Page 1

Visor Cooker Hood - CH 520 and CH 610

Operating and Installation Instructions

Page 2

CONTENTS

Please refer to the sections in this booklet that apply to your particular model: Page

CONTENTS 1

WARNINGS 2

GENERAL 3

INSTALLATION INSTRUCTIONS ELECTRICAL CONNECTION 4

UNPACKING 5

POSITIONING 5

WALL FITTING 5

WALL CABINET FITTING 6

DUCTING FITTING 6

OPERATING INSTRUCTIONS 7

DO’S AND DON’TS 7

MAINTENANCE AND CLEANING WORKTOP LIGHTING 8

MAINTENANCE AND CLEANING FILTERS 8

HELP US TO HELP YOU 9

TECHNICAL SPECIFICATIONS

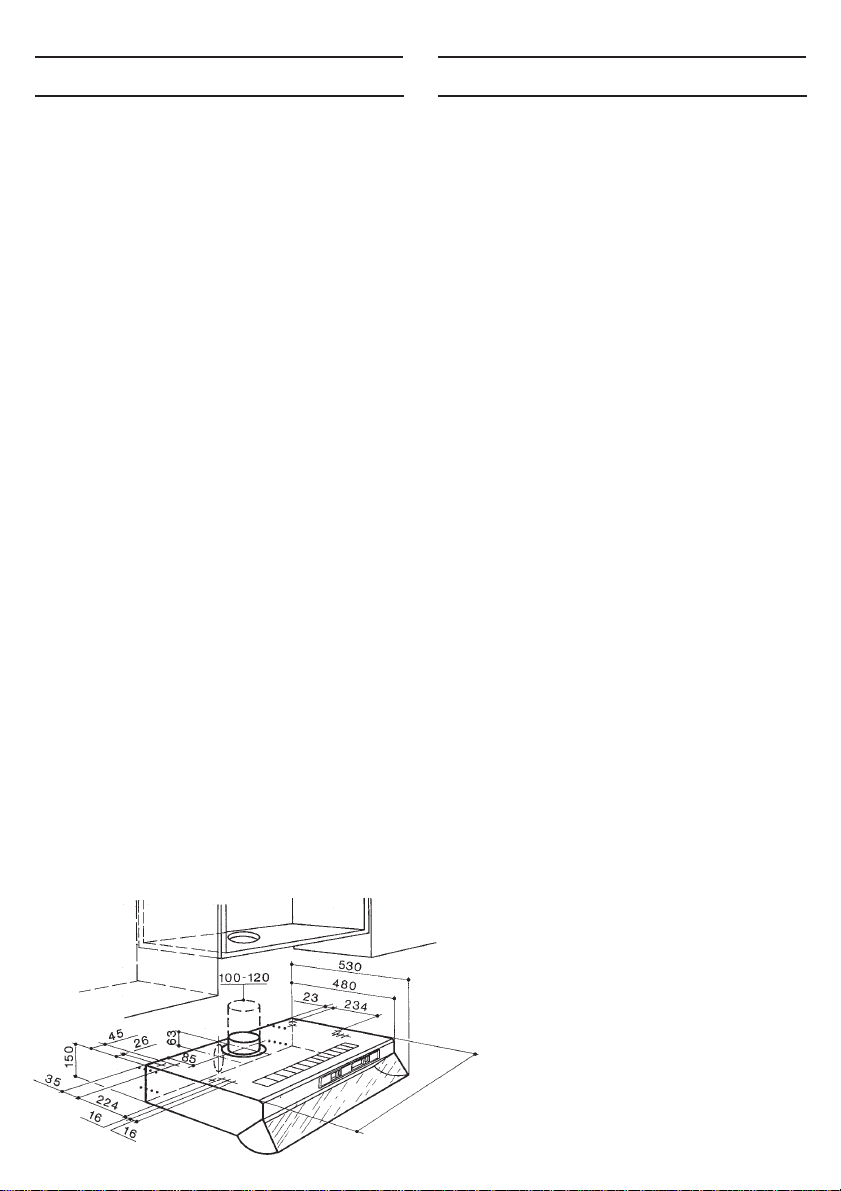

DIMENSIONS CH520 Width cm 49.8

CH610 Width cm 59.8

Height cm 15.0

Depth cm 48.0

Depth with visor open cm 53.0

WEIGHT CH520 Gross kg 8.2

Net kg 7.2

CH610 Gross kg 8.7

Net kg 7.7

ELECTRICAL CONNECTION Voltage 220-240V ~ 50Hz

Fan 110W

Lamps 2x40W 80 W

Total Consumption 190W

PERFORMANCE Speed 1 2 3

Capacity m

3

/h 130 180 250

Capacity lt/sec 36 50 69

Pressure mmH

Noise level dbA 45 51 59

O10 1825

2

1

Page 3

WARNINGS WARNINGS

It is most important that this instruction

book should be retained with the appliance

for future reference. Should the appliance

be sold or transferred to another owner, or

should you move house and leave the

appliance always ensure that the book is

supplied with the appliance in order that

the new owner can be acquainted with the

functioning of the appliance and the

relevant warnings. Please ensure that you

have read the whole instruction book before

using the appliance and that you follow the

recommendations given.

These warnings are provided in the interest

of safety. They must be read carefully

before installing or using this appliance.

This appliance is designed to be operated by

adults. Children should not be allowed to

tamper with the controls or play with the

product.

It is dangerous to alter the specifications or

modify the product in any way.

Any installation work must be undertaken by

a qualified electrician or a competent person.

This product should be serviced by an

authorised Tricity Bendix Service Centre, and

only genuine Tricity Bendix spare parts should

be used.

Never leave frying pans unattended during use

as overheated fats and oils may catch fire.

Never do flambe cooking under this cooker

hood.

It is a possible fire hazard if the grease and

charcoal filter are not replaced as

recommended.

When used in the extraction mode the cooker

hood must not be connected to a flue which is

used for exhausting fumes from appliances

supplied with energy other than electric such

as a central heating flue or water heater.

If the room where the cooker hood is to be

used contains a fuel burning appliance such

as a central heating boiler then its flue must

be of the room sealed or balanced flue type.

If other types of flue or appliances are fitted

ensure that there is an adequate supply of air

to the room.

All installations must comply with the local

authorities requirements for the discharge of

exhaust air.

If the hood is installed for use above a gas

appliance then the provision for ventilation

must be in accordance with the Gas Safety

(Installation & Use) Regulations 1994 No.1886

and the relevant building regulations. Details

are contained in the following British Standard

Codes of Practise BS.6172 BS.5440 and

BS.6891 Current Edition.

The fan motor of this cooker hood incorporates

a thermal cut-out device which will operate if

the cooker hood is installed below the

minimum height recommended in this booklet,

or if the motor becomes overheated. If the

cut-out device is acti-vated, switch off the fan

motor and allow the cooker hood to cool.

The cut-out device will reset itself when the

fan motor has cooled significantly.

This cooker hood has been designed for

installation over an electric hotplate with a

maximum input of 7Kw or a gas hotplate

with a maximum input of 10Kw when fitted

in accordance with the heights

recommended in this booklet.

Under no circumstances should you attempt

to repair the appliance yourself. Repairs

carried out by an inexperienced person may

cause injury or more serious malfunctioning.

Refer to your local Tricity Bendix Service

Centre. Always insist on genuine Tricity Bendix

spare parts.

2

Page 4

GENERAL INFORMATION ELECTRICAL CONNECTION

This instruction book applies to the

following models:

Tricity Bendix CH520B Brown 50cm

Tricity Bendix CH520W White 50cm

Tricity Bendix CH610B Brown 60cm

Tricity Bendix CH610W White 60cm

This cooker hood is guaranteed and will

give lasting service. The guarantee is only

applicable if the hood has been installed in

accordance with the installation instructions

detailed in this booklet.

This cooker hood has been designed for

use fixed beneath a wall cabinet or directly

onto the wall using the special brackets

supplied and should be installed in

accordance with the following fitting

instructions.

The cooker hood can be used to extract

odours to the outside or to recirculate the

air within the kitchen after passing the

contaminated air through a cleansing

charcoal filter which is supplied as

standard.

The cooker hood is convertible to either

function by the movement of a change-over

slider control. This enables the cooker hood

when installed in the extraction mode, to be

converted to recircu-lation during the winter

months.

The installation instructions which follow

give instructions on how and where this

hood may be fitted. If already installed

check with the installer that all the

requirements have been met. If not then

draw these to the attention of the installer

who should be a qualified electrician or a

competent person.

Tricity Bendix disclaims all liability for any

damage or injury caused as a result of not

following the instructions contained in the

following text.

Before connecting to the mains supply ensure that

the mains voltage corresponds to the voltage on

the rating plate inside the cooker hood.

WARNING: THIS APPLIANCE MUST BE

EARTHED

This appliance is fitted with a 3 core mains supply

cable and should be permanently connected to

the electricity supply via a double-pole switch

having 3mm minimum contact gap on each pole.

A Switched Fuse Connection Unit to BS.1363 Part

4 (fitted with a 3A fuse), is a recommended mains

supply connection accessory to ensure compliance with the Safety Requirements applicable to

fixed wiring instructions.

CONNECTION TO THE MAINS POWER

SUPPLY

Any permanent electrical installation must comply

with the latest I.E.E. Regulations and local

Electricity Board regulations. For your own safety

this should be undertaken by a qualified

electrician e.g. your local Electricity Board, or a

contractor who is on the roll of the National

Inspection Council for Electrical Installation

Contracting (NICEIC).

WARNING: INCORRECT INSTALLATION

COULD AFFECT THE SAFETY OF THIS

CHIMNEY HOOD.

DISCONNECT THE HOOD FROM THE MAINS

SUPPLY BEFORE CARRYING OUT ANY KIND

OF MAINTENANCE OR CLEANING.

This appliance conforms to BS.800:1988 and

EEC Directive 87/308 regarding suppression of

radio and television interference.

Width: CH520B - CH520W 498mm

Width: CH610B - CH610W 598mm

3

Page 5

INSTALLATION INSTALLATION

UNPACKING

Care should be taken when unpacking the

cooker hood to ensure that the fixing kit,

ducting spigot, blanking plate and literature

pack are retained with the hood.

The fixing kit comprises:

1- Wall/Suspended fixing template.

2- Wall fixing brackets.

4- Plastic rawl plugs.

4- Wall/Suspended fixing screws.

2- Shakeproof washers.

2- Security nuts.

POSITIONING

When installed above an electric cooking

appliance the minimum distance between the

surface of the hob elements and the lower

grille of the cooker hood must be 65cm (25 1/

2").

When installed above a gas cooking appliance

the minimum distance between the surface of

the hob pan supports and the lower grille of

the cooker hood must be 70cm (27 1/2").

However, if you are installing above a

Tricity Bendix hob the minimum distance

between the surface of the hob elements/

pan supports and the lower grille of the

cooker hood may be reduced to 60cm (23

5/8”)

When installed above a cooking appliance with

a high level grill the minimum distance between

the upper surface of the grill and the lower

grille of the cooker hood must be 45cm (17 3/

4").

The distance between the underside of

adjoining wall cabinets and the worktop must

not be less than 40cm (15 3/4").

WALL FITTING

The cooker hood may be fitted to any rigid

vertical surface. All the fittings supplied are to

be found in a polythene bag inside the carton.

IMPORTANT: Before installation check the wall

to which the cooker hood is to be fitted for

electric cables, water pipes or gas pipes before

drilling.

If it is necessary to fix the hood to a hollow construction plaster or partition board structure

then it must be sufficiently reinforced to be quite

rigid in the area of the cooker hood mounting

brackets. The hood must not be fitted using the

key hole fixing points but with the special

brackets supplied.

Use the paper template provided to mark the

hole positions on the wall for the bracket fixing

screws.

Check the hole distances are correct with a

tape measure as stated on the template.

At this stage it is important to allow 15mm (1/

2") clear space above the cooker hood to

enable it to be hooked onto the brackets and

for subsequent removal for decorating or

servicing.

When drilling the holes for the wall fixing

brackets care must be taken to ensure that

they are quite level as there is minimal vertical

height adjustment of the fixing brackets.

The brackets should be fitted with the round

end at the bottom using the plastic rawl plugs

and screws provided.

If the brackets are to be fitted to a hollow

plaster or partition board structure then the

plastic rawl plugs provided should not be used.

Once the brackets are secured lift the hood

squarely to the wall slightly higher than the

brackets and lower the cooker hood until the

cooker hood locates onto the two brackets.

Ensure that the cooker hood is correctly

located before letting go.

Access to the two wall levelling screws and

the security fixing system will require the

removal of the lower inlet grille that supports

the grease mat filter.

To remove the lower grille press inwardly on

the two slide catches located towards either

side of the grille near the front and the grille

will open from the front. The grille pivots at

the rear. Slide the right edge of the grille

forward until it clears the guide and then

unhook the left hinge pin.

Care should be taken to fully support the grille

when removing it from the guides.

The two wall levelling screws will be visible

toward either end of the back panel, visible

when the grille has been removed. Turn the

screws clockwise to lift the front edge of the

hood and use a spirit level to check the hood

is positioned at right angles to the wall before

fitting the security system.

The wall brackets have two studs and when

the cooker hood is hung onto the brackets

the studs project through the two holes above

the levelling screws.

When the hood is level fit the two shakeproof

washers and nuts supplied to fully secure the

cooker hood.

4

Page 6

INSTALLATION Cont’d OPERATING INSTRUCTIONS

WALL CABINET FITTING

Before fitting the cooker hood beneath any

type of wall cabinet ensure it is firmly fixed to

the wall in accordance with the manufacturers

instructions.

Use the paper template provided to mark the

hole positions on the underside of the cabinet.

When marking the underside of the cabinet

the front edge of the template must be aligned

with the front edge of the cabinet carcase.

Check the distances of the holes are correct

with a tape measure as stated on the template.

The four holes are 5mm (1/4") dia.

A pad saw or similar cutter will be required to

cut the circular hole for the ducting spigot if it

is to be used.

Insert the fixing screws through the holes from

inside the cabinet. Supporting the cooker hood

tighten each screw about half way to ensure

that the cooker hood is correctly positioned

before fully tightening the screws.

DUCTING FITTING

If the hood is to be ducted to the outside then

the blanking plate supplied must be fitted in

the aperture that will not be used.

Fit the ducting spigot into the selected aperture

and make an air tight connection.

To fit the ducting spigot and blanking plate align

the inter-locking lugs on the fitting with the

recesses in the aperture and insert turning

clockwise to lock the spigot and blanking plate

into position.

The ducting used must be 100mm (4")

diameter and be manufactured from fire

retardent material conforming to the relevant

British Standard or DIN 4102-B1.

The cooker hood functions are controlled by

two slide switches and a change-over slider

control. The two slide switches, which are

located on the right hand side in the front

fascia panel, control the fan speed and

worktop illumination.

The change-over slider control is located inside

the hood behind the inlet grille immediately in

front of the lamp assembly.

Ensure the hood is in, or wired in and the

power supply is switched on.

The switch marked with the lamp symbol and

numbered 0-1 controls the worktop lighting.

Position -1 indicates the light is operating.

The switch marked with the fan symbol and

numbered 0-1-2-3 controls the fan speed, -1

Low, -2 Normal and -3 Boost.

Position -1 Should be selected when

simmering or when using one pan.

Position -2 Should be selected for normal

cooking up to four pans.

Position -3 Should be selected when frying

or cooking food with strong odour.

In the recirculation position, slider towards the

charcoal filter, air enters the cooker hood,

passes through the grease and charcoal filter

and out through the holes in front of the casing

top panel.

To convert the hood from extraction to

recircula-tion open the metal inlet grille and

slide the change-over control to the right.

Remove the thumb screw from the motor

support. Take the charcoal filter and place it

over the motor support and secure by passing

the thumb screw through the hole in the filter

and into the captivated nut in the centre of

the motor support.

In the ducting position, slider away from the

charcoal filter, the air passes through the

grease filter and out through ducting to the

atmosphere. When the ducting position is

selected, the charcoal filter is not required.

Where flexible ducting is fitted it should not

be turned through very tight bends as this

could impair the performance of the hood. (The

maximum length of ducting including one 90

bend should be 3 metres, to be reduced by 1

metre for each 90 degree bend installed in

the duct run).

When the ducting mode is selected the

charcoal filter is not required.

NOTE: The hood is more effective when used

in the extraction (ducting) mode, therefore this

position should be selected during the warmer

o

months of the year when no room heating is

required. When the room is being heated if the

recirculation position is selected heat will not

be wasted.

To obtain the best performance it is advisable

to switch on the hood a few minutes before

you start cooking and leave it running for

approximately 15 minutes after finishing.

5

Page 7

MAINTENANCE MAINTENANCE

DISCONNECT THE HOOD FROM THE

MAINS SUPPLY BEFORE CARRYING OUT

ANY KIND OF MAINTENANCE OR

CLEANING.

WORKTOP LIGHTING

If a lamp fails to function at any time first check

that it is fully screwed into the holder.

When changing the lamp an identical

replacement must be fitted to ensure the safe

working of the cooker hood. Replacement

lamps are specified 230-240Volts 40Watt

clear cylindrical, candle, or tulip shape with

small Edison (E14) screw thread cap.

CLEANING

For your own safety and in the interests of

hygiene your cooker hood needs to be kept

clean. A build up of grease or fat from cooking

could cause a fire hazard.

Never use excessive amounts of water when

clea-ning particularly around the control panel

area.

The metal casing, lower grille assembly and glass

visor should be cleaned at least once a month

to keep it looking like new. Wipe over the hood

with a soft cloth wrung out in hot water and

containing a mild household cleaner and dry with

a soft cloth. Always wear protective gloves when

cleaning the hood.

NOTE: Never use scouring pads or abrasive

cleaners as they might scratch or damage the

surface.

CHARCOAL FILTER

The charcoal filter cannot be cleaned. It should

be replaced at least once every three months

or more frequently if the cooker hood is used

for more than three hours a day.

kept away from children as the wire clips

have sharp points.

IMPORTANT: There could be a possible fire

hazard if the grease and charcoal filters are

not replaced according to these instructions.

For replacement filters please use the order

form enclosed.

DO’S AND DON’TS

Do’s

Do have the visor open when using the hob

even if the fan on the hood is not switched

on.

Do take extra care when frying.

Do keep heating areas on your hob covered

over with pots and pans when using the hob

and cooker hood simultaneously.

Don’ts

Don’t leave naked flames under the hood.

Don’t leave frying pans unattended during use

as over heated fats and oils may catch fire.

Don’t do flambe cooking under this cooker

hood.

GREASE FILTER

The grease filter is fitted to absorb grease

and dust during cooking to help keep the

appliance clean inside.

FOAM GREASE FILTER

The foam grease filter should be cleaned at

least once a month with normal usage or more

frequently if the cooker hood is used for more

than three hours a day.

The foam filter may be washed by hand in warm

water and mild household detergent or liquid

soap or machine washed at a low 50

temperature wash. The foam filter should be

squeezed dry and not wrung dry.

To remove the grease filter open the metal inlet

grille. carefully ease out the metal retaining

clips to remove the grease filter. Please ensure

that the wire clips are handled with care and

o

C maximum

6

Page 8

HELP US TO HELP YOU

HELP US TO HELP YOU

Please determine your type of enquiry before

writing or telephoning.

SERVICE

In the event of your appliance requiring service, Tricity Bendix have an arrangement with

Electrolux Group Service.

Before calling out an engineer, please ensure

you have read the details under the heading

‘Before Calling a Service Engineer’ and have

the model number and purchase date to hand.

The telephone number and address for service

is detailed on the list headed ‘Tricity Bendix

Service Centres’.

PLEASE NOTE that all enquiries concerning

serv-ice should be addressed to your local

Customer Service Centre.

CUSTOMER CARE DEPARTMENT

FOR GENERAL ENQUIRIES concerning your

Tricity Bendix appliance, or further information

on Cookers, Cooker Hoods, Microwave Ovens,

Refrigeration or Home Laundry equipment, you

are invited to contact our Customer Care

Department.

We have fully trained Home Economists and

Advisors just a telephone call away who can

provide information and brochures.

Do not hesitate to contact us by letter or

telephone as follows:

Customer Care Department

Tricity Bendix

55 - 77 High Street

Slough

Berkshire

SL1 1DZ

BEFORE CALLING A SERVICE

ENGINEER

We strongly recommend that you carry out the

following checks on your appliance before

calling a Service Engineer. it may be that the

problem is a simple one, which you can solve

yourself without the expense of a Service call.

If our Service Engineer finds that the problem

is listed below you will be charged for the call

whether or not the appliance is under

guarantee:

- Make sure the appliance is properly wired

in and that the Connection Unit is

switched “ON”.

- Check there is power to the Connection

Unit.

- Check the fuse in the Connection Unit.

- Check the mains fuse.

Telephone: 08705 950 950 *

* calls to this number may be recorded

for training purposes.

7

Page 9

Page 10

Page 11

Page 12

Rating Plate

The rating plate is situated inside the casing on the back panel. It gives the MODEL

AND SERIAL NUMBER, which should be quoted in any communication or if the

service department is contacted.

It is advisable to make a note of these below and keep for reference before the

appliance is installed.

MAKE AND MODEL NO. SERIAL NO. DATE OF PURCHASE

CH 520 B

CH 520 W

CH 610 B

CH 610 W

PLEASE TICK V APPROPRIATE BOX

This handbook is accurate at the date of printing but will be suspended and should be disregarded if

specifications or appearance are changed in the interests of continued improvement.

Dir. 89/336/CEE

73/23/CEE

© Electrolux Household Appliances Limited 2000

4323984 03 - 280300

Loading...

Loading...