Page 1

TRICITY BENDIX

Better Products. Better Value.

Operating and Installation Instructions

Model No.

AW 660

Page 2

CONTENTS

Important information ......................Page 3

Installation ..........................Page 4

Unpacking ..........................Page 4

Positioning ..........................Page 4

Water inlet ..........................Page 4

Water drainage .........................Page 5

Levelling ...........................Page 5

Electrical connection .......................Page 6

Getting to know your machine ....................Page 7

Control panel .........................Page 7

Washing hints .........................Page 8

Wash care symbols ........................Page 9

Programmes for cotton and linen ....................Page 10

Programmes for synthetics, delicates and wool ................Page 11

Use of detergent and additives ....................Page 12

Using your machine .......................Page 13

Washing 4.5 kg of white cotton at 95°C ..................Page 13

Washing 2 kg of synthetic fabrics at 40°C .................Page 14

Maintenance and cleaning .....................Page 15

Descaling, after each wash, external cleaning ................Page 15

Cleaning the dispenser drawer, cleaning the drawer recess, the dangers of freezing .....Page 15

Cleaning the filter ........................Page 16

The water inlet filters .......................Page 16

Servicing ..........................Page 17

Tricity Bendix guarantee conditions ..................Page 18

Tricity Bendix service centres ....................Page 19

TECHNICAL SPECIFICATIONS

DIMENSIONS Height 85 cm (33.5”)

Width 60 cm (23.6”)

Depth 57 cm (22.4”)

POWER SUPPLY VOLTAGE 220-240 V/50 Hz

TOTAL POWER ABSORBED 2550 W (13A)

WATER PRESSURE Minimum (hot) 005 psi (3.5 N/cm2)

Minimum (cold) 007 psi (4.8 N/cm2)

Maximum 110 psi (76 N/cm2)

MAXIMUM RECOMMENDED Cotton, linen 4.5 kg (10 lb)

LOAD Synthetics, delicate fabrics 2 kg (4.5 lb)

Wool 1 kg (2.2 lb)

SPIN SPEED Maximum 1200 rpm

This appliance complies with the following E.E.C. Directives:

- 73/23 EEC of 19.2.73 (Low Voltage Directive) and subsequent modifications;

- 89/336 EEC of 3.5.89 (Electromagnetic Compatibility Directive) and subsequent modifications.

2

Page 3

IMPORTANT INFORMATION

It is most important that this instruction book should

be retained with the appliance for future reference.

Should the appliance be sold or transferred to

another owner, or should you move house and leave

the appliance, always ensure that the book is supplied with the appliance in order that the new owner

can get to know the functioning of the appliance and

the relevant warnings.

These warnings have been provided in the interest

of safety. You MUST read them carefully before

installing or using the appliance.

INSTALLATION

■

This appliance is heavy. Care should be taken when

moving it.

■

All packing and transit bolts must be removed before

use. Serious damage can occur to the product and to

property if this is not adhered to. See relevant section

in instructions.

■

Any plumbing work required to install this appliance

should be carried out by a qualified plumber or competent person.

■

Any electrical work required to install this appliance

should be carried out by a qualified electrician or

competent person.

■

Care must be taken to ensure that the appliance

does not stand on the electrical supply cable.

■

If the machine is situated on a carpeted floor,

please adjust the feet in order to allow air to circulate freely.

USE

■

Always unplug the appliance and turn off the water

after use.

■

Do not overload the appliance. See relevant section

in instruction book.

■

Only wash fabrics which are designed to be machine

washed. If in doubt, consult the care label on the

clothes.

■

Before washing, ensure that all pockets are empty

and buttons and zips are fastened. Avoid washing

frayed or torn articles and treat stains such as paint,

ink, rust, and grass before washing. Underwired bras

must NOT be machine washed.

■

Any objects such as coins, safety pins, nails, screws,

stones or any other hard, sharp material can cause

extensive damage and must not be placed into the

machine.

■

Garments which have been in contact with volatile

petroleum products should not be machine washed.

If volatile cleaning fluids are used, care should be

taken to ensure that the fluid is removed from the

garment before placing in the machine.

■

Wash small items such as socks, laces, washable

belts etc in a washing bag or pillow case as it is possible for such items to slip down between the tub and

the inner drum.

■

Only use the advised quantities of fabric softener.

Damage to the fabric can ensue if you over-fill. Refer

to the manufacturer’s recommendations of quantities.

■

As some duvets and eiderdowns should be washed

in large commercial machines because of their bulk,

please check with the manufacturer of the item before washing in a domestic machine.

■

The users should always check that they have not

left their gas lighters (disposable or otherwise) in their

clothing.

■

Leave the porthole door slightly ajar between washes

to preserve the door seal.

SERVICE/REPAIR

■

Under no circumstances should you attempt to repair

the machine yourself. Repairs carried out by inexperienced persons may cause injury or serious malfunctioning. Contact your local Tricity Bendix Service

Centre. Always insist on genuine Tricity Bendix

spare parts.

GENERAL SAFETY

■

It is dangerous to alter the specifications or attempt to

modify this product in any way.

■

This appliance is designed to be operated by adults.

Children should not be allowed to tamper with the

controls or play with the product.

■

Pets and children have been known to climb into

washing machines. Please check your drum before

use.

■

The glass door becomes very hot during the washing

cycle. Keep children away from the vicinity of the

appliance whilst it is in operation.

■

When disposing of your old washing machine, the

electric cable must be cut off and the door catch must

be made unusable.

3

Page 4

INSTALLATION

Unpacking

Before starting the machine up, the packing must be

removed as follows.

You are advised to keep all the packaging for re-use in

case the machine is to be transported again.

Using a spanner unscrew

and remove the rear right

bolt. Lay the machine

gently on its back, making

sure that the hoses are

not squashed.

P0255

2

1

P0234

P0233

Positioning

Your new washing machine has been designed to be

permanently plumbed in to your home’s water supply

and drainage system. However, if this is not possible, it

may be connected to suitable existing taps with the drain

hose discharging into a sink.

The appliance has two inlet hoses, hot and cold, with

female 3/4” BSP thread connectors. If this connection is

not compatible with the plumbing of the existing installation, a variety of connectors are available from good

hardware stores and plumbers merchants to suit most

domestic plumbing. Any alteration to your existing plumbing must be carried out by a competent person, or qualified plumber.

Water inlet

The inlets on the back of the appliance are colour coded,

blue for cold and red for hot.

Before connecting the

hoses be sure to fit the

mesh filters supplied as

per diagram.

Remove the polystyrene block from the bottom of the

machine.

Carefully slide out the right polythene bag (1), removing

it toward the centre of the machine.

Repeat the operation for the left polythene bag (2),

removing it toward the centre of the machine.

Remove the polystyrene

base, set the machine

upright and unscrew the

two remaining rear bolts.

P0256

P0001

P0002

Slide out the 3 plastic spacers and plug the 3 holes with

the 3 plastic plugs which you can find at the back of the

machine.

P0003

If only a cold water supply is available, connect the two

hoses to a cold water outlet by means of a «Y» connection piece.

Installation should comply with local water authority and

building regulations’ requirements.

The appliance must be given a separate cold water supply and not be connected to a mixer tap, a single outlet

water heater or a booster pump. A minimum water pressure of 7 psi is required for safe operation of the appliance.

If you cannot make the cold water connection direct from

the rising mains, you may be able to operate the appliance from your cold water storage system.

1

There should be a minimum distance of 5.02m (16

/

ft)

2

between the appliance’s inlet and the bottom of the tank.

There will be sufficient pressure for the hot water supply

from the hot water cylinder if the height between the

appliance’s inlet and the bottom of the cold water storage cistern (not between the appliance and hot water

cylinder) is at least 2.74m (9ft).

Set the hoses correctly by

loosening the ring nuts.

After positioning the inlet

hoses, be sure to tighten

the ring nuts again to prevent leaks.

P0021

4

Page 5

Water drainage

If you intend the drain hose from the machine to empty

into a sink, make sure that the sink is empty and that the

plug hole is not blocked.

If the machine is permanently plumbed in, hook the end

of the hose into a standpipe installed for the purpose.

The standpipe must have an internal diameter of at least

40 mm (1 1/2") in order that there is an air gap between

the drain hose and the standpipe. Make sure, that it is

designed in such a way, that the end of the drain hose

cannot be covered with water.

3 pin

40 mm

inside dia min

600 mm min

P0376

Important

Before connecting up the machine to new pipework or to

pipework that has not been used for some time, run off a

reasonable amount of water to flush out any debris that

may have collected in the pipes.

Whether discharging into a sink or a standpipe check

that the end of the drain hose is neither too high nor too

low. The top of the curve in the hose’s end should be no

more than 90 cm (35.4”), and no less than 60cm (23.6”)

above floor level.

900 mm max

Warning

The machine should NOT be placed on deep pile carpeting.

Note

Please ensure that when the appliance is installed it is

easily accessible for the engineer in the event of a breakdown.

All plumbing and electrical work required to install this

appliance must be carried out by competent persons or

qualified plumbers or electricians.

In the interest of the environment

Washing machines and dishwashers should be connected to the FOUL drainage system, the water will then be

taken to a sewage works for treatment before being

discharged safely into a river.

It is essential that these appliances are not connected to

the surface water drainage system as this water is

discharged directly into a river or stream and may cause

pollution.

If you require any further advice please contact your

local authority drainage department.

Levelling

Level the washing machine by raising or lowering the feet. The feet

may be tight to adjust as

they incorporate a self

locking nut, but the machine MUST be level.

Any necessary adjustment

P0850

prevents vibration, noise and displacement of the machine during operation.

Some vibration is inevitable, especially if mounted on a

wooden floor.

Sprung wooden floors are particularly susceptible to

vibration. For advice, consult a builder. If possible,

always place the machine on a solid floor.

Special conditions

If the floor is carpeted with a deep-pile carpet or covered

with crumbly or soft material, insert a rigid support base

under the feet to prevent noise, vibration or displacement. The base should protrude a few centimetres

beyond the edges of the machine.

can be made with a spanner. Accurate levelling

P0987

RAINWATER

'RUN-OFF'

SURFACE WA TER

DRAINS & SEWERS

UNTREATED

DISCHARGE

RIVER

SHOWER

BATH

WASHING

MACHINE

SINK TOILET

DISHWASHER

BIDET

FOUL DRAIN

FOUL SEWERS

SEWAGE

TREATMENT

WORKS

TREATED

DISCHARGE

RIVER

5

Page 6

Electrical connections

WARNING: THIS APPLIANCE MUST BE EARTHED.

The manufacturer declines any liability should this

safety measure not be observed.

If the plug that is fitted to your appliance is not suitable

for your socket outlet, it must be cut off and the appropriate plug fitted.

Remove the fuse from the cut off plug.

The cut off plug should then be disposed of to prevent

the hazard of shocks in case it should be plugged into a

13 Amp socket in another part of your home.

IMPORTANT

The wires in the mains lead are coloured in accordance

with the following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

If you fit your own plug, the colours of the wires in the

mains lead of your appliance may not correspond with

the markings identifying the terminals in your plug, proceed as follows:

GREEN & YELLOW

BLUE

P0329

13 AMP FUSE

13 AMP

BROWN

CORD CLAMP

Connect the green and yellow (earth) wire to the terminal

in the plug which is marked with the letter «E» or the

earth symbol or coloured green and yellow.

Connect the blue (neutral) wire to the terminal in the plug

which is marked with the letter «N» or coloured black.

Connect the brown (live) wire to the terminal in the plug

which is marked with the letter «L» or coloured red.

The plug moulded on to the lead incorporates a fuse.

For replacement, use a 13 Amp BS1362 fuse. Only

ASTA or BSI approved fuses should be used.

The plug must not be used if the fuse cover/carrier is

lost. The cover/carrier is indicated by the coloured insert

at the base of the plug.

A replacement cover/carrier must be obtained from your

local Tricity Bendix Service Centre.

There is a list of these at the end of this instruction book.

6

Page 7

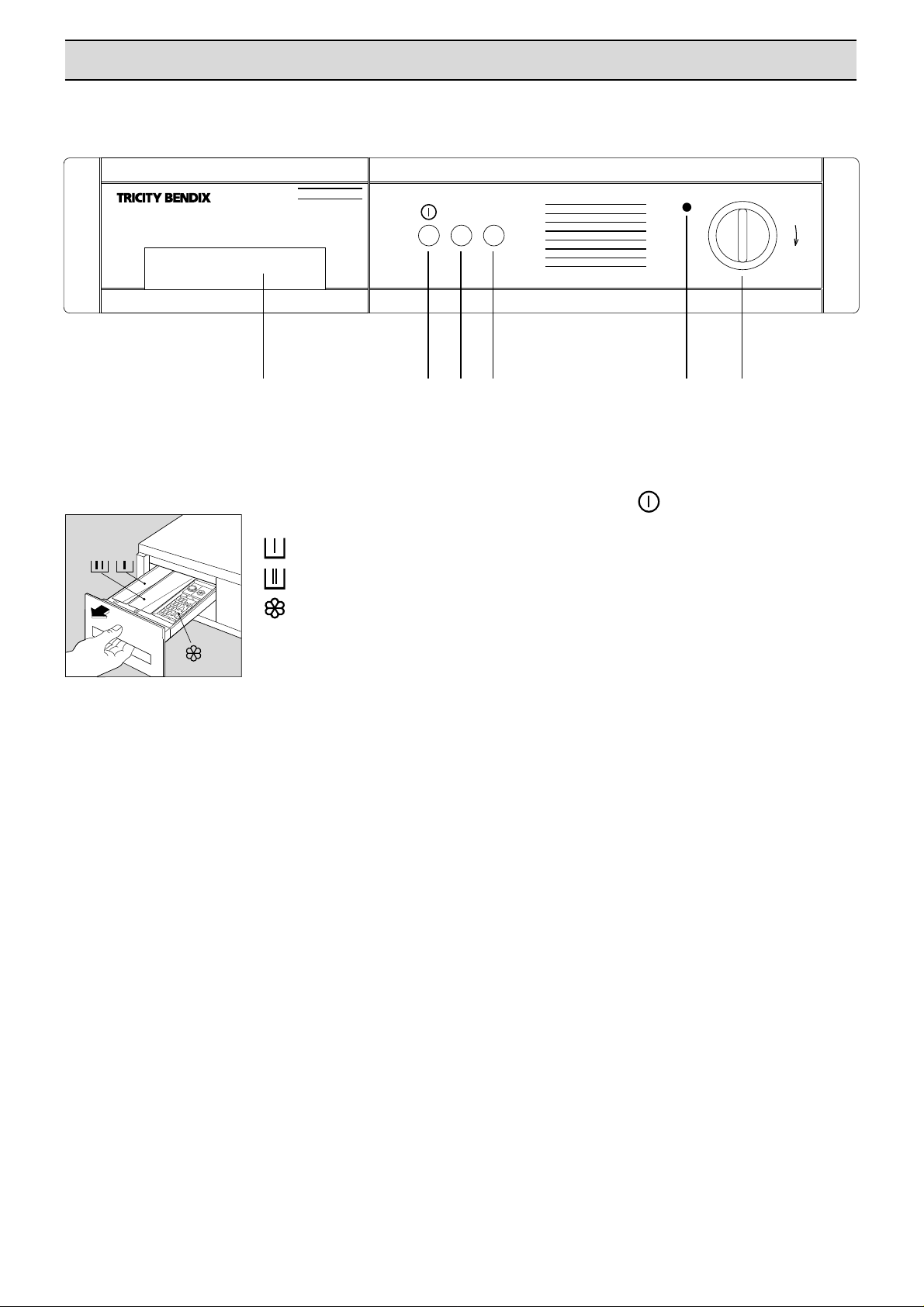

GETTING TO KNOW YOUR MACHINE

Control panel

SHOWER

AUTOWASHER

IMPORTANT : PLEASE READ THE INSTRUCTION MANUAL BEFORE USE

1200

SYSTEM

HALF

LOAD

QUICK

WASH

1

1 Detergent dispenser drawer

Symbols

Prewash

Wash

Fabric softener

P0992

3

2 4 5

2 ON/OFF button

By depressing this button the machine starts operating.

When depressing it again, the machine stops.

3 Half load button

Select this button to reduce water consumption on the

rinse cycle when washing a smaller load of cottons or

linens (maximum load size = 2.25 kg).

4 Quick wash button

By depressing this button on programmes 2-3-4 and 6

the wash time will be reduced by approx. 20 mins.

This is suitable only for garments which are lightly

soiled.

5 Mains-on light

This light illuminates when the machine starts working

and goes out when the ON/OFF button is released.

6

6 Programme selector knob

With the programme selector knob you choose the

desired washing programme. Turn it clockwise.

Before setting the knob to any position the machine

must be switched off by depressing the ON/OFF button.

7

Page 8

Washing hints

Do NOT overload the machine. Weigh the laundry the

first few times you use the appliance.

The average weights of the most common items are

listed below as a guide:

1000g = 1 kg

Sheet 700-1000 g

Pillow case 100-200 g

Tablecloth 400-500 g

Serviette 50-100 g

Tea towel 70-120 g

Linen hand towel 100-150 g

Towelling hand towel 150-250 g

Towelling bath towel 700-1000 g

Bath robe 1000-1500 g

Man’s shirt 200-300 g

■

Some stains such as fruit, wine, grass, rust etc. are

difficult to remove and should be treated before

washing with specific products, which can be found in

most household shops. In some cases it may help to

soak the stain before washing with a special pre-soak

product or biological detergent.

■

Only wool marked «Pure New Wool - washable, preshrunk» can be washed in the machine using the

wool programme; other types of wool should be

washed by hand or dry cleaned.

■

If you have used the machine to wash, rinse or spin

only non-colour fast garments, there may be dye left

in the sump. To ensure any subsequent wash is not

contaminated with the dye, select and carry out a

rinse and spin programme, without any garments, to

ensure that any dye is removed from the sump.

■

Once you have finished using the machine, you are

advised to unplug it and turn off the water taps.

Apron 150-200 g

■

Load the laundry loosely alternating large items with

small ones.

■

Sort the laundry according to the type of fabric,

colour-fastness and how dirty it is.

■

Avoid washing unhemmed or torn items as they may

unravel.

■

Before washing, empty all pockets of small objects

which may have been left inside (coins, keys, screws

etc). as these could damage the drain pump.

■

When washing curtains, remove the hooks.

■

Close poppers and zips and fasten loose buttons.

■

It is essential to wash new coloured items separately

when washing for the first time.

■

When washing fabrics requiring different wash temperatures together, always select the lowest temperature.

■

White items should not be washed with coloured

items.

■

Very small items (handkerchiefs, ribbons, socks etc)

should be washed in a washing bag or a pillow case.

■

Use a good quality detergent suitable for automatic

washing machines.

■

Use the correct quantities of detergent.

■

For wool, use gentle detergent only in small quantities.

■

Bleach is very corrosive; it should be used with care

and kept out of reach of children.

8

Page 9

WASH CARE SYMBOLS

Wash care labels inside garments recommend how to launder your clothes with the best results. The care labelling code

is in line with care labelling used in the rest of Europe. The symbols used make it easy to select the correct programme

on your washing machine.

WASHING SYMBOL

BLEACHING

IRONING

95

60

50

40

40

40

WASH ACTION FABRIC

Normal (Maximum)

Normal (Maximum)

Reduced (Medium)

Normal (Maximum)

Reduced (Medium)

Much Reduced (Minimum)

Hand wash only

Chlorine bleach may be used

White Cotton or Linen

without Special Finishes

Cotton, Linen or Viscose

without Special Finishes

Colourfast at 60°C.

Nylon, Polyester/Cotton, Viscose with

Special Finishes, Cotton/Acrylic Mix.

Cotton, Linen or Viscose

Colourfast at 40°C but not 60°C.

Acrylics, Acetate, Triacetate, Wool

mixes, Polyester/wool blends.

Wool, wool mixtures, Silks

Do not machine wash

DRY CLEANING

P

TUMBLE DRYING

X

IMPORTANT NOTES

Hot iron

Warm iron

Cool iron

May be dry cleaned. Other letters and/or a bar beneath the circle will

indicate the required process to the dry cleaner.

May be tumble dried

with high heat setting

with low heat setting

A cross through any symbol means «DO NOT»

Cotten, Linen, Viscose

Polyester mixtures, Wool

Acrylic, Nylon, Polyester

For best results, always use the dispenser drawer for

dispensing detergents and liquid additives.

Once the dispenser has been filled, close it by pushing it

in gently. This is particularly important if you are using

fabric conditioner to avoid the conditioner entering the

machine prematurely.

When using liquid detergent and a prewash programme,

place the detergent into the correct compartment in the

dispenser drawer, after the prewash has finished.

9

Page 10

Programmes for cotton and linen

Recommended load: max. 4.5 kg (10 lb)

Programmes

PREWASH

&

BOILWASH

BOILWASH Normal

HOT WASH Normal

WARM WASH Light

Degree

of soil

Heavy

Compartments

to use ( if

required)

Programme

dial position

1

2

3

4

Description

Prewash at 40°C

Wash at 95 °C

4 rinses

Spin

Wash at 95 °C

4 rinses

Spin

Wash at 60 °C

4 rinses

Spin

Wash at 40 °C

4 rinses

Spin

SPIN 1200

Water filling: 30°/40°/50° programmes: cold water filling

Water filling: 60° programmes: hot and cold filling

Water filling: 95° programmes: hot filling

5

Spin at 1200 rpm

10

Page 11

Programmes for synthetics, delicates and wool

Recommended load: max. 2 kg (4.5 lb); wool max. 1 kg (2.2 lb)

Programmes

NORMAL

WASH

DELICATE

WASH

WOOL

WASH

30

QUICK & COOL

RINSES

Degree

of soil

Normal

Normal

Normal

Light

Compartments

to use ( if

required)

Programme

dial position

6

7

8

9

10

Description

Wash at 50 °C

3 rinses

Stop with water left in the tub

Wash at 40 °C

3 rinses

Stop with water left in the tub

Wash at 40 °C

3 rinses

Stop with water left in the tub

Wash at 30 °C

3 rinses

Stop with water left in the tub

3 rinses, with fabric

softener, if required

Stop with water left in the tub

CONDITIONER

RINSE

SPIN 650

DRAIN

Important! At the end of the last rinse, the washing machine stops without draining the water so that the garments do not

crease. To drain the water, select programme 12 (short spin) or 13 (draining).

11

12

13

1 rinse, with fabric

softener, if required

Stop with water left in the tub

Draining of water

and short spin at 650 rpm

Draining of water

11

Page 12

WHICH DETERGENT TO USE?....

For most clothes and household textiles,

CONVENTIONAL DETERGENTS will give good

washing results. Conventional detergents are available in

either a biological, such as Ariel, or a non-biological

form, such as Fairy, and are particularly suitable for

whites. Biological detergents provide improved stain

removal, especially at lower temperatures.

For coloured clothes and household textiles, you should

use COLOUR DETERGENTS, like Ariel Color, which

are designed to maintain the original colour of these

items, as well as providing excellent cleaning performance. These are all biological detergents. They are particularly suitable for matching and co-ordinated sets of

lingerie, bedding or towels.

AND IN WHICH FORM?

Not only are there different types of detergent, but they

are also available in different forms.

POWDERS OR LIQUIDS

Powders and their liquid equivalent provide similar cleaning properties, although liquids dissolve faster when

hand washing and at lower temperature washes.

BIOLOGICAL OR NON-BIOLOGICAL

All Biological detergents contain enzymes.

Different types of enzymes assist with the removal of

protein, starch and fat-based stains, such as blood, egg,

chocolate and gravy. However, some people prefer nonbiological detergents which do not contain enzymes.

LOW SUDS

In a front loading automatic washing machine, you

should only use a low suds detergent. The majority of

detergents are now low suds products.

For washing wool and silk, COLOUR DETERGENTS

ARE NOT SUITABLE.

For wool items, you should use a GENTLE/FINE WASH

DETERGENT, such as Dreft, which has been tested and

approved by the International Wool Secretariat and carries the ‘Woolmark’. A similar detergent should also be

used for silk.

To maintain the appearance of your clothes and household textiles and to make them last longer, you should

use different types of detergent for different washes,

whether for whites, colours or delicates. Although this

may require buying two or three different products, you

do not need to use any more powder, or liquid, than if

you were buying just one.

«BIG BOX» OR COMPACT

Compared to their traditional «Big Box»equivalents,

compacts (or concentrates as they are also known) have

an improved performance and environmental profile, as

well as requiring a smaller dosage level.

FABRIC CONDITIONERS

These are ideal for improving ‘softness’. They also reduce static cling on synthetics and make ironing easier.

Fabric Conditioners come in three forms:

Liquids (regular or concentrated) which work in the final

rinse.

Sheets for use in the tumble dryer, and

Combined Detergent and Fabric Softener

USE OF DETERGENT AND ADDITIVES

Choosing the Right Detergent

Always use a low lather powder or liquid. This is important as too much lather prevents the articles from being

properly cleansed and may damage the machine.

Use of Powder Detergent

The washing powder should be placed in the appropriate

compartments in the detergent dispenser drawer before

starting the programme.

Use of Liquid Detergent

A liquid detergent can be used in the middle compartment of the dispenser drawer. Start the machine immediately upon placing the liquid in the dispenser drawer.

12

Use of Fabric Conditioners

Any liquid additives for softening or dressing the laundry

must be poured into the appropriate compartment of the

detergent dispenser drawer before starting the programme.

The compartment with the symbol is for softeners

and dressing agents; never exceed the MAX. Ievel.

When using super concentrated fabric conditioners,

please follow the manufacturer’s instructions carefully.

Page 13

USING YOUR MACHINE

WASHING 4.5 KG OF WHITE COTTON AT 95°C

Suppose you have 4.5 kg of normally dirty laundry to

wash. It is white cotton and is suitable for high temperature washing.

1 Load the laundry

Open the door by pulling

the catch outward. Load

the items one at a time

and close the door.

P0004

2 Measure out the detergent

5 Select the required wash programme

Turn the programme

selector dial clockwise to

the required programme

2

P0998

(2).

6 Start the machine

Before starting up the machine check that:

■

the appliance is plugged in

■

the water supply taps are turned on

■

the drain hose is correctly and securely positioned

■

the door and the detergent dispenser drawer are

closed.

Depress the ON/OFF button: the mains-on light illuminates and the machine

starts operating.

P0992

P0994

Pull out the detergent dispenser drawer from the control

panel. Measure out the amount of detergent required

and pour into the main wash compartment.

If you wish to carry out a programme with prewash, pour

the amount of detergent required into the «prewash»

compartment.

3 Add the fabric softener if required

Pour the fabric softener, if

required, into the compartment marked .

Do not exceed the MAX

level and then close the

drawer gently.

P0995

4 Select the required options

Depress Half load button and/or Quick wash, if desired.

P0033

7 At the end of the programme

The machine stops automatically.

The door is controlled by a safety device which releases

2 minutes after the end of the programme.

Switch the machine off by depressing the ON/OFF but-

ton again. The mains-on light goes out.

When the programme has finished you are advised to

unplug the appliance and turn off the water taps.

13

Page 14

WASHING 2 KG OF SYNTHETIC FABRICS AT 40°C

Suppose you have 2 kg of synthetic fabric laundry to

wash. They are rather delicate fabrics and should not be

washed at a high temperature.

1 Load the laundry

Open the door by pulling

the catch outward.

Load the items one at a

time and close the door.

P0004

2 Measure out the detergent

4 Select the required wash programme

Turn the programme

selector dial clockwise to

the required programme

(7).

P0993

13

12

7

5 Start the machine

Before starting up the machine check that:

■

the appliance is plugged in

■

the water supply taps are turned on

■

the drain hose is correctly and securely positioned

■

the door and the detergent dispenser drawer are

closed.

Depress the ON/OFF button: the mains-on light illuminates and the machine

starts operating.

P0992

P0994

Pull out the detergent dispenser drawer from the control

panel. Measure out the amount of detergent required

and pour into the main wash compartment.

3 Add the fabric softener if required

Pour the fabric softener, if

required, into the compartment marked .

Do not exceed the MAX

level and then close the

drawer gently.

P0995

P0033

6 At the end of the programme

The machine will stop after the last rinse with the water

left in the wash tub, to prevent the fabric from creasing.

To drain the water select programme 12 or 13.

The door is controlled by a safety device which releases

2 minutes after the end of the programme.

Switch the machine off by depressing the ON/OFF button again. The mains-on light goes out.

When the programme has finished you are advised to

unplug the appliance and turn off the water taps.

14

Page 15

MAINTENANCE AND CLEANING

Before any maintenance or cleaning is carried out you

must DISCONNECT the appliance from the electricity

supply.

Descaling

The water we normally use contains lime. It is a good

idea to periodically use a water softening powder in the

machine. Do this separately from any laundry washing,

and according to the softening powder manufacturer's

instructions. This will help to prevent the formation of

lime deposits.

After each wash

Leave the door open for a while. This helps to prevent

mould and stagnant smells forming inside the appliance.

Keeping the door open after a wash will also help to preserve the door seal.

External cleaning

Clean the exterior cabinet of the appliance with soap and

water only, and then dry thoroughly.

Cleaning the dispenser drawer

From time to time the washing powder and additive

dispenser drawer should be cleaned.

Remove the drawer by pressing the catch downwards

and by pulling it out. Flush it out under a tap, to remove

any traces of accumulated powder.

The dangers of freezing

If the machine is exposed to temperatures below 0°C,

certain precautions should be taken.

■

Turn off the water taps.

■

Select a wash programme and run for a few seconds.

■

Unscrew the inlet hoses.

■

Unhook the drain hose from the rear support and

position the end in a bowl. Run the draining programme for a few seconds.

■

When you intend to start the machine up again,

make sure that the room temperature is above 0°C.

P0996

P0997

Cleaning the drawer recess

Having removed the

drawer, use a small brush

to clean the recess, ensuring that all washing

powder residue is removed from the upper and

lower part of the recess.

Replace the drawer and

P0038

run the rinse programme

for a few minutes without

any clothes in the drum.

15

Page 16

Cleaning the filter

The water drain filter

A clean filter is important for the correct functioning of the

machine, and should therefore be cleaned after every

wash.

Open the filter door and

place a container underneath to catch any spillage. If the filter is blocked

and the machine is unable

to drain you will need to

drain the water manually

from the machine at this

P0011

standpipe or sink and hold the end of the hose over a

bowl on the floor. The water should drain by gravity into

the bowl. When the bowl is full, hook the hose back up

and empty the bowl. Repeat the procedure until water

stops flowing out.

Unscrew and remove the filter.

stage. To do this, unhook

the drain hose from the

The water inlet filters

If your water is very hard or contains traces of lime deposit, the water inlet filters may become clogged.

It is therefore a good idea to clean them from time to

time.

Turn off the water taps. Unscrew the water inlet hoses.

Remove and clean the filters using a hard bristle

brush. Replace the filters

and tighten up the inlet

hoses.

P0041

P0132

P0133

Clean carefully under a

fast running tap.

P0040

Warning

When the appliance is in use and depending on the programme selected there can be hot water in the filter.

Never remove the filter during a wash cycle, always wait

until the appliance has finished the cycle, and is empty.

When replacing the filter, ensure it is securely retightened so as to stop leaks and young children being able

to remove it.

16

Page 17

SER VICING

Before contacting your local Tricity Bendix

Service Centre, please make the following

checks:

The machine does not start up

■

The ON/OFF button has not been depressed

■

The door is not closed properly

■

No water is entering the machine (see: the machine

does not fill)

■

The selector dial is not correctly positioned

The machine does not fill

■

The water taps are not turned on

■

The water supply has been disconnected

■

The inlet hoses are kinked

■

The water pressure is too low

■

The water inlet filters are clogged

■

The door is not closed properly

The machine empties as it fills

■

The end of the drain hose is too low

■

The end of the drain hose is submerged in water

■

Drain pipe has no vent-hole

If, after the above checks, there is still a fault, call your

local Tricity Bendix Service Centre.

Please make sure you give the model and serial number

of the appliance.

Rating plate

Mod. ..........

Prod. No. ...........

Ser. No. .........

This information can be

found on the rating plate

(see picture) or on the

guarantee card.

Mod. ..........

Prod. No. ...........

P0042

Ser. No. .........

Original spare parts can be purchased from Tricity

Bendix Service Centres.

In-guarantee customers should ensure that the

above checks have been made as the engineer will

make a charge if the fault is not a mechanical or

electrical breakdown.

Please note that proof of purchase is required for

any in-guarantee service calls.

The machine does not drain or spin

■

You have selected a gentle wash cycle

■

The drain filter is clogged

■

The drain hose is kinked

■

The drainage system pipes are blocked

■

The drain hose extension is incorrect

■

The wash load is unbalanced: redistribute the clothes

inside the drum to allow the machine to spin

The machine leaks or overflows

■

Too much detergent

■

Unsuitable detergent

■

The inlet hose(s) is (are) loose

■

The detergent dispenser drawer or recess is clogged

■

The end of the drain hose is not securely positioned

■

The drainage system pipes are blocked

The machine vibrates or is noisy

■

The internal packing has not been removed

■

The machine is not level

■

The machine is in contact with the wall or furniture

■

The washing load is badly distributed

■

The machine is overloaded

The door does not open

■

The safety device has locked it

■

Water in the tub: the door cannot be opened if water

is present in the tub

17

Page 18

TRICITY BENDIX GUARANTEE CONDITIONS

We, Tricity Bendix, undertake that if within 12 months of

the date of the purchase this TRICITY BENDIX appliance or any part thereof is proved to be defective by reason only of faulty workmanship or materials, we will, at

our option repair or replace the same FREE OF ANY

CHARGE for labour, materials or carriage on condition

that:

■

The appliance has been installed correctly and used

only on the electricity supply stated on the rating

plate.

■

The appliance has been used for normal domestic

purposes only, and in accordance with the manufacturer's operating and maintenance instructions.

■

The appliance has not been serviced, maintained,

repaired, taken apart or tampered with, by any person not authorised by us.

All service work under this guarantee must be undertaken by a Tricity Bendix service representative or authorised agent.

Any appliance or defective part replaced shall become

our property.

This guarantee is in addition to your statutory and other

legal rights.

Home visits are made between 8.30 am and 5.30 pm

Monday to Friday. Visits may be available outside these

hours in which case a charge will be made.

Exclusions

This guarantee does not cover:

■

Damage or calls resulting from transportation, improper use or neglect, the replacement of any light bulbs

or removable parts of glass or plastic, or vacuum

cleaner drive belts, brushes or dust bags.

■

Costs incurred for calls to put right an appliance

which is improperly installed or calls to appliances

outside the United Kingdom.

■

Appliances found to be in use within a commercial

environment, plus those which are subject to rental

agreements.

■

Products of Tricity Bendix manufacture which are not

marketed by Tricity Bendix Ltd.

■

EEC Countries. The standard guarantee is applicable

but subject to the owner's responsibility and cost to

ensure the appliance meets the standards set by the

country to which the product is taken.

Proof of purchase may be required. Electrolux

Aftersales Service in the country concerned, with

whom Tricity Bendix have an arrangement, will be

pleased to advise further.

18

Page 19

TRICITY BENDIX SERVICE CENTRES

CENTRE

ABERDEEN

ARGYLL

BARNSTAPLE

BORDERS

POSTAL DISTRICTS

AB

PA 24-61

EX 18-23

31-39

TD

SERVICE

APPOINTMENTS

01224-696569

01369-703161

01271-328826

01573-224411

ADDRESS

Tricity Bendix After Sales Service

Northeast Appliance Service

8 Cornhill Arcade

Cornhill Drive

Aberdeen

AB2 5UT

Tricity Bendix After Sales Service

T.D.C. Refrigeration

Briar Hill

7 Hill Street

Dunoon

Argyll

PA 23 7AL

Tricity Bendix After Sales Service

McBain Refrigeration

Unit 4 Upcott Avenue

Pottington Industrial Estate

Barnstaple

North Devon

EX31 1HN

Tricity Bendix After Sales Service

James Stewart & Son

2-8 Wood Market

Kelso

Borders

TD 5 7AX

BRISTOL

CANVEY

CARDIFF

CUMBRIA

BA BSSP TA

EECENNNWWC

AL CB HA HP LU MK SG UB

WD

CM CO IG RM SS

IP NR PE 14-19,30-38

or

CF, NP 1-4, 6, 9-44

SA 1-18 SA 21-32

CA

0117-9211876

0181-443-3464

0181-965-9699

0181-965-9699

01268-694144

01603-667017

01266-694144

01222-460131

01228-594747

Tricity Bendix After Sales Service

Unit BE46

PO Box 37

Bristol

BS 99 1UD

Tricity Bendix After Sales Service

2-4 Sandhurst

Kings Road

Canvey Island

SS8 OQY

Tricity Bendix After Sales Service

Guardian Industrial Estate

Clydesmuir Road

Tremorfa

Cardiff

CF2 2QS

Tricity Bendix After Sales Service

E.T.B. Services

Carlisle Enterprise Centre

James Street

Carlisle

CA2 5AP

DUMFRIES &

GALLOWAY

DG 1-14

01387-265166

Tricity Bendix After Sales Service

Allan Crossan (Service)

93 Irish Street

Dumfries

Scotland

DG1 2PQ

19

Page 20

TRICITY BENDIX SERVICE CENTRES

CENTRE

DUNDEE

GLASGOW

GUERNSEY

HAVERFORDWEST

POSTAL DISTRICTS

DD1-14

PH8-18

EH FK G KA KY1-16 ML

PA 1-23, PH 1-7

All Codes

SA33-39,

SA41-44,

SA61-73

SERVICE

APPOINTMENTS

01250-876285

0141-6474381

01481-46931

01437-710914

ADDRESS

Tricity Bendix After Sales Service

I Brogan Domestics

41 Lesley Street

Blairgowrie

Perthshire

PH 10 6AT

Tricity Bendix After Sales Service

20 Cunningham Road

Clyde Estate

Rutherglen

Glasgow

G73 1PP

Guernsey Electricity

PO Box 4

Vale

Guernsey

Channel Island

Tricity Bendix After Sales Service

C Butherway

1 Church Road

Roch

Haverfordwest

Dyfed/Wales

SA 62 6AG

HEREFORD

HULL

INVERNESS

INVERNESS

HR1-9

LD1-8

SY7,18

NP5,

NP7,

NP8

YO4

YO11-18

YO25

HU1-19

DN14

IV1-28, 30-36, 52-56

PH19-26, 42-44

KW1-14

PH30-41 IV40-51

01432-340334

01482-58567

01463-792952

01855-821315

Tricity Bendix After Sales Service

Domestic Repair Centre

Unit 3 Bank Buildings

Cattle Market

Hereford

HR4 9HX

Tricity Bendix After Sales Service

John Sizer

Unit 1, Boulevard Unit

Factory Estate

Hul

HU3 4AY

Tricity Bendix After Sales Service

Highland Appliances

Unit 3B3 Smithton Industrial

Estate

Smithton

Inverness

IV 1 2PD

Tricity Bendix After Sales Service

George Ross Electrical

Forrestry Workshop

Inchree

Onich

Invernesshire

PH33 6SE

ISLE OF WIGHT

20

PO30-41

01983-872552

Tricity Bendix After Sales Service

Wyatts Electrical Service

4 Forelands Road

Bembridge

Isle of Wight

PO35 5XW

Page 21

TRICITY BENDIX SERVICE CENTRES

CENTRE

ISLE OF ARRAN

ISLE OF LEWIS

ISLE OF MAN

ISLE OF MULL

JERSEY

LAMPETER

POSTAL DISTRICTS

KA27

PA83-87

IM

PA62-75

All Codes

SA19, 20

SA 40

SA45-48

SY23-25

SERVICE APPOINTMENTS

01770-302909

01851-705555

01624-687794

01688-302262

01534-505050

01570-423020

ADDRESS

Tricity Bendix After Sales Service

Arran Domestics

Unit 4 The Douglas Centre

Brodick

Isle of Arran

KA27 8AJ

Tricity Bendix After Sales Service

N D Macleod

Churchhouse

16 James Street

Stornoway

Isle of Lewis

PA87 2QW

Tricity Bendix After Sales Service

Manx Electricity

Service Workshop

North Quay

Douglas

Isle of Man

Tricity Bendix After Sales Service

B Hogg

Braeside

Raeric Road

Tobermory

Isle of Mull

PA75 6PU

Jersey Electricity Company

PO Box 45

Queens Road

St Helier

Jersey, Channel Islands

JE4 8NY

Tricity Bendix After Sales Service

Lampeter Domestic Appliance

Service

Unit 16 Lampeter Industrial Estate

Lampeter, Dyfed

SA48 7DY

LANCASTER

LEEDS

LINCOLN

LIVERPOOL

LA1-23

BD DN1-7, 10-12 HD HG HX

LS SWF YO1-3, 5-8 DE

NG1-22 & 25

DN21 subcd. 1, 2 & 5 only

LN1, 2, 4-6

LN3 subcodes 4 & 5 only

LN8-10

NG23, 24 31-34

PE 1-13, 20-25

FY PR L WN CH CW WA

(Not WA14-15)

01772-316175

0113-2608511

01522-514603

0151-254 1724

Tricity Bendix After Sales Service

NL Services

Unit 333 Ranglet Road

Walton Summit

Bamber Bridge

Preston, Lancashire, PR5 8AR

Tricity Bendix After Sales Service

64-66 Cross Gates Road

Leeds, LS15 7NN

Tricity Bendix After Sales Service

Brian Hudson

Unit 8 Stonefield Park

Clifton Street

Lincoln, LN 5 8AA

Tricity Bendix After Sales Service

Unit 1 Honeys Green Precinct

Honeys Green Lane

West Derby

Liverpool, L12 9JH

21

Page 22

TRICITY BENDIX SERVICE CENTRES

CENTRE

MANCHESTER

NEWTON ABBOTT

NORTH WALES

NORTHERN

NORTHERN IRELAND

EAST

POSTAL DISTRICTS

BB BL OLM SK

WA14 & 15 only

EX1-17

PL1-9, 16, 19-21

TQ

LL

DL TSDH YO21,22

DH NESR

BT1-30,36-57,63-67

SERVICE

APPOINTMENTS

0161-477 7758

01626-65909

01745-591616

01745-590096

01325-301400

0191-493-2025

01232-746591

ADDRESS

Tricity Bendix After Sales Service

Unit 30 Oakhill Trading Estate

Devonshire Road

Worsley

Manchester, M28 3PT

Tricity Bendix After Sales Service

South West Domestic Service

Unit 2 Zealley Industrial Estate

Kingsteignton

Newton Abbott

South Devon, TQ12 3SJ

Tricity Bendix After Sales Service

GMS (Cymru)

Unit 2 Coed - Parc

Abergele Road

Rhuddlan

Clwyd, Wales, LL18 5UG

Tricity Bendix After Sales Service

PO Box 40

Preston Road

Aycliffe Industrial Estate

Newton Aycliffe, Co Durham

DL5 6XA

Tricity Bendix After Sales Service

Unit C3

Edenderry Industrial Estate

326 Crumlin Road

Belfast, BT14 7EE

NORTHERN IRELAND

WEST

NUNEATON

ORKNEY

REDDITCH

REDRUTH

BT31-35, 60-62

BT68-82, 92-94

B1-48, 62-79, 90-94 DY ST

WR15 WS WV

NN CV LE

KW15-17

GL OX WR (Not WR15) SN

B49, 50, 60, 61, 80, 95-98

TR1-20, 26, 27

PL10-15, 17, 18, 22-35

01861-510400

0121-358-7076

0121-358-7076

0121-358-5051

01203-354424

01856-875457

01527 512919

01993 704411

01209-314407

Tricity Bendix After Sales Service

G & O (Armagh) Service

Owenmore House

Kilwee Business Park

Upper Dunmurray Lane

Belfast, BT17 0HD

Tricity Bendix After Sales Service

Unit 23-24 Alliance Business

Park

Townsend Drive

Nuneaton

Warwickshire, CV11 6RX

Tricity Bendix After Sales Service

Refrigeration Sales and Service

Hatson Ind. Estate

Kirkwall

Orkney

Tricity Bendix After Sales Service

Heming Road

Washford

Redditch

Worcestershire, B98 ODH

Tricity Bendix After Sales Service

Cornwall Domestic Service

Unit 7D Pool Industrial Estate

Wilson Way

Redruth, Cornwall

TR15 3QW

ROTHESAY

22

PA20 01700-504777

Tricity Bendix After Sales Service

D McGlashan

Walker Engineering

Glenmhor

Upper Serpentine

Rothesay, PA20

Page 23

TRICITY BENDIX SERVICE CENTRES

CENTRE

SHETLAND

SHETLAND

SHETLAND

SHETLAND

POSTAL DISTRICTS

Own Sales

Own Sales

Own Sales

ZE2

SERVICE

APPOINTMENTS

01595-692915

01595-692225

01595-692855

01806-566546

ADDRESS

Tricity Bendix After Sales Service

G. Robertson Ltd.

3/4 Carlton Place

Lerwick

Shetland

ZE1 OED

Tricity Bendix After Sales Service

Tait Electronic Systems Ltd

Holmsgarth Road

Lerwick

Shetland

ZE1 OPW

Tricity Bendix After Sales Service

Bolts Shetland Ltd

26 North Road

Lerwick

Shetland

ZE1 OPE

Tricity Bendix After Sales Service

Leask Electrical

Harsdale

Symbister

Shetland

ZE2 9AA

SHREWSBURY

SOUTH COAST

SOUTH HUMBERSIDE

TONBRIDGE

SY1-6

SY8-17

SY19-22

TF

BH DT PO1-22 SO

TR 21-25

DN8, 9

DN15-20

DN21 subcodes 3, 4 only

DN31-40

LN3 subcode 6 only

LN7, 11-13

GU1-35 RG SL

CT DA METN

BN1-18 20-27 RH

TW BR CRSE SW SM KT

01743-450279

01705-667411

0117-9211876

01472-267978

01252-24505

01732-357722

01273-694341

0181-658-9069

Tricity Bendix After Sales Service

BLI Service

6 Harlescott Barn

Harlescott Lane

Shrewsbury, Shropshire

SY1 3SY

Tricity Bendix After Sales Service

Limberline Road

Hilsea

Portsmouth

Hampshire

PO3 5JJ

Tricity Bendix After Sales Service

John Robinson (Electrical)

81 Pasture Street

Grimsby

DN32 9EP

Tricity Bendix After Sales Service

Unit 30

Deacon Trading Estate

Morley Road

Tonbridge

Kent

TN9 1RA

WESTERN ISLES

HS9 01871-890206

Tricity Bendix After Sales Service

Mr. J. Zerfahs

244 Bruernish

Isle of Barra

Western Islands

HS9 5QY

23

Page 24

TRICITY BENDIX

Better Products. Better Value.

Tricity Bendix, 99 Oakley Road, Luton, Beds LU 4 9QQ

124986480

Model No.

AW 660

A DIVISION OF EMACO LIMITED.

REGISTERED IN ENGLAND NO. 176547

Part No.

124986480

Loading...

Loading...