Page 1

STOCK# LENGTH PCS/

SCREW. ATTACH TO

MINERAL WOOL STUFFED

STOCK# LENGTH PCS/BOX

9280

9284 10' 20

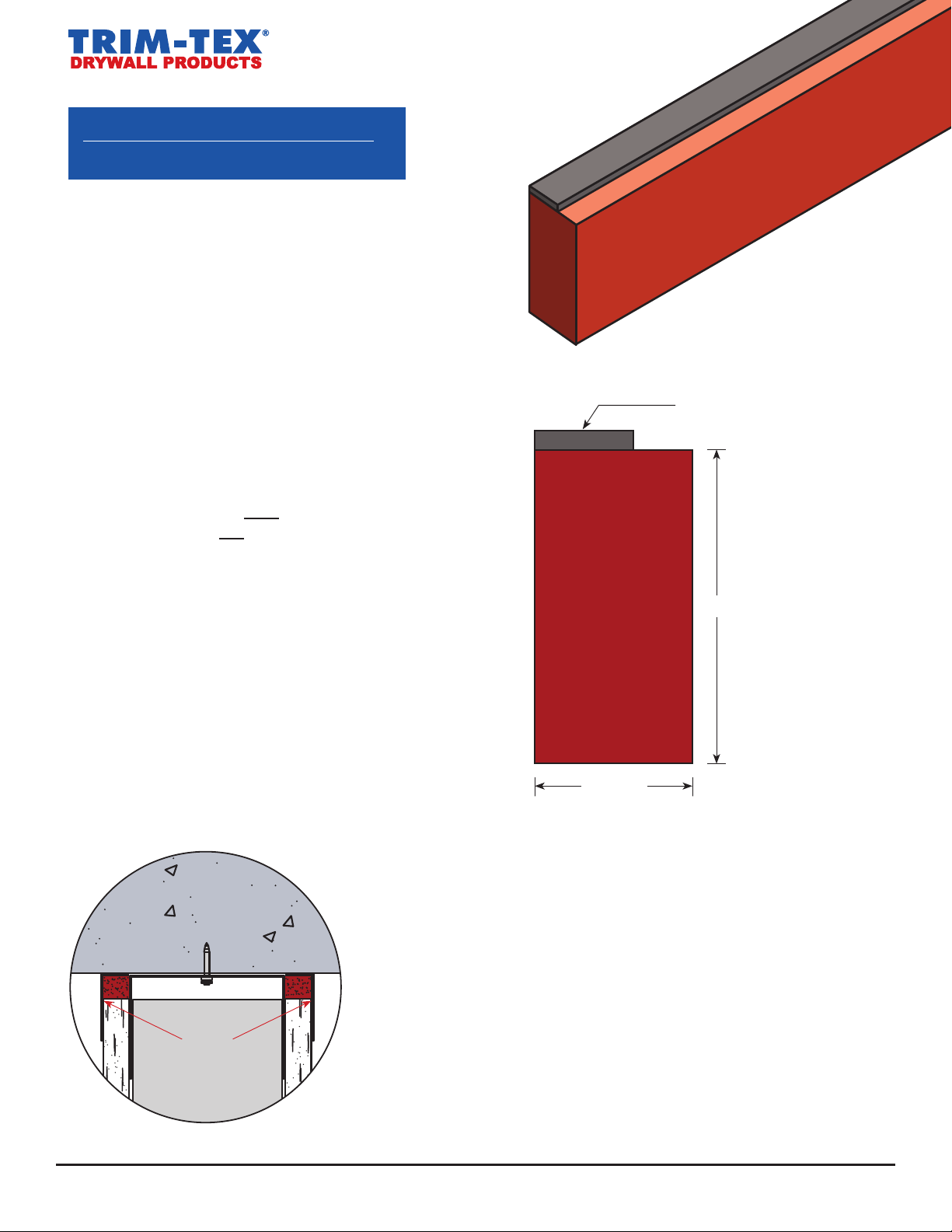

HOTROD TYPE-X

Trim-Tex® HOTROD TYPE-X is a compressible

intumescent restopping that provides 1 and 2

hour re-ratings for both dynamic and static joints

according to UL-2079 5

and uted decks without spray over mineral wool

(for both standard walls and shaft walls) and is

sound tested according to ASTM E90, tested up

to a STC 68. HOTROD TYPE-X has a rectangular

prole and is easily compressed into the deection

gap between the edge of the drywall and adjoining

structure. It is red in color and is easily identied

by the inspector. HOTROD TYPE-X is non-

wicking as it does not wick water, and is non-

hygroscopic. It will not absorb water readily under

eld conditions and it takes the place of BOTH re

and sound sealant and will not shrink, pull away,

or harden over time. HOTROD TYPE-X can be

installed by itself or can be covered with tape and

joint compound for exposed walls. It provides an

L-rating Less Than 1 CFM/Lin Ft for ambient and

400 degrees F.

th

edition on both concrete

1.5 mm x 5/16" Intumescent Tape

align to edge of foam prole

1.00

.500 or 1.00

Installation Instructions

Option 1. Pre-install Hotrod Type-X before

installing the drywall. Remove the release paper of the

Installation

Adhesive Foam

(release)

Optional joint compound

and tape can be applied.

3700 W Pratt Avenue, Lincolnwood, IL 60712 • 800-874-2333 • www.Trim-Tex.com

pressure-sensitive tape on the inside leg and install

directly to the top of the track.

Option 2. Install the drywall until it compresses the Hotrod

Type-X. If a 1/2" gap is left between the ceiling and

drywall, HOTROD Type-X can be left exposed. If a 3/4"

gap is left, install a secondary product like a Trim-Tex Flat

Deection Bead to cover the HOTORD Type-X.

Page 2

STOCK# LENGTH PCS/BOX

Approvals (Signatures or Stamps)

9286 100' 1 ROLL

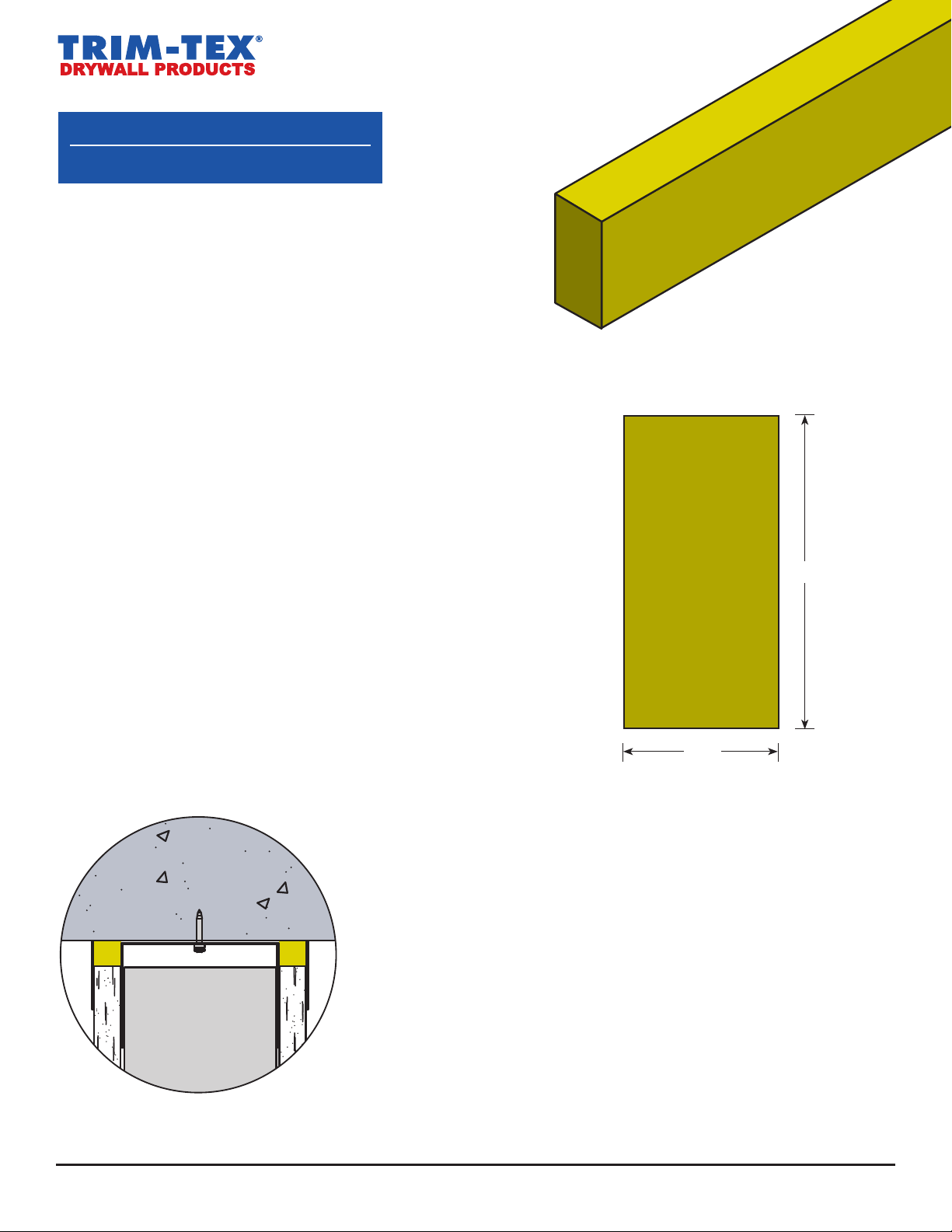

SMOKE AND SOUND STOP

Trim-Tex® SMOKE AND SOUND STOP is a

compressible rectangular foam that provides a

exible backing for smoke and sound abatement

at interior building joints and is sound tested

according to ASTM E90. SMOKE AND SOUND

STOP is continuous lengths of exible, fabricated

open cell polyurethane in a yellow color. SMOKE

AND SOUND STOP should be installed at interior

perimeter building joints only, free from all loose

materials, dry and free from frost, not recommended

for wet areas. The rectangular prole is easily

compressed into the gap between the edge of

the drywall and adjoining structure. The open cell

composition provides a exible backing capable of

receiving nishing materials such as drywall joint

compound and tape or sealant. Exposed surface

shall be covered with tape and joint compound, or

sealant, or decorative trim. SMOKE AND SOUND

STOP maintains exibility for the life of the interior

building joint and will not shrink or pull away or

harden over time. It will resist oil, gasoline and most

solvents, the material is odorless, will not stain, and

the open cell composition prevents out-gassing.

1.00

0.500

Installation Instructions

Step 1. Install drywall and leave a 1/2” gap between ceiling

Sound Deadening

Foam (non-release)

Installation

Adhesive Foam

(release)

3700 W Pratt Avenue, Lincolnwood, IL 60712 • 800-874-2333 • www.Trim-Tex.com

and drywall.

Step 2. Insert Smoke and Sound Stop in gap. Make sure

there’s no voids when installing the Smoke and Sound Stop.

Step 3. Finish by installing a Trim-Tex Flat Deection Bead

over the gap.

Loading...

Loading...