Page 1

2

Better Products. Better Value.

MODEL NOS.

GAS HOB

INSTRUCTION BOOKLET - INSTALLATION AND SERVICING INSTRUCTIONS

HG 250

35668-9401

GB

Page 2

3

WARNINGS AND GUIDANCE

It is most important that this instruction book should be retained with the appliance for

future reference. Should the appliance be sold or transferred to another owner, or should

you move house and leave the appliance, always ensure that the book is left with the

appliance in order that the new owner can get to know the functions of the appliance and

the relevant warnings.

These warnings are provided in the interest of safety. You MUST read them carefully

before installing or using the appliance.

• This appliance is designed to be operated by

adults, for non professional purpose in private

houses only. Children should not be allowed to

tamper with the controls or play with the product.

• Any installation and electrical work must be

undertaken by a qualified electrician or competent

person. The appliance must be installed

according to the instructions.

• It is dangerous to alter the specifications or

modify the product in any way.

• Ensure that the gas supply complies with the gas

type stated on the identification label, placed near

the gas supply pipe.

• Using a gas cooking appliance will produce heat

and moisture in the room which it has been

installed in. Ensure a continuous air supply,

keeping the air vents in good conditions or

installing a cooker hood with discharge tube.

• In case of intensive or long time use of the

appliance, make the ventilation more efficient,

by opening a window or increasing the electric

exhaust fan power.

• Do not use this appliance if it is in contact with

water. Do not operate the appliance with wet

hands.

• Always ensure that the control knobs are in the

'OFF' position when not in use.

• Hobs became very hot with use and retain their

heat for a long period of time after use. You must

therefore take great care when using the

appliance. Children should be supervised at all

times and should not be allowed to touch the hot

surface or be in the vicinity when in use or until

the appliance has cooled after use. Children also

can injure themselves by pulling pans or pots off

the hob.

• The cooking zones heat up quickly when they are

turned on. Turn them on only when you have

placed a saucepan onto the cooking area.

• If you use an electric socket close to the hob, take

care when using an electrical appliance that the

cable does not touch the hot surface of the hob.

• Do not leave items on the hob surface. Any item

you place on the hob could be damaged if the hob

is accidentaly turned on.

• Unstable or misshapen pans should not be used

on the hob as unstable pans can cause an

accident by tipping or spillage.

• Never leave the hob unattended when working

with oil and fats because of the danger of fire.

• Never use plastic or aluminium foil dishes on the

hob surface.

• Always remove any spillage from the surface of

the hob immediately. Do not allow spills to dry and

harden.

• If you use a saucepan which is smaller than the

heated area of the hob, the handle may become

hot. Please, ensure that you protect your hands

before touching the handle.

• Certain food, plastic items and areosols can be

affected by heat and should NOT be stored above

or below the hob unit.

• Under no circumstances should you attempt to

repair the appliance yourself. Repairs carried out

by inexperienced persons may cause injury or

more serious malfunctioning. Refer to your local

Tricity Bendix Service Centre. Always insist on

genuine Tricity Bendix spare parts.

Your safety is of paramount importance.

Therefore, if you sre unsure about any of the

meanings of these WARNINGS, contact the

Customer Care Department (See page 7).

Page 3

4

CONTENTS

SECTION 1 - Instructions for the User Page 5

Description of the Appliance Page 5

Operation Page 6

Maintenance and Cleaning Page 6

Help us to help You Page 7

Tricity Bendix Service Force Addresses Page 8

Guarantee for 12 Months Page 10

SECTION 2 - Instructions for the Installer - Technical Data Page 11

Installation Page 12

Gas Connection Page 12

Installation above Cupboard or Drawer Page 13

Important Safety Requirements Page 14

Electrical Connection Page 15

Wiring Diagram Page 16

Fault Finding Page 17

Commissioning Page 19

Servicing Page 20

Convert from natural gas to LPG Page 20

These instructions are only for the country stated by the symbol

printed on the front cover of this instruction book.

CLASS APPLIANCE: 3

APPLIANCE CATEGORY: II2H3+

APPLIANCE GAS SUPPLY: Natural gas G20 / 20mbar

MANUFACTURER: ELECTROLUX ZANUSSI ELETTRODOMESTICI S.p.A.

Viale Bologna 298

47100 FORLÌ (Italy)

73/23 EEC - 90/683 EEC - 93/68 EEC - 89/336 EEC - 90/396 EEC,

current edition.

This appliance is manufactured according to

the following EEC directives:

Page 4

5

INSTALLATION

It is mandatory that all operations required for the

installation are carried out by a Competent Gas

Installer (CORGI registered installers normally meet

this criteria), and in accordance with existing rules

and regulations.

The relevant instructions are to be found in the

second section of this manual.

Please, ensure that, once the appliance is installed, it

is easily accessible for the engineer in the event of a

breakdown.

INSTRUCTIONS FOR THE USER

This appliance meets the requirements laid down

in EEC directive No. 89/336 relating to the

suppression of radio and TV interferences.

WHEN THE HOB IS FIRST INSTALLED

Once the hob has been installed, it is important to

remove any protective materials, which were put on

in the factory.

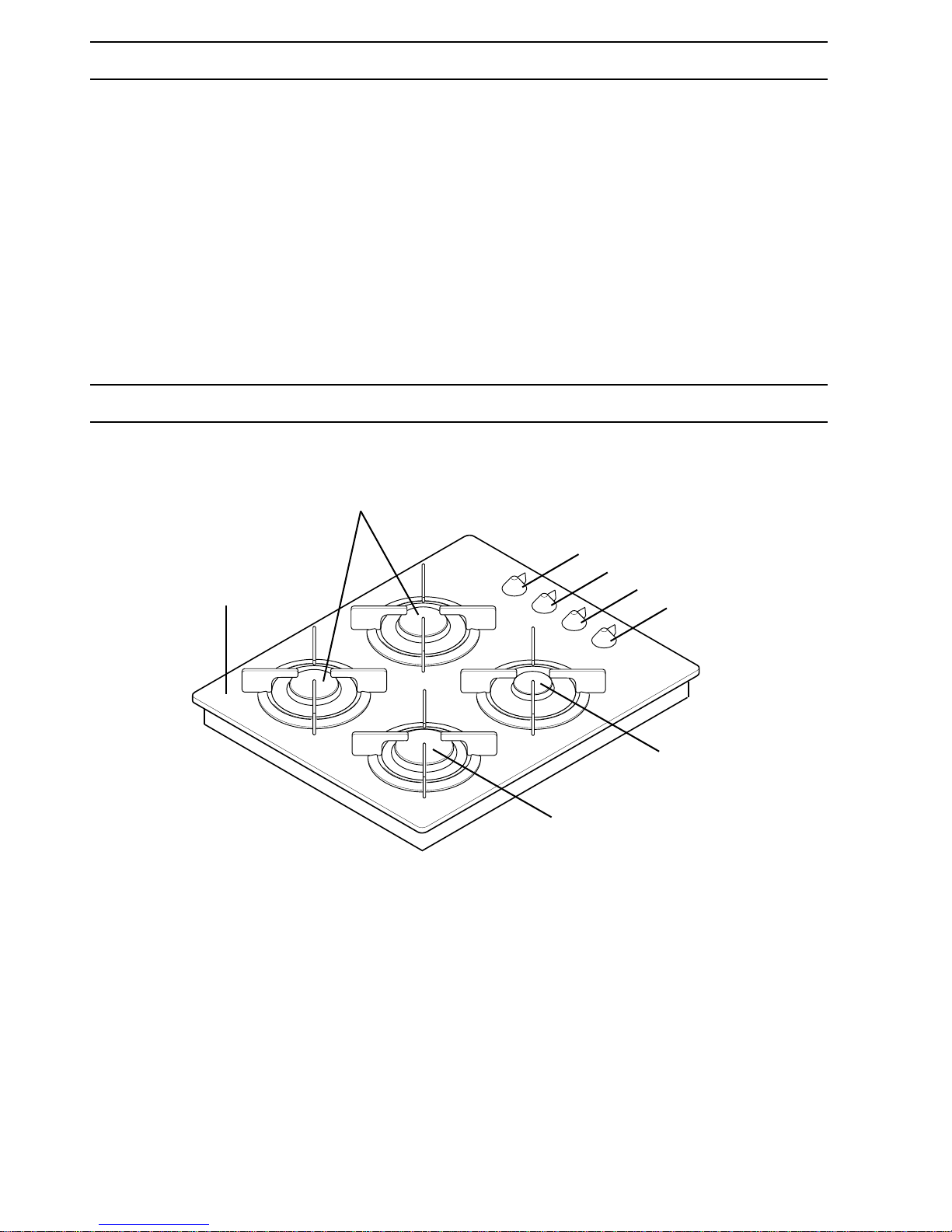

DESCRIPTION OF THE APPLIANCE

1. Hob Top

2. Rapid Burner

3. Semirapid Burners

4. Auxiliary Burner

5. Control knob for back right burner (semirapid)

6. Control knob for back left burner (semirapid)

7. Control knob for front left burner (rapid)

8. Control knob for front right burner (auxiliary)

1

3

5

6

7

8

4

2

Page 5

6

MAINTENANCE AND CLEANING

Before any maintenance or cleaning can be

carried out, you must DISCONNECT the

appliance from the electricity supply.

The hob is best cleaned whilst it is still warm, as

spellage can be removed more easily that if it is

left to cool.

The pan supports, burner caps and crowns can

be lifted off for cleaning.

Regularly wipe over the hob top using a soft

cloth weel wrung out in warm water to which a

little liquid detergent has been added. Avoid the

use of the following:

- household detergent and bleaches;

- impregnated pads unsuitable for non-stick

saucepans;

- steel wool pads;

- bath/sink stain removers.

OPERATION

HOB BURNERS

To light a burner, turn the relevant knob

anticlockwise to maximum position and push

down the knob to ignite.

Then adjust the flame as required.

If the burner does not ignite, turn the control

knob to zero, and try again.

When switching on the mains, after installation

or a power cut, it is quite normal for the spark

generator to be activated automatically.

To ensure maximum burner efficiency, it is

strongly recommended that you use only pots

and pans with a flat bottom fitting the size of the

burner used (see table), so that flame will not

spread beyond the bottom of the vessel. It is

also advisable, as soon as a liquid starts boiling,

to turn down the flame so that it will barely keep

the liquid simmering.

IMPORTANT

Be very careful when frying food in hot oil or fat,

as the overheated splashes could easily ignite.

IMPORTANT

If the control knobs become difficult to turn,

please contact your local Tricity Bendix Service

Centre.

FO 0252

Should the hob top become heavily soiled, it is

recommended that a cleaning product such as

Hob Brite is used.

Clean the pan supports, the burners taps and

crowns using hot detergent water, and remove

marks with a mild paste cleaner. A weel

moistened soap impregnated stell wool pad can

be used with caution, if the marks are

particularly difficult to remove. The burner crown

may loose its matt surface after several

cleanings but this will no way impair ist function.

After cleaning, be sure to wipe dry with a soft

cloth.

The pan supports are dishwasher proof. If

washinf them by hand, take care when drying

them as the enamelling process occasionally

leaves rough edges.

Burner minimum maximum

diameter diameter

Big (rapid) 160 mm. 240 mm.

Medium (semirapid) 120 mm. 220 mm.

Small (Auxiliary) 80 mm. 160 mm.

Page 6

7

HELP US TO HELP YOU

SERVICE

In the event of your appliance requiring servive

Tricity Bendix have an arrangement with

Electrolux Group Service. Before calling out an

engineer, please ensure you have followed the

checklist and purchase date to hand.

Telephone numbers are detailed on the list

headed “Tricity Bendix Service Force”.

Please note that all enquiries concerning service

should be addressed to your local service

centre.

When booking a service call we will need to

know the model number and date of purchase

together with your name, address with postcode

(service areas are defined by the postcode),

telephone number, and what appears to be

wrong.

Keep the receipt with this booklet as proof of

purchase.

CUSTOMER RELATIONS DEPARTMENT

For general enquiries concerning your Tricity

Bendix appliance, or further information on

Cookers, Microwaves, Refrigeration or Home

Laundry equipment you are invented to contact

our Customer Relations Department by letter or

telephone as follows:

Customer Care Department

Tricity Bendix (99, Oakley RD)

Beds LU4 9QQ

Tel.: 01582 - 585858

Page 7

8

TRICITY BENDIX SERVICE FORCE

POSTCODE TO SERVICE CENTRE CROSS REFERENCE

Postcode Telephone Service Centre Postcode Telephone Service Centre

Postcode Telephone Service Centre

AB 01224-696569 Aberdeen

AL 0181-965 9699 Canvey

B1-48, 62-79

B90-94 0121-3587076 Nuneaton

B49, 50, 60

61, 80, 95-98 01527-512919 Redditch

BA 0117-9211876 Bristol

BB 0161-4777758 Manchester

BD 0113-2608511 Leeds

BH 01705-667411 South Coast

BL 0161-4777758 Manchester

BN1-18, 20-27 01273-694341 Tonbridge

BR 0181-6589069 Tonbridge

BS 0117-9211876 Bristol

BT1-30, 36-57

BT63-67 01232-746591 N/I East

BT31-35, 60-62

BT68-82, 92-94 01861-510400 N/I West

CA 01228-594747 Cumbria

CB 0181-9659699 Canvey

CF 01222-460131 Cardiff

CH 0151-2541724 Liverpool

CM 01268-694144 Canvey

CO 01268-694144 Canvey

CR 0181-6589069 Tonbridge

CT 01732-357722 Tonbridge

CV 01203-354424 Nuneaton

CW 0151-2541724 Liverpool

DA 01732-357722 Tonbridge

DD 01250-876285 Dundee

DE 0113-2608511 Leeds

DG 01387-265166 Dumfries

DH 01325-301400/

0191-4932025 Northern

DL 01325-301400 Northern

DN1-7,10-12 0113-2608511 Leeds

DN8-9,15-20

DN21

Subcodes 3,4

DN31-40 01472-267978 S. Humberside

DN14 01482-585678 Hull

DN21

Subcodes 1,2,5 01522-514603 Lincoln

DT 01705-667411 South Coast

Dundee Gas Only

01382-642828 Tayside

Refrigeration

DY 0121-3587076 Nuneaton

E 0181-4433464 Canvey

EC 0181-4433464 Canvey

EH 0141-6474381 Glasgow

EN 0181-4433464 Canvey

EX1-17 01626-65909 Newton Abbot

EX18-23

EX31-39 01271-328826 Barnstaple

FK 0141-6474381 Glasgow

FY 0151-2541724 Liverpool

G 0141-6474381 Glasgow

GL 01527-512919 Redditch

GU1-35 01252-24505 Tonbridge

Guernsey 01481-46931 Guernsey Elec.

HA 0181-9659699 Canvey

HD 0113-2608511 Leeds

HG 0113-2608511 Leeds

HP 0181-9659699 Canvey

HR 01432-340334 Hereford

HS9 Isle of Barra 01871-890206 J. Zerfahs

HU 01482-585678 Hull

HX 0113-2608511 Leeds

IG 01268-694144 Canvey

IM 01624-687794 Manx Electricity

IP 01603-667017 Canvey

IV1-39, 52-56 01463-792952 Highland

Appliances

IV40-51Inverness 01855-821315 G. Ross

Jersey 01534-505050 Jersey Electricity

KA1-26, 28-30

0141-6474381 Glasgow

KA27 01773-302909 Arran Domestics

KT 0181-6589069 Tonbridge

KW1-14 01463-792952 Highland

Appliances

KW15-17 01856-875457

Refrigeration Sales

& Service

KY 0141-6474381 Glasgow

L 0151-2541724 Liverpool

LA 01772-316175 Lancaster

LD 01432-340334 Hereford

LE 01203-354424 Nuneaton

LL 01745-591616 North Wales

LN1, 2, 4-6

LN3 Subcodes 4 & 5

LN8-10 01522-514603 Lincoln

LN3 Subcode 6 only

LN7,11-13 01472-267978 S. Humberside

LS 0113-2608511 Leeds

LU 0181-9659699 Canvey

M 0161-4777758 Manchester

ME 01732-357722 Tonbridge

MK 0181-9659699 Canvey

ML 0141-6474381 Glasgow

N 0181-4433464 Canvey

NE 0191-4932025 Northern

NG1-22, 25 0113-2608511 Leeds

NG23, 24, 31-34 01522-514603 Lincoln

NN 01203-354424 Nuneaton

NP1-4, 6, 9-44 01222-460131 Cardiff

NP5, 7, 8 01432-340334 Hereford

NR 01603-667017 Canvey

NW 0181-4433464 Canvey

OL 0161-4777758 Manchester

OX 01527-512919 Redditch

PA1-19, 21-23 0141-6474381 Glasgow

PA20 01700-504777 D McGlashan

PA24-26, 28-61 01369-703161 Argylle

PA62-75 01688-302262 B Hogg Is. of Mull

PA83-87 01851-705555 Isle of Lewis

PE1-13, 20-25 01522-514603 Lincoln

PE14-19, 30-38 01603-667017 Canvey

PH1-7 0141-6474381 Glasgow

PH8-18 01250-876285 Dundee

PH19-26, 42-44 01463-792952 Highland

Appliances

PH30-41

Inverness

01855-821315 G. Ross

PL1-9, 16, 19-21 01626-65909 Newton Abbott

PL10-15, 17, 18

PL 22-35 01209-314407 Redruth

PO1-22 01705-667411 South Coast

PO30-41 01983-872552 Isle of Wight

PR 0151-2541724 Liverpool

RG 01252-24505 Tonbridge

RH 01273-694341 Tonbridge

RM 01268-694144 Canvey

S 0113-2608511 Leeds

SA1-18, 21-32

SA19, 20, 40

SA45-48 01222-461972 Cardiff

SA33-39, 41-44

SA61-73 01437-710914 Haverfordwest

SE 0181-6589069 Tonbridge

SG 0181-9659699 Canvey

Shetland 01595-692855 Bolts

01806-566546 Leask Electrical

Retailer's own

01595-692915 G. Robertson

sales

01595-692225 Tait Electronics

SK 0161-4777758 Manchester

SL 01252-24505 Tonbridge

SM 0181-6589069 Tonbridge

SN

01527-512919 Redditch

SO 01705-667411 South Coast

SP 0117-9211876 Bristol

SR 0191-4932025 Northern

SS 01268-694144 Canvey

ST 0121-3587076 Nuneaton

SW 0181-6589069 Tonbridge

SY1-6, 8-17

SY19-22 01743-450279 Shrewsbury

SY7, 18 01432-340334 Hereford

SY23-25 01222-461972 Cardiff

TA 0117-9211876 Bristol

TD 01573-224411 Borders

TF 01743-450279 Shrewsbury

TN 01732-357722 Tonbridge

TQ 01626-65909 Newton Abbott

TR1-20, 26, 27 01209-314407 Redruth

TR21-25 0117-9211876 South Coast

TS 01325-301400 Northern

TW 0181-6589069 Tonbridge

UB 0181-9659699 Canvey

W 0181-4433464 Canvey

WA (Not 14, 15) 0151-2541724 Liverpool

WA14, 15 0161-4777758 Manchester

WC 0181-4433464 Canvey

WD 0181-9659699 Canvey

WF 0113-2608511 Leeds

WN 0151-2541724 Liverpool

WR (Not WR 15)

01527-512919 Redditch

WR15 01203-354424 Nuneaton

WS 0121-3585051 Nuneaton

WV 0121-3585051 Nuneaton

YO1-3, 5-8 0113-2608511 Leeds

YO4, 11-18, 25

01482-585678 Hull

YO21, 22 01325-301444 Northern

Page 8

9

TRICITY BENDIX SERVICE FORCE ADDRESSES

CENTRE ADDRESS CENTRE ADDRESS CENTRE ADDRESS

INVERNESS Tricity Bendix Service Force

George Ross

Forrestry Workshop

Inchree

Onich

Invernesshire PH33 6SE

ISLE OF ARRAN Tricity Bendix Service Force

Arran Domestics

Unit 4 The DouglasCentre

Brodick

Isle of Arran KA27 8AJ

ISLE OF BARRA Tricity Bendix Service Force

John Zerfahs

244 Bruernish

Isle of Barra

Western Islands HS9 5QY

ISLE OF LEWIS Tricity Bendix Service Force

N.D. Macleod

Churchouse

16 James Street

Stornoway

Isle of Lewis PA87 2QW

ISLE OF MAN Tricity Bendix Service Force

Manx Electricity

Service Workshop

North Quay

Douglas, Isle of Man

ISLE OF MULL Tricity Bendix Service Force

Brian Hogg

Braeside

Raeric Road

Tobermory

Isle of Mull PA75 6PU

ISLE OF WIGHT Tricity Bendix Service Force

Wyatts Electrical Service

4 Forelands Road

Bembridge

Isle of Wight PO35 5X

JERSEY Jersey Electricity Company

PO Box 45

Queens Road

St Helier

Jersey

Channel Islands JE4 8NY

LANCASTER Tricity Bendix Service Force

NL Services

Unit 333 Ranglet Road

Walton Summit

Bamber Bridge Preston

Lancashire PR5 8AR

LEEDS Tricity Bendix Service Force

64-66 Cross Gates Road

Leeds LS15 7NN

LINCOLN Tricity Bendix Service Force

Brian Hudson

Unit 8 Stonefield Park

Clifton Street

Lincoln LN5 8AA

LIVERPOOL Tricity Bendix Service Force

1 Honeys Green Precinct

Honeys Green Lane

West Derby

Liverpool L12 9JH

MANCHESTER Tricity Bendix Service Force

Unit 30 Oakhill Trading Estate

Devonshire Road

Worsley

Manchester M28 3PT

NEWTON ABBOT

Tricity Bendix Service Force

South West Domestic Service

Unit 2 Zealley Industrial Estate

Kingsteignton

Newton Abbott

South Devon TQ12 3TD

NORTH WALES Tricity Bendix Service Force

GMS (Cymru)

Unit 2 Coed - Parc

Abergele Road

Rhuddlan

Clwyd

Wales LL18 5UG

NORTHERN Tricity Bendix Service Force

PO Box 40 Preston Road

Aycliffe Industrial Estate

Newton Aycliffe

Co. Durham DL5 6XA

NORTHERN Tricity Bendix Service Force

IRELAND EAST Unit C3 Edenderry Indust. Est.

326, Crumlin Road

Belfast BT14 7EE

NORTHERN Tricity Bendix Service Force

IRELAND WEST G & O (Armagh) Service

Owenmore House

Kilwee Business Park

Upper Dunmurray Lane

Belfast BT17 0HD

NUNEATON Tricity Bendix Service Force

Unit 23-24 Alliance Business Park

Townsend Drive

Nuneaton

Warwickshire CV11 6RX

ORKNEY Tricity Bendix Service Force

Refrigeration Sales and Services

Hatson Ind. Estate

Kirkwall

Orkney KW15 1RE

REDDITCH Tricity Bendix Service Force

Heming Road

Washford

Redditch

Worchestershire B98 0DH

REDRUTH Tricity Bendix Service Force

Cornwall Domestic Service

Unit 7D Pool Industrial Estate

Wilson Way

Redruth

Cornwall TR15 3QW

ROTHSAY Tricity Bendix Service Force

D McGlashan Walker Eng.

Glenmhor

Upper Serpentine

Rothsay

Strathclyde PA20

SHETLAND Tricity Bendix Service Force

George Robertson

3/4 Carlton Place

Lerwick

Shetland ZE1 0ED

SHETLAND Tricity Bendix Service Force

Tait Electronic Systems Ltd

Holmsgarth Road

Lerwick

Shetland ZE1 0PW

SHETLAND Tricity Bendix Service Force

Bolts Shetland Ltd.

26 North Road

Lerwick

Shetland ZE1 0PE

SHETLAND Tricity Bendix Service Force

Leask Electrical

Harsdale

Symbister

Whalsay

Shetland ZE2 9AA

SHREWSBURY Tricity Bendix Service Force

BLI Service

6, Harlescott Barn

Harlescott Lane

Shrewsbury

Shrops SY1 3SY

SOUTH COAST Tricity Bendix Service Force

Limberline Road

Hilsea, Portsmouth

Hampshire PO3 5JJ

SOUTH Tricity Bendix Service Force

HUMBERSIDE John Robinson (Electrical)

81 Pasture Street

Grimsby

DN32 9EP

TONBRIDGE Tricity Bendix Service Force

Unit 30 Deacon Trading Estate

Morley Road

Tonbridge

Kent TN9 1RA

ABERDEEN Tricity Bendix Service Force

Northeast Appliance Service

8 Cornhill Arcade

Cornhill Drive

Aberdeen AB2 5UT

ARGYLL Tricity Bendix Service Force

T.D.C. Refrigeration

Briar Hill

7 Hill Street, Dunoon

Argyll PA23 7AL

BARNSTAPLE Tricity Bendix Service Force

Mc Bain Refrigeration

P.O. Box 12

Barnstaple

North Devon EX31 2YB

BORDERS Tricity Bendix Service Force

James Stewart & Son

2-8 Wood Market

Kelso

Borders TD5 7AX

BRISTOL Tricity Bendix Service Force

Unit BE 46

PO Box 372

Bristol BS 99 1UD

CANVEY Tricity Bendix Service Force

2-4 Sandhurst

Kings Road

Canvey Island SS8 0QY

CARDIFF Tricity Bendix Service Force

Guardian Industrial Estate

Clydesmuir Road

Tremorfa, Cardiff CF2 2QS

CUMBRIA Tricity Bendix Service Force

E.T.B. Services

Carlisle Enterprise Centre

James Street

Carlisle CA2 5AP

DUMFRIES & Tricity Bendix Service Force

GALLOWAY Allan Crossan (Service)

93 Irish Street

Dumfries

Scotland DG1 2PQ

DUNDEE Tricity Bendix Service Force

Gas Only Tayside Refrigeration

3-7 Blackness Street

Dundee DD1 5LR

DUNDEE Tricity Bendix Service Force

I Brogan Domestic

41 Leslie Street

Blairgowrie

Perthshire PH10 6AT

GLASGOW Tricity Bendix Service Force

20 Cunningham Road

Clyde Estate

Rutherglen

Glasgow G73 1PP

GUERNSEY Guernsey Electricity

PO Box 4

Vale, Guernsey

Channel Islands

HAVERFORDWEST

Tricity Bendix Service Force

C Butherway

1 Church Road

Roch

Haverfordwest

Dyfed, Wales SA62 6AG

HEREFORD Tricity Bendix Service Force

Domestic Repair Centre

Unit 3 Bank Buildings

Cattle Market

Hereford HR4 9HX

HULL Electrolux Aftersales Service

John Sizer

Unit 1 Boulevard Unit

Factory Estate

Hull HU3 4 AY

INVERNESS Tricity Bendix Service Force

Highland Appliances

Unit 3B3 Smithton Indust. Est.

Smithton

Inverness IV1 2PD

Page 9

10

GUARANTEE FOR 12 MONTHS

TRICITY BENDIX STANDARD

GUARANTEE CONDITIONS

This guarantee is in addition to your statutory

and other legal rights .

We, Tricity Bendix undertake that if, within the

12 months of the date of the purchase, this

Tricity Bendix appliance or any part thereof is

proved to be defective by any reason only of

faulty workmanship or materials, we will, at our

option, repair or replace the same FREE OF

ANY CHARGE for labour, materials or carriage

on condition that:

* The appliance has been correctly installed

and used only on the gas and electricity

supply stated on the rating plate.

* The appliance has been used for normal

domestic purpose only, and in accordance

with the manufacturer's operating and

maintenance istructions.

* The appliance has not been serviced,

maintained, repaired, taken apart or

tampered with by any person not authorised

by us.

All service work under this guarantee must be

undertaken by an Electrolux Group Service

Centre.

Home visits are made between 9.00am and

5.00pm Monday to Friday. Visit may be

available outside these hours, in which case a

premium will be charged.

Any appliance or defective part replaced shall

become our property.

EXCLUSIONS

This guarantee does not cover:

* Damage or calls resulting from transportation,

improper use or neglect, the replacement of

any light bulbs or removable parts of glass or

plastic.

* Costs incurred for calls to put right machines

improperly installed or calls to machines

outside the UK and the Republic of Ireland.

* Appliances found to be in use within a

commercial or similar environment, plus

those which are the subject to rental

agreements.

* Products of Tricity Bendix manufacture which

are NOT marketed by Tricity Bendix.

* EU Countries - The standard guarantee is

applicable but subject to owner's

responsibility and cost to ensure the

appliance meets the standards set by the

country to which the product is taken. Proof

of purchase may be required. Electrolux

Afersales Service in the country concerned,

with whom Tricity Bendix have an agreement,

will be pleased to advise further.

Page 10

11

Ignition HT Spark

Spark Generator Ispra Control's BF 50046 - 240V 0.6 YA T 120

Spark Gap Fixed

Rear Left Burner (semi rapid)

Heat Input 1.9 kW (6483 BTU/HR)

Front Left Burner (rapid)

Heat Input 2.9 kW Natural Gas (9895 BTU/HR)

2.7 kW L.P.G. (9212 BTU/HR)

OVERALL DIMENSIONS

Width: 580 mm.

Depth: 510 mm.

Thickness: 40 mm.

Height: 88 mm.

Weight: 11 Kg.

SUPPLY CONNECTIONS

Gas:

RC 1/2 inch (1/2 inch male) Rear right hand corner

Electric:

240V 50Hz supply, 3 core flexible cable with non rewireable plug fitted with a 3 amp cartridge fuse.

This appliance complies with the EEC Directive No 89/336, concerning suppression of radio electrical

interference.

Burner Dia. Tap By-pass Tap colour

1/100 mm

Auxiliary 28 Red/Red

Semi-rapid 32 Blue/Blue

Rapid 40 Black/Black

Aeration adjustement none

INSTRUCTIONS FOR THE INSTALLER - TECHNICAL DATA

CUT OUT DIMENSIONS

Width: 550 mm.

Depth: 470 mm.

BURNER RAPID SEMI-RAPID AUXILIARY

(large) (medium) (small)

POSITION MAX MIN MAX MIN MAX MIN

NOMINAL THERMAL

POWER kW 2.9 0.65 1.9 0.45 1.0 0.33

NOMINAL FLOW

RATE m

3

/h 0.276 0.062 0.181 0.043 0.095 0.031

NOZZLE REFERENCE 119 Adjust. 96 Adjust. 70 Adjust.

NOMINAL THERMAL

POWER kW 2.7 0.65 1.9 0.45 1.0 0.33

NOMINAL FLOW

RATE g/h 195 46.8 137 32.4 72 23.8

NOZZLE REFERENCE 86 40 71 32 50 28

NATURAL GAS

20 mbar

TYPE OF

GAS

CHARACTERISTICS

LPG GAS

28-30/37 mbar

1/100 mm

1/100 mm

VALUE = 49.92 MJ/Kg

VALUE = 37.78 MJ/m

3

Ws - 50.7 MJ/ m

3

Rear Right Burner (semi rapid)

Heat Input 1.9 kW (6483 BTU/HR)

Front Right Burner (auxiliary)

Heat Input 1.0 kW (3412 BTU/HR)

Page 11

12

INSTALLATION

IMPORTANT

It is essential that a competent installer is

employed to fit this appliance.

The manufacturer will not accept liability, should

the above instruction or any of the other safety

instructions incorporated in this book be ignored.

On the end of the shaft, which includes the GJ

1/2" threaded nut, adjustment is fixed so that the

washer is interposed between the components

as shown in Figure 1. Screw the parts together

without using excessive force, orientate the

adjustment in the desired direction and then lock

it all together.

Rectangular cut-out size for hob

Fig. 1

A) End of shaft with nut

B) Washer

C) Adjustable join

It is important to install the elbow correctly,

with the shoulder on the end of the thread,

fitted to the hob connecting pipe.

Failure to ensure the correct assembly will

cause leakage of gas.

Fig. 2

FO 0264

FO 0814

550

470

580

510

55 min.

FO 2109

Connection to the gas supply should be with

either rigid or semi-rigid pipe, i.e. steel or

copper.

The connection should be suitable for

connecting to RC 1/2 (1/2 BSP male thread).

When the final connection has been made, it is

essential that a thorough leak test is carried out

on the hob and installation.

Ensure that the main connection pipe does not

exert any strain on the hob.

If using flexible metallic pipes, be careful they

do not come in contact with mobile parts or

they are not squeezed. Use the same

attention when the hob is combinated with an

oven.

Page 12

13

INSTALLATION ABOVE CUPBOARD OR DRAWER

If the hob is to be installed above a cupboard or

drawer it will be necessary to fit a heat resistant

board below the base of the hob on the

underside of the work surface.

a) Sealing gasket

FITTING THE HOB TO THE WORKTOP

Before fitting the hob into the cut out, an

adhesive seal must be fitted to the underside

outside edge (Fig. 3) of the hob. It is essential

that no gaps are left in this seal in order to

prevent spillage near the hob seeping into the

cabinet below.

1) Remove the pan supports, the burners caps

and crowns and turn the hob upside down,

taking care the ignition candles are not

damaged in this operation.

2) Place the sealing gasket all around the glass

top edge as shown in Fig. 3.

3) Fit the hob in the cut out and push it down

until the glass top and the working top come in

touch, as shown in Fig. 4

ON/OFF SWITCH

FLEX

OUTLET

ON/OFF SWITCH

FLEX

OUTLET

FO 0763

FO 0764

Fig. 3

It is also recommended to carry out the electrical

connection to the hob as shown in illustrations A

and B.

A

Fig. 4

FO 2108

FO 2107

30

20 min

60

a

b

FO 1013

BUILDING IN KITCHEN UNIT WITH DOOR

Proper arrangements must be taken in

designing the forniture unit, in order to avoid any

contact with the bottom of the hob which can be

heated when it is operated. The recommended

solution is shown in inllustration C.

The panel fitted under the hob ("a") should be

easily removable to allow an easy access if a

technical assistance intervention is needed. The

space behind the kitchen unit ("b") can be used

for connections.

A

B

C

Page 13

14

650 mm

420 mm

420 mm

100 mm

50 mm

50 mm

55 mm

600 mm

700 mm

420 mm

100 mm

420 mm

50 mm

55 mm

50 mm

IMPORTANT SAFETY REQUIREMENTS

This appliance must be installed in accordance

with the Gas Safety (Installation and Use)

Regulations (Current Edition) and the IEE Wiring

Regulations (Current Edition).

Detailed recommendations are contained in the

following British Standards Codes Of Practice:

B.S. 6172/ B.S. 5440, Par. 2 and B.S. 6891

Current Editions.

The hob should not be installed in a bed sitting

room with a volume of less than 20 m

3

. If it is

installed in a room of volume less than 5 m

3

an

air vent of effective area of 110 cm

2

is required.

If it is installed in a room of volume between 5 m

3

and 10 m3 an air vent of effective area of 50 cm

2

is required, while if the volume exceeds 11 m3 no

air is required.

However, if the room has a door which opens

directly to the outside no air vent is required even

with the volume is between 5 m

3

and 11 m3.

If there are other fuel burning appliances in the

same room, B.S. 5440 Part 2 Current Edition,

should be consulted to determine the requisite

air vent requirements.

LOCATION

The hob may be located in a kitchen, a kitchen/

diner or bed sitting room, but not in a bathroom

or shower room.

Before making the cut out in the worktop ensure

that the edges of the hob that are to be near

either a side or rear wall have a minimum

distance of 55 mm. between the edge of the hob

and the wall.

The minimum distance combustible material can

be fitted above the hob in line with the edges of

the hob is 420 mm. If it is fitted below 420 mm. a

space of 50 mm. must be allowed from the

edges of the hob.

The minimum distance combustible material can

be fitted directly above the hob is 700 mm.

A minimum distance of 100 mm. must be left

between the side edges of the hob and any

adjacent cabinets or walls.

INSTALLATION GUIDANCE INSTRUCTIONS

CLEARANCES REQUIRED WHEN FITTING

ZANUSSI GAS HOB

WITHOUT A COOKER HOOD ABOVE

INSTALLATION GUIDANCE INSTRUCTIONS

CLEARANCES REQUIRED WHEN FITTING

ZANUSSI GAS HOB

WITH A COOKER HOOD ABOVE

FO 0813FO 0812

Page 14

15

ELECTRICAL CONNECTIONS

All electrical connections must be carried out by

competent persons in accordance with the current

regulations. This appliance is designed to be

connected to a 240V 50Hz AC electrical supply.

The appliance is fitted with a 3 core flexible supply

cord incorporating a moulded 3amp plug top fitted

with a 3amp ASTA rated fuse.

THIS APPLIANCE MUST BE EARTHED.

The manufacturer will not accept liability should

this safety measure be ignored.

If the plug that is fitted to your appliance is not

suitable for the socket outlet, it must be cut off and

the appropriate plug fitted.

The cut off plug should be disposed of to prevent the

hazard of electric shocks should it be plugged into a

13amp socket elsewhere in the house.

IMPORTANT

The wires in this flexible supply cord are coloured in

accordance with the following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

To fit the plug, the colours of the wires in the flexible

supply cord may not correspond with the markings

identifying the terminals in the alternative plug. In this

case follow the procedure below:

- Connect the green and yellow (earth) wire to the

terminal in the plug which is marked with the letter

'E' or the earth symbol or coloured green and

yellow.

- Connect the blue (neutral) wire to the terminal in

the plug which is marked with the letter 'N' or

coloured black.

- Connect the brown (live) wire to the terminal in

the plug which is marked with the letter 'L' or

coloured red.

When replacing the plug top fuse only a 3amp

BS1362 ASTA rated replacement should be used.

The plug must not be used if the fuse cover/carrier is

lost.

A replacement cover/carrier must be obtained from a

Zanussi Service Force Centre. (See rear of user

instructions for address and telephone number of

your local centre).

This appliance complies with E.E.C. Directive

No.89/336 relative to radio interference

suppression.

IMPORTANT

Ensure that the hob supply cord does not come into

contact with surfaces with temperatures higher than

50 deg. C.

FO 0390

Page 15

16

WIRING DIAGRAM

1. TAPS IGNITOR SWITCHES

2. IGNITOR UNIT

1

2

L

N

0

220

240

1

2

3

4

Page 16

17

FAULT FINDING

PRELIMINARY ELECTRICAL SYSTEMS

CHECK

A. EARTH CONTINUITY CHECK appliance must be electrically

disconnected - meter set on Ω (Ohms) x 1

scale and adjust zero if necessary.

a) Test leads from any appliance earth

point to earth pin on plug. Resistance

should be less than 0.1 Ω (Ohm), check

all earth wires for continuity and all

contacts clean and tight.

B. INSULATION CHECK - appliance

electrically disconnected, all switches ON.

a) meter set on Ω (Ohms) x 1 scale.

Test leads from L to N in appliance

terminal block. If meter reads «0» then

there is a short circuit.

b) meter set on Ω (Ohm) x 100 scale.

Repeat test with leads from L to E. If

meter reads less than ∞ (infinity) there

is a fault.

NOTE - Should it be found that the fuse

has failed but no fault is indicated - a

detailed continuity check (i.e. by

disconnecting and checking each

component) is required to trace the faulty

component.

It is possible that a fault could occur as a

result of local burning/arcing but no fault

could be found under test. However a

detailed visual inspection should reveal

evidence of burning around the fault.

START

Isolate appliance

and carry out:

A: Earth Continuity

check.

Has inlet fuse blown?

Carry out:

C: Polarity check.

Electricity supply

should now be

satisfactory.

Carry out:

D: Resistance to

Earth check.

Inlet wiring

faulty.

Rectify any

fault.

Isolate appliance and

carry out:

B: Insulation check.

Rectify any fault

including replacing

fuses as necessary.

SOCKET

(face view)

PLUG (with cover removed)

Earth Wire

Green/Yellow

Neutral Wire

Blue

Brown

Blue

Green

Yellow

Green

Yellow

Brown

Blue

( )

FUSE

( )

E

N

L

NO YES

NO

YES

Page 17

18

IGNITION SYSTEM / GAS IGNITION

YES

Check plug top fuse and

replace if necessary

Check polarity and earth

continuity of supply point

Check earth continuity

of appliance

Ignitor does not spark

Check fitting of burners

Check position of the

electrode

Check by pass simmer

adjusted

Light burner manually

Check gas supply at

burner

Check continuity from 'N' on the

mains connector block and "O" on

the ignitor unit

Check continuity from 'L' on the

mains connector block and the

taps ignition switches

Check continuity from ignition

switches connector to ignitor unit

Check continuity from the tip of

each electrode to the terminals 1

to 4 on the ignitor unit

Check for breaks in the insulation

of the HT leads

Change the taps ignition

switches

NO

Change the ignitor unit

Page 18

19

COMMISSIONING

When the hob has been fully installed it will be

necessary to check the minimum flame setting.

To do this, follow the procedure below.

- Turn the gas tap to the MAX position and

ignite.

- Set the gas tap to the MIN flame position

then turn the control knob from MIN to MAX

several times. If the flame is unstable or is

extinguished follow the procedure below.

Procedure:

Re-ignite the burner and set to MIN.

Remove the control knob, insert a thin bladed

screwdriver down the centre of the gas tap

control shaft and turn the adjustment screw until

the flame is steady and does not extinguish,

when the knob is turned from MIN to MAX.

Repeat this procedure for all burners.

Pressure Testing

Remove left hand pan support and front left

burner cap and crown.

Fit manometer tube over the injector.

Turn on the burner gas supply and ignite

another burner supply.

The pressure reading should be nominally

20mbar and must be between 17 mbar and

25mbar.

Turn off the burner supplies.

a) Minimum adjust.screw

b) Tap

FO 1042

Page 19

20

SERVICING

A: Removal Of Hob Top

1. Remove the panstands and each burner cap and

crown.

2. Lift the hob from off the working top.

3. Remove the two self tapping screws from each

burner and the two fixing screws on the right hand

side of the hob.

B: Removal Of the Hob Taps

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. With the aid of a 7mm spanner remove the

clamping bolt from the fixing clamp.

3. Loosen the pipe connection nut from the gas tap

with the aid of a 16mm spanner. Remove fixing

clamps.

4. Reassemble in reverse order and carry out leak

test.

C: Removal Of Mains Terminal Block

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. Disconnect supply flex connections from terminal

block.

3. From the underside of the hob remove 1 self

tapping screw from the terminal block.

4. Reassemble in reverse order.

D: Removal Of Burner

1. Follow the procedures in Section A.

2. With the aid a 12mm spanner loosen off the pipe

connection nut.

3. From the underside of the hob remove 2 self

tapping screws from the burner body.

4. Reassemble in reverse order and carry out leak

test.

E: Removal Of Ignitor Unit

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. Disconnect H.T. leads and the ignition switches

connector.

3. With the aid of a pair of thin nose pliers, pull the

spring clip sidewards off of the underside of the

ignitor.

4. Reassemble in reverse order and check with

wiring diagram for correct reconnection.

F: Remove Taps Ignition Switches

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. Disconnect the switches connector from the

ignitor unit and remove the supply cables pulling

the tabs connection off.

3. Reassemble in reverse order and check with

wiring diagram for correct reconnection.

CONVERT FROM NATURAL GAS TO LPG

It is important to note that this model is designed for

use with natural gas but can be converted for use

with butane or propane gas providing the correct

injectors are fitted. The gas rate is adjusted to suit.

METHOD

• Ensure that the gas taps are in the 'OFF' position

• Isolate the appliance from the electricity supply

• Remove all pan supports, burner caps, rings,

crowns and control knobs.

• With the aid of a 7mm box spanner the burner

injectors can then be unscrewed and replaced by

the appropriate LPG injectors.

TO ADJUST THE GAS RATE

With the aid of a thin bladed screwdriver completely

tighten down the by pass adjustment screw, which is

located down the centre of the gas tap control shaft.

Upon completion stick the replacement rating plate

on the under side of the hob.

IMPORTANT

The replacement/conversion of the gas hob

should only be undertaken by a competent

person

Page 20

21

MODEL NO.

HG 250

PART NO.

35668-_____

Better Products. Better V alue.

TRICITY BENDIX, 99 OAKLEY ROAD, LUTON, BEDFORDSHIRE, LU4 9QQ.

A Division od Emaco Limited - Registered in England No. 176547 - Registered Office. 101 Oakley Road, Luton LU4 9RJ.

Loading...

Loading...