Triangle Engineering CC3623, CC3022, CC3023, CC3622, CC4223 Installation And Operation Manual

...

OWNER’S

MANUAL

Keep for

COMFORT COOLER

Whole House Fans

future reference

READ AND SAVE THESE INSTRUCTIONS!

INSTALLATION AND OPERATION

®

IMPORTANT: Carefully read these instructions

before you install or operate your new whole house

fan. Proper installation is important to achieve

maximum cooling efficiency. It is necessary to provide adequate ventilation to meet minimum exhaust

CAUTION - SAFETY RULES

WARNING - TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

Before servicing or cleaning unit, switch power

off at service panel and lock service disconnecting

means to prevent power from being switched on

accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

Installation Work And Electrical Wiring Must Be

Done By Qualified Person(s) In Accordance With All

Applicable Codes And Standards, Including Fire-rated

Construction.

Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent back drafting. Follow

the heating equipment manufacturer’s guideline and

safety standards such as those published by the

National Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration and Air

requirements. This prevents pressure build-up in

the attic which will reduce the fan's efficiency. Refer

to the ventilation work sheet on the back page of

this instruction sheet to determine the exhaust air

requirements.

Conditioning Engineers (ASHRAE), and local code

authorities.

When cutting or drilling into wall or ceiling, DO NOT

damage electrical wiring and other hidden utilities.

CAUTION - For General Ventilating Only, Do Not

Use To Exhaust Hazardous Or Explosive Materials

And Vapors.

CAUTION - This Unit Has An Unguarded Impeller.

Do Not Use In Locations Readily Accessible To

People Or Animals.

Your whole house fan will operate only on 120 Volt,

A.C., 60 Hz (cycle) current.

Permanent THREE WIRE (grounded) wiring must

be used. DO NOT USE AN EXTENSION CORD.

To avoid risk of electrical shock, fire and other

injuries DISCONNECT MAIN POWER SUPPLY prior

to installation.

This fan is to be mounted in a location where the

entrance of drawn in water (rain) is unlikely.

If shutter is removed for servicing, replace before

normal operation.

WARNING: TO REDUCE THE RISK OF FIRE OR

ELECTRICAL SHOCK, DO NOT USE THIS FAN WITH

ANY SOLID-STATE FAN SPEED CONTROL DEVICE.

Do not operate this fan in areas where gas or oil

fired equipment are in operation.

Wear safety goggles when drilling, hammering or

cutting materials.

TRIANgLE ENgINEERINg Of ARkANSAS, INc.

E-mail: mail@trianglefans.com • Website: www.trianglefans.com

TM

1101 North Redmond Road • Jacksonville, Arkansas 72076 • (501) 982-7558 • Fax (501) 982-5691 • 1-800-255-9014

LIMITED

10 YEAR

WARRANTY

INSTALLATION RECORD Please complete for future use.

Model # ____________________________________________

Serial # ____________________________________________

Purchased from ______________________________________

Date Purchased ____________ Date installed ______________

Page 1

Revised 5/12

Tools required for installation

• Hammer

• Utility Knife or sheetrock saw

• Power or handsaw

• Pencil

• Framing square

• Straight edge

• Measuring tape

• Screwdriver

• Safety goggles

• Power or hand drill

Other materials required

• Framing lumber

• Platform lumber

• Automatic ceiling shutter

• Code required electrical materials

A

(square)

C

B

VERTICAL INSTALLATION:

Contact the factory

for information and

instructions on vertical

installation of the

Comfort Cooler Fan.

C.F.M. Blade Weight Dimensions Cools

Model H.P. Hi-Lo Dia. LBS. A B C Sq. Ft.

CC 2422 1/3 5,600 / 3,700 24" 57 30" 4" 15" up to 800

CC 3022 1/3 7,600 / 5,100 30" 62 34" 4" 15" 800 - 1,200

CC 3023 1/2 8,400 / 5,600 30" 67 34" 4" 15" 900 - 1,500

CC 3622 1/3 9,700 / 6,400 36" 77 40" 4" 15" 1,200 - 1,800

CC 3623 1/2 10,600 / 7,100 36" 82 40" 4" 15" 1,500 - 2,500

CC 4223 1/2 12,600 / 8,400 42" 91 46" 4" 15" 2,200 - 3,200

CC 4823 1/2 14,500 / 9,700 48" 107 52" 4" 15" 2,500 - 4,000

SPECIFICATIONS - FANS

STOP!

SHUTTER INSTALLATION NOTICE!!!

If you have purchased this fan with a Model “CSS”

shutter, read the section for “CSS” shutter installation

only. (See pages 4,5).

If you have purchased this fan with a Model

“AS” shutter, read the section for “AS” Shutter

installation only. (Pages 2,3).

LOCATION OF FAN: The most logical place to

locate your whole house fan is near the central part

of the house. Check attic area to be certain there

is a clearance space above the fan equal to the

diameter of the fan blade. Inspect the area where

the fan is to be installed. The area must be free of

electrical wiring and pipes.

CAUTION: DO NOT OPERATE THIS FAN UNTIL

SHUTTER IS INSTALLED!

“AS” SERIES SHUTTER INSTALLATION

“AS” SHUTTERS

Fan Outside Inside

Model Size Dimension Dimension

AS10 24" 26" x 26" 24" x 24"

AS11 30" 32" x 32" 30" x 30"

AS13 30" 32" x 38" 30" x 36"

AS14 30" 34" x 36" 32" x 34"

AS15 36" 35" x 38" 33" x 36"

AS16 36" 34" x 45" 32" x 43"

AS18 42" 36" x 48" 34" x 46"

AS26 48" 38" x 58" 36" x 56"

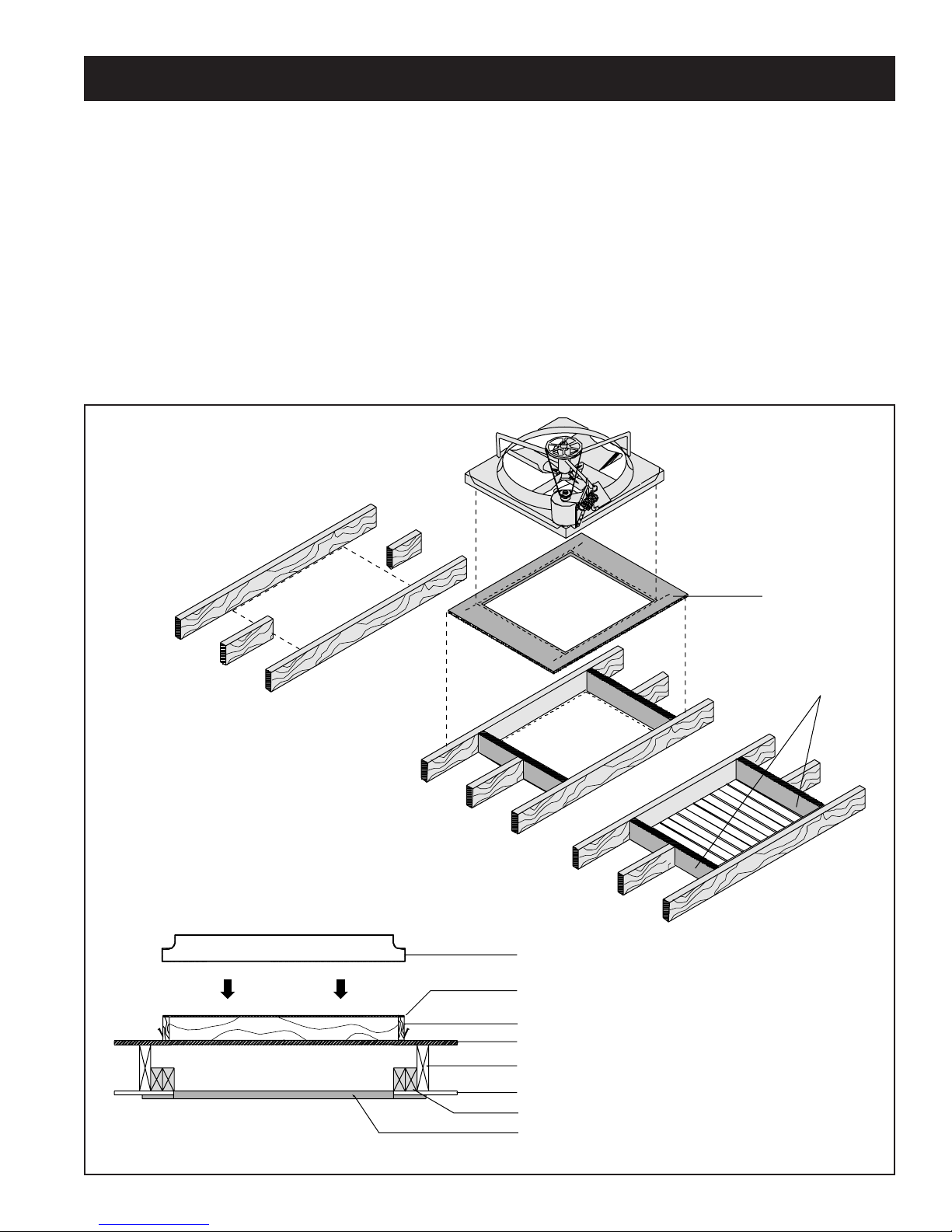

STEP 1. After the installation site has been

selected, clear the area of all insulation.

Establish the location of the shutter on the finished

side of the ceiling. Use the INSIDE DIMENSIONS of

the shutter and draw the four corners of the opening.

Drill a

1

/4" hole at each corner. Return to the attic

and inspect the area to make certain that the fan

and shutter installation area will not be obstructed

and that area is conveniently located for ease of

THE SAME SIZE

inside dimensions

as shown in this

CAUTION:

DO NOT CUT

THE SHUTTER

OPENING

AS THE FAN

OPENING.

Use the shutter

chart.

installation. Use a utility knife or sheetrock saw and

carefully cut the shutter opening. (See fig. 1).

STEP 2. From the attic side cut the ceiling joist 1

back from shutter opening. This is to accommodate

additional framing to support the joists that have

been cut. (See fig. 1).

STEP 3. Frame the opening using lumber EQUAL

TO THE EXISTING JOISTS. Attach the new framing to

the existing joists. Before fastening, make sure that

the existing joists that were cut DO NOT sag below

the uncut joists and new framing. (See fig. 2).

STEP 4. If additional framing or blocking is needed to

support the shutter, install it at this time. (See fig. 4).

STEP 5. Remove the two (2) screws that secure

the fan to the plenum. Pass the fan and plenum into

the attic through the framed opening in the ceiling

and set them aside at this time.

STEP 6. Build a platform to support the fan using

lumber, plywood or other material a minimum of

3

/4" thick. The platform must be constructed so that

it supports all four sides of the fan, and should be

wide enough to prevent Attic Air from being drawn

Page 2

1

/2"

“AS” SERIES SHUTTER INSTALLATION, continued

into the fan. With some combinations of fan and

shutter, a portion of the opening may be blocked

by the platform. This will not effect the efficiency of

the fan. Fasten the platform to the joists and new

framing. (See fig. 2).

STEP 7. Center the plenum on the platform and

toe nail it in place. NOTE: WHEN TOE NAILING

PLENUM TO PLATFORM MAKE CERTAIN THAT THE

SIDES OF THE PLENUM REMAIN STRAIGHT AND

SQUARE OR THE FAN WILL NOT FIT PROPERLY.

STEP 8. To prevent Attic Air from entering the

plenum, tape all of the joints of the new framing,

platform and plenum with duct tape or aluminum

foil tape.

STEP 9. Place the fan on the plenum making sure

that the rubber isolation mount is in place between

the fan and plenum. DO NOT REPLACE SCREWS.

This is to permit the fan to “float” on the rubber

mount which helps reduce noise. (See fig. 4).

STEP 10. Install the flush mounted ceiling shutter

into the ceiling opening using the screws provided.

Caution should be taken not to effect the free

operating action of the shutter. (See figs. 3 & 4).

REFER TO THE “ELECTRICAL WIRING”

SECTION ON PAGES 5 & 6.

Fig. 1

Fig. 4

Platform

New framing

Fig. 2

Fig. 3

Fan Frame

Rubber Mount

Plenum

Platform

Existing Joist

Ceiling

Blocking as needed

Shutter

Page 3

“CSS” SERIES SHUTTER INSTALLATION

Models CSS-24, CSS-30 & CSS-36, install on joists with 16" or 24" centers.

Model CSS-42 installs on 24” centers only.

CAUTION: DO NOT CUT THE SHUTTER OPENING

THE SAME SIZE AS THE FAN OPENING.

Use the shutter inside dimensions as shown in the

shutter specification chart below.

“CSS” SHUTTERS

OPENING SIZES - Installs centered on a joist with 16" or 24" centers.

Cut two openings, one on each side of center joist per shutter model:

Model Fan Size Outside Dimension Opening Size

1

CSS-24 24" 24" x 32" 10

CSS-30 30" 32" x 35" 14

CSS-36 36" 32" x 43" 14

*CSS-42 42" 38" x 49" 17

For 24" o.c. joists only

*

STEP 1. After the installation site has been

selected for the fan, remove any insulation from the

area and select a ceiling joist to be the center line

of the fan.

Use the shutter carton to make a template for the

opening your shutter requires. (See above) FROM

THE ATTIC SIDE OF THE INSTALLATION SITE place

/4" x 301/4"

1

/4" x 341/4"

1

/4" x 411/4"

1

/4" x 463/4"

the template on the ceiling and against the joist that

will be the center of the fan. With a pencil trace

around the template. Repeat this procedure on the

1

exact opposite side of the joist. Drill a

/4" hole at each

corner of the pencil lines. YOU SHOULD HAVE EIGHT

(8) HOLES. From directly below the attic, check to be

sure that the location is correct.

STEP 2. Return to the attic, and using a utility knife

or sheetrock saw carefully cut the shutter opening

following the pattern on both sides of the joist. (See

fig. 5).

DO NOT REMOVE THE SHEETROCK

FROM THE CENTER JOIST.

STEP 3. Frame the opening using lumber EQUAL

TO THE SIZE OF THE EXISTING JOISTS. (See fig. 6).

STEP 4. If the opening is less than the distance

between the joists, fasten supports between the new

framing along the edge of the opening. (See fig. 8.).

STEP 5. Remove the two (2) screws that secure the

fan frame to the plenum. Pass the fan and plenum into

the attic through the framed opening in the ceiling.*

Set them aside at this time.

Fig. 5

*If the fan does not fit through

the framed opening, use your

attic access opening. The current

building code requires this access

opening to be at least 22" x 30".

Platform

New framing

Fig. 6

Fig. 7

Page 4

“CSS” SERIES SHUTTER INSTALLATION, continued

STEP 6. Build a platform to support the fan using

lumber, plywood or other suitable material a minimum

3

of

/4" thick. The platform must be constructed so

that it supports all four sides of the fan, and should

be wide enough to prevent Attic Air from being

drawn into the fan. With some combinations of fan

and shutter, a portion of the opening may be blocked

by the platform. This will not effect the efficiency of

the fan. Fasten the platform to the joists and new

framing. (See fig. 6).

STEP 7. Center the plenum on the platform and

toe nail it in place.

Fig. 8

Fan Frame

Rubber Mount

Plenum

Platform

Existing Joist

Ceiling

No Cut Joist Shutter (CSS)

Blocking as needed

NOTE: WHEN TOE NAILING PLENUM TO PLATFORM

MAKE CERTAIN THAT THE SIDES OF THE PLENUM

REMAIN STRAIGHT AND SQUARE OR THE FAN

WILL NOT FIT PROPERLY.

STEP 8. To prevent Attic Air from entering the

plenum, tape all of the joints of the new framing,

platform and plenum with duct tape or aluminum

foil tape.

STEP 9. Place the fan on the plenum making sure

that the rubber isolation mount is in place between

the fan and the plenum. DO NOT REPLACE SCREWS.

This is to permit the fan to “float” on the rubber

mount which helps reduce noise. (See fig. 8).

STEP 10. Install the flush

mounted ceiling shutter into

the ceiling opening using the

screws provided. Caution

should be taken not to effect

the free operating action of

the shutter. (See fig. 8).

REFER TO THE "ELECTRICAL

WIRING" SECTION BELOW.

This fan requires a 120 Volt AC. power source with

at least 15 amp capacity. All electrical wiring must be in

accordance with local electric codes. Use 12 gauge or

larger for all the fan wiring.

STEP 1. Get professional help If you are not familiar

with electrical wiring and local wiring codes.

STEP 2. Turn OFF power at the Fuse/Circuit Breaker

Box before wiring. (See safety rules on pg. 1).

STEP 3. WARNING: TO REDUCE THE RISK OF

ELECTRICAL SHOCK AND DAMAGE TO THE FAN

MOTOR, DO NOT USE THIS UNIT WITH ANY SOLID

STATE OR VARIABLE SPEED CONTROL DEVICE.

STEP 4. For ease of electrical wiring installation it is

recommended that a junction box is mounted in the close

proximity of the fan motor. This should be mounted to a

ceiling joist within a few feet of the fan. REFER TO THE

WIRING DIAGRAMS (figs. 9 & 10) BEFORE STARTING

INSTALLATION.

STEP 5. Select a wall in the structure in a convenient

location and as close to the fan as possible, to mount

the switch that will operate the fan. Once selected, cut a

rectangular hole in the wall to mount a standard electrical

box. This hole should be next to a stud and at the height

of the standard wall switches throughout the structure.

ELECTRICAL WIRING

STEP 6. Once this hole is cut, and before the electrical

box is mounted inside the wall, return to the attic space

and drill at least a 1" diameter hole in the wall top plate

directly above the location where the hole was cut in the

wall.

STEP 7. Feed the electrical wire through the 1" hole in

the top plate until the wire extends down through the wall

to the point it can be brought through the hole in the wall

at the switch location. Working from the switch location,

pull at least 18" of wire through the switch hole.

STEP 8. Feed the wire through the top hole of the

switch box making sure that the wire is anchored to the

box correctly, and insert the box into the rectangular

hole. When the box is installed correctly, the sides of

the box should be flush with the outside surface of the

sheetrock and the box must be secured to the stud.

NOTE: SINCE THERE ARE VARIOUS TYPES OF

ELECTRICAL BOXES THAT CAN BE USED,

CONSULT YOUR LOCAL ELECTRICAL SUPPLIER

STEP 9. Return to the location of the junction box

and insert the opposite end of the wire from the switch

through one of the holes in the side of this box. After the

wire is inserted and anchored properly, the wire may be

Page 5

FOR HIS SUGGESTIONS.

(continued)

ELECTRICAL WIRING, continued

cut off leaving approximately 12" inside the junction

box. (See fig. 10).

STEP 10. Go to the fan motor and connect the wires

as shown in appropriate wiring diagram. (See fig. 9).

Route the wire from the motor through the junction

box, anchor securely, and cut leaving approximately

12" in the box. (See fig. 10).

STEP 11. For the power source, it will be necessary

to route from the fuse/circuit breaker box to the

junction box in the attic space. To accomplish this, it

will be necessary to add a circuit breaker. An alternate

method is to use an existing electrical source already

in the attic space. With either method, route this wire

to another hole in the junction box and cut off leaving

approximately 12" of wire in the box. YOU SHOULD

NOW HAVE THREE SEPARATE LINES (WIRES) IN THE

JUNCTION B0X, ONE FROM THE SWITCH LOCATION,

ONE FROM THE FAN MOTOR AND ONE FROM THE

POWER SOURCE.

STEP 12. Using wire nuts connect all wires as

shown in the wiring diagram. It will be necessary to cut

off some of the excess wire in the switch and junction

boxes since these wires must be placed inside these

boxes with the covers anchored securely in place.

When the switch is installed in the switch box BE SURE

THAT THE WALL SWITCH IS IN THE OFF POSITION.

Fig. 9

Fig. 10

STEP 13. Return to the attic. MAKE CERTAIN THAT

THE FAN BLADES ARE CLEAR AND THAT NO WIRES

OR OTHER OBSTRUCTIONS ARE NEAR THE BLADES.

STEP 14. Verify all electrical connections. Switch

power ON at the Fuse/Circuit Breaker Box.

NOTE: WINDOWS IN AT LEAST ONE ROOM OF

STRUCTURE MUST BE OPEN BEFORE TESTING THE

FAN.

STEP 15. TESTING THE FAN. (See fig. 9). Turn

the switch on to High, allow the fan to run for several

seconds, then turn the switch to Low.

STEM 16. With the fan operating, return to the attic

and observe the fan. If the V-Belt is vibrating, turn

OFF the fan, and switch the power at the Fuse/Circuit

Box to the OFF position. See the SAFETY RULES on

page 1. Move the fan spring to the end hole of the

motor-mounting plate. (See page 7). After repositioning

the spring, switch the power at the Fuse/Circuit Breaker

Box to the On position. Re-test the fan.

STEP 17. After testing, replace the insulation around

the plenum and new framing.

Junction Box

To 120V

Power Source

Wall Switch

Page 6

REPAIR & REPLACEMENT PARTS

Key

No. Description

1 Fan Frame 24" (Venturi)

Fan Frame 30" (Venturi)

Fan Frame 36" (Venturi)

Fan Frame 42" (Venturi)

Fan Frame 48" (Venturi)

1

2 Motor

Motor

/3 HP, 2 Speed

1

/2 HP, 2 speed

3 Blade Assembly 24"

Blade Assembly 30"

Blade Assembly 36"

Blade Assembly 42"

Blade Assembly 48"

5

4 Carriage Bolt

/16" 18x3/4"

5 Nut 5/16" 18 (4 req'd)

6 Fan Spring

7 Wood Frame 24"

Wood Frame 30"

Wood Frame 36"

Wood Frame 42"

Wood Frame 48"

8 V-Belt 24"

V-Belt 30"

V-Belt 36"

V-Belt 42"

V-Belt 48"

9 Motor Pulley 24"

Motor Pulley 30"

Motor Pulley 36"

Motor Pulley 42"

Motor Pulley 48"

10 Fan Pulley 24"

Fan Pulley 30"

Fan Pulley 36"

Fan Pulley 42"

Fan Pulley 48"

11 Fan Shaft

12 Bearing (2 req'd)

†* 2-Speed Wall Switch

†* 12 Hour Timer

(4 req'd)

REPAIR PARTS

When ordering repair parts, always give the

following information:

1. Part description

2. Fan model no.

3. Fan serial no.

10

12

11

8

9

12

6

4

7

NOTICE:

been removed.

TO REPOSITION OR REPLACE SPRING:

A. Remove V-Belt (8).

B. Hook spring (6) as shown.

C. Position V-Belt (8) onto motor pulley (9)

while pulling the V-Belt to position it onto the

fan pulley (10).

SAFETY WARNING: Do not rotate fan by pulling

on V-Belt. Severe injury could result if fingers are

entrapped between the V-Belt and pulley. Read the

safety rules on page 1 of this manual.

5

2

3

Replace spring (6) in area shown if it has

1

SEE

NOTICE

BELOW

ON

SPRIN

G

†* = optional

Page 7

VENTILATION REQUIREMENTS

The following work sheet is provided so you may determine the existing ventilation in your attic. It is necessary

that you provide adequate ventilation to meet the minimum

exhaust requirements for the fan you have selected. Should

Turbine Ventilator

(12" throat) 3

A

Roofcap

2

Under Eave Vent

1

A

B

B

Type QTY.A (ft.) B (ft.)

A

xxxx

1

2

3

4

5

OTHER FORMS OF VENTILATION

TOTA L NET FREE EXHAUST AREA

NET VENT

(sq. ft.)

1

.13

you calculations show your exhaust area is inadequate,

additional ventilation must be provided. Failure to meet

minimum exhaust requirements will result in a reduction

of fan efficiency and motor failure.

Roof Ridge

Ventilator

4

LOSS

FACTOR

.5

.6

.6

(sq. ft.)

A

NET FREE

=

AREA (sq. ft.)

B

Louvers

5

(Rectangular &

Triangular)

B

A

Min. Free

Exhaust

Model Area Req’d

CC 2422 8 sq. ft.

CC 3022 10 sq. ft.

CC 3023 11 sq. ft.

CC 3622 12 sq. ft.

CC 3623 16 sq. ft.

CC 4223 18 sq. ft.

CC 4823 22 sq. ft.

LIMITED TEN YEAR WARRANTY

Do not return product to original place of purchase

Triangle Engineering of Arkansas, Inc. (Manufacturer) warrants, from

the date of purchase, to the original purchaser only, that the product

manufactured by Manufacturer is free from defects in material and

workmanship for a period of TEN (10) YEARS. Motors, capacitors,

v-belts and switches are excluded from this warranty, but shall have

a limited one year warranty from date of purchase to the original

purchaser.

If a failure of the product occurs, contact the Manufacturer at: 1-800-

255-9014 and give the model number of the product, the purchase

date, and a description of the problem to the customer service agent.

Once the problem is diagnosed, and proof of purchase date is

verified, Manufacturer will have the option of shipping the necessary

repair part(s) to the Customer, freight prepaid or having the product

returned to Manufacturer for repair or replacement. If the product is

returned to the Manufacturer, Customer is responsible for prepayment

of all inbound freight charges. Upon repair or replacement, which shall

be at the discretion of Manufacturer, the Manufacturer will prepay all

outbound freight charges for the return of the product to the customer.

However, if Manufacturer finds product to be in operating condition

and no problems are diagnosed, product will be returned to customer

freight collect.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE HEREOF except as provided by this express

warranty, the goods are sold “as is” without any implied warranties.

This limited warranty does not cover labor to replace warrantied parts

or motors, nor does it cover failure of the installer to provide adequate

ventilation to meet minimum exhaust requirements, damage resulting

from accident, misuse or abuse, lack of proper maintenance, improper

installation, affixing of any parts or attachments not authorized by

Manufacturer, or loss of parts.

In no event shall Manufacturer be liable for any special, incidental, or

consequential damages; which may result from any defect in material

or workmanship.

It is expressly understood that Buyer’s sole and exclusive remedy

shall be repair or replacement of defective parts, and that Triangle

Engineering shall not be liable for injury to persons or property. Should

the goods prove so defective, however, as to preclude the remedying

of warranted defects by repair or replacement, the Buyer’s sole and

exclusive remedy shall then be a refund of the purchase price.

This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

MOTOR REPLACEMENT DURING WARRANTY PERIOD:

If the motor on your WHOLE HOUSE FAN should fail during the first

year of operation, simply remove the LABEL ONLY from the motor

and mail the original label and copy of purchase receipt to Triangle

Engineering. Once the label is received, and if the motor is still under

warranty, we will ship a new motor within 24 hours, UPS prepaid. DO

NOT RETURN MOTOR.

Page 8

Loading...

Loading...