Page 1

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 1

TMC211 – DATASHEET

Micro Stepping Stepper Motor

Controller / Driver with LIN Interface

TRINAMIC

®

Motion Control GmbH & Co. KG

Sternstraße 67

D – 20357 Hamburg

GERMANY

P +49 - (0) 40 - 51 48 06 - 0

F +49 - (0) 40 - 51 48 06 - 60

www.trinamic.com

info@trinamic.com

19

18

17

16

15

14

13

20

SWI

VBAT

OA1

GND

OB1

OA2

GND

12

OB2

VBAT

TMC211

SOIC-20

HW01

VDD3GND4TST5LIN6GND

HW1

2

HW2

CPN

7

8

9

11

VCP

CPP

10

1 Features

The TMC211 is a combined micro-stepping stepper motor motion controller and driver with RAM and

OTP memory. The RAM or OTP memory is used to store motor parameters and configuration settings.

The TMC211 allows up to four bit of microstepping and a coil current of up to 800 mA. After

initialization it performs all time critical tasks autonomously based on target positions and velocity

parameters. Communications to a host takes place via LIN. Together with an inexpensive

microcontroller the TMC211 forms a complete motion control system. The main benefits of the

TMC211 are:

• Motor driver

• Controls one stepper motor with four bit microstepping

• Programmable Coil current up to 800 mA

• Supply voltage operating range 8V ... 29V

• Fixed frequency PWM current control with automatic selection of fast and slow decay mode

• Full step frequencies up to 1 kHz

• High temperature, open circuit, short, over-current and under-voltage diagnostics

• Motion controller

• Internal 16-bit wide position counter

• Configurable speed and acceleration settings

• Build-in ramp generator for autonomous positioning and speed control

• On-the-fly alteration of target position

• reference switch input available for read out

• LIN interface

• Physical and Data-Link Layers conform to LIN specification rev. 1.3

• Field-programmable node addresses (128)

• Dynamically allocated identifiers

• Diagnostics and status information as well as motion parameters accessable

• LIN bus short-circuit protection to supply and ground

• Lost LIN safe operation

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 2

2 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

Life support policy

TRINAMIC Motion Control GmbH & Co. KG does

not authorize or warrant any of its products for

use in life support systems, without the specific

written consent of TRINAMIC Motion Control

GmbH & Co. KG.

Life support systems are equipment intended to

support or sustain life, and whose failure to

perform, when properly used in accordance with

instructions provided, can be reasonably

expected to result in personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2005

Information given in this data sheet is believed to

be accurate and reliable. However no

responsibility is assumed for the consequences

of its use nor for any infringement of patents or

other rights of third parties which may result form

its use.

Specifications subject to change without notice.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 3

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 3

Table of Contents

1 FEATURES .....................................................................................................................................1

2 GENERAL DESCRIPTION .............................................................................................................5

2.1 BLOCK DIAGRAMM......................................................................................................................5

2.2 POSITION CONTROLLER / MAIN CONTROL ...................................................................................5

2.3 STEPPER MOTOR DRIVER...........................................................................................................5

2.4 LIN INTERFACE ..........................................................................................................................6

2.5 MISCELLANEOUS ........................................................................................................................6

2.6 PIN AND SIGNAL DESCRIPTIONS..................................................................................................6

3 TYPICAL APPLICATION................................................................................................................7

4 ORDERING INFORMATION ..........................................................................................................7

5 FUNCTIONAL DESCRIPTION .......................................................................................................8

5.1 POSITION CONTROLLER AND MAIN CONTROLLER.........................................................................8

5.1.1 Stepping Modes ................................................................................................................ 8

5.1.2 Velocity Ramp...................................................................................................................8

5.1.3 Examples for different Velocity Ramps.............................................................................9

5.1.4 Vmax Parameter .............................................................................................................10

5.1.5 Vmin Parameter ..............................................................................................................11

5.1.6 Acceleration Parameter ..................................................................................................11

5.1.7 Position Ranges..............................................................................................................12

5.1.8 Secure Position...............................................................................................................12

5.1.9 External Switch ...............................................................................................................12

5.1.10 Motor Shutdown Management........................................................................................ 13

5.1.11 Reference Search / Position initialization........................................................................14

5.1.12 Sleep Mode.....................................................................................................................14

5.1.13 Temperature Management .............................................................................................15

5.1.14 Battery Voltage Management .........................................................................................16

5.1.15 Internal handling of commands and flags .......................................................................17

5.2 RAM AND OTP MEMORY .........................................................................................................19

5.2.1 RAM Registers................................................................................................................ 19

5.2.2 Status Flags ....................................................................................................................20

5.2.3 OTP Memory Structure...................................................................................................21

5.3 STEPPER MOTOR DRIVER.........................................................................................................21

5.3.1 Coil current shapes .........................................................................................................22

5.3.2 Transition Irun to Ihold ....................................................................................................23

5.3.3 Chopper Mechanism....................................................................................................... 24

6 LIN INTERFACE...........................................................................................................................25

6.1 GENERAL DESCRIPTION ...........................................................................................................25

6.2 PHYSICAL LAYER......................................................................................................................25

6.3 ANALOG PART..........................................................................................................................26

6.4 SLAVE OPERATIONAL RANGE FOR PROPER SELF SYNCHRONIZATION ...........................................26

6.5 PHYSICAL ADDRESS OF THE CIRCUIT .........................................................................................27

6.6 ELECTRO MAGNETIC COMPABILITY ...........................................................................................27

6.7 ERROR STATUS REGISTER .......................................................................................................27

6.8 DYNAMIC ASSIGNMENT OF LIN IDENTIFIERS ..............................................................................28

6.9 LIN MESSAGE FRAMES ............................................................................................................29

6.9.1 Writing Frames ...............................................................................................................29

6.9.2 Writing Frame Type#1 (2 or 4 bytes)..............................................................................30

6.9.3 Writing Frame Type#2 (2, 4 or 8 bytes)..........................................................................30

6.9.4 Writing Frame Type#3 (2 bytes) .....................................................................................30

6.9.5 Writing Frame Type#4 (8 bytes) .....................................................................................30

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 4

4 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

6.9.6 Reading Frames ............................................................................................................ 31

6.9.7 Reading Frame Type#5 (2, 4 or 8 bytes) ....................................................................... 31

6.9.8 Reading Frame Type#6 (8 bytes) .................................................................................. 31

6.9.9 Reading Frame Type#7 (Preparing frame) .................................................................... 32

6.9.10 Reading Frame Type#8 (Preparing frame) .................................................................... 32

6.10 APPLICATION COMMANDS OVERVIEW ................................................................................... 33

6.11 COMMAND DESCRIPTION...................................................................................................... 34

6.11.1 GetActualPos ................................................................................................................. 34

6.11.2 GetFullStatus ................................................................................................................. 36

6.11.3 GetOTPParam ............................................................................................................... 38

6.11.4 GetStatus .......................................................................................................................39

6.11.5 GotoSecurePosition ....................................................................................................... 39

6.11.6 HardStop ........................................................................................................................39

6.11.7 ResetPosition ................................................................................................................. 40

6.11.8 ResetToDefault .............................................................................................................. 40

6.11.9 RunInit............................................................................................................................ 41

6.11.10 SetMotorParam .......................................................................................................... 42

6.11.11 SetOTPParam ............................................................................................................ 42

6.11.12 SetPosition ................................................................................................................. 43

6.11.13 SetPositionShort......................................................................................................... 44

6.11.14 SoftStop...................................................................................................................... 45

6.11.15 Sleep Mode ................................................................................................................ 45

6.12 POSITIONING TASK EXAMPLE ............................................................................................... 46

7 FREQUENTLY ASKED QUESTIONS ......................................................................................... 48

7.1 USING THE BUS INTERFACE...................................................................................................... 48

7.2 GENERAL PROBLEMS WHEN GETTING STARTED......................................................................... 48

7.3 USING THE DEVICE .................................................................................................................. 49

7.4 FINDING THE REFERENCE POSITION .......................................................................................... 50

8 PACKAGE OUTLINE ................................................................................................................... 51

8.1 SOIC-20 ................................................................................................................................ 51

9 PACKAGE THERMAL RESISTANCE AND LAYOUT CONSIDERATIONS ............................... 52

9.1 SOIC-20 PACKAGE ................................................................................................................. 52

10 ELECTRICAL CHARACTERISTICS ........................................................................................ 53

10.1 ABSOLUTE MAXIMUM RATINGS ............................................................................................. 53

10.2 OPERATING RANGES ........................................................................................................... 53

10.3 DC PARAMETERS ................................................................................................................ 53

10.4 AC PARAMETERS ................................................................................................................ 55

11 REVISION HISTORY................................................................................................................56

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 5

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 5

2 General Description

2.1 Block Diagramm

SWI

PWM

regulator

X

PWM

regulator

Y

Reference voltage

&

Thermal monitoring

LIN

HW0

HW1

HW2

TST

VBAT

VDD

LIN

transceiver

LIN

slave

controller

Sy nchro nous

I/O controller

(test)

Voltage

regulator

Position controller

Main control

Registers

&

OTP + ROM

Oscillator

Decoder

Sinewave

table

DACs

Charge pump

VCP CP2 CP1

2.2 Position Controller / Main Control

Motor parameters, e.g. acceleration, velocity and position parameters are passed to the main control

block via the LIN interface. These information are stored internally in RAM or OTP memory and are

accessable by the position controller. This block takes over all time critical tasks to drive a stepper

motor to the desired position under abiding the desired motion parameters.

The main controller gets feedback from the stepper motor driver block and is able to arrange internal

actions in case of possible problems. Diagnostics information about problems and errors are

transferred to the LIN interface block.

2.3 Stepper Motor Driver

Two H-bridges are employed to drive both windings of a bipolar stepper motor. The internal transistors

can reach an output current of up to 800 mA. The PWM principle is used to force the given current

through the coils. The regulation loop performs a comparison between the sensed output current and

the internal reference. The PW M signals to drive the power transistors are derived from the output of

the current comparator.

OA1

OA2

OB1

OB2

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 6

6 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

2.4 LIN Interface

Communication between a host and the TMC211 takes places via the bi-directional LIN interface.

Motion Instructions and diagnostic information are provided to or from the Main Control block. It is

possible to connect up to 128 devices on the same bus. Slave addresses are programmable via OTP

memory or external pins. The LIN interface implements the MAC and LLC layers according to the OSI

reference model.

2.5 Miscellaneous

Besides the main blocks the TMC211 contains the following:

• an internal charge pump is used to drive the high side transistors.

• an internal oscillator running at 4 MHz +/- 10% to clock the LIN protocol handler, the positioning

unit, and the main control block

• internal voltage reference for precise referencing

• a 5 Volts voltage regulator to supply the digital logic

• protection block featuring Thermal Shutdown, Power-On-Reset, etc.

2.6 Pin and Signal Descriptions

Pin SOIC20 Description

HW0 1 hard-wired LIN address bit #0 input

HW1 2 hard-wired LIN address bit #1 input

VDD 3 Internal supply (needs external decoupling capacitor)

GND 4,7,14,17 ground, heat sink

TST 5 test pin (to be tied to ground in normal operation)

LIN 6 LIN-bus connection

HW2 8 hard-wired LIN address bit #2 input

CPN 9 negative connection of external charge pump capacitor

CPP 10 positive connection of external charge pump capacitor

VCP 11 connection of external charge pump filter capacitor

VBAT 12,19 battery voltage supply

OB2 13 negative end of phase B coil

OB1 15 positive end of phase B coil

OA2 16 negative end of phase A coil

OA1 18 positive end of phase A coil

SWI 20 reference switch input

HW0

HW1

VDD

GND

TST

LIN

GND

HW2

CPN

CPP

1

2

3

4

5

6

7

8

9

10

TMC211

20

SWI

19

VBAT

18

OA1

17

GND

16

OA2

15

OB1

14

GND

13

OB2

12

TRINA M IC

VBAT

11

VCP

Table 1: TMC211 Signal Description

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 7

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 7

3 Typical Application

Connect to GND or

+5V (VDD, Pin 3)

Connect to GND or

+5V (VDD, Pin 3)

100 nF

1 µF

Tantalum

HW0 SWI

1 20

HW1

2

VDD

3

GND

4

VBAT

OA1

GND

Ω

/1/4W

1k

19

18

17

100 nF

SWI

2.7 nF

Connect to

GND or V

BAT

M

OA2

OB1

GND

OB2

VBAT

VCP

16

15

14

13

12

11

Connect to

GND or V

BAT

2.7 nF

LIN Bus

VDR 27V

1kΩ /1/4W

220 nF

16 V

TST

5

LIN

6

GND

7

HW2

8

CPN

9

CPP

10

Figure 1: TMC211 Typical Application

Notes :

• Resistors tolerance +- 5%

• 2.7nF capacitors: 2.7nF is the minimum value, 10nF is the maximum value

• the 1µF and 100µF must have a low ESR value

• 100nF capacitors must be close to pins V

and VDD

BB

• 220nF capacitors must be as close as possible to pins CPN, CPP, V

100 nF

220 nF

16 V

and VBB to reduce EMC radiation.

CP

100 µF

V

BAT

8...29 V

4 Ordering Information

Part No. Package Peak Current Temperature Range

TMC211-PA20

(pre-series marking,

same IC as TMC211-SA)

TMC211-SA SOIC-20 800mA -40°C..125°C

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

SOIC-20 800 mA -40°C..125°C

Table 2: Ordering Information

Page 8

8 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

5 Functional Description

5.1 Position Controller and Main Controller

5.1.1 Stepping Modes

The TMC211 supports up to 16 micro steps per full step, which leads to smooth and low torque ripple

motion of the stepping motor. Four stepping modes (micro step resolutions) are selectable by the user:

See also 5.3 Stepper Motor Driver on page 21.

• Half step Mode

• 1/4 Micro stepping

• 1/8 Micro stepping

• 1/16 Micro stepping

5.1.2 Velocity Ramp

A common velocity ramp where a motor drives to a desired position is shown in the figure below. The

motion consists of an acceleration phase, a phase of constant speed and a final deceleration phase.

Both the acceleration and the deceleration are symmetrical. The acceleration factor can be chosen

from a table with 16 entries. (Table 5: Acc Parameter on page 11). A typical motion begins with a start

velocity Vmin. During acceleration phase the velocity is increased until Vmax is reached. After

acceleration phase the motion is continued with velocity Vmax until the velocity has to be decreased in

order to stop at the desired target position. Both velocity parameters Vmin and Vmax are

programmable, whereas Vmin is a programmable ratio of Vmax (see Table 3: Vmax Parameter on

page 10 and Table 4: Vmin on page 11). The user has to take into account that Vmin is not allowed to

change while a motion is ongoing. Vmax is only allowed to change under special circumstances. (See

5.1.4 Vmax Parameter on page 10).

The peak current value to be fed to each coil of the stepper-motor is selectable from a table with 16

possible values. It has to be distinguished between the run current Irun and the hold current Ihold. Irun

is fed through the stepper motor coils while a motion is performed, whereas Ihold is the current to hold

the stepper motor before or after a motion. More details about Irun and Ihold can be found in 5.3.1 and

5.3.2.

Velocity resp. acceleration parameters are accessable via the LIN interface. These parameters are

written via the SetMotorParam command (See Page 42) and read via the GetFullStatus command

(See Page 36).

Velocity V

[FS/s]

V

max

V

mi n

X

start

State of Motion

No

Move ment

Acceleration

Phase Constant Velocity

Deceler ation

Phase

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

X

target

No

Move ment

time

[s]

Page 9

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 9

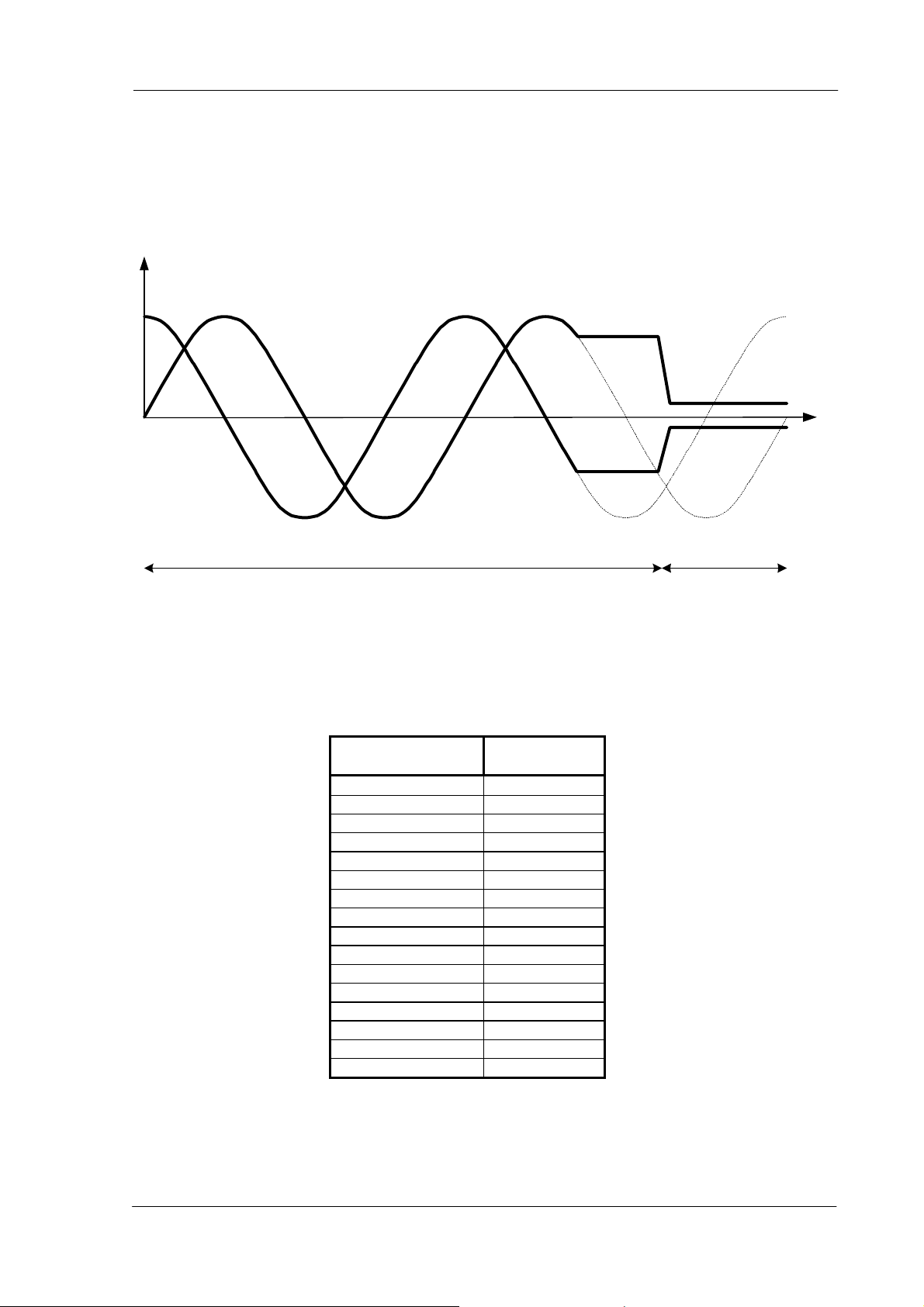

5.1.3 Examples for different Velocity Ramps

The following figures show some examples of typical motions under different conditions:

Velocity V

V

max

V

mi n

X

start

X

target_1

X

target_2

time

Figure 2: Motion with change of target position

Velocity V

V

max

V

mi n

X

start

X

target_1

X

target_2

time

Figure 3: Motion with change of target position while in deceleration phase

Velocity V

V

max

V

mi n

X

start

X

target

time

Figure 4: Short Motion Vmax is not reached

Velocity V

V

max

V

mi n

X

start

X

target_1

X

target_2

time

Figure 5: Motion with change of target position in opposite direction (linear zero crossing)

In Figure 5 the motor crosses zero velocity with a linear shape. The velocity can be less than the

programmed Vmin value during zero crossing. Linear zero crossing provides very low torque ripple to

the stepper motor during crossing.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 10

10 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

5.1.4 Vmax Parameter

The desired maximum velocity Vmax can be chosen from the table below:

Stepping Mode Vmax

1/8 micro

stepping

[micro-steps/s]

1/16 micro

stepping

[micro-steps/s]

index

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Vmax

[FS/s]

99

136 273 546 1091 2182

167 334 668 1335 2670

197 395 790 1579 3159

213 425 851 1701 3403

228 456 912 1823 3647

243

273 546 1091 2182 4364

303 607 1213 2426 4852

334 668 1335 2670 5341

364 729 1457 2914 5829

395 790 1579 3159 6317

456

546 1091 2182 4364 8728

729 1457 2914 5829 11658

973

Vmax

group

A

B

C

D

Half-Step

Mode

[half-steps/s]

197 395 790 1579

486 973 1945 3891

912 1823 3647 7294

1945 3891 7782 15564

1/4 micro

stepping

[micro-steps/s]

Table 3: Vmax Parameter

Under special circumstances it is possible to change the Vmax parameters while a motion is ongoing.

All 16 entries for the Vmax parameter are divided into four groups A, B, C and D. W hen changing

Vmax during a motion take care that the new Vmax value is within the same group. Background: The

TMC211 uses an internal pre-divider for positioning calculations. Within one group the pre-divider is

equal. When changing Vmax between different groups during a motion, correct positioning is not

ensured anymore.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 11

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 11

V

5.1.5 Vmin Parameter

The minimum velocity parameter is a programmable ratio between 1/32 and 15/32 of Vmax. It is also

possible to set Vmin to the same velocity as Vmax by setting Vmin index to zero. The table below

shows the possible rounded values.

min

Vmax

index

factor

0 1

1 1/32

2 2/32

3 3/32

4 4/32

5 5/32

6 6/32

7 7/32

8 8/32

9 9/32

10 10/32

11 11/32

12 12/32

13 13/32

14 14/32

15 15/32

A B C D

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

136 167 197 213 228 243 273 303 334 364 395 456 546 729 973

99

4 5 6 6 7 7 8 8 10 10 11 13 15 19 26

3

6

8 10 11 12 13 14 15 17 19 21 23 27 30 42 57

12 15 18 19 21 22 25 27 30 32 36 42 50 65 88

9

16 20 24 26 28 30 32 36 40 44 48 55 65 88 118

12

21 26 30 32 35 37 42 46 52 55 61 71 84 111 149

15

25 30 36 39 42 45 50 55 61 67 72 84 99 134 179

18

30 36 43 46 50 52 59 65 72 78 86 99 118 156 210

22

33 41 49 52 56 60 67 74 82 90 97 112 134 179 240

24

28

38 47 55 59 64 68 76 84 94 101 111 128 153 202 271

42 52 61 66 71 75 84 94 103 112 122 141 168 225 301

30

47 57 68 72 78 83 94 103 114 124 135 156 187 248 332

34

50 62 73 79 85 91 101 112 124 135 147 170 202 271 362

37

55 68 80 86 92 98 111 122 135 147 160 185 221 294 393

40

59 72 86 92 99 106 118 132 145 158 172 198 236 317 423

43

64 78 92 99 107 114 128 141 156 170 185 214 256 340 454

46

Vmax group [A...D] and Vmax index [0…15]

Table 4: Vmin values for all Vmin index – Vmax index combinations

5.1.6 Acceleration Parameter

The acceleration parameter can be chosen from a wide range of available values as described in the

table below. Please note that the acceleration parameter is not to change while a motion is ongoing.

Acceleration Values in [FS/s2] dependent on Vmax

Acc index

0 49 106 473

1 218 735

2 1004

3 3609

4 6228

5 8848

6 11409

7 13970

8 16531

9 19092

10 21886

11 24447

12 27008

13 29570

14 34925

15

99 136 167 197 213 228 243 273 303 334 364 395 456 546 729 973

14785

29570

Vmax [FS/s]

40047

Table 5: Acc Parameter

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 12

12 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

The amount of equivalent full steps during acceleration phase can be computed by the next equation:

V

Acc

2

minmax

8192 half-steps

213

16384 micro-steps

214

32768 micro-steps

215

65536 micro-steps

216

2

V

step

N

=

5.1.7 Position Ranges

Position information is coded by using two’s complement format. Depending on the stepping mode

(see 5.1.1) the position ranges are as listed in the following table:

Stepping Mode Position Range Full range excursion

Half-stepping -4096…+4095

1/4 micro-stepping -8192…+8191

1/8 micro-stepping -16384…+16383

1/16 micro-stepping -32768…+32767

Table 6: Position Ranges

(-2

(-2

(-2

(-2

12

13

14

15

−

⋅

2

…+212-1)

…+213-1)

…+214-1)

…+215-1)

Target positions can be programmed via LIN interface by using the SetPosition command (see

6.11.11). The actual motor position can be read by the GetActualPos command (see 6.11.1).

5.1.8 Secure Position

In case of emergency (communication loss) or GotoSecurePosition command (6.11.5) the motor

drives to the secure position. The secure position is programmable by the user. Secure position is

coded with 11 bits, therefore the resolution is lower than for normal positioning commands, as shown

in the following table.

Stepping Mode Secure Position Resolution

Half-stepping 4 half steps

1/4 micro stepping 8 micro steps (1/4th)

1/8 micro stepping 16 micro steps (1/8th)

1/16 micro stepping 32 micro steps (1/16th)

Table 7: Secure Position Resolution

5.1.9 External Switch

Pin SWI will alternately attempt to source and sink current in/from the external switch (Figure 1:

TMC211 Typical Application on page 7). This is to check whether the external switch is open or closed,

resp. if the pin is connected to ground or Vbat. The status of the switch can be read by using the

GetFullStatus or the GetActualPos command. As long as the switch is open, the <ESW> flag is set to

zero.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 13

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 13

5.1.10 Motor Shutdown Management

The TMC211 is set into motor shutdown mode as soon as one of the following conditions occur:

• The chip temperature rises above the thermal shutdown threshold T

. See 5.1.13 Temperature

tsd

Management on Page 15

• The battery voltage drops below UV2 See 5.1.14 Battery Voltage Management on Page 16.

• An electrical problem occurred, e.g. short circuit, open circuit, etc. In case of such a problem flag

<ElDef> is set to one.

• Chargepump failure, indicated by <CPFail> flag set to one.

During motor shutdown the following actions are performed by the main controller:

• H-bridges are set into high impedance mode

• The target position register TagPos is loaded with the contents of the actual position register

ActPos.

The LIN interface remains active during motor shutdown. To leave the motor shutdown state the

following conditions must be true:

• Conditions which led to a motor shutdown are not active anymore

• A GetFullStatus command is performed via LIN interface.

Leaving the motor shutdown state initiates the following

• H-bridges in Ihold mode

• Clock for the motor control digital circuitry is enabled

• The charge pump is active again

Now the TMC211 is ready to execute any positioning command.

IMPORTANT NOTE:

First, a GetFullStatus command has to be executed after power-on to activate the TMC211.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 14

14 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

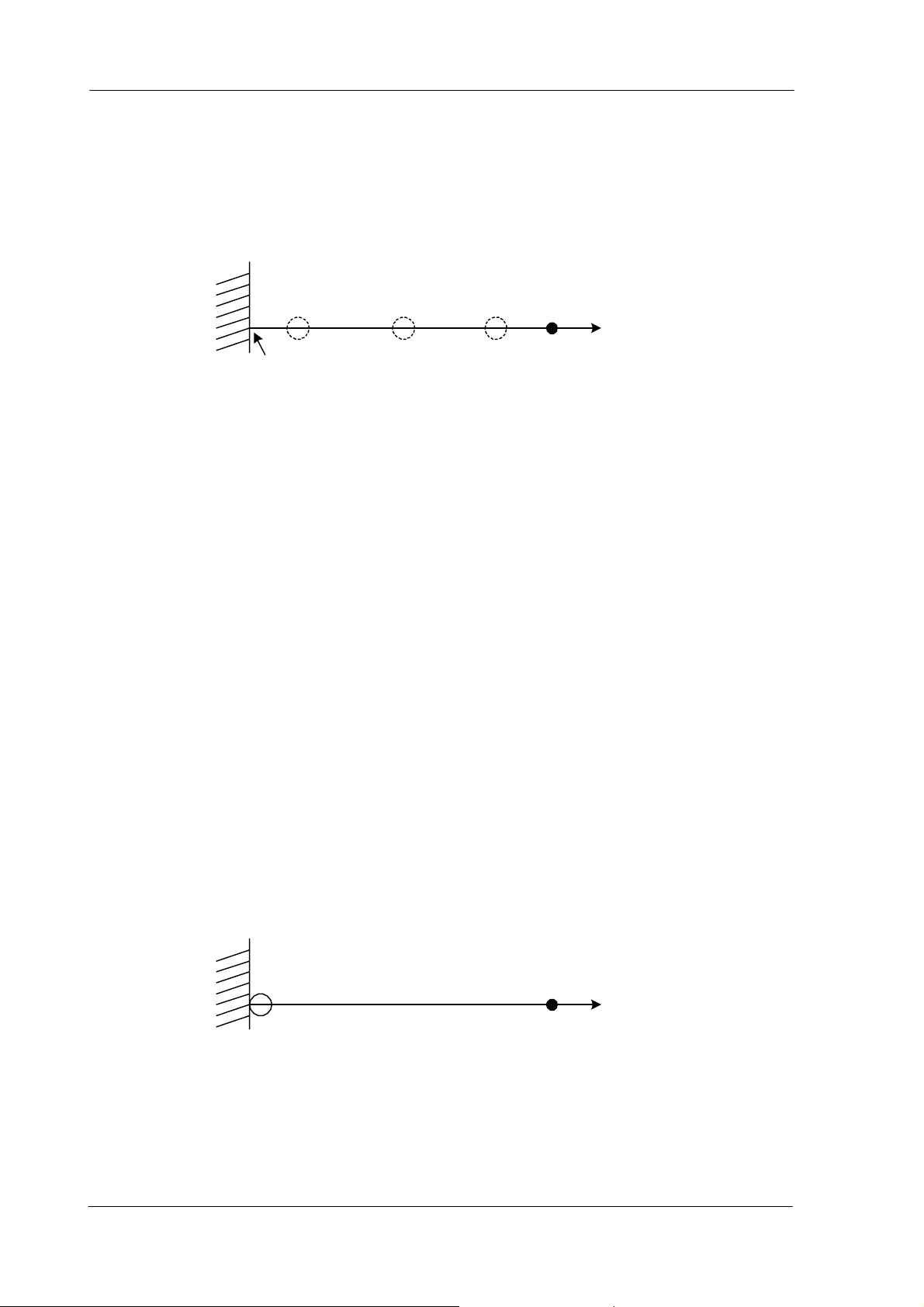

5.1.11 Reference Search / Position initialization

A stepper motor does not provide information about the actual position of the motor. Therefore it is

recommended to perform a reference drive after power-up or if a motor shutdown happened in case of

a problem. The RunInit command initiates the reference search. The RunInit command consists of a

Vmin and a Vmax parameter and also position information about the end of first and second motion.

(6.11.9 RunInit).

A reference drive consists of two motions (Figure 6: RunInit): The first motion is to drive the motor into

a stall position or a reference switch. The first motion is performed under compliance of the selected

Vmax and Vmin parameter and the acceleration parameter specified in the RAM. The second motion

has got a rectangular shape without an acceleration phase and is to drive the motor out of the stall

position or slowly towards the stall position again to compensate for the bouncing of the faster first

motion to stop as close to the stall position as possible. The maximum velocity of the second motion

equals to Vmin. After the second motion the actual position register is set to zero. Finally, the secure

position will be traveled to if it is enabled (different from the most negative decimal value of –1024).

Once the RunInit command is started it can not be interrupted by any other command except a

condition occurs which leads to a motor shutdown (See 5.1.10 Motor Shutdown Management) or a

HardStop command is received. Furthermore the master has to ensure that the target position of the

first motion is not equal to the actual position of the stepper motor and that the target positions of the

first and the second motion are not equal. This is very important otherwise the circuit goes into a

deadlock state. Once the circuit finds itself in a deadlock state only a HardStop command followed by a

GetFullStatus command will cause the circuit to leave the deadlock state.

Velocity V

[FS/s]

1st Motion

2nd Motion

V

max

V

min

Position X

Pos1 Pos2

[FS]

Figure 6: RunInit

5.1.12 Sleep Mode

When entering Sleep mode, the stepper-motor is driven to the secure position if the secure position is

enabled (SecPos[10:0] different from the most negative decimal value of –1024). Then the circuit is

completely powered down, apart from the LIN receiver which remains active to detect a dominant state

on the bus. In case sleep mode is entered while a motion is ongoing, a transition will occur towards

secure position as described above.

The Sleep mode can be entered in the following cases:

• The circuit receives a LIN frame with identifier 0x3C and first data byte containing 0x00, as

required by LIN specification rev. 1.3.

• The LIN bus remains inactive or is lost during more than 25000 LIN bit times (1.30s at 19.2 kbit/s).

The circuit will return to normal mode once a valid LIN frame is received while in the Sleep mode (this

valid frame can be addressed to another slave). For more information refer to 6.11.15 Sleep Mode on

page 45.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 15

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 15

5.1.13 Temperature Management

The TMC211 provides an internal temperature monitoring. The circuit goes into shutdown mode if the

temperature exceeds threshold T

, furthermore two thresholds are implemented to generate a

tsd

temperature pre-warning.

Low Temperatur

<Tinfo> = "01"

<TW> = '0'

<TSD> = '0'

T° > TlowT° < Tlow

Normal Temp.

T° < Ttw &

GetFullStatus

<Tinfo> = "00"

<TW> = '0'

<TSD> = '0'

T° > Ttw

T° < Ttw &

GetFullStatus

Post

Thermal Warning

<Tinfo> = "00"

<TW> = ' 1'

<TSD> = '0'

Thermal Warning

<Tinfo> = "10"

<TW> = '1'

<TSD> = '0'

T° > TtsdT° < TtwT° > Ttw

Thermal Shutdown

<Tinfo> = "11"

<TW> = '1'

<TSD> = '1'

SoftStop, if motion

Motion = disabled

T° < TtsdT° > Ttsd

Post Thermal

Shutdown 1

<Tinfo> = "10"

<TW> = '1'

<TSD> = '1'

Motion = disabled

T° < TtwT° > Ttw

Post Thermal

Shutdown 2

<Tinfo> = "00"

<TW> = '1'

<TSD> = '1'

Motion = disabled

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 16

16 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

5.1.14 Battery Voltage Management

The TMC211 provides an internal battery voltage monitoring. The circuit goes into shutdown mode if

the battery voltage falls below threshold UV2, furthermore one threshold UV1 is implemented to

generate a low voltage warning.

Vbat > UV1 &

GetFullStatus

Normal Voltage

<UV2> = '0'

<StepLoss> = '0'

Motion = enabled

Vbat < UV1Vbat > UV1

Low Voltage

<UV2> = '0'

<StepLoss> = '0'

Motion = enabled

Vbat > UV1 &

GetFullStatus

Vbat < UV2

(no Motion)

Stop Mode 1

<UV2> = '1'

<StepLoss> = '0'

Motion = disabled

Vbat < UV2

(Motion)

Stop Mode 2

<UV2> = '1'

<StepLoss> = '1'

HardStop

Motion = disabled

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 17

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 17

5.1.15 Internal handling of commands and flags

Due to the sleep mode, the internal handling of commands and flags differs. Commands are handled

with different priorities depending on the current state and the current status of internal flags, see figure

below. Details can be found in Table 8: Priority Encoder.

Note: A HardStop command is sent by the master or triggered internally in case of an electrical defect

or over temperature.

A description of the available commands can be found in 6.11 Command Description. A list of the

internal flags can be found in 5.2.2 Status Flags.

As an example: When the circuit drives the motor to its programmed target position, state “GotoPos” is

entered. There are three events which can cause to leave this state: HardStop command received,

SoftStop command received or target position reached. If all three events occur at the same time the

HardStop command is executed since it has the highest priority. The Motion finished event (target

position reached) has the lowest priority and thus will only cause transition to “Stopped” state when

both other events do not occur.

Power On

Reset

<Sleep>

or LIN timeout

ShutDown

Sleep

HardStop

Thermal Shutdown

GetFullStatus

AND <TSD> + <HS> = 0

Any LIN command

<Sleep> AND (not <SecEn>)

OR <SecEn> AND ActPos== SecPos

OR <Stop>

Figure 7: Internal handling of commands and flags

RunInit SoftStop

RunInitMotion finished

Stopped

Thermal Shutdown

HardStop HardStop

HardStop

Motion finished

GotoSecurePosi tion

SetPosition

Motion finished

Motion finished

HardStop

Thermal Shutdown

SoftStop

GotoPos

Priorities

High

Low

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 18

18 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

State →→→→

Command

↓↓↓↓

GetActualPos

GetOTPParam

GetFullStatus

or GetStatus

[attempt to clear

<TSD> and <HS>

flags]

ResetToDefault

[ActPos and TagPos

are not altered]

SetMotorParam

[Master takes care

about proper update]

ResetPosition

SetPosition

SetPositionShor

t

[half-step mode only)]

GotoSecurePosit

ion

RunInit

HardStop

SoftStop

Sleep or LIN

timeout

[ ⇒ <Sleep> = ‘1’,

reset by any LIN

command received

later ]

HardStop

[ ⇔ (<CPFail> or

<UV2> or <ElDef>) =

‘1’ ⇒ <HS> = ‘1’ ]

Thermal shutdown

[ <TSD> = ‘1’ ]

Motion finished

Stopped GotoPos RunInit SoftStop HardStop ShutDown Sleep

motor stopped,

Ihold in coils

LIN in-frame

response

OTP refresh;

LIN in-frame

LIN in-frame

response

OTP refresh;

OTP to RAM;

AccShape reset

RAM update RAM update RAM update RAM update RAM update RAM update

TagPos and

ActPos reset

TagPos updated;

→→→→GotoPos

TagPos updated;

→→→→GotoPos

If <SecEn> = ‘1’

then TagPos =

SecPos;

→→→→GotoPos

→→→→RunInit

See note 9

→→→→Shutdown →→→→HardStop →→→→HardStop →→→→HardStop

→→→→Shutdown →→→→SoftStop →→→→SoftStop

n.a.

motor motion

ongoing

LIN in-frame

response

OTP refresh;

LIN in-frame

LIN in-frame

response

OTP refresh;

OTP to RAM;

AccShape reset

TagPos updated TagPos updated

TagPos updated TagPos updated

If <SecEn> = ‘1’

then TagPos =

SecPos

→→→→HardStop;

<StepLoss> =

‘1’

→→→→SoftStop

If <SecEn> = ‘1’

then TagPos =

SecPos

else → SoftStop

→→→→Stopped →→→→Stopped

no influence on

RAM and

TagPos

LIN in-frame

response

OTP refresh;

LIN in-frame

LIN in-frame

response

OTP refresh;

OTP to RAM;

AccShape reset

(note 3)

If <SecEn> = ‘1’

then TagPos =

SecPos

→→→→HardStop;

<StepLoss> =

‘1’

If <SecEn> = ‘1’

then TagPos =

SecPos;

will be evaluated

after RunInit

motor

decelerating

LIN in-frame

response

OTP refresh;

LIN in-frame

LIN in-frame

response

OTP refresh;

OTP to RAM;

AccShape reset

→→→→HardStop;

<StepLoss> =

‘1’

No action;

<Sleep> flag will

be evaluated

when motor

stops

→→→→Stopped;

TagPos

=ActPos

motor forced to

stop

LIN in-frame

response

OTP refresh;

LIN in-frame

LIN in-frame

response

OTP refresh;

OTP to RAM;

AccShape reset

No action;

<Sleep> flag will

be evaluated

when motor

stops

→→→→Stopped;

TagPos

=ActPos

motor stopped,

H-bridges in

Hi-Z

LIN in-frame

response

OTP refresh;

LIN in-frame

LIN in-frame

response;

if (<TSD> or

<HS>) = ‘1’

then

→→→→ Stopped

OTP refresh;

OTP to RAM;

AccShape

reset

TagPos and

ActPos reset

→→→→Sleep

n.a. n.a.

no

power

(note 1)

Table 8: Priority Encoder

Color code:

Command ignored

Transition to another state

Master is responsible for proper update (see note 7)

Notes:

1 Leaving Sleep state is equivalent to Power on reset.

2 After Power on reset, the Shutdown state is entered. The Shutdown state can only be left after a GetStatus or a

GetFullStatus command (so that the Master could read the <VddReset> flag).

3 A RunInit sequence runs with a separate set of RAM registers. The parameters which are not specified in a RunInit

command are loaded with the values stored in RAM at the moment the RunInit sequence starts. AccShape is forced

to ‘1’ during second motion even if a ResetToDefault command is issued during a RunInit sequence, in which case

AccShape at ‘0’ will be taken into account after the RunInit sequence.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 19

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 19

4 The <Sleep> flag is set to ‘1’ when a LIN timeout or a Sleep command occurs. It is reset by the next LIN command

(<Sleep> is cancelled if not activated yet).

5 Shutdown state can be left only when <TSD> and <HS> flags are reset.

6 Flags can be reset only after the master could read them via a GetStatus or GetFullStatus command, and

provided the physical conditions allow for it (normal temperature, correct battery voltage and no electrical or charge

pump defect).

7 A SetMotorParam command sent while a motion is ongoing (state GotoPos) should not attempt to modify Acc and

Vmin values. This can be done during a RunInit sequence since this motion uses its own parameters, the new

parameters will be taken into account at the next SetPosition or SetPositionShort command.

8

Some transitions like GotoPos → Sleep are actually done via several states: GotoPos → SoftStop → Stopped →

Sleep (see diagram below).

9 Two transitions are possible from state Stopped when <Sleep> = ‘1’:

10 <SecEn> = ‘1’ when register SecPos is loaded with a value different from the most negative value (i.e. different from

11 <Stop> flag allows to distinguish whether state Stopped was entered after HardStop/SoftStop or not. <Stop> is set

12 Command for dynamic assignment of IDs is decoded in all states except Sleep and has not effect on the current state

13

14 If <StepLoss> is active, then SetPosition, SetPositionShort and GotoSecurePosition commands are

1) Transition to state Sleep if (<SecEn> = ‘0’) or ((<SecEn> = ‘1’) and (ActPos = SecPos)) or <Stop> = ‘1’

2) Otherwise transition to state GotoPos, with TagPos = SecPos

0x400 = “100 0000 0000”)

to ‘1’ when leaving state HardStop or SoftStop and is reset during first clock edge occurring in state Stopped.

While in state Stopped, if ActPos ≠ TagPos there is a transition to state GotoPos. This transition has the lowest

priority, meaning that <Sleep>, <Stop>, <TSD>, etc. are first evaluated for possible transitions.

ignored (they will not modify TagPos register whatever the state), and motion to secure position is forbidden after a

Sleep command or a LIN timeout (the circuit will go into Sleep state immediately, without positioning to secure

position). Other command like RunInit or ResetPosition will be executed if allowed by current state.

<StepLoss> can only be cleared by a GetStatus or GetFullStatus command.

5.2 RAM and OTP Memory

5.2.1 RAM Registers

Register Mnemonic Length

Actual

Position

Target

Position

Acceleration

Shape

Coil Peak

Current

Coil Hold

Current

Minimum

Velocity

Maximum

Velocity

Shaft Shaft 1 GetFullStatus

Acceleration

Deceleration

Secure

Position

Stepping

Mode

ActPos 16 GetFullStatus

TagPos 16 SetPosition

AccShape 1 GetFullStatus

Irun 4 GetFullStatus

Ihold 4 GetFullStatus

Vmin 4 GetFullStatus

Vmax 4 GetFullStatus

Acc 4 GetFullStatus

SecPos 11 GetFullStatus

StepMode 2 GetFullStatus

(bit)

Related

commands

ResetPosition

GetFullStatus

ResetPosition

SetMotorParam

ResetToDefault

SetMotorParam

ResetToDefault

SetMotorParam

ResetToDefault

SetMotorParam

ResetToDefault

SetMotorParam

ResetToDefault

SetMotorParam

ResetToDefault

SetMotorParam

ResetToDefault

ResetToDefault

ResetToDefault

Comment Reset

Actual Position of the Stepper Motor. 16-bit signed

Target Position of the Stepper Motor. 16-bit signed

0 = Acceleration with Acc Parameter.

1 = Velocity set to Vmin, without acceleration

Coil current when motion is ongoing

(Table 12: Irun / Ihold Settings)

Coil current when motor stands still

(Table 12: Irun / Ihold Settings)

Start Velocity of the stepper motor

(Table 4: Vmin )

Target Velocity of the stepper motor

(Table 3: Vmax Parameter)

Direction of motion

Parameter for acceleration

(Table 5: Acc Parameter)

Target Position for GotoSecurePosition command

(6.11.5 GotoSecurePosition) or when LIN connection

fails; 11 MSBs of 16-bit position (LSBs fixed to ‘0’)

Micro stepping mode

(5.1.1 Stepping Modes)

State

0x0000

OTP

Memory

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 20

20 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

5.2.2 Status Flags

The table below shows the flags which are accessable by the LIN interface in order to receive

information about the internal status of the TMC211.

Flag Mnemonic Length

Digital supply

Reset

Over current in coil A OVC1 1 GetFullStatus Set to ‘1’ if an over current in coil #1 was detected. Is set to

Over current in coil B OVC2 1 GetFullStatus Set to ‘1’ if an over current in coil #2 was detected. Is set to

StepLoss StepLoss 1 GetFullStatus Set to ‘1’ when under voltage, over current or over

Secure position

enabled

Circuit in Sleep

mode

Electrical Defect ElDef 1 GetFullStatus Set to ‘1’ if open circuit or a short was detected, (<OVC1>

Temperature Info Tinfo 2 GetFullStatus Indicates the chip temperature

Thermal Warning TW 1 GetFullStatus Set to one if temperature raises above 145 °C. Is set to ‘0’

Thermal Shutdown TSD 1 GetFullStatus Set to one if temperature raises above 155° C. Is set to ‘0’

Motion Status Motion 3 GetFullStatus Indicates the actual behavior of the position controller.

External Switch

Status

Charge Pump

failure

Electrical flag HS 1 Internal use <CPFail> or <UV2> or <ElDef> ‘0’

VddReset 1 GetFullStatus Set to ‘1’ after power-up or after a micro-cut in the supply

SecEn 1 Internal use

Sleep 1 Internal use

ESW 1 GetFullStatus Indicates the status of the external switch.

CPFail 1 GetFullStatus ‘0’ charge pump OK

(bit)

Related

Command

Comment Reset

voltage to warn that RAM contents may have been lost.

Is set to ‘0’ after GetFullStatus command.

‘0’ after GetFullStatus command.

‘0’ after GetFullStatus command.

temperature event was detected. Is set to ‘0’ after

GetFullStatus command. SetPosition and

GotoSecurePosition commands are ignored when

<StepLoss> = 1

‘0’ if SecPos = “100 0000 0000”

‘1’ otherwise

‘1’ = Sleep mode

reset by LIN command

or <OVC2>). Is set to ‘0’ after GetFullStatus command.

“00” = normal temperature

“01 = low temperature warning

“10” = high temperature warning

“11” = motor shutdown

after GetFullStatus command.

after GetFullStatus command and Tinfo = “00”.

“000”: Actual Position = Target Position; Velocity = 0

“001”: Positive Acceleration; Velocity > 0

“010”: Negative Acceleration; Velocity > 0

“011”: Acceleration = 0 Velocity = maximum pos Velocity

“100”: Actual Position /= Target Position; Velocity = 0

“101”: Positive Acceleration; Velocity < 0

“110”: Positive Acceleration; Velocity < 0

“111”: Acceleration = 0 Velocity = maximum neg Velocity

‘0’ = open

‘1’ = close

‘1’ charge pump failure

state

n.a.

“00”

“000”

‘1’

‘0’

‘0’

‘0’

‘0’

‘0’

‘0’

‘0’

‘0’

‘0’

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 21

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 21

5.2.3 OTP Memory Structure

The table below shows where the OTP parameters are stored in the OTP memory.

Note: If the OTP memory has not been programmed, or if the RAM has not been programmed by a

SetMotorParam command, or if anyhow <VddReset> = ‘1’, any positioning command will be ignored, in

order to avoid any consequence due to unwanted RAM content. Please check that the correct supply

voltage is applied to the circuit before zapping the OTP (See: Table 25: DC Parameters Supply and

Voltage regulator on page 54), otherwise the circuit will be destroyed.

OTP Bit OrderOTP

Address

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

7 6 5 4 3 2 1 0

OSC3 OSC2 OSC1 OSC0 IREF3 IREF2 IREF1 IREF0

EnableLIN TSD2 TSD1 TSD0 BG3 BG2 BG1 BG0

ADM AD3 AD2 AD1 AD0

Irun3 Irun2 Irun1 Irun0 Ihold3 Ihold2 Ihold1 Ihold0

Vmax3 Vmax2 Vmax1 Vmax0 Vmin3 Vmin2 Vmin1 Vmin0

SecPos10 SecPos9 SecPos8 Shaft Acc3 Acc2 Acc1 Acc0

SecPos7 SecPos6 SecPos5 SecPos4 SecPos3 SecPos2 SecPos1 SecPos0

StepMode1 StepMode0 LOCKBT LOCKBG

Table 9: OTP Memory Structure

Parameters stored at address 0x00 and 0x01 and bit LOCKBT are already programmed in the OTP

memory at circuit delivery, they correspond to the calibration of the circuit and are just documented

here as an indication. Each OPT bit is at ‘0’ when not zapped. Zapping a bit will set it to ‘1’. Thus only

bits having to be at ‘1’ must be zapped. Zapping of a bit already at ‘1’ is disabled, to avoid any damage

of the Zener diode. It is important to note that only one single OTP byte can be programmed at the

same time (see command SetOTPParam).

Once OTP programming is completed, bit LOCKBG can be zapped, to disable unwanted future

zapping, otherwise any OTP bit at ‘0’ could still be zapped.

Lock bit Protected byte

LOCKBG 0x02 to 0x07

Table 10: OTP Lock bits

The command used to load the application parameters via the LIN bus into the RAM prior to an OTP

memory programming is SetMotorParam. This allows for a functional verification before using a

SetOTPParam command to program and zap separately one OTP memory byte. A GetOTPParam

command issued after each SetOTPParam command allows to verify the correct byte zapping.

5.3 Stepper Motor Driver

The StepMode parameter in SetMotorParam command (6.11.10 SetMotorParam on page 42) is used

to select different stepping modes. Following modes are available:

StepMode parameter Mode

00 Half Stepping

01 ¼ µStepping

10 1/8 µStepping

11 1/16 µStepping

Table 11: StepMode

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 22

22 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

5.3.1 Coil current shapes

The next four figures show the current shapes fed to each coil of the motor in different stepping

modes.

i

t

Figure 8: Coil Current for Half Stepping Mode

i

t

Figure 9: Coil Current for 1/4 Micro Stepping Mode

i

t

Figure 10: Coil Current for 1/8 Micro Stepping Mode

i

Figure 11: Coil Current for 1/16 Micro Stepping Mode

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

t

Page 23

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 23

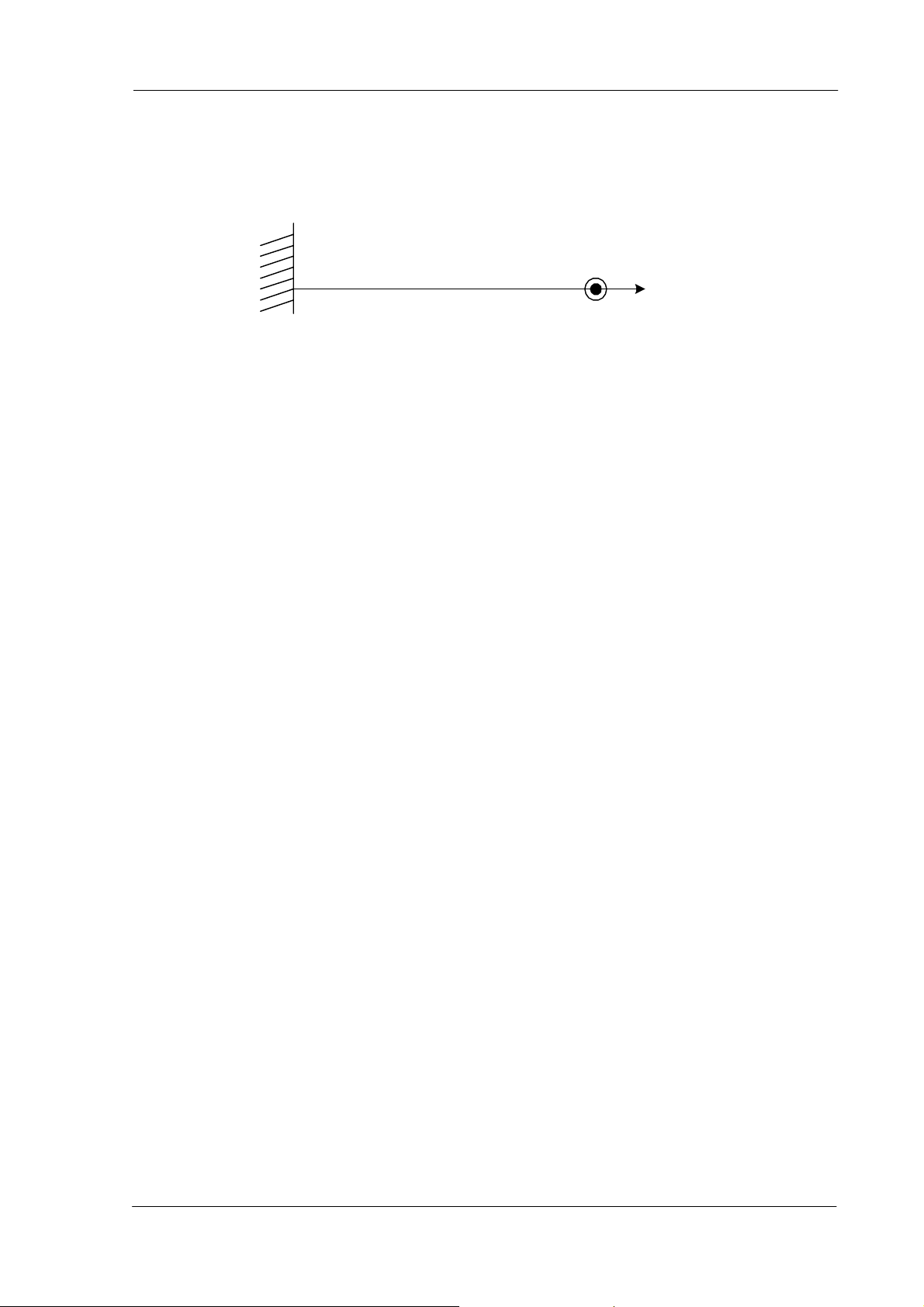

5.3.2 Transition Irun to Ihold

At the end of a motor motion the actual coil currents Irun are maintained in the coils at their actual DC

level for a quarter of an electrical period (two half steps) at minimum velocity. Afterwards the currents

are then set to their hold values Ihold. The figure below illustrates the mechanism:

i

t

I = I

run

I = I

hold

Figure 12: Transition Irun to Ihold

Both currents Irun and Ihold are parameterizeable using the command SetMotorParam. 16 values are

available for Irun current and 16 values for Ihold current. The table below shows the corresponding

current values.

Irun / Ihold setting

(hexadecimal)

Peak Current

[mA]

0x0 59

0x1 71

0x2 84

0x3 100

0x4 119

0x5 141

0x6 168

0x7 200

0x8 238

0x9 283

0xA 336

0xB 400

0xC 476

0xD 566

0xE 673

0xF 800

Table 12: Irun / Ihold Settings

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 24

24 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

5.3.3 Chopper Mechanism

The chopper frequency is fixed as specified in chapter 10.4 AC Parameters on page 55. The TMC211

uses an intelligent chopper algorithm to provide a smooth operation with low resonance. The TMC211

uses internal measurements to derive current flowing through coils. If the current is less than the

desired current, the TMC211 switches a H-bridge in a way that the current will increase. Otherwise if

the current is too high, the H-bridge will be switched to decrease the current. For decreasing two

modes are available, slow decay and fast decay, whereas fast decay decreases the current faster than

slow decay. The figure below shows the chopper behavior.

Figure 13: Different Chopper Cycles with Fast and Slow Decay

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 25

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 25

6 LIN Interface

6.1 General Description

The LIN (Local Interconnect Network) is a serial communication protocol that is used mainly for

distributed mechatronic systems in automotive applications. The LIN implementation in the TMC211

corresponds to one slave node which follows to LIN specification rev. 1.2.

Features:

• Single master / multiple-slave communication

• Self synchronizing slave nodes / no quartz or ceramics resonator necessary

• Deterministic latency times for signal transmission

• Single-wire communication

• Transmission speed 19.2 kbit/s

• Selectable length of Message Frame: 2, 4, and 8 bytes

• Configuration flexibility

• Data checksum security and error detection

• Detection of defective nodes in the network

For more information about the LIN protocol please refer to the official website and the LIN Protocol

Specification. Both can be found at http://www.lin-subbus.org/.

6.2 Physical Layer

The physical layer is a single wire with pull-up resistor in every node. The bus is directly powered from

the vehicle power net V

.

bb

V

bb

LIN

HW0

HW1

HW2

R=30K

R

R

Ω

Wake-Up

INH Ctrl

INH

to 5V

regulator

Receiver

EN

RxD

Driver +

Slope Control

LIN Protocol

Handler

TxD

to control

block

Figure 14: LIN Physical Layer

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 26

26 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

6.3 Analog Part

The transmitter is a low-side driver with a pull-up resistor and slope control. The figure below shows

the characteristics of the transmitted signal, including the delay between internal TxD Signal and LIN

Signal. See Table 32: AC Parameters LIN Transmitter on page 55 and Table 33: AC Parameters LIN

Receiver on page 55 for timing values.

TxD

50%

50%

T_tr_F

LIN

95%

t_slope_F t_slope_R

LIN

50%

RxD

50%

T_rec_F

T_tr_R

60%

40%

5%

50%

T_rec_R

50%

t

100%

0%

t

t

t

Figure 15: LIN Signal Characteristics

6.4 Slave operational range for proper self synchronization

The internal oscillator having a ± 10% accuracy over the voltage and temperature range, will

synchronize properly in the following conditions:

• Vbb ≥ 8 V

• Ground shift between Master node and Slave node < ± 1 Volt

It is highly recommended to use the same type of reverse battery voltage protection diode for the

Master and the Slave nodes.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 27

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 27

6.5 Physical Address of the circuit

The circuit must be provided with a physical address in order to discriminate this circuit from other

ones on the LIN bus. This address is coded on seven bits, yielding the theoretical possibility of 128

different circuits on the same bus. It is a combination of four OTP memory bits (see 5.2.3 OTP Memory

Structure) and three hardwired address bits (pins HW0, HW1 and HW2). Pins HW0 and HW1 are 5V

digital inputs, whereas pin HW2 is compliant with a 12V level. HW2 must either be connected to Vbat

or ground. Pin HW2 uses the same principle to check whether it is connected to ground or Vbat like

the SWI input (see 5.1.9 External Switch).

The TCM211 supports broadcasting. When the <Broad> bit is set to zero, broadcasting is active and

each slave on the LIN bus will be addressed.

AD5AD6 AD1AD2AD3AD4 AD0

OTP_AD3 OTP_AD1OTP_AD2 OTP_AD0

HW 2HW 1HW0

Figure 16: Physical Slave Address

The amount of physical addresses can be expanded by using bit ADM. This bit allows for the following

expansion:

ADM AD6 AD5 AD4 AD3 AD2 AD1 AD0

0 HW0 HW1 HW2 PA3 PA2 PA1 PA0

1 PA0 HW0 HW1 HW2 PA3 PA2 PA1

Physical address

OTP Memory

Hardwired Bits

Table 13: Physical Address Expansion

6.6 Electro Magnetic Compability

EMC behavior fulfills requirements defined by LIN specification rev. 1.3.

6.7 Error Status Register

The LIN interface implements a register containing an error status of the LIN communication. This

register is specified as follows:

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Not used Not used Not used Not used Timeout

Error Flag

Table 14: LIN Error Status Register

Note:

Data Error Flag = Checksum error OR StopBit error OR Length error

Header Error Flag = Parity error OR Synch Field error

A GetFullStatus command will reset the error status register

Data Error

Flag

Header

Error Flag

Bit Error

Flag

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 28

28 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

6.8 Dynamic Assignment of LIN Identifiers

The identifier field in the LIN message frame denotes the content of the message. Six identifier bits

and two parity bits are used to represent the content. The identifiers 0x3C to 0x3F are reserved for

command frames and extended frames. Slave nodes need to be very flexible to adapt itself to a given

LIN network in order to avoid conflicts with slave nodes from different manufacturers. Dynamic

assignment of identifiers fulfills this requirement by writing identifiers into the circuits RAM. ROM

pointers are linking commands and dynamic identifiers together.

A writing frame with identifier 0x3C issued by the LIN master writes dynamic identifiers into the RAM.

One writing frame is able to assign 4 identifiers, therefore 3 frames are needed to assign all identifiers.

Each ROM pointer ROMp_x [3:0] places the corresponding dynamic identifier Dyn_ID_x [5:0] at the

correct place in the RAM, see table below. When setting <BROAD> to zero broadcasting is active and

each slave on the LIN bus will store the same dynamic identifiers, otherwise only the slave with the

corresponding slave address is programmed.

Dynamic Identifiers Writing Frame

Byte Content Structure

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 Identifier 0x3C

1 AppCMD 0x80

2 CMD 1 0x11

3 Address Broad AD6 AD5 AD4 AD3 AD2 AD1 AD0

4 Data DynID_1 [3:0] ROMp_1 [3:0]

5 Data DynID_2 [1:0] ROMp_2 [3:0] DynID_1 [5:4]

6 Data ROMp_3 [3:0] DynID_2 [5:2]

7 Data ROMp_4 [1:0] DynID_3 [5:0]

8 Data DynID_4 [5:0] ROMp_4 [3:2]

Dynamic ID

user defined

user defined

user defined

user defined

user defined

user defined

user defined

user defined

user defined

ROM pointer

(binary)

0000

0001

0010

0011

0100

0101

0110

0111

1000

Application command

General purpose 2 data bytes

General purpose 4 data bytes

GetActualPosition

GetStatus

SetPosition (2 data bytes)

SetPositionShort (1 Motor)

SetPositionShort (2 Motors)

SetPositionShort (4 Motors)

Preparation frame

Dynamic assignment done at start-up

Command assignment via Dynamic ID during operation

Figure 17: Principle of dynamic command assignment

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 29

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 29

Command Byte (CMD) Command Mnemonic

binary hex

Dynamic ID

(binary; example)

ROM pointer

(binary)

GetActualPos 000000 0x00 100xxx 0010

GetFullStatus 000001 0x01 Not used

GetOTPParam 000010 0x02 Not used

GetStatus 000011 0x03 000xxx 0011

GotoSecurePosition 000100 0x04 Not used

HardStop 000101 0x05 Not used

ResetPosition 000110 0x06 Not used

ResetToDefault 000111 0x07 Not used

RunInit 001000 0x08 Not used

SetMotorParam 001001 0x09 Not used

SetPosition 001011 0x0B 010xxx 0100

SetPositionShort (1 Motor) 001100 0x0C 001001 0101

SetPositionShort (2 Motors) 001101 0x0D 101001 0110

SetPositionShort (4 Motors) 001110 0x0E 111001 0111

Sleep Not used Not used

SoftStop 001111 0x0F Not used

SetOTPParam 010000 0x10 Not used

Dynamic ID assignment 010001 0x11 Not used

General Purpose 2 Data Bytes 011000 0000

General Purpose 4 Data Bytes 101000 0001

Preparing Frame 011010 1000

Table 15: Commands and Corresponding Dynamic IDs

Note: xxx allows to address physically a slave node. Therefore, these dynamic IDs cannot be used for more than 8 stepper

motors.

6.9 LIN Message Frames

As specified in LIN specification rev. 1.3 a LIN frame consists of an 8-bit identifier field, followed by 2, 4

or 8 data fields and a checksum field. A LIN frame can either be a writing frame, with one of the

following tasks:

• Program the OTP memory

• Provide motion parameters, e.g. velocity, position, torque to the TMC211

Or a LIN frame can be a reading frame which is used to:

• Read actual position or status information of the stepper motor

• Verify correct programming and configuration

6.9.1 Writing Frames

According to the LIN specification there is only a fixed amount of identifiers available. In order to

expand the amount of identifiers resp. the amount of commands different types of writing frames are

introduced. The TMC211 supports four different writing frames. The following figures illustrate the

differences.

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 30

30 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

6.9.2 Writing Frame Type#1 (2 or 4 bytes)

General purpose 2 or 4 data bytes writing frame with a dynamically assigned identifier. This type is

used to provide 2 or 4 bytes of data to the slave nodes. When <Broad> is set to zero, broadcasting is

active and the command is valid for all slave nodes. When <Broad> is one the command is only valid

for one slave node whose physical address corresponds to the one provided by the writing frame.

A writing frame of 2 bytes issues only a defined command to the slave node(s), e.g. HardStop

command. Whereas a writing frame of 4 bytes issues a command and 2 bytes of data to the slave

node(s), e.g. SetPosition command.

ID Data1 Data2

ID [7:0]

Identifier Parameters

Command

Physical

Address

Data3 Data4

BCMD [6:0] 1

6.9.3 Writing Frame Type#2 (2, 4 or 8 bytes)

2, 4 or 8 data bytes writing frame with an identifier dynamically assigned to a particular application

command, regardless of the physical address of the circuit. e.g. SetPositionShort command.

ID Data1 Data2

ID [5:0] B

Dynamic

Identifier

pp

AD [3:0]

physi cal

address

Parameter [10:0]

6.9.4 Writing Frame Type#3 (2 bytes)

2 data bytes writing frame with an identifier dynamically assigned to a particular slave node and

application command. This type of frame requires that there are as many dynamically assigned

identifiers as there are TMC211 circuits connected to the LIN bus using this command.

ID Data1 Data2

ID [5:0] pp

Dynamic

Identifier

Parameter [15:0]

6.9.5 Writing Frame Type#4 (8 bytes)

8 data bytes writing frame with fixed identifier 0x3C. The structure is similar to type#1 but uses the

reserved identifier 0x3C. Using a reserved identifier followed by a particular application command will

expand the amount of possible LIN commands.

ID Data1 Data2 Data4Data3 Data5 Data6 Data7 Data8

0x3C 00 0x80 CMD [6:0] 1 B

physical

address

Parameters send from LIN master to LIN slave nodefixed identifier AppCMD Command

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 31

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 31

6.9.6 Reading Frames

When using reading frames the master initiates the communication by sending a header field, which

contains the synchronization and identifier field. The TMC211 supports two types of identifiers:

• Direct ID: The identifier points to a particular slave node. As described in the LIN specification the

slave sends the data as in-frame response. Direct ID gives the fastest access to the required data.

• Indirect ID: Indirect ID contains of two datagrams. The first datagram, called preparing frame,

issues the slave’s physical address to the particular slave node. The second datagram specifies

only a reading command by using the reserved identifier 0x3D. Indirect ID has the advantage to

use a reserved identifier and therefore provides more flexibility.

6.9.7 Reading Frame Type#5 (2, 4 or 8 bytes)

Type#5 is a reading frame, which uses a direct ID, therefore the master initiates the communication

and the slave responds after receiving the identifier. Dependent on the identifier the slave transmits 2,

4 or 8 bytes of data. GetActualPos command uses Type#5 reading frame.

Master

Task

In-Frame

Slave

Sy nch B reak

Sy nch Fie ld

ID

ID [5:0]

Dynamic

Identifier

pp

Data1 Data2

Data8Datax

Response

(2, 4 or 8 bytes)

Parameters back to master

6.9.8 Reading Frame Type#6 (8 bytes)

Reading frame Type#6 uses indirect ID and therefore a preparing frame of Type#7 or #8 is needed.

The preparing frame dumps the reading command into a particular slave node. Data from the slave is

then transmitted after the next reading frame. The reading frame must always be consecutive to a

preparing frame, otherwise it is not valid and not taken into account.

Master Task 1.

Master Task 2.

(Reading Frame)

Slave

Response

(8 bytes)

Preparing Frame Type#7 or Type#8

ID

ID [7:0]

Sy nch Br eak

Sy nch Fi el d

Identifier

0x3D

Data1 Data2

Parameters back to master

Data8Datax

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 32

32 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

6.9.9 Reading Frame Type#7 (Preparing frame)

A preparing frame prepares a particular slave node, that it has to answer after the next reading frame.

Preparing frames are needed when using indirect ID. Type#7 preparing frame consists of a

dynamically assigned identifier, the command indicating which kind of information is to provide to the

master and the physical address of the slave.

ID Data1 Data2

ID [7:0]

Identifier

CMD [6:0]

Command

AD [6:0]

Physical

Address

6.9.10 Reading Frame Type#8 (Preparing frame)

Type#8 preparing frame uses the reserved identifier 0x3C, followed by the application command 0x80,

then the particular reading command and the physical address is provided to the slave.

ID

ID [7:0]

Identifier

0x3C

Data1 Data2 Data3 Data4 Data8

AppCMD [7:0]

AppCMD

0x80

CMD [6:0]

Command

AD [6:0] 0xFF 0xFF

Slave

Address

0xFF

Data 4...8 = 0xFF

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 33

TMC211 DATASHEET (V. 1.04 / January 7, 2005) 33

6.10 Application Commands Overview

Communications between the TMC211 and a LIN Master takes place via a set of commands.

Reading commands are used to:

• Get actual status information, e.g. error flags

• Get actual position of the Stepper Motor

• Verify the right programming and configuration of the TMC211

Writing commands are used to:

• Program the OTP Memory

• Configure the TMC211 with motion parameters (e.g. max/min speed, acceleration, stepping mode,

etc.)

• Provide target positions to the Stepper motor

Command Mnemonic Function

GetActualPos Returns actual position of the motor

GetFullStatus Returns actual, target and secure position and also the complete

status of the circuit

GetOTPParam Returns OTP memory content

GetStatus Returns quick status of the circuit

GotoSecurePosition Drives motor to secure position

HardStop Immediate full stop

ResetPosition Actual and target position becomes zero

ResetToDefault Overwrites the chip RAM with OTP contents

RunInit Reference Search

SetMotorParam Sets motor parameter

SetPosition Drives the motor to the target position

SetPositionShort (1 Motor) Drives the motor to the target position (Half stepping mode only)

SetPositionShort (2 Motors) Drives 2 motors to the target position (Half stepping mode only)

SetPositionShort (4 Motors) Drives 4 motors to the target position (Half stepping mode only)

SoftStop Stops the motor with deceleration phase

SetOTPParam Programs the selected byte of OTP memory

Sleep Causes circuit to go into sleep mode

Table 16: Command Overview

Copyright © 2004-2005 TRINAMIC Motion Control GmbH & Co. KG

Page 34

34 TMC211 DATASHEET (V. 1.04 / January 7, 2005)

6.11 Command Description

6.11.1 GetActualPos

This command is provided to the circuit by the LIN master to get the actual position of the stepper

motor. GetActualPos provides also a quick status of the circuit and of the stepper motor, identical to

that obtained by command GetFullStatus. The GetActualPos will not attempt to reset any flags. This

command can be sent using direct or indirect ID:

1. Direct ID (immediate in-frame slave response):

GetActualPos direct ID reading frame(type#5)

Structure Source Byte Content

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Master 0 Identifier * * 1 0 ID3 ID2 ID1 ID0

1 Slave Address ESW AD [6:0]

Slave

Note: * according to parity calculation

Or:

2. Indirect ID (preparing frame followed by indirect ID reading frame):

Master

Note: * according to parity calculation

Master

2 Actual Position ActPos [15:8]

3 ActPos [7:0]

4 Status

ID [3:0]: Dynamically allocated identifier to GetActualPos command.

VddReset StepLoss

ElDef UV2 TSD TW Tinfo [1:0]

The master sends either type#7 or type#8 preparing frame:

GetActualPos preparing frame (type#7)

Structure Source Byte Content

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 Identifier * * 0 ID4 ID3 ID2 ID1 ID0

1 Command 1 CMD [6:0] = 0x00

2 Slave Address 1 AD [6:0]

ID [4:0]: Dynamically allocated identifier to type#7 preparing frame.

GetActualPos preparing frame (type#8)

Structure Source Byte Content