Page 1

IDX (IDX 4803 and IDX 7505)

Manual

STEPPER motor controller/driver modules

IDX / IDX 4803: 3.5A RMS (5A peak) / 48V

IDX 7505: 5.0A RMS (7A peak) / 75V

with RS485 and step-/ direction interface

Trinamic Motion Control GmbH & Co. KG

D – 20357 Hamburg, Germany

Phone +49-40-51 48 06 – 0

FAX: +49-40-51 48 06 – 60

http://www.trinamic.com

INFO@TRINAMIC.COM

Sternstraße 67

Page 2

IDX Manual (V1.08 / August 30th, 2006) 2

Table of Contents

1

Features ........................................................................................................................................... 4

2 Life support policy ............................................................................................................................ 5

3 Electrical and Mechanical Interfacing............................................................................................... 6

3.1 Pinning ...................................................................................................................................... 6

3.2 Dimensions ............................................................................................................................... 7

3.3 Connectors................................................................................................................................ 7

4 Operational Ratings ......................................................................................................................... 8

4.1 Practical maximum motor current ratings ................................................................................. 9

4.2 Step, Direction and Disable Inputs.......................................................................................... 10

5 Getting Started ............................................................................................................................... 11

5.1 Motor ....................................................................................................................................... 11

5.1.1 Motor Choice...................................................................................................................... 11

5.1.1.1 Motor velocity.............................................................................................................. 11

5.1.1.2 Chopper Modes 0 (SPI / Default Mode) and 1 (PWM) ............................................... 11

5.1.1.3 Chopper Mode 2 (PHASE) ......................................................................................... 12

5.2 Connecting Motor and Power Supply ..................................................................................... 14

5.3 Power Supply Requirements .................................................................................................. 14

5.4 Connections for Step / Direction- Mode.................................................................................. 15

5.5 Connections for RS485 Interface............................................................................................ 16

5.5.1 Interface installation ........................................................................................................... 16

5.5.2 Control with terminal program............................................................................................ 16

6 Functional Description.................................................................................................................... 17

6.1 Disable Function ..................................................................................................................... 17

6.2 RS485 Control Interface .........................................................................................................17

6.2.1 RS485 Commands............................................................................................................. 18

6.2.1.1 Examples for test move .............................................................................................. 19

6.2.1.2 Motor Current (C)........................................................................................................ 19

6.2.1.3 Failure Readout (E)..................................................................................................... 19

6.2.1.4 StallGuard (G)............................................................................................................. 20

6.2.1.5 Limit Switch (L) ........................................................................................................... 20

6.2.1.6 Output setting (O) ....................................................................................................... 20

6.2.1.7 I/Os Readout (Q)......................................................................................................... 21

6.2.1.8 Baud Rate (U) ............................................................................................................. 21

6.2.1.9 Velocity Mode (V)........................................................................................................ 21

6.2.1.10 Store Parameters to EEPROM (W) ............................................................................ 22

6.2.1.11 Microstep Resolution (Z)............................................................................................. 22

6.2.2 Chopper Modes ................................................................................................................. 22

6.2.2.1 Chopper Mode 0 (SPI) / Default Mode ....................................................................... 22

6.2.2.2 Chopper Mode 1 (PWM)............................................................................................. 23

6.2.2.3 Chopper Mode 2 (PHASE) ......................................................................................... 23

6.2.2.4 Chopper mode 3 (Phase and SPI).............................................................................. 24

6.2.2.5 Chopper mode 4 (PWM and SPI) ............................................................................... 24

6.3 Step / Direction........................................................................................................................ 25

6.3.1 Direction ............................................................................................................................. 25

6.3.2 Step.................................................................................................................................... 26

6.4 Reset to factory default ........................................................................................................... 26

6.5 Firmware Update..................................................................................................................... 27

6.6 Option: Pseudo DC-Motor mode (not supported by software yet).......................................... 28

6.6.1 Setting up the module ........................................................................................................ 28

6.6.2 Parameterizing with RS485 ............................................................................................... 28

6.6.3 Motion Control.................................................................................................................... 28

7 Revision History ............................................................................................................................. 29

7.1 Documentation Revision ......................................................................................................... 29

7.2 Firmware Revision .................................................................................................................. 29

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 3

IDX Manual (V1.08 / August 30th, 2006) 3

List of Figures

Figure 3.1: Pinning of IDX ....................................................................................................................... 6

Figure 3.2: Dimensions............................................................................................................................ 7

Figure 3.3: Base Plate Dimensions ......................................................................................................... 7

Figure 4.1: Step, Direction and Disable Inputs...................................................................................... 10

Figure 5.1: Maximum voltage regarding motor current and inductivity ................................................. 13

Figure 5.2: Connecting Motor and Power Supply ................................................................................. 14

Figure 5.3: Contacts for Step-Direction ................................................................................................. 15

Figure 5.4: Contacts for RS485 with an adapter ................................................................................... 16

Figure 5.5 : Connection settings for RS485 .......................................................................................... 16

Figure 6.1: GPO wiring scheme ............................................................................................................ 20

Figure 6.2: Step-Direction signals and motor reactions ........................................................................ 25

Figure 6.3: Step and Direction Signal.................................................................................................... 26

Figure 6.4: Reset to factory default ....................................................................................................... 26

Figure 6.5: Firmware update tool .......................................................................................................... 27

Figure 6.6: GPI wiring scheme .............................................................................................................. 28

Figure 6.7: Layout Changes for DC-Motor option ................................................................................. 28

List of Tables

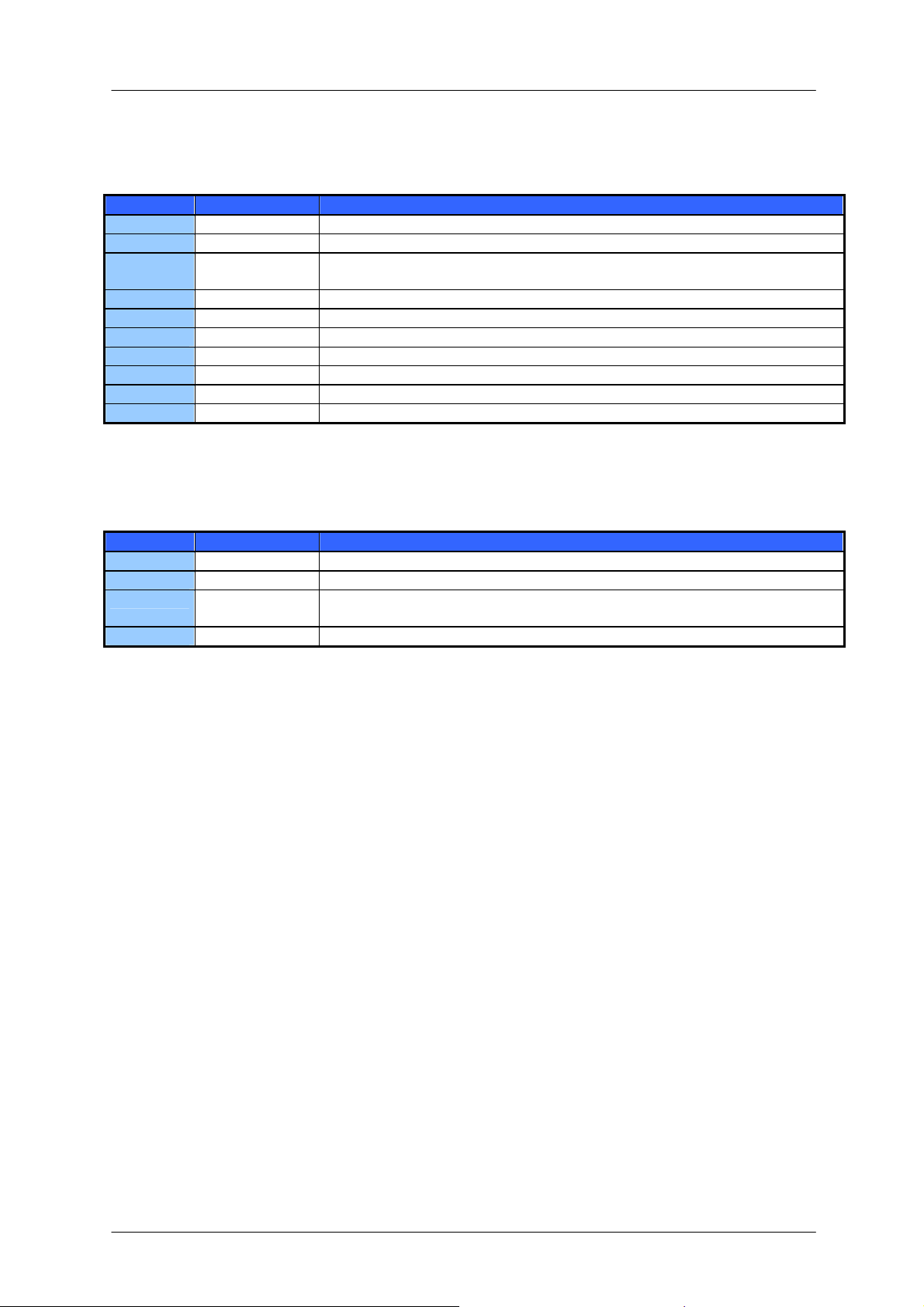

Table 1.1: Order codes............................................................................................................................ 4

Table 3.1: Power and Motor Pinning ....................................................................................................... 6

Table 3.2: Controls Pinning ..................................................................................................................... 6

Table 4.1: Operational Ratings (Orange: Different values for IDX 7505)................................................ 8

Table 4.2.1: Practical motor current limitations for IDX 7505.................................................................. 9

Table 5.1: Maximum voltage regarding motor current and inductivity .................................................. 12

Table 6.1: RS485 Commands ............................................................................................................... 18

Table 6.2: Motor Current Examples for IDX / IDX 4803 ........................................................................ 19

Table 6.3: Failure readout in SPI mode................................................................................................. 19

Table 6.4: StallGuard............................................................................................................................. 20

Table 6.5: Limit switch ........................................................................................................................... 20

Table 6.6: Output adjustment ................................................................................................................ 20

Table 6.7: I/Os Readout ........................................................................................................................ 21

Table 6.8: Baud rate .............................................................................................................................. 21

Table 6.9: Adjustment of Microstep Resolution..................................................................................... 22

Table 6.10: Chopper mode 3 switching velocities.................................................................................24

Table 6.11: External signals and motor reactions ................................................................................. 25

Table 7.1: Documentation Revisions..................................................................................................... 29

Table 7.2: Firmware Revisions.............................................................................................................. 29

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 4

IDX Manual (V1.08 / August 30th, 2006) 4

1 Features

The TRINAMIC IDX is a small and rugged step / direction stepper motor driver system with a supply

voltage of up to 50V and up to 3.5A RMS motor coil current (up to 75V and up to 5A RMS for

IDX 7505). It can be controlled via an RS-485 interface. Up to 256 micro steps are supported for either

high accuracy or high speed. An update of the firmware is possible via the serial interface. The system

features sensorless stall detection (StallGuard

comes with a stand-alone reference search feature.

The motor, switches and power supply can be connected easily with screw terminal connectors.

The housing is based on a thick aluminum plate which is used as a heatsink.

Applications

• Step-/ Direction stepper driver for industrial applications

• Robotics

• Remote diagnostics / feedback allows for high-reliability drives

• Centralized motor driver mounted in switchboard

• Decentralized motor driver mounted near motor

Motor type

• Coil current from 500mA to 3.5A RMS (5A peak) (IDX / IDX 4803)

Coil current from 500mA to 5.0A RMS (7A peak) (IDX 7505)

• 12V to 50V nominal supply voltage (or any value in between) (IDX / IDX 4803)

12V to 75V nominal supply voltage (or any value in between) (IDX 7505)

Highlights

• Remote controlled diagnostics and parameterization (RS485)

• Reference move and turn CW / CCW via RS485

• Stand-alone operation, adjusted via RS485

• Fully protected drive

• Digital selection of motor current and standby current

• Local reference move using sensorless StallGuard feature or reference switch

• All setup parameters are stored in internal EEPROM, no bus system required in end application

• Micro step resolution can be changed to get high accuracy or high speed with the possibility to

combine both

• Different chopper modes allow best adaptation to application / motor

• Many adjustment possibilities make this module the solution for a great field of demands

Order code Description

IDX or IDX 4805 48V, 3.5A IDX module

IDX 7505 75V, 5A IDX module

TM

) and full protection. The module is fully protected and

(available anticipated Sept. 2006)

Table 1.1: Order codes

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 5

IDX Manual (V1.08 / August 30th, 2006) 5

2 Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent

of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to

support or sustain life, and whose failure to perform,

when properly used in accordance with instructions

provided, can be reasonably expected to result in

personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2005

Information given in this data sheet is believed to be

accurate and reliable. However no responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties,

which may result form its use.

Specifications subject to change without notice.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 6

IDX Manual (V1.08 / August 30th, 2006) 6

3 Electrical and Mechanical Interfacing

3.1 Pinning

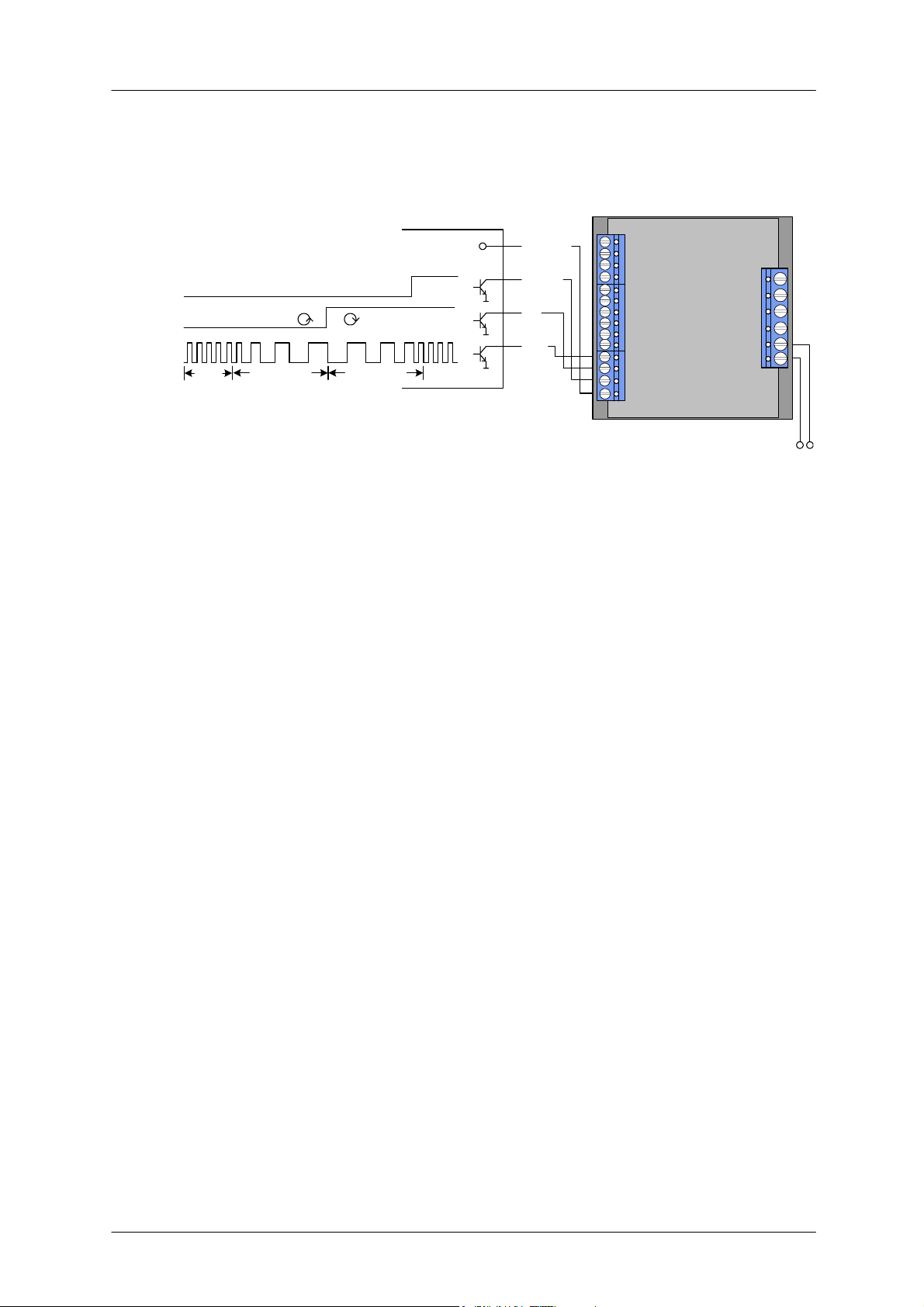

RS485B

RS485A

RS485B

Controls

RS485A

GPO

GPI

GND

RefB

RefA

+5V

Step

Dir

Disable

Common

IDX

Figure 3.1: Pinning of IDX

OB2

OB1

OA2

OA1

GND

+VS

Power

&

Motor

Pin Number Function

OB1, OB2 1, 2 Connections for motor coil B

OA1, OA2 3, 4 Connections for motor coil A

GND 5 GND, power

+VS 6 Positive power supply voltage

Table 3.1: Power and Motor Pinning

Pin Number Function

RS485 - 1, 3 RS485 remote control access -, TTL input

RS485 + 2, 4 RS485 remote control access +, TTL input

GPO 5 General Purpose Output, for wiring scheme see Figure 6.1

GPI 6 General Purpose Input, for wiring scheme see Figure 6.6

GND 7 GND reference

REF B 8 Reference signal B (integrated 3.9 K pull up resistor to +5V)

REF A 9 Reference signal A (integrated 3.9 K pull up resistor to +5V)

+5V 10 Constant +5V output, reference

Step 11 Opto-decoupled input (negative terminal):

Each impulse causes one motor microstep

Direction 12 Opto-decoupled input (negative terminal):

Polarity determines motor direction

Disable 13 Opto-decoupled input (negative terminal):

Tie to opto-coupler negative supply voltage to disable motor driver

Common 14 5…24V, Opto-coupler positive supply voltage

Table 3.2: Controls Pinning

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 7

IDX Manual (V1.08 / August 30th, 2006) 7

3.2 Dimensions

63.5mm

3mm

19mm

29.5mm

34mm

63.5mm

Figure 3.2: Dimensions

63.0mm

3mm

12mm

4mm

7mm

6.5mm

4.5mm

63.5mm

Figure 3.3: Base Plate Dimensions

29.5mm

3.3 Connectors

Both connectors are RIA connectors.

Power and motor: 6 pin connector RM 5.0 (07_06_RM5)

Control: Two 4 pin and one 6 pin connectors RM 3.5, (2x 166_04_RM3.5, 1x 166_06_RM35)

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 8

IDX Manual (V1.08 / August 30th, 2006) 8

4 Operational Ratings

The operational ratings show the intended / the characteristic range for the values and should be used

as design values. In no case shall the maximum values be exceeded.

Symbol Parameter Min Typ Max Unit

VS Power supply voltage (IDX 4803) 12 ... 48 58.5 V

VS Power supply voltage (IDX 7505) 12 ... 75 78.5 V

I

Motor coil current for sine wave peak

COIL

(chopper regulated, adjustable via

software) (IDX 4803)

I

Motor peak coil current (IDX 7505) 0.7 … 6.4 7.1 A

COIL

IMC Nominal RMS motor current (IDX 4803) 0.5 ... 3 3.5 A

IMC Nominal motor current (IDX 7505) 0.5 ... 4.5 5 A

f

Motor chopper frequency (actual

CHOP

frequency depends on operation mode)

0.7 … 4.3 5 A

20 or 36 kHz

t

Coil output slope 300 Ns

SLP

IS Power supply current << I

V

Isolation voltage of optocoupler ± 42 ±100 V

ISO

V

Supply voltage for step, direction and

COM

5 ... 24 27 V

1.4 * I

COIL

COIL

disable; (inputs have negative logic)

V

Signal active voltage at disable, step and

OPTON

3.5 4.5 .. 24 27 V

direction input (optocoupler on,

V

OPTOFF

measured from U

Signal inactive voltage at disable, step

to input)

COM

-3 0 2 V

and direction input (optocoupler off,

measured from U

I

Optocoupler current (internally

OPT

to input))

COM

4 8 mA

regulated)

f

Step frequency via step input 350 kHz

Step

t

delay

Direction hold time after step impulse

0.7 µs

active (falling) edge

t

setup

V

REF

V

REF

V

Input voltage on GPI -2 0 ... 5 30 V

GPI

V

GPO

I

Output current on GPO (open collector) -150 mA

GPO

T

ENV

TC Temperature of case back (cooling

setup time before step impulse 2.0 µs

Input low voltage on REFA / REFB -2 0 0.8 V

Input high voltage on REFA / REFB 2.4 5 30 V

Output voltage on GPO (open collector) -1 100 V

Environment temperature -25 70 °C

-25 85 °C

plate), operating

A

Table 4.1: Operational Ratings (Orange: Different values for IDX 7505)

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 9

IDX Manual (V1.08 / August 30th, 2006) 9

4.1 Practical maximum motor current ratings

The IDX 7505 (IDX 4803) uses eight high power 80V (60V) transistors with low internal on resistance

of only 15mOhm (24mOhm) to drive the motor. Due to this, power loss is just a few watts at maximum

current. In order to avoid EMV problems and to keep electromagnetic emission low, the transistors are

switched smoothly on and off with 300ns transitions. On the other hand, this produces dynamic losses

and thus additional power dissipation. The resulting power dissipation has to be cooled away by air

convection and via the metal base plate, in order to keep transistor and board temperature well below

125°C (Integrated thermal limit). This especially becomes a limiting point for the IDX7505, because of

its high voltage capability. The following table gives some examples for the current capability in a

typical mounting situation, where the module is mounted to a metal base plate (heat sink with fins,

overall dimensions 100*50*15mm³). In this situation the base plate was always kept at maximum

60°C. However, the actual motor type and velocity setting also influences power dissipation of the

module.

Chopper

mode

0, 1 75V 3.5A 50%

0, 1 70V 4A 60%

0, 1 60V 4.5A 80%

0, 1 ≤50V 5A 100%

2 15V … 75V 4A *) n/a

Supply

voltage

for continuous operation

Maximum

I

RMS

COIL

Maximum

duty cycle for

full current

Table 4.2.1: Practical motor current limitations for IDX 7505

*) This limit is due to the higher current ripple in chopper mode 2, which allows a maximum of 75% to

90% of the maximum current setting. It is not a thermal limit.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 10

IDX Manual (V1.08 / August 30th, 2006) 10

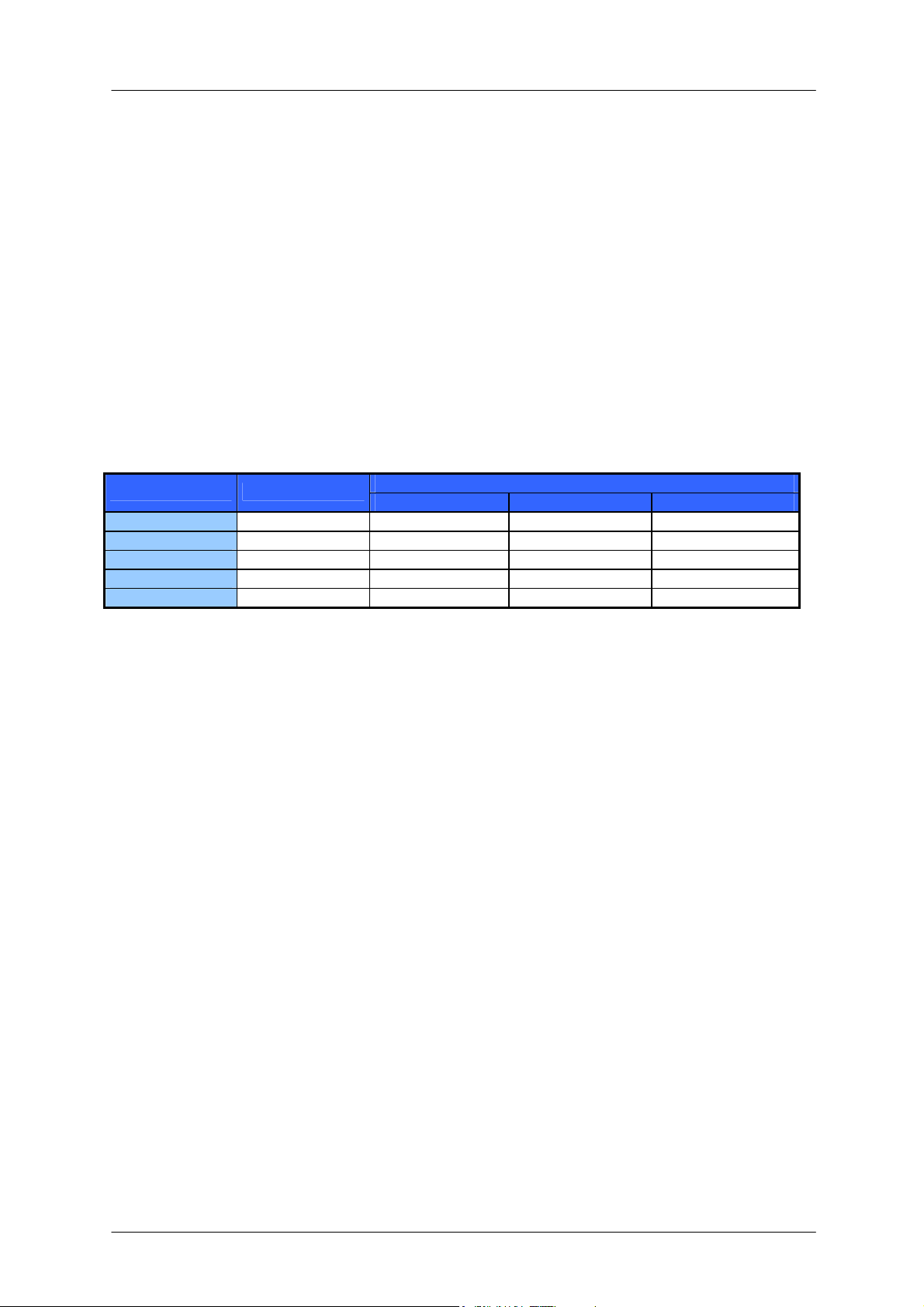

4.2 Step, Direction and Disable Inputs

The inputs disable, dir and step are electrically isolated from the module. The inputs are related to

V

. In a typical application, U

COM

inputs are driven by open collector or push / pull outputs. V

avoid reverse polarity for the opto couplers.

OFF: V

ON: V

- VIN < 1.0V

COM

- VIN >= 3.5V

COM

shall be tied to the positive supply voltage of the master and the

COM

OPTOFF

and V

must not exceed V

OPTON

COM

to

Examples:

U

COM

5..24V

Disable

Dir

Step

+5V

A

C

A

C

A

C

E

C

E

C

µC

A: Anode

C: Cathode

C: Collector

C

E

E: Emitter

GND

Figure 4.1: Step, Direction and Disable Inputs

V

= 5V

COM

V

OPTOFF

V

OPTOFF

20V19.0V16.5V

V

V

V

STEP

V

OPTON

= 0V 1.5V 4.0V 5V

STEP

= 20V

COM

V

OPTON

undefined

undefined

= 0V

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 11

IDX Manual (V1.08 / August 30th, 2006) 11

5 Getting Started

5.1 Motor

Attention: Do not connect or disconnect the motor while power on. Damage to the module may occur.

Attention: A too high motor current setting can damage you motor! If in doubt, start with a low current

setting and check motor temperature. If the motor heats up very quickly, check all settings. The motor

shall never reach a temperature above 100°C under any circumstances. Some stepper motors need

contact to metallic parts to allow continuous operation. Mind the default settings, when you operate in

step / direction mode the first time! You can store your own settings in the module permanently.

5.1.1 Motor Choice

Care has to be taken concerning the selection of motor and supply voltage. In the different chopper

modes different criteria apply. Modes 0 and 1 are quite insensitive to the motor choice, while Mode 2

is very sensitive, because it uses a different motor current regulation scheme. This chapter gives

some mathematical information on the motor choice, but you can skip it if you want to experiment with

a given motor. Normally, best results will be achieved when operating the given motor in a range of 50

to 100% of nominal motor current (see motor data sheet). Mode 2 and mode 1 are mainly intended for

slow, smooth and very exact movements, due to the high microstepping resolution. For most dynamic

operation choose mode 0, or the combined modes 3 and 4 which use mode 1 or 2 for slow

movements and switch to mode 0 at a defined velocity.

5.1.1.1 Motor velocity

Whenever it is desired to maximize the motor velocity in a given application, it is important to

understand limitations due to supply voltage and motor inductivity. Please consult your motor data

sheet for this, as well as the choice of the chopper mode. Chopper mode 0 allows maximum motor

velocity.

5.1.1.2 Chopper Modes 0 (SPI / Default Mode) and 1 (PWM)

In these two modes the maximum supply voltage (VS) of the motor must not exceed 22-25 times the

nominal motor voltage (V

lead to an excess of motor rating.

The minimum supply voltage has to be above two times the nominal motor voltage.

), regarding the multiplication of I

N

V25...22VV2

⋅≤≤⋅

NSN

RIV

⋅=

MOTORMAX,COILN

COIL, MAX

and R

. A higher value would

MOTOR

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 12

IDX Manual (V1.08 / August 30th, 2006) 12

5.1.1.3 Chopper Mode 2 (PHASE)

In Table 5.1 and Figure 5.1 examples of maximum power supply voltages regarding current I

inductivity of your motor are specified.

For further information, including a formula and description how to calculate the maximum voltage for

your setup, refer to 6.2.2.3

I

(RMS) L (min.) VS (max.)

COIL

456 mH 48 V

3.5 A

342 mH 36 V

228 mH 24 V

114 mH 12 V

533 mH 48 V

3.0 A

400 mH 36 V

266 mH 24 V

133 mH 12 V

800 mH 48 V

2.0 A

600 mH 36 V

400 mH 24 V

200 mH 12 V

1600 mH 48 V

1.0 A

1200 mH 36 V

800 mH 24 V

400 mH 12 V

3200 mH 48 V

0.5 A

2400 mH 36 V

1600 mH 24 V

800 mH 12 V

5333 mH 48 V

0.3 A

4000 mH 36 V

2666 mH 24 V

1333 mH 12 V

COIL

and

Table 5.1: Maximum voltage regarding motor current and inductivity

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 13

IDX Manual (V1.08 / August 30th, 2006) 13

5000.0

4000.0

3000.0

L /mH

2000.0

1000.0

0.0

0.3 0.8 1.3 1.8 2.3 2.8 3.3

ICOIL /A

VS = 48V VS = 36V VS = 24V VS = 12V

Figure 5.1: Maximum voltage regarding motor current and inductivity

Any combination of motor coil current and inductivity which is above the curve for

maximum supply voltage (V

) is possible to drive the motor in this mode.

S

Check your motor data sheet, please.

1600.0

1400.0

1200.0

1000.0

800.0

L /mH

600.0

400.0

200.0

0.0

11.522.533.5

ICOIL /A

If in doubt, please start with a lower supply voltage and check motor heating when raising the voltage.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 14

IDX Manual (V1.08 / August 30th, 2006) 14

5.2 Connecting Motor and Power Supply

IDX

keep distance

short

Figure 5.2: Connecting Motor and Power Supply

C

Power supply

5.3 Power Supply Requirements

The power supply voltage shall be in the limits as given in the chapter 4 under operational ratings.

Please note that there is no protection against reverse polarity or too high voltage. The power supply

typically should be within a range which fits the motor requirements, as described in chapter 5.1.1.

When using supply voltages near the upper limit, a regulated power supply becomes a must. Please

ensure, that enough power filtering capacitors are provided in the system (1000µF for each ampere of

RMS motor current or more recommended), in order to absorb mechanical energy fed back by the

motor in stalling conditions. In larger systems a zener diode circuitry might be required, when motors

are operated at high velocities.

The power supply should be designed in a way, that it supplies the nominal motor voltage at the

desired maximum motor power. In no case shall the supply value exceed the upper / lower voltage

limit. To ensure reliable operation of the unit, the power supply has to have a sufficient output

capacitor and the supply cables should have a low resistance, so that the chopper operation does not

lead to an increased power supply ripple directly at the unit. Power supply ripple due to the chopper

operation should be kept at a maximum of a few 100mV.

Therefore we recommend to

a) keep power supply cables as short as possible

b) use large diameter for power supply cables

c) if the distance to the power supply is large (i.e. more than 2-3m), use a robust 4700µF (IDX

7505) or 2200µF (IDX 4803) or similar additional filtering capacitor located near to the motor

driver unit. Choose the capacitor voltage rating fitting to the maximum operating voltage.

The overall power rating mainly depends on the motor used and on the mechanical output power, i.e.

the motor velocity and desired torque. As a thumb rule, a 42mm class motor will require a 10W (short

motor) to 20W (long motor) power supply, while a 57mm motor will require 15W to 30W, when

operated at maximum rated current and low velocities. Operation at very high velocities will increase

the power demand up to the double value.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 15

IDX Manual (V1.08 / August 30th, 2006) 15

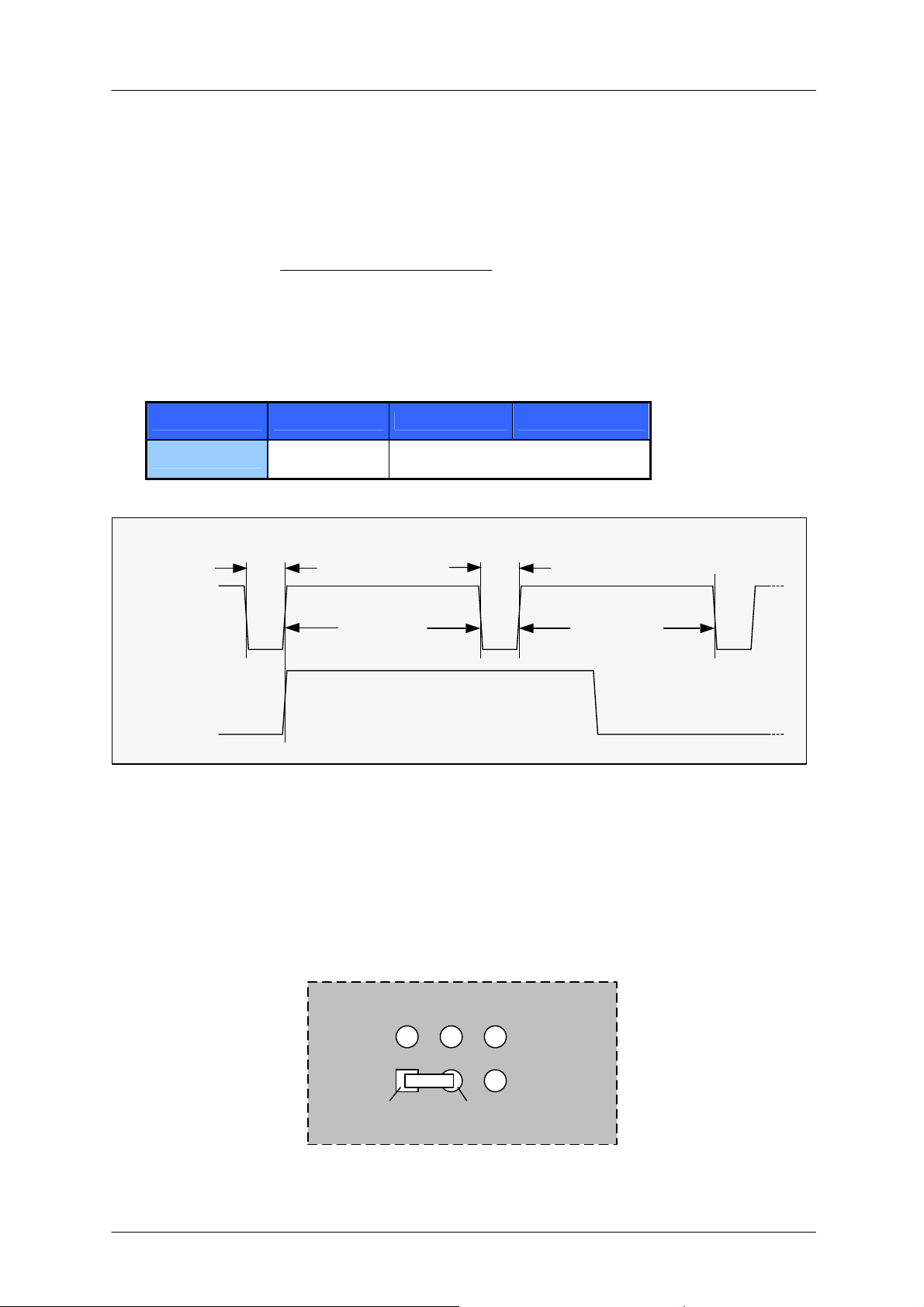

5.4 Connections for Step / Direction- Mode

The step-direction-mode is enabled if the acceleration is set to 0 (default) using the RS485 interface.

Common

Disable

Dir

Step

Disable

Dir

Step

Common

0 V

Common

0 V

Common

0 V

Velocity Deceleration Accel eration

rotating direction

const.

5 ... 24 V

rotation off on

GND

GND

GND

Figure 5.3: Contacts for Step-Direction

The maximum step frequency is 350 kHz (limited by the opto couplers).

TMCM-IDX

PWR 12...50 V

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 16

IDX Manual (V1.08 / August 30th, 2006) 16

5.5 Connections for RS485 Interface

The RS485-mode allows for configuration of motor parameters as well as remote control of the motor.

5.5.1 Interface installation

To connect the module to a PC a RS485 interface is required, for example TRINAMIC’s new USB-2485 or any other RS485 adapter, like the standard RS232 to RS485-converters. Input A has to be

connected to RS485A of the IDX and Input B with RS485B.

Either use a RS232 to

Terminal

RS-232-port

USB-port

RS485 or alternatively

a USB to RS485 adapter

RS232toRS485

4 3 2 1

to

+ -

USB

RS485

alternative

-

+

-

+

TMCM-IDX

Figure 5.4: Contacts for RS485 with an adapter

5.5.2 Control with terminal program

Having installed the hardware, the IDX can be controlled with any terminal program, like

HyperTerminal that comes with MS-Windows. Following steps are described for HyperTerminal but

are similar for the other terminal programs:

1. Start HyperTerminal

2. A window for a new connection opens. Fill in a name and press OK.

3. Select the appropriate COM-port and press OK.

4. Fill in the values like in Figure 5.5 and confirm with OK.

Bit rate:

Data bits:

Parity:

Stop bits:

Flow control:

none

none

Figure 5.5 : Connection settings for RS485

Type into the terminal window commands like “AV 50000”, “AA 300” or “Ac” and execute each with

ENTER. Pay attention to the spaces between command and value. With standard RS485 adapters the

typed value may be echoed and lines like AAVV 5500000000 for the typed AV 50000 appear. If this

happens best is to pay no attention to the screen and just type in the commands and press ENTER.

The value sent to the module is only the typed and not the displayed. First command to the module

should be an acceleration differing from 0 to enable RS485 mode. If this value is stored to the

EEPROM step/direction control is not possible until acceleration is set to zero again (and eventually

stored) or the board is reset to factory default.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 17

IDX Manual (V1.08 / August 30th, 2006) 17

6 Functional Description

The IDX module has three different modes to control a stepper motor: step-direction, RS485 and

stand alone. With the RS485 it is possible to change parameters and save them to the EEPROM of

the module to have all options in any mode. Therefore there are different settings like microstep

resolution possible in step-direction mode also.

6.1 Disable Function

Description: The disable works as an emergency shutdown. Connected to ground all power to the

motor will shut down independent of the current settings.

It is in the users responsibility to stop the step impulses or set the velocity to zero before enabling the

motor again, because it would start abrupt otherwise.

Function Table:

V

open wire V

OPTON

motor disabled motor enabled

OPTOFF

6.2 RS485 Control Interface

The RS485 interface can control all functions of the IDX. It is possible to change parameters, with this

interface which are also valid in the other modes like max. velocity or acceleration. The parameters

can be written to the EEPROM to obtain the changes after a restart.

A Reset to factory default is possible. Default address byte is “A” and default baud rate is 9600 baud.

This mode can only be used with an appropriate RS485 interface. Commands are sent with a terminal

program, refer 5.5.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 18

IDX Manual (V1.08 / August 30th, 2006) 18

6.2.1 RS485 Commands

For RS485 commands write the address byte (default is A) first, followed by an command from the

following list. A small command letter provides the actual setting. All values are ASCII.

Command Function Description Range

A, a Acceleration Acceleration: v = 28.96 * a 0..2500000 0

C, c

E

G, g StallGuard

L, l Limit switch

M, m

O, o Set Output Output adjustments, Refer 6.2.1.6 2 bit 0

P Set Position Set position without moving the motor 32 bit

Q Read I/Os

R

S

T, t

U, u

V, v

W

X

Y, y

Z, z

Set Motor

Current

Failure

readout

Select

Mode

Read

Current

Position

Changes

address

byte

RS485Timeout

Set baud

rate

Velocity for

Rotation

Store

parameters

to EEPROM

Version

number

Standby

current

Microstep

Resolution

Motor current in percentage of maximum

current

(0..100% * IDX max. current). Refer 6.2.1.2

Provides failure readout. Refer 6.2.1.3

In mode 0 (SPI) the StallGuard feature is

functional. ‘g’ provides the actual StallGuard

value, not the setting. Refer 6.2.1.4

Used to switch on and off reference run

values. Refer 6.2.1.5

Select chopper mode: 0:SPI (default), 1:PWM,

2:PHASE, 3 & 4: Combinations, Refer 6.2.2

Provides out of the I/O the values of the ports

GPI, REF_A, REF_B, GPO and ALARM. Refer

6.2.1.7

Provides the current position of the motor 32 bit

Capital letter followed by the command ‘S’

makes this letter the new address byte

Sets the RS485-Timeout

Sets baud rate for RS485 communication.

Refer to 6.2.1.8

Velocity for rotation / reference run

v = n * 0.149157 usteps/s

Additional Parameter is 0 or missing: Carriage

Return (CR) comes after acceleration phase

Additional Parameter is 1: no delay of CR

Stores different parameters to the EEPROM to

restart with the same performance. Refer

6.2.1.9

Provides version number of implemented

Software

Sets 0..100% of maximum current after 1

second motor inactivity. For no standby current

use the same value as for “Set motor current”.

Sets the maximum microstep resolution (0:

max; 4: min), Refer 6.2.1.11

0..100 50

8 Bit (SPI)

1 Bit (others)

-7..0..+7 0

byte -

0, 1, 2, 3, 4 0

A

0…7 0

+/- 2500000,

0 or 1

0..100 20

0..4 0

Factory

Default

0

Table 6.1: RS485 Commands

Examples:

1. Set chopper mode to SPI Mode:

AM 0

⇒ ENTER

2. Read out the actual mode

Am

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

⇒ ENTER

Page 19

IDX Manual (V1.08 / August 30th, 2006) 19

6.2.1.1 Examples for test move

• Different accelerations and velocities

AA 500, AV 50000, AV –50000

⇒ try other AA 100…8000, AV 0…400000

• Max. current – test of torque

AA 500, AV 50000, AC 255

⇒ test torque manually ⇒ AC 50 ⇒ test torque

• Coil current change

AV 0, AA 500, AV 50000, AC 200, AI 0 (100%), AI 18 (50%), AI 45 (33%), AI 63 (25%)

AC 100, AI 0, AI 18, AI 45, AI 63

• Read and set position

AR, AP 0, AR, AA 500, AV 50000, AR

6.2.1.2 Motor Current (C)

The motor current can be set by the user. To do this use the RS485 command “AC” in addition with a

percent value. To calculate the actual setting, please use the 100% values as shown in the table.

Internally the current is regulated by two independent parameters for the best module/motor

performance possible.

For chopper mode 2, the maximum setting is about 75% to 90% - at higher settings, motor microstep

behaviour may become harsh. The actual maximum depends upon the actual motor. This is to avoid

the motor coil current raising above the 100% setting at any time. Not all currents can be continuously

driven at all supply voltages / cooling circumstances. Please refer to motor current limitations.

AC

100

75

66

50

33

25

10

I

COIL,PP

IDX 7505

7.1A 5.0A

5.3A 3.8A

4.7A 3.3A

3.5A 2.5A

2.4A 1.7A

1.8A 1.26A

0.71A 0.50A

I

COIL,RMS

IDX 7505

I

COIL,PP

IDX 4803

I

COIL,RMS

IDX 4803

% to max.

I

4.8A 3.4A 100% *)

3.6A 2.6A 75%

3.2A 2.2A 66%

2.4A 1.7A 50%

1.6A 1.1A 33%

1.2A 0.85A 25%

0.5A 0.35A 10%

COIL

Table 6.2: Motor Current Examples for IDX / IDX 4803

*) Not possible for chopper mode 2.

6.2.1.3 Failure Readout (E)

The IDX provides a full driver failure analysis in SPI mode (8 Bit). The returned bit assignments are as

follows:

Bit Name Function Remark

7 OT Overtemperature “1” = driver chip off due to overtemperature

6 OTPW temperature prewarning “1” = driver chip prewarning temperature exceeded

5 UV driver undervoltage “1” = undervoltage on VS – does not cover all cases

4 OCHS overcurrent high side (not available in current hardware implementation)

3 OLB open load bridge B Open load detection can occur at fast motion also.

2 OLA open load bridge B Open load detection can occur at fast motion also.

1 OCB overcurrent bridge B low side Short circuit detected. Please check motor wiring.

0 OCA overcurrent bridge A low side Short circuit detected. Please check motor wiring.

Table 6.3: Failure readout in SPI mode

In the other two modes the failure analysis consists of only one bit:

1: short circuit or overtemperature

0: no failure

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 20

IDX Manual (V1.08 / August 30th, 2006) 20

6.2.1.4 StallGuard (G)

The StallGuard feature is available in the default mode 0 (SPI) only. It is a sensorless load

measurement and stall-detection. Overload is indicated before steps are lost. The command letter ‘g’

provides the actual StallGuard value of the motor so easy calibration is possible. To use StallGuard in

an actual application, some manual tests should be done first, because the StallGuard level depends

upon the motor velocities and on the occurrence of resonances. When switching on StallGuard, the

motor operation mode is changed and microstep resolution may be worse. Thus, StallGuard should be

switched off when not in use.

Value Description

-7..-1

0 StallGuard function is deactivated (default)

1..7 Motor stops when StallGuard value is reached and position is not set zero.

Motor stops when StallGuard value is reached and position is set zero

(useful for reference run).

Table 6.4: StallGuard

6.2.1.5 Limit Switch (L)

The parameter ‘L’ defines the different reference entrances of the module. The motor stops when the

defined position is reached.

Bit Motor stops at

0 REF_B = 0

1 REF_A = 0

2 GPI = 0

3 REF_B = 1

4 REF_A = 1

5 GPI = 1

6 0: soft stop, 1: hard stop

0: sets position zero

7

1: sets position not to zero

Table 6.5: Limit switch

To activate a reference switch set the appropriate bit to 1. When motor stops the position counter is

set to zero.

Example:

AL 8

⇒ ENTER : Activates REF_B = 1. When destination reached motor stops and position counter is

set to zero.

6.2.1.6 Output setting (O)

The bit settings are as follows:

Bit Description

0: GPO is inactive (LED off)

0

1: GPO is active (LED on)

1 1: Output is changed at end of reference run

Table 6.6: Output adjustment

Figure 6.1: GPO wiring scheme

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 21

IDX Manual (V1.08 / August 30th, 2006) 21

=

6.2.1.7 I/Os Readout (Q)

Command:

⇒ ENTER

AQ

Bit

Port

7 6 5 4 3 2 1 0

0 0 0 GPI REF_B REF_A GPO ALARM

Table 6.7: I/Os Readout

6.2.1.8 Baud Rate (U)

The parameter ‘U’ changes the baud rate of the module for RS485 communication.

Parameter U Baud rate

0 9600 baud

1 14400 baud

2 19200 baud

3 28800 baud

4 38400 baud

5 57600 baud

6 76800 baud

7 115200 baud

Table 6.8: Baud rate

6.2.1.9 Velocity Mode (V)

The velocity mode allows rotation of the motor without external signals. In order to rotate the motor,

please set an acceleration value different from zero. The velocity is given by the following equation,

when parameter “AV n” is used:

⋅

⋅

]s/steps[v

For a 200 step motor at 64 microsteps, this gives

A practical limit with most stepper motor types is about 20 rotations / second in chopper mode 0 and 5

rotations / second in chopper mode 2.

As a second parameter, value “0” or “1” is optional. Standard is 0 and sends back the Carriage Return

character at once. If it is set to “1” sending back of the Carriage Return character is delayed until the

target velocity is reached.

Example:

AV –50000

AV 0 1

return until target velocity has been reached

⇒ ENTER: Accelerates motor to given velocity

⇒ ENTER: Accelerates motor to velocity zero (standstill) and delays echoing of carriage

=

]s/rotations[v

=

]s/rotations[v =

85815

149157.0n

resolutionMicrostep

149157.0n

⋅

n

]s/rotations[

]s/microsteps[149157.0n]s/microsteps[v

]s/steps[

⋅

motorofFullstepsresolutionMicrostep

]s/rotations[

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 22

IDX Manual (V1.08 / August 30th, 2006) 22

6.2.1.10 Store Parameters to EEPROM (W)

This command stores the actual parameters to the EEPROM to restart with the same performance

after power down.

Stored parameters are:

• Current setting (C)

• Selected Mode (M)

• Output adjustment (O)

• RS485 parameters (U)

• Microstep resolution (Z)

6.2.1.11 Microstep Resolution (Z)

The microstep resolution can be set by the user. It depends on the maximum resolution witch differs in

the three different chopper modes (see 6.2.2).

The maximum resolution is set by the parameter ‘Z’.

Parameter Z

SPI PWM Phase (default)

0 max resolution 64 *) 64 256

1 1/2 max 32 *) 32 128

2 1/4 max 16 16 64

3 1/8 max 8 8 32

4 1/16 max 4 4 16

Microstep resolution

Table 6.9: Adjustment of Microstep Resolution

*) Simulated microsteps, the actual microsteps of the motor are not improved.

Example:

AZ 2

⇒ ENTER : Sets the microstep resolution to a quarter of the maximum resolution.

6.2.2 Chopper Modes

6.2.2.1 Chopper Mode 0 (SPI) / Default Mode

In this mode, the motor coil current is regulated on a chopper-cycle-by chopper-cycle bias. This is the

standard operation mode for most motor drivers. It brings a medium microstep resolution of 16

microsteps and typically works good with most motors and a high range of supply voltage and motor

current settings. A resolution of up to 64 microsteps can be simulated but the motor precision is not

improved compared to 16 microsteps.

The maximum supply voltage (V

voltage (V

), regarding the multiplication of I

N

excess of motor rating.

The minimum supply voltage has to be above two times the nominal motor voltage.

RIV

⋅=

It uses a chopper frequency of about 36kHz.

) of the motor must not exceed 22-25 times the nominal motor

S

COIL, MAX

V25...22VV2

⋅≤≤⋅

NSN

MOTORMAX,COILN

and R

. A higher value would lead to an

MOTOR

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 23

IDX Manual (V1.08 / August 30th, 2006) 23

⋅

6.2.2.2 Chopper Mode 1 (PWM)

This mode is identical to the chopper mode 0 (SPI) mode, but it increases the microstep resolution at

low velocities / stand still.

V25...22VV2

⋅≤≤⋅

NSN

RIV

⋅=

MOTORMAX,COILN

6.2.2.3 Chopper Mode 2 (PHASE)

This mode uses a different chopper scheme, which provides a very high microstep resolution and

smooth motor operation. However motor dynamics and maximum velocity are quite limited. Care has

to be taken concerning the selection of motor and supply voltage:

The motor is chopped with 20kHz, and the coil sees a 50% duty cycle at full supply voltage when the

coil current is meant to be zero. This is only true for the average, but the motor still sees an alternating

current and thus an alternating magnetic field. Now, care has to be taken in order to keep this current

to a value which is significantly lower than the motor maximum coil current. If it is too high, the motor

has significant magnetization losses and coil power dissipation, and would get much too hot, even with

zero average current. The only possibility to limit this effect, is to operate with a comparatively low

supply voltage. The following calculation is based on the assumption that full motor current is set.

Check list:

Please take the motor inductivity L [mH] and motor rated full step coil current I

data sheet:

Now choose a supply voltage for the module to fulfil the following comparison:

s25V

µ⋅

S

L

COIL

5.0I

⋅≤

Ù

COILS

[]

mHL20IV

⋅≤

If your parameters do not fulfil the equation, i.e. you calculate a supply voltage which is below the

modules’ operation specs or which does not fit your system requirements, try the following:

Calculate x:

V

x

I

COIL

S

⋅=

025.0

[]

mHL

If x is below 0.5, everything is OK.

If x is in the range 0.5 to 1.0, try operating your motor and check if motor or driver gets too hot.

If x is above 1.0, choose one of the other chopper modes.

See also 5.1.1.3 for graphical demonstration.

[A] from the motor’s

COIL

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 24

IDX Manual (V1.08 / August 30th, 2006) 24

6.2.2.4 Chopper mode 3 (Phase and SPI)

This mode combines the modes 2 (Phase) and 0 (SPI) in order to provide highest accuracy at lower

velocities and also the possibility for faster movements. Through the switching between modes some

microsteps may be lost. Microstep resolution must not be higher than 64. It is set according to Phase

mode, so possible values for Z (microstep resolution) are 2, 3 or 4.

µ-steps

V-value Rounds/s V-value Rounds/s

Phase to SPI SPI to Phase

64 192000 2.24 25000 0.29

32 96000 2.24 12500 0.29

16 48000 2.24 6250 0.29

Table 6.10: Chopper mode 3 switching velocities

Conversion of values above to motors with different fullstep resolutions:

motor

table

)s/rounds(v

200

)s/rounds(v

⋅=

revolutionperfullstepsmotors

6.2.2.5 Chopper mode 4 (PWM and SPI)

This mode combines the modes 1 (PWM) and 0 (SPI) in order to provide higher accuracy (up to 64

microsteps) at lower velocities and also the possibility for faster movements. For higher velocities in

SPI mode the microstep resolution is always 16, but set resolution is simulated. Through the switching

between modes some microsteps may be lost. Microstep resolution must not be higher than 64. It is

set according to Phase mode, so possible values for Z (microstep resolution) are 2, 3 or 4. This mode

should only be used in very special occasions and mode 3 should be preferred if a combination of high

accuracy at slow movements and high speed is needed.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 25

IDX Manual (V1.08 / August 30th, 2006) 25

6.3 Step / Direction

Additional Parameters can be set by RS485 i.e. to set a maximum velocity or microsteps per round.

The Step-Direction controls are as follows:

Motor Velocity Acceleration Rotate right Rotate left

Control

Disable

Direction

Step

Direction open

wired or connected

Step frequency

Increase of Step

frequency

Table 6.11: External signals and motor reactions

V

com

0 V

V

com

rotating direction

0 V

V

com

0 V

Velocity Deceleration Acceleration

const.

to V

COM

Direction

connected to

Ground

rotating on off

Speed

Motor

0

rotate right

rotate left

Figure 6.2: Step-Direction signals and motor reactions

6.3.1 Direction

Description: The Direction signal changes the motors rotation from clockwise (CW) to

counterclockwise (CCW) and

Function Table:

GND open wire V

motor CW motor CCW

vice versa.

= 5…24V

COM

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 26

IDX Manual (V1.08 / August 30th, 2006) 26

6.3.2 Step

Description: The Step signal adjusts the velocity and acceleration of the motor. The velocity is

depending on the frequency, the acceleration on the change of it. One step impulse represents one

microstep.

Calculation of rotations per second (refer to 6.2.1.11):

]s/rotations[v

=

Frequency: The maximum Step input frequency is 350 kHz, aligned to the Direction signal. The

minimum logic ”0” time is 0.7 µs and the minimum logic “1” time is 2.0 µs.

Maximum frequency at a duty cycle of 1 (“0” time is 2.0 µs and “1” time is 2.0 µs) is 250 kHz.

Function Table:

frequencyinputStep

⋅

resolutionMicrostepFullsteps

]s/rotations[

direction

Extern GND open wire V

Intern

0.7µs min

step pulse

HIGH LOW

2.0µs min

same minimum times as above

Figure 6.3: Step and Direction Signal

0.7µs min

= 5…24V

COM

2.0µs min

6.4 Reset to factory default

If the module seems to function weird this could usually is caused by unintended settings. In this case

a reset to factory default might be useful. To do this switch off the module and short-circuit pin 1 and

pin 3 of the free contacts for a 6-pin connector on the backside of the module. See Figure 6.4. Turn on

the module and switch it off again to remove the short-circuit. All settings are now at factory default.

pin 1

(quadratic)

Figure 6.4: Reset to factory default

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

pin 3

Page 27

IDX Manual (V1.08 / August 30th, 2006) 27

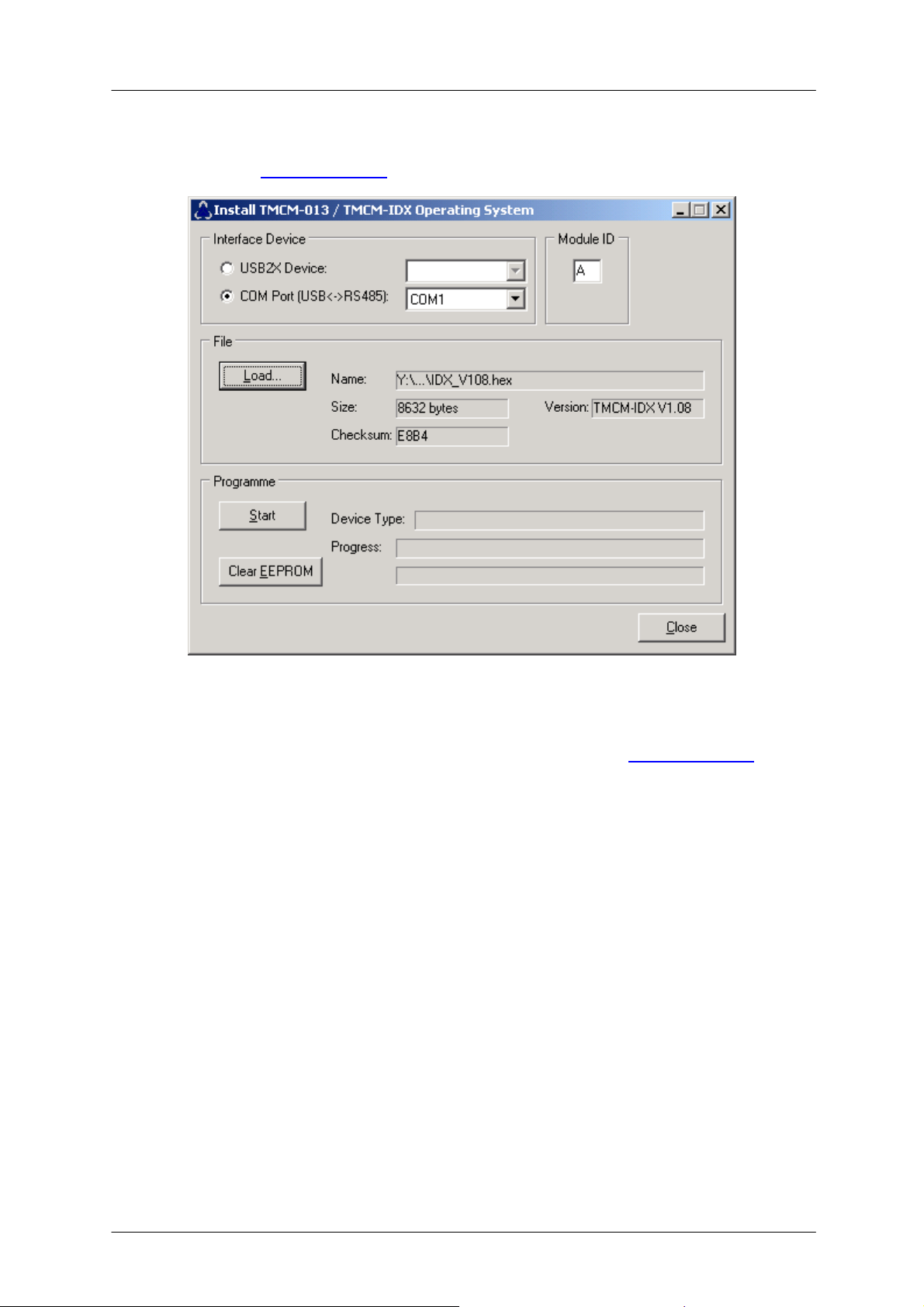

6.5 Firmware Update

For Firmware update start the program TMCM013boot.exe contained in the IDX-Folder of your

TMCTechLibCD or at www.trinamic.com:

Figure 6.5: Firmware update tool

1. Choose your RS485 connection.

2. Select your Module ID (default is A).

3. Load the new firmware file (e.g. IDX_V1.08.hex), to download from www.trinamic.com

4. Start the update process.

At the end of the update process check your firmware version with command “AX”.

.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 28

IDX Manual (V1.08 / August 30th, 2006) 28

6.6 Option: Pseudo DC-Motor mode (not supported by

software yet)

The velocity of the motor in this mode is

changed through a constant voltage at the

General Purpose input. The operational

voltage is 7...48V. This option may be

available in a future firmware version.

6.6.1 Setting up the module

It is advised to connect an external voltage

divider to the GPI pin, as depicted.

Figure 6.6: GPI wiring scheme

However, there are two free places for 0805 SMD resistors to be equipped directly on the module IDX.

To enable this mode solder use resistors as follows:

Attention: Do not try to make changes on the board until you are absolutely sure.

be absolutely sure before

making changes on board:

mounting hole

+V

S

7V...V

R = 120k

S

GPI

R = 2.2k

GND

T

IC

free Pads for 2.2k and 120k

Figure 6.7: Layout Changes for DC-Motor option

connector RM 3.5

T

IC

T

IC

DDD

ATM

168

6.6.2 Parameterizing with RS485

First set Parameters for minimum voltage, maximum voltage and a zero point in between. Other

values can be changed also like max. acceleration, max. velocity, microsteps,…

Before enabling this mode with the RS485 command … connect a voltage of 7…48V to General

Purpose Input (GPI). The voltage has to exceed zero point voltage before the regulation works.

6.6.3 Motion Control

Change the voltage at GPI between 7…48V. The motor will accelerate and decelerate relative to the

specified zero point. Additional parameters like resolutions of microsteps can be stored in the

EEPROM.

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Page 29

IDX Manual (V1.08 / August 30th, 2006) 29

7 Revision History

7.1 Documentation Revision

Version Comment Description

1.00 First Release Full functionality for Firmware V1.05

1.01 Limit switch Added limit switch to documentation

1.02 Additions StallGuard added with RS485 command ‘G’, formerly used for output

setting (LED) now command ‘O’. Switched default mode to SPI.

1.04 Updates Added / modified some details

1.05 Updates RS485 connection documentation revised

1.06 Updates Corrected current default value, included IDX 7505 information

1.07 Updates Modes 3, 4 and GPO, GPI wiring scheme included

1.08 Updates Firmware update included

Table 7.1: Documentation Revisions

7.2 Firmware Revision

Version Comment Description

Pre 1.07 Please update

1.07 First Release Full functionality (except DC-Motor) with some possibilities to expand

1.08 Bug fix, new

options

Added chopper modes 3 and 4, modified V command, corrected RS485

bug (always echoing of CR at earlier versions)

Table 7.2: Firmware Revisions

Copyright © 2005, TRINAMIC Motion Control GmbH & Co. KG

Loading...

Loading...