Page 1

Air Operated Priming System

AirPrime™

Operation and Installation Guide

™

All AirPrime Models

Automatic

Controls

Lift Gauge Option u

AirPrime Pressure Regulator

For use with high pressure SCBA cylinders

q Standard Control

Manual

Controls

t Lift Gauge Option

Standard Control q

AIRPOWER

™

™

™

SC

Self Contained Priming System

1901

™

SC

Self Contained Priming System

1906

™

Page 2

AirPrime™ Fire Pump Priming System

Contents

Available Models ��������������������������������������������������������������������������������������������������������������������������������������������������������������������2

AirPrime™ Overview ��������������������������������������������������������������������������������������������������������������������������������������������������������������2

AirPrime™ - How Does It Work ����������������������������������������������������������������������������������������������������������������������������������������������3

Installer Responsibilities ��������������������������������������������������������������������������������������������������������������������������������������������������������� 4

Air Schematic, PPV, Air Hose and Connections ���������������������������������������������������������������������������������������������������������������������5

Automatic Single Location AirPrime™ System ���������������������������������������������������������������������������������������������������������������������� 6

Automatic Single Location AirPrime™ System with Optional Vacuum Gauge ����������������������������������������������������������������������7

Manual Single Location AirPrime™ Systems ������������������������������������������������������������������������������������������������������������������������� 8

Multi Location Installation and Operating Instructions ����������������������������������������������������������������������������������������������������������� 9

Multi Location Automatic AirPrime™ System Diagram �������������������������������������������������������������������������������������������������������� 10

Multi Location Manual AirPrime™ System Diagram ������������������������������������������������������������������������������������������������������������11

Trouble Shooting Guide ��������������������������������������������������������������������������������������������������������������������������������������������������������12

Trouble Shooting Guide (Continued) ������������������������������������������������������������������������������������������������������������������������������������13

AirPrime™ Industrial and SC Systems ��������������������������������������������������������������������������������������������������������������������������������� 13

Annual Primer Testing �����������������������������������������������������������������������������������������������������������������������������������������������������������14

Warranty and Product Information ���������������������������������������������������������������������������������������������������������������������������������������15

Repair/Replacement Parts ���������������������������������������������������������������������������������������������������������������������������������������������������16

™

Available Models

Automatic Control

Automatic Base Model

Automatic Base Model with Lift Gauge

Automatic Multi Location

Automatic Multi Location with Lift Gauge

Manual Control

Manual Base Model

Manual Base Model with Lift Gauge

Manual Multi Location

Manual Multi Location with Lift Gauge

AirPrime™ Overview

Trident has several AirPrime models to meet your specic

operational requirements.

Base Models: All models available in 2 or 3 barrel design

(depending on your water pump capacity and chassis air

compressor size CFM).

Direct Mount: Models bolt directly to a Hale Q Model midship

pump’s priming port with two bolts. The Hale pump model name

must begin with a Q. e.g. Qmax.

Remote Mount: This type can be used with any pump, have a

3

⁄4" female NPT connection and require a simple bracket to hold the

unit to the frame.

Multi-Location: Priming from multiple locations.

Variations and Options:

1. The AirPrime is available in either manual and automatic single

location models.

1. Multi-Location AirPrime is available in manual or automatic

models.

2. Automatic versions are available in 12 and 24 Volt models.

3. Lift Gauge which indicates how much vacuum (in feet-ofwater) the primer is creating to prime the pump.

4. Conversion Kits for Manual to Automatic and for adding more

locations are available. Refer to Page 16.

5. AirPrime is also available for small trucks without air brakes.

See Page 5 for additional information.

Trident Emergency Products, LLC

2

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

For more information on all available models please visit:

www.TridentDirect.com or www.TridentAutoAirPrime.com

Page 3

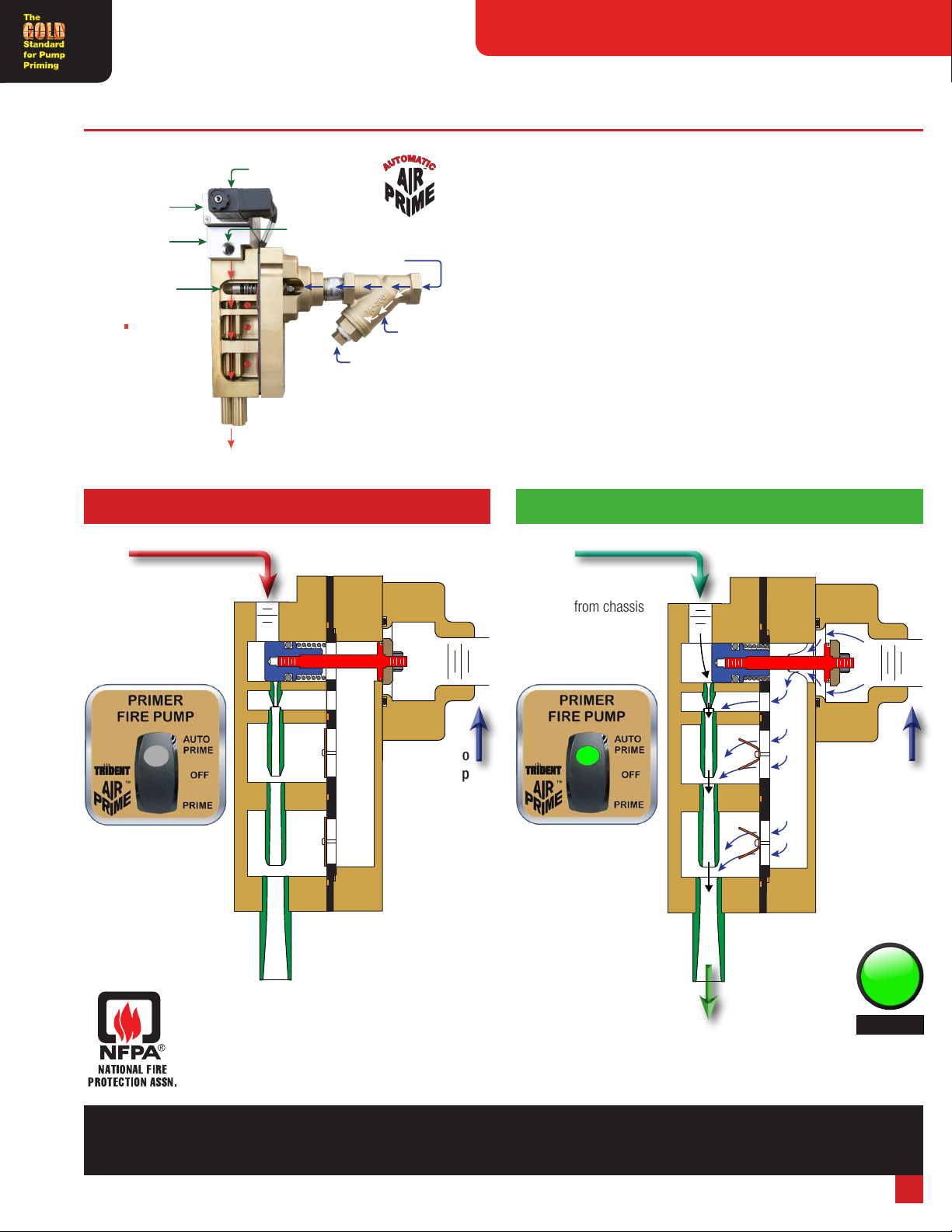

AirPrime™ - How Does It Work

Installation and Operation Guide

Air In

From Chassis

Air Brake

System

Manifold

Piston Valve

Opens With

Air Pressure

Orange Arrows…

Air Flows Through

The Primer Body In 3

Stages for Maximum

Flow and Vacuum.

The Venturi Action

Creates the Vacuum

to Prime the Pump.

Incoming Air Flow OFF.

Air supply from chassis

brake system is OFF.

Control Solenoid

Used For Additional Priming

Points To Be Pre-Primed

1

2

3

Discharged Air Out

Vacuum Inlet from

Priming Points

White Arrows

Indicate Debris

Into Strainer Area

Strainer Cleanout

1

⁄4" NPT Air Supply Inlet

How Does It Work?

AirPrime utilizes air supplied from the chassis air brake

compressor to operate the re pump primer� This is

proven to be far more efcient and reliable than electric

motor driven rotary vane primers�

AirPrime virtually eliminates the impact load on the

electrical system improving vehicle reliability�

AirPrime also improves performance in the elapsed time

for establishing water supply resulting in improved re

ground operations and safety�

Auto Prime Move Switch to the upper position� The

Green LED light will illuminate� The primer will activate

when the OK TO PUMP light is ON and the Pump

Pressure is below 20 PSIG�

The Auto Mode only operates when the re pump is

engaged�

Auto Prime PositionOff Position

Incoming Air Flow OPEN.

1

⁄4" NPT Air Supply Inlet

Air supply from chassis

brake system is ON.

Air enters and activates

primer.

To

Primer switch shown

in OFF position. LED

indicator light is OFF.

Switch will illuminate

when in AUTO PRIME

position.

Water Pump

Priming Point

Primer switch shown in

AUTO PRIME position.

Green LED indicator light

is ON.

1. Press switch DOWN

and hold for Manual

Water Pump

Priming Point

Prime.

2. Press switch UP for

AUTO PRIME.

3. Center position is OFF.

Discharged Air

NFPA #1901 and #1906 – Fully Compliant to Standards

Pump Panel Noise Level – Lowest dB in the Industry

AirPrime Primers can be used for both New and Retro-Fit installations. In Retro-Fit scenarios, AirPrime may be used to augment the

existing primer or as a complete replacement. Automatic AirPrime models provide instant re-priming of the pump when required.

An existing rotary vane primer can be upgraded to an Automatic Primer by adding a single location Auto AirPrime.

( 215-293-0700 7 215-293-0701

sales@tridentdirect.com

To

OK TO PUMP

3

Page 4

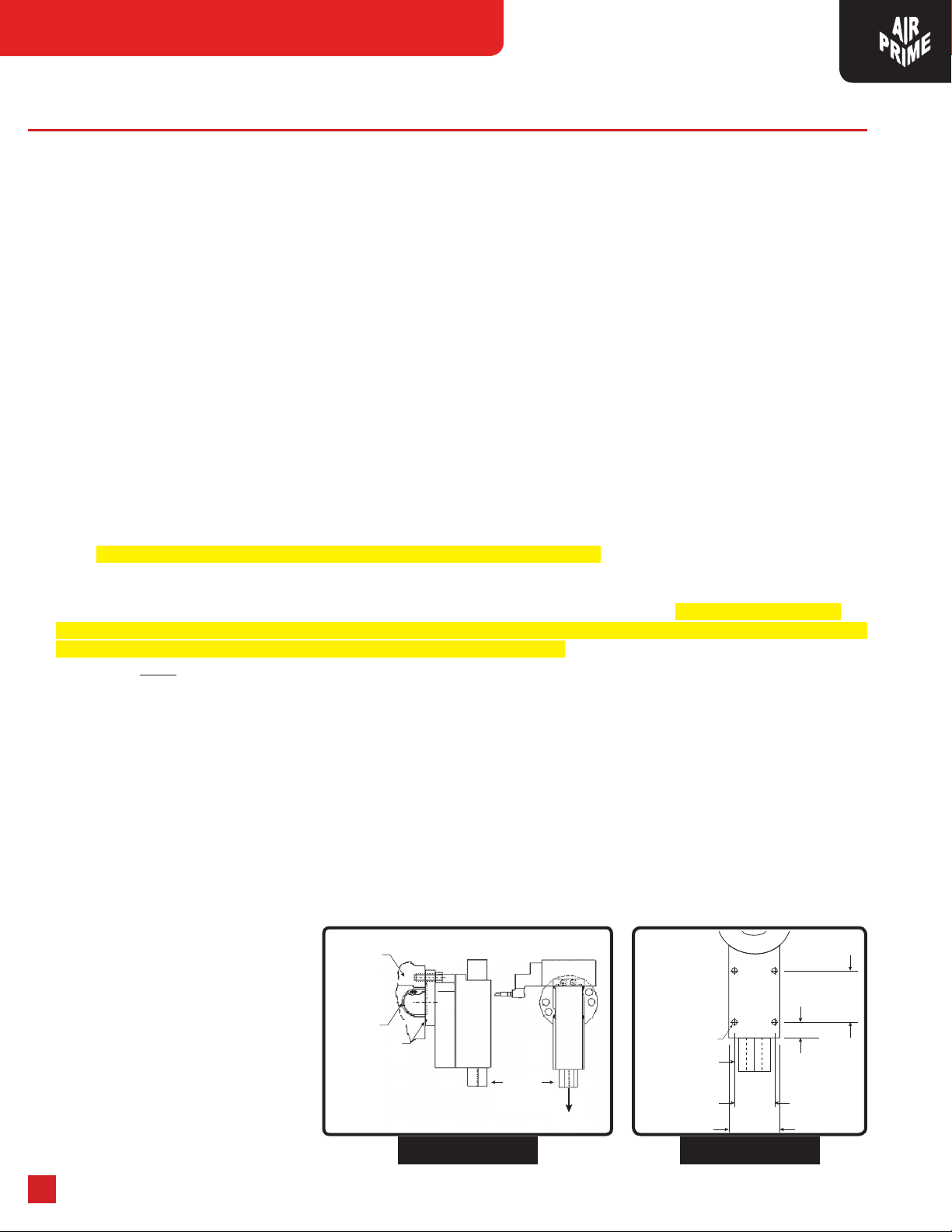

AirPrime™ Fire Pump Priming System

1.563"

2.00"

2.00"

.625"

(4) Mounting Holes

1/4"-20TPI x 5/8" Deep

Primer

Outlet

Primer Body

Mounting Template

Pump

Body

O-Ring

Hale

Black

Plastic

Strainer

Primer

Outlet

Hale Direct Mounting

Installer Responsibilities

Air Compressor Size

1. The 2-barrel AirPrime must be used only on re pumps rated 1000 GPM [3800LPM] and less. The chassis shall be equipped with a

minimum of 13.2 CFM [0. 3 74 Cubic Meters per Minute] air compressor.

2. The 3-barrel AirPrime must be used only on re pumps rated 1250 GPM [4700LPM] and more. The chassis shall be equipped with a

minimum of 15.6 CFM [0.442 Cubic Meters per Minute] air compressor.

3. For Industrial Pumpers The Dual Unit requires an air compressor with greater than 20 CFM [6.09 Cubic Meters per Minute] capacity. The

Triple Unit requires an air compressor with greater than 30 CFM [ 9.14 Cubic Meters per Minute] capacity.

NOTE: For operations above 4000 feet [1219 meters] of elevation and lifts greater than 15 feet [4.5 meters], a minimum air compressor size

of 18 CFM [0.510 Cubic Meters per Minute] or larger is required.

Basic Materials Supplied by Installer

1. A 3/8"OD (.251 ID) air hose from the air tank (primary or auxiliary tank) with 1/4" NPT connections (length determined by installer).

2. Primer mounting bracket. (Only required for remote mount.) See Figure #2.

3. Non-collapsible 3/4" minimum inside diameter (ID) air hose from primer to re pump with 3/4" NPT connections.

4. A Pressure Protection Valve (PPV) (Optionally available from Trident, Part # 30.053.0).

5. A 1-1/4" [32 mm] inside diameter hose may be connected to the primer outlet using a hose clamp to secure it in place. NOTE: Loosely

tighten this hose clamp to avoid damage to the primer discharge ports. This hose can direct the water that is discharged from the

primer to any convenient location under the vehicle. Be sure this hose is properly secured, kept as short as possible, free of any kinks,

sharp bends and pitched to allow drainage.

6. Liquid thread sealant or Teon tape is required for all threaded pneumatic ttings.

NOTE: Use sparingly while applying sealant to avoid blockage of the internal mesh air lter. See Page 5, Figure #5.

™

Remote Primer Mounting

1. An installer supplied primer bracket shall be installed to secure the primer within the pump enclosure. The mounting height for all

priming components must be ABOVE the highest priming point on suction side of re pump (or above the highest remote priming valve

for multiple location systems) to permit air removal and allow for complete drainage. See Figure #2 for mounting bolt hole template.

NOTE: Primer MUST be mounted VERTICALLY with the Primer Outlet discharge (round) ports facing downward as shown in Figure #1.

2. Hose from the 3/4" NPT cleanable wye strainer on the primer inlet to the 3/4" NPT re pump priming port shall be non-collapsible 3/4"

minimum inside diameter.

3. The AirPrime and attached wye strainer shall be installed in an accessible location for serviceability per Figure #3 on Page 5. The

installer may choose from one of the options below as a method of draining the strainer:

a) Remove threaded plug on wye strainer for draining during annual pump service. Refer to Page 13 for Troubleshooting Guide.

b) For draining purposes, the strainer may be piped to the Master Drain of the re pump system by the installer, especially helpful in

climates with freezing conditions.

c) Alternatively a separate drain with valve and label may be piped to the bottom of the pump enclosure by the installer.

NOTE: If a front suction inlet is provided, a REMOTE PRIMER mounting is required. Refer to drawings of front suction plumbing on Pages 11

and 12.

Primer Mounting

Figure #1 illustrates the proper mounting

of the primer to a Hale Q Series cross-frame

midship re pump. Use the black plastic

strainer provided with the re pump from

Hale.

Figure #2 shows the dimensions for the

tapped holes in the primer body.

Trident Emergency Products, LLC

4

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

Figure 2Figure 1

Page 5

Air Schematic, PPV, Air Hose and Connections

3/4" NPT

Hose

Strainer

Inlet Strainer Mounting

™

Primer Outlet

Point

Straight

Down

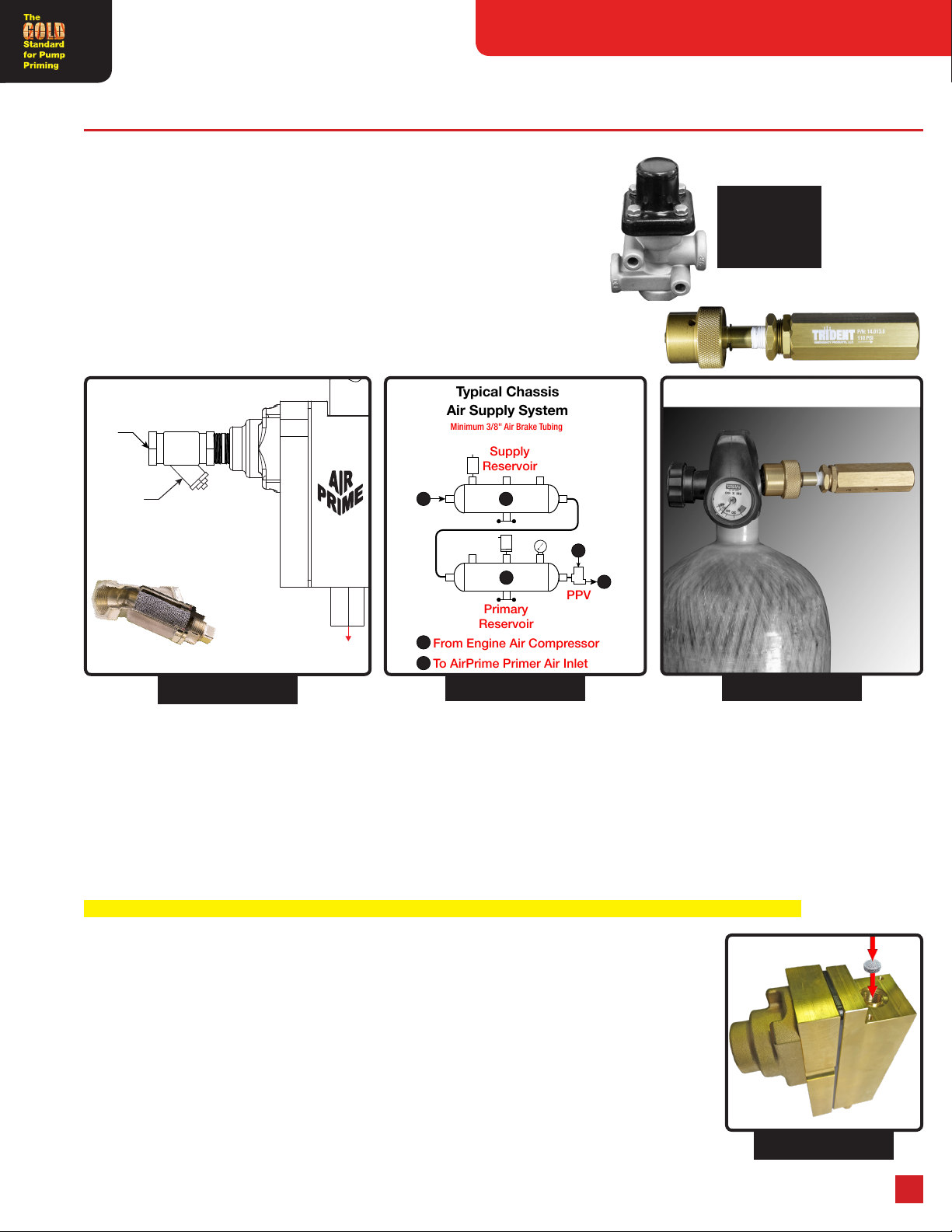

Typical Chassis

Air Supply System

From Engine Air Compressor

Primary

Reservoir

PPV

Supply

Reservoir

Minimum 3/8" Air Brake Tubing

To AirPrime Primer Air Inlet

Air Supply Schematic

The AirPrime must be connected to the vehicle’s air brake system exactly as shown

in Figure 4 below. The schematic below is typical for most trucks built today.

1. Air compressor supply is shown as .

2. Supply reservoir (wet tank) is shown as .

3. Primary reservoir (typically for the rear brakes) is shown as .

4. Pressure Protection Valve (PPV) is shown as and in photo at right.

5. Figure a shows a customer supplied SCBA Cylinder used with the Trident

Pressure Regulator for use on trucks without airbrakes.

The regulator is available separately as Part #14.013.0.

Installation and Operation Guide

PPV

#30.053.0

Sold Separately

Alternate Air Supply and Regulator

Figure 3

1 2

3

1

5

Figure 4

4

5

Figure 4a

Air Supply, Hose and Connections

The air source used to supply the AirPrime shall be from the primary air reservoir in Figure #4 or a secondary air reservoir (normally

used for air horns, air accessories or re pump shifting system).

The supply line from the Pressure Protection Valve (PPV) in Figure #4 to the primer control should be a minimum size of 3/8" OD air

brake tubing and connected at both ends with 1/4" NPT ttings (connections and tubing must be rated for air brake service). The tubing

should be kept as short as possible, secured at regular intervals, free of any kinks or bends and must not be run near exhaust pipes

(Stay 6" [150 mm] away from any exhaust or hot components), mufer, or rotating shafts. Use grommets to protect the tubing lines from

contacting sharp edges at hole locations.

When the length of tubing required exceeds 20 feet [ 6.1 m] , a minimum size of 1/2” OD air brake tubing should be used.

Pressure Protection Valve (PPV)

The Pressure Protection Valve (4) is not supplied with the basic primer kit. A Trident PPV, Part #30.053.0

may be purchased separately, a Bendix PPV, Style PR-4, Part #288323 or its equivalent may be used.

The PPV valve must be installed per Figure #4 between the primary air supply reservoir and the

AirPrime primer air inlet. The valve protects the air brake system from any leaks that may occur in the

primer control or the line from the PPV to the primer control. The pressure setting for the PPV is 80 PSIG

maximum.

Air Filter Port

This cleanable porous lter is located inside the top of the primer body, below the threaded area on the

air supply connection or solenoid connection. See Figure #5.

A replacement lter is available as Part #21.002.0. When replacing, the domed side faces up.

Figure 5

( 215-293-0700 7 215-293-0701

sales@tridentdirect.com

5

Page 6

AirPrime™ Fire Pump Priming System

2.00"

Panel Cutout Dimensions

.281" Diameter

1.00"

1.00"

1.50"

3.22"

1.125"

3.22

™

Automatic Single Location AirPrime™ System

Installation

1. Install the AirPrime unit within pump enclosure. Unit must be VERTICALLY mounted ABOVE the highest priming point in suction piping.

2. Install 3/8" OD air hose piping from the Pressure Protected (PPV) air tank to the primer solenoid (See Figure #7).

3. Install the rocker switch electric primer control on pump panel (See Figure #8).

4. Install the pump pressure switch in a 1/4" NPT pressure opening on the top of the re pump.

Install switch in a vertical orientation and in a position that allows for proper drainage (See Figure #6).

5. Install the Automatic AirPrime wiring harness as follows: (See Page 7 and Figures 10, 11, 12)

Gray 5-prong plug to rocker switch control in pump panel bezel, and connect 6" pigtail to wiring harness

5a

(gray plug).

White wire to the OK TO PUMP light circuit or to re pump shift control circuit (PTO or split shaft)

5b

(1-1/2 feet long) [.5 m].

Red (+) and Black (-) wires to power supply (1 foot long) (Wiring and 1 amp fuse by installer).

5c

Plug in to AirPrime solenoid connection (5 feet of cable) [1.8 m].

5d

5e

Plug in to re pump discharge pressure switch (5 feet of cable) [1.8 m] (See Figure #6).

Figure 6

™

3/8" Air Hose

Solenoid

Air Supply

Pressure

Protection

Valve

Figure 7

Figure 8

Operation: Automatic Priming Control

AUTO PRIME Mode (Top Position)

1. Normally, leave the AirPrime rocker switch in AUTO PRIME mode.

2. If drafting, connect all suction hoses, strainer, and tighten accordingly. Utilize wheel chocks. In cab: Apply parking brake, Engage

pump per manufacturers recommendations (AirPrime will start priming automatically when the pump is engaged). NOTE: Never run a

re pump dry for more than 45 seconds.

3. Pump Panel: Verify that the green OK TO PUMP light is ON and then increase RPM. When the discharge pressure increases above 20

PSIG [1.4 Bar] the primer will disengage. When master gauge indicates greater than 20 PSIG [1.4 Bar] pressure, the discharges can be

opened and pumping operations established.

4. Automatic Operation: If the pump prime is lost, AirPrime will automatically start and re-prime the re pump. It will automatically turn

off when the pump pressure reaches 20 PSIG [1.4 Bar].

OFF Mode (Center Position)

1. Disengages the AirPrime pump primer at all times.

PRIME Mode (Lower Position)

1. Push and Hold the momentary switch for manual engagement of the primer at any time.

2. For Operation: Properly engage the re pump, verify that the green OK TO PUMP light is on, advance the throttle to 1000 RPM, push

and hold the AirPrime momentary switch until pump is primed, open discharges slowly. Rocker switch can be changed to AUTO mode

at any time.

3. The manual mode can be used without having the re pump engaged for vacuum testing or training on the primer system.

Trident Emergency Products, LLC

6

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

Page 7

Installation and Operation Guide

Automatic Single Location AirPrime™ System with Optional Vacuum Gauge

Installation

1. Install AirPrime primer within pump enclosure. Unit must be VERTICALLY mounted ABOVE the highest priming point in suction piping.

2. Install 3/8" OD air hose piping from the PPV valve protected air tank to the primer.

3. Install the rocker switch electric primer control with lift gauge on the pump panel (See Figure #9).

4. Install the pump pressure switch in a 1/4" NPT pressure opening on the top of the re pump (See Figure #6 on Page 6).

5. Install the Automatic AirPrime wiring harness as follows (See Figures 10, 11, 12):

5a

Gray 5-prong plug to rocker switch control in pump panel bezel, and connect 6" pigtail to wiring harness (gray plug).

White wire to Hot (+) Side of OK TO PUMP light circuit or to re pump shift control circuit (PTO or split shaft) (1.5 feet long) [.5 m].

5b

Red (+) and Black (-) wires to power supply (1 foot long) (wiring and 1 amp fuse by installer).

5c

Plug in to AirPrime solenoid connection, 5 feet of cable [1.8 m].

5d

Plug in to re pump discharge pressure switch, 5 feet of cable [1.8 m] (See Figure #6 on Page 6).

5e

6. Connect a 1/4" OD [6.35 mm] tubing line (Not supplied) from the push-to-connect tting supplied on the back of the panel lift gauge to

the 1/8" NPT connection on side of the primer body using the 1/8" male NPT x 1/4" push-to-connect swivel elbow provided with the

AirPrime unit. See photo below.

The lift gauge provides the following features:

a) Indication of the vertical lift of water during priming operation.

b) Lift gauge will not be damaged by positive water pressure supply line.

c) Lift gauge can be used for positive periodic in-service ramp test without having the re pump engaged.

d) Operation is the same as Automatic AirPrime without a lift gauge.

3.22"

2.38"

5.22"

2.50"

1.00"

1.125"

1.00

"

2.00"

Panel Cutout Dimensions

Figure 9

.281" Hole

1.50"

Swivel Connection for

1/4" OD Lift Gauge Tubing

Figure 11

6

™

5a

Part Numbers: #41.001.2 (12V)

#41.001.3 (24V)

5b 5c 5d 5e

Wiring Harness

Part #41.0 01.2

Figure 10

Figure 12

( 215-293-0700 7 215-293-0701

sales@tridentdirect.com

7

Page 8

AirPrime™ Fire Pump Priming System

Manual Single Location AirPrime™ Systems

Installation

1. Install the AirPrime unit VERTICALLY within the pump enclosure. Unit must be mounted ABOVE the highest point in suction piping.

2. Install the manually operated primer push-to-operate air control on pump panel (see Figure #13).

3. Install 3/8" OD air hose piping with 1/4" NPT ttings from the PPV protected air tank to the primer manually operated push-to-operate

control and then to the primer unit. (See Figure #14).

4. If the AirPrime is equipped with an optional lift gauge, connect a 1/4" tubing line from the push-to-connect tting supplied on the back

of the panel lift gauge to the 1/8" NPT connection on side of the primer body using the 1/8" male NPT x 1/4" push-to-connect swivel

elbow provided with the AirPrime unit. (See photo bottom right for tubing connection location).

3.22

™

Panel Cutout

3.22"

1.125"

1.00"

2.00"

.781"

.281" Diameter

Primary Air Supply

Plugged

Opening

Panel

Push

Button

Pressure

Protection

Valve

Filter

Port

™

Figure 13 Figure 14

OPERATION: Manual Priming Control

The manual AirPrime pump primer is operated simply by increasing the engine speed to a maximum of 1000 RPM and depressing the push

button on the panel. Hold the button down until the discharge pressure gauge begins to rise. The primer will stop running when the push

button is released. The push button will operate the primer regardless of whether the re pump is engaged or not.

1. Depressing the Push-To-Prime button directs air to the primer inlet.

2. An internal valve to the water pump is opened with air pressure from chassis air system.

3. Vacuum for drafting is created by air-ow through multi-stage internal venturi nozzles.

4. The Panel Control Valve has no water, plumbing or electrical lines.

5. Never run a dry pump at engine speeds above 1200 RPM for more than 45 seconds in accordance with re pump manufacturer's

operating instructions.

3.22"

2.38"

5.22"

2.50"

1.125"

Panel Cutout

1.00"

2.00"

Figure 15

Trident Emergency Products, LLC

8

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

.781"

.281" Hole

The lift gauge provides the following features:

a) Visual indication of the vertical lift of water during priming operation.

b) Lift gauge will not be damaged by positive water pressure supply line.

c) Lift gauge can be used for positive periodic in-service ramp test without

pump engagement.

d) Operation is the same as a manual

AirPrime without a lift gauge.

Swivel Connection for

1/4" OD Lift Gauge Tubing

Page 9

Installation and Operation Guide

Multi Location Installation and Operating Instructions

Key Points for All Installations

1. The AirPrime unit MUST be VERTICALLY mounted ABOVE the highest point in suction piping.

2. Remote Priming Valves MUST be mounted ABOVE the highest priming point in the suction plumbing.

3. If the RPV priming valve is mounted below the AirPrime unit, add drain lines from all low points to a drain valve to prevent freezing.

4. It is common to have up to four (4) remote locations with the AirPrime Multi-Location priming system.

5. If front suction pre-priming is required, refer to drawings on the bottom Pages 11 and 12 for installation recommendations.

Installation Notes for Multi-Location Priming Systems

1. Automatic System: Follow the instructions on Page 6 and Page 7 with lift gauge for mounting the rst control on the pump panel.

2. Automatic System: Refer to schematics in Figur e 17 on Page 11 for air lines, electric wiring and suction plumbing.

3. Automatic AirPrime Connections: See Figure 7 on Page 6 and information on Page 5.

4. Manual System: Follow the instructions on Page 8 for mounting the rst control on the pump panel.

5. Manual System: Refer to schematics in Figure 16 on Page 10 for air lines, electric wiring, and suction plumbing.

6. For additional priming locations mount a push-button control as shown in Photo 5.

7. Gold labels are provided for LEFT, RIGHT, FRONT and REAR remote priming locations as shown in Photo 6.

8. See Photos 3 and 4 to note that the cast in arrows on the RPVs and Check Valves are in the proper direction of ow.

Operating Instructions for Multi-Location Automatic Priming System

1. See operating instructions for automatic priming system on Page 6 for the initial re pump priming procedures.

2. Be sure the AirPrime switch is in the AU TOMATIC position when opening the remote location valve control.

3. To pre-prime a remote location, push the PRIME button of that location for 45 seconds or until water appears at top of hose.

Operating Instructions for Multi-Location Manual Priming System

1. See operating instructions for manual priming system on Page 8 for the initial re pump priming procedures.

2. To pre-prime a remote location, push the manual button for that location for 45 seconds or until water appears at top of hose.

3. Be prepared to push the Fire Pump manual AirPrime Push-To-Prime button when remote location valve control is opened to remove

any trapped air.

Multi-Location Components

1. Primer solenoid and Multi Location air inlets are shown below in Photos 1 and 2.

2. RPV Valve and Air Check Valve noted with directional arrows as shown below in Photos 3 and 4.

3. Additional pre-priming panel control and choice of appropriate labels shown in Photo 5 and 6.

Solenoid

Air Supply

Connection

Front View of

AirPrime Pump

Additional

Air Inlets

Plug the

Unused Ports

Air Flow

1 2 3

Flow

Direction

4 5 6

( 215-293-0700 7 215-293-0701

sales@tridentdirect.com

9

Page 10

AirPrime™ Fire Pump Priming System

™

™

Multi Location Automatic AirPrime™ System Diagram

™

Jumper

Wiring

Harness

Drawing Denotes Two (2) Additional

Multi-location Priming Points.

Connect to

"Pump Engaged"

Light Circuit

Panel Switch

Automatic

AirPrime

Compressed

Air In

1/4" Tubing (Minimum)

3/8" Tubing (Min)

Closed Position

Panel

Intake #2

Valve

Out

3/8" Tubing (Min)

In

Open

Connect to

Center Port

3/8" Tubing (Minimum)

Check

Valve

Panel

Intake #3

Valve

Check

Valve

3/8" Tubing (Minimum)

of Solenoid Valve

Up to 4 Ports

are Available

for Air Inlets

Part #

41.003.0

Top View of AirPrime Pump

Shown for Electrical Wiring

41.001.0 Wire Harness

Pressure Switch, Pump Discharge

41.003.0 Jumper Wire Harness

(See photo inset, lower left corner)

Strainer

3/4" Tubing (Minimum)

Plumb to Drain Valve

Color Key

Electric Lines

Air Supply Lines

Vacuum Priming Lines

Multi Location Wiring Harness

Leave Open

for vent.

Use one of these ports

for Green Air Supply line.

Plug the unused 1/8" NPT Port.

Mufers

3/4" Tubing (Minimum)

From

Main Pump

Priming Tap

RPV 1 (Remote Priming Valve)

Closed

Main Fire Pump

From

Intake #2

Closed

3/4" Tubing (Minimum)

RPV 2

Priming Tap

From

Intake #3

Open

3/4" Tubing (Minimum)

RPV

Priming Tap

Intake 3

NOTES:

1. More than two valve sets may be ganged in a

similar manner with kit 27.005.1 for each.

2. If priming valve is mounted below AirPrime, add

line(s) from low point(s) to drain valve(s).

Priming

Valve

Closed

5" or 6"

Buttery Valve

By OEM

Color Key

3/4" ID External Flex Line

Trident Emergency Products, LLC

10

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

Merge All "High Point" Pick-ups

At The Valve Location

(Higher Than The "High Points")

3/4" ID External

Flex Tubing

3/4" ID External Flex Line

3/4" ID External

Flex Tubing

Figure 16

Front Axle Area

Through Bumper Installation

Front Suction Plumbing

Highest Point Above Front Axle

Page 11

Multi Location Manual AirPrime™ System Diagram

™

Compressed

Air In

3/8" Tubing (Minimum)

Drawing Denotes One (1)

Additional Priming Location

Installation and Operation Guide

Leave Open

for vent.

Open

3/8" Tubing (Minimum)

Closed

Panel Valve

Fire Pump

Panel Valve

Remote

Check Valve

3/8" Tubing

(Minimum)

1/4" Tubing (Minimum)

Check Valve

3/8" Tubing (Minimum)

Strainer

™

Plumb To

Drain Valve

1/4" Tubing (Minimum)

Color Key

3/4" Tubing (Minimum)

3/4" Tubing (Minimum)

Use one of these ports

for Green Air Supply line.

Plug the unused 1/8" NPT Port.

RPV

Fire Pump

Open

3/4" Tubing (Min)

Closed

3/4" Tubing (Min)

RPV

Remote Location

From

Fire Pump

From

Remote Location

Air Supply Lines

Vacuum Priming Lines

Figure 17

Priming

Valve

Closed

5" or 6"

Buttery Valve

**

By OEM

Color Key

Merge All "High Point" Pickups

At The Valve Location (Higher Than The "High Points")

3/4" ID External Flex Tubing**

3/4" ID External Flex Line to Low Point Drain

1/2" ID Internal Flex Line

3/4" ID External Flex Lines

1/2" or 5/8" ID External Flex Line

3/4" ID External Flex Tubing**

Special Strainer

*

1/2" ID Internal

**

Flexible Tubing

Fittings In Kit From

Outside Of Pipe

*

Front Axle Area

Front Suction Plumbing

To Inside

Priming Line

**

Drain Valve

Highest Point at Front Inlet

Contact Trident for Front Suction Kits.

3/4" Weld Coupling

1/2" or 5/8" ID

External Flexible Tubing

**

**

( 215-293-0700 7 215-293-0701

* Trident Kit Supplied Items

** Installer Supplied Items

Kit Part Numbers

5" NH Kit: #27.011.1

6" NH Kit: #27.011.0

sales@tridentdirect.com

11

Page 12

AirPrime™ Fire Pump Priming System

Trouble Shooting Guide

Problem Likely Cause Corrective Action

• Master Drain Valve Open.

System Does Not

Hold Vacuum.

System Will Not

Reach 22" Hg.

AirPrime Leaks

Water.

Manual System:

Air continues to

ow when button

is released.

Automatic

System: Air

continues to ow

when button is

released.

• Discharge or Intake Valves Open.

• Bleeder or Drain Valves Open.

• Relief Valve Drain Open.

Intake Relief Valve Allowing Air Into

Pump System.

AirPrime Exhaust Outlets Drawing

Back Vacuum.

Inadequate air supply.

Pressure Protection Valve.

Air lter on intake side of air supply

connection to AirPrime body.

For details on lter inspection/

replacement visit/click QR codes at right.

Slight air leak in discharge or intake

valves in re pump plumbing.

Check the interior check valves

inside the primer.

Check the interior primer body

venturi nozzles for foreign material

or blockage.

Defective Primer. Replace or rebuild primer with Kit #27.003.3. See Instructions Here

Check the AirPrime integral priming

valve.

Bad push button manual valve.

Push button air plumbing installed

incorrectly.

Panel switch inoperable.

Air solenoid on top of primer is

defective.

Solenoid is on backwards.

Double check all drains, discharge and intake valves to make sure all are

closed.

a) Adjust intake valve to closed position (be careful to count the number of

turns to close and re-open the same number of turns).

b) Cap the discharge side of the intake relief valve (NPT or NH).

Be sure to remove cap after testing.

The integral priming valve is not closing all the way, air is moving upward into

the barrels, into the pump, as the water falls back into the hard suction hose to

the water level or as vacuum is lost through the re pump system.

a) Check the CFM rating of the engine air compressor. See Page 4.

b) Check air pressure at “supply” side of AirPrime (should be over 70-PSIG/

[3.8 Bar]). Install a tee and air gauge in input for test purposes. If the air

pressure is not the same as the cab dash air pressure gauge, check for

under sized airline, kinks or obstructions in air line, or air line is too long

(under 20 ft [6 m] from primary tank.

Check Pressure Protection Valve air on/off settings (should shut-off in the 60

to 80-PSIG / [4.2 to 5.5 Bar] range) and OPEN no higher than 80-PSIG / [5.5 Bar]

to AirPrime.

a) Manual AirPrime: Remove air supply piping, remove ne mesh lter, clean

or replace. Part#: 21.002.0

b) Automatic AirPrime: Remove air supply piping, remove air solenoid

assembly, remove ne mesh lter, clean or replace. Part #: 21.002.0

Hydrostatic test the plumbing system to NFPA #1901 standard with wet re

pump and closed valves: 250-PSIG [17.2 Bar] for 10 minutes w/ pressure loss.

Remove and disassemble primer to inspect the (3) small rubber check valves

to venturi orices.

Remove and disassemble primer to inspect venturi nozzle openings or clean

with small wire to assure open orices.

a) The priming valve is not seating in the shut-off position: Remove primer,

disassemble, and check the priming valve spring, seat and operation.

b) The priming valve is “stuck”, check for damaged O-Ring or check to see if

piston is fully threaded on the valve stem.

Replace the Push Button with a new valve, Part #27.003.1.

Refer to air schematic drawing, Figure 14 on Page #8 of this manual.

Refer to parts list on Page 16, order replacement switch, Part #27.003.2.

Refer to parts list, order replacement solenoid, Part #30.003.0 (12 Volt) or

#30.003.1 (24 Volt).

Reverse orientation of solenoid on top of manifold. Ports on solenoid and

manifold should be on the same side.

™

Visit www.TridentAutoAirPrime.com for additional AirPrime information.

Trident Emergency Products, LLC

12

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

Page 13

Trouble Shooting Guide (Continued)

Problem Likely Cause Corrective Action

Slow Prime Time.

Leaking air into the

plumbing system.

Low air pressure.

Pressure Protection Valve.

Check wye strainer on

intake from re pump,

could be clogged.

Check Air line to the

AirPrime.

Check discharge and

intake valves.

Check gated Master Intake

Valves on suction intakes.

Check the AirPrime integral

priming valve.

Suction lift too high. Do not attempt lifts exceeding 24 feet.

Blocked suction strainer.

Leaking Suction Hose

connections.

Air Trap in suction line.

Double check all drains, discharge, and intake valves to make sure all are

closed.

Check air pressure at supply side of AirPrime (Should be over 70-PSIG/[3.8

Bar]). Install a tee and air gauge in input for test purposes. If the air pressure

is not the same as the cab dash air pressure gauge, check for an under sized

airline, kinks or obstructions in air line. Or the air line may be too long (Must be

under 20 feet [6 m] from primary tank).

Check Pressure Protection Valve air on/off settings (should shut-off in 60 to

80-PSIG / [4.2 to 5.5 Bar] range) and OPEN no higher than 80-PSIG / [5.5 Bar] to

AirPrime.

Remote primer installation: The line from the re pump to the AirPrime has

a wye type strainer just before connecting into the primer body. Remove the

plug, then strainer, and clean the strainer of debris, reinstall strainer and plug.

a) Direct mount on Hale pump installation: Remove the primer from the Hale Q

re pump, check the black plastic strainer (Supplied by Hale).

The air supply line from the air tank is either kinked, undersized or over length.

Replace air line accordingly (NOTE: Found mainly on new installations).

Cap or plug the discharge and intake valves to prove the valves are not leaking

air into the plumbing system (Hydrostatic pump test is useful for such testing).

a) Remove the MIV and cap intake.

b) Install a cap on the discharge side of the relief valve.

c) Cap the Storz or NH intake.

a) The priming valve is not seating in the shut-off position, remove primer,

disassemble, and check the priming valve spring, seat, and operation.

b) The priming valve is “stuck”, check for damaged O-Ring or check to see

that the piston is still fully threaded on the valve stem.

Remove any obstructions or debris from hose strainer, do not allow suction

hose or strainer to rest on the bottom of water supply.

Clean and tighten all suction hose connections, check hose washers and

replace as necessary.

Suction hose should be positioned with a constant decline to the water supply.

If a trap is unavoidable, repeated priming may be required to eliminate air

pocket.

Installation and Operation Guide

Multi Location Specic

Problem Likely Cause Corrective Action

Trouble Priming

or Pre-Priming

from Locations

Other Than

Pump.

Not priming from highest

suction plumbing point.

Remote Priming Valve

(RPV) not opening.

Water trap in RPV line.

Check suction plumbing elevations, shown on bottom of Pages 10 and 11.

Check for changes in suction high point when truck is drafting on an incline.

Defective RPV, defective panel push button, check system plumbing using

schematics on Page 10 (Automatic) Figure 16 and Page 11 (Manual) Figure 17.

Lines must ascend from highest suction plumbing points to RPV(s) for natural

drainage and to avoid water traps.

AirPrime™ Industrial and SC Systems

AirPrime units are available for high volume Industrial Pumpers/Trailers with engine driven air compressors and small Wildland Trucks

without air brakes. Contact Trident for more information.

( 215-293-0700 7 215-293-0701

sales@tridentdirect.com

13

Page 14

AirPrime™ Fire Pump Priming System

Annual Primer Testing

The AirPrime™ primer is designed to meet the NFPA requirements of: Dry Vacuum (TEST #1) and Priming Time (TEST #2). These tests

should be performed on an annual basis, or whenever major repairs or modications have been made to the re pump, plumbing or primer.

TEST #1 Dry Vacuum Test: Checks the primer’s ability to produce 22 inches (Hg) [.74 5 B a r] of vacuum, and the pump and plumbing’s

ability to hold that vacuum. The test may be run with the pump in gear or not engaged. Never run a dry pump at engine speeds above

1200 RPM. There is no time requirement for the vacuum to reach 22 inches. If the compressor has a capacity of 13.2 CFM [374 cu. cm.

displacement], it can take several minutes to reach 22 inches [.75 Bar]. This time can be shortened by not engaging the pump and increasing

the engine speed to 1200 RPM. The test process is as follows:

1. Drain all water from pump and plumbing.

2. Close all valves and drains. Cap all suction openings and the outlet off of the suction side relief valve (if so equipped).

3. Connect a test vacuum gauge to the intake test gauge connection on the pump panel.

4. Operate the AirPrime with the air system at over 100 PSIG [ 7. 0 B ar ] pressure, air tanks lled to capacity, and at 1000 RPM engine

speed; until the vacuum gauge indicates 22 inches (Hg) [.75 Bar] or more of vacuum. (If the primer is an Automatic AirPrime, use the

PRIME mode switch position to engage the primer).

5. Watch the gauge, if the vacuum falls more than 10 inches in 5 minutes the test has failed and is a certain indication of an air leak(s).

Vacuum leaks may be detected by ear, with the engine turned off. Correct leaks immediately and test the priming system again.

™

TEST #2 Priming Time Test: This test is to prove that the re pump and primer has the capability of attain a prime and creating

discharge water pressure in a set period of time. This test is also conducted by the apparatus builder prior to delivery. The re pump shall

be engaged and primer actuated. The test is part of an annual pump performance test and is performed as follows:

1. Set up the apparatus in accordance with the pumping test outlined in the NFPA standards.

2. Engage the pump, and increase the throttle to a maximum engine speed of 1000 RPM.

3. Operate the AirPrime with the air system at over 100 PSIG [ 7. 0 B ar ] pressure, air tanks lled to capacity, and at 1000 RPM engine

speed.

• For the Manual controlled primer, release the push button when a discharge pressure over 20 PSIG [1.4 Bar] is obtained.

• For the Automatic AirPrime, place the switch in the AUTO position, it will turn the primer off automatically when priming is attained.

4. The time to prime should not exceed 30 seconds for 1250 GPM [4700 LPM] and smaller pumps. The time to prime should not exceed

45 seconds for 1500 GPM [5600 LPM] and larger pumps. An additional 15 seconds is allowed for pumps with auxiliary suctions using

4" or larger piping.

Higher lifts and operating at higher elevations will slow down time to prime. The air compressor rating should be a minimum of 18 CFM

[410 cu. cm. displacement] for elevations over 4000 feet [1200 m] and lifts in excess of 15 feet [4.5 m]. Operation at these extremes may

require the primer to be operated at engine speeds in excess of 1000 RPM without engaging the pump, until water reaches the impeller.

Never run a dry pump at engine speeds above 1200 RPM.

IN-SERVICE OPERATIONAL TEST (Ramp Test)

The integrity and operation can be quickly checked (on a daily or weekly basis) as outlined below, without re pump engagement:

1. Drain all water from pump and plumbing.

2. Close all valves and drains. Cap all suction openings.

• Operate the AirPrime with the air system at over 100 PSIG [7.0 Bar] pressure, air tanks lled to capacity, and the engine running at

1000 RPM (with an Automatic AirPrime electrically controlled model, use the PRIME mode switch position).

3. Stop running the primer.

Time to reach 15 inches HG [.50 Bar] or 17 feet [5.0 m] on lift gauge should be within the time allowed in list below for the pump tested.

Small Body Pump (Up To 1250 GPM): Vacuum Time

10 inches HG [.33 Bar] (11 feet) 6 Seconds

15 inches HG [.50 Bar] (17 feet) 15 Seconds

Large Body Pump (Over 1250 GPM): Vacuum Time

10 inches HG [.33 Bar] (11 feet) 8 Seconds

15 inches HG [.50 Bar] (17 feet) 20 Seconds

Trident Emergency Products, LLC

14

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

Note: Vacuum Time listed in the table at left are for operations up

to 2000 feet [609 m] of elevation. When running this In-Service

Operational Ramp Test at higher elevations, the vacuum should be

reduced by 1 inch (1.13 feet) for each 1000 feet [304 m] of elevation

over 2000 feet [609 m].

Page 15

Warranty and Product Information

Installation and Operation Guide

5 Year Warranty

For ve years after the date of purchase, Trident Emergency

Products, LLC warrants its products to be free from defects in

materials and workmanship when properly installed, operated,

and maintained.

If during the warranty period, a product is discovered to be

defective, Trident will, at its option, replace or repair the warranted product or grant the

purchaser a credit for the product claimed to be defective. Trident will have the sole

discretion to determine whether the product was defective.

This warranty is null and void if the product is damaged due to abuse, misuse,

negligence or accidental causes.

No warranty of merchantability or tness for a particular purpose, nor any warranty,

express or implied, is made by Trident. The foregoing states Trident Emergency Products,

LLC's entire and exclusive liability and buyer's exclusive remedy for any claim or

damages In connection with the sale of its products. In no event shall Trident be liable for

any special incidental, or consequential damages whatsoever.

5

Safety First!!!

Serious Injury and Destruction of Property can result from improper selection or improper use of products

described in this instruction manual. Since TRIDENT has no control over the number and variety of applications

for which its products may be purchased or the conditions under which they may be used, TRIDENT liability on

any claim, whether in contract, tort (including negligence), or otherwise, for any loss or damage shall in no case

exceed the price paid for the product or any part thereof which give rise to claim. As always, TRIDENT technical

assistance and support is available for your convenience.

Ordering

Please use Trident part numbers and descriptions when placing orders.

All orders must be written, E-Mail (sales@tridentdirect.com) or Fax

to (215) 293-0701 or placed online at www.tridentdirect.com.

All orders will be acknowledged by Trident within 2-days and shall

become nal after acknowledgment, if not challenged.

No verbal orders will be accepted.

Terms

1%10-NET30 days on approved credit, or with MC/Visa credit card.

Service charge 1.5% on past due accounts.

Freight

F.O.B. Hatboro, PA, USA. Our responsibility ceases upon delivery to common carrier.

Consignee must le claim for storage and damaged freight with the carrier.

Delivery

Most standard items are shipped in ve business days or less. Consult with customer

service for availability, special threads, or special order products.

Return Policy

No material will be accepted for return without authorization by the factory, and a return

goods authorization number assigned. Materials must be returned prepaid. A 20%

restocking fee normally applies. No material will be accepted for a credit after one year

from the date of purchase.

Custom products and special orders are not returnable.

Warning ‐ User Responsibilities

The customer, installer and end-user shall assume sole responsibility in making the nal selection of products and accessories. Furthermore, these parties shall

hold TRIDENT harmless for all liability, claims, suits and expenses incurred. These parties shall ensure maintenance, safety precautions and warnings regarding

the application are enforced at all times. TRIDENT is not responsible for use of products in excess of rated and recommended capacities, design functions or

abnormal conditions.

Caution ‐ Proper Selection of Accessories

TRIDENT offers a wide variety of accessory items and optional features for its products. It is the sole responsibility of the customer, installer and end users to

ensure that the proper items and features have been selected to t the application.

Warning ‐ Follow Instructions

The customer, installer, and end users shall ensure that all potential users of these products receive continual training and access to all relevant product manuals

and safety instructions. This information should be thoroughly reviewed prior to installation, stored and reviewed continually during use of the product. TRIDENT

assumes no responsibility for tness of installation and continued use in specic applications.

Customer Service Phone (215) 293-0700

We pride ourselves with exceptional customer service and are available to answer questions pertaining to new or existing orders and any of your after the sale

support concerns. If a product needs to be returned, please call and request a Returned Goods Authorization (RGA) number. Warranty claims must be made by

an authorized TRIDENT employee. Be prepared to provide the product model number and purchase invoice number. Replacement parts ordered will be invoiced

to your account. Once an RGA number is received, you must write it on all boxes and paperwork. TRIDENT will not accept your returned goods without an RGA

number. Upon receiving the return, if it is determined to be covered under warranty, a credit memo will be issued and mailed to you for your records.

Note: All designs, specications, and dimensional data contained in this catalog are subject to change without notice. No additional warranties, express or

implied, including warranties of merchantability for tness for a particular purpose, are created by the descriptions and depictions of the products on or in this

catalog. Not responsible for typographical errors.

( 215-293-0700 7 215-293-0701

sales@tridentdirect.com

15

Page 16

Repair/Replacement Parts

4

1 5

a,b

2

3

7

8 9

21.003 .1

10

a,b

6

6

13

a,b

11

14

12

22

23

Air Flow

15

a,b

16

24

a,b

Automatic

AirPrime Parts

17 18

20

19

21

25

26

a,b,c,d

REF # DESCRIPTION PART #

1a

Solenoid Valve 12-Volt 30.003.2

1b

Solenoid Valve 24-Volt 30.003.3

2 Air Filter Replacement for 1/4" NPT Bore 21.002.0

3 Piston 11.00 1.0

4 Valve Stem 05.002.0

5 Seal Washer 04.004.0

6 3/4" Wye Strainer (Replacement Screen: 21.003.1) 21.003.0

7 Rebuild K it (Seals, Mesh Filter, Spring Valve Plate, Fasteners) 27.003.3

8 Pressure Protection Valve ( PPV ) 30.053.0

9 Lift Gauge 14.006.0

10a

Rocker Switch 12-Volt and Label Assembly 27. 00 3. 5

10b

Rocker Switch 24-Volt and Label Assembly 2 7.0 03.6

11 Label Only: Rocker Switch 02.004.2

12 Pressure Switch and Connector 4 0.0 02 .1

13a

Rocker Switch 12-Volt, Label, Mounting Plate, Lift Gauge Assembly 27. 00 3. 7

13b

Rocker Switch 24-Volt, L abel, Mounting Plate, Lift Gauge Assembly 27.0 03.8

14 Label Only: Rocker Switch with Lift Gauge 02.004.4

Manual

AirPrime Parts

REF # DESCRIPTION PART #

15a

Rocker Switch 12-Volt Replacement 40.001.2

15b

Rocker Switch 24-Volt Replacement 40.001.3

16 Wiring Harness for Auto AirPrime 41.001.0

17 Push Button, Label, and Mounting Plate Assembly 27. 00 3.1

18 Label Only: Push Button 02.006.4

19 Push Button Replacement 30.005.3

20 Push Button, Label, Mounting Plate and Lift Gauge Assembly 30.005.4

21 Label Only: Push Button with Lift Gauge 02 .00 6.10

22 Remote Priming Valve (RPV) 30 .0 35 .1

23 1/4" NPT Air C heck Valve 30.012.0

24a

Remote Priming Valve with 12-Volt Solenoid 30 .0 35 .10

24b

Remote Priming Valve with 24-Volt Solenoid 3 0.03 5.11

25 Multi-Location Push-Button w/ Mounting Plate 27.003.9

26a Label Only: Primer Front Intake 02.006.5

26b Label Only: Primer Rear Intake 02.006.6

26c Label Only: Primer Left Side 02.006.7

26d Label Only: Primer Right Side 02.006.8

Multi-Location

AirPrime Parts

AirPrime Conversion Kits and Rebuild Kit

Conversion Kit: Single Lo cation AirP rime Syst em, Conver ts Manual to Automatic 27.014.0

Conver sion Kit: Multi-Location AirPrime System, Converts Manual to Automatic 2 7.01 4.1

Conver sion Kit: Man ual AirP rime Syst em, Conver ts Single (1) Loc ation to Du al (2) Loca tion 27. 005 .2

Conver sion Kit: Aut omatic AirPr ime System, Co nverts S ingle (1) Loc ation to Du al (2) Loca tion 27. 005 .3

Conver sion Kit: Multi-Location AirPrime System, Adds Additional Locations Going From (2) Location to (3) Location. Or From (3) Location to (4) Locatio n 27. 005 .1

Conver sion Kit: Aut omatic AirPr ime System, Ad ding a Lif t Gauge to exi sting Automatic A irPrime. Requires .125" NP T Port. Con tact Fac tory for D etails 27. 005 .5

Conver sion Kit: Man ual AirP rime Syst em, Adding a L ift Gauge to ex isting Manual AirP rime. Requ ires .125" NPT Po rt. Con tact Factor y for Details 27. 005 .4

Conver sion Kit: Man ual AirP rime, Conv erting to A uto with Lif t Gauge. Requires .125" NPT P ort. Co ntact Facto ry for Det ails 27. 005 .6

Rebuild Kit: Conta ins Seals , O-Ring s, Spring Va lve Plate, D omed Inle t Filter and F asteners 27. 003 .3

™

Trident Emergency Products, LLC

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

215-293-0700 Phone

215-293-0701 Fax

sales@tridentdirect.com Email

TridentDirect.com

#02.003.1e • 06/25/2019

World Class

Fire Industry

Products

AirPrime™ is a trademark of

Trident Emergency Products, LLC

Loading...

Loading...