TMC23x / TMC24x

stepper motor driver chips all status bits are accessible.

www.trinamic.com

Page 9

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 9

2 General Definitions, Units, and Notations

2.1 Notations

- Decimal numbers are used as usual without additional identification.

- Binary numbers are identified by a prefixed % character.

- Hexadecimal numbers are identified by a prefixed $ character.

EXAMPLE

Decimal: 42

Binary: %101010

Hexadecimal: $2A

TMC429 DATAGRAMS ARE WRITTEN AS 32 BIT NUMBERS, E.G.:

$1234ABCD = %0001 0010 0011 0100 1010 1011 1100 1101

TWO TO THE POWER OF N

In addition to the basic arithmetic operators (+, -, *, /) the operator two to the power of n is required

at different sections of this data sheet. For better readability instead of 2n the notation 2^n is used.

2.2 Signal Polarities

External and internal signals are high active per default, but the polarity of some signals is

programmable to be inverted. A pre-fixed lower case n indicates low active signals (e.g. nSCS_C,

nSCS_S). See chapter 8.2, too.

2.3 Units of Motion Parameters

The motion parameters position, velocity, and acceleration are given as integer values within TMC429

specific units. With a given stepper motor resolution one can calculate physical units for angle,

angular velocity, angular acceleration. (See chapter 8.1.13)

2.4 Representation of Signed Values by Two’s Complement

Motion parameters which have to cover negative and positive motion direction are processed as

signed numbers represented by two’s complement as usual. Limit motion parameters are represented

as unsigned binary numbers.

SIGNED MOTION PARAMETERS ARE:

V_TARGET / V_ACTUAL / A_ACTUAL / A_THRESHOLD

UNSIGNED MOTION PARAMETERS ARE:

V_MIN / V_MAX / A_MAX

POSITIONS

X_TARGET / X_ACTUAL can be treated as signed or unsigned, as desired.

www.trinamic.com

Page 10

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 10

including SPI and Step/Dir driver

- Fits best to TMC26x and TMC389.

p to three stepper driver

he right reference switch for motor 3 is not

SPI interface for up to three stepper motor driver

inputs

n additional multiplexer 74hc157 might be

necessary. The multiplexing control signal is only

available in SPI stepper motor driver chain mode.

3 Package Variants

The TMC429 is available in three different package variants, qualified for the industrial temperature

range. An additional variant is available for the automotive temperature range. All package variants

are RoHS compilant.

Order code Package Characteristics JEDEC Drawing

TMC429-LI QFN32 5x5mm, 32 pins, plastic package, industrial (-40… +85°C) MO-220 ?

TMC429-PI24 SOP24 300 mils, 24 pins, plastic package, industrial (-40… +85°C) MS-013 (300 mils)

TMC429-I SSOP16 150 mils, 16 pins, plastic package, industrial (-40… +85°C) MO-137 (150 mils)

4 Pin Assignments

The three package variants of the TMC429 offer different signal sets for various applications:

Type Package Compatibility Remarks

Full functionality

TMC429-LI QFN32

TMC429-PI24 SOP24 TMC428-PI24

replacement

TMC429-I SSOP16

TMC428-I

replacement

interfaces for up to three stepper motor driver chips

-

SPI interface for up to three stepper driver chips

- STEP/DIR interface for u

chips

- T

available.

chips (complements the TMC24x).

- Step/Dir interface for up to two motors.

- The additional reference right side switch

REF1R, REF2R, and REF3R are not available.

- A

Some third party SPI stepper motor drivers have no serial data output and therefore cannot simply be

arranged in a daisy chain to drive more than one motor. The package variants SOP24 and QFN32 have

two additional driver selection outputs nSCS2 and nSCS3 for stepper motor drivers without serial data

output.

All inputs are Schmitt-Trigger. Unused inputs (REF1, REF2, REF3, and SDI_S) need to be connected to

ground. Unused reference switch inputs have to be connected to ground, too. A pull-down resistor is

necessary at the SDI_S input of the TMC429 for those serial peripheral interface stepper motor drivers

that set their serial data output to high impedance Z while inactive.

STEP function outputs are S1, S2, and S3. Corresponding DIR outputs are D1, D2, and D3. The

multiplexed output nINT_SDO_C of TMC429-LI and TMC429-PI24 can be configured in a de-multiplexed

mode. An additional output named POSCMP is available for triggering when moving over a

programmable position.

Attention

- After power on-reset, the TMC429 starts in TMC428 mode. That is, because the TMC429 is a 100%

compatible successor of the TMC428 motion controller. Additional outputs of the TMC429

including specific functions have to be activated by dedicated TMC429 configuration registers.

- Preferably, long wires to the reference switch inputs (REF1, REF2, and REF3) should be avoided.

For long wires, a low pass filter for spike suppression should be provided (refer the TMC429

evaluation board schematic as example).

www.trinamic.com

Page 11

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 11

TMC429-I

V33

nSCS_C

GND

SDI_C

TEST V5

SCK_C

SDI_S_D2

nINT_SDO_C

CLK nSCS_S_S2

REF2

REF1

REF3

SCK_S_D1

SDO_S_S1

1

2

3

4

5

6

7

8

16

10

11

12

13

14

15

9

SSOP16 (150 MILS)

TMC429-PI24

V33

nSCS_C

GND

SDI_C

TEST

V5

SCK_C

SDI_S_D2

nINT_SDO_C

CLK

nSCS_S_S2

REF2

REF1

REF3

SCK_S_D1

SDO_S_S1

3

4

5

6

7

8

9

10

23

15

16

17

20

21

22

14

1

2

11

12

24

13

18

nSCS2_S3

19

nSCS3_D3

SOP24 (300 MILS)

V5

GND

REFR1 [n.c. @ TMC428]

REFR2 [n.c. @ TMC428]

[n.c. @ TMC428] POSCMP

[n.c. @ TMC428] SDOZ_C

TMC429-LI

nSCS_C

TEST

SCK_C

CLK

REF2

REF3

3

4

5

6

7

8

9

1

2

QFN32 5x5mm

V5

GND

n.c.

10 11 12 13 14 15 16

32 31 30 29 28 27 26 25

22

21

20

19

18

17

24

23

REF1

n.c.

SDI_C

n.c.

SDOZ_C

REFR2

nINT_SDO_C

SDO_S_S1

n.c.

SCK_S_D1

nSCS_S_S2

nSCS2_S3

nSCS3_D3

V5

V33

GND

n.c.

SDI_S_D2

REFR1

REFR3

POSCMP

GND

n.c.

4.1 Package Outlines

Please refer to the application note

PCB_Guidelines_TRINAMIC_packages

for a practical guideline for all

available TRINAMIC IC packages and

PCB footprints. The application note

covers package dimensions, example

footprints and general information on

PCB footprints for these packages. It is

available on www.trinamic.com.

Figure 4.1 TMC429 pin out

www.trinamic.com

Page 12

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 12

Pin

SSOP16

SOP24

QFN32

In/Out

Description

Reset

- - - - Internal power-on reset.

CLK

5 7 5 I Clock input

nSCS_C

6 9 7 I Low active SPI chip select input driven from µC

SCK_C

7

10 8 I

Serial data clock input driven from µC

SDI_C

8

11

10 I Serial data input driven from µC

Multiplexed nINTERRUPT output if communication with

SDO_C will never be high impedance; the TMC429 is

equipped with an additional pin named SDOZ_C that

nSCS_S_S2

12

17

18 O SPI chip select signal to stepper motor driving chain

Step output S2 (for motor 2) in Step/Dir mode

nSCS3_D3

-

19

20 O SPI chip select signal (SOP24 only) /

SCK_S_D1

Serial data clock output to SPI stepper motor driver

DIR output D1 (for motor 1) in Step/Dir mode

SDO_S_S1

10

15

15 O Serial data output to SPI stepper motor driver chain /

SDI_S_D2

16

23

27

I

O

Serial data input from SPI stepper motor driver chain

down resistor at SDI_S avoids high

DIR output D2 (for motor 2) in Step/Dir mode

REF1

1 2 31 I Reference switch input 1

REF2

2 3 1 I Reference switch input 2

(no internal pull-up resistor)

(no internal pull-up resistor)

V5

13

5, 20

3, 21

+5V supply / +3.3V supply

V33

14

21

22 470nF ceramic capacitor pin / +3.3V supply

GND

15

8, 22

6, 23, 25

Ground

TEST

4 6 4 I Must be connected to GND as close as possible to the

n.c.

26, 32

POSCMP

- 1 30

n.c. / O

Position compare output for SOP24 and QFN32 /

SDOZ_C

-

12

12

O / Z

SDOZ_C becomes high impedance (Z) when nSCS_C=1 /

configured with TMC429

register to give the nINT signal directly without

multiplexing

REFR1 - 24

28 I Reference switch right 1 input

Only available for TMC429 in SOP24 package and

REFR2

SOP24 package and

QFN32 package (with internal pull-up resistor)

REFR3

- - 29 I Reference switch right 3 input

4.2 Signal Descriptions

No external reset input pin is available.

nINT_SDO_C

nSCS2_S3

REF3 3 4 2 I Reference switch input 3

9 14 14 O Serial data output to µC input /

µC is idle (resp. nSCS_C = 1)

becomes high impedance when nSCS_C=1.

- 18 19 O SPI chip select signal (SOP24 only) /

Step output S3 (for motor 3) in Step/Dir mode

DIR output D3 (for motor 3) in Step/Dir mode

11 16 17 O

chain /

STEP output S1 (for motor 1) in Step/Dir mode

(pull-up/impedance; SDI_S input is the power-on default) /

(no internal pull-up resistor)

- - 9, 11,

16, 24,

- 13 13 I Reference switch right 2 input

www.trinamic.com

chip. No user function.

- Not connected pins

Output for pos_comp function

The nINT signal is not mapped to SDOZ_C pin /

The pin nINT_SDO_C can be

QFN32 package (with internal pull-up resistor)

Only available for TMC429 in

Only available for TMC429 in QFN32 package

(with internal pull-up resistor)

Page 13

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 13

SCK_S_D1

SDO_S_S1

SDI_S_D2

nSCS_S_S2

REF2

REF3

REF1

TEST GND

SDI_C

nSCS_C

SCK_C

nINT_SDO_C

CLK

V5V33

TMC429-LI

nSCS3_D3

nSCS2_S3

POSCMP

REFR3

REFR2

REFR1

SDOZ_C

STP_3

DIR_3

STP_2

DIR_2

STP_1

DIR_1

MISO

MOSI

SCK

nSCS

µC

TMC26x

TMC26x

TMC26x

STEP

DIR

CSN

SCK

SDI

SDO

TMC26x

#1

STEP

DIR

CSN

SCK

SDI

SDO

TMC26x

#2

STEP

DIR

CSN

SCK

SDI

SDO

TMC26x

#3

nSCS2_S3

nSCS3_D3

nSCS_S_S2

SDI_S_D2

SDO_S_S1

SCK_S_D1

nSCS_C

SCK_C

SDI_C

SDOZ_C

MOSI

MISO

SCK

TMC429-LI

CSn_0

CSn_1

CSn_2

CSn_3

CLKCLK

100K

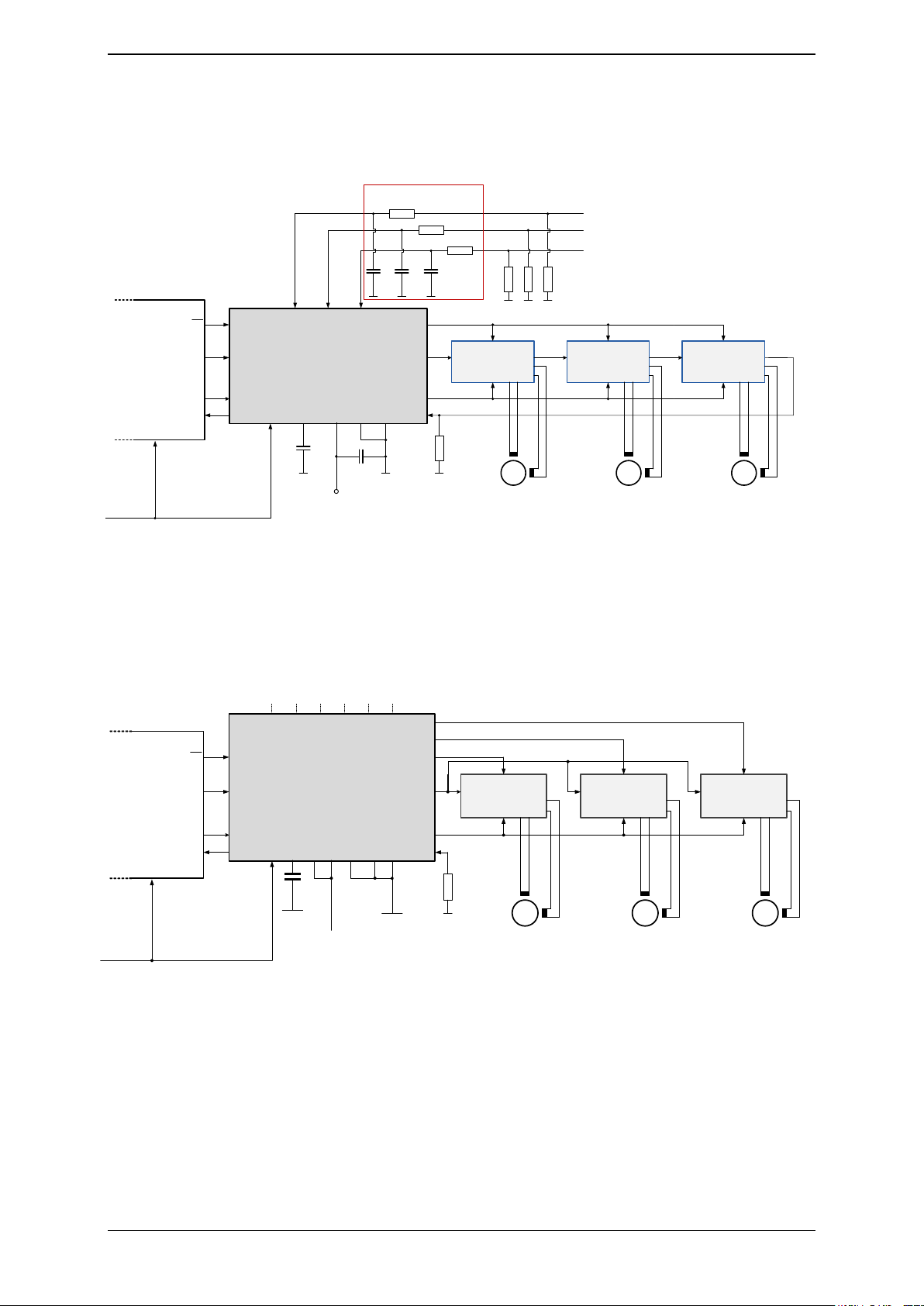

5 Sample Circuits

The sample circuits show the connection of the external components.

5.1 Application Example: TMC429 in QFN32 Package

All signals of the TMC429 are available with the QFN32 package. We recommend this package for

applications using TRINAMICs TMC26x smart power driver family.

Figure 5.1 TMC429 within QFN32 package

Figure 5.2 TMC429 / TMC26x outline for configuration via SPI and STEP/DIR for motion

PPLICATION ENVIRONMENT OF TMC429 (QFN32 PACKAGE) AND 3 X TMC26X STEPPER MOTOR DRIVER:

A

- One SPI chip select signal CSN_0 selects the TMC429 SPI microcontroller interface.

- Up to three SPI chip select signals (CSN_3, CSN_2, CSN1) select up to three TMC262 SPI for

- The TMC429 SDOZ_C is high impedance when nSCS_C is 1.

configuration.

www.trinamic.com

Page 14

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 14

10K

SCK_S

SDO_S

SDI_S

nSCS_S

SDO

CSN

SDI

SCK

SDO

CSN

SDI

SCK

SDO

CSN

SDI

SCK

TMC23x / TMC24x

TMC23x / TMC24x TMC23x / TMC24x

REF2 REF3

REF1

TEST

GND

µC

SCK

MOSI

MISO

SS

SDI_C

nSCS_C

SCK_C

SDO_C

CLK

CLK

V5V33

470 nF

+5 V

1K 1K

Reference Switch Inputs

active high

SM#3

SM#2

SM#1

TMC429-LI

1K

100 nF

Output SDO_C will nerver

be high impedance

10nF

10nF

10nF

4.7K

4.7K

4.7K

Optional filter for long cables and to avoid

failure if switch wires are next to motor

cables.

10K

SCK_S

SDO_S

SDI_S

nSCS_S

nSCS

SDI

SCK

nSCS

SDI

SCK

nSCS

SDI

SCK

Driver

w/ o SDO

Driver

w/ o SDO

REF2 REF3

REF1

TEST

GND

µC

SCK

MOSI

MISO

SS

SDI_C

nSCS_C

SCK_C

SDO_C/

SDOZ_C

CLK

CLK

V5V33

470 nF

+ 5 V

SM#3 SM#2

SM#1

TMC429- LI /

TMC429-PI24

nSCS2

nSCS3

V5 GND

Output SDO_ C will nerver

be high impedance

Driver

w/ o SDO

REFR1 REFR2 REFR3

5.2 Application Example: TMC429 in SSOP16 Package

The low-prized TMC429-I is an optimum choice for SPI stepper motor drivers if the additional

functions of the TMC429-LI are not required. We recommend this package for TRINAMICs TMC23x and

TMC24x stepper driver family.

Figure 5.3 TMC429 application environment with TMC429 in SSOP16 package

5.3 Application Example: TMC429 with Drivers without Serial

For driver chips without serial data output the TMC429-LI and the TMC429-PI24 with two additional

chip select outputs are available. The TMC429 sends data to the driver chain on demand only, which

minimizes the interface traffic and reduces the power consumption.

Figure 5.4 Usage of drivers without serial data output (SDO) with TMC429 in SOP24 or in QFN32

packages

www.trinamic.com

Data Output (SDO)

Page 15

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 15

Bus clock input

SCK_C

Serial data input

SDI_C

Serial data output

SDO_C

6 Control Interface

The communication takes place via four wire serial interfaces and 32 bit datagrams of fixed length.

Stepper motor drivers with parallel inputs can be used in connection with the TMC429 with some

additional glue logic.

RESPONSIBILITIES ARE DEFINED AS FOLLOWS:

- The microcontroller is master of the TMC429.

- The TMC429 is master of the stepper motor driver daisy chain.

AUTOMATIC POWER-ON RESET:

- The TMC429 cannot be accessed before the power-on reset is completed and the clock is stable.

- All register bits are initialized with 0 during power-on-reset, except the SPI clock pre-divider

clk2_div that is initialized with 15 (see section 8.2.5.3).

6.1 Bus Signals

Signal Description TMC429 Microcontroller

Chip select input nSCS_C

6.2 Serial Peripheral Interface for µC

The serial microcontroller interface of the TMC429 acts as a 32 bit shift register.

COMMUNICATION BETWEEN µC AND THE TMC429

1. The serial µC interface shifts serial data into SDI_C with each rising edge of the clock signal

SCK_C.

2. Then, it copies the content of the 32 bit shift register into a buffer register with the rising

edge of the selection signal nSCS_C.

3. The serial interface of the TMC429 immediately sends back data read from registers or read

from internal RAM via the signal SDO_C.

4. The signal SDO_C can be sampled with the rising edge of SCK_C. SDO_C becomes valid at

least four CLK clock cycles after SCK_C becomes low as outlined in the timing diagram.

6.2.1 Timing

A complete serial datagram frame has a fixed length of 32 bit. Because of on-the-fly processing of the

input data stream, the serial µC interface of the TMC429 requires the serial data clock signal SCK_C to

have a minimum low / high time of three clock cycles. The SPI signals from the µC interface may be

asynchronous to the clock signal CLK of the TMC429.

If the microcontroller and the TMC429 work on different clock domains that run asynchronously by

the timing of the SPI interface of the microcontroller should be made conservative in the way that

the length of one SPI clock cycle equals 8 or more clock cycles of the TMC429 clock CLK.

www.trinamic.com

Page 16

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 16

t

SD

t

SD

CLK

sdi_c_bit#31

t

SCKCL

t

SCKCH

t

SUCSC

t

HDCSC

1 x SDI_C sampled

one full 32 bit datagram

SDO_C

(for TMC429-I)

SDI_C

SCK_C

nSCS_C

sdi_c_bit#30 . . . sdi_c_bit#1

30 x sampled SDI_C

sdi_c_bit#0

1 x SDI_C sampled

t

CLK

t

DATAGRAMuC

t

PD

t

IS

t

SD

t

SI

t

HDCSC

t

SUCSC

sdo_c_bit#31

sdo_c_bit#30 ... sdo_c_bit#1

sdo_c_bit#0

nINT

sdo_c_bit#31

sdo_c_bit#30 ... sdo_c_bit#1

sdo_c_bit#0

nINT

SDOZ_C

Figure 6.1 Timing diagram of the serial µC interface

EXPLANATORY NOTES

- While the data transmission from the microcontroller to the TMC429 is idle, the low active serial

chip select input nSCS_C and also the serial data clock signal SCK_C are set to high.

- While the signal nSCS_C is high, the TMC429 assigns the status of the internal low active

interrupt signal nINT to the serial data output SDO_C.

- The data signal SDI_C driven by the microcontroller has to be valid at the rising edge of the

serial data clock input SCK_C. The maximum duration of the serial data clock period is unlimited.

- While the µC interface of the TMC429 is idle, the SDO_C signal is the (active low) interrupt status

nINT of the integrated interrupt controller of the TMC429. The timing of the multiplexed interrupt

status signal nINT is characterized by the parameters t

The following SPI clock frequencies are recommended in order to avoid possible issues concerning

the SPI frequency between microcontroller and TMC429:

- For fCLK = 16MHz an upper SPI clock frequency of 1MHz is recommended.

- For fCLK = 32MHz an upper SPI clock frequency of 2MHz is recommended.

PROCEDURE OF DATA TRANSMISSION

1. The signal nSCS_C has to be high for at least three clock cycles before starting a datagram

transmission. To initiate a transmission, the signal nSCS_C has to be set to low.

2. Three clock cycles later the serial data clock may go low.

3. The most significant bit (MSB) of a 32 bit wide datagram comes first and the least significant

bit (LSB) is transmitted as the last one.

4. A data transmission is finished by setting nSCS_C high three or more CLK cycles after the last

rising SCK_C slope.

5. So, nSCS_C and SCK_C change in opposite order from low to high at the end of a data

transmission as these signals change from high to low at the beginning.

Information for TMC429-I / 16-pin package

In contrast to most other SPI compatible devices, the serial data output SDO_C of the TMC429-I is

always driven. It will never be high impedance Z. If high impedance is required for the SDO_C

connected to the microcontroller, it can be realized using a single gate 74HCT1G125. An additional pin

named SDOZ_C is available for the TMC429 with an integrated high impedance driver.

www.trinamic.com

and tSI (see chapter 16.3).

IS

Page 17

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 17

SCK_

S

SDO_

S

SDI_S

nSCS

_S

REF

2

REF

3

REF

1

TEST GND

CLK

V

5V

33

TMC

429

SCK

_C

SDI

_C

nSCS_C

SDOZ_C

SCK

_C

SDI_

C

nSCS_

C

SDOZ_C

nINT_SDO_C

nINT

nINTERRUPT status valid after

MSB

LSB

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

0

RRS

RW

Figure 6.2 The TMC429 has a high impedance pin SDOZ_C. The nINT_SDO_C can be configured as

non multiplexed interrupt output nINT if required.

TIMING CHARACTERISTICS OF THE SERIAL MICROCONTROLLER INTERFACE

Symbol Parameter Min Typ Max Unit

tSUCSC Setup Clocks for nSCS_C 3

tHDCSC Hold Clocks for nSCS_C 3

tSCKCL Serial Clock Low 3

tSCKCH Serial Clock High 3

∞

∞

∞

∞

CLK periods

CLK periods

CLK periods

CLK periods

tSD SDO_C valid after SCK_C low 2.5 3.5 CLK periods

tIS

2.5 CLK periods

nSCS_C low

tSI SDO_C valid after nSCS_C high 4.5 CLK periods

tDAMAGRAMuC Datagram Length 3+3+32*6= 198

tDAMAGRAMuC Datagram Length 12.375

∞

∞

CLK periods

µs

fCLK Clock Frequency 0 32 MHz

tCLK Clock Period tCLK = 1 / fCLK 31.25

tPD CLK-rising-edge-to-Output

5 ns

∞

ns

Propagation Delay

6.2.2 Datagram Structure

The µC communicates with the TMC429 via the four wire serial interface. Each datagram sent to the

TMC429 via the pin SDI_C and each datagram received from the TMC429 via the pin SDO_C is 32 bits

long.

The first bit sent is the most significant bit (MSB) sdi_c_bit#31. The last bit sent is the least significant

bit (LSB) sdi_c_bit#0 (see Figure 6.1). During the reception of a datagram, the TMC429 immediately

sends back a datagram of the same length to the microcontroller. This return datagram consists of

requested read data in the lower 24 datagram bits and status bits in the higher 8 datagram bits. A

read request is distinguished from a write request by the read/not write datagram bit (RW).

6.2.2.1 Datagrams Sent to the TMC429

The datagrams sent to the TMC429 are assorted in four groups of bits:

RRS The register RAM select (RRS) bit selects either registers or the on-chip RAM.

ADDRESS Address bits address memory within the register set or within the RAM area.

RW The read / not write (RW) bit distinguishes between read access and write access:

DATA Data bits are only for write access. For read access these bits are not used (don’t

ADDRESS

www.trinamic.com

read: RW = 1 / write RW = 0.

care) and should be set to 0.

32 BIT DATAGRAM SENT FROM µC TO THE TMC429 VIA PIN SDI_C

DATA

Page 18

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 18

MSB

LSB

INT

CDGW

SM3

SM2

SM1

RS3

xEQt3

RS2

xEQt2

RS1

xEQt1

NOTE

- Different internal registers of the TMC429 have different lengths. For some registers only a subset

of 24 data bits is used.

- Unused data bits should be set to 0.

- Some addresses select a couple of registers mapped together into the 24 data bit space.

6.2.2.2 Datagrams received by µC from the TMC429

The datagrams received by the µC from the TMC429 contain two groups of bits:

STATUS BITS The status bits, sent back with each datagram, comprehend the most important

internal status bits of the TMC429 and the settings of the reference switches

DATA BITS Data bits are only for write access.

The most significant bit MSB is received first; the least significant bit LSB is received last. The TMC429

only sends datagrams on demand.

32 BIT DATAGRAM SENT BACK FROM THE TMC429 TO µC VIA PIN SDO_C

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

STATUS BITS DATA BITS

STATUS INFORMATION BITS

INT The status bit INT is the internal high active interrupt controller status output

signal. Handling of interrupt conditions without using interrupt techniques is

possible by polling this status bit.

The interrupt signal is also directly available at the SDO_C pin of the TMC429

(set SDO_INT=1 in if_configuration_429 register). The pin SDO_C may directly be

connected to an interrupt input of the microcontroller.

Since the SDO_C / nINT output on TMC429-I (16-pin package) is multiplexed, the

microcontroller has to disable its interrupt input while it sends a datagram to

the TMC429. The SDO_C signal driven by the TMC429 alternates during datagram

transmission.

CDGW The CDGW cover datagram waiting bit is a handshake signal for the

microcontroller. It shows the state of a datagram covering mechanism that is

necessary for direct configuration data transmission to the stepper motor driver

chain, e.g. for configuring the drivers in the initialization phase.

The CDGW status bit also gives the status of the datagram_high_word and

datagram_low_word.

RS3, RS2, RS1 The status bits RS3, RS2 and RS1 represent the state of the left reference switch

inputs. They are also accessible in register %1111100 as l3, l2 and l1.

xEQt3, xEQt2, xEQt1 The three status bits xEQt3, xEQt2, and xEQt1 indicate individually for each

stepper motor, if it has reached its target position.

The status bits r1, r2, r3 and l1, l2, l3 and bits xEQt3, xEQt2, and xEQt1 can trigger an interrupt or

enable simple polling techniques.

www.trinamic.com

Page 19

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 19

6.2.3 Simple Datagram Examples

The % prefix – normally indicating binary representation in this data sheet – is omitted for the

following datagram examples. Assuming, one would like to write (RW=0) to a register (RRS=0) at the

address %001101 the following data word %0000 0000 0000 0001 0010 0011, one would have to send

the following 32 bit datagram

00011010000000000000000100100011

to the TMC429. With inactive interrupt (INT=0), no cover datagram waiting (CDGW=0), all reference

switches inactive (RS3=0, RS2=0, RS1=0), and all stepper motors at target position (xEQt3=1, xEQt2=1,

xEQt1=1) the status bits would be %10010101 the TMC429 would send back the 32 bit datagram:

10010101000000000000000000000000

To read (RW=1) back the register written before, one would have to send the 32 bit datagram

00011011000000000000000000000000

to the TMC429 and the TMC429 would reply with the datagram

10010101000000000000000100100011.

Write (RW=0) access to on-chip RAM (RRS=1) to an address %111111 occurs similar to register access,

but with RRS=1. To write two 6 bit data words %100001 and %100011 to successive pair-wise RAM

addresses %1111110 and %1111111 (%100001 to %1111110 and %100011 to %1111111) which are

commonly addressed by one datagram, one would have to send the datagram

11111110000000000010001100100001.

To read (rw=1) from that on-chip memory address, one would have to send the datagram

11111111000000000000000000000000.

www.trinamic.com

Page 20

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 20

with up to

7 Address Space Partitions

The functionality of the TMC429 is mapped to registers which are combined to groups and mapped to

the address space:

- Each stepper motor has a set of registers individually assigned to it and arranged within a

contiguous address space.

- A set of registers within the address space holds the global parameters which are common for

all stepper motors. A single dedicated global parameter register is essential for the configuration

of the serial four wire stepper motor driver interface.

- One half of the on-chip RAM address space holds the configuration parameters for the stepper

motor driver chain (used for SPI mode, only).

- The other half of the on-chip RAM address space is provided to store a microstep table if

required (used for SPI mode, only).

- The first seven datagram bits (sdi_c_bit#31 and sdi_c_bit#30 ... sdi_c_bit#25, respectively RRS and

ADDRESS) address the whole address space of the TMC429.

ADDRESS SPACE PARTITIONS

Address ranges (incl. RRS) Assignment

%000 0000 . . . %000 1111 16 registers for stepper motor #1

%001 0000 . . . %001 1111 16 registers for stepper motor #2

%010 0000 . . . %010 1111 16 registers for stepper motor #3

%011 0000 . . . %011 1110 15 common registers

%011 1111 1 global parameter register

%100 0000 . . . %101 1111 32 addresses of 2x6 bit for driver chain configuration

%110 0000 . . . %111 1111 32 addresses of 2x6 bit for microstep table

Registers

24 bits

RAM

128x6 bit

CHANGING TARGET POSITION OR TARGET VELOCITY OF SINGLE MOTORS

The stepper motors are controlled directly by writing motion parameters into associated registers.

Only one register write access is necessary for changing a target motion parameter. Thus the

microcontroller has to send one 32 bit datagram to the TMC429 for altering the target position or the

target velocity of one stepper motor.

CHANGING DRIVER CONFIGURATION OR MICROSTEP TABLE OF ALL MOTORS

Some parameters are packed together in a single data word at a single address. These parameters

have to be initialized once and remain unchanged during operation. They have to be changed in

common. The access to the on-chip RAM addresses concern two successive RAM addresses. So, always

two data words are modified with each write access to the on-chip RAM.

Once initialized after power-up, the content of the RAM is usually left unchanged.

7.1 Read and Write

Read and write access is selected by the RW bit (sdi_c_bit#24) of the datagram sent from the µC to

the TMC429. The on-chip configuration RAM and the registers are writeable with read-back option.

Some addresses are read-only. Write access (RW=0) to some of those read-only registers triggers

additional functions, explained in detail later.

7.2 Register Set

The register address mapping is given in chapter 7.3. The registers are initialized internally during

power-up. During power-up initialization, the TMC429 does not send any datagrams to the stepper

motor driver chain.

The TMC429 loads a default RAM configuration for a TMC236 / TMC239 / TMC246 / TMC249 SPI driver

chain on power-on reset. For a Step/Dir driver chain this is of no relevance.

www.trinamic.com

Page 21

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 21

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

0

RRS

RW

RW=0 : WRITE access / RW=1 : READ access

0 0 0

1

X_ACTUAL

0 0 1 1

V_MAX

0 1 0 0

V_TARGET

0 1 0 1

V_ACTUAL

0 1 1 0

A_MAX

0 1 1 1

A_ACTUAL

1 0 0 0

A_THRESHOLD

1 0 1 0

REF_CONF

R_M

1 1 0 0 PULSE_DIV

RAMP_DIV

USRS

1 1 1

0

X_LATCHED

1 1 1 1 USTEP_COUNT_429

C

(SMDA=11)

0 0 0

0

DATAGRAM_LOW_WORD

0 0 1

0

COVER_POSITION

COVER_LEN

0 1 0 0

IF_CONFIGURATION_429

0 1 0

1

POS_COMP_429

0 1 1 0 POS_COMP_INT_429

M

I

P

1 1 1 0

mot1r

refmux

cont_update

cs_ComInd

dac_ab

fd_ab

ph_ab

sck_s

nscs_s

SMDA =

stepper motor driver address

M =

mask

cw =

cover waiting

RRS =

register RAM select

l1, l2, l3 =

left switch 1/2/3 (read-out)

r1, r2, r3 =

right switch 1/2/3 (read-out)

unused bits

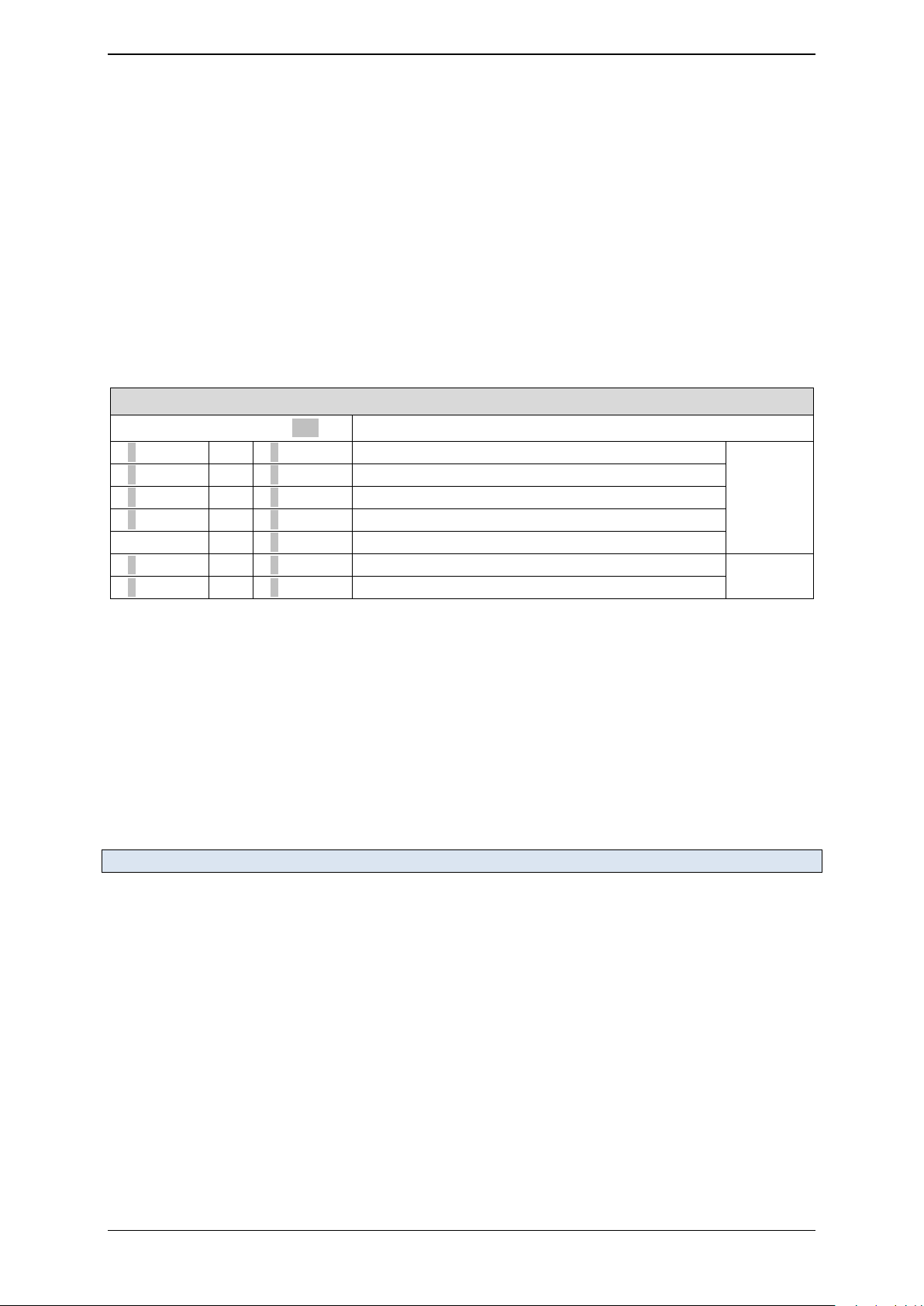

7.3 Register Mapping

All register bits are initialized with 0 during power on reset, except the SPI clock pre-divider clk2_div

(see section 8.2.5.3) that is initialized with 15. The on-chip RAM of the TMC429 is initialized internally

during power-up. It can be modified by the microcontroller as required.

TMC429 REGISTER MAPPING

32 BIT DATAGRAM SENT FROM µC TO THE TMC429 VIA PIN SDI_C

0

SMDA

0

0

0

1

1

0

1 1

ADDRESS

IDX

THREE STEPPER MOTOR REGISTER SETS (SMDA={00, 01, 10})

DATA

0 0 0 0 X_TARGET

0 0 1 0 V_MIN

IS_AGTAT

IS_ALEAT

IS_v0

1 0 0 1 1 PMUL PDIV

lp

1 0 1 1 INTERRUPT_MASK INTERRUPF_FLAGS

1 1 0 1 DX_REF_TOLERANCE

JDX

OMMON REGISTERS

0 0 0 1 DATAGRAM_HIGH_WORD

cw

0 0 1 1 COVER_DATAGRAM

1 0 0 0

1 0 0 1 TYPE_VERSION_429 (= $429101 for TMC429 version 1.01, read-only)

1 1 1 1 1 1

R_M = RAMP_MODE I = interrupt

www.trinamic.com

OWER-DOWN

l3 r3 l2 r2 l1 r1

POLARITIES

CLK2_DIV

LSMD

0 0 0 0

STPDIV_429

(if en_sd=1)

Page 22

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 22

X_TARGET

R/W

24 bit

This register holds the current target position in units of

X_ACTUAL

24 bit

The current position of each stepper motor is available by read

Positions can be treated as signed or

unsigned.

V_MAX

R/W

11 bit

This parameter sets the maximum motor velocity.

of V_TARGET depends on the chosen mode of operation.

V_ACTUAL

12 bit signed

This read-only register holds the current velocity of the

A_MAX

R/W

11 bit

This register defines the absolute value of the desired

with a value range from 0 to 2047.

A_ACTUAL

R

12 bit signed

The actual acceleration can be read out by the microcontroller

IS_AGTAT

R/W

3 bit

unsigned

in SPI

RAMP_MODE

R/W

2 bit

The two bits RAMP_MODE (R_M) select one of the four possible

select the behavior of the

The bit called lp (latched position) is a read only status bit.

INTERRUPT_MASK

R/W

8 bit

The TMC429 provides one interrupt register of eight flags for

RAMP_DIV

R/W

4 bit

The parameter RAMP_DIV scales the acceleration parameter

s used for

setting the microstep resolution in SPI mode.

DX_REF_TOLERANCE

R/W

12 bit

DX_REF_TOLERANCE excludes a motion range to allow motion

unsigned

a change of the reference switch state.

holds the actual

8 Register Description

The TMC429 provides axis parameter registers and global parameter registers.

8.1 Axis Parameter Registers

The registers hold binary coded numbers. Some are unsigned (positive) numbers, some are signed

numbers in two’s complement, and some are control bits or single flags. The functionality of different

registers depends on the RAMP_MODE (refer to chapter 8.1.11).

OVERVIEW AXIS PARAMETER REGISTER MAPPING

REGISTER R / W TYPE DESCRIPTION

microsteps. Positions can be treated as signed or unsigned.

R/W*2

out of this register.

V_MIN R/W 11 bit

unsigned

unsigned

V_TARGET R/W 12 bit signed The V_TARGET register holds the current target velocity. The use

R*1

unsigned

IS_ALEAT

IS_V0

A_THRESHOLD

PMUL

PDIV

REF_CONF

lp

R/W

R/W

R/W

R/W

R/W

R/W

R

3 bit

3 bit

11 bit

1+7 bit

4 bit

unsigned

4 bit

1 bit

This register holds the absolute velocity value at or below which

the stepper motor can be stopped abruptly.

associated stepper motor.

acceleration for velocity_mode and ramp_mode (resp. soft_mode)

from the A_ACTUAL read-only register.

These parameters control the current scaling values I

driver mode. Depending on the ramp phase they are applied to

the motor by scaling the amplitudes of the internal sequencer.

These values form a floating point number with PMUL as

mantissa and PDIV as exponent. PMUL and PDIV are used for

calculating the deceleration ramp.

modes of operation.

The configuration bits REF_CONF

reference switches.

S

INTERRUPT_FLAGS

PULSE_DIV

USRS

X_LATCHED

USTEP_COUNT_429 R/W 8 bit The read-write register USTEP_COUNT_429

1

*

in hold_mode only, this register is a read-write register.

2

*

before overwriting X_ACTUAL choose velocity_mode or hold_mode. Refer to chapter 8.1.2.

www.trinamic.com

R/W

R/W

R/W

8 bit

4 bit

2 bit

R 24 bit

each stepper motor.

A_MAX.

The pulse generator clock – defining the maximum step pulse

rate – is determined by the parameter PULSE_DIV. The parameter

PULSE_DIV scales the velocity parameters.

The parameter USRS (µstep resolution selection) i

near the reference position.

This read-only register stores the actual position X_ACTUAL upon

microstep pointer of the internal sequencer.

Page 23

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 23

8.1.1 X_TARGET (IDX=%0000)

This register holds the current target position in units of microsteps.

UNIT OF TARGET POSITION

The unit of the target position depends on the setting of the associated microstep resolution register

usrs.

POSITIONING

- If the difference X_TARGET to X_ACTUAL is not zero and R_M = ramp_mode or soft_mode, the

TMC429 moves the stepper motor in the direction of X_TARGET in order to position X_ACTUAL to

X_TARGET. Usually X_TARGET is modified to start a positioning.

- The condition | X_TARGET – X_ACTUAL | < 2

- Target position X_TARGET and current position X_ACTUAL may be altered on the fly.

- To move from one position to another, the ramp generator of the TMC429 automatically

generates ramp profiles in consideration of the velocity limits V_MIN and V_MAX and acceleration

limit A_MAX.

The registers X_TARGET, X_ACTUAL, V_MIN, V_MAX, and A_MAX are initialized with zero after power up.

23

must be satisfied for motion into correct direction.

8.1.2 X_ACTUAL (IDX=%0001)

The current position of each stepper motor is available by read out of the registers called X_ACTUAL.

The actual position can be overwritten by the microcontroller. This feature is important for the

reference switch position calibration controlled by the microcontroller.

UNIT OF CURRENT POSITION

The unit of the target position depends on the setting of the associated microstep resolution register

usrs.

Attention

Before overwriting X_ACTUAL choose velocity_mode or hold_mode.

If X_ACTUAL is overwritten in ramp_mode or soft_mode the motor directly drives to X_TARGET.

www.trinamic.com

Page 24

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 24

t

v(t)

t

0

t

1

A

_

MAX

t3t

4

t

2

Δv

t

7

t

8

t

5

Δv

A_MAX

- A_MAX

- A_MAX

t

6

acceleration constant velocity deceleration

acceleration deceleration

Δt

01

Δt

56

8.1.3 V_MIN (IDX=%0010)

This register holds the absolute velocity value at or below which the stepper motor can be stopped

abruptly.

UNIT OF VELOCITY

The unit of velocity parameters is steps per time unit. The scale of velocity parameters (V_MIN, V_MAX,

V_TARGET, V_ACTUAL) is defined by the parameter PULSE_DIV (see page 8.1.13 for details) and depends

on the clock frequency of the TMC429.

DECELERATION

- The parameter V_MIN is relevant for deceleration while reaching a target position. V_MIN should

be set greater than zero.

- This control value allows reaching the target position faster because the stepper motor is not

slowed down below V_MIN before the target is reached.

- Due to the finite numerical representation of integral relations the target position cannot be

reached exactly, if the calculated velocity is less than one, before the target is reached. Setting

V_MIN to at least one assures reaching each target position exactly.

Figure 8.1 Velocity ramp parameters and velocity profiles

8.1.4 V_MAX (IDX=%0011)

This parameter sets the maximum motor velocity. The absolute value of the velocity will not exceed

this limit, except if the limit V_MAX is changed during motion to a value below the current velocity.

UNIT OF VELOCITY

The unit of velocity parameters is steps per time unit. The scale of velocity parameters (V_MIN, V_MAX,

V_TARGET, V_ACTUAL) is defined by the parameter PULSE_DIV (see page 8.1.13 for details) and depends

on the clock frequency of the TMC429.

HOMING PROCEDURE

To set target position X_TARGET and current position X_ACTUAL to an equivalent value (e.g. to set

both to zero at a reference point) the assigned stepper motor should be stopped first and the

parameter V_MAX should be set to zero to hold the assigned stepper motor at rest before writing into

the register X_TARGET and X_ACTUAL.

Attention

Before overwriting X_ACTUAL choose velocity_mode or hold_mode.

If X_ACTUAL is overwritten in ramp_mode or soft_mode the motor directly drives to X_TARGET.

www.trinamic.com

Page 25

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 25

ramp_mode

The V_TARGET register holds the current target velocity calculated internally

by the ramp generator.

register. The associated

stepper motor accelerates until it reaches the specified target velocity. The

velocity is changed according to the motion parameter limits if the register

hold_mode

The register V_TARGET is ignored.

register holds the current target velocity calculated internally

8.1.5 V_TARGET (IDX=%0100)

The use of V_TARGET depends on the chosen mode of operation:

Mode of operation Functionality of V_TARGET

velocity_mode A target velocity can be written into the V_TARGET

V_TARGET is changed.

soft_mode The V_TARGET

by the ramp generator.

UNIT OF VELOCITY

The unit of velocity parameters is steps per time unit. The scale of velocity parameters (V_MIN, V_MAX,

V_TARGET, V_ACTUAL) is defined by the parameter PULSE_DIV (see chapter 8.1.13 for details) and

depends on the clock frequency of the TMC429.

8.1.6 V_ACTUAL (IDX=%0101)

This read-only register holds the current velocity of the associated stepper motor. Internally, the ramp

generator of the TMC429 processes with 20 bits while only 12 bits (the most significant bits) can be

read out as V_ACTUAL.

In hold_mode only, this register is a read-write register. Writing zero to the register V_ACTUAL

immediately stops the associated stepper motor, because hidden bits are set to zero with each write

access to the register V_ACTUAL. In hold_mode motion parameters are ignored and the

microcontroller has the full control to generate a ramp. The TMC429 only handles the microstepping

and datagram generation for the associated stepper motor of the daisy chain.

UNIT

The unit of velocity parameters is steps per time unit. The scale of velocity parameters (V_MIN, V_MAX,

V_TARGET, and V_ACTUAL) is defined by the parameter PULSE_DIV (see chapter 8.1.13 for details) and

depends on the clock frequency of the TMC429.

An actual velocity of zero read out by the microcontroller means that the current velocity is in an

interval between zero and one. Therefore the actual velocity should not be used to detect a stop of a

stepper motor. It is advised to detect the target_reached flag instead.

8.1.7 A_MAX (IDX=%0110)

This register defines the absolute value of the desired acceleration for velocity_mode and ramp_mode

(resp. soft_mode) with a value range from 0 to 2047.

Note

The motion controller cannot stop the stepper motor if A_MAX is set to zero on the fly because

afterwards the velocity cannot be changed automatically any more.

UNIT

The unit of the acceleration is change of step frequency per time unit divided by 256. The scale of

acceleration parameters (A_MAX, A_ACTUAL, and A_THRESHOLD) is defined by the parameter RAMP_DIV

(see section 8.1.13) and depends on the clock frequency of the TMC429.

8.1.7.1 A_MAX in ramp_mode

As long as RAMP_DIV ≥ PULSE_DIV – 1 is valid, any value of A_MAX within its range (0… 2047) is

allowed and there exists a valid pair {PMUL, PDIV} for each A_MAX. The reason is that the acceleration

scaling determined by RAMP_DIV is compatible with the step velocity scaling determined by

PULSE_DIV. A large RAMP_DIV stands for low acceleration and a large PULSE_DIV stands for low

velocity. Low acceleration is compatible with low speed and high speed as well, but high acceleration

is more compatible with high speed.

www.trinamic.com

Page 26

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 26

Changing one parameter out of the triple {A_MAX, RAMP_DIV, PULSE_DIV} requires re-calculation of the

parameter pair {PMUL, PDIV} to update the associated register. For description of the parameters PMUL

and PDIV see section 8.1.10.

8.1.7.1.1 Deceleration in ramp_mode and soft_mode

If RAMP_DIV and PULSE_DIV differ more than one while deceleration in ramp_mode or soft_mode the

parameter A_MAX needs to have a lower limit (>1) and an upper limit (<2047). The reason is that the

deceleration ramp is internally limited to 2

THE LOWER LIMIT OF A_MAX IS GIVEN BY

19

steps (respectively microsteps).

_

- With V_MAX set to

_

- If RAMP_DIV – PULSE_DIV – 1 ≤ 0 the limit A_MAX

(__)

= 2

(≈ 1448) or lower the A_MAX

√

LOWER_LIMIT

LOWER_LIMIT

is half of this value.

is 1 and the parameter A_MAX may be

set to 1.

THE UPPER LIMIT OF A_MAX IS GIVEN BY

_

_

- If RAMP_DIV – PULSE_DIV + 1 ≥ 0 the A_MAX_UPPER_LIMIT is > 2048 and the parameter A_MAX

might be set to any value up to 2047.

(__)

= 2

- 1

CONDITIONS

The parameter A_MAX must not be set below A_MAX

A_MAX ≥ A_MAX

LOWER_LIMIT

as well as A_MAX ≤ A_MAX

LOWER_LIMIT

UPPER_LIMIT

position without oscillations. If that condition is not satisfied, oscillations around a target position

may occur.

except A_MAX is set to 0. The condition

must be satisfied to reach any target

8.1.8 A_ACTUAL (IDX=%0111)

The actual acceleration can be read out by the microcontroller from the A_ACTUAL read-only register.

The actual acceleration is used to select scale factors for the coil currents. It is updated with each

clock. The returned value A_ACTUAL is smoothed to avoid oscillations of the readout value. Thus,

returned A_ACTUAL values should not be used directly for precise calculations.

UNIT

The unit of the acceleration is change of step frequency per time unit divided by 256. The scale of

acceleration parameters (A_MAX, A_ACTUAL, and A_THRESHOLD) is defined by the parameter RAMP_DIV

(see section 8.1.13) and depends on the clock frequency of the TMC429.

8.1.9 IS_AGTAT, IS_ALEAT, IS_V0, and A_THRESHOLD (IDX=%1000)

These parameters are only relevant in SPI mode. The parameters IS_AGTAT, IS_ALEAT, IS_V0, and

A_THRESHOLD represent the current scaling values I

to the motor by scaling the current amplitudes of the internal sequencer.

The automatic motion dependent current scale feature of the TMC429 is provided primarily for

microstep operation. It may also be applied for full step or half step drivers, if those provide current

control bits. In this special case it is possible to initialize the microstep table with a constant

function, square function or sine wave using the two most significant DAC bits.

IS_AGTAT The parameter IS_AGTAT is applied if the acceleration is greater than the threshold

acceleration. This is used to increase current during acceleration phases.

IS_ALEAT The parameter IS_ALEAT is applied if the acceleration is lower than or equal to the

threshold acceleration. This is the nominal motor current.

IS_V0 The third parameter IS_V0 is applied if the stepper motor is at rest. The parameter is

used to save power, keep it cool, and avoid noise probably caused by chopper

drivers.

A_THRESHOLD The parameter A_THRESHOLD is the threshold used for comparing with the current

acceleration in order to select the current scale factor.

. Depending on the ramp phase they are applied

S

www.trinamic.com

Page 27

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 27

0 0 0

1

= 100 % 0 0 1

1 / 8

= 12.5 % 0 1 0

2 / 8

= 25 % 0 1 1

3 / 8

= 37.5 % 1 0 0

4 / 8

= 50 % 1 0 1

5 / 8

= 62.5 % 1 1 0

6 / 8

= 75 % 1 1 1

7 / 8

= 87.5

%

Velocity value

A

THRESHOLD

value

IS scale factor selection

A

THRESHOLD

> 1023

IS :=

*3)

| a | ≤ A

IS :=

| a | > A

THRESHOLD

IS :=

RELATIONSHIP BETWEEN IS_AGTAT, IS_ALEAT, AND IS_V0 AND THE INTERIM BIT VECTOR I_SCALE

The parameters IS_AGTAT, IS_ALEAT, and IS_V0 are bit vectors of three bit width. One of these bit

vectors is selected conditionally and assigned to the interim bit vector I_SCALE.

I_SCALE IS

NOTE

- The maximum current scaling factor 1 is selected by I_SCALE = %000. This is the power-on

default.

- The minimum current scaling factor 1/8 = 0.125 is selected by I_SCALE = %001.

- The current scaling factor I

step. For example, with I_SCALE = %100 (= 4/8 = 50%) the number of effective microsteps per full

step is halved.

- When a low current scaling factor I

step may decrease, because less DAC steps are used to distinguish the same number of current

levels. Therefore, it is advised to operate the application normally at 50% to 100% current scale.

proportionally reduces the effective number of microsteps per full

S

becomes used, the effective number of microsteps per full

S

The current scale selection scheme shows which of the scale factors IS_AGTAT, IS_ALEAT, and IS_V0 is

selected corresponding to their conditions:

If the velocity is zero, the parameter IS_V0 is used for scaling.

If the velocity is not zero, either IS_ALEAT or IS_AGTAT is used for scaling. This depends on the

absolute value of the acceleration and the acceleration threshold A_THRESHOLD.

CURRENT SCALE SELECTION SCHEME

v= 0*1) IS := IS_V0*2)

IS_ALEAT

v ≠ 0

1)

*

The configuration bit continuous_update of the stepper motor global parameter register must be

THRESHOLD

IS_ALEAT

IS_AGTAT

set to 1 to make sure that the coil current is scaled for v=0 if all motors are at rest. The current

scale for V=0 takes place delayed to avoid mechanical step loss due to oscillations of the motor

after it has been stopped.

_

[]

)

×(×

The delay time is:

2)

For selection of current scaling IS_V0 (at rest) IS_AGTAT and IS_ALEAT must be larger than 0.

*

3)

It is not advised to use A_THRESHOLD > 1023. Due to comparing of A_THRESHOLD with A_MAX a

*

__[]

=

setting of A_THRESHOLD with a value greater than 1023 results in using IS_ALEAT if A_MAX is

greater than 1023 during acceleration.

For most applications setting IS_ALEAT and IS_AGTAT to the same value and using a lower value for

IS_V0 is the best choice.

www.trinamic.com

Page 28

TMC429 DATASHEET (Rev. 2.04 / 2015-JUN-03) 28

V_MAX

Target Position

Calculation

Velocity Ramp

Generator

(Micro-) Step pulses

V_TARGET

X_TARGET

X_ACTUAL

PDIVPMUL

A_MAXV_MIN

PULSE_DIVRAMP_DIV

clk32

CLOCK_DIV32clk

V_ACTUAL

Puls Generator

8.1.10 PMUL & PDIV (IDX=%1001)

In ramp mode, the TMC429 uses an internal algorithm to calculate the deceleration ramp on the fly.

This algorithm requires an additional proportionality factor P which allows the TMC429 to calculate

the velocity required for stopping in time to exactly reach the target position without overshooting.

This calculation is done for each ramp step. The result of this calculation can be read in the register