1

TriMetric TM-2030

Battery system monitor, Models TM-2030-RV and TM-2030-A

Technical Manual

INSTALLATION Page 1-7

USER GUIDE Page 8-23

revised June 2017

IMPORTANT: The wiring installation for this meter, especially the shunt installation

must be performed by someone knowledgeable in proper wiring, electrical practices,

and safety. If you do not have this knowledge please have someone install it who does,

or at least get some competent help to supervise the installation.

To install:

1. Please read or scan two pages of introductory information in section A.

2. Consult drawings Figure 1 and 2 (pages 7-8).

3. Follow step by step installation instructions in section B.

4. Program the two most important parameters into meter (section C1).

A. Before installing the TriMetric meter:

B. How to Install Meter and Shunt:

C1. How to determine program item P3: “battery system capacity”

C2. How to program your meter for the 100A/100mV shunt.

C3. Optional: Now or later you may wish to program P4, P5, P6

Warranty and customer service

Limited warranty

The TriMetric TM-2030 is warranted for three years against any manufacturing defect. Any meter not meeting the

specification or rated performance shall be replaced or repaired, at Bogart Engineering’s discretion, provided it has not

been subjected to abuse or misapplication. For warranty service, please email bogart@bogartengineering.com. A return

merchandise authorization is required for all merchandise to be returned to Bogart Engineering.

How to obtain customer service

Please review our support page before attempting to contact us. Our distributors are able to answer simple

questions about Bogart Engineering products. For technical support, send an email to

bogart@bogartengineering and someone will assist you.

BOGART ENGINEERING

www.bogartengineering.com

2

A: What you may need to know before installing the TriMetric meter.

Review this (briefly) before installing.

The TriMetric is usually located in the living area where people using the power can readily observe it. It is usually

located less than 100 ft from batteries. For greater distances refer to section B2 for details. If the optional SC-2030

Solar charger is also to be used, the charger is typically located near the batteries where it can be completely controlled

from the TriMetric TM-2030.

The TM-2030 measures volts, amps, watts, percent full on your “main” system. In addition, it will monitor voltage

only on a second battery having a common negative connection, which could be the engine starting battery.

Permissible battery voltage: This meter is suitable for battery systems with nominal voltage from 8 to 65 volts. It should

not be connected to systems which will ever exceed 65 volts.

You may choose three different operating levels from simplest to more complex: The meter comes initially

programmed at the lowest Operating Level: L1 which will furnish the most important data. There are also levels “L2” or

“L3” which add more functionality, but with more complexity. For new users, begin with L1, and after becoming familiar

with the meter advance to L2 or L3 later at any time. L4 adds (only) a more stringent requirement for what is considered

to be "charged," intended mainly when using the optional SC-2030 solar charger. These levels are described in the

TriMetric User’s Instructions.

Lightning considerations: The meter has been designed with good protection against lightning.

It is possible to wire the TriMetric so it reads only total solar input current, or only total load current (and amp-

hours): In this case refer to our web site: BogartEngineering, SUPPORT/APPLICATION NOTES” entitled : Using

TriMetric for measuring only wind or solar charging source.

Serial data output is available for all real time data— This is a data access method for techies. See application note on

the Bogart Engineering web site under SUPPORT/APPLICATION NOTES entitled: TM-2025-TM-2030 Technical

Information on Serial Data Output

Mounting the meter: There are two versions of the TM2030 which differ only in their size, front label colors and whether

the meter includes its own enclosure.

The TM-2030 RV model comes in a white, surface mount enclosure (3 x 4-1/4 x 1-1/4 inch deep). It can be mounted

to a wall with screws at the top and bottom flanges.

The TM-2030 A can be mounted in many standard “double gang” electrical boxes available in hardware stores.

For detailed drawings, see application notes on the Bogart Engineering web site under SUPPORT/APPLICATION

NOTES: “Mounting Drawings for .TM-2020/TM2030.”

A shunt (an accurate, very low resistance power resistor) must be wired into your battery system as described in

section B of these instructions, shown on the wiring diagram page 8. The “amps” shown on the meter measures

whatever current passes through this shunt—so it must be wired in series with the wire which carries the current to be

measured. The shunt is almost always installed between the negative terminal of the battery and all the loads and

charging sources (see Figure 1 on page 7.) It is located near the batteries, since the high current carrying wires must be

kept short. The TriMetric meter measures the current ("amps") by measuring the very small voltage drop across this

shunt. The voltage drop across the shunt is very small—with the 500A/50mV shunt it is equivalent to only a 2 foot

additional length of 0000 gauge cable in series with your main wiring.

TriMetric maximum current capability: The TriMetric meter itself will measure current (amps) properly up to 999 amps

with a 500A/50 mV shunt. With the 100A/100 mV shunt the meter measurements will be OK up to 300 amps. However,

at these currents the shunt is going to get too hot. The typical 500A/50mV shunt will be OK up to 420 amps. The

typical 100A/100A shunt will be OK up to 70 amps maximum. These are charging or discharging amps values, NOT amp

hour numbers.

MORE SHUNT INFORMATION

There are two choices of shunt, depending on your system size: the 500A/50mV or 100A/100mV size. Most systems

will use the 500 amp-50 mV shunt. This gives an “ampere” resolution as low as 0.1 amp and will read to a steady 430

amps before the shunt overheats. For smaller systems (with 12V systems with inverter 800 watts or less) you could use a

100A/100mV shunt It has the advantage that you can read currents as low as 0.01 amp, however has the 70 amp

maximum amp limitation noted above. The correct shunt must be programmed as described in section C2 on page 6

Technical note: It is only the shunt ratio between amps to mV. which is important to the meter--so, for example, a 200 amp-

200 mV. shunt can, from the meter's point of view, be considered equivalent to the 100 amp-100 mV shunt. The implication,

when a shunt is rated at "100 amps-100 mV." is that it may safely carry up to 100 amps maximum--however in many cases so-

called "100 amp" shunts will not carry this much without overheating. For more information see application note on the

Bogart Engineering web site under SUPPORT/APPLICATION NOTES entitled: Shunt Info.

3

B. How to Install METER and SHUNT

B.1. Preliminary

•IMPORTANT: A qualified person familiar with safe electrical practices and the local electrical

code should install this meter--particularly when installing the shunt. Accidentally shorting

the battery with a tool or other metal such as a finger ring can result in severe burns

from an arc. Mistakes in wiring could seriously damage your electrical system.

•Refer to wiring drawing on last page--please read all notes.

•To prevent damage to meter, do not install into a battery system that has a voltage that will rise

above 65 volts. It is designed for a maximum “nominal” 48 volt battery system.

•A (1Amp, fast-blow) fuse shown located near the battery for each battery in the wiring diagram will

protect the wire and the meter even if you accidentally miswire to the terminal block.. If not

provided with your meter, such "in line" fuses are available at Radio Shack and other electrical

supply stores.

B.2:For installation you will need:

•Suitable wrench or tools for connecting the large cables to battery and shunt

•Very small screwdriver for connecting wires to terminal block on the back of the TM-2030.

•Small Phillips screwdriver for removing front panel of meter

•Medium screwdriver for connecting wires to shunt

•For TM-2030-RV only: A drill for making a small hole to allow wires to enter the meter box

•For TM-2030-A only: A “double gang” electrical box of suitable size to accommodate the meter panel.

• One shunt (usually 500A/50mV size). This is the sensor that measures the “amps”.

•“shunt to battery cable:” Prepare or obtain from an electrical supply or auto store a “shunt-battery cable” (about

6 inches to several feet long as needed,) with diameter at least as large as the largest cable going to the negative

battery connection. The cable size must be large enough to accommodate the maximum system charging or

discharge amps from the battery. It should have suitable bolt lugs at each end. One end will connect to one large

bolt on the shunt—the other end to the battery negative post. See Figure 1 on page 7.

• Small, 4 or 5 wire cable long enough to connect from meter to battery system—with one or two 1Amp

fuseholders: Virtually any multi conductor cable available in a hardware or electrical supply house will be OK,

including CAT5. Or 4 or 5 individual wires may be used. Required wire size shown next paragraph. (Five wires

if two batteries are being measured.) The wire used for the + connection of both the main (and secondary

battery if used) should each have a 1A fuse at the battery end to protect against a short in the wire.

Minimum size wire for distances shown: #26 gauge: 45 feet. #24 gauge: 70 feet. #22 gauge: 110 feet. #20 gauge:

180 feet. #18 gauge: 300 feet.

For long runs over 100 feet our website has an application note describing how to use Cat 5 cable for going up

to 350 feet. See the Bogart Engineering web site under SUPPORT/APPLICATION NOTES entitled: Using

CAT5 cable up o 350 ft. for TriMetric.

B.3: Eight steps to install shunt and meter:

Steps 1-3: Install Shunt

Steps 4-6: Connect wires from meter to shunt and batteries.

Step 7: Check of wiring.

Step 8: Install two program values for your system

STEP 1:Turn off main breaker to battery. Check figure 1 on page 7 to see how the shunt will be

connected when you complete step 3. Remove EVERY wire and EVERY cable connected to the

negative side of your battery system. After you have accomplished this step you will be left with one or

more dangling cables that will be reconnected to the shunt in STEP 2. A common error is to leave one

or more still connected.

If your system has one battery, or if you have two (or more) batteries in series, then before step 2

you will have one negative pole (on one battery) that should be completely bare, disconnected from

any (current carrying) wires or cables, such as chassis ground.

4

If your system has four 6V batteries in series-parallel, or two 12V batteries in parallel, then on the

negative side of the battery system you will then have only one cable connecting two negative poles

from two different batteries connected together. Before step 2, there must be no other wires going to

inverters, grounds, solar controllers or ANYTHING ELSE connected to the negative side of the

battery system except for one cable that connects the two battery negative poles together.

We emphasize this because quite often people make the mistake of leaving chassis ground, or one

or more other device still connected to the negative side of the battery system—which will result

in the wrong battery “amps” being read on the TriMetric.

STEP 2: Reconnect all the cables you took off in STEP 1 to either of the two large bolts on the shunt. All

such cables must be connected to one side of the shunt—leaving the other bolt empty for step 3. This

doesn’t mean that they have to go directly to the bolt itself—but must connect electrically to this side of the

shunt. Arrange the shunt so the two small “Kelvin” screws on the side or top of shunt are accessible for

connecting later (Step 5).

STEP 3: Obtain “shunt to battery cable” referred to in B2 above. See diagram page 7, Figure 1B,

“After cable installation”.

Connect one end of cable to the now empty large bolt on the shunt.

Connect the other end of cable to the now bare battery negative battery connection provided in STEP1.

PREPARE FOR STEPS 4-6: Connecting wires from meter to battery and shunt. Refer to the

wiring diagram on the last page of these instructions to see how the wires connect from the meter to the

battery system. Every system will require a minimum of four wires shown as G1, G2, SIG +B1 shown in

table below. If you also wish to also monitor the voltage (only) of a secondary battery you will also need

to connect a fifth wire from the positive post of this battery to meter as shown in wiring diagram.

The terminal block on the TriMetric circuit board accommodates wire size from 16 to 26 AWG. Use a

cable with different colored wires to reduce the probability of wiring errors. On the chart below write

the colors for each wire. It has suggested colors if your cable uses these colors—Note that G1 and G2

may be the same color, as they both join together at the Kelvin screw on the shunt.

The +B1 terminal must be connected to the + terminal of the main battery set. We suggest connecting

directly to the + battery terminals so that the meter will operate even if a main breaker is turned off. The

+B2 wire is only used if you wish to measure the voltage only of a second battery.

Ignore this paragraph unless twisted pair wires in a cable are used: Twisted pair wires are not

necessary unless you run the wires very close to other high current carrying wires for 10 feet or more. However if

used, the wires labeled “G2” and “SIG” should be run with one twisted pair, and if another pair is used, “G1” and

“+B1” may be run in an another pair, although twisted pair here will not give any benefit. Clearly establish which

wires in the cable are “paired” together. This often requires stripping quite a bit of insulation to see which pairs are

twisted together. Then choose one twisted pair for G2 and SIG (the ones for which twisted pair is helpful), and

record the wire colors for that pair below in the chart. You may want to use a piece of tape at each end of the

cable to tie these two together, to clearly mark the pair. Then you can also choose a pair for G1 and +B1 and

record their colors on the chart above, and an extra wire for +B2, if used.

STEP 4: Connect wires at battery/shunt end: Using chart above for wire colors:

a. First connect both the G1 and G2 wires to the Kelvin “load side” terminal (on the shunt farthest from the

minus battery terminal lead,) as also shown in Figure 2. These two wires must join together only right at

this terminal.

5

b. Then connect the SIG wire to the other Kelvin “battery side” terminal (closest to the minus battery

connection.)

c. Connect the wire for the +B1 connection to one side of the one amp fuse holder. Don’t yet put in the fuse.

d. A wire from the other side of the fuse holder must connect to the + terminal of the main battery set. We

suggest connecting it directly to the + battery terminals so that the meter will operate even if a main

breaker is turned off.

e. Then, if you are measuring a secondary battery use a second fuse to connect the secondary battery +

terminal to its +B2 wire.

STEP 5: Connecting wires to meter: Check that the fuse holders installed in STEP 4B still have their fuses

removed.

TM-2030-RV only: Take the meter out of its box by removing 4 screws. Drill a hole in the plastic box in a

desired location and size to allow the cable or wires to enter the box. Thread the wires through the hole.

TM-2030-A only: The panel can mount in a suitably sized “double gang” electrical box that is mounted 90

degrees from its usual orientation on the wall. Thread the wires through a suitable hole in the box.

The meter circuit board has a 5 pin terminal block on the rear. The five connections are labeled: G1, G2, SIG and

+B1 and +B2. Strip insulation off each wire 1/4 inch or so.

STEP 6: Use a small screwdriver to loosen the screws on the connector and insert each wire in a separate

connector hole using the chart above and/or wiring diagram (Figure 2) to determine which wire goes to which

terminal, and tighten each screw to hold the wires securely, taking care that there is no danger of shorts

between the wires.

Make a final check of the wiring. Install meter in box and finally insert the 1A fuse(s) in the battery fuse

holder(s). Digits should light up on the meter. If fuse blows, wiring is probably wrong: before

replacing fuse: carefully check that B1+ wire from battery and fuse goes to proper “B1+” terminal on the

meter. (See wiring, Figure 2)

If you installed the more common 500A/50mV shunt, proceed to next step 7. If you used the 100A/100mV

shunt, see section C2 below: “How to program your meter for the 100A/100mV shunt”

STEP 7: Here’s how to check that you’ve probably wired you meter and shunt properly:

1. Push “SELECT” to illuminate the front panel light: B1 VOLTS. The battery volts should display.

2. Push SELECT to show AMPS. Turn all charging sources and all loads off, with the inverter completely off (not

even in “standby”). The meter “amps” display should show near 0. (0.0 to 0.1 amps if using the 500A/50mV

shunt. If using the 100A/100mV shunt minus 0.03-0.05 amps which is the current used by the TM2030 itself )

3. Turn on a known load of over 20 watts. (One or more lights, for example,.) This should cause the “AMPS”

reading to become more negative. The “amp” value should be about equal to the watts divided by 12 for a

12V system plus a little more for the inverter power. (20÷12 = 1.8 amps) Divide by 24 for a 24V system.

4. Check AMPS charging from every charging source. As you turn each charging source on (solar, alternator,

battery charger, etc) be sure that for each source the amps become more positive by about the amount you

would expect from that source.

STEP 8 FINAL STEP: program two important program values for your system. This is necessary to

make the “% full” display work correctly::

1. Hold the SELECT button down, and when “P1” appears in the display, release the button. If you

miss it, just hold it down again until you succeed. The display will show the “Charged voltage

setting”, alternating with “P1”

2. Momentarily push BOTH SELECT and RESET at the same time—to get the three green lights

on the meter to flash on and off. Now you can change the number.

3. For a 12V system enter 14.3 volts. For a 24V system enter 28.6 volts or 48V system 57.2. Push

the RESET button to make the number go up. To make numbers go DOWN you must go all the

way to 65.0—then it will jump to 10.0 and go up again.

4. Next Push SELECT a few times to show “P3.” This will display “battery capacity.”

6

5. As before, momentarily push both SELECT and RESET—three green lights will flash. Enter

your “battery capacity” in amp hours. If you do not know what your “battery capacity” is,

see below “How to determine battery system capacity. As before, the RESET button will

increase the numbers. Note that the display can’t show above 999, so above this you will see a

flashing decimal point. The flashing decimal point means “multiply the number by 1000.” . To

go down in this display, you will need to go all the way up to 9.99, (9990 amp hours) then down

to 10.

These numbers cause the Percent Full to reset to “100%” every time the battery is fully charged.

This occurs when the voltage exceeds the P1 value and the charging amps are less than P2

(expressed as a percent) times P3 (amp hours.) Refer to TM-2030 Users manual, Section 6.2 for

a comprehensive description of what these do.

*******************************************************************************

C1. How to determine program item P3: “battery system capacity” This is a number in

“amp hours” that indicates how much charge your batteries hold when they are fully charged. For “deep

cycle” batteries this number is specified by the battery manufacturer. Find the “capacity” in amp hours from

the manufacturer. If several different values of “capacity” are given, you can use the “20 hour discharge”

value. If you have only one battery then use that value in P3: It is more usual to have more than one battery

connected together as shown in Figure 1: Batteries A and B are connected “in series”. String A-B is then

connected “in parallel” with string C and D.

When combining batteries here’s how to calculate total amp hours:

When you put identical type batteries in series the amp hour of the series string is the same as the

amp hour rating of each single battery in the string. (Add the voltage of each for total volts.)

When you put them in parallel then you add the amp hours of each string or battery. (Total volts are

SAME as each.)

When you have batteries that are both in series and in parallel, first compute the amp hour of

EACH series string. Then add those together for as many series string as you have to get the total

value. Put this value in the “battery system capacity” (P3) in Table 1 on page 7. Values over 1000

amp hours will appear with flashing decimal point: e.g. 1.02 (decimal point flashing) means

1020 Amp hours.

C2. How to program your meter for the 100A/100mV shunt. If you are using the

100A/100mV shunt you must program the TM-2030 for this—otherwise the “amps” values will

show as ten times higher than they should. Follow these steps:

1. Hold SELECT switch until “P1” comes into display. Then release SELECT. If you miss the P1, hold SELECT

again .and it will come back around.

2. Push SELECT about 6 times to show “P7”.

3. Push SELECT and RESET both momentarily together—and release: 3 green lights should flash.

4. Push RESET a few times to change the display to “L3.”

5. Push SELECT several times until display shows “P11” It will probably show “Sh.H”.

6. Push SELECT and RESET both momentarily together—and release: 3 green lights should flash.

7. Push RESET once to change display to “Sh.L”

8. Push SELECT a number of times and you will be back to the normal display. Continue with step 7 above.

C3. Optional: Now or later you may wish to program P4, P5, P6. For information

about these, see TM-2030 User’s instructions, Table 2, page 6.

P4: Allows the main display to show “watts” instead of “amps”

P5: Sets up meter to let you know when too many days have elapsed since last full charge for your

batteries. Most useful for people that are continually using their batteries. Not as useful for people that

only occasionally use batteries such as many RV’ers or weekend cabin users.

P6: Set up a timer to remind you to equalize your batteries at some set number of days.

+

-

maintained for accuracy.

The reason the G1 and G2 wires must be connected together ONLY

at the shunt, is that to measure current through the battery the TriMetric measures voltages

across the shunt between the SIG and G2 wires as small as 10 microvolts. The voltage drop

TECHNICAL NOTE:

across the G1 wire fromthe shuntto themeter (dueto currentflow throughthe wire)can easilybe

The two wires:G1, G2 must be connected toeach other

SHUNT TO METER CABLE (unshielded): Can be up to 300 ft. long if

cable has #18 or larger wires, or 100 feet using #22 wires. Twisted

pair is normally not necessary. However, if it is used, we recommend

wiring it as shown in the diagram. Use one twisted pair for the G1 and

+ wires, and another twisted pair for the G2 and SIG wires (as shown).

IMPORTANT NOTE:

ONLY right at the shunt terminal at the small screw (Kelvin connection) for

accurate current measurements. (Otherwise meter will show residual

"amps" when it should be showing zero.) Also, good connections must be

100 millivolts. Only when the connections are made as shown, the G2 wire carries no current,

thus there is no error causing voltage drop across it. (1 volt=1000 millivolts = 1,000,000

microvolts.)

2nd BATTERY SYSTEM TO MEASURE VOLTS

ONLY: (if used) NEGATIVE side connects as shown

here, to this side of shunt, not directly to main battery

system negative.

SYSTEM GROUND ON THIS SIDE OF SHUNT (if used)

Minus terminal of charge controller, inverter, and all other

loads and chargers connect to this side of shunt (not the

negative post of battery).

O CHARGING SYSTEM

T (SOLAR PANELS including

CONTROLLER, CHARGER, ALTERNATOR, ETC.)

AND ALL LOADS (INVERTER, ETC.)

SHUNT NOTE: Use a 50 mv/500 amp shunt or 100 mv/100

amp shunt. Shunt must be connected to minus side of

battery. To read correct current and amp-hours, TriMetric

battery monitor must be programmed for correct shunt type

being used, as described in instructions.

2nd Batt.

measure volts

KELVIN CONNECTIONS: These are the two smaller screws on the shunt

which should be used for current sensing wires only. For measurement

accuracy, don’t connect wires containing high currents to these connections.

B2+

only

B1+

3/20/14

OPTIONAL SECOND BATTERY:

B2+ may be connected (for

To SC-2030

charger if used

Magnified view of

TM-2030

example) to the + terminal of a

starting battery so you can use the

meter to observevoltage.

5 TERMINAL

STRIP located on

circuit board.

G2

B2+

B1+

SIG

G2

G1

G1

B1+

SIG

TriMetric

IMPORTANT: Be sure this side of

shunt is connected to nothing but

negative terminal(s) of the battery

set that you want to monitor the

"amps". Otherwise your meter amps

will not be correct. (If 2nd battery is

used, with only volts measured,

NOTE: The SIG wire must be connected

to the small screw (kelvin connection) on

the shunt, not the larger bolt which

connects to the battery. If not, "amps"

measurements will be inaccurate.

connect asshown atright.)

G1

SIG

G2

BATTERY

12 TO 48V

SHUNT: 50 MV/500 AMP

SYSTEM

amps, % full.

Measure volts,

OR 100 MV/100 AMP

battery monitor panel.

Back view of

FOR SAFETY: Place a

1 amp (fast blow) fuse

in series with the + wire

near the battery, as

shown. That way, if

there is ever a short

between this wire and

the other wires, you

won't melt down the

wires, you will only blow

the fuse. ALSO

protects the meter if

accidentally miswired.

FIGURE 2: TM-2030 TriMetric Battery Monitor Connections

8

USER GUIDE

1. Overview of TM-2030-RV or TM2030-A battery system monitor

2. Basic instructions for Operating Level L1

2.1 More details on the five less used display items

2.2 What are Battery Reminders?

2.3 Who might want to use operational level L2, L3 or L4?

IMPORTANT! Be sure that the installer of this meter has

installed the two required parameters (P1 and P3) into this meter

suitable for your batteries, otherwise this meter will not give

correct data on “Battery % full” and “days since charged”

Additional information and reference

3. Beyond Beginners: Instructions for Operating Levels L2, L3 L4.

4. History Data Available with the TM-2030

5. Summary of Programming instructions

6. Reference section

6.1. Specifications

6.2 How the TriMetric keeps track of Battery % full

6.3. What History data can tell you about your system.

6.4 Further description of each programming function

Bonus information on battery care

7. Important information on how to keep from killing your batteries.

BOGART ENGINEERING

www.bogartengineering.com

9

1. Overview of TM-2030-RV and TM-2030-A battery system monitor

The TM 2030 is intended to keep you informed about 12V to 48V battery systems, such as ones found in

RV’s or off grid homes—which are regularly charged and discharged and use “deep cycle” batteries.

The TM2030 may also be used with the new, optional Bogart Engineering SC-2030 30 amp solar charger.

These two will together allow both flexible and accurate solar charging and comprehensive monitoring

of batteries.

How the TM-2030 can be useful to you;

The “amps” or “watts” display measures the rate of energy going in or out of your batteries so you can

check your charging systems, and also to see how much energy each of your appliances use to help you

conserve energy. The “% Full” display is the most accurate way to keep track of how charged or discharged

your batteries are until battery volts gets really low. When battery volts goes below 11.5 volts, (for 12 volt

systems) the “volts” display can warn that you are near discharge. The "volts" display also lets you discover

if your charger is charging to an optimum voltage, (also see data logging below) which is important for

maximizing your battery life. The “days since charged” display shows how recently the main battery

(system) was fully charged, so if it hasn’t been charged recently you can perform extra charging if necessary

to help maintain the capacity of your batteries. The TM-2030 also measure voltage only of a second battery

set, such as the motor starting battery, or even a solar panel input voltage if desired.

New to the TM-2030: an audible alarm can signal a low battery (to activate see p.4, sec 2.2.3) And a new

display shows Replaced Percentage (rPC): shows how much of the most recent discharge has been

replaced to your batteries during the next day's charging. Ideally this should reach 110% or even more.

Data logging for technical people to diagnose system problems: For each of the last 5 days the daily

maximum battery voltage level, and minimum charging amps is recorded as well as the percent of

overcharge achieved. Many battery companies say proper overcharge is important for battery maintenance.

It also logs for up to five of the most recent charge/discharge cycles: cycle length, charge efficiency,

minimum battery% full and minimum voltage level for each cycle. This is useful diagnostic information

which a technician can use to determine that your whole system is working properly.

Serial data output: For extreme techies only: The TM-2030 also has a serial 0-5V output with streaming “real

time” serial (ASCII) data that could be used to control other electronics. This is described on our website:

www.bogartengineering.com, under “support”, “application notes”, TriMetric 2025.

You may select 4 Operating Levels at which this meter will operate: Level L1, L2 , L3 or L4. It is factory set

to Level L1, the basic level suitable for most users and recommended for starting. Section 2 of this manual

describes the operation for level L1. L2 allows observing Data Logging. Levels L3 and l4 allow additional

functions described page 4: Who might want to use operational level L2 ,L3 or L4.

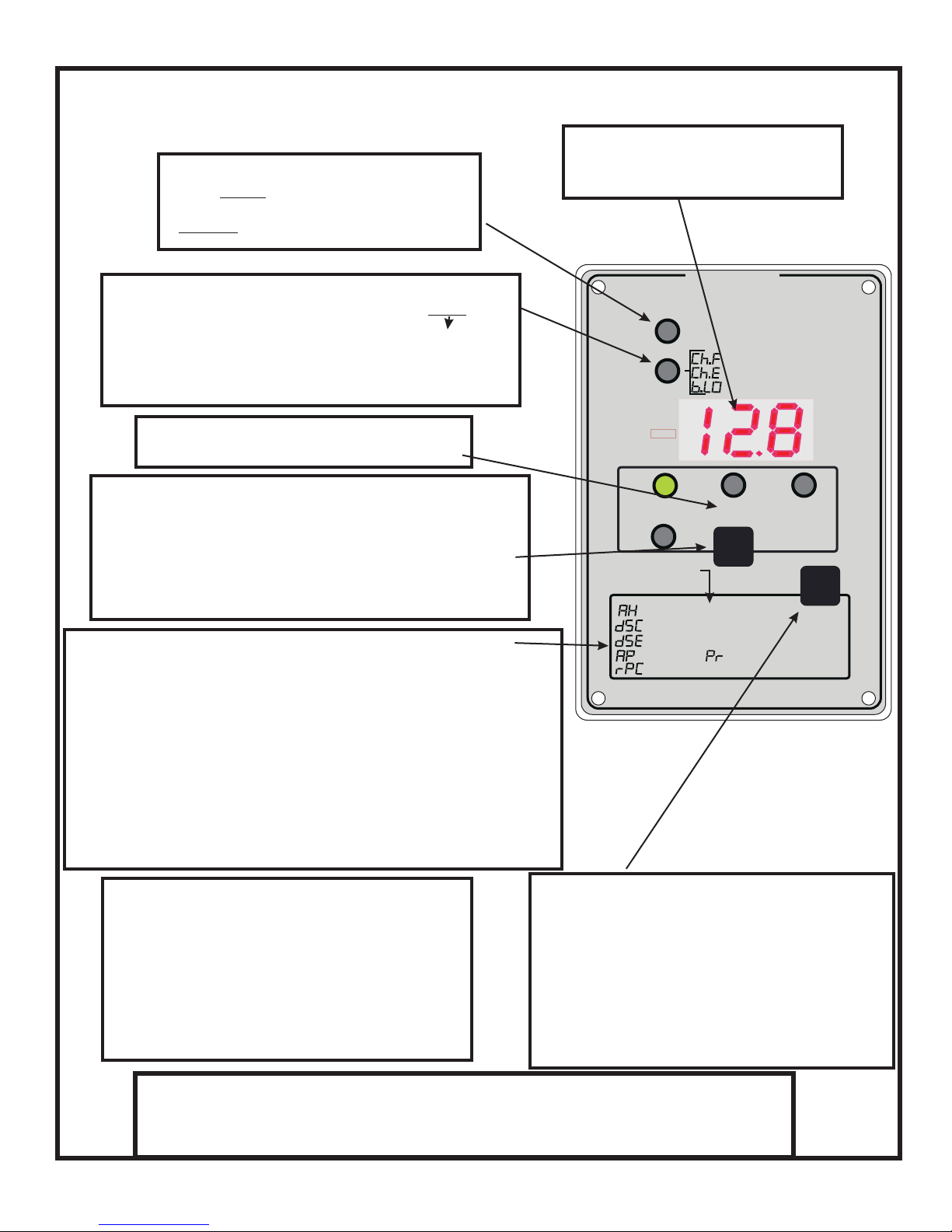

2. Basic instructions for Operating Level L1: Refer to figure 1 which covers basic

operation. It also has references for further information. Note that “% full” will display only 3 dashes until system

is fully charged for the first time.

2.1 More details on the five less used display items (which you may not need to know):

AH This is the measure of Amp hours from a full battery. See section 6.2: How the TriMetric keeps track of

battery % full for a description of how this is measured. This is just another way to look at the "% full" data. For

this number to be accurate you must set Program numbers P1, P2, P3 as described in separate instructions:

“Installer’s Instructions for TriMetric TM-2030.” If you use this meter at Level L3 then also P10 and P14 must be

correct. Continued page 4

CHARGING LIGHT:

When shows “battery 1 is charging”

lighted

(“amps” or “watts” is positive)

Flashing

lamp means battery is charged.

IMPORTANT DISPLAY NOTE:

Flashing decimal point means “multiply

the number seen by 1000”

BATTERY REMINDERS: (optional)

Lamp flashes and display occasionally shows letters

these

when:

battery should be recharged “Ch.F”

or “battery should be equalized” “Ch.E”

or “battery voltage low” “b.LO”

See section 2.2 for details

DO YOU PREFER “AMPS” OR “WATTS” to

show in primary display?

See Table 2, Program P4, to change

TO ACCESS PRIMARY (MOST OFTEN USED) DISPLAYS

Push quickly to make display toggle through:“SELECT”

VOLTS (first battery B2, then battery B1)

AMPS (or WATTS) entering(+) or leaving(-) battery B1

%FULL (for battery 1)

charged fully at least once before this will display.

Battery B1 must be

TO ACCESS SECONDARY (LESS OFTEN USED) DISPLAYS

Push and hold for 3 seconds until " " pops into

display. Immediately release " ". You will see:

AH = Amp-hours discharged from a full battery.

“SELECT” AH

SELECT

Push " " quickly to toggle through:SELECT

dSC= Number of days since the batteries have been fully charged

dSE= days since the batteries have been equalized (if used)Number of

AP Pr

or = Shows amps or watts entering/leaving the batteries

Amps : “ ” or Watts: “ ” (Which one? see table 2, page 7.)

rPC Shows how much energy you’ve replaced of the last discharge

AP Pr P4

See Section 2.1 for more details on these 5 items.

TM 2030-RV

Bogart Engineering

CHARGING

BATTERY

REMINDERS

B1

B2

Hold SELECT 3

seconds to view

Operating and programming instructions at

when flashing-meets "CHARGED" criteria

=TIME TO CHARGE

=TIME TO EQUALIZE

=BATT. VOLTS LOW

VOLTS

AMP-HOURS FROM "FULL"............RESET: to 0Amp-hours

DAYS SINCE "CHARGED"................RESET: to 0 days

DAYS SINCE EQUALIZED................RESET: to 0 days

=AMPS or =WATTS

REPLACED PERCENTAGE FROM LAST DISCHARGE

www.bogartengineering.com/ins

AMPS

SELECT

% FULL

RESET

TO ACCESS PROGRAM OR HISTORY DATA

Hold down and watch for “ ” (Program) or

SELECT P1

“ ”(History) at left in display, then release

H1.1

SELECT

program history

. See sections 5 and 6.4 for details on

data. See sections 4 and 6.3 on

data.

NOT SURE WHERE YOU ARE?

repeatedly until you get back home.

FIGURE 1

RESET

:

The button will reset any of the following:

“Batt% full” (to 100%)

Amp Hours from full (to 0 Ahr)

Days since charged (to 0 days)

Days since equalized (to 0 days)

To RESET any of these:

(1) Use SELECT to view it on display.

(2) Push and hold RESET for 5

Push SELECT

Except

when viewing rPC: hold down to

seconds.

“previous discharge minimum Amp-hours".

TM-2030 Operation Summary

Shows view of TM-2030-RV, but

TM-2030-A operation is identical.

3

RESET view

11

dSC Shows the number of days since the battery has been fully charged. This display gradually increases by 1.00

every day until the battery is charged, at which time this value is automatically reset to 0.00. To understand precisely what

the TriMetric considers “charged”, refer to section 6.2: How the TriMetric keeps track of Battery%Full. For this

number to be correct, Program values P1, P2 and P3 must be correct as described in “Installer’s Instructions for TriMetric

TM-2030.”

dSE Days since the battery was equalized. “Equalization” refers to occasionally overcharging a battery to help it

maintain its capacity. It is usually recommended only for liquid electrolyte lead acid batteries, not AGM or Gel

types. This display is intended to remind you when to equalize your batteries if this is not done automatically by

your charging system. It is essentially just a manual timer, that reads in DAYS, so that you can see how long it

has been since your batteries were equalized. Each day when not reset will advance by 1.00 day. Then it must

be MANUALLY RESET by you when you take action to equalize the batteries. For how to reset this, refer to

Figure 1, in reference to the RESET button.

A or Pr (A shows Amps, Pr shows Watts) This display shows either AMPS or WATTS, depending on what has

been programmed in P4 (see table 2 on page 6). If the primary display shows AMPS then this one will show

WATTS. And vice versa

rPC: "Replaced Percentage of recently discharged energy. (Not the same as % full, above.) This shows the

percentage of charge that is being replaced--compared to the amount that was recently removed during the last

discharge cycle. While discharging this display shows 0. When charging it increases--when it shows 100% it has

replaced the same amp hours that was last removed. To preserve capacity of liquid lead acid batteries it is often

recommended to overcharge to 110-120% before going into "float". For AGM batteries to 103-108%.

While showing “rPC”: hold the RESET button down to view how many amp hours were removed during the

last discharge cycle. This is the “base” on which rPC is calculated. The reason for showin this is that if batteries

were only slightly discharged, then a large percentage showing as rPC could be insignificant. (TM2030 Version

2.2 or higher)

2.2 What are Battery Reminders? This is an optional feature that is designed to help you keep your

batteries maintained, which can remind you to periodically charge your batteries to maximize their life. It comes from

the factory turned OFF. More detailed information about the need for proper charging can be found in section 7 of

these instructions: Important information on how to keep from killing your batteries.

At basic Operating level L1, there are two reminders which you can invoke if you wish:

2.2.1 “Ch.F” (Charge Full) Reminder to charge batteries fully if they haven’t been charged in several days. You

can choose how many days. Lead acid batteries need to be frequently fully charged, otherwise they will lose

capacity. We recommend no longer than about 5 days. (See program P5, table 2). If you set it for 5 days then if

5 days pass without fully charging the batteries the message “Ch.F” will occasionally blink in the display, until

batteries are again fully charged.

2.2.2. “Ch.E” (Charge Equalize) See the end of Section 7 for a discussion of equalization. This display will blink

“Ch.E” as a reminder to equalize batteries, (typically monthly) should you choose to use it. Set the display

interval in days, or turn this feature off by using program P6, see table 2. After you accomplish equalization you

must manually reset the “Days since equalized” number to zero to stop the blinking. First: access the “dSE”

display as described in figure 1. Then use the RESET button. After the equalization period elapses it will blink

again

This function is also used to start equalization with SC-2030 charger. See SC-2030 User’s instructions.)

2.2.3 To activate audible alarm, see P9 and P13 on page 12 (after reading section 5)

2.3 Who might want to use operational level L2, L3 or L4? (See section 3)

Level 2 will allow observing the History data (always being recorded)—see page 5

Level 3 will allow these additional functions:

●Allows addition of the optional Bogart Engineering SC-2030 30 Amp solar charger for your batteries.

●Allows setting up the audible and visual “low battery” alarm. (Table 3, P9 and P13)

●Using a 100A/100mV shunt instead of the more usual 500A/50mV shunt (see Table 3, P11)

●Allow disabling the “automatic reset” when the batteries are charged. (see Table 3, P12)

●Choice of “efficiency factor” different from the default 94% (see Table 3, P10 and Section 6.2)

●Calibrate the battery voltage (see Table 3, P18)

●Allows observation of “filtered” values of volts and amps, used for determining when batteries are

“charged”. (See section 3 and section 6.2, step5, “Level L3 and L4”)

12

3. Beyond beginners: Instructions for Operating levels L2, L3, L4. To

change: see Table 2, program P7.

Level L2 has all the functions of L1, but also allows access to some history information (see below) intended to help technicians

in analyzing systems to see that they are operating properly. Section 4 has a brief description. Section 6.3 has more details.

Level L3 and L4 have all functions of L2, and also adds additional programming functions summarized in Table 3 and detailed

in section 2.3 and 6.4. Also, Level L3 and L4 allow you to observe the “filtered values” of “Volts B1” or “Amps” (which are

extremely sluggish versions of these items) by pushing and holding the RESET button while viewing “VoltsB1” or

“Amps”. The meaning of the filtered values is described in section 6.2, step 5.

The difference between L3 and L4 is that the L4 level raises the requirement for a "charged" battery--beyond the usual

volts/amps requirement.(see Section 6.2 of these instructions). The additional requirement is that the battery must meet the

"float" requirement. defined for the SC-2030 charger described in “SC-2030 Solar Charge Controller User’s Manual”, section

6.5 Primarily useful with the SC-2030 charger. Not recommended unless you understand the “float” requirement.

4. History data available with the TM-2030. Table 1 below summarizes the 36 items of history

data. It is available at Operating Levels L2 , L3 or L4. It is being recorded at level 1, but is only accessible at L2 or higher. These

are useful for a technician to determine if your system is working properly, or to diagnose a battery system problem.

To view the History data: Go to page 16 (last page of these instructions) which describes how to access this data. A chart is

provided there for recording the data.

To understand what this History data can tell you about your system: See section 6.3 on page 9.

The items H2 through H6 refer to data during the last 5 battery “charge/discharge” cycles.*

The items H7 through H9 refer to data during the last 5 days.

*A charge/discharge cycle refers to the time beginning from a fully charged battery, followed by partial

discharge (to less than 98%), and ending when charging it back up to “charged” again. Data is displayed

only when discharge again goes below 98%.

Display

Identifier

No. of

items

Summary History Description

(See section 6.3 for more detailed explanation)

H1 1 Cumulative lifetime battery (discharging) amp hours. Analogous to a car odometer, this

display shows how much wear has occurred on your batteries due to the repeated cycling of

your battery system. Every time you remove energy from your batteries this display

records the amp hours you are taking out, but it does NOT record the charging amp hours

when you charge. In this way it measures the wear caused by the discharging and charging

chemical activity on the battery over its lifetime. RESET to ZERO by pushing and

holding RESET for 4 seconds while displaying this data.

H2.1-2.5

5

For last 5 charge/discharge cycles*: Hours since the end of each cycle.

H3.1-3.5

5

For last 5 charge/discharge cycles*: Length of each cycle, hours.

H4.1-4.5

5

For last 5 charge/discharge cycles*: Charge efficiency measurement: Shows how much

more amp hours to charge compared to last discharge (in percentage) for entire last

discharge/charge cycle.

H5.1-5.5

5

For last 5 charge/discharge cycles*: Lowest % Full value during each cycle.

H6.1-6.5

5

For last 5 charge/discharge cycles*: Lowest battery voltage for each cycle.

H7.1-7.5

5

For last 5 days: Highest battery (B1) voltage attained for each day

H8.1-8.5

5

For last 5 days: If “highest voltage (H7) was less than “charged voltage setpoint” P1 then

this shows amps value while voltage was highest.

If “highest voltage (H7) exceeded “charged voltage setpoint” P1 then this shows the

lowest amps value during time that voltage was above setpoint.

Purpose: To show how close it got to voltage/amp charged setpoints.

H9.1-9.5

5

For last 5 days: for each day, shows charge percent that was replaced on that day,

compared to the previous lowest discharge.

TABLE 1. See section 6.3 for more discussion of these

13

5. Summary of Programming instructions Program functions applicable for Operating

Level L1 are summarized in Table 2 below. As mentioned above, it is most important that items P1, P2

and P3 (below in Table 1) be correctly programmed for the Battery%Full data to be correct. A step by

step procedure for doing this is described in the “Installer’s Instructions for TriMetric 2030. The additional

functions applicable to level L3 are summarized in Table 3 below. If you need more information than given

in Tables 2 or 3, look at references in section 6.4 of these instructions.

To observe program data follow steps 1 and 2.

To change program data follow additional steps 3 and 4.

(1) HOLD DOWN the SELECT button and watch as the display cycles through several different displays. When

you see P1 in the display, immediately release SELECT. If you don’t release quickly enough, just wait

longer holding down SELECT until you see the P1 again, then release. Then the “Charged” setpoint

voltage (first item shown in table below) will alternate with “P1”, so you can observe its value.

(2) Push SELECT repeatedly to observe programmable data P2, P3, etc, as shown in the left two columns

below. After going through all of these it will go back to observing normal display data. (Volts, Amps, etc.)

(3) If during step 2 you see programmable data that you wish to CHANGE, push both SELECT and RESET

briefly, but firmly at the same time. Three green lamps will flash to indicate that you can now change the

data. Successive pushes to RESET will increase the numbers slowly. Hold RESET down longer to speed up

the change—this will cause data to cycle more quickly through all the possibilities. To make values go

down, you will need to keep increasing until it finally jumps to its lowest value again.

(4) When satisfied with the programmable data, push SELECT to get back into OBSERVE mode. Now either

continue programming as described in step 2, or to get back to regular displays, push SELECT repeatedly.

PROGRAM

MODE

NUMBER

*Used by

SC-2030

charger

PROGRAMMABLE DATA

and ADJUSTMENT RANGE

Factory

value

WHAT IT IS FOR (SUMMARY)

For more information, see Section 6.4

Your

value

*P1

"Charged" setpoint voltage.

10.0 to 65.0 volts

14.3

The TriMetric determines that battery is charged when

actual volts is greater than setpoint voltage, and amps is

less than setpoint amps. When this is true the “charging”

lamp flashes to indicate a full battery. This resets “amp

hours from full” to 0 and “battery % full” to 100%, and the

“Days since charged” to 0 Details see section 6.4

*P2

"Charged" setpoint amps multiplier, in %

0.1 to 10 percent of the value of “battery

capacity,” P3. If P2 value is 02.0, and P3=400,

setpoint amps=2% of 400 =8 amps.

02.0

*P3

"Battery capacity" amp-hours

10 to 10,000 amp hours. Note: flashing decimal

point means “multiply number by 1000”; so 1.02

means 1020 amp hours

220

Enter the battery capacity in amp hours. This setting

influences only the “Battery % full” display numbers and

uses this information to display this % value correctly for

your batteries. Also see section 6.4

P4

WATTS or AMPS choice

Pr= WATTS (“Power”), A=Amps

A

Chooses whether AMPS or WATTS shows up on the

Primary display, just after “B1 volts”. If you choose

AMPS, then WATTS shows on the secondary display. And

vice versa.

P5

Days before "time to recharge" reminder

1-100 days, or OFF

OFF

When "Days since charged" equals or exceeds this number,

the "time to recharge"(Ch.F) reminder will flash

periodically in display. See section 2.2

P6

Days before "time to equalize" reminder.

1-100 days, or OFF.

OFF

When "Days since equalized" exceeds this, the "time to

equalize” (Ch.E) reminder will display. See section 2.2

P7

Chooses Operational level; Choose L1, L2,L3

or L4.

L1

L1 is simplest level. L2=next level: shows historical data

L3 Shows all of L1 and L2 plus additional programming

options. See section 3 for meaning of L4

TABLE 2. Program modes for Operating level “L1” (simplest)

14

PROGRAM

MODE

NUMBER

*Used by

SC-2030

charger

PROGRAMMABLE DATA

and ADJUSTMENT RANGE

Factory

(and L1,L2)

value.

WHAT IT IS FOR (SUMMARY)

Where to find more information.

write your

value here

*P8

Max Allowed Charger Voltage 10.0-65.0V

Used only by SC-2030 charger See SC-2030 instructions

P9

Low Battery Audible Alarm Setpoint

0ff or 1-100 percent

OFF

When not OFF, audible alarm will sound and “battery

reminder” (bLO) will flash when “% full” is less than this

value, or if battery “volts” less than P13 setting.

P10

Assumed efficiency factor

60 to 100 percent

94

When meter calculates amp hours: Discharging always

decreases amp-hrs at 100% rate. When charging increases

amp hours at this specified percent rate. Also see section

6.2 step 4.

P11

Shunt type:

Sh.H = 500A/50mV shunt

Sh.L = 100A/100mV shunt

Sh.H

Shunt type for correct Amps and amp hour values. Also

see section 6.4, P11

P12

Automatic reset

ON

OFF

ON

When “ON”, Batt % full reset to 100, and Amp-hrs reset

to 0 when Charge criteria are met: P1, P2. Also see

section 6.2 Step 3, and section 6.4, P12.

P13

Battery low volts alarm:

10.0-65.0 volts

10.0

When volts is at or lower than this value, “b.LO” flashes

occasionally in display as “battery reminder.” Also

audible alarm occurs when P9 is not “OFF”. Also see

section 2.2.3 and section 6.4, P13. .

*P14

For SC-2030 Charger: sets maximum time

allowed to be in “absorb” before “float”

0.0 – 25.0 hours

0.0

For exact description, see charging profile graphs, near

page 14 of SC-2030 Solar Charge Controller User’s

Manual. . See section 6.2 step 4 and section 6.4, P14.

*P15

For SC-2030 charger: Max. voltage allowed

during." finish charge" stage.

10.0-65.0 volts

Used only by SC-2030 charger. See SC-2030

instructions

*P16

For SC-2030 charger: Float voltage

10.0-65.0 volts

Used only by SC-2030 charger See SC-2030 instructions

P17

Time before daily maximum measurement

will be recorded.

0-23 hours

(N/A)

For history data: H7, H8 and H9 (only): Adjust this to

number of hours after present time that daily measurement

should be recorded. (Usually to occur late at night). Also

see section 6.4, P17.

P18

Voltage calibrate. Set to correct batt voltage

(N/A)

This allows slight adjustment of battery voltage. Use

accurate digital voltmeter and adjust to that value. HOLD

RESET to INCREASE. Push RESET repeatedly to

DECREASE. Also see section 6.4, P18

P19

Program all factory values

Sets all values shown as “Factory values” in this table.

Hold RESET for about 4 seconds to accomplish. Also see

section 6.4, P19

*P20

Percent overcharge before float. 0-20 %

Used only by SC-2030 charger See SC-2030 instructions

*P21

Percent of P3 to which "amps" is limited

during "finish charge". 0-10%

Used only by SC-2030 charger See SC-2030 instructions

*P22

One button auto entry of eight most

important program data. Profiles: 1-31

Allows quick entry of all or most program data, especially

when used with SC-2030 charge controller

TABLE 3. Additional program modes for Operating Level “L3 and L4”

15

6. Reference section: more technical information:

6.1 TM-2030 Specifications

Main battery (B1): Measures Volts, Amps, Watts, Battery % Full, Amp-hours from full, Days since charged, Timer

for days since Equalized. Also data logging (history data) described below.

Secondary Battery (B2) sharing common negative with main battery: Measures volts only

Battery Volts: From 10.0 – 65.0 volts for main battery. From 0.0 to 100 volts on secondary battery. Resolution 0.1 volt.

Accuracy ± 0.3%

Amps charging or discharging: With 500A/50mV shunt: 00.0 to ± 999 Amps, resolution 0.1A. With 100A/100mV shunt

0.00-300 Amps, resolution 0.01 Amp. ±1% ± least significant digit.

Note: Maximum amps is often limited by the shunt capability: maximum current for a typical 500A/50mV shunt is

about ±400A. For a 100A/100mV shunt about ±70 Amps. (Depending on shunt design and ambient temperature)

Watts: ±20,000 Watts. (With 500A shunt: when “Amps” read greater than 10.0, Watts accuracy ±1.5% ± least significant

digit.) When “Amps” value is lower, watts accuracy depends on “amps” resolution accuracy.

Amp-hours: Measurement accuracy: 0.00 to ±80,000 Amp-hours to same accuracy as amps.

Battery % Full: Measurement accuracy ±1%. Also measures overcharge. Typical system accuracy, if batteries are

charged full at least every 5 days : typical ±5%. With “efficiency” set to suggested 94% the Battery % Full

Display will be conservative (i.e. display a little lower than actual).

Meter Power requirement: About 30 mA when display is on and about 16mA when display turned off.

Efficiency factor adjustable: 60-100%

Battery capacity settable 10 to 10,000 Amp-hrs.

Serial Data: 5V output stream with all TriMetric real time data ASCII coded.

Charge criteria defined by: Filtered voltage above Vset. Filtered amps less than Iset. Time greater than Tset, all three

adjustable. (Filtered time constant: 140 seconds). See Section 6.2 for detailed description.

Power Requirement: Power from main battery B1: 9-65V, 32mA with display lighted. 16 mA with display off.

Size: TM-2030-RV: Box is 4-1/4 high x 3 x 1-3/8 inch depth with 1/2 in. mounting tabs top and bottom. (10.8 x 7.6 x 3.5 cm.)

TM-2030-A: 4-1/2 x 4-3/4 panel with circuit board 1-1/8 (max) in. deep. (11.4 x 12.1 x 2.85 cm.)

History data: retained in memory when power turned off

●Cumulative amps discharged during battery lifetime (0-999,000 amp hours) to measure battery wear

for last 5 charge/discharge cycles the following are recorded:

●Hours ago since end of cycle

●Length of cycle (hours)

●Amp hour efficiency factor for each complete cycle (to show charge efficiency of battery system)

●Minimum voltage for each cycle.

●Minimum battery %Full for each cycle

For the last 5 days:

●Maximum voltage each day

●Amps value: intended to show how close to “charged” the battery system got

When maximum voltage greater than charged setpoint volts: shows minimum amps.

When maximum voltage less than charged setpoint volts: shows amps at maximum voltage

●Maximum value percent charge returned compared to most recent discharge

6.2 How the TriMetric keeps track of battery % full. The TriMetric uses

“Capacity (P3)”, “charged setpoint volts (P1) , “charged setpoint amps percentage” (P2) and “efficiency factor”

(P10).

Initially when the TriMetric is first turned on it does not have any way of knowing how full the battery is. The

“battery % full” display will start out blank : “---” Here are the steps it uses to determine the % full

1.First the battery must be initially charged fully. When the TriMetric is charging, there are two choices you can

select for what defines “full charge”:

A: More common choice, if program P7 is in level L1, L2, L3: Two conditions must be met simultaneously:

(1) while charging, the battery voltage must exceed the “Charged setpoint voltage” (which you set by Program

P1.) and (2) the charge current (amps) must decline to below the “Charged setpoint amps” (which percentage

you set by Program P2). Note that filtered versions of “Battery voltage” and “battery amps” are used,

described in step 5, below.

B: Less common choice if program P7 is in level L4: This is typically a higher level standard for “charged”

than when in Levels 1-3. It allows additional requirements for charging time, and degree of overcharge

percentage required. It is possible to use this to define “charged” with or without the SC-2030 connected. The

16

batteries must reach the “float” condition as described in the “SC-2030 Solar Charge Controller User’s

Manual” section 6.5.

2. When the above occurs, the TriMetric then declares the battery “charged” by flashing the “charging” light and

resets the “Days since charged” to 0.

3.When the charging is completed, and the batteries start to discharge again the “Amp hours from full” display is

reset to 0.00, and Battery%Full is reset to 100%. This assumes that the “auto reset” is on—(Program P12), which

is always the case in Level L1 or L2. It may be turned off if desired in Level L3

4. As the battery discharges, the TriMetric “amp hours from full” gradually go negative at a rate depending on the

number of amps, and go positive when charging. For example if the batteries are discharging with “amps” =

minus 10.0, the "amp-hours from full" display gradually decreases by exactly 10.0 for every hour that goes by.

Similarly, when amps are positive 10 amps (charging) the "amp-hours from full" display gradually increases by

almost 10 amps for every hour. The "almost" has to do with "charge efficiency factor" which can be adjusted by

program P10. If the efficiency factor is set to 100%, the amp-hours will go up by exactly 10 per hour , however if

the efficiency factor is 94%, the "amp-hours from full" display goes up by only 94% of 10, or 9.4 amp-hours for

every hour. The purpose of this is to account for the fact that you don't get as many amp-hours out of the battery as

you put in, so that the TriMetric "amp-hours from full" display will give a reading of amp-hours which reasonably

closely estimates how many amp hours have been removed.

5. It was mentioned in step 1 above that filtered values of “volts” and “amps” are used to judge when the batteries

are charged. This means that before using these values they are filtered so as to be only very slowly responsive

versions of “volts” and “amps” are used, so that quick variations of voltage or current don’t give a false “charged”

signal. (They are filtered with a time constant of about 2.4 minutes.) These “filtered” versions can be viewed, if

desired, by putting the TriMetric in Operating Level L3 or L4—when viewing the “volts” or “amps” display you

will see the “filtered” version by holding down on the “RESET” button.

The “battery % full” reading of the TriMetric just puts the “amp hours from full” number in a different form,

which depends on the “amp hours “Capacity” number that has been programmed in to the TriMetric in program

number P3. When the battery is full and the “amp hours from full” value is 0 then the Battery% full will be 100.

When the battery is depleted so that the “amp hours from full” goes to a negative value equal to the “capacity”

programmed in P3 then the Battery% full goes to zero.

6.3 What History data can tell you about your system See the chart on

the last page to see how to access and record this data. As explained in detail at the top of page 16:

There are 9 types of data recorded as “History” data. These are labeled H1 through H9.

1. Use program P7 to put meter in complexity level 2, 3 or 4.

1. Get to history data by holding “SELECT” down until you see H1.1 come into display.

2. Push SELECT button to advance to each of 9 types of data

3. For each data item, (except for item 1.1) push RESET to go back in time, up to 5 days, or 5 cycles.

`H1.1: “Battery Odometer”: Cumulative Lifetime Battery (discharging) Amp hours: Analogous to an odometer

in a car: Displays how many amp-hours you got from the battery system over its lifetime. This number starts at

0 when manually reset which would usually be at the time of initial installation of the batteries. To manually reset to

0: when this value shows in display hold the RESET button down for 5 seconds or so. Whenever the value of amps is

negative (charge is leaving the battery) the display counts "amp-hours" down. It does not record when battery is

charging (amps is positive). It is analogous to a car odometer—rather than miles travelled it shows how much total

energy the batteries have delivered.

Evaluate performance of the batteries and the level of care which they received. In case of power interruption to

the meter you will only lose a maximum of 3 hours of this data--because this data is automatically stored to

non volatile memory every 3 hours. This number can be displayed to -999,000 amp hours, which is longer

than most battery sets would be expected to last. If it approaches this, you should record the value and

manually reset it--since it does not just roll over to zero by itself after 999,999.)

Often battery life of "deep cycle" batteries is rated by the number of discharge cycles they will undergo without

failure--however this usually assumes a fairly complete discharge during each cycle, followed by complete

recharge. The life of deep cycle batteries is increased if the discharge depth is less--in fact the number of

cycles of life is inversely related to the depth of discharge of each cycle--so if you discharge only half the

amount during each "cycle" the battery typically will last about twice as many cycles.

When buying batteries you have a choice whether to double the number of batteries in your battery set—which

will reduce the average cycle depth of discharge to one-half, which should approximately double their number

of cycles. If the number of cycles did actually double there would be no cost benefit since twice the battery size

17

would cost twice as much to replace. (Of course you’d get more days of autonomy.) But in a vehicle it would

add extra weight. This measurement is a way of getting quantitative data on these kinds of questions.

H2-H6: Battery Charge Cycle Data provide answers to these system questions for the last five

charge/discharge cycles: A discharge/charge cycle begins at the time the battery is “fully charged” and ends at the

next “full charge”—a precise definition is given in section 6.2: How the TriMetric keeps track of battery % full.

H2 and H3: Did too many days go between full charges?

H4: System efficiency: Is a reasonable percent of the total charging energy being recovered during

each discharge(80-97%)—not too much or too little?

H5: How deeply are the batteries being discharged?

H6: How low does the battery voltage go?

More detail about what H2-H6 can tell you:

H2.1 through H2.5: (somewhat redundant information to H3) How many hours ago that the cycle in

question ended (H2.1 most recent cycle. H2.5 oldest cycle data).

H3.1 through H3.5: Length of the cycle in question, in hours. This shows how much time goes by between full

battery charges. Frequent charging helps keep them from permanently losing capacity. If solar charging is

used, and the days are sunny, they should charge nearly every day. If times are too long, say over 4 or 5 days

(96-120 hours) in a system that is being significantly discharged every day batteries may not being charged

sufficiently to maintain their capacity—although this could be OK if they are hardly used and mainly on float.

Long times could also mean either that the charger “absorb voltage” or “absorb time” is set wrong, or

that the “charged” setpoints in the TM-2030 programs P1 and P2 may be set incorrectly so that the

charging system cannot reasonably reach them. Then refer to data in H7-H9 (below) to show why.

H4.1 through H4.5: Total charge efficiency over each cycle (records total discharge divided by total charge)

which shows how efficiently the batteries are storing energy for that cycle—which from a theoretical system

efficiency standpoint would be ideal if 100%--but for a real system will be less. If this number is

consistently over 100% that means that the wiring to the shunt is incorrect, (batteries cannot be more than

100% efficient!)—possibly a charging source (possibly solar controller, or chassis ground?) connected to the

negative post of the battery instead of on the load side of the shunt, so the meter is not measuring it. If

unreasonably low, say below 70%, that may also indicate a miswiring—in this case a load that is connected

to the negative post of the battery. Or perhaps the batteries are old and inefficient. Or the charger could be

overcharging the batteries (which could also be damaging batteries—but this may not be significant if batteries

have been recently very lightly used—see “rPC” in section 2.1 page 4). For liquid electrolyte batteries an

average number between 80 and 90 is reasonable. If a higher average, the batteries are getting less than

10% overcharge, which is usually less than optimal for liquid electrolyte batteries. For AGM batteries ideal

could be 92-96% as they do not need as much overcharge. Another cause of an occasional high

percentage is that the temperature has gone down significantly between one full charge and the next. This can

cause the “charge setpoints” to be achieved with a lower state of charge than before—so less energy was able

to be charged. Similarly, an occasional low percentage could result if the temperature has risen at the

batteries, because when warmer they can accept more charge than before when cooler, which will reduce the

apparent efficiency value.

There should be some consistency in the readings. Although the values should ordinarily be less than 100%, as

said they can occasionally be greater than 100% when the temperature of your batteries drops as explained

above. If readings are wildly inconsistent it could be a wiring error, with a source or load that is connected to

the negative side of the battery, (a frequent installer mistake!) instead of on the load side of the shunt. (See

Figure 1 of TM2030 Installation instruction.)

H5.1-through H5.5: Minimum Battery % full during each cycle. This is another check to see how much

usage the batteries are getting, that they are not being run too low between charges.

H6.1 through H6.5: Minimum voltage during each cycle. This can show if the battery voltage is too low

before being recharged. Going below 11.5V or so (12V system) would indicate batteries are nearing their low

limit.

H7, H8, H9 check if proper charging is taking place. Charging data for each of the last 5

days: H7:Maximum charging volts. H8:Minimum charging Amps. H9:Maximum overcharge percentage

18

●Each recorded data represents a 24 hour period that ends at a time of day (or night) that you can determine by

referring to Program 17, on page 13

Purpose of H7, H8 data: The way that the TriMetric determines that the batteries are “charged” (in Level 1, 2 and 3

operation) is to sense that the battery volts exceeded the programmed P1 value, and the charging Amps are less

than the value of P2 times P3 (P2 is expressed as a percentage). The H7 and H8 history data track these values

so you can see, during each 24 hour period, how high the volts actually got, and how low the Amps got—so if

these values were not achieved you can understand why.

The H7 data shows the maximum voltage the batteries were charged on that day. The H8 data shows the

minimum amps that were attained when the voltage was near that maximum (Filtered values of volts and

amps are recorded, as defined in section 6.2.5.) The meter (in Level 1, 2 or 3) will only indicate “charged” on

days when the H7 maximum volts data is equal or greater than the P1 program data—and the H8

“minimum amps” data is less than the product of P2(percent) times P3, so the H7, H8 data allow you to

discover how close these values got, on each of the last 5 days.

Purpose of H9 data: When the meter is in “Level 4” operation, in addition to the above, to sense “charged” it also

requires that the returned percentage of charge exceeds the P20 value. That is what the H9 History data tracks.

Also use the H7 maximum daily voltage data to:

verify that the charge controller or chargers are charging to correct absorb voltage.

verify that sufficient charging is taken place during that day to reach the “absorb” voltage.

Also use the H8 maximum daily voltage data to:

verify that enough charging time occurred to reduce the amps to a satisfactory low value.

Also use H9 to see how much daily overcharge in percent was achieved

verify that sufficient overcharge took place that day (compared with the most recent low charge point) has been

during the day. According to many battery experts, properly charged liquid electrolyte lead acid batteries

should be charged with 110-120% more than the (low) level to which were just previously discharged to ensure

they will not gradually lose capacity. AGM batteries should be charged to 104-109% of previous discharge.

●Technical note: The value recorded for the H8 minimum current data depends on whether the voltage on that day exceeded

the “charged voltage” setpoint programmed in program P1.

If the H7 (maximum filtered voltage) on a particular day is less than the “charged voltage” setpoint :

Then the amps value (for that day) is the (filtered) amps value at the moment that the maximum voltage

occurred.

If the H7 (maximum filtered voltage) on a particular day is greater than the “charged voltage: setpoint:

Then the amps value is the minimum (filtered) amps during the time that the volts exceeded the setpoint

6.4 Further description of each programming function. Instructions for

observing and changing programming items is in section 5

P1 and P2: "Charged" setpoint voltage and "charged" setpoint amps.

Purpose of data: The "charged" voltage (P1) and amp (P2) setpoints provide information the TriMetric uses to

determine when your battery set is "charged". Details are given in section 6.2. The amp setpoint (P2) is now

entered as a percentage of P3, unlike with the TM2020 or TM2025, when the amps were entered directly. So

the actual amps value, below which the batteries need to be charged, is the percentage in P2 times the capacity P3.

About voltage and current "charged" setpoints: Of these two setpoints, the “voltage” setpoint is the most critical,

and the “current” setpoint less so. If you have only low current charging sources you could set the current setpoint to

“OFF”—however both should be used if at least one of your chargers is a high current charging source such as a

generator charger or inverter/charger. More specifics follow.

Choosing “charged setpoint volts”: Section C1 of the “Installers instructions for TriMetric TM2030” has simpler

instructions on determining these parameters. Similar information is given in section 7 of these instructions.

Some technical details: For a 12 V lead acid battery system, the voltage setpoint will usually be between 14.0 and 14.8 volts. Double these

numbers for 24V systems or multiply by 4 for 48V systems. As pointed out in Section 7, your chargers and charge controllers must be set

according to information from the battery manufacturer. Once those are set, the TriMetric voltage setpoint should be 1% or so lower than

the charger settings. If this is done the TriMetric "charging" lamp will begin to flash (as indicated on the top “charging” lamp on the

panel) some time before the charging system decides that the batteries are charged and stops charging your batteries. If you have two or

more chargers, such as solar and generator, both chargers would normally be set to charge to the same voltage, and the TriMetric should be

set with the voltage low enough for either one to reach when the batteries approach full charge.

Choosing the “charged setpoint percentage amps”: IMPORTANT: New for the TM-2030: enter this percentage directly into

program P2 from 1.0 to 10.0%. The method of setting this has been changed from the older TM-2020 or TM-2025. If you have a

generator or other charger that has high charging current capability it becomes important to also set the “charged setpoint amps” in the

TriMetric. This is because a high current charging source can force the battery voltage to rise and meet the “charged voltage” setpoint even

though the batteries are not yet well charged. With such a charger, once the voltage reaches its maximum “bulk voltage” the charging

current (amps) will start out high, then gradually reduce as the batteries become more charged. Proper adjustment of the “current setpoint”

will ensure that the TriMetric will not consider the batteries “charged” until the charging current goes below the setpoint amps. T he lower

you set this value, the more “charged” the battery must be before the TriMetric will declare the battery to be “charged”. To set this value

19

you must know the amp-hour capacity of your battery system which has been set in program P3. We often suggest value for the “current

setpoint” setting that is 2% of C, which is the default setting when the meter is new, where C=battery system capacity in amp-hours that is

programmed in P3. For example if you put =700 amp hours into P3, then a P2 amps setting of 2% would be 2% of 700 = 14 amps. Better

charging would result using 1% of C or even 0.5%, for the battery to be really charged—however this may require more solar time (for

example) than is usually available. If you are in complexity levels L1, L2 or L3, when you enter the current setpoint the TriMetric will

require that simultaneously both the filtered voltage setpoint be equal or exceeded, and the filtered current (amps) value be less than or

equal to the current setpoint before the TriMetric will indicate that the batteries are “charged”. In level L4, further requirements need

be met, as described in the SC-2030 Solar Charger manual. The “filtered” values are very sluggish versions of these parameters—

explained in Section 6.2 step 5. Also, if you are set to complexity level 3 or 4 (using Program P7) you can observe these filtered values of

amps and volts. To do so, when observing either amps or volts, when you hold the reset key down the filtered value will show in the

display.

Usually in float mode? Another possibility we should address is if your charging system stays much of the time in "float" mode, which may

be true for a “line tied” system, or a battery system in an RV that is only occasionally used, with its battery usually connected to a charger

that maintains it at “float” voltage . With a lead-acid liquid electrolyte battery the "float" voltage may be 13.4 volts (for 12V system) For a

system that is usually in “float” mode, the TriMetric voltage setting can be just below 13.4, (or whatever the float voltage is) and the

"amps" setting can be for some low value, such as C90 or so, or to a value which the "amps" would only go below during the "float"

condition. Then the TriMetric will reset only after the "float" condition is attained.

P3: Battery assumed capacity. This is the basis for calculating the Battery % full number. The Battery % Full is

calculated as = (Capacity – AmpHoursFromFull) ÷ (Capacity), expressed as a percentage. The Capacity (in amp hours) is