Page 1

MOPS/586

Technical Manual

Rev. 1.4

JUMPtec

Industrielle Computertechnik AG

Brunnwiesenstraße 16

94469 Deggendorf/ Germany

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 2

MOPS/586 Table of Contents

Table of Contents

TABLE OF CONTENTS..........................................................................................................................................2

USER INFORMATION............................................................................................................................................4

T

RADEMARKS ............................................................................................................................................................4

G

ENERAL ..................................................................................................................................................................4

W

ARRANTY................................................................................................................................................................5

I

NTRODUCTION ..........................................................................................................................................................5

FEATURES .............................................................................................................................................................6

I/O MAP...................................................................................................................................................................7

MEMORY MAP FOR BIOS, SSD AND JRC SUPPORT........................................................................................8

ONBOARD SSD (DOS-COMPATIBLE) .................................................................................................................9

BLOCK DIAGRAM................................................................................................................................................10

CONNECTOR ARRANGEMENT..........................................................................................................................11

BIOS-DESCRIPTION............................................................................................................................................12

RTC-CMOS

AIN MENU.............................................................................................................................................................12

M

S

TANDARD CMOS SETUP........................................................................................................................................12

A

DVANCED CMOS SETUP .......................................................................................................................................14

P

OWER MANAGEMENT SETUP..................................................................................................................................16

P

ERIPHERAL SETUP.................................................................................................................................................17

UTO-DETECT HARD DISKS .....................................................................................................................................18

A

C

HANGE USER PASSWORD ......................................................................................................................................18

C

HANGE SUPERVISOR PASSWORD ...........................................................................................................................18

A

UTO CONFIGURATION WITH OPTIMAL SETTINGS.......................................................................................................18

A

UTO CONFIGURATION WITH FAIL SAFE SETTINGS ....................................................................................................18

S

AVE SETTINGS AND EXIT ........................................................................................................................................18

XIT WITHOUT SAVING.............................................................................................................................................18

E

AMIBIOS C

SETUP MENU .......................................................................................................................................12

ONFIGURATION SCREEN ........................................................................................................................19

HARDWARE DESCRIPTION................................................................................................................................20

HIPSET FEATURES ..........................................................................................................................................20

ALI-C

M

EMORY CONFIGURATION........................................................................................................................................20

I

NTERRUPTS............................................................................................................................................................21

DMA.......................................................................................................................................................................21

HE JIDA STANDARD ..............................................................................................................................................22

T

W

ATCHDOG EXTENSION...........................................................................................................................................25

NETWORK OPERATION......................................................................................................................................26

VERVIEW...............................................................................................................................................................26

O

SPECIFICATIONS ................................................................................................................................................27

M

ECHANICAL SPECIFICATIONS..................................................................................................................................27

E

LECTRICAL SPECIFICATIONS...................................................................................................................................27

E

NVIRONMENTAL SPECIFICATIONS............................................................................................................................27

PERIPHERAL INTERFACE..................................................................................................................................28

EYBOARD, RESET, BATTERY, SPEAKER..................................................................................................................28

K

ERIAL PORT COM 1, 2 (RS232C) .........................................................................................................................29

S

P

ARALLEL PORT LPT 1............................................................................................................................................30

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 3

MOPS/586 Table of Contents

FLOPPY CONNECTOR...............................................................................................................................................30

IDE C

ONNECTOR FOR 2,5" HARD DISK.....................................................................................................................31

E

THERNET CONNECTOR...........................................................................................................................................31

F

EATURE CONNECTOR.............................................................................................................................................31

P

OWER CONNECTOR ...............................................................................................................................................32

PC/104-C

ONNECTOR ..............................................................................................................................................33

LITERATURE, STANDARDS, LINKS ..................................................................................................................34

PC/104-B

ISA-B

US...........................................................................................................................................................34

US, STANDARD PS/2 - CONNECTORS..............................................................................................................34

RS232C.................................................................................................................................................................34

DOCUMENT REVISION HISTORY ......................................................................................................................35

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 4

MOPS/586 User Information

User Information

Copyright 1997 JUMPtec® Industrielle Computertechnik AG.

In this document JUMPtec

"JUMPtec

®

".

The information in this document has been carefully checked and is believed to be accurate and reliable.

However, no responsibility is assumed for inaccuracies. Furthermore, JUMPtec

changes to any portion of this manual to improve reliability, function or design. JUMPtec

®

Industrielle Computertechnik AG will also be referred to by the short form

®

reserves the right to make

®

does not assume any

liability for any product or circuit described herein.

Trademarks

AT and IBM are trademarks of International Business Machines

XT, AT, PS/2 and Personal System/2 are trademarks of International Business Machines Corporation.

Microsoft is a registered trademark of Microsoft Corporation.

Intel is a registered trademark of Intel Corporation.

All other products and trademarks mentioned in this manual are trademarks of their respective owners.

The reproduction, transmission or use of this document or its contents is not permitted without expressed written

authority.

Offenders will be liable for damages. All rights created by patent grant or registration of a utility model or

design, are reserved.

(C) JUMPtec

®

AG 1993

General

For the circuits, descriptions and tables indicated no responsibility is assumed as far as patents or other rights of

third parties are concerned.

The information in the Technical Descriptions describes the type of the boards and shall not be considered as

assured characteristics.

The reproduction, transmission or use of this document or its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights, including rights created by patent grant or registration

of a utility model or design, are reserved.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 5

MOPS/586 User Information

Warranty

Each board is tested carefully and thoroughly before being shipped. If, however, problems should occur during

the operation, please check your user specific settings of all boards included in your system. This is often the

source of the fault. If a board is defective, it can be sent to your supplier for repair. Please take care of the

following steps:

1. The board returned should have the factory default settings since a test is only possible with these

settings.

2. In order to repair your board as fast as possible we require some additional information from you.

Please fill out the attached Repair Form and include it with the defective board.

3. If possible the board will be upgraded to the latest version without additional cost.

4. Upon receipt of the board please be aware that your user specific settings were changed during the

test.

Within the warranty period the repair is free of charge as long as the warranty conditions are observed. Because

of the high test expenditure you will be charged with the test cost if no fault is found. Repair after the warranty

period will be charged.

This JUMPtec

the date of shipment. During the warranty period JUMPtec

®

product is warranted against defects in material and workmanship for the warranty period from

®

will at its option either repair or replace defective

products.

For warranty service or repair the product must be returned to a service facility designated by JUMPtec

®

.

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance or

handling by buyer, unauthorized modification or misuse, operation outside of the product´s environmental

specifications or improper installation or maintenance.

JUMPtec

are caused by a faulty JUMPtec

®

will not be responsible for any defects or damages to other products not supplied by JUMPtec® that

®

product.

Introduction

The MOPS/586 integrates the complete functionality of an 80486 motherboard with CPU, System-BIOS, 8

Mbyte to 32 MByte DRAM, keyboard-controller, real time clock and additional peripheral functions like COM1,

COM2, LPT1, Floppy-interface, EIDE-harddisk-interface, watchdog and optional Ethernet access. The system

runs with CPU clock speed 133MHz.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 6

MOPS/586 Features

Features

• Processor

®

AMD Am5x86

• Chipset

ALI 1489/1487 PCI Chipset

• Power Supply

5V only supply

• Memory

4 MB onboard and 4/8/16/32MB 5V-DIMM module DRAM with Fast Page Mode or

EDO DRAM on the lower SO-DIMM-Connector

• Ethernet 10BaseT (Twisted Pair)

with 133 MHz internal Clock and 16 kByte write-back-Cache

• Two serial ports, (COM1 and COM2)

standard RS232C serial ports with FIFO, 16550 compatible

• Parallel port, LPT1

With ECP/EPP-support

• Floppy-interface

• EIDE-PCI-hard disk-interface

PCI Bus Master IDE port (up to 2 IDE Devices)

supports PIO Mode 3,4 IDE & ATAPI CD-ROM

supports JUMPtec CHIPdisk

• Watchdog

• 128 KByte FLASH-BIOS (AMI) and 1,6 Mbyte onboard SSD (DOS-compatible)

• Real Time Clock

With external Battery-support

• Keyboard Controller

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 7

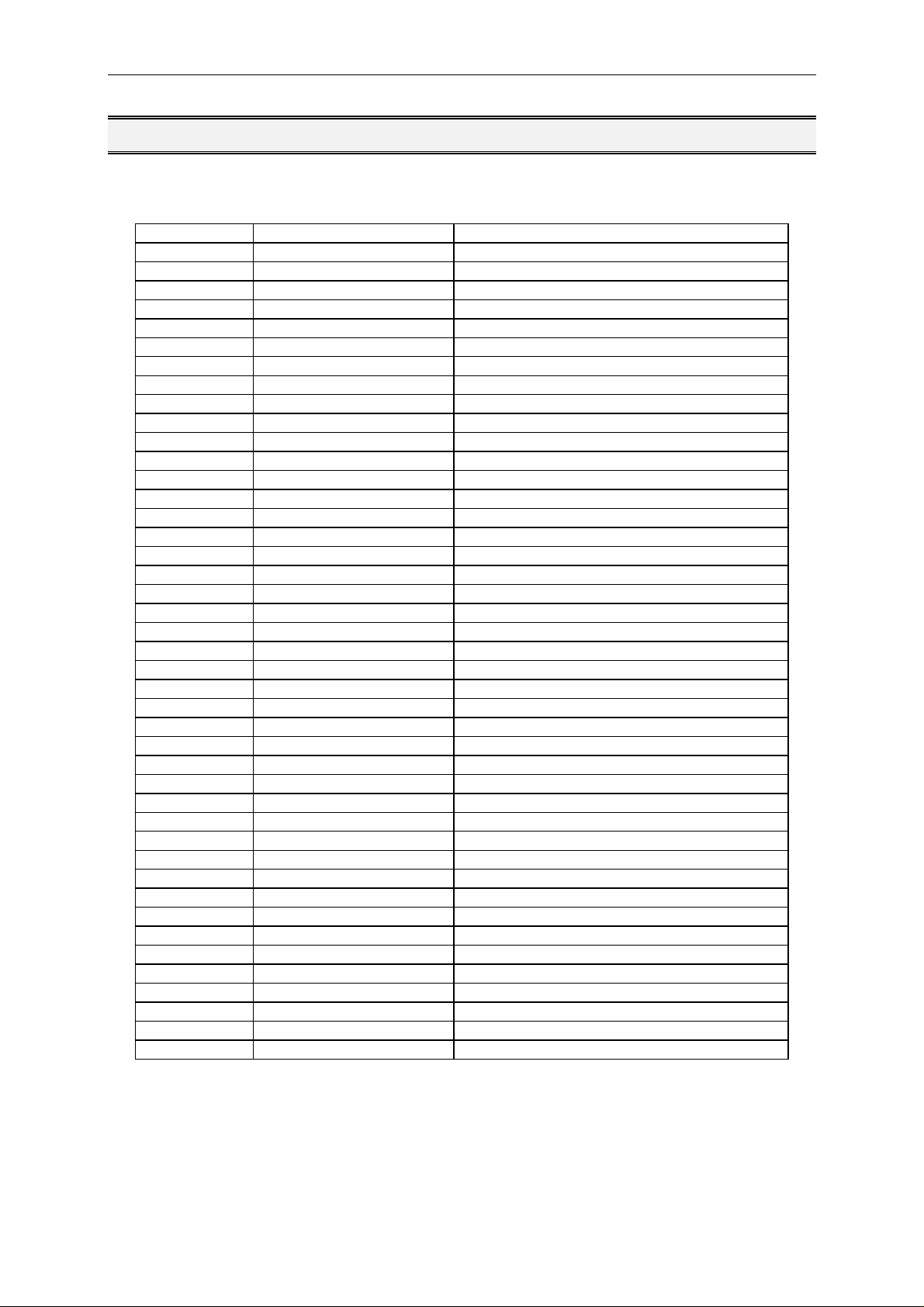

MOPS/586 I/O Map

I/O Map

The I/O-port addresses of the processor module MOPS/586 are functionally identical with a standard PC/AT.

I/O Addresses MOPS/586 - onboard Function

0000 - 001F X DMA-Controller 1

0020 - 003F X Interrupt-Controller 1

0040 - 0043 X Timer

0050 - 005F Onboard Control Registers

0060 - 0064 X Keyboard-controller

0061 X Port B Register

0070 X NMI Enable Register

0070 - 0071 X Real Time Clock

0080 - 008F X DMA Page Register 74LS612

0092 X Port A Register (Fast A20 Gate)

00A0 - 00BF X Interrupt-Controller 2

00C0 - 00DF X DMA-Controller 2

00F0 - 00FF X Math-Coprocessor

0100 – 10F X Onboard Control Registers

01F0 - 01F8 X Fixed Disk

0200 – 0207 Game I/O

020C-020D Reserved

021F Reserved

0274 Control Register 1 External SSD (Board 0 - 3)

0275 Control Register 1 External SSD (Board 4 - 7)

0278 – 027F Parallel Port 2

02B0 - 02DF Alternate Enhanced Graphics Adapter

02E1 GPIB (adapter 0)

02E2 - 02E3 Data acquisition (Adapter 0)

02E8 - 02EF Serial Port 4

02F8 - 02FF X Serial Port 2

0300 – 030F X Onboard Network (default configuration)

0310 – 031F Prototype Card

0360 – 0363 PC Network (low Address)

0364 – 0367 Reserved

0368 – 036B PC Network (high Address)

036C – 036F Reserved

0370 – 0377 Config. Space for second SMC Controller

0378 – 037F X Parallel Port 1

0380 – 038F SDLC, Bisynchronous 2

0390 – 0393 Cluster

03A0 - 03AF Bisynchronous 1

03B0 - 03BF Monochrom Disp. and Printer Adap.

03C0 - 03CF Enhanced Graphic Adapter

03D0 - 03DF Color/Graphic Monitor Adapter

03E8 - 03EF Serial Port 3

03F0 - 03F7 X Diskette Controller

03F8 - 03FF X Serial Port 1

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 8

MOPS/586 Memory Map for BIOS, SSD and JRC Support

Memory Map for BIOS, SSD and JRC Support

The BIOS includes two special extensions to support the onboard silicon state disk and Jumptec Remote Control.

If the SSD is enabled in setup or the JRC client finds a host the code of the bios extension will be copied into

shadow ram. The location where the biosextension is placed is automatically determined by the system bios .

The user can not influence this! So care must be taken, when a Extended Memory Manager is used. To avoid

memory conflicts exclude the area E0000h-EFFFFh and do’nt include the area C0000h-DFFFFh !

DOS allows to address 1MByte directly. The memory area above 1MByte (high memory, extended memory) is

accessed under DOS via special drivers like HIMEM.SYS, EMM386.EXE etc. Other operating systems (OS/2,

Windows-NT) allow to address the full memory area directly.

Standard Memory Map

000000h +-------------------+ ¦ Interruptvectors ¦ ¦ 640KByte

¦ BIOS-variables ¦ ¦ of

¦ IO.SYS, MSDOS.SYS ¦ ¦ main memory

¦ COMMAND.COM ¦ ¦

¦ Applications ¦ ¦

0A0000h +-------------------¦ +

¦ EGA/VGA Video- ¦ ¦

¦ Adapter ¦ ¦ upper memory

0B0000h +-------------------¦ ¦ area

¦ MGA/CGA Video- ¦ ¦ (RAM areas not

¦ Adapter ¦ ¦ used by video

0C0000h +-------------------¦ ¦ cards can be ¦ VGA BIOS ¦ ¦ used otherwise) ¦ 48KByte

0CC000h +-------------------¦ ¦ ¦ Shadow RAM

¦ BIOS-extensions ¦ ¦ (all not used ¦ Shadow-RAM ¦ ¦ areas could be

¦ Dual port RAM ¦ ¦ used otherwise)

¦ etc. ¦ ¦

0E0000h +-------------------¦ ¦ ¦ System-Setup ¦ ¦ ¦ 128KByte

¦ System-BIOS ¦ ¦ ¦ Shadow RAM

100000h +-------------------¦ + ¦ ¦ ¦ higher memory area

110000h +-------------------¦ +

¦ ¦ ¦ extended or

¦ ¦ ¦ expanded memory

+-------------------+

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 9

MOPS/586 Onboard SSD (DOS-compatible)

Expanded Memory Map

The user can convert (up to 20Mbytes) Extended Memory into Expanded Memory (EMS). The selected

Expanded Memory is devided into 16KByte pages, of which four can be mapped into the EMS-frame. The EMSframe is located within the first 1MByte address space and has a length of 64KByte. The start address of the

EMS-page can be selected between CC000h and E0000h in steps of 16KBytes. Most Expanded Memory

Managers are choosing their frame address location by themselves if it is not explicit set..

000000h +-------------------+ ¦ Interruptvectors ¦ ¦ 640KByte

¦ BIOS-variables ¦ ¦ of

¦ IO.SYS, MSDOS.SYS ¦ ¦ main memory

¦ COMMAND.COM ¦ ¦

¦ HIMEM, EMM386 ¦ ¦

¦ Applications ¦ ¦

0A0000h +-------------------¦ +

¦ EGA/VGA Video- ¦ ¦

¦ Adapter ¦ ¦ upper memory

0B0000h +-------------------¦ ¦ area

¦ MGA/CGA Video- ¦ ¦ (RAM areas not

¦ Adapter ¦ ¦ used by video

0C0000h +-------------------¦ ¦ cards can be ¦ VGA BIOS ¦ ¦ used otherwise) ¦ 48KByte

0CC000h +-------------------¦ ¦ ¦ Shadow RAM

¦ BIOS-extensions ¦ ¦ (all not used ¦ Shadow-RAM ¦ ¦ areas could be

¦ Dual port RAM ¦ ¦ used otherwise)

¦ EMS-Pages ¦ ¦

¦ etc. ¦ ¦

0E0000h +-------------------¦ ¦ ¦ System-Setup ¦ ¦ ¦ 128KByte

¦ System-BIOS ¦ ¦ ¦ Shadow RAM

100000h +-------------------¦ + ¦ ¦ ¦ higher memory area

110000h +-------------------¦ +

¦ ¦ ¦ extended or

¦ ¦ ¦ expanded memory

+-------------------+

To be able to work with Expanded Memory under MS-DOS, you have to add the following drivers to your

CONFIG.SYS:

HIMEM.SYS and EMM386.EXE

The MOPS/586 uses a 32KByte extension BIOS (many other boards do this, too) which is mapped to a

configurable memory area. Some other kind of boards have no extension BIOS, but are using drivers which

communicate with their corresponding devices via memory mapped I/O. All these boards have one thing in

common, they have to share the upper memory area with the Expanded Memory Manager. This is often the

reason for several problems in the system. Make sure you excluded all areas in the upper memory, which are

used by extension BIOSes and memory mapped I/O. Your instruction in the CONFIG.SYS concerning the

Expanded Memory Manager should look like this: (questionmarks for location of extension BIOS)

DEVICE=EMM386.EXE X=E000-EFFF

Onboard SSD (DOS-compatible)

The onboard Solid State Disk (SSD) won’t work under any protected mode operating system, like WINDOWS

3.1, WINDOWS FOR WORKGROUPS 3.11, WINDOWS NT, OS/2 etc.

For SSD-Setup look to Fehler! Verweisquelle konnte nicht gefunden werden. on page Fehler! Textmarke

nicht definiert..

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 10

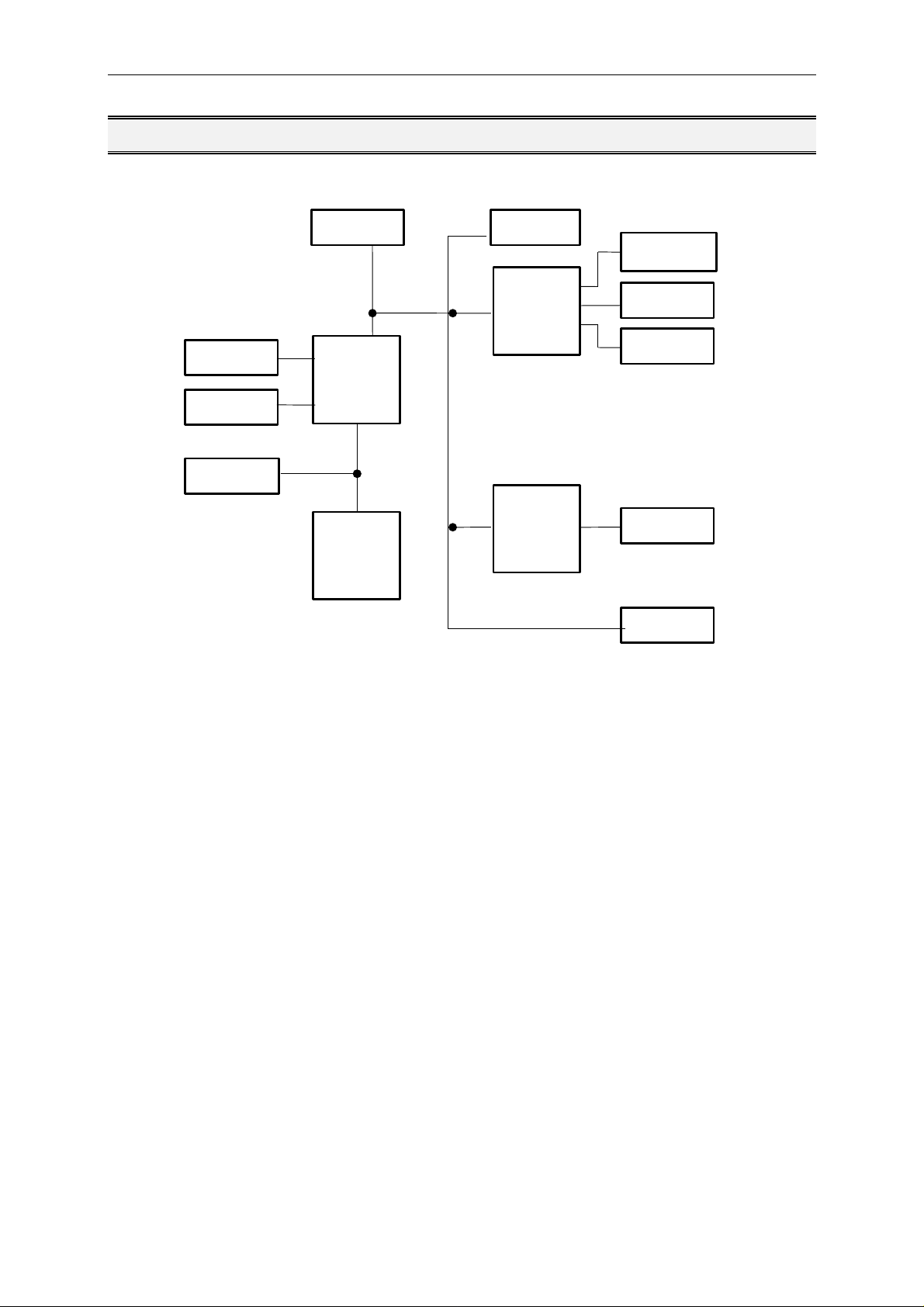

MOPS/586 Block Diagram

Block Diagram

EIDE

DRAM

Cache

BIOS

ALI

Chipset

CPU

RTC

IO-Con-

troller

Ethernet-

Con-

troller

LPT1

COM1

COM2

10baseT

ISA-Con.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 11

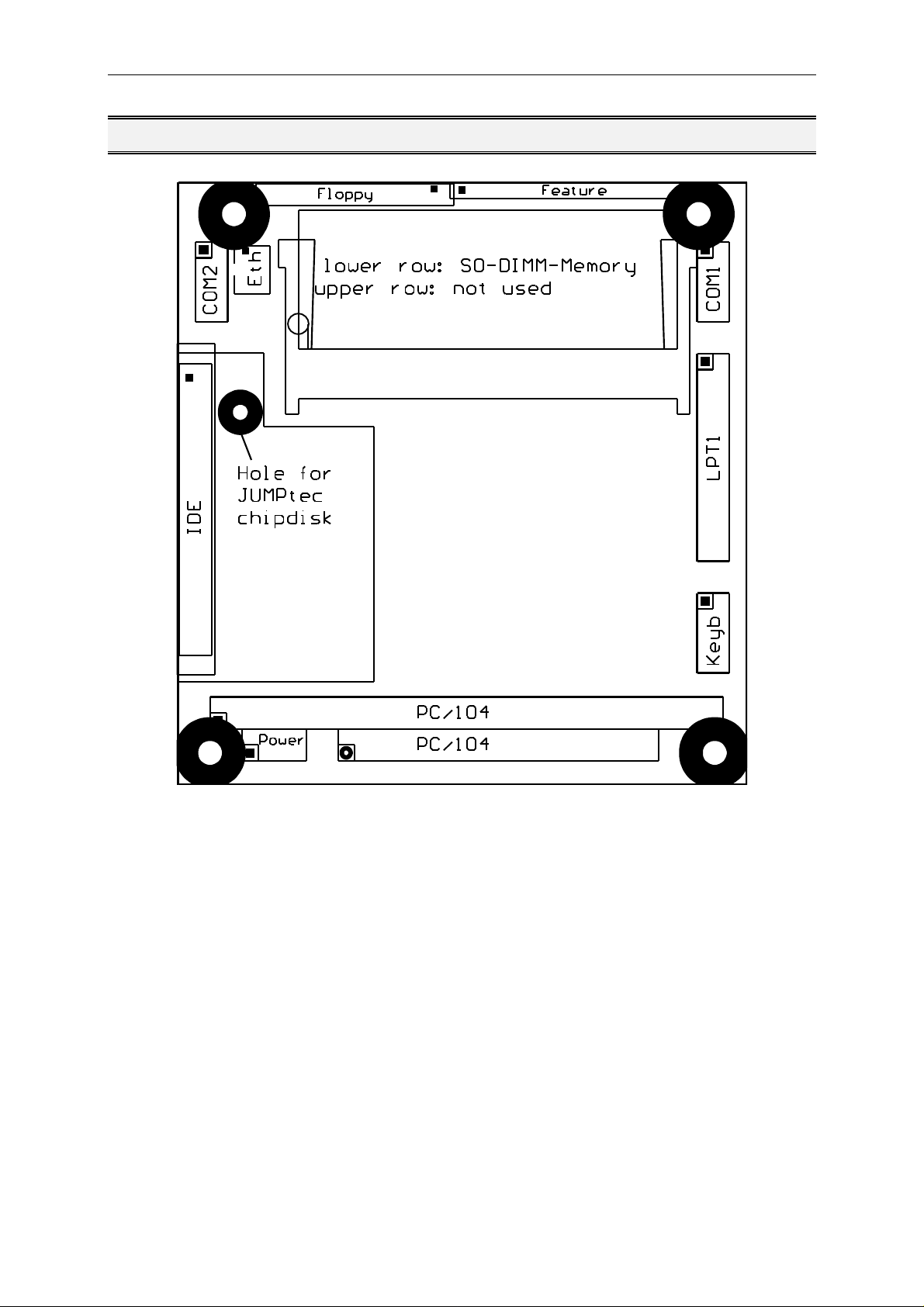

MOPS/586 Connector Arrangement

Connector Arrangement

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 12

MOPS/586 BIOS-Description

BIOS-Description

The Standard AMI-BIOS is located in the Flash EPROM onboard. This device has 8 bit wide access. 16 bit

access is enabled by the shadow RAM feature (Standard).

RTC-CMOS setup menu

During boot sequence the CMOS setup can be entered by pressing the <DEL>-key while the memory test is in

progress.

Main Menu

• Standard CMOS Setup

• Advanced CMOS Setup

• Power Management Setup

• Peripheral Setup

• Auto-Detect Hard Disks

• Change User Password

• Change Supervisor Password

• Auto Configuration with Optimal Settings

• Auto Configuration with Fail Safe Settings

• Save Settings and Exit

• Exit Without Saving

Standard CMOS Setup

Date/Time

Select the Date/Time option to change the date or time. The current date and time are displayed.

Floppy Drive A, B

Choose the Floppy Drive A or B to specify the floppy drive type. The settings are Not Installed, 360 KB

5¼”, 1.2 MB 5¼”, 720 KB 3½”, 1.44 MB 3½”, or 2.88 MB 3½”.

Pri Master, Pri Slave, Sec Master, Sec Slave

Enter the correct settings for the attached mass storage drive. Possible settings are Not Installed, 1-46

(predefined types), User, AUTO, CDROM.

Configuring an MFM Drive: If configuring an old MFM hard disk drive, you must know the drive

parameters (number of heads, number of cylinders, number of sectors, the starting write

precompensation cylinder, and drive capacity). Choose Type and choose the appropriate hard disk

drive type (1 - 46). The old MFM hard drive types are listed on page 13. If the drive parameters of your

MFM drive do not match any drive type listed on page 13, select User in the Type field and enter the

drive parameters on the screen that appears.

User-Defined Drive: If you are configuring a SCSI drive or an MFM, RLL, ARLL, or ESDI drive with

drive parameters that do not match drive types 1-46, you can select the User in the Type field. You

must then enter the drive parameters on the screen that appears. The drive parameters include:

• Size (drive capacity, calculated automatically)

• Cyln (number of cylinders),

• Head (number of heads),

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 13

MOPS/586 BIOS-Description

• WPcom (starting write precompensation cylinder)

• Sec (number of sectors)

Parameter Description

Type The number for a drive with certain identification parameters.

Cylinders The number of cylinders in the disk drive.

Heads The number of heads.

Write

Precompensation

The size of a sector gets progressively smaller as the track diameter diminishes. Yet each sector must still hold 512

bytes. Write precompensation circuitry on the hard disk compensates for the physical difference in sector size by

boosting the write current for sectors on inner tracks. This parameter is the track number where write

precompensation begins.

Landing Zone This number is the cylinder location where the heads will normally park when the system is shut down.

Sectors The number of sectors per track. MFM drives have 17 sectors per track. RLL drives have 26 sectors per track. ESDI

Size The formatted capacity of the drive is (Number of heads) x (Number of cylinders) x (Number of sectors per track) x

drives have 34 sectors per track. SCSI and IDE drives have more sectors per track.

(512 bytes per sector)

Configuring IDE Drives: If the hard disk drive to be configured is an IDE drive, select the option

AUTO and press <ENTER> to detect all drive parameters automatically.

AMIBIOS automatically detects the IDE drive parameters (including ATAPI CD-ROM drives) and

displays them. You can set the parameters manually if you are absolutely certain that you know the

correct IDE drive parameters.

Set LBA Mode to On to enable support for IDE drives with capacities greater than 528 MB.

Set Blk Mode to On to support IDE drives that use Block Mode.

Choose PIO Mode to select the IDE Programmed I/O mode. PIO programming also works with ATAPI

CD-ROM drives. The settings are Auto, 0, 1, 2, 3, 4, or 5. Use Auto to allow AMIBIOS to automatically

find the PIO mode that the IDE drive being configured uses. If you select 0-5 you must make

absolutely certain that you are selecting the PIO mode supported by the IDE drive being configured.

Set 32Bit Mode to On to support IDE drives that permit 32-bit accesses.

Configuring a CD-ROM Drive: Select the appropriate drive (Pri Master, Pri Slave, Sec Master, or Sec

Slave). Choose the Type parameter and select CDROM. You can boot the computer from a CD-ROM

drive. You can also choose Auto and let AMIBIOS automatically set the correct drive parameters.

Hard Disk Drive Types

Please look for Setup-Screen.

Boot Sector Virus Protection

If enabled, any write access to the hard disks boot sector will be trapped and reported on the screen.

The user himself decides if the access accomplishes. The Optimal and Fail Safe default settings are

Disabled.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 14

MOPS/586 BIOS-Description

Advanced CMOS Setup

Quick Boot

Set this option to Enabled to instruct AMIBIOS to boot quickly when the computer is powered on. This

option replaces the former Above 1 MB Memory Test Advanced Setup option. The settings are:

Setting Description

Disabled AMIBIOS tests all system memory. AMIBIOS waits up to 40 seconds for a READY signal from the IDE hard disk drive.

AMIBIOS waits for 0.5 seconds after sending a RESET signal to the IDE drive to allow the IDE drive time to get ready again.

AMIBIOS checks for a <DEL> key press and runs Setup if the key has been pressed.

Enabled AMIBIOS does not test system memory above 1 MB.

AMIBIOS does not wait up to 40 seconds for a READY signal from the IDE hard disk drive. If a READY signal is not

received immediately from the IDE drive, AMIBIOS does not configure that drive. AMIBIOS does not wait for 0.5 seconds

after sending a RESET signal to the IDE drive to allow the IDE drive time to get ready again.

The Optimal default setting is Enabled. The Fail Safe default setting is Disabled.

BootUp Sequence

Choose the type of the boot device and the order to boot from. Possible settings are „C:,A:,CDROM“,

„A:, C:, CDROM“ and „CDROM, A:, C:“.

BootUp Num-Lock

Set this option to Off to turn the Num Lock key off when the computer is booted so you can use the

arrow keys on both the numeric keypad and the keyboard. The settings are On or Off. The Optimal

and Fail Safe default settings are On.

Floppy Drive Swap

Set this option to Enabled to permit drives A: and B: to be swapped. The settings are Enabled or

Disabled. The Optimal and Fail Safe default settings are Disabled.

System Keyboard

This option specifies that a keyboard is attached to the computer. The settings are Present or Absent.

The Optimal and Fail Safe default settings are Absent.

Primary Display

This option specifies the type of display monitor and adapter in the computer. The settings are Mono,

CGA40x25, CGA80x25, VGA/EGA, or Absent. The Optimal and Fail Safe default settings are Absent.

Password Check

This option enables password checking every time the computer is powered on or every time Setup is

executed. If Always is chosen, a user password prompt appears every time the computer is turned on.

If Setup is chosen, the password prompt appears if Setup is executed. The Optimal and Fail Safe

default settings are Setup.

OS/2 Compatible Mode

Set this option to Enabled to permit AMIBIOS to run with IBM OS/2. This in only necessary if more

than 64MB of system dram is present. The settings are Enabled or Disabled. The Optimal and Fail

Safe default settings are Disabled.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 15

MOPS/586 BIOS-Description

Wait For 'F1' if Error

If this option is Enabled the system will wait on power up for the user to press the <F1> key on any

occurring error. The Optimal and Fail Safe default settings are Disabled.

Hit ‚Del‘ Message Display

If this option is Enabled the system will display the String „Hit DEL if you want to run Setup“ on the

screen while accepting the DEL key to enter setup. If the option is set to Disabled the string want be

displayed.

Internal Cache

This option specifies the caching algorithm used for L1 internal cache memory. The settings are:

Setting Description

Disabled The L1 internal cache memory on the CPU is disabled

WriteBack

Use the write-back caching algorithm

(Optimal and Fail

Save default)

Shadow Region Cacheability

When this option is set to Enabled, the contents of the shadow region can be read from or written to

cache memory. System BIOS, Video BIOS and Biosextensions are mostly copied from the BIOS ROM

to system RAM for faster execution. The settings are Enabled or Disabled. The Optimal default setting

is Enabled. The Fail Safe default setting is Disabled.

C000,16k Shadow, C400,16k Shadow, C800,16K Shadow, CC00,16K Shadow, D000,16K

Shadow; D400,16K Shadow; D800,16K Shadow; DC00, 16K Shadow

These options control the location of the contents of the 16KB of ROM beginning at the specified

memory location. If no adaptor ROM is using the named ROM area, this area is made available to the

local bus. The settings are:

Setting Description

Disabled The ROM is not copied to RAM. The contents of the

Enabled The ROM contents are written to the same address in

ROM cannot be read from or written to cache memory

system memory (RAM) for faster execution

NOTE: If an onboard video controller is present (MOPSlcd4), the BIOS automatically copies the

video bios into shadow ram blocks C000, C400 and C800. In that case these options are

grayed and not accessible in setup!

Watchdog Mode

With these settings, the type of watchdog is specified. Possible settings are Disabled, Reset, NMI. The

Optimal and Fail Safe default settings are Disabled.

Watchdog Delay (available only if Watchdog Mode is not Disabled)

Time delay before the watchdog timer is set. Used for example, to let the system boot without the

need to trigger the watchdog. Possible time settings are 1 Sec, 5 Sec, 10 Sec, 30 Sec, 1 Min, 5 Min,

10 Min, 30 Min.

Watchdog Timeout (available only if Watchdog Mode is not Disabled)

The watchdog must be triggered (reset) within this span of time. Possible time settings are 0.4 Sec, 1

Sec, 5 Sec, 10 Sec, 30 Sec, 1 Min, 5 Min, 10 Min.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 16

MOPS/586 BIOS-Description

Power Management Setup

Power Management/APM

If this option is Disabled, none of the below listed options are available, the system doesn't provide

you with power save features. The Optimal and Fail Safe default settings are Disabled.

Instant On Support

Instant On is a Power Managment Software for Windows 95. Must be Enabled to support this

Software. The Optimal and Fail Safe default settings are Disabled.

Green PC Monitor Power State

This option specifies the power management state that the Green PC-compliant video monitor enters

after the specified period of display inactivity has expired. The settings are Stand By, Suspend, Off.

Video Power Down Mode

This option specifies the power management state that the video subsystem enters after the specified

period of display inactivity has expired. The settings are Disabled, Standby, or Suspend.

Hard Disk Power Down Mode

This option specifies the power management state that the hard disk drive enters after the specified

period of HDD inactivity has expired. The settings are Disabled, Standby, or Suspend.

Hard Disk Time Out (Minute)

After this period, the hard disk drive is entering its power down mode. Possible settings are Disabled,

1, 2, 3, 4, 5....14.

Standby Time Out (Minute)

After this period, the specified devices are entering the standby mode. In Standby mode, some power

use is curtailed. Possible settings are Disabled, 1, 2, 3, 4, 5....14.

Suspend Time Out (Minute)

After this period, the specified devices are entering the suspend mode. In Suspend mode, nearly all

power use is curtailed. Possible settings are Disabled, 1, 2, 3, 4, 5....14.

Display Activity, IRQ3, IRQ4, IRQ5, IRQ7, IRQ9, IRQ10, IRQ11, IRQ12, IRQ13, IRQ14, IRQ15

These options enable event monitoring. When the computer is in a power saving mode, activity on the

named interrupt request line is monitored by AMIBIOS. When any activity occurs, the computer enters

Full On mode. Each of these options can be set to Monitor or Ignore. The Fail Safe default setting is

Ignore.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 17

MOPS/586 BIOS-Description

Peripheral Setup

Onboard IDE

This option enables the onboard IDE controller. The settings are Disabled and Enabled. The Optimal

and Fail Safe default settings are Enabled.

Onboard FDC

This option enables the floppy drive controller on the motherboard. The settings are Enabled or

Disabled. The Optimal and Fail Safe default settings are Enabled.

Onboard Serial Port1

This option enables serial port 1 on the motherboard and specifies the base I/O port address for serial

port 1. The settings are Disabled, 3F8, 2F8, 3E8,2F8. The Optimal and Fail Safe default settings are

3F8.

Onboard Serial Port2

This option enables serial port 2 on the motherboard and specifies the base I/O port address for serial

port 2. The settings are Disabled, 3F8, 2F8, 3E8,2F8. The Optimal and Fail Safe default settings are

2F8.

Onboard Parallel Port

This option enables the parallel port on the motherboard and specifies the parallel port base I/O port

address. The settings are Disabled, 378, 278, 3BC. The Optimal and Fail Safe default settings are

378.

Parallel Port Mode

This option specifies the parallel port mode. EPP and ECP are bidirectional data transfer schemes that

adhere to the IEEE P1284 specifications. The settings are:

Setting Description

Normal The normal parallel port mode is used. This is the default

BI-DIR The bidirectional parallel port mode is used.

setting.

EPP 1.7 The parallel port can be used with devices that adhere to the

Enhanced Parallel Port (EPP) specification version 1.7. EPP

uses the existing parallel port signals to provide asymmetric

bidirectional data transfer driven by the host device.

EPP 1.9 The parallel port can be used with devices that adhere to the

ECP The parallel port can be used with devices that adhere to the

Enhanced Parallel Port (EPP) specification version 1.9.

Enhanced Capabilities Port (ECP) specification.

Parallel Port IRQ (available only if Onboard Parallel Port is not set to Auto)

This option specifies the IRQ line for the parallel port. The settings are 5, 7. The Optimal and Fail Safe

default settings are 7.

Note: If Parallel Port Mode is ECP DMA channel 3 is used!

SSD INT13h Drive Mapping

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 18

MOPS/586 BIOS-Description

This option enables the silicon state disk as either drive 80h, 81h, 82h, or 83h (C, D, E or F). The

settings are Disabled, 80h, 81h,82h, 83h. The Optimal and Fail Safe default settings are Disabled.

SSD Write Protect

This option allows to write protect the silicon state disk. The settings are Disabled and Enabled. The

Optimal and Fail Safe default settings are Disabled.

SSD Erase On Next Boot

If this option is set to Enabled, the silicon state disk will be erased on the next boot. The settings are

Disabled and Enabled. The Optimal and Fail Safe default settings are Disabled.

Auto-Detect Hard Disks

This useful option helps to identify the drive parameters of IDE hard disks. The BIOS shows the

Standard CMOS setup and enters the detected HDD parameters automatically.

Change User Password

Use this option to enter the password for system or setup protection. It is available after the

Supervisor Password is defined. Refer also to option Password Check of the Advanced CMOS

Setup Screen.

Change Supervisor Password

Use this option to enter the password for system or setup protection. After this password is set, the

User Password can be defined. To change the Supervisor Password first erase the User

Password. Refer also to option Password Check of the Advanced CMOS Setup Screen.

Auto Configuration with Optimal Settings

Use this option to configure the system with highspeed settings for increasing the system

performance.

Auto Configuration with Fail Safe Settings

Use this option to configure the system with fail safe settings for increasing the system stability.

Save Settings and Exit

Use this option to save all setup changes to the NV-EEPROM. This option is also available in the

Main Menu by pressing <F10>.

Exit Without Saving

Use this option to discard all setup changes. This option is also available in the Main Menu by

pressing <ESC>.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 19

MOPS/586 BIOS-Description

AMIBIOS Configuration Screen

AMIBIOS System Configuration (C) 1985-1996, American Megatrends Inc.,

Main Processor : Am5x86 (X5) Base Memory Size : 640KB

Math Processor : Built-In Ext. Memory Size : 3072KB

Floppy Drive A: : 1.44 MB 3½" Display Type : VGA/EGA

Floppy Drive B: : None Serial Port(s) : 3F8,2F8

AMIBIOS Date : 07/15/95 Parallel Port(s) : 378

Pocessor Clock : 133MHz Power Management : Disabled

Hard Disks(s) Cyl Head Sector Size LBA

Mode

Primary Master

: 1010 6 55 163MB Off Off 8sec 0

32Bit

Mode

Block

Mode

Example screen for board equipped with an AMD5x86 133MHz, 4MB RAM, booting from a 163 MB hard disk.

PIO

Mode

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 20

MOPS/586 Hardware Description

Hardware Description

ALI-Chipset Features

The MOPS/586 Board operates with the chipset ALI 1489/87, which provides following features:

• 32 bit PCI Interface

• integrated DRAM controller

• integrated PMU controller

• integrated PCI to ISA bridge (fully compliant to PCI 2.0)

• enhanced DMA functions

• build-in two 8259A interrupt controllers

• fast PCI IDE Master Controller for ATA PIO mode 4 harddisks

Memory configuration

One memory bank for DRAM extension is located at the bottom of the MOPS/586 board. The following

memory configurations are available:

total memory technology

64 MB single sided

32 MB double sided

16 MB single sided

8 MB single sided

8 MB double sided

4 MB single sided

1 MB single sided

The chipset support FPM- and EDO-Memory.

For highest memory performance, it is recommended to use EDO-Memory-modules.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 21

MOPS/586 Hardware Description

Interrupts

IRQ0 System Timer

IRQ1 Keyboard

IRQ2 Cascade

IRQ3 COM 2 note (1)

IRQ4 COM 1 note (1)

IRQ5 Ethernet (default) note (2)

IRQ6 Floppy

IRQ7 LPT 1

IRQ8 Clock/Calendar

IRQ9 Available

IRQ10 Available notes (2)

IRQ11 Available notes (2)

IRQ12 Available note (2)

IRQ13 Numeric-processor

IRQ14 EIDE Channel 1

IRQ15 Available

Notes:

(1) if serial ports are disabled via system bios, these interrupts are available for other devices.

(2) possible settings for Ethernet controller, IRQ5 is the factory default.

DMA

DMA 0 Available

DMA 1 Available

DMA 2 Floppy

DMA 3 Available

DMA 4 Cascade

DMA 5 Available

DMA 6 Available

DMA 7 Available

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 22

MOPS/586 Hardware Description

The JIDA Standard

JIDA is the abbreviation for JUMPtec® Intelligent Device Architecture.

Every board with onboard BIOS extension shall support the following function calls, which supply

information about the board. JIDA functions are called via Interrupt 15h with AH=EAh, AL=function

number, DX=4648h (security word), CL=board number (starting with 1).

The interrupt will return with CL#0, if a board with the number specified in CL does not exist. CL will be

equal to 0 if the board number exists. In this case, the content of DX is used to determine, if operation

was successful. DX=6B6Fh indicates successful operation, any other value indicates an error.

To get information about the installed boards following the JIDA standard, the following procedrue is

recommended:

Call ”Get Device ID” with CL=1. The name of the first device installed will be returned. If result was

”Board exists” (CL=0), increment CL and call ”Get Device ID” again. Repeat until result is ”Board not

present” (CL#0). You now know the names of all boards within your systen that follow the JIDA

standard. More information about a specific board may then be obtained by calling the appropriate

inquiry function with the board’s number in CL.

WARNING: Association between board and board number may change due to configuration changes.

Do not rely on any association between board and board number. Instead, always use the

procedure described in the preceding paragraph first, to determine the association between board and

board number.

The source of a Turbo-Pascal unit called JIDA_ACC.PAS showing JIDA access is included on the

support disk.

Get Manufacturer ID

Input:

Int 15h

AX = EA00h DX = 4648h

CL = Board number (1=first board a.s.o.)

ES:BX = Pointer to destination data area

Output:

Description:

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Error

If CL=0 and DX=6B6Fh, then 4 Byte manufacturer ID were copied to the

area pointed to by ES:BX

By default, the result will be ”JUMP”.

Note: There is no ending zero byte.

Function must be implemented on every device supporting the JIDA.

Get Device ID

Input:

Int 15h

AX = EA01h DX = 4648h

CL = Board number

ES:BX = Pointer to destination data area

Output:

Description:

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Error

If CL=0 and DX=6B6Fh, then 7 Byte device ID were copied to area pointed

to by ES:BX

By default, the result will be ” ”

Note: There is no ending zero byte.

Function must be implemented on every device supporting the JIDA.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 23

MOPS/586 Hardware Description

Get Manufacturing Date

Input:

Output:

Description

Get Serial Number

Input:

Output:

Description:

Int 15h

AX = EA02h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BX = Manufacturing date

If CL=0 and DX=6B6Fh, then BX=Manufacturing date. Date format is the

same as used for DOS files:

Bit0..4: Day

Bit5..8: Month

Bit9..15: Years since 1980

Int 15h

AX = EA03h DX = 4648h

CL = Board number

ES:BX = Pointer to destination data area

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

If CL=0 and DX=6B6Fh, then 10 Byte serial number were copied to area

pointed to by ES:BX

The result is different for each single P488.

Note: There is no ending zero byte.

Get Hardware Revision

Input:

Output:

Get Firmware Revision

Input:

Output:

Get Last Repair Date

Input:

Output:

Int 15h

AX = EA04h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BH=Major revision number

BL=Minor revision number

Int 15h

AX = EA05h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BH=Major revision number

BL=Minor revision number

Int 15h

AX = EA06h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BX = Last repair date.

Description:

If CL=0 and DX=6B6Fh, then BX=Last repair date. For date format see

function ”Get Manufacturing Date”.

If board was never repaired, result will be equal to manufacturing date.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 24

MOPS/586 Hardware Description

Read Running Time Meter

Input:

Output:

ReadBoot Counter

Input:

Output:

Get JIDA Revision Level

Input:

Output:

Int 15h

AX = EA07h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BX=Running time (hours)

CH=Overflow counter

Int 15h

AX = EA08h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BX = Boot counter

Int 15h

AX = EA09h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn. not implemented

BH = Major revision number (currently 2)

BL = Minor revision number (currently 4)

Read User Byte from

EEPROM

Input:

Output:

Write User Byte to EEPROM

Input:

Output:

Get Number of User Bytes

available in EEPROM

Input:

Output:

Int 15h

AX = EA40h DX = 4648h

CL = Board number

BH = Number of byte to read (0..15 allowed)

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BL = Value read

Int 15h

AX = EA41h DX = 4648h

CL = Board number

BH = Number of byte to write (0..15 allowed)

BL = Value to write

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

Int 15h

AX = EA42h DX = 4648h

CL = Board number

CL=0: Board present

CL≠0: Board not present

DX=6B6Fh: Function successful

DX≠6B6Fh: Fn.not implemented

BL=Number of Bytes available

Note: BL=0 means 256 Bytes

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 25

MOPS/586 Hardware Description

Watchdog Extension

With the aid of a special Interrupt 15h function, the watchdog on a JUMPtec board can be controlled

very easily.

The respective functions have the following calling conventions:

Watchdog init

Input:

Int 15h 00h

AH = E0h

AL = 00h

BX = timeout in 0.2sec increments

CX = delay in 0.2sec increments

DX = watchdog action (0 = reset, 1 = NMI)

Output:

Description:

None

This funcion is a public JUMPtec INT15h extension used to init the

watchdog on JUMPtec boards.

Watchdog trigger

Input:

Int 15h 01h

AH = E0h

AL = 01h

Output:

Description:

None

This funcion is a public JUMPtec INT15h extension used to trigger the

watchdog on JUMPtec boards.

Detailed description of the watchdog function:

Programming:

The function Init watchdog must be called only once. The three parameters delay time, timeout time

an trigger event must be set. After initialisation the watchdog will be active only after the delay time

has expired. The watchdog must be reset during the timeout time with the trigger watchdog function.

Otherwise a RESET or NMI will occur depending on trigger event.

The trigger- and the delay time can be set in steps of 0.2 sec.

The maximum values are:

Ÿ timeout time 65535*0.2sec. = 13107s ≅ 3h 38min

Ÿ delay time 32767*0.2sec. = 6553s ≅ 1h 49min

The system BIOS makes it very easy to use the watchdog via software interrupt 15h. Two ways are

possible to access the watchdog: The simplest way is to use AH=0E0h to init or trigger the watchdog.

The second way is to use the functions ”Write I

bus protocol.

A) Simple with AH = E0h

Init Watchdog (Int 15h, AH=E0h)

Called with AX E000h

BX timeout time

BX = 0 ð watchdog off. BX

CX delay time

CX = 0 ð no delay. CX

DX trigger event

DX = 0 ð RESET, DX = 1 ð IOCHCHK

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

2

C” and ”Read I2C” with AH=0E1h and handling the I2C

= 0FFFFh

max

= 07FFFh

max

Page 26

MOPS/586 Network Operation

Returns no

Example

mov ax,0E000h ; Watchdog set

mov bx,5 ; 5*0,2s = 1s Timeout

mov cx,5 ; 5*0,2s = 1s Delay

mov dx,0 ; after Timeout and Delay generate RESET

int 15h

Network Operation

Overview

The Crystal LAN™ CS8900 ISA Ethernet Adapter from Crystal Semiconductor follows IEEE 802.3

standards and supports half- or full-duplex operation in ISA bus computers on 10 Mbps Ethernet

networks.

The driver can be download from the webpage:

http://www.jump.de/jumpdata/software/ETHERNET.EXE

For further information read the readme-File or contact the technical support.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 27

MOPS/586 Specifications

Specifications

Mechanical Specifications

PC/104 Bus connector: 2 pieces of 2*32 pin male and 2*20 pin male connector

Module-dimensions: length * width 95 mm * 90 mm (3,7" * 3,5 ")

Electrical Specifications

Supply voltage: 5V DC +/- 5%

Supply voltage ripple: 100 mV peak to peak 0 - 20 MHz

Supply current (maximal): 1,6 A + current DRAM + current Prozessor = 3,5 A

( Σ max. current all Parts)

Prozessor maximal current (AMD-data-sheet): 931 mA

DRAM maximal current (MICRON data sheet): 4 Meg x 32 0,80 A

4 Meg x 32 0,82 A

Supply current (typical, DOS-Prompt):

with 4 MB DRAM 1,29 A

external RTC battery voltage 2,4 – 4,0 V

external RTC battery quiescent current max. 4,5 uA

Environmental Specifications

Temperature: operating 0 to +60 C ((*)with appropriate airflow))

non operating: -10 to +85 °C

Humidity: operating: 10% to 90% (non-condensing)

non operating: 5% to 95% (non-condensing)

(*) The maximum operating temperature is the maximum measurable temperature on any spot on the

modules´s surface. It is the user´s responsibility to maintain this temperature within the above

specification.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 28

MOPS/586 Peripheral Interface

Peripheral Interface

Keyboard, Reset, Battery, Speaker

Pin Signal

name

1 SPKR speaker output

2 GND ground

3 POWERGOOD reset input

4 /KLOCK keyboard lock

5 KDATA keyboard data 2 1

6 KCLK keyboard clock 1 5

7 GND ground 4 3

8 VCC +5V 5 4

9 VBAT VBAT input (3,6V)

10 POWERGOOD reset input

Function 5-pin diode

keyboard

adapter

6-pin minidin

keyboard

adapter (PS2)

/KLOCK (keyboard lock)

input on CPU modules

output on any other module

input to the keyboard controller input port 1 bit 7 .

POWERGOOD (reset input)

input on CPU modules

open collector output on all other module

When power good goes high, it starts the reset generator on the CPU module to pull the

onboard reset line high after a valid reset period. This pin can also be used as a low active

hardware reset for modules.

SPKR (speaker output)

open collector output on modules which can drive a loudspeaker.

input on modules which connect a 8 Ohm loudspeaker to this pin

An 8 Ohm loudspeaker is connected between SPEAKER and GND. Only one loudspeaker

should be connected to this pin. Usually only the CPU drives this pin, however other modules

can also use this signal to drive the system loudspeaker.

KDATA (keyboard data)

bi-directional I/O pin on CPU modules

Keyboard data signal.

KCLK (keyboard clock)

bi-directional I/O pin on CPU modules

Keyboard clock signal.

VBAT (system battery connection)

This pin connects a system battery to all modules.

The battery voltage has to be higher than 3.0V and lower than 4.0V. Either a 3V or 3.6V

battery is recommended.

Note, that there is no battery needed to hold the CMOS-setup data. Your configuration

concerning hard disks, floppy drives etc. is automatically saved in an onboard FRAM.

Nevertheless the battery is necessary to serve the CMOS date and time while power

consumption is turned off.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 29

MOPS/586 Peripheral Interface

1 (Speaker)

2 (GND)

3,10 (PowerGood)

4 (/KLOCK)

5 (KDATA)

6 (KCLK)

5

7 (GND)

2

4

3

1

8 (+ 5V)

9 (VBAT)

Serial Port COM 1, 2 (RS232C)

Pin Signalname In / Out DSUB-25

(need Adapter)

1 DCD In 8 1

2 DSR In 6 6

3 RxD In 3 2

4 RTS Out 4 7

5 TxD Out 2 3

6 CTS In 5 8

7 DTR Out 20 4

8 RI In 22 9

9 GND -- 7 5

10 +5V -- -- -For signal description please refer additional literatur.

The four serial input/output interfaces can be set to any I/O-address on the periphal setup. The serial

ports are completely compatible with the serial port implementation used on the IBM Serial Adapter.

Their interrupts are mapped to IRQ4, IRQ3, IRQ10, IRQ11.

DSUB-9

(need Adapter)

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 30

MOPS/586 Peripheral Interface

Parallel Port LPT 1

Pin Signalname Function In / Out DSUB-25

(need Adapter)

1 /Strobe Out 1

3 Data 0 I/O 2

5 Data 1 I/O 3

7 Data 2 I/O 4

9 Data 3 I/O 5

11 Data 4 I/O 6

13 Data 5 I/O 7

15 Data 6 I/O 8

17 Data 7 I/O 9

19 /ACK in 10

21 BUSY in 11

23 PAPER out in 12

25 SEL out in 13

2 /AUTOFD out 14

4 /ERROR in 15

6 /INIT out 16

8 SEL in out 17

26 Vcc + 5 V -- NC

10,12 GND Signal Ground -- 18 - 25

14,16 GND Signal Ground -- 18 - 25

18,20 GND Signal Ground -- 18 - 25

22,24 GND Signal Ground -- 18 - 25

For signal description please refer additional literatur.

The Centronics printer interface can be programmed via the system setup menu.Refer the periphal

setup for more informations. The parallel port is completely compatible with the parallel port

implementation used in the IBM PS-II-Parallel Adapter.

Floppy Connector

Pin Signal Function Pin Signal Function

1 VCC + 5V 2 IDX index

3 VCC + 5V 4 DS0 drive select 0

5 VCC + 5V 6 /DCHNG disk change

7 NC - 8 NC 9 NC - 10 Mo0 motor on

11 NC - 12 DIR direction select

13 NC - 14 STEP step

15 GND ground 16 WD write data

17 GND ground 18 WG write gate

19 GND ground 20 TR00 track 00

21 GND ground 22 WP write protect

23 GND ground 24 RD read data

25 GND ground 26 SIDE side one select

For signal description please refer additional literatur.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 31

IDE Connector for 2,5" Hard Disk

Pin Signal Pin Signal

1 /RESET 2 GND

3 D7 4 D8

5 D6 6 D9

7 D5 8 D10

9 D4 10 D11

11 D3 12 D12

13 D2 14 D13

15 D1 16 D14

17 D0 18 D15

19 GND 20 NC

21 NC 22 GND

23 /IOW 24 GND

25 /IOR 26 GND

27 NC 28 BALE

29 NC 30 GND

31 IRQ14 32 /IOCS16

33 SA1 34 NC

35 SA 0 36 SA2

37 /CS0 38 /CS1

39 /HDLED 40 GND

41 VCC 42 VCC

43 GND 44 NC

For signal description please refer additional literatur.

Ethernet Connector

Pin Signalname Function In/Out

1 TXD+ 10BASE-T Transmit differential Output

2 TXD- 10BASE-T Transmit differential Output

3 RXD+ 10BASE-T Receive differential Input

4 NC unused Pin

5 NC unused Pin

6 RXD- 10BASE-T Receive differential Input

7 LNLED LED Output

8 LKLED LED Output

TXD+, TXD-

Differential output pair drives 10 Mb/s Manchester encoded data to the 10BASE-T transmit

lines.

RXD+, RXD-

Differential input pair receives 10 Mb/s Manchester encoded data from the 10BASE-T receive

lines.

LKLED, LNLED

Connect with Cathode of Ethernet-LED‘s.

Feature Connector

Only for manufacture, not for use by customer

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 32

MOPS/586 Peripheral Interface

Power Connector

Pin Pin function

1 GND

2 +5V

3 keypin

4 +12V

5 -5V

6 -12V

7 GND

8 +5V

Power Pins

The MOPS/586 is a +5 V only module. Nevertheless the power connector offers the possibility

to supply with the additional voltages +12V, -12V and -5V which may be needed by other

boards in the PC/104 system. The power consumption of all available power pins on the

MOPS/586 is limited to 5A in total (1A per pin, with 2 pins on the power connector, 2 pins on

the XT-bus and 1 pin on the AT-bus) and at GND up to 8A. Systems consuming more then 2A

shouldn’t be served over the power connector only. Systems consuming more then 5A must

provide power supply through an additional connector on another board.

Keypin

The keypin avoids wrong insertion of the 8 pin power connector offered by JUMPTEC.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 33

MOPS/586 Peripheral Interface

PC/104-Connector

Specification XT Bus

Pin Signal Name Pin Signal Name

A1 /IOCHCK B1 GND

A2 SD7 B2 RESETDRV

A3 SD6 B3 +5V

A4 SD5 B4 IRQ9

A5 SD4 B5 -5V

A6 SD3 B6 DRQ2

A7 SD2 B7 -12V

A8 SD1 B8 /0WS

A9 SD0 B9 +12V

A10 IOCHRDY B10 GND (*)

A11 AEN B11 /SMEMW

A12 SA19 B12 /SMEMR

A13 SA18 B13 /IOW

A14 SA17 B14 /IOR

A15 SA16 B15 /DACK3

A16 SA15 B16 DRQ3

A17 SA14 B17 /DACK1

A18 SA13 B18 DRQ1

A19 SA12 B19 /REFRESH

A20 SA11 B20 SYSCLK

A21 SA10 B21 IRQ7

A22 SA9 B22 IRQ6

A23 SA8 B23 IRQ5

A24 SA7 B24 IRQ4

A25 SA6 B25 IRQ3

A26 SA5 B26 /DACK2

A27 SA4 B27 TC

A28 SA3 B28 BALE

A29 SA2 B29 +5V

A30 SA1 B30 OSC

A31 SA0 B31 GND

A32 GND B32 GND

Specification AT Bus X2, C0 - C19

Pin Signal Name Pin Signal Name

C0 GND D0 GND

C1 /SBHE D1 /MEMCS16

C2 LA23 D2 /IOCS16

C3 LA22 D3 IRQ10

C4 LA21 D4 IRQ11

C5 LA20 D5 IRQ12

C6 LA19 D6 IRQ15

C7 LA18 D7 IRQ14

C8 LA17 D8 /DACK0

C9 /MEMR D9 DRQ0

C10 /MEMW D10 /DACK5

C11 SD8 D11 DRQ5

C12 SD9 D12 /DACK6

C13 SD10 D13 DRQ6

C14 SD11 D14 /DACK7

C15 SD12 D15 DRQ7

C16 SD13 D16 +5V

C17 SD14 D17 /MASTER

C18 SD15 D18 GND

C19 GND (*) D19 GND

(*) Key pin for PC/104; GND for PC/104+ - specification

For signal description and periphal driver current refer the PC/104 Specification.

Any signals are open collector for multiple sources and can not drive by TTL.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 34

MOPS/586 Literature, Standards, Links

Literature, Standards, Links

PC/104-Bus

• PC/104 Specification Version 2.3 June 1996

PC/104 Consortium; www.pc104.org

• Embedded PCs Markt&Technik GmbH, ISBN 3-8272-5314-4 (german)

ISA-Bus, Standard PS/2 - Connectors

• ISA System Architecture Addison-Wesley Publishing Company

• Edward Solari, AT BUS Design IEEE P996 Compatible, Annabooks San Diego CA. ISBN 0-929392-08-6

www.annabooks.com

• PC Handbook, Sixth Edition, John P. Choisser and John O. Foster, Annabooks San Diego CA. ISBN 0-

929392-36-1www.annabooks.com

• AT IBM Technical Reference Vol 1&2, 1985

• ISA Bus Specifications and Application Notes, January 30, 1990, Intel

• Technical Reference Guide, Extended Industry Standard Architecture Expansion Bus, Compaq 1989

• Personal Computer Bus Standard P996, Draft D2.00, January 18, 1990, IEEE Inc

• Embedded PCs Markt&Technik GmbH, ISBN 3-8272-5314-4 (german)

RS232C

• EIA-232-E Interface between data terminal equipment and date circuit-terminating equipment employing

serial binary data interchange (ANSI/IEA-232-D)

National Semiconductor's Interface Data Book includes any applications notes. These notes are also available

online at http://www.national.com/. A search engine is provided to search the text of the available application

notes. Entering „232“ as search criteria to get a current list of related application notes.

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Page 35

MOPS/586 Document Revision History

Document Revision History

Filename Date Edited by Alteration to preceding revision

P488M210 10.09.98 KW Created

P488M211 16.09.98 KW Add SSD

P488M212 28.09.98 KW Onboard-DRAM, superMOPSpro replaced

P488M213 10.01.99 KW Add L1-Cache

P488M214 22.12.99 Ba changed typ. current in chapter Electrical specifications,

changed IRQ10 and IRQ11 to available in chapter

Interrupts

Tri-M Systems Inc., 6-1301 Ketch Court, Coquitlam, B.C., V3K 6X7, Canada

Phone: (604) 527-1100, (800) 665-5600 Fax: (604) 527-1110

Email: info@Tri-M.com Web: www.Tri-M.com

Loading...

Loading...